torque DODGE HORNET 2023 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: HORNET, Model: DODGE HORNET 2023Pages: 288, PDF Size: 14.2 MB

Page 157 of 288

SAFETY155

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

Your vehicle is equipped with an advanced Electronic

Brake Control (EBC) system. This system includes

Anti-Lock Brake System (ABS), Brake Assist System (BAS),

Electronic Brake Force Distribution (EBD), Electronic Roll

Mitigation (ERM), Electronic Stability Control (ESC), Hill

Start Assist (HSA), and Traction Control System (TCS).

These systems work together to enhance both vehicle

stability and control in various driving conditions.

Your vehicle may also be equipped with Dynamic Steering

Torque (DST), Hill Descent Control (HDC), Rain Brake

Support (RBS), Ready Alert Braking (RAB), and Trailer

Sway Control (TSC).

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s braking

capability during emergency braking maneuvers. The

system detects an emergency braking situation by sensing

the rate and amount of brake application and then applies

optimum pressure to the brakes. This can help reduce

braking distances. The BAS complements the Anti-Lock

Brake System (ABS). Applying the brakes very quickly

results in the best BAS assistance. To receive the benefit

of the system, you must apply continuous braking

pressure during the stopping sequence (do not “pump”

the brakes). Do not reduce brake pedal pressure unless

braking is no longer desired. Once the brake pedal is

released, the BAS is deactivated.

Brake System Warning Light

The red Brake System Warning Light will turn on when the

ignition is placed in the ON/RUN mode and may stay on for

as long as four seconds.

If the Brake System Warning Light remains on or comes on

while driving, it indicates that the brake system is not

functioning properly and that immediate service is

required. If the Brake System Warning Light does not

come on when the ignition is placed in the ON/RUN mode,

have the light repaired as soon as possible.

Dynamic Steering Torque (DST)

DST is a feature of the Electronic Stability Control (ESC)

and Electric Power Steering (EPS) modules that provides

torque at the steering wheel for certain driving conditions

in which the ESC module is detecting vehicle instability.

The torque that the steering wheel receives is only meant

to help the driver realize optimal steering behavior in order to reach/maintain vehicle stability. The only notification

the driver receives that the feature is active is the torque

applied to the steering wheel.

NOTE:The DST feature is only meant to help the driver realize the

correct course of action through small torques on the

steering wheel, which means the effectiveness of the DST

feature is highly dependent on the driver’s sensitivity and

overall reaction to the applied torque. It is very important

to realize that this feature will not steer the vehicle,

meaning the driver is still responsible for steering the

vehicle.

Electronic Brake Force Distribution (EBD)

EBD manages the distribution of the braking torque

between the front and rear axles by limiting braking

pressure to the rear axle. This is done to prevent overslip

of the rear wheels to avoid vehicle instability, and to

prevent the rear axle from entering ABS before the

front axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by monitoring

the driver’s steering wheel input and the speed of the

vehicle. When ERM determines that the rate of change of

the steering wheel angle and vehicle’s speed are

sufficient to potentially cause wheel lift, it then applies the

appropriate brake and may also reduce engine power to

lessen the chance that wheel lift will occur. ERM can only

reduce the chance of wheel lift occurring during severe or

evasive driving maneuvers; it cannot prevent wheel lift

due to other factors, such as road conditions, leaving the

roadway, or striking objects or other vehicles.

WARNING!

The Brake Assist System (BAS) cannot prevent the

natural laws of physics from acting on the vehicle, nor

can it increase the traction afforded by prevailing road

conditions. BAS cannot prevent collisions, including

those resulting from excessive speed in turns, driving

on very slippery surfaces, or hydroplaning. The

capabilities of a BAS-equipped vehicle must never be

exploited in a reckless or dangerous manner, which

could jeopardize the user's safety or the safety of

others.

6

23_GG_OM_EN_USC_t.book Page 155

Page 159 of 288

SAFETY157

Full Off

To enter the “Full Off” mode, push the Sport Mode button

and then hold the ESC OFF button for two seconds while

the vehicle is stopped with the engine running. After two

seconds, a chime will sound, the ESC OFF Indicator Light

will illuminate, and the “ESC OFF” message will display in

the instrument cluster. To turn ESC on again, momentarily

push the ESC OFF button.ESC Activation/Malfunction Indicator Light

And ESC OFF Indicator Light

The ESC Activation/Malfunction Indicator Light

in the instrument cluster will come on when the

ignition is placed in the ON mode. It should go

out with the engine running. If the ESC

Activation/Malfunction Indicator Light comes on

continuously with the engine running, a malfunction has

been detected in the ESC system. If this light remains on

after several ignition cycles, and the vehicle has been

driven several miles (km) at speeds greater than 30 mph

(48 km/h), see an authorized dealer as soon as possible

to have the problem diagnosed and corrected.

The ESC Activation/Malfunction Indicator Light starts to

flash as soon as the tires lose traction and the ESC system

becomes active. The ESC Activation/Malfunction Indicator

Light also flashes when Traction Control System (TCS) is

active. If the ESC Activation/Malfunction Indicator Light

begins to flash during acceleration, ease up on the

accelerator and apply as little throttle as possible. Be sure

to adapt your speed and driving to the prevailing road

conditions.

The ESC OFF Indicator Light indicates the

customer has elected to have the Electronic

Stability Control (ESC) in a reduced mode.

NOTE:

The ESC Activation/Malfunction Indicator Light and the

ESC OFF Indicator Light come on momentarily each

time the ignition is placed in the ON/RUN position.

Each time the ignition is placed in the ON/RUN posi -

tion, the ESC system will be on even if it was turned off

previously.

The ESC system will make buzzing or clicking sounds

when it is active. This is normal; the sounds will stop

when ESC becomes inactive following the maneuver

that caused the ESC activation.

Emergency Stop Signal (ESS) —

If Equipped

The ESS activates the hazard lights at a faster than normal

speed when heavy brake pressure is applied. ESS will only

activate when the speed is above 31 mph (50 km/h). The

ESS operates independently of other lamps, and will turn

on and off automatically. This indicates to others that the

vehicle is stopping quickly.

NOTE:

A warning light will illuminate within the instrument

cluster to inform the driver that the ESS feature has

been activated.

When towing a trailer, ESS will also activate the rear

indicator lights of the trailer.

WARNING!

In the ESC “Full Off” mode, the engine torque reduc -

tion and stability features are disabled. Therefore,

enhanced vehicle stability offered by the ESC system

is unavailable. In an emergency evasive maneuver,

the ESC system will not engage to assist in main -

taining stability. ESC “Full Off” mode is intended for

off-highway or off-road use only.

With the ESC switched off, the enhanced vehicle

stability offered by ESC is unavailable. In an

emergency evasive maneuver, the ESC system

will not engage to assist in maintaining stability.

ESC “Full Off” mode is only intended for off-highway

or off-road use.

The Electronic Stability Control (ESC) cannot prevent

the natural laws of physics from acting on the

vehicle, nor can it increase the traction afforded by

prevailing road conditions. ESC cannot prevent all

accidents, including those resulting from excessive

speed in turns, driving on very slippery surfaces, or

hydroplaning. ESC also cannot prevent collisions.

6

23_GG_OM_EN_USC_t.book Page 157

Page 160 of 288

158SAFETY

Hill Start Assist (HSA)

HSA is designed to mitigate roll back from a complete stop

while on an incline. If the driver releases the brake while

stopped on an incline, HSA will continue to hold the brake

pressure for a short period. If the driver does not apply the

throttle before this time expires, the system will release

brake pressure and the vehicle will roll down the hill as

normal.

The following conditions must be met in order for HSA to

activate:

The feature must be enabled.

The vehicle must be stopped.

The parking brake must be off.

The driver’s door must be closed.

The vehicle must be on a sufficient grade.

The gear selection must match vehicle uphill direction

(i.e., vehicle facing uphill is in forward gear; vehicle

backing uphill is in REVERSE gear).

HSA will work in REVERSE gear and all forward gears.

The system will not activate if the transmission is in

PARK or NEUTRAL.

Rain Brake Support (RBS)

RBS may improve braking performance in wet conditions.

It will periodically apply a small amount of brake pressure

to remove any water buildup on the front brake rotors.

It functions when the windshield wipers are in LO or

HI speed. When Rain Brake Support is active, there is

no notification to the driver and no driver interaction

is required.

Ready Alert Braking (RAB)

RAB may reduce the time required to reach full braking

during emergency braking situations. It anticipates when

an emergency braking situation may occur by monitoring

how fast the throttle is released by the driver. The

Electronic Brake Controller (EBC) system will prepare

the brake system for a panic stop.

Traction Control System (TCS)

The TCS monitors the amount of wheel spin for each of the

driven wheels. If wheel spin is detected, the TCS may apply

brake pressure to the spinning wheel(s) and/or reduce

vehicle power to provide enhanced acceleration and

stability. A feature of the TCS, Brake Limited Differential

(BLD) functions similarly to a limited slip differential and

controls the wheel spin across a driven axle. If one wheel

on a driven axle is spinning faster than the other, the

system will apply the brake of the spinning wheel. This will

allow more vehicle torque to be applied to the wheel that

is not spinning. BLD may remain enabled even if TCS and

ESC are in reduced modes.

WARNING!

There may be situations where the Hill Start Assist

(HSA) will not activate and slight rolling may occur, such

as on minor hills or with a loaded vehicle, or while

pulling a trailer. HSA is not a substitute for active driving

involvement. It is always the driver’s responsibility to be

attentive to distance to other vehicles, people, and

objects, and most importantly brake operation to

ensure safe operation of the vehicle under all road

conditions. Your complete attention is always required

while driving to maintain safe control of your vehicle.

Failure to follow these warnings can result in a collision

or serious personal injury.

23_GG_OM_EN_USC_t.book Page 158

Page 162 of 288

160SAFETY

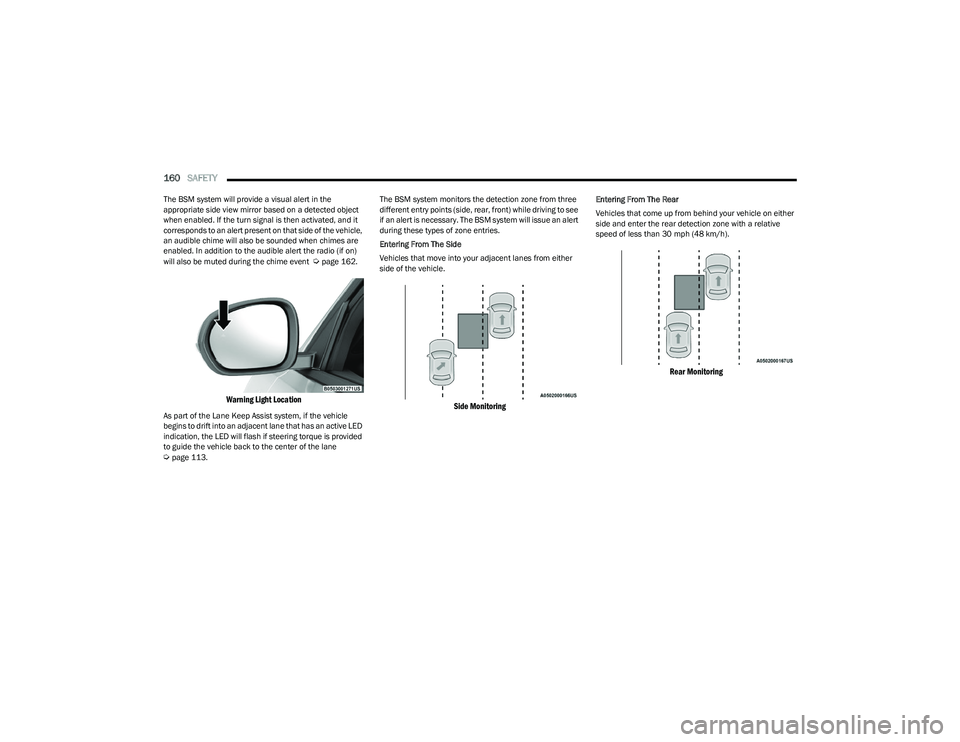

The BSM system will provide a visual alert in the

appropriate side view mirror based on a detected object

when enabled. If the turn signal is then activated, and it

corresponds to an alert present on that side of the vehicle,

an audible chime will also be sounded when chimes are

enabled. In addition to the audible alert the radio (if on)

will also be muted during the chime event

Úpage 162.

Warning Light Location

As part of the Lane Keep Assist system, if the vehicle

begins to drift into an adjacent lane that has an active LED

indication, the LED will flash if steering torque is provided

to guide the vehicle back to the center of the lane

Úpage 113. The BSM system monitors the detection zone from three

different entry points (side, rear, front) while driving to see

if an alert is necessary. The BSM system will issue an alert

during these types of zone entries.

Entering From The Side

Vehicles that move into your adjacent lanes from either

side of the vehicle.

Side Monitoring

Entering From The Rear

Vehicles that come up from behind your vehicle on either

side and enter the rear detection zone with a relative

speed of less than 30 mph (48 km/h).

Rear Monitoring

23_GG_OM_EN_USC_t.book Page 160

Page 203 of 288

SAFETY201

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight parking for

fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the floor mat (e.g.,

towels, keys, etc.). These objects could change the

position of the floor mat and may cause interference

with the accelerator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

6

23_GG_OM_EN_USC_t.book Page 201

Page 212 of 288

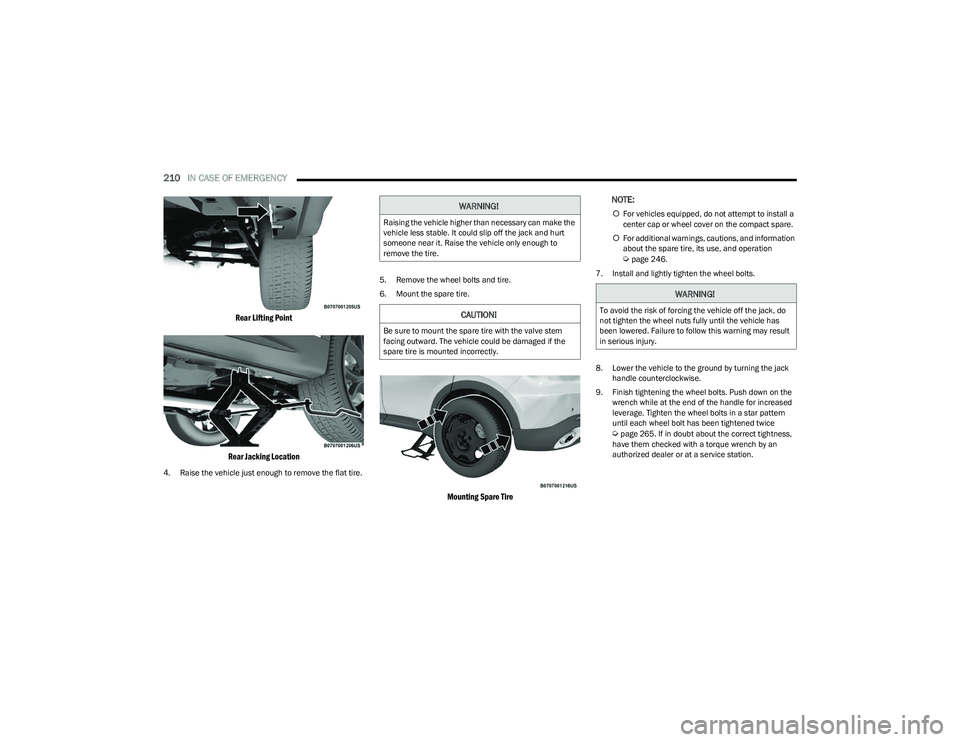

210IN CASE OF EMERGENCY

Rear Lifting Point

Rear Jacking Location

4. Raise the vehicle just enough to remove the flat tire. 5. Remove the wheel bolts and tire.

6. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

For additional warnings, cautions, and information

about the spare tire, its use, and operation

Úpage 246.

7. Install and lightly tighten the wheel bolts.

8. Lower the vehicle to the ground by turning the jack handle counterclockwise.

9. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice

Úpage 265. If in doubt about the correct tightness,

have them checked with a torque wrench by an

authorized dealer or at a service station.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

23_GG_OM_EN_USC_t.book Page 210

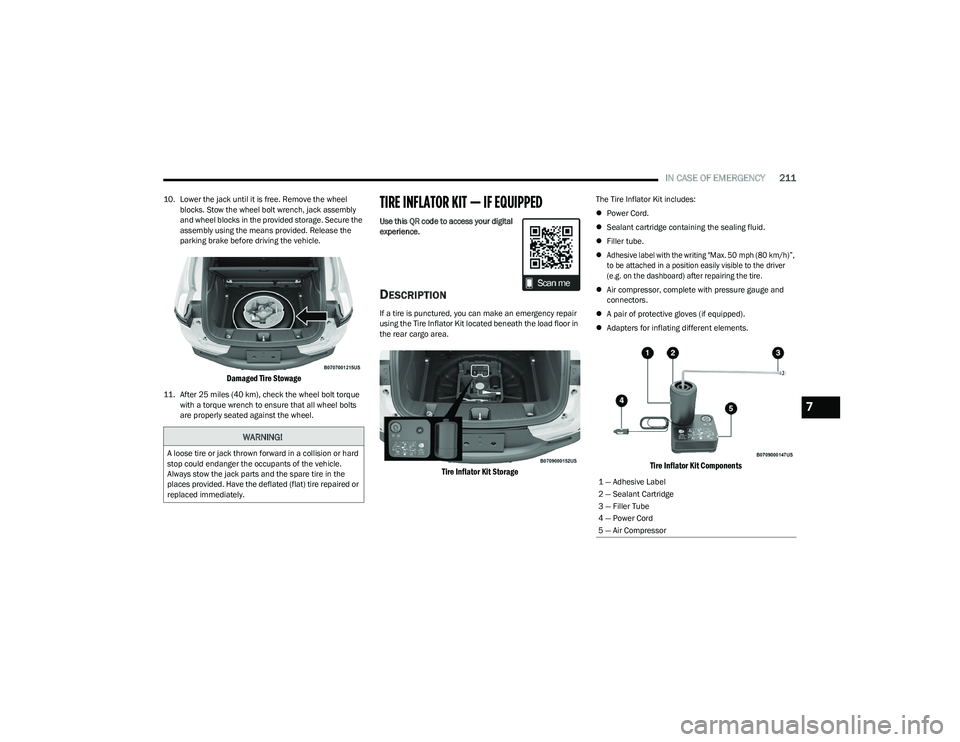

Page 213 of 288

IN CASE OF EMERGENCY211

10. Lower the jack until it is free. Remove the wheel

blocks. Stow the wheel bolt wrench, jack assembly

and wheel blocks in the provided storage. Secure the

assembly using the means provided. Release the

parking brake before driving the vehicle.

Damaged Tire Stowage

11. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all wheel bolts

are properly seated against the wheel.

TIRE INFLATOR KIT — IF EQUIPPED

Use this QR code to access your digital

experience.

DESCRIPTION

If a tire is punctured, you can make an emergency repair

using the Tire Inflator Kit located beneath the load floor in

the rear cargo area.

Tire Inflator Kit Storage

The Tire Inflator Kit includes:

Power Cord.

Sealant cartridge containing the sealing fluid.

Filler tube.

Adhesive label with the writing "Max. 50 mph (80 km/h)”,

to be attached in a position easily visible to the driver

(e.g. on the dashboard) after repairing the tire.

Air compressor, complete with pressure gauge and

connectors.

A pair of protective gloves (if equipped).

Adapters for inflating different elements.

Tire Inflator Kit Components

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.

1 — Adhesive Label

2 — Sealant Cartridge

3 — Filler Tube

4 — Power Cord

5 — Air Compressor

7

23_GG_OM_EN_USC_t.book Page 211

Page 239 of 288

SERVICING AND MAINTENANCE237

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the life

of the vehicle.

Routine fluid and filter changes are not required. However,

change the fluid and filter if the fluid becomes

contaminated (with water, etc.), or if the transmission is

disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life.

Use only the manufacturer specified transmission fluid

Úpage 269. It is important to maintain the transmission

fluid at the correct level using the recommended fluid.

NOTE:No chemical flushes should be used in any transmission;

only the approved lubricant should be used.

FUSES

General Information

The fuses protect electrical systems against excessive

current.

When a device does not work, you must check the fuse

element inside the blade fuse for a break/melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may result in

vehicle battery discharge.

Blade Fuses

CAUTION!

If a transmission fluid leak occurs, visit an authorized

dealer immediately. Severe transmission damage may

occur. An authorized dealer has the proper tools to

adjust the fluid level accurately.

CAUTION!

Using a transmission fluid other than the manufacturer

recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder. For fluid specifications

Úpage 269.

WARNING!

When replacing a blown fuse, always use an appro -

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity or vice

versa. Failure to use proper fuses may result in

serious personal injury, fire and/or property damage.

Before replacing a fuse, make sure that the ignition

is off and that all the other services are switched off

and/or disengaged.

If the replaced fuse blows again, contact an autho -

rized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit systems

(engine system, transmission system) or steering

system blows, contact an authorized dealer.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse element

3 — Blade Fuse with a bad/not functional fuse element

(blown fuse)

8

23_GG_OM_EN_USC_t.book Page 237

Page 267 of 288

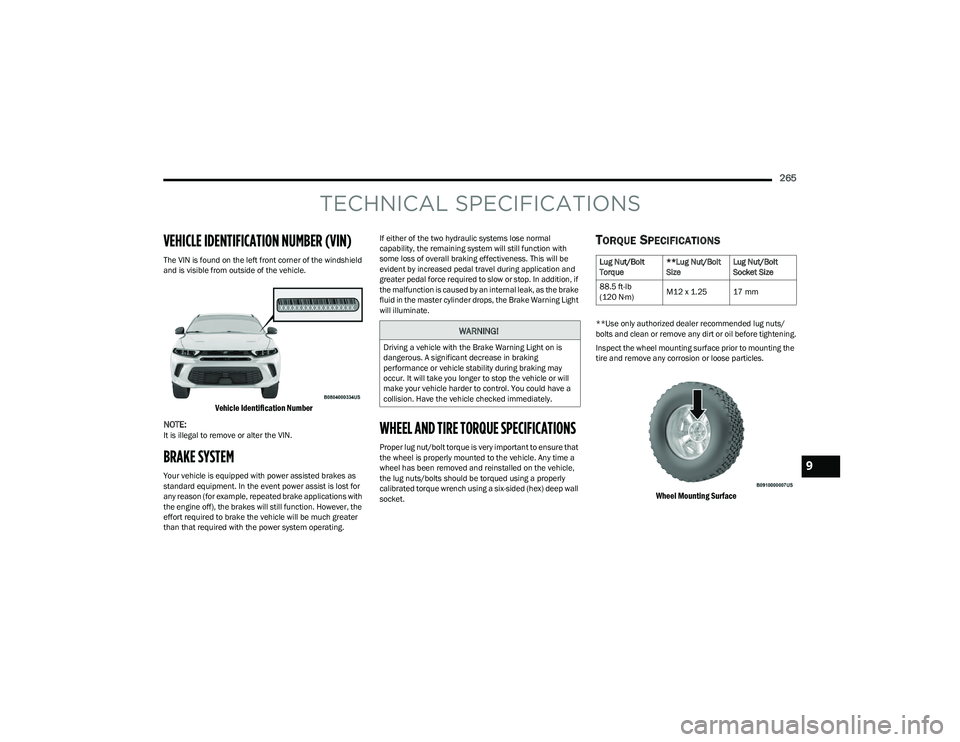

265

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the windshield

and is visible from outside of the vehicle.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with power assisted brakes as

standard equipment. In the event power assist is lost for

any reason (for example, repeated brake applications with

the engine off), the brakes will still function. However, the

effort required to brake the vehicle will be much greater

than that required with the power system operating. If either of the two hydraulic systems lose normal

capability, the remaining system will still function with

some loss of overall braking effectiveness. This will be

evident by increased pedal travel during application and

greater pedal force required to slow or stop. In addition, if

the malfunction is caused by an internal leak, as the brake

fluid in the master cylinder drops, the Brake Warning Light

will illuminate.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle,

the lug nuts/bolts should be torqued using a properly

calibrated torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/

bolts and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.

Wheel Mounting Surface

WARNING!

Driving a vehicle with the Brake Warning Light on is

dangerous. A significant decrease in braking

performance or vehicle stability during braking may

occur. It will take you longer to stop the vehicle or will

make your vehicle harder to control. You could have a

collision. Have the vehicle checked immediately.

Lug Nut/Bolt

Torque

**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

88.5 ft-lb

(120 N·m) M12 x 1.25 17 mm

9

23_GG_OM_EN_USC_t.book Page 265

Page 268 of 288

266TECHNICAL SPECIFICATIONS

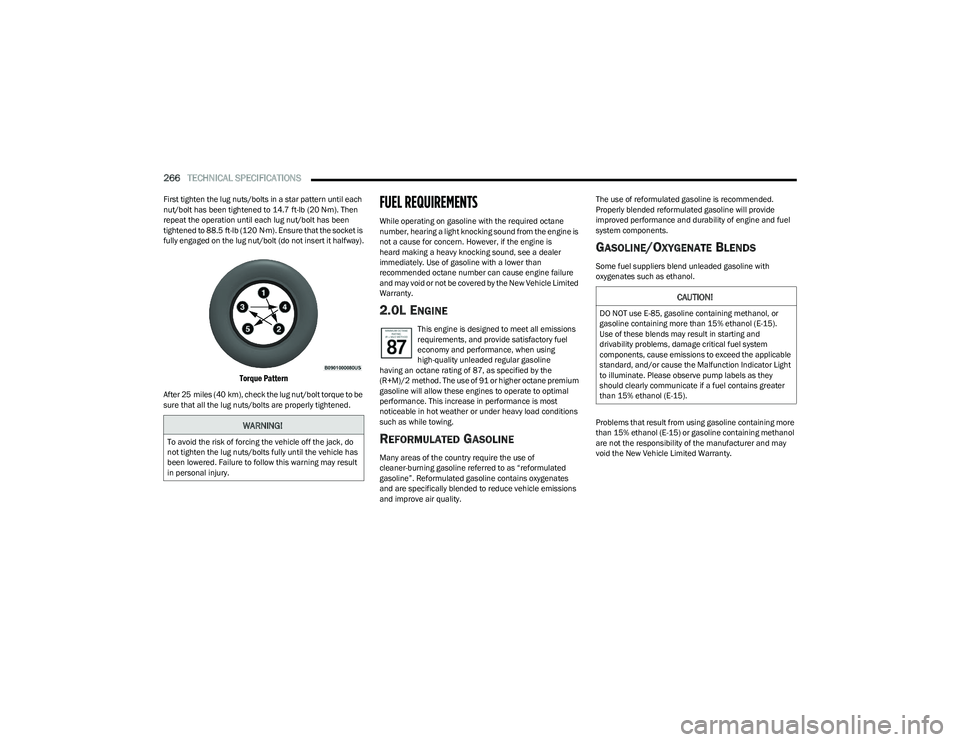

First tighten the lug nuts/bolts in a star pattern until each

nut/bolt has been tightened to 14.7 ft-lb (20 N·m). Then

repeat the operation until each lug nut/bolt has been

tightened to 88.5 ft-lb (120 N·m). Ensure that the socket is

fully engaged on the lug nut/bolt (do not insert it halfway).

Torque Pattern

After 25 miles (40 km), check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly tightened.

FUEL REQUIREMENTS

While operating on gasoline with the required octane

number, hearing a light knocking sound from the engine is

not a cause for concern. However, if the engine is

heard making a heavy knocking sound, see a dealer

immediately. Use of gasoline with a lower than

recommended octane number can cause engine failure

and may void or not be covered by the New Vehicle Limited

Warranty.

2.0L ENGINE

This engine is designed to meet all emissions

requirements, and provide satisfactory fuel

economy and performance, when using

high-quality unleaded regular gasoline

having an octane rating of 87, as specified by the

(R+M)/2 method. The use of 91 or higher octane premium

gasoline will allow these engines to operate to optimal

performance. This increase in performance is most

noticeable in hot weather or under heavy load conditions

such as while towing.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner-burning gasoline referred to as “reformulated

gasoline”. Reformulated gasoline contains oxygenates

and are specifically blended to reduce vehicle emissions

and improve air quality. The use of reformulated gasoline is recommended.

Properly blended reformulated gasoline will provide

improved performance and durability of engine and fuel

system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as ethanol.

Problems that result from using gasoline containing more

than 15% ethanol (E-15) or gasoline containing methanol

are not the responsibility of the manufacturer and may

void the New Vehicle Limited Warranty.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the lug nuts/bolts fully until the vehicle has

been lowered. Failure to follow this warning may result

in personal injury.

CAUTION!

DO NOT use E-85, gasoline containing methanol, or

gasoline containing more than 15% ethanol (E-15).

Use of these blends may result in starting and

drivability problems, damage critical fuel system

components, cause emissions to exceed the applicable

standard, and/or cause the Malfunction Indicator Light

to illuminate. Please observe pump labels as they

should clearly communicate if a fuel contains greater

than 15% ethanol (E-15).

23_GG_OM_EN_USC_t.book Page 266