DODGE JOURNEY 2015 1.G Owners Manual

Manufacturer: DODGE, Model Year: 2015, Model line: JOURNEY, Model: DODGE JOURNEY 2015 1.GPages: 140, PDF Size: 23.09 MB

Page 91 of 140

WARNING!

Ahotenginecoolingsystemisdangerous.Youorotherscouldbebadlyburnedby

steam or boiling coolant.

-SeatBeltReminderLight

When the ignition switch is first turned to the ON/RUN position, this light will turn on for

four to eight seconds as a bulb check. During the bulb check, if the driver's seat belt is

unbuckled, a chime will sound. After the bulb check or when driving, if the driver or front

passenger seat belt remains unbuckled, the Seat Belt Indicator Light will flash or remain

on continuously. Refer to “Seat Belt Systems” in “Things To Know Before Starting” in the

OM on your DVD for further information.

-BrakeWarningLight

This light monitors various brake functions, including brake fluid level and parking brake

application. If the brake light turns on it may indicate that the parking brake is applied,

that the brake fluid level is low, or that there is a problem with the anti-lock brake system

reservoir.

If the light remains on when the parking brake has been disengaged, and the fluid level is

at the full mark on the master cylinder reservoir, it indicates a possible brake hydraulic

system malfunction or that a problem with the Brake Booster has been detected by the

Anti-Lock Brake System (ABS)/Electronic Stability Control (ESC) system. In this case, the

light will remain on until the condition has been corrected. If the problem is related to the

brake booster, the ABS pump will run when applying the brake and a brake pedal

pulsation may be felt during each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to a

portion of the hydraulic system. A leak in either half of the dual brake system is indicated

by the Brake Warning Light, which will turn on when the brake fluid level in the master

cylinder has dropped below a specified level. The light will remain on until the cause is

corrected.

Vehicles equipped with the Anti-Lock Brake System (ABS), are also equipped with

Electronic Brake Force Distribution (EBD). In the event of an EBD failure, the Brake

Warning Light will turn on along with the ABS Light. Immediate repair to the ABS system

is required.

Operation of the Brake Warning Light can be checked by turning the ignition switch from

the OFF position to the ON/RUN position. The light should illuminate for approximately

two seconds. The light should then turn off unless the parking brake is applied or a brake

fault is detected. If the light does not illuminate, have the light inspected by an authorized

dealer.

The light also will turn on when the parking brake is applied with the ignition switch in the

ON/RUN position.

WHAT TO DO IN EMERGENCIES

89

Page 92 of 140

NOTE:

This light shows only that the parking brake is applied. It does not show the degree of

brake application.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may

have failed. It will take longer to stop the vehicle. You could have a collision. Have the

vehicle checked immediately.

-MalfunctionIndicatorLight(MIL)

The Malfunction Indicator Light (MIL) is part of an onboard diagnostic system called OBD

II that monitors engine and automatic transmission control systems. The light will

illuminate when the key is in the ON/RUN position before engine start. If the bulb does not

come on when turning the key from OFF to ON/RUN, have the condition checked

promptly.

Certain conditions, poor fuel quality, etc., may illuminate the light after engine start. The

vehicle should be serviced if the light stays on through several of your typical driving

cycles. In most situations, the vehicle will drive normally and will not require towing.

CAUTION!

Prolonged driving with the Malfunction Indicator Light (MIL) on could cause damage to

the engine control system. It also could affect fuel economy and driveability. If the MIL

is flashing, severe catalytic converter damage and power loss will soon occur. Imme-

diate service is required.

WARNING!

Amalfunctioningcatalyticconverter,asreferencedabove,canreachhighertempera-

tures than in normal operating conditions. This can cause a fire if you drive slowly or

park over flammable substances such as dry plants, wood, cardboard, etc. This could

result in death or serious injury to the driver, occupants or others.

-ElectronicStabilityControl(ESC)Activation/MalfunctionIndicatorLight

•Ifthisindicatorlightflashesduringacceleration,applyaslittlethrottleaspossible.

While driving, ease up on the accelerator. Adapt your speed and driving to the prevailing

road conditions. To improve the vehicle's traction when starting off in deep snow, sand

or gravel, it may be desirable to switch the ESC system off.

WHAT TO DO IN EMERGENCIES

90

Page 93 of 140

INSTRUMENT CLUSTER INDICATOR LIGHTS

-TurnSignalIndicator

The arrows will flash with the exterior turn signals when the turn signal lever is operated.

Atonewillchime,andaEVICmessagewillappearifeitherturnsignalisleftonformore

than 1 mile (1.6 km).

NOTE:

If either indicator flashes at a rapid rate, check for a defective outside light bulb.

-HighBeamIndicator

Indicates that headlights are on high beam.

-FrontFogLightIndicator

This indicator will illuminate when the front fog lights are on.

-VehicleSecurityLight

This light will flash rapidly for approximately 15 seconds when the vehicle theft alarm is

arming. The light will flash at a slower speed continuously after the alarm is set. The

security light will also come on for about three seconds when the ignition is first turned on.

-ElectronicStabilityControl(ESC)OFFIndicatorLight

The ESC OFF indicator will illuminate when the Electronic Stability Control (ESC) is

turned off.

-ElectronicSpeedControlONIndicator

This indicator will illuminate when the electronic speed control has been activated to the

“ON” position.

-ElectronicSpeedControlSETIndicator

This indicator will illuminate when the cruising speed has been set.

Oil Change Due

Yo u r v e h i c l e i s e q u i p p e d w i t h a n e n g i n e o i l c h a n g e i n d i c a t o r s y s t e m . T h e “ O i l C h a n g e

Due” message will flash in the EVIC display for approximately 10 seconds after a single

chime has sounded to indicate the next scheduled oil change interval. The engine oil

change indicator system is duty cycle based, which means the engine oil change interval

may fluctuate dependent upon your personal driving style.

WHAT TO DO IN EMERGENCIES

91

Page 94 of 140

Resetting The Light After Servicing

•Withoutpressingthebrakepedal,pushtheENGINESTART/STOPbuttonandcyclethe

ignition to the ON/RUN position (Do not start the engine.)

•Fullydepresstheacceleratorpedal,slowly,threetimeswithin10seconds.

•Withoutpressingthebrakepedal,pushtheENGINESTART/STOPbuttononceto

return the ignition to the OFF/LOCK position.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the potential for overheating by taking

the appropriate action:

•Onthehighways—slowdown.

•Incitytraffic—whilestopped,shiftthetransmissiontoNEUTRAL,butdonotincrease

engine idle speed.

NOTE:

There are steps that you can take to slow down an impending overheat condition:

•Ifyourairconditioner(A/C)ison,turnitoff.TheA/Csystemaddsheattotheengine

cooling system and turning the A/C off can help remove this heat.

•Youcanalsoturnthetemperaturecontroltomaximumheat,themodecontroltofloor

and the blower control to high. This allows the heater core to act as a supplement to the

radiator and aids in removing heat from the engine cooling system.

CAUTION!

Driving with a hot cooling system could damage your vehicle. If the temperature gauge

reads HOT (H), pull over and stop the vehicle. Idle the vehicle with the air conditioner

turned off until the pointer drops back into the normal range. If the pointer remains on

HOT (H), and you hear continuous chimes, turn the engine off immediately, and call for

service.

WARNING!

Yo u o r o t h e r s c a n b e b a d l y b u r n e d b y h o t e n g i n e c o o l a n t ( a n t i f r e e z e ) o r s t e a m f r o m y o u r

radiator. If you see or hear steam coming from under the hood, do not open the hood

until the radiator has had time to cool. Never try to open a cooling system pressure cap

when the radiator or coolant bottle is hot.

WHAT TO DO IN EMERGENCIES

92

Page 95 of 140

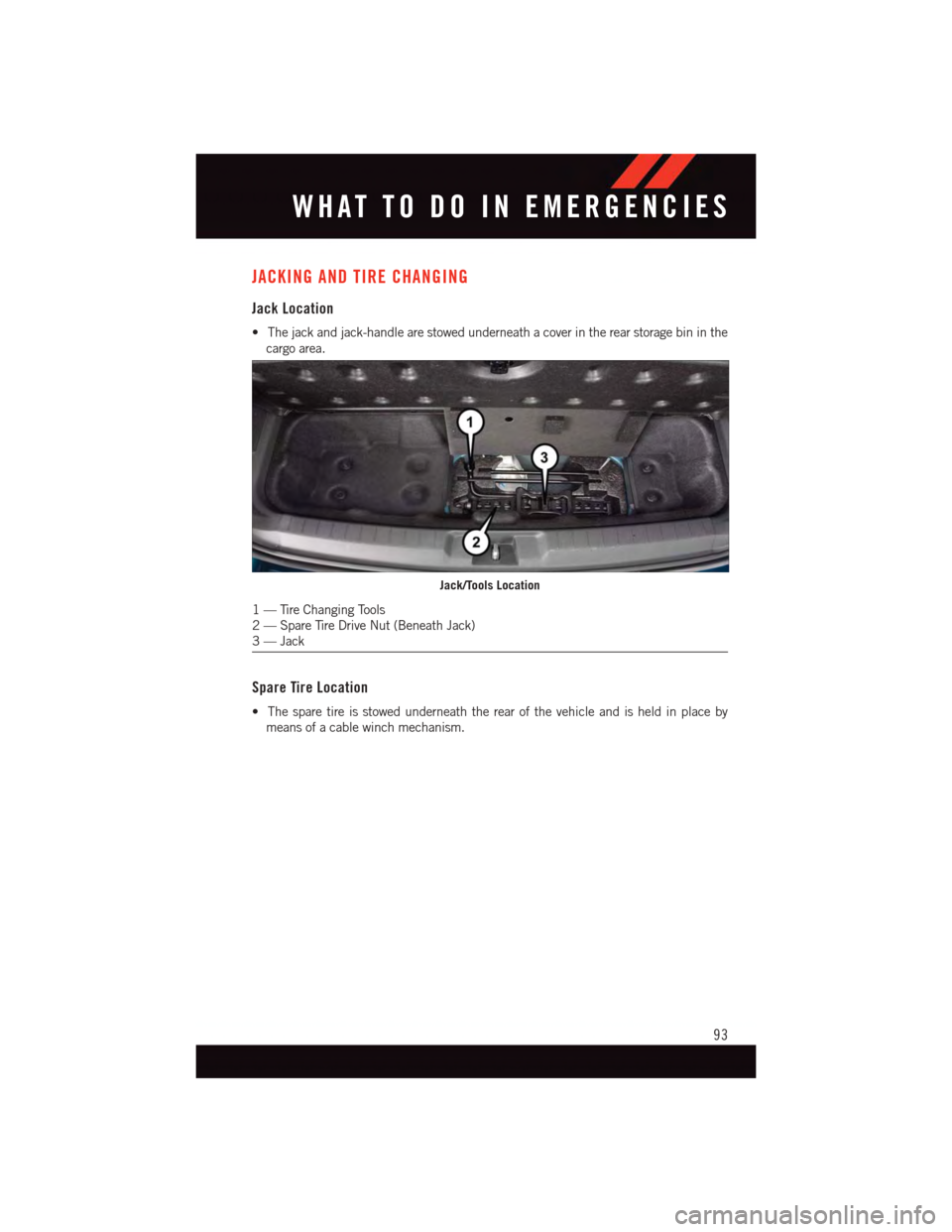

JACKING AND TIRE CHANGING

Jack Location

•Thejackandjack-handlearestowedunderneathacoverintherearstoragebininthe

cargo area.

Spare Tire Location

•Thesparetireisstowedunderneaththerearofthevehicleandisheldinplaceby

means of a cable winch mechanism.

Jack/Tools Location

1—TireChangingTools2—SpareTireDriveNut(BeneathJack)3—Jack

WHAT TO DO IN EMERGENCIES

93

Page 96 of 140

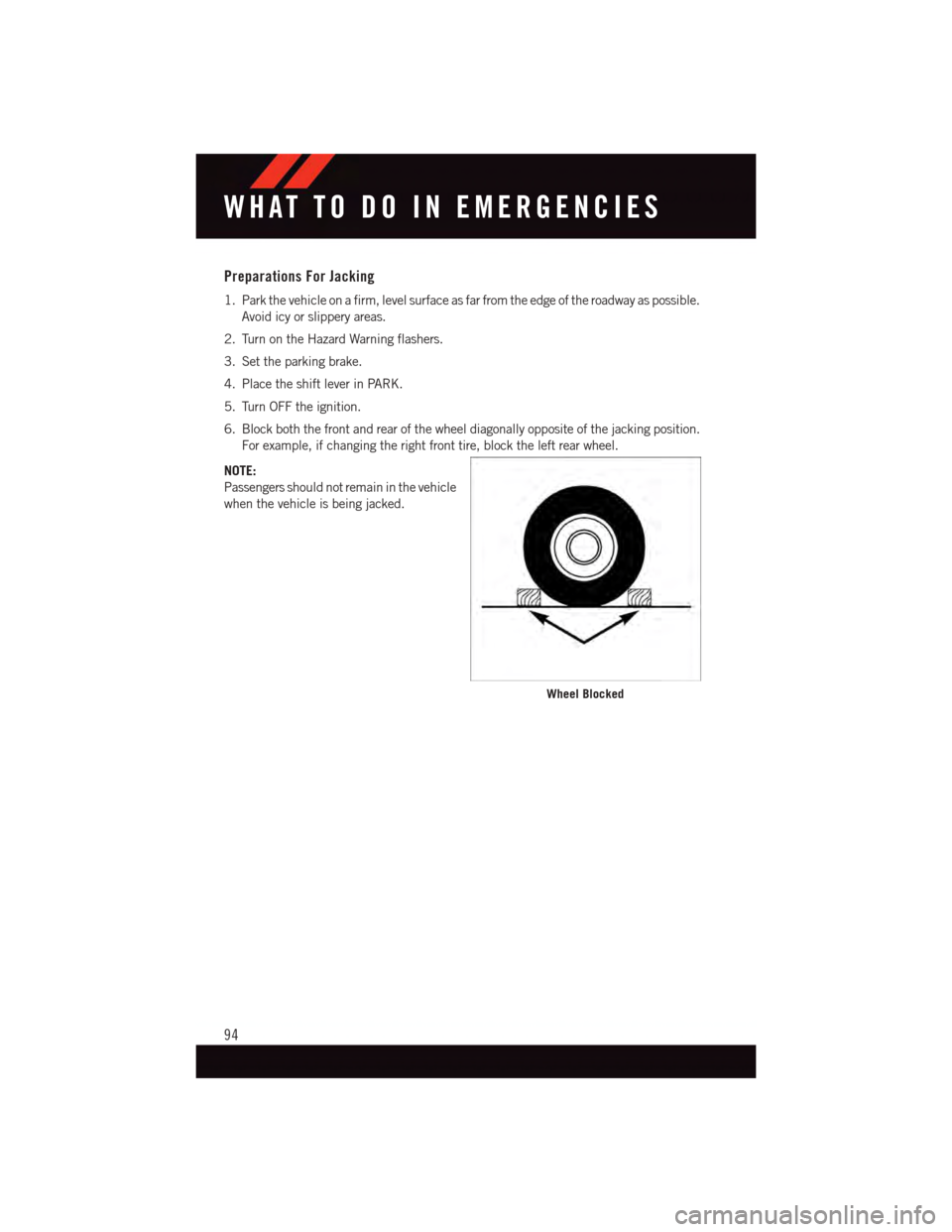

Preparations For Jacking

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as possible.

Avoid icy or slippery areas.

2. Turn on the Hazard Warning flashers.

3. Set the parking brake.

4. Place the shift lever in PARK.

5. Turn OFF the ignition.

6. Block both the front and rear of the wheel diagonally opposite of the jacking position.

For example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Wheel Blocked

WHAT TO DO IN EMERGENCIES

94

Page 97 of 140

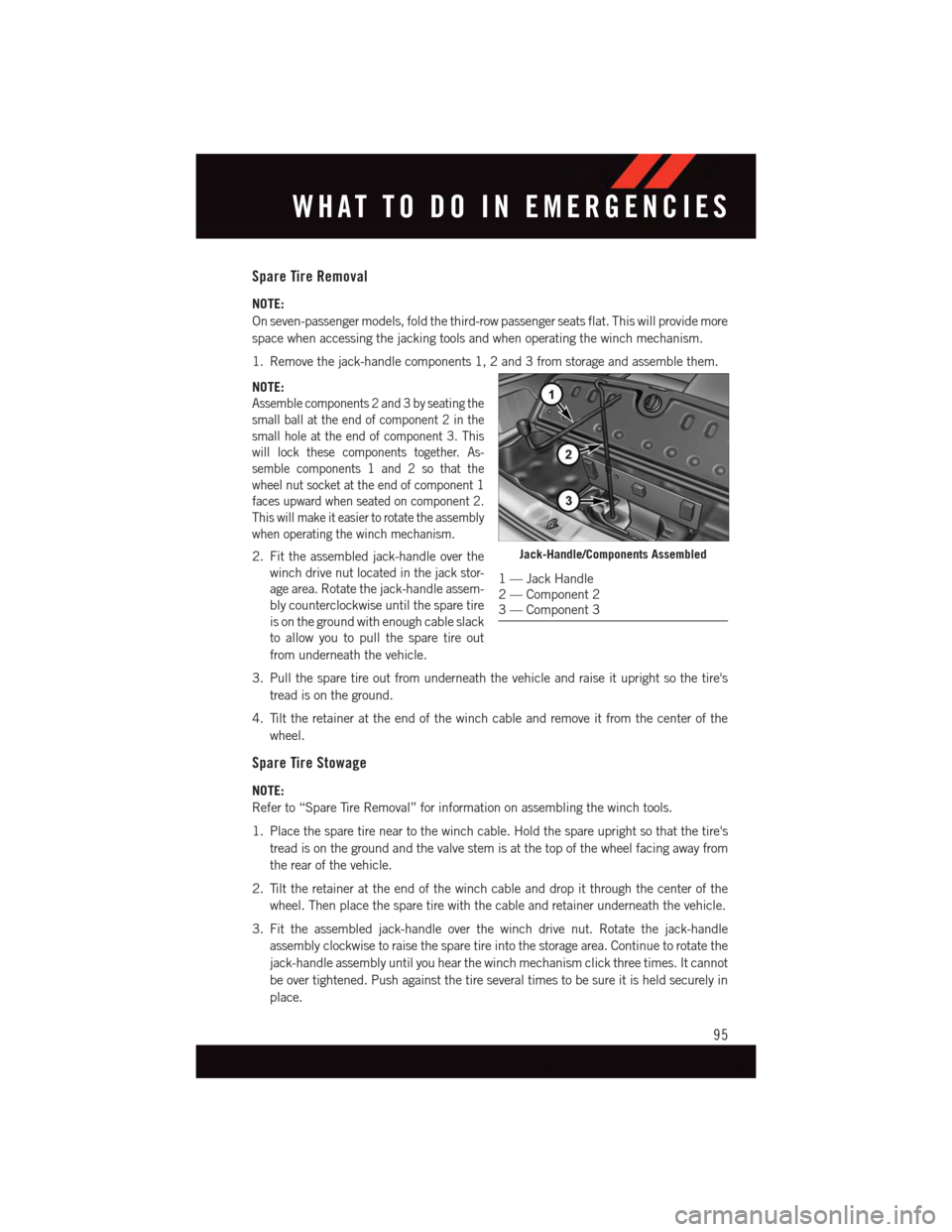

Spare Tire Removal

NOTE:

On seven-passenger models, fold the third-row passenger seats flat. This will provide more

space when accessing the jacking tools and when operating the winch mechanism.

1. Remove the jack-handle components 1, 2 and 3 from storage and assemble them.

NOTE:

Assemble components 2 and 3 by seating the

small ball at the end of component 2 in the

small hole at the end of component 3. This

will lock these components together. As-

semble components 1 and 2 so that the

wheel nut socket at the end of component 1

faces upward when seated on component 2.

This will make it easier to rotate the assembly

when operating the winch mechanism.

2. Fit the assembled jack-handle over the

winch drive nut located in the jack stor-

age area. Rotate the jack-handle assem-

bly counterclockwise until the spare tire

is on the ground with enough cable slack

to allow you to pull the spare tire out

from underneath the vehicle.

3. Pull the spare tire out from underneath the vehicle and raise it upright so the tire's

tread is on the ground.

4. Tilt the retainer at the end of the winch cable and remove it from the center of the

wheel.

Spare Tire Stowage

NOTE:

Refer to “Spare Tire Removal” for information on assembling the winch tools.

1. Place the spare tire near to the winch cable. Hold the spare upright so that the tire's

tread is on the ground and the valve stem is at the top of the wheel facing away from

the rear of the vehicle.

2. Tilt the retainer at the end of the winch cable and drop it through the center of the

wheel. Then place the spare tire with the cable and retainer underneath the vehicle.

3. Fit the assembled jack-handle over the winch drive nut. Rotate the jack-handle

assembly clockwise to raise the spare tire into the storage area. Continue to rotate the

jack-handle assembly until you hear the winch mechanism click three times. It cannot

be over tightened. Push against the tire several times to be sure it is held securely in

place.

Jack-Handle/Components Assembled

1—JackHandle2—Component23—Component3

WHAT TO DO IN EMERGENCIES

95

Page 98 of 140

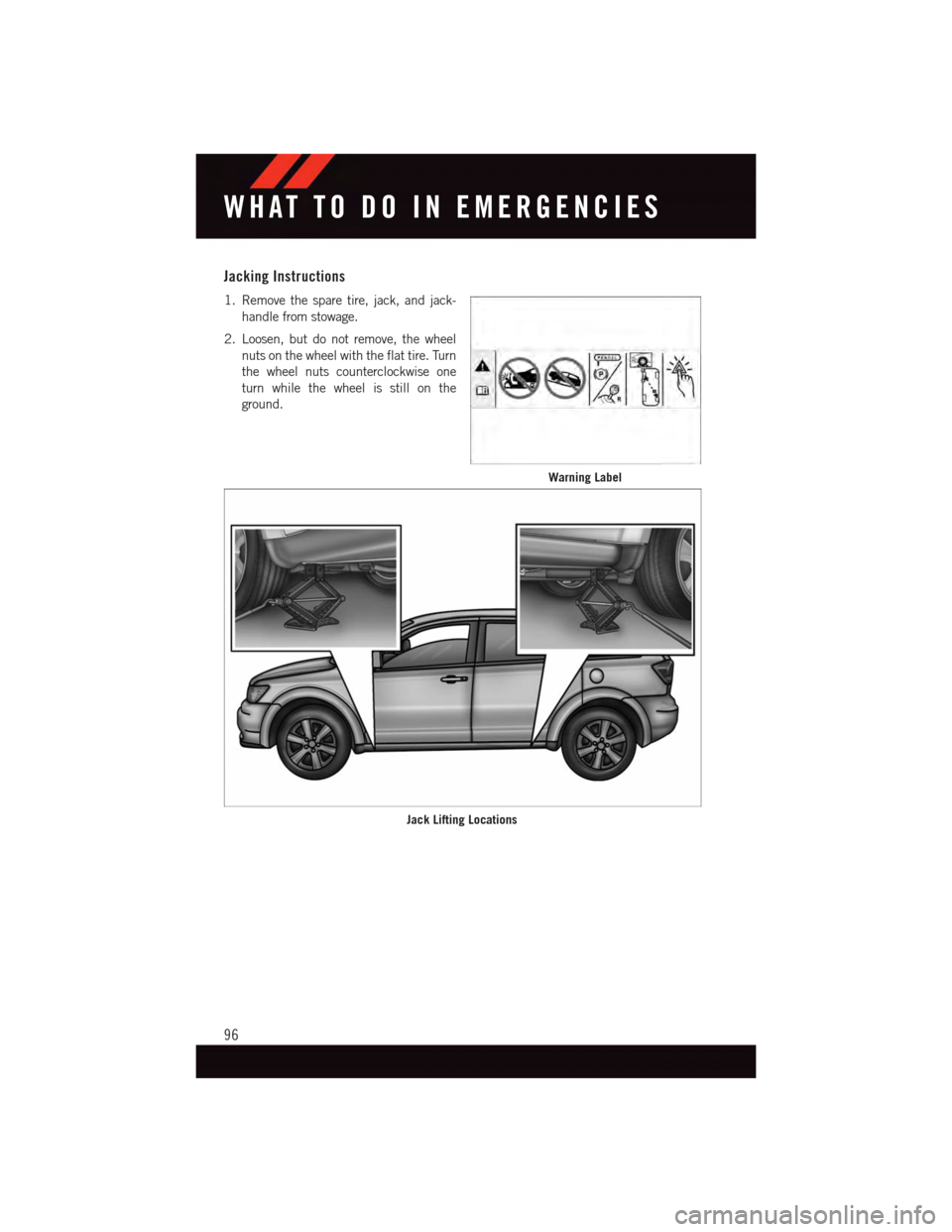

Jacking Instructions

1. Remove the spare tire, jack, and jack-

handle from stowage.

2. Loosen, but do not remove, the wheel

nuts on the wheel with the flat tire. Turn

the wheel nuts counterclockwise one

turn while the wheel is still on the

ground.

Warning Label

Jack Lifting Locations

WHAT TO DO IN EMERGENCIES

96

Page 99 of 140

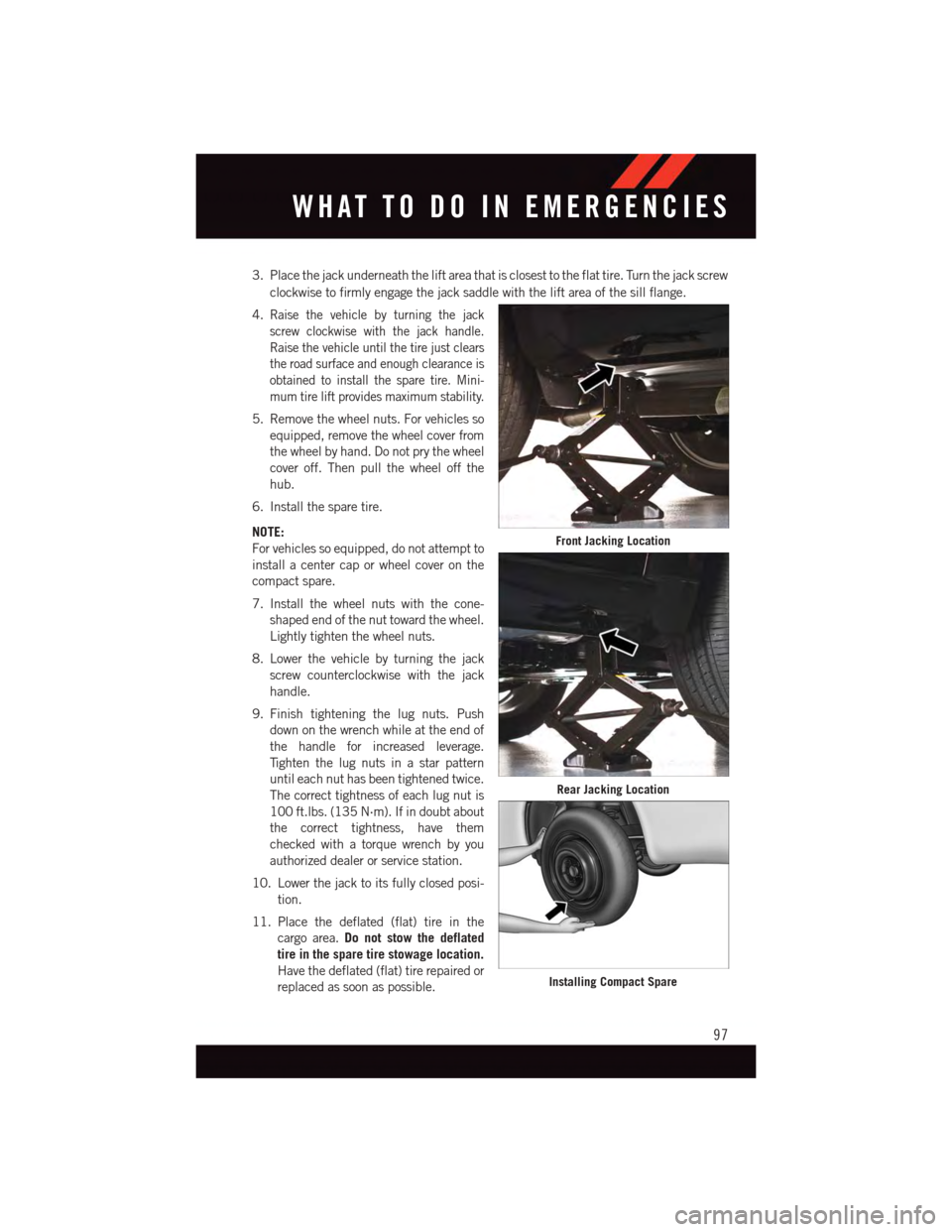

3. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw

clockwise to firmly engage the jack saddle with the lift area of the sill flange.

4.Raise the vehicle by turning the jack

screw clockwise with the jack handle.

Raise the vehicle until the tire just clears

the road surface and enough clearance is

obtained to install the spare tire. Mini-

mum tire lift provides maximum stability.

5. Remove the wheel nuts. For vehicles so

equipped, remove the wheel cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the

hub.

6. Install the spare tire.

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

7. Install the wheel nuts with the cone-

shaped end of the nut toward the wheel.

Lightly tighten the wheel nuts.

8. Lower the vehicle by turning the jack

screw counterclockwise with the jack

handle.

9. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e l u g n u t s i n a s t a r p a t t e r n

until each nut has been tightened twice.

The correct tightness of each lug nut is

100 ft.lbs. (135 N·m). If in doubt about

the correct tightness, have them

checked with a torque wrench by you

authorized dealer or service station.

10. Lower the jack to its fully closed posi-

tion.

11. Place the deflated (flat) tire in the

cargo area.Do not stow the deflated

tire in the spare tire stowage location.

Have the deflated (flat) tire repaired or

replaced as soon as possible.

Front Jacking Location

Rear Jacking Location

Installing Compact Spare

WHAT TO DO IN EMERGENCIES

97

Page 100 of 140

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch

drive nut. Rotate the jack-handle assembly clockwise until you hear the winch

mechanism click three times. It cannot be over tightened.

13. Stow the jack-handle and jack.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

Road Tire Installation

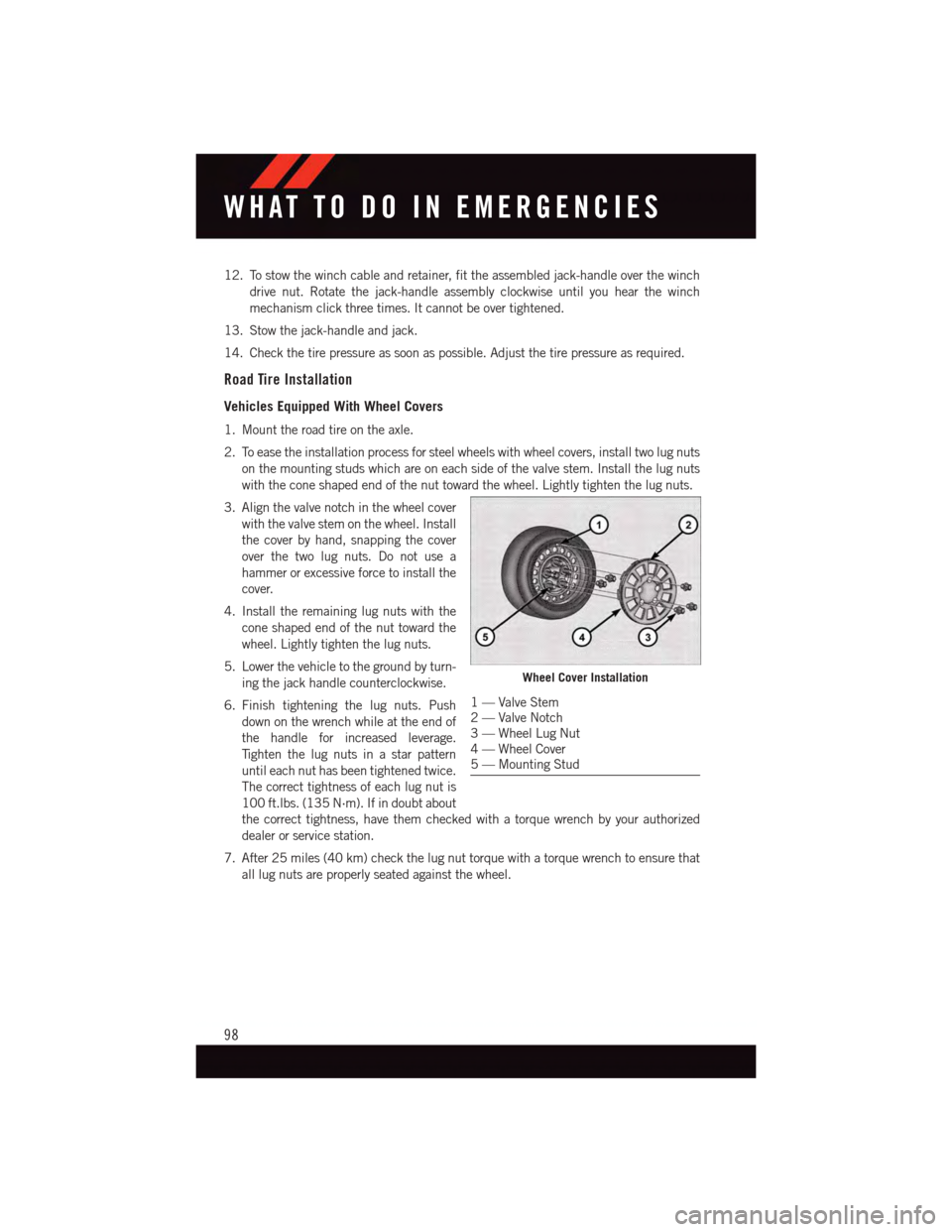

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts

on the mounting studs which are on each side of the valve stem. Install the lug nuts

with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Align the valve notch in the wheel cover

with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two lug nuts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e l u g n u t s i n a s t a r p a t t e r n

until each nut has been tightened twice.

The correct tightness of each lug nut is

100 ft.lbs. (135 N·m). If in doubt about

the correct tightness, have them checked with a torque wrench by your authorized

dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the wheel.

Wheel Cover Installation

1—ValveStem2—ValveNotch3—WheelLugNut4—WheelCover5—MountingStud

WHAT TO DO IN EMERGENCIES

98