warning DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 625 of 1200

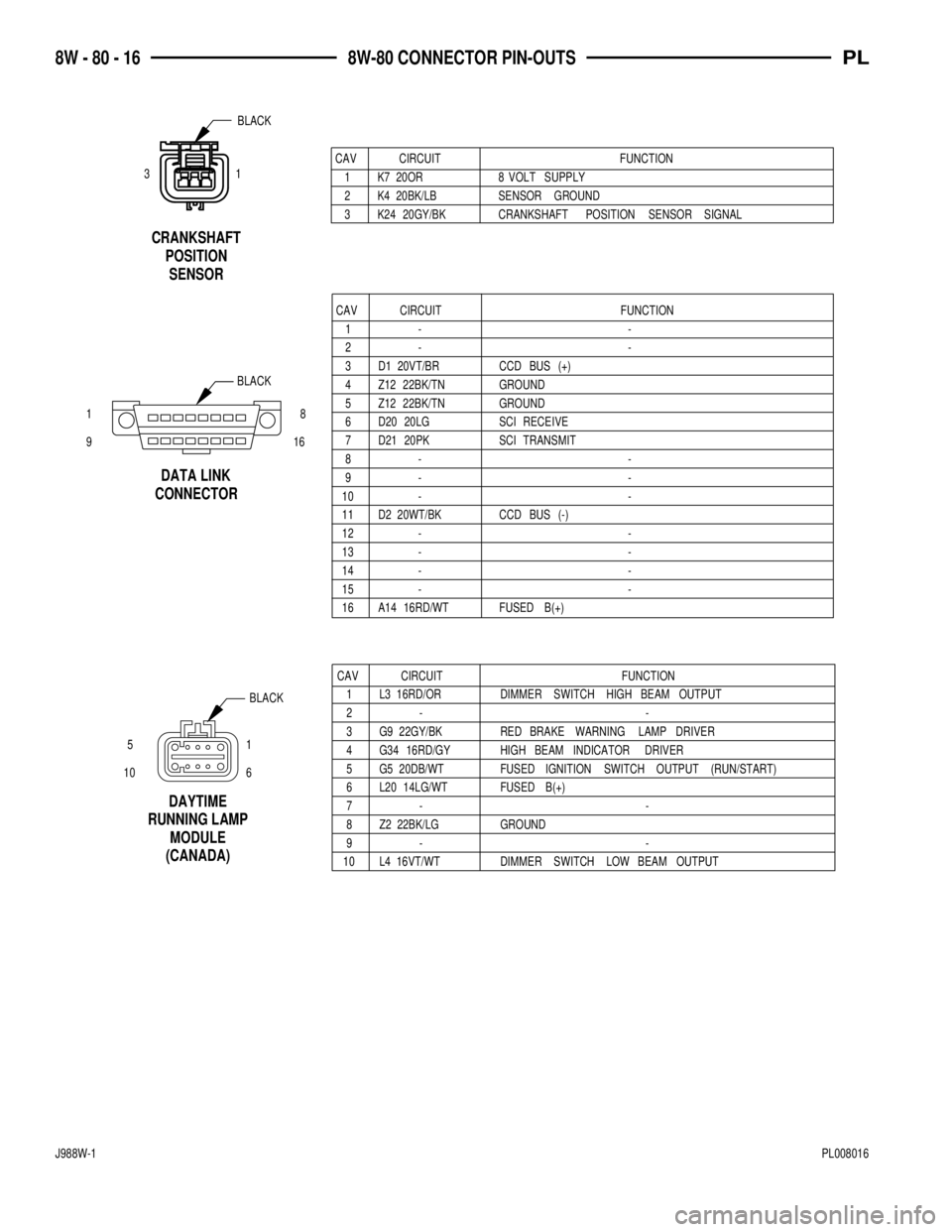

CAV CIRCUIT FUNCTION

1 K7 20OR 8 VOLT SUPPLY

2 K4 20BK/LB SENSOR GROUND

3 K24 20GY/BK CRANKSHAFT POSITION SENSOR SIGNAL

CAV CIRCUIT FUNCTION

1- -

2- -

3 D1 20VT/BR CCD BUS (+)

4 Z12 22BK/TN GROUND

5 Z12 22BK/TN GROUND

6 D20 20LG SCI RECEIVE

7 D21 20PK SCI TRANSMIT

8- -

9- -

10 - -

11 D2 20WT/BK CCD BUS (-)

12 - -

13 - -

14 - -

15 - -

16 A14 16RD/WT FUSED B(+)

BLACK

18

916

CAV CIRCUIT FUNCTION

1 L3 16RD/OR DIMMER SWITCH HIGH BEAM OUTPUT

2- -

3 G9 22GY/BK RED BRAKE WARNING LAMP DRIVER

4 G34 16RD/GY HIGH BEAM INDICATOR DRIVER

5 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN/START)

6 L20 14LG/WT FUSED B(+)

7- -

8 Z2 22BK/LG GROUND

9- -

10 L4 16VT/WT DIMMER SWITCH LOW BEAM OUTPUT

BLACK

51

10 6

31

BLACK

CRANKSHAFT

POSITION

SENSOR

DATA LINK

CONNECTOR

DAYTIME

RUNNING LAMP

MODULE

(CANADA)

8W - 80 - 16 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008016

Page 631 of 1200

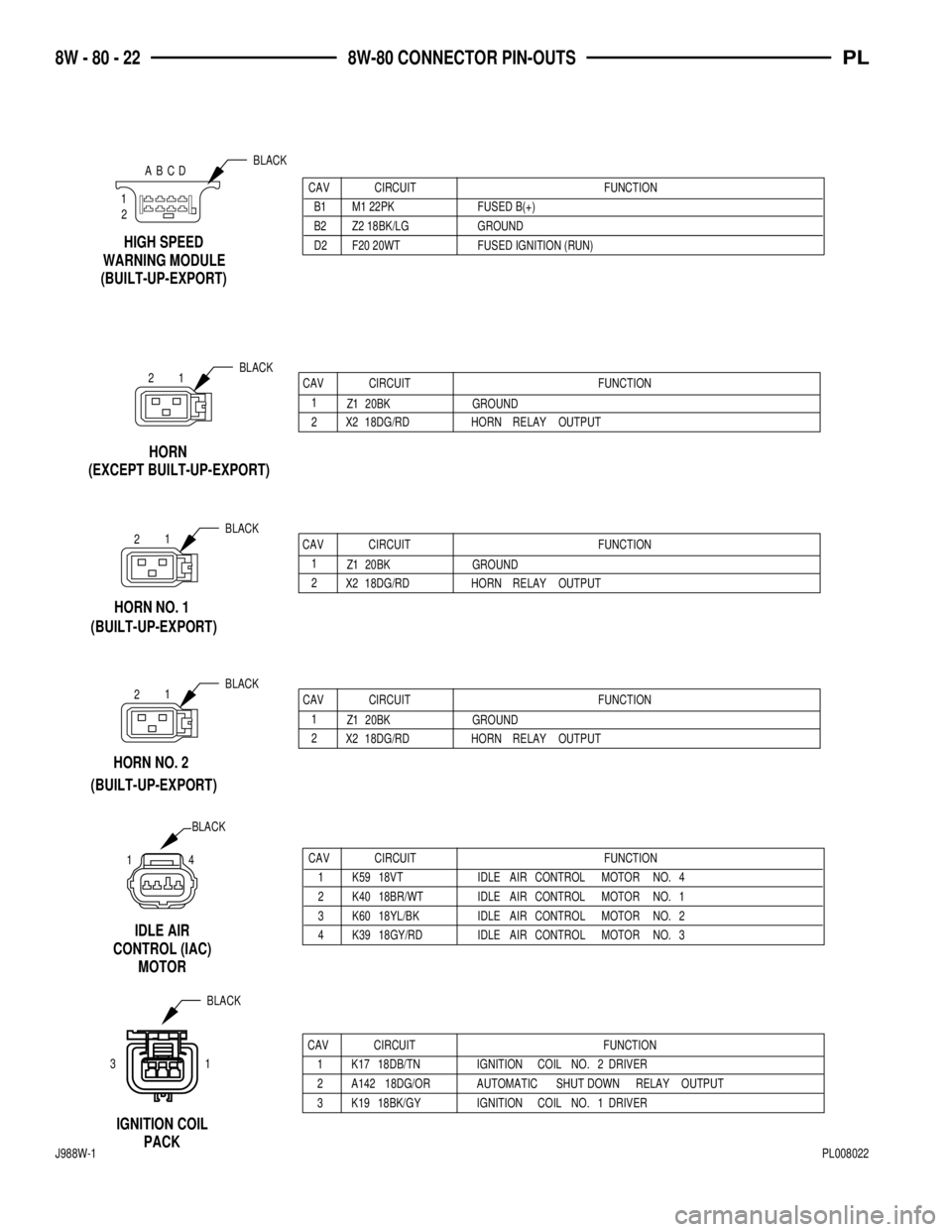

CAV CIRCUIT FUNCTION

1

X2 18DG/RD HORN RELAY OUTPUT 2Z1 20BK GROUND

CAV CIRCUIT FUNCTION

1 K59 18VT IDLE AIR CONTROL MOTOR NO. 4

2 K40 18BR/WT IDLE AIR CONTROL MOTOR NO. 1

3 K60 18YL/BK IDLE AIR CONTROL MOTOR NO. 2

4 K39 18GY/RD IDLE AIR CONTROL MOTOR NO. 3

CAV CIRCUIT FUNCTION

1 K17 18DB/TN IGNITION COIL NO. 2 DRIVER

2 A142 18DG/OR AUTOMATIC SHUT DOWN RELAY OUTPUT

3 K19 18BK/GY IGNITION COIL NO. 1 DRIVER

14

BLACK

31

BLACKBLACK

1

2

21BLACK

GROUND 20BK Z1

2

OUTPUT RELAY HORN 18DG/RD X2 1

FUNCTION CIRCUIT CAV

CAV CIRCUIT FUNCTION

1

X2 18DG/RD HORN RELAY OUTPUT 2Z1 20BK GROUND

BLACK

12

HORN

HORN NO. 1

HORN NO. 2

MOTOR CONTROL (IAC)IDLE AIR

IGNITION COIL

PACK (EXCEPT BUILT-UP-EXPORT)

(BUILT-UP-EXPORT)

(BUILT-UP-EXPORT)

FUSED IGNITION (RUN) F20 20WT D2

GROUND Z2 18BK/LG B2

FUSED B(+) M1 22PK B1

FUNCTION CIRCUIT CAV

HIGH SPEED

WARNING MODULE

(BUILT-UP-EXPORT)

BLACK

2 1ABCD

8W - 80 - 22 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008022

Page 632 of 1200

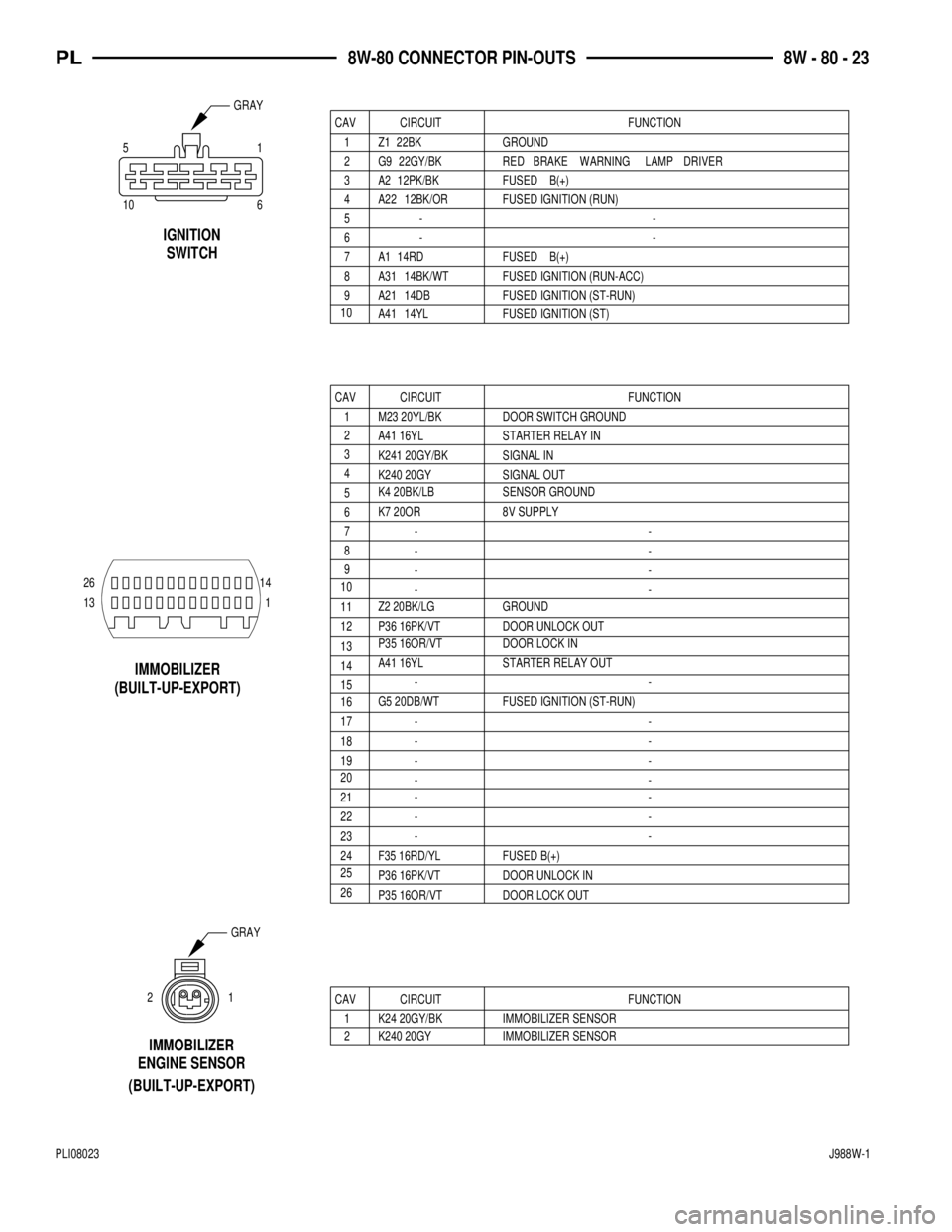

GRAY

51

10 6

CAV CIRCUIT FUNCTION

1 Z1 22BK GROUND

2 G9 22GY/BK RED BRAKE WARNING LAMP DRIVER

3 A2 12PK/BK FUSED B(+)

4 A22 12BK/OR FUSED IGNITION (RUN)

5- -

6- -

7 A1 14RD FUSED B(+)

8 A31 14BK/WT FUSED IGNITION (RUN-ACC)

9 A21 14DB FUSED IGNITION (ST-RUN)

10

A41 14YL FUSED IGNITION (ST)

IMMOBILIZER SENSOR K240 20GY 2IMMOBILIZER SENSOR K24 20GY/BK 1

FUNCTION CIRCUIT CAV1 2

IGNITION

SWITCH

IMMOBILIZER

ENGINE SENSOR

GRAY

(BUILT-UP-EXPORT)

109

8

7

6

5

4

3

2

DOOR SWITCH GROUND M23 20YL/BK 1

FUNCTION CIRCUIT CAV

11

16 15

20

21

25

26 22

23

24 18 17

19 14 13

12

A41 16YL STARTER RELAY IN

K240 20GY K241 20GY/BK SIGNAL IN

SIGNAL OUT

K4 20BK/LB

K7 20OR

-SENSOR GROUND

8V SUPPLY

-

Z2 20BK/LG

P36 16PK/VTGROUND

DOOR UNLOCK OUT

P35 16OR/VT

A41 16YL

G5 20DB/WTDOOR LOCK IN

STARTER RELAY OUT

FUSED IGNITION (ST-RUN)

P35 16OR/VT P36 16PK/VT

F35 16RD/YL FUSED B(+)

DOOR UNLOCK IN

DOOR LOCK OUT --

--

--

--

--

--

--

--

--

--

--

26 14

13 1

(BUILT-UP-EXPORT)IMMOBILIZER

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 23

PLI08023J988W-1

Page 633 of 1200

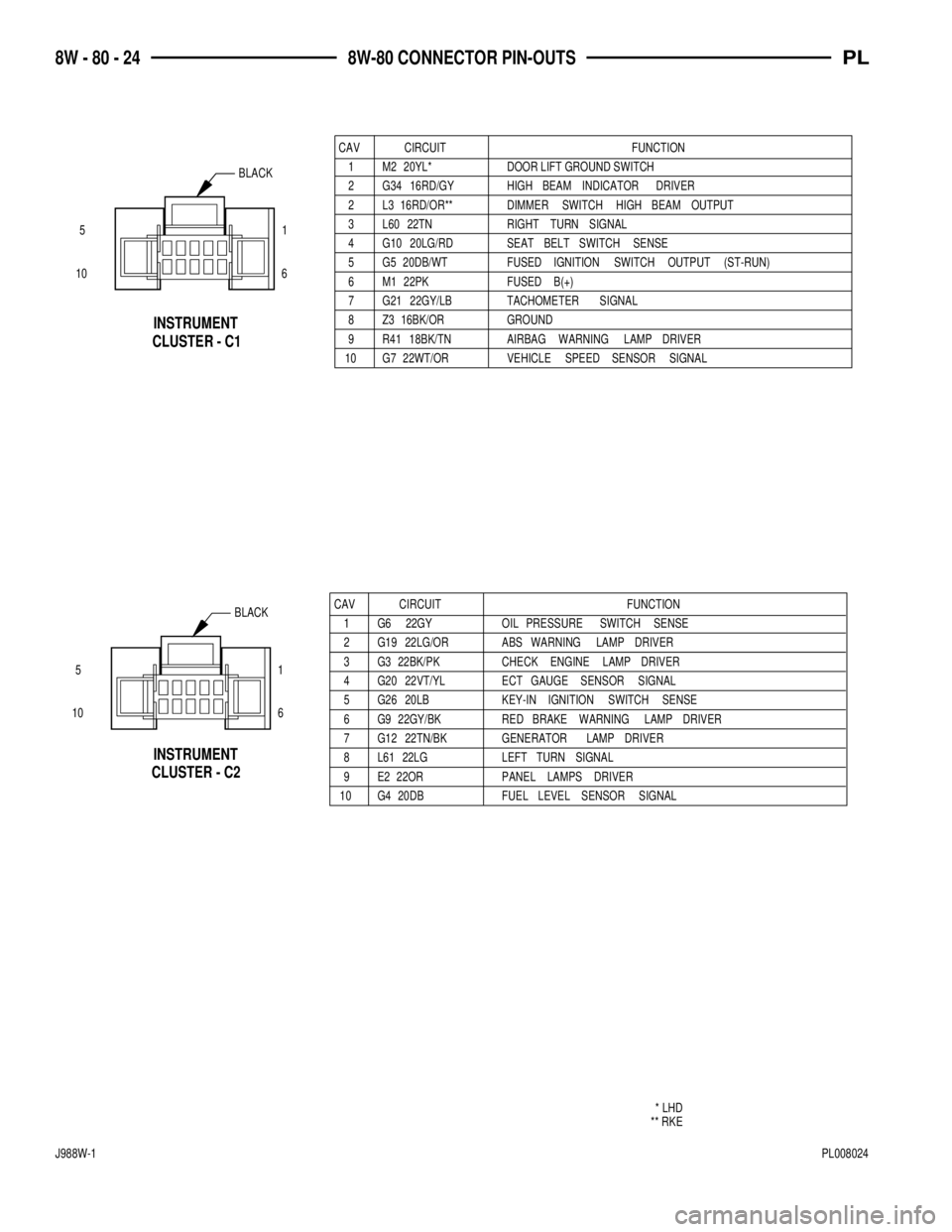

CAV CIRCUIT FUNCTION

1 M2 20YL* DOOR LIFT GROUND SWITCH

2 G34 16RD/GY HIGH BEAM INDICATOR DRIVER

2 L3 16RD/OR** DIMMER SWITCH HIGH BEAM OUTPUT

3 L60 22TN RIGHT TURN SIGNAL

4 G10 20LG/RD SEAT BELT SWITCH SENSE

5 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (ST-RUN)

6 M1 22PK FUSED B(+)

7 G21 22GY/LB TACHOMETER SIGNAL

8 Z3 16BK/OR GROUND

9 R41 18BK/TN AIRBAG WARNING LAMP DRIVER

10 G7 22WT/OR VEHICLE SPEED SENSOR SIGNAL

BLACK

51

10 6

** RKE

CAV CIRCUIT FUNCTION

1 G6 22GY OIL PRESSURE SWITCH SENSE

2 G19 22LG/OR ABS WARNING LAMP DRIVER

3 G3 22BK/PK CHECK ENGINE LAMP DRIVER

4 G20 22VT/YL ECT GAUGE SENSOR SIGNAL

5 G26 20LB KEY-IN IGNITION SWITCH SENSE

6 G9 22GY/BK RED BRAKE WARNING LAMP DRIVER

7 G12 22TN/BK GENERATOR LAMP DRIVER

8 L61 22LG LEFT TURN SIGNAL

9 E2 22OR PANEL LAMPS DRIVER

10 G4 20DB FUEL LEVEL SENSOR SIGNAL

BLACK

51

10 6

INSTRUMENT

CLUSTER - C1

CLUSTER - C2INSTRUMENT

* LHD

8W - 80 - 24 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008024

Page 654 of 1200

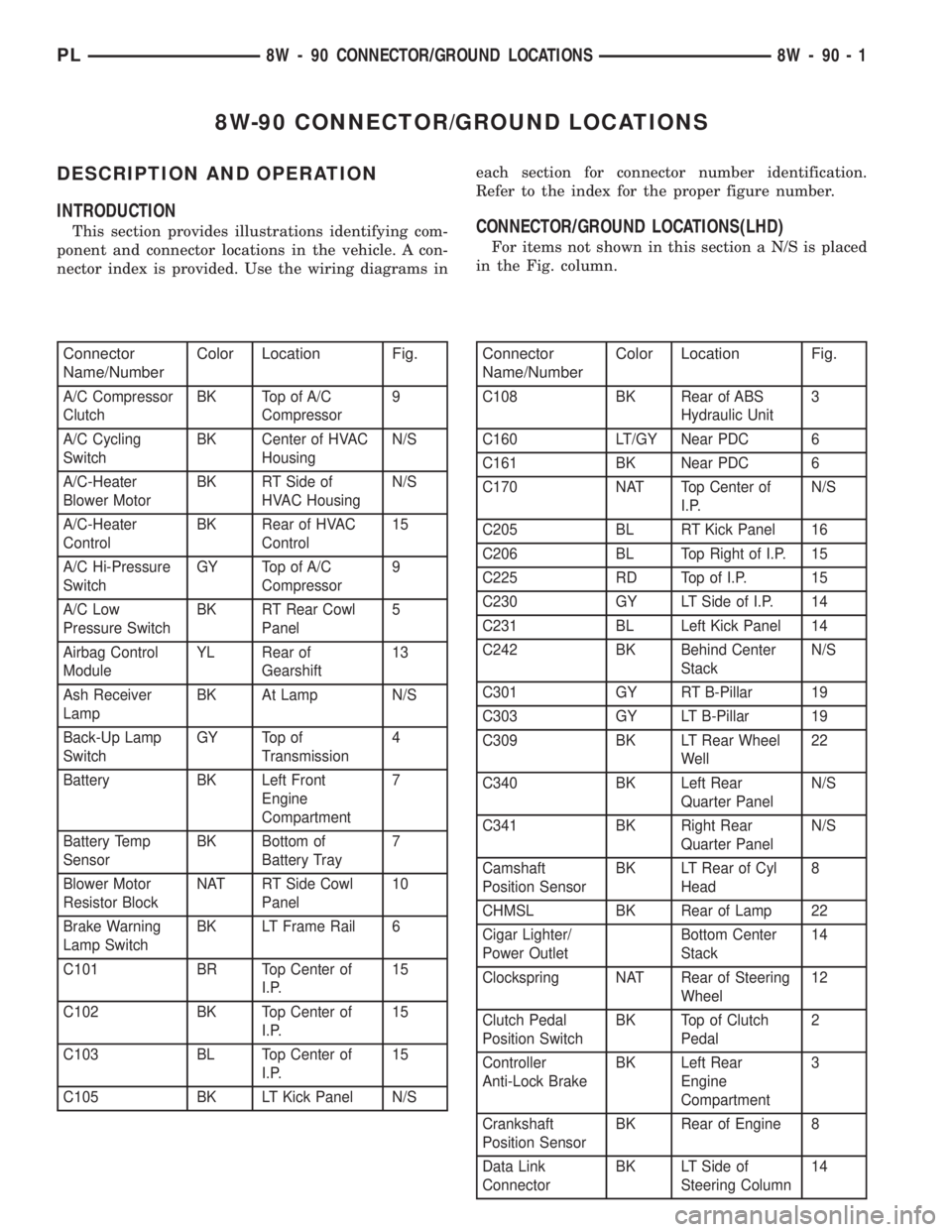

8W-90 CONNECTOR/GROUND LOCATIONS

DESCRIPTION AND OPERATION

INTRODUCTION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-

nector index is provided. Use the wiring diagrams ineach section for connector number identification.

Refer to the index for the proper figure number.CONNECTOR/GROUND LOCATIONS(LHD)

For items not shown in this section a N/S is placed

in the Fig. column.

Connector

Name/NumberColor Location Fig.

A/C Compressor

ClutchBK Top of A/C

Compressor9

A/C Cycling

SwitchBK Center of HVAC

HousingN/S

A/C-Heater

Blower MotorBK RT Side of

HVAC HousingN/S

A/C-Heater

ControlBK Rear of HVAC

Control15

A/C Hi-Pressure

SwitchGY Top of A/C

Compressor9

A/C Low

Pressure SwitchBK RT Rear Cowl

Panel5

Airbag Control

ModuleYL Rear of

Gearshift13

Ash Receiver

LampBK At Lamp N/S

Back-Up Lamp

SwitchGY Top of

Transmission4

Battery BK Left Front

Engine

Compartment7

Battery Temp

SensorBK Bottom of

Battery Tray7

Blower Motor

Resistor BlockNAT RT Side Cowl

Panel10

Brake Warning

Lamp SwitchBK LT Frame Rail 6

C101 BR Top Center of

I.P.15

C102 BK Top Center of

I.P.15

C103 BL Top Center of

I.P.15

C105 BK LT Kick Panel N/S

Connector

Name/NumberColor Location Fig.

C108 BK Rear of ABS

Hydraulic Unit3

C160 LT/GY Near PDC 6

C161 BK Near PDC 6

C170 NAT Top Center of

I.P.N/S

C205 BL RT Kick Panel 16

C206 BL Top Right of I.P. 15

C225 RD Top of I.P. 15

C230 GY LT Side of I.P. 14

C231 BL Left Kick Panel 14

C242 BK Behind Center

StackN/S

C301 GY RT B-Pillar 19

C303 GY LT B-Pillar 19

C309 BK LT Rear Wheel

Well22

C340 BK Left Rear

Quarter PanelN/S

C341 BK Right Rear

Quarter PanelN/S

Camshaft

Position SensorBK LT Rear of Cyl

Head8

CHMSL BK Rear of Lamp 22

Cigar Lighter/

Power OutletBottom Center

Stack14

Clockspring NAT Rear of Steering

Wheel12

Clutch Pedal

Position SwitchBK Top of Clutch

Pedal2

Controller

Anti-Lock BrakeBK Left Rear

Engine

Compartment3

Crankshaft

Position SensorBK Rear of Engine 8

Data Link

ConnectorBK LT Side of

Steering Column14

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 1

Page 676 of 1200

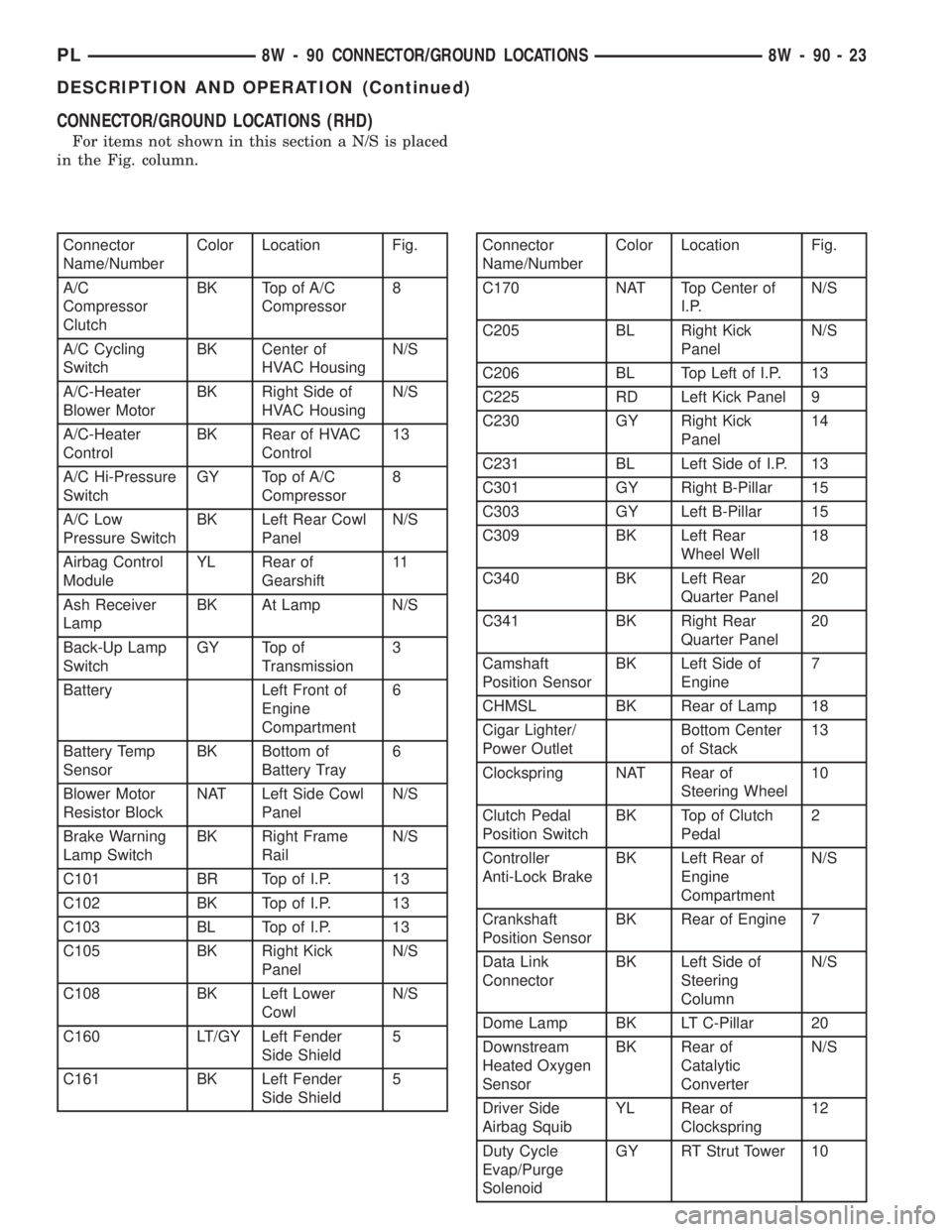

CONNECTOR/GROUND LOCATIONS (RHD)

For items not shown in this section a N/S is placed

in the Fig. column.

Connector

Name/NumberColor Location Fig.

A/C

Compressor

ClutchBK Top of A/C

Compressor8

A/C Cycling

SwitchBK Center of

HVAC HousingN/S

A/C-Heater

Blower MotorBK Right Side of

HVAC HousingN/S

A/C-Heater

ControlBK Rear of HVAC

Control13

A/C Hi-Pressure

SwitchGY Top of A/C

Compressor8

A/C Low

Pressure SwitchBK Left Rear Cowl

PanelN/S

Airbag Control

ModuleYL Rear of

Gearshift11

Ash Receiver

LampBK At Lamp N/S

Back-Up Lamp

SwitchGY Top of

Transmission3

Battery Left Front of

Engine

Compartment6

Battery Temp

SensorBK Bottom of

Battery Tray6

Blower Motor

Resistor BlockNAT Left Side Cowl

PanelN/S

Brake Warning

Lamp SwitchBK Right Frame

RailN/S

C101 BR Top of I.P. 13

C102 BK Top of I.P. 13

C103 BL Top of I.P. 13

C105 BK Right Kick

PanelN/S

C108 BK Left Lower

CowlN/S

C160 LT/GY Left Fender

Side Shield5

C161 BK Left Fender

Side Shield5Connector

Name/NumberColor Location Fig.

C170 NAT Top Center of

I.P.N/S

C205 BL Right Kick

PanelN/S

C206 BL Top Left of I.P. 13

C225 RD Left Kick Panel 9

C230 GY Right Kick

Panel14

C231 BL Left Side of I.P. 13

C301 GY Right B-Pillar 15

C303 GY Left B-Pillar 15

C309 BK Left Rear

Wheel Well18

C340 BK Left Rear

Quarter Panel20

C341 BK Right Rear

Quarter Panel20

Camshaft

Position SensorBK Left Side of

Engine7

CHMSL BK Rear of Lamp 18

Cigar Lighter/

Power OutletBottom Center

of Stack13

Clockspring NAT Rear of

Steering Wheel10

Clutch Pedal

Position SwitchBK Top of Clutch

Pedal2

Controller

Anti-Lock BrakeBK Left Rear of

Engine

CompartmentN/S

Crankshaft

Position SensorBK Rear of Engine 7

Data Link

ConnectorBK Left Side of

Steering

ColumnN/S

Dome Lamp BK LT C-Pillar 20

Downstream

Heated Oxygen

SensorBK Rear of

Catalytic

ConverterN/S

Driver Side

Airbag SquibYL Rear of

Clockspring12

Duty Cycle

Evap/Purge

SolenoidGY RT Strut Tower 10

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 23

DESCRIPTION AND OPERATION (Continued)

Page 718 of 1200

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., Connecting

Rods, Pistons, Valves etc.)

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

CAUTION: Squirt approximately 1 teaspoon of oil

into cylinders, rotate engine to lubricate the cylin-

der walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

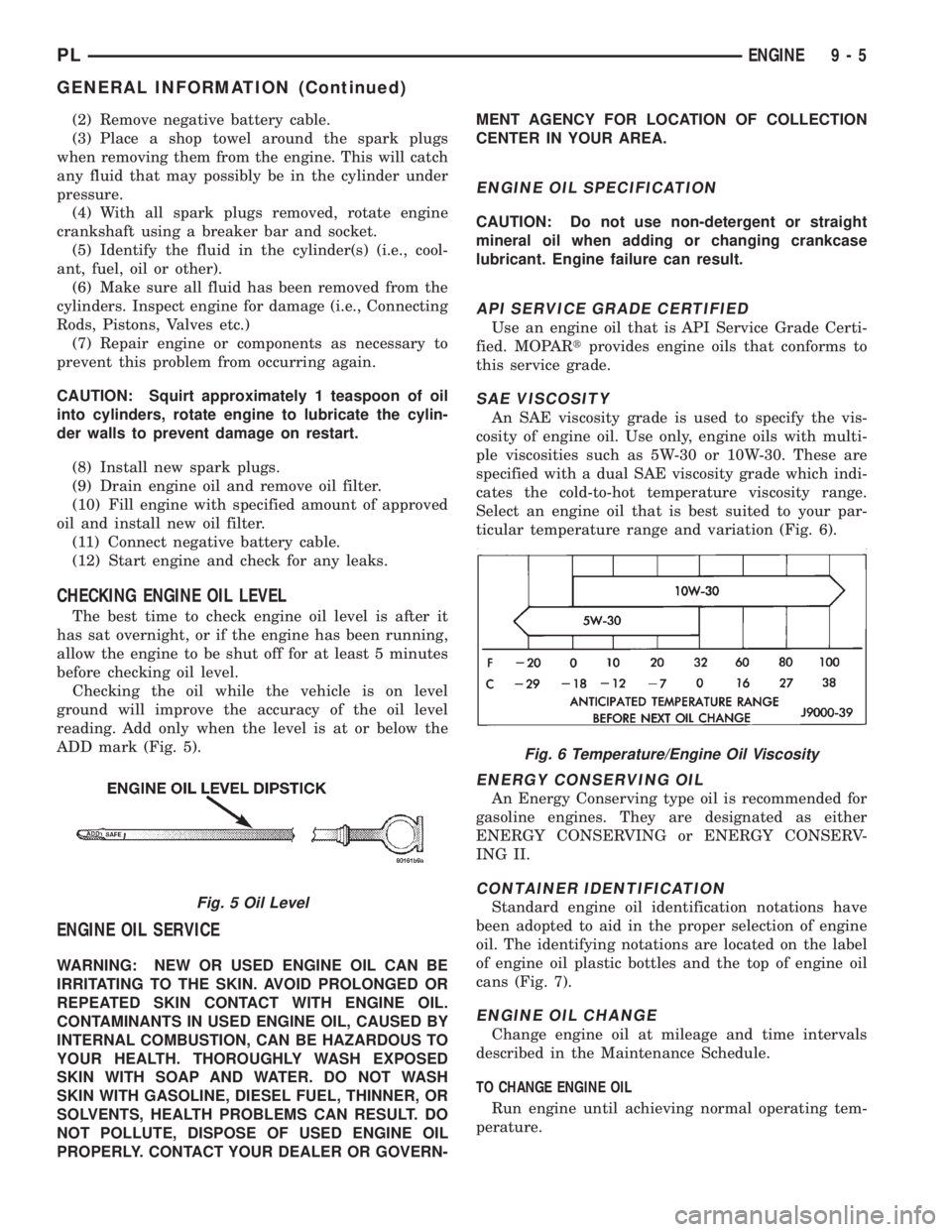

CHECKING ENGINE OIL LEVEL

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Add only when the level is at or below the

ADD mark (Fig. 5).

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

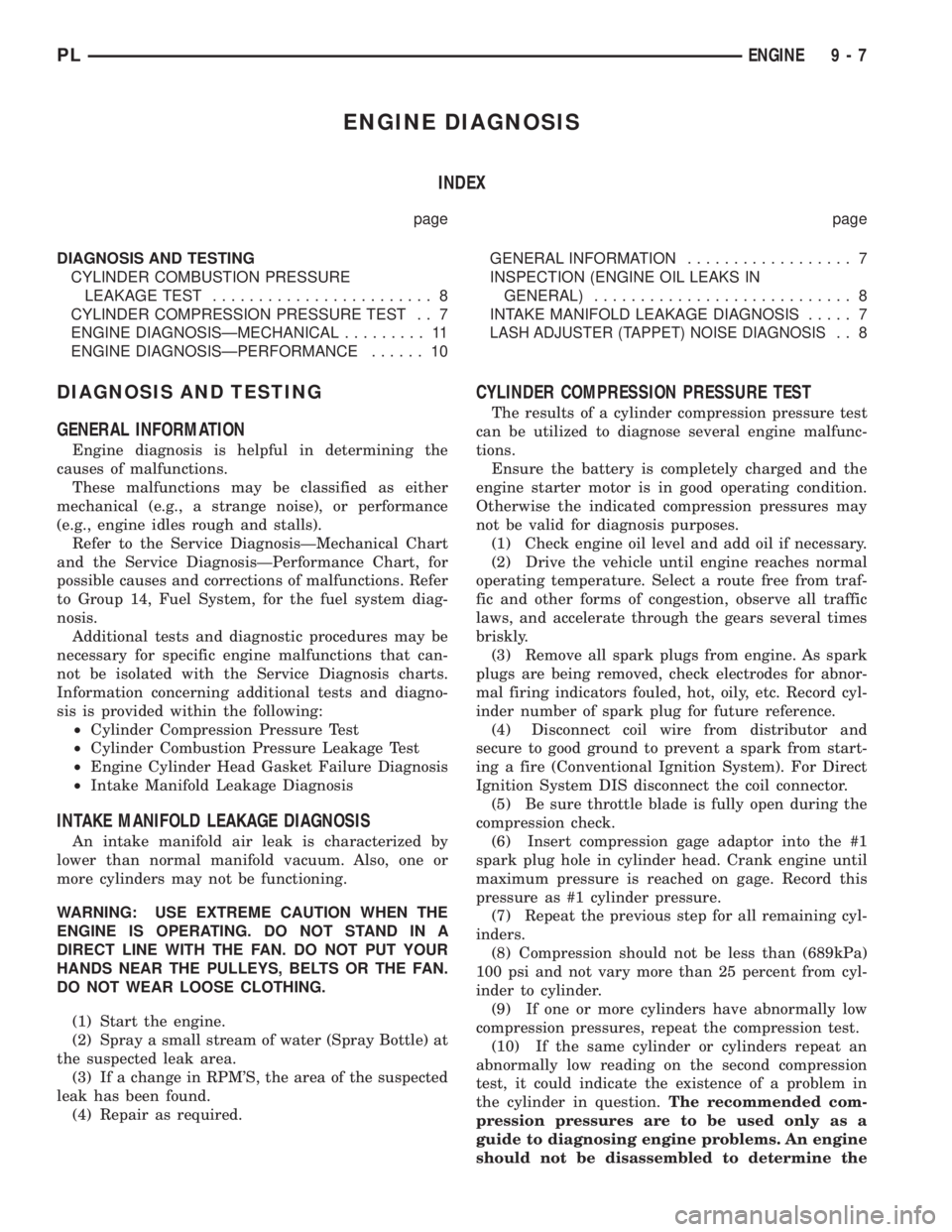

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 6).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either

ENERGY CONSERVING or ENERGY CONSERV-

ING II.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 7).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

Fig. 5 Oil Level

Fig. 6 Temperature/Engine Oil Viscosity

PLENGINE 9 - 5

GENERAL INFORMATION (Continued)

Page 720 of 1200

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST........................ 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 11

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)............................ 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS.. 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

PLENGINE 9 - 7

Page 721 of 1200

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

9 - 8 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 821 of 1200

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble catalytic convertor to exhaust mani-

fold connection. Use a new flange gasket (LEV only)

(Fig. 9) or (Fig. 10).

(2) Assemble exhaust pipe to catalytic convertor

and the support to the underbody

(3) Install the muffler to exhaust pipe and the sup-

ports to the underbody.

(4) Working from the front of system;

(5) Align and tighten the catalytic convertor to

exhaust manifold ball joint bolts to 27 N´m (20 ft.

lbs.) (Fig. 9) or flex-joint attaching nuts (LEV) to 28

N´m (250 in. lbs.).

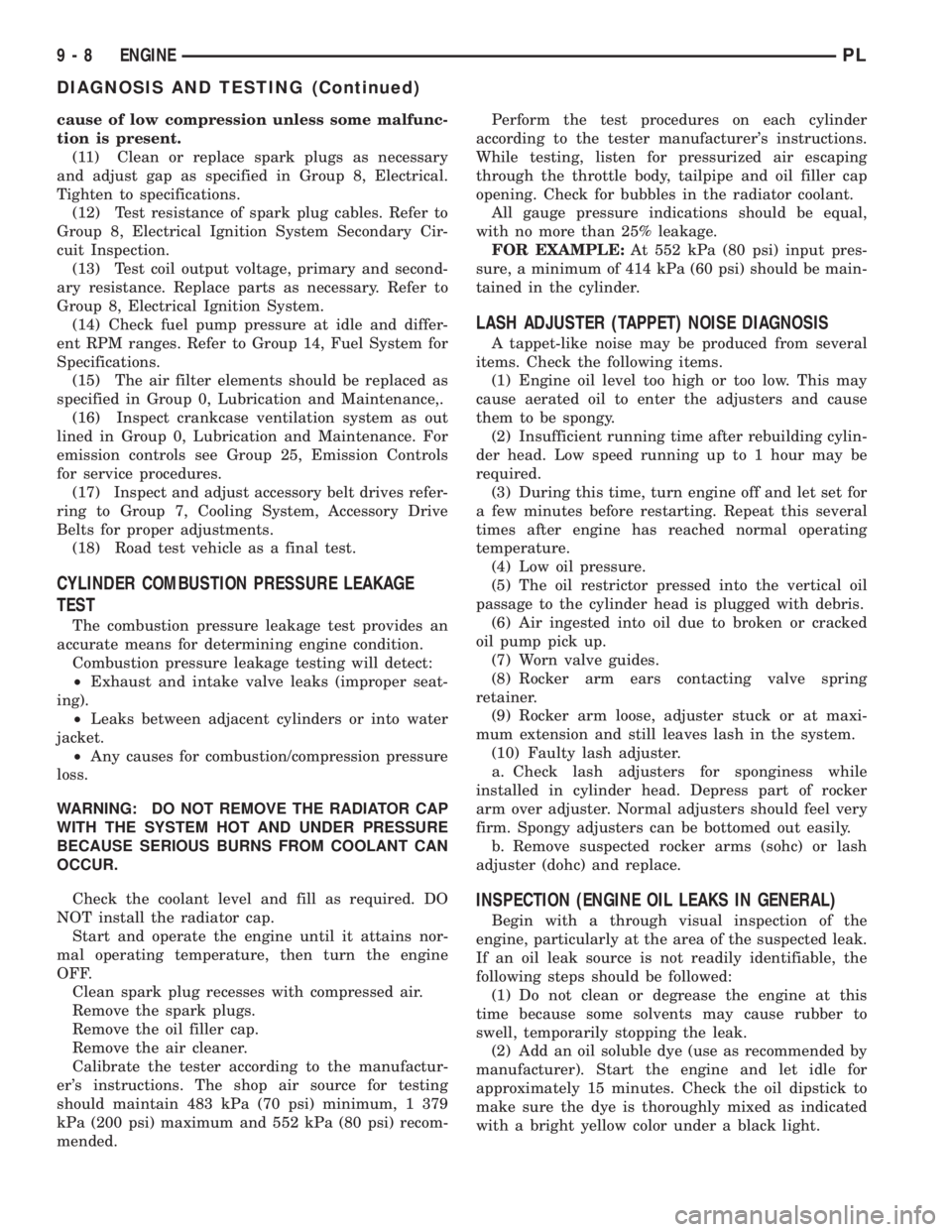

(6) Align each component to maintain position and

proper clearance with underbody parts (Fig. 11) and

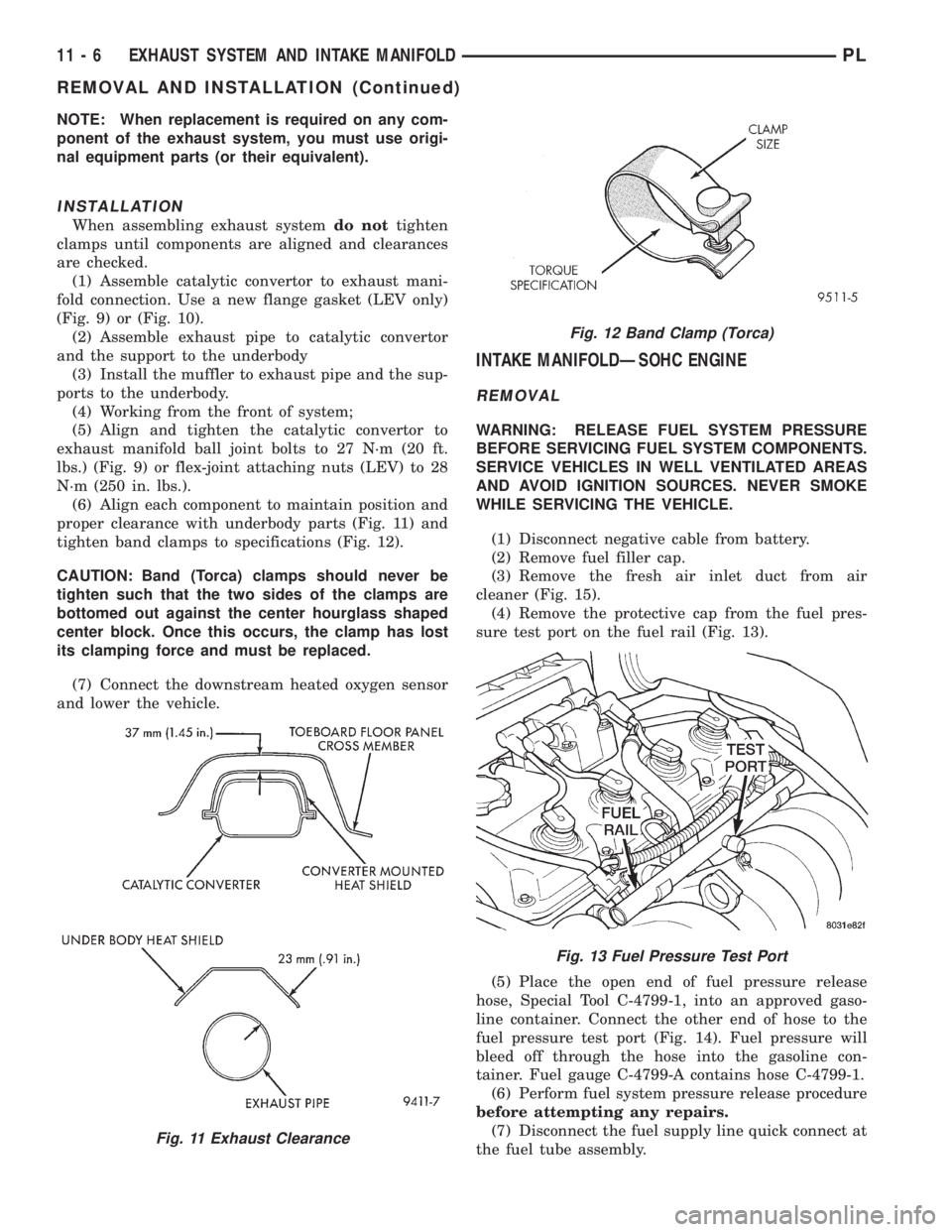

tighten band clamps to specifications (Fig. 12).

CAUTION: Band (Torca) clamps should never be

tighten such that the two sides of the clamps are

bottomed out against the center hourglass shaped

center block. Once this occurs, the clamp has lost

its clamping force and must be replaced.

(7) Connect the downstream heated oxygen sensor

and lower the vehicle.

INTAKE MANIFOLDÐSOHC ENGINE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the fresh air inlet duct from air

cleaner (Fig. 15).

(4) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 13).

(5) Place the open end of fuel pressure release

hose, Special Tool C-4799-1, into an approved gaso-

line container. Connect the other end of hose to the

fuel pressure test port (Fig. 14). Fuel pressure will

bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1.

(6) Perform fuel system pressure release procedure

before attempting any repairs.

(7) Disconnect the fuel supply line quick connect at

the fuel tube assembly.

Fig. 11 Exhaust Clearance

Fig. 12 Band Clamp (Torca)

Fig. 13 Fuel Pressure Test Port

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)