ABS DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 100 of 1200

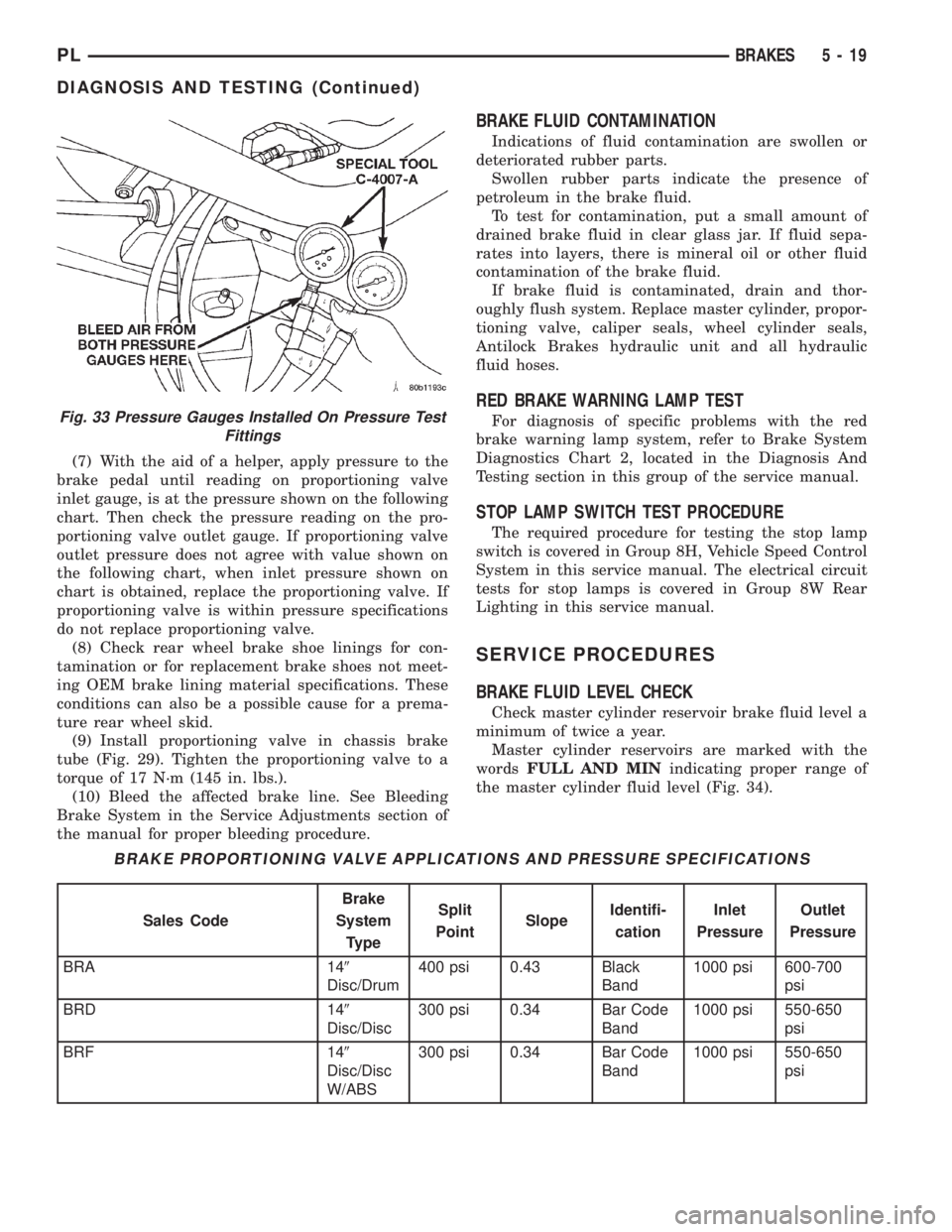

(7) With the aid of a helper, apply pressure to the

brake pedal until reading on proportioning valve

inlet gauge, is at the pressure shown on the following

chart. Then check the pressure reading on the pro-

portioning valve outlet gauge. If proportioning valve

outlet pressure does not agree with value shown on

the following chart, when inlet pressure shown on

chart is obtained, replace the proportioning valve. If

proportioning valve is within pressure specifications

do not replace proportioning valve.

(8) Check rear wheel brake shoe linings for con-

tamination or for replacement brake shoes not meet-

ing OEM brake lining material specifications. These

conditions can also be a possible cause for a prema-

ture rear wheel skid.

(9) Install proportioning valve in chassis brake

tube (Fig. 29). Tighten the proportioning valve to a

torque of 17 N´m (145 in. lbs.).

(10) Bleed the affected brake line. See Bleeding

Brake System in the Service Adjustments section of

the manual for proper bleeding procedure.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

RED BRAKE WARNING LAMP TEST

For diagnosis of specific problems with the red

brake warning lamp system, refer to Brake System

Diagnostics Chart 2, located in the Diagnosis And

Testing section in this group of the service manual.

STOP LAMP SWITCH TEST PROCEDURE

The required procedure for testing the stop lamp

switch is covered in Group 8H, Vehicle Speed Control

System in this service manual. The electrical circuit

tests for stop lamps is covered in Group 8W Rear

Lighting in this service manual.

SERVICE PROCEDURES

BRAKE FLUID LEVEL CHECK

Check master cylinder reservoir brake fluid level a

minimum of twice a year.

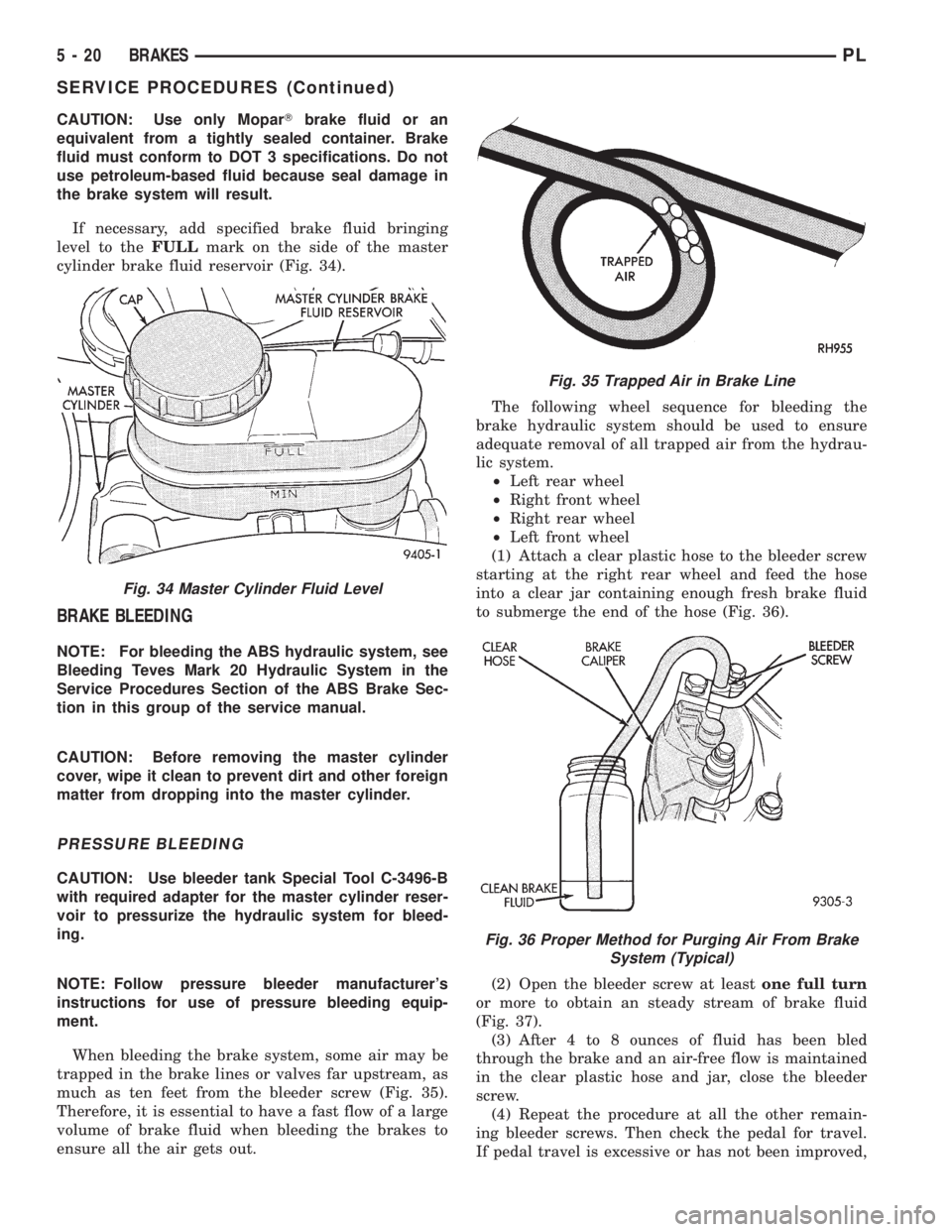

Master cylinder reservoirs are marked with the

wordsFULL AND MINindicating proper range of

the master cylinder fluid level (Fig. 34).

Fig. 33 Pressure Gauges Installed On Pressure Test

Fittings

BRAKE PROPORTIONING VALVE APPLICATIONS AND PRESSURE SPECIFICATIONS

Sales CodeBrake

System

TypeSplit

PointSlopeIdentifi-

cationInlet

PressureOutlet

Pressure

BRA 149

Disc/Drum400 psi 0.43 Black

Band1000 psi 600-700

psi

BRD 149

Disc/Disc300 psi 0.34 Bar Code

Band1000 psi 550-650

psi

BRF 149

Disc/Disc

W/ABS300 psi 0.34 Bar Code

Band1000 psi 550-650

psi

PLBRAKES 5 - 19

DIAGNOSIS AND TESTING (Continued)

Page 101 of 1200

CAUTION: Use only MoparTbrake fluid or an

equivalent from a tightly sealed container. Brake

fluid must conform to DOT 3 specifications. Do not

use petroleum-based fluid because seal damage in

the brake system will result.

If necessary, add specified brake fluid bringing

level to theFULLmark on the side of the master

cylinder brake fluid reservoir (Fig. 34).

BRAKE BLEEDING

NOTE: For bleeding the ABS hydraulic system, see

Bleeding Teves Mark 20 Hydraulic System in the

Service Procedures Section of the ABS Brake Sec-

tion in this group of the service manual.

CAUTION: Before removing the master cylinder

cover, wipe it clean to prevent dirt and other foreign

matter from dropping into the master cylinder.

PRESSURE BLEEDING

CAUTION: Use bleeder tank Special Tool C-3496-B

with required adapter for the master cylinder reser-

voir to pressurize the hydraulic system for bleed-

ing.

NOTE: Follow pressure bleeder manufacturer's

instructions for use of pressure bleeding equip-

ment.

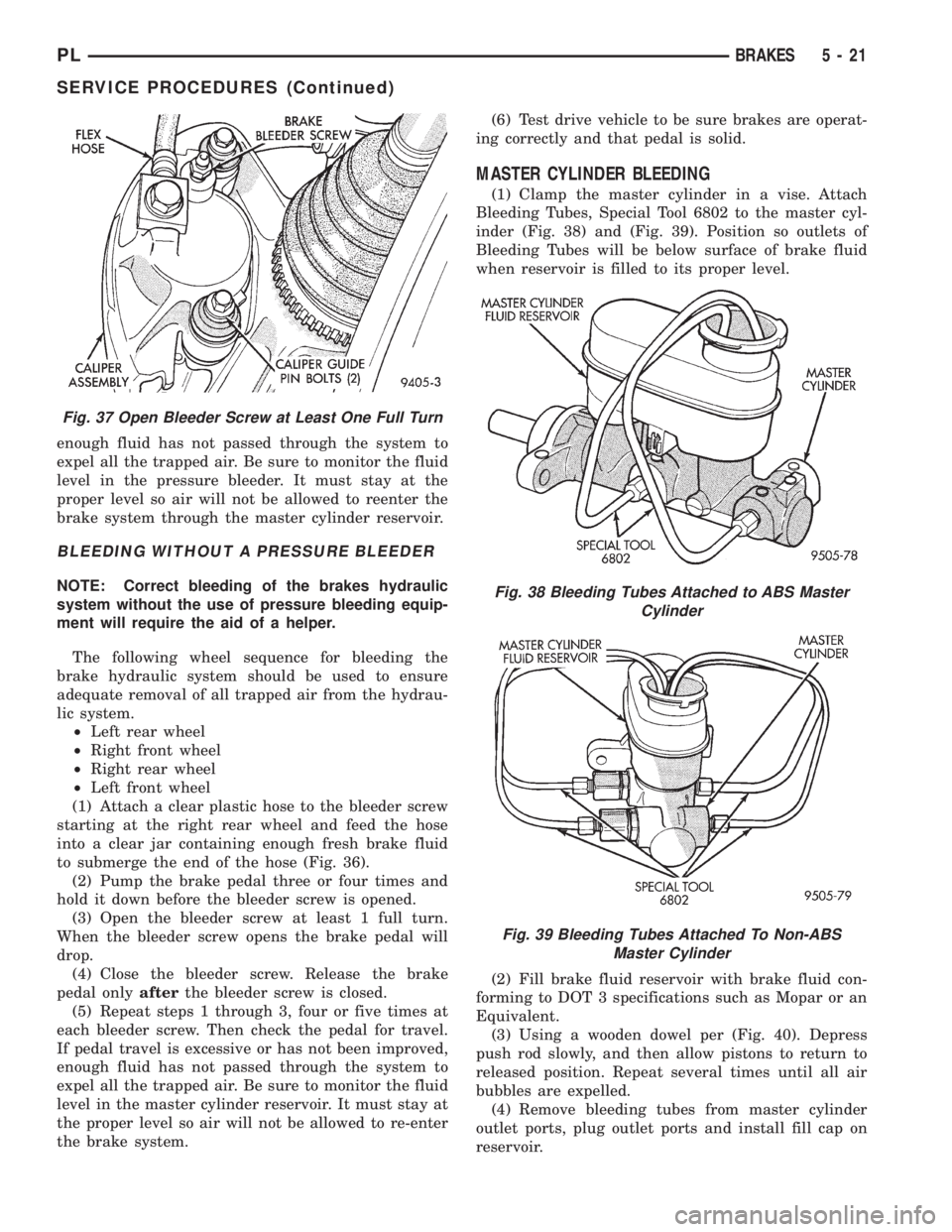

When bleeding the brake system, some air may be

trapped in the brake lines or valves far upstream, as

much as ten feet from the bleeder screw (Fig. 35).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure

adequate removal of all trapped air from the hydrau-

lic system.

²Left rear wheel

²Right front wheel

²Right rear wheel

²Left front wheel

(1) Attach a clear plastic hose to the bleeder screw

starting at the right rear wheel and feed the hose

into a clear jar containing enough fresh brake fluid

to submerge the end of the hose (Fig. 36).

(2) Open the bleeder screw at leastone full turn

or more to obtain an steady stream of brake fluid

(Fig. 37).

(3) After 4 to 8 ounces of fluid has been bled

through the brake and an air-free flow is maintained

in the clear plastic hose and jar, close the bleeder

screw.

(4) Repeat the procedure at all the other remain-

ing bleeder screws. Then check the pedal for travel.

If pedal travel is excessive or has not been improved,

Fig. 34 Master Cylinder Fluid Level

Fig. 35 Trapped Air in Brake Line

Fig. 36 Proper Method for Purging Air From Brake

System (Typical)

5 - 20 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 102 of 1200

enough fluid has not passed through the system to

expel all the trapped air. Be sure to monitor the fluid

level in the pressure bleeder. It must stay at the

proper level so air will not be allowed to reenter the

brake system through the master cylinder reservoir.

BLEEDING WITHOUT A PRESSURE BLEEDER

NOTE: Correct bleeding of the brakes hydraulic

system without the use of pressure bleeding equip-

ment will require the aid of a helper.

The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure

adequate removal of all trapped air from the hydrau-

lic system.

²Left rear wheel

²Right front wheel

²Right rear wheel

²Left front wheel

(1) Attach a clear plastic hose to the bleeder screw

starting at the right rear wheel and feed the hose

into a clear jar containing enough fresh brake fluid

to submerge the end of the hose (Fig. 36).

(2) Pump the brake pedal three or four times and

hold it down before the bleeder screw is opened.

(3) Open the bleeder screw at least 1 full turn.

When the bleeder screw opens the brake pedal will

drop.

(4) Close the bleeder screw. Release the brake

pedal onlyafterthe bleeder screw is closed.

(5) Repeat steps 1 through 3, four or five times at

each bleeder screw. Then check the pedal for travel.

If pedal travel is excessive or has not been improved,

enough fluid has not passed through the system to

expel all the trapped air. Be sure to monitor the fluid

level in the master cylinder reservoir. It must stay at

the proper level so air will not be allowed to re-enter

the brake system.(6) Test drive vehicle to be sure brakes are operat-

ing correctly and that pedal is solid.

MASTER CYLINDER BLEEDING

(1) Clamp the master cylinder in a vise. Attach

Bleeding Tubes, Special Tool 6802 to the master cyl-

inder (Fig. 38) and (Fig. 39). Position so outlets of

Bleeding Tubes will be below surface of brake fluid

when reservoir is filled to its proper level.

(2) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(3) Using a wooden dowel per (Fig. 40). Depress

push rod slowly, and then allow pistons to return to

released position. Repeat several times until all air

bubbles are expelled.

(4) Remove bleeding tubes from master cylinder

outlet ports, plug outlet ports and install fill cap on

reservoir.

Fig. 37 Open Bleeder Screw at Least One Full Turn

Fig. 38 Bleeding Tubes Attached to ABS Master

Cylinder

Fig. 39 Bleeding Tubes Attached To Non-ABS

Master Cylinder

PLBRAKES 5 - 21

SERVICE PROCEDURES (Continued)

Page 122 of 1200

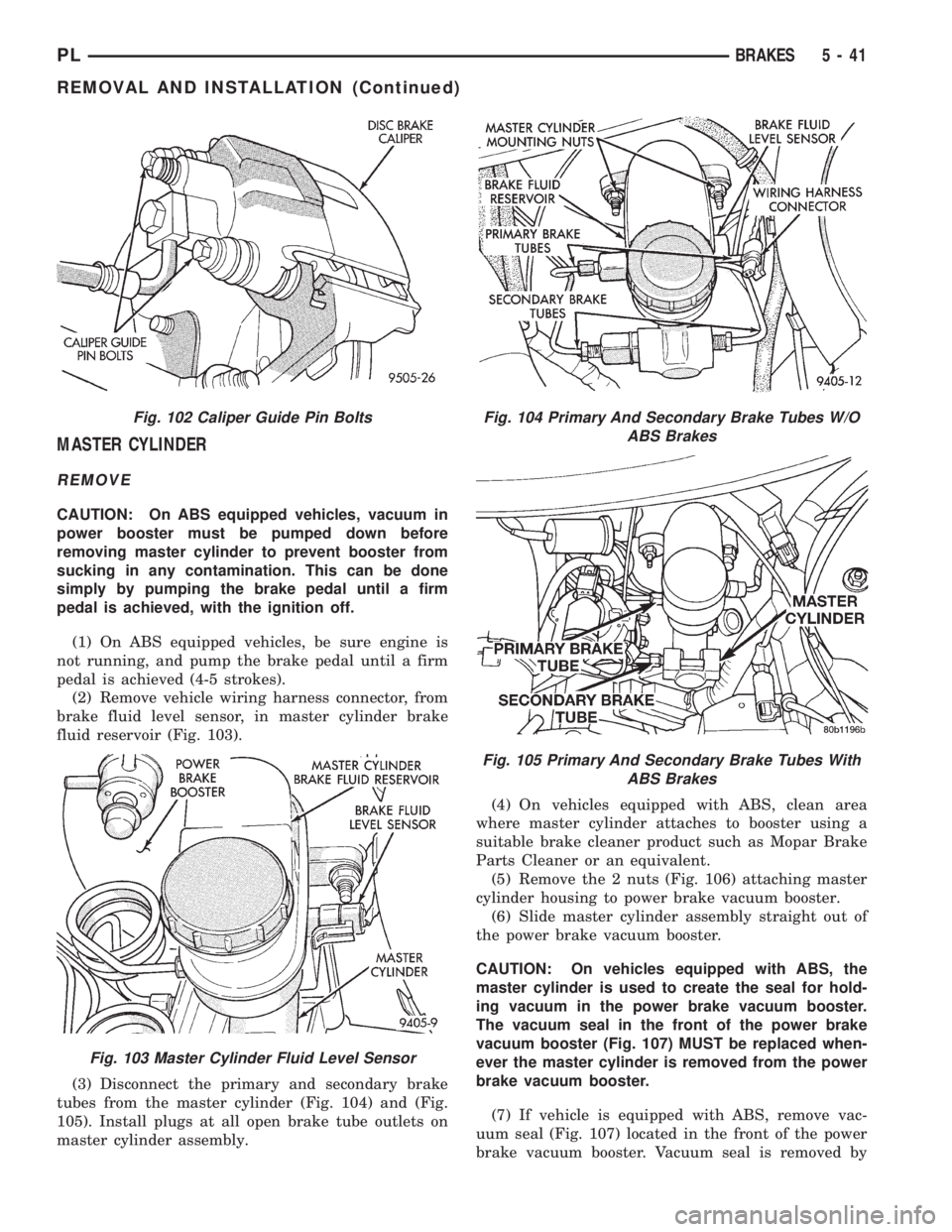

MASTER CYLINDER

REMOVE

CAUTION: On ABS equipped vehicles, vacuum in

power booster must be pumped down before

removing master cylinder to prevent booster from

sucking in any contamination. This can be done

simply by pumping the brake pedal until a firm

pedal is achieved, with the ignition off.

(1) On ABS equipped vehicles, be sure engine is

not running, and pump the brake pedal until a firm

pedal is achieved (4-5 strokes).

(2) Remove vehicle wiring harness connector, from

brake fluid level sensor, in master cylinder brake

fluid reservoir (Fig. 103).

(3) Disconnect the primary and secondary brake

tubes from the master cylinder (Fig. 104) and (Fig.

105). Install plugs at all open brake tube outlets on

master cylinder assembly.(4) On vehicles equipped with ABS, clean area

where master cylinder attaches to booster using a

suitable brake cleaner product such as Mopar Brake

Parts Cleaner or an equivalent.

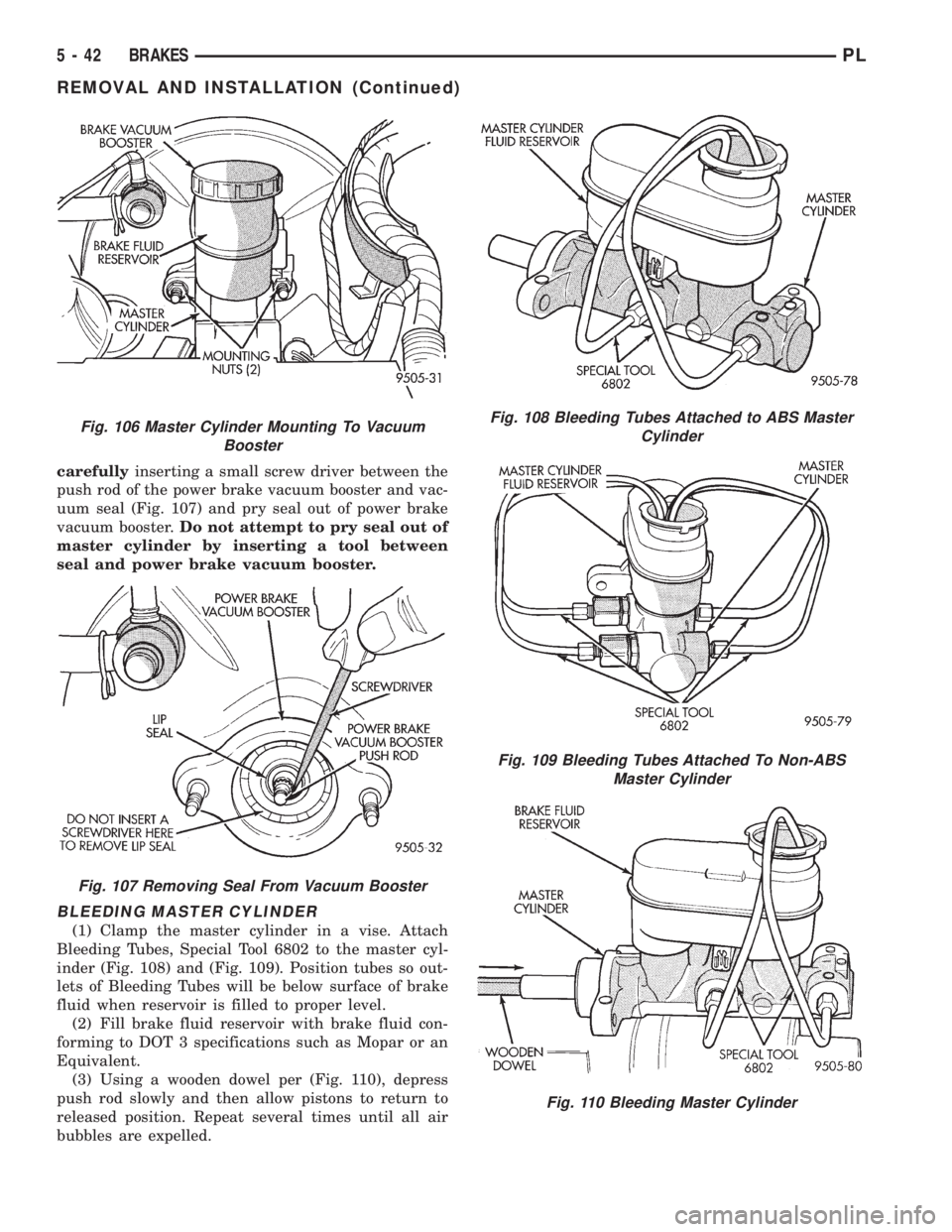

(5) Remove the 2 nuts (Fig. 106) attaching master

cylinder housing to power brake vacuum booster.

(6) Slide master cylinder assembly straight out of

the power brake vacuum booster.

CAUTION: On vehicles equipped with ABS, the

master cylinder is used to create the seal for hold-

ing vacuum in the power brake vacuum booster.

The vacuum seal in the front of the power brake

vacuum booster (Fig. 107) MUST be replaced when-

ever the master cylinder is removed from the power

brake vacuum booster.

(7) If vehicle is equipped with ABS, remove vac-

uum seal (Fig. 107) located in the front of the power

brake vacuum booster. Vacuum seal is removed by

Fig. 102 Caliper Guide Pin Bolts

Fig. 103 Master Cylinder Fluid Level Sensor

Fig. 104 Primary And Secondary Brake Tubes W/O

ABS Brakes

Fig. 105 Primary And Secondary Brake Tubes With

ABS Brakes

PLBRAKES 5 - 41

REMOVAL AND INSTALLATION (Continued)

Page 123 of 1200

carefullyinserting a small screw driver between the

push rod of the power brake vacuum booster and vac-

uum seal (Fig. 107) and pry seal out of power brake

vacuum booster.Do not attempt to pry seal out of

master cylinder by inserting a tool between

seal and power brake vacuum booster.

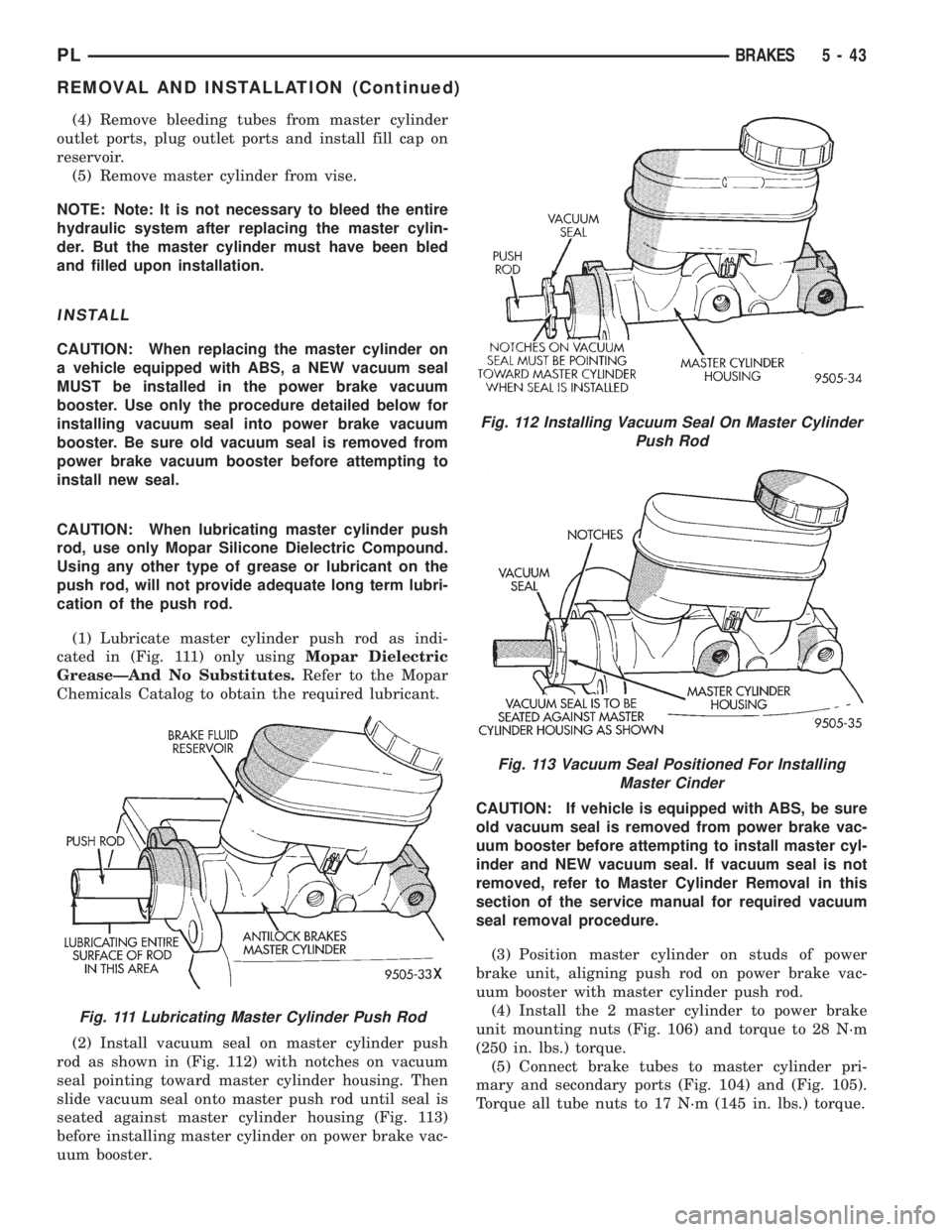

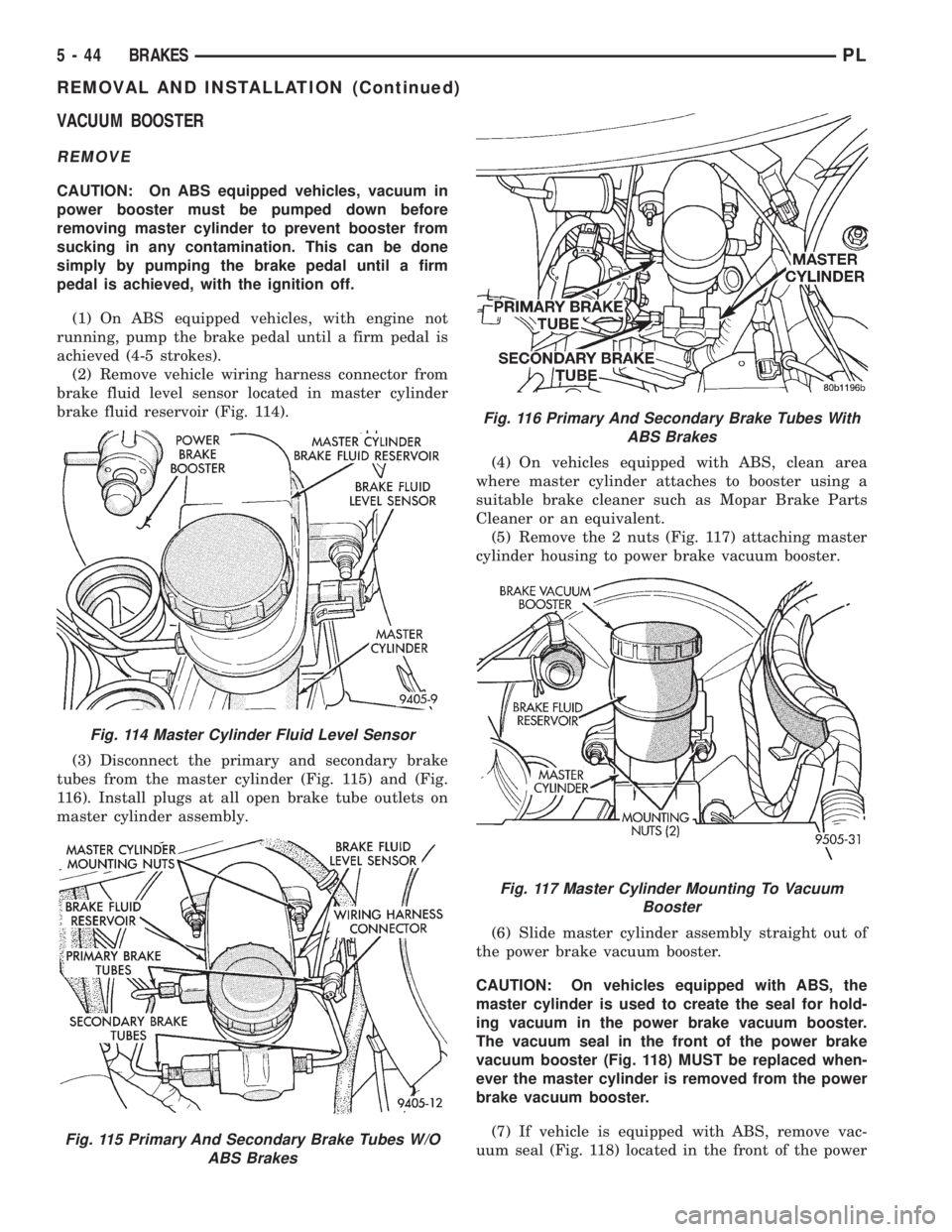

BLEEDING MASTER CYLINDER

(1) Clamp the master cylinder in a vise. Attach

Bleeding Tubes, Special Tool 6802 to the master cyl-

inder (Fig. 108) and (Fig. 109). Position tubes so out-

lets of Bleeding Tubes will be below surface of brake

fluid when reservoir is filled to proper level.

(2) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

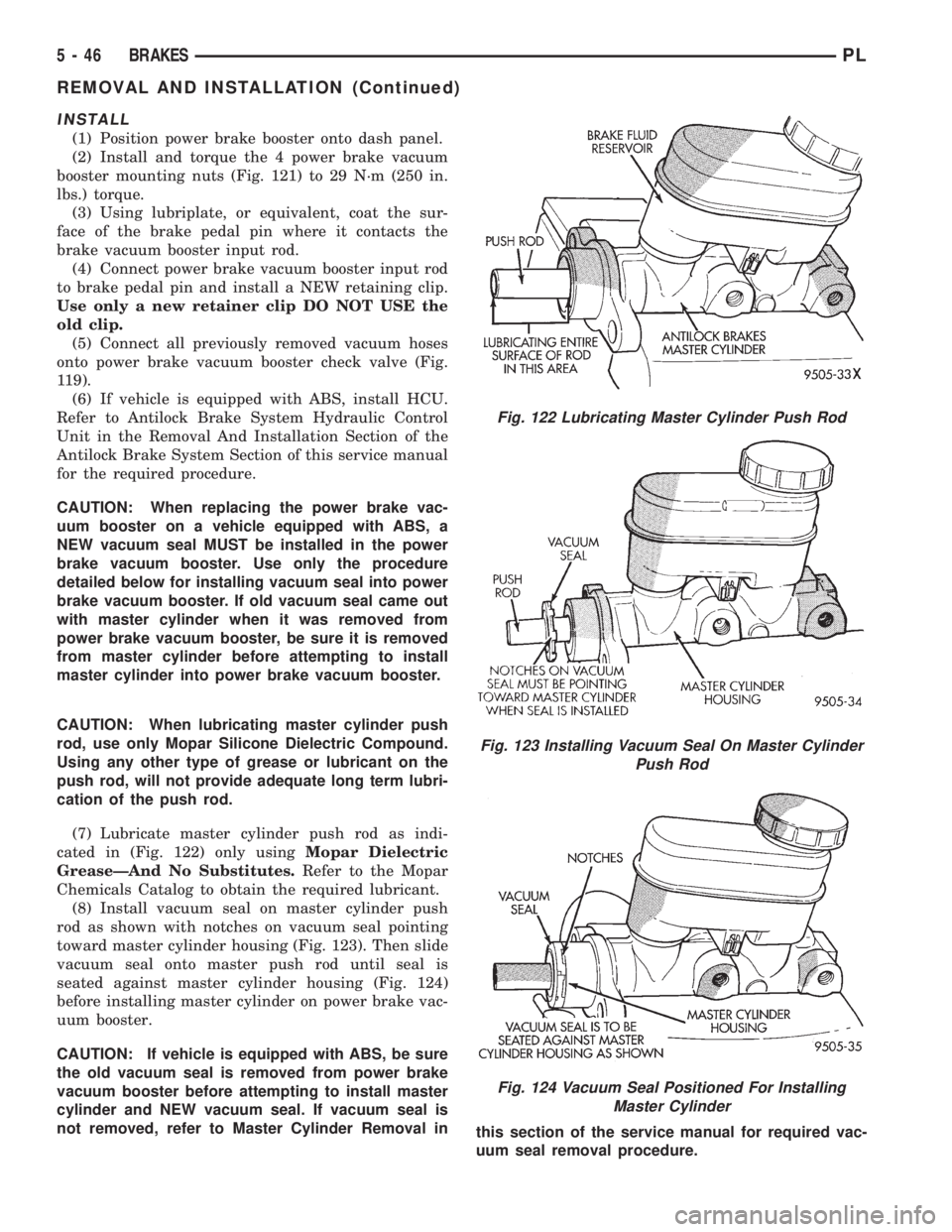

(3) Using a wooden dowel per (Fig. 110), depress

push rod slowly and then allow pistons to return to

released position. Repeat several times until all air

bubbles are expelled.

Fig. 106 Master Cylinder Mounting To Vacuum

Booster

Fig. 107 Removing Seal From Vacuum Booster

Fig. 108 Bleeding Tubes Attached to ABS Master

Cylinder

Fig. 109 Bleeding Tubes Attached To Non-ABS

Master Cylinder

Fig. 110 Bleeding Master Cylinder

5 - 42 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 124 of 1200

(4) Remove bleeding tubes from master cylinder

outlet ports, plug outlet ports and install fill cap on

reservoir.

(5) Remove master cylinder from vise.

NOTE: Note: It is not necessary to bleed the entire

hydraulic system after replacing the master cylin-

der. But the master cylinder must have been bled

and filled upon installation.

INSTALL

CAUTION: When replacing the master cylinder on

a vehicle equipped with ABS, a NEW vacuum seal

MUST be installed in the power brake vacuum

booster. Use only the procedure detailed below for

installing vacuum seal into power brake vacuum

booster. Be sure old vacuum seal is removed from

power brake vacuum booster before attempting to

install new seal.

CAUTION: When lubricating master cylinder push

rod, use only Mopar Silicone Dielectric Compound.

Using any other type of grease or lubricant on the

push rod, will not provide adequate long term lubri-

cation of the push rod.

(1) Lubricate master cylinder push rod as indi-

cated in (Fig. 111) only usingMopar Dielectric

GreaseÐAnd No Substitutes.Refer to the Mopar

Chemicals Catalog to obtain the required lubricant.

(2) Install vacuum seal on master cylinder push

rod as shown in (Fig. 112) with notches on vacuum

seal pointing toward master cylinder housing. Then

slide vacuum seal onto master push rod until seal is

seated against master cylinder housing (Fig. 113)

before installing master cylinder on power brake vac-

uum booster.CAUTION: If vehicle is equipped with ABS, be sure

old vacuum seal is removed from power brake vac-

uum booster before attempting to install master cyl-

inder and NEW vacuum seal. If vacuum seal is not

removed, refer to Master Cylinder Removal in this

section of the service manual for required vacuum

seal removal procedure.

(3) Position master cylinder on studs of power

brake unit, aligning push rod on power brake vac-

uum booster with master cylinder push rod.

(4) Install the 2 master cylinder to power brake

unit mounting nuts (Fig. 106) and torque to 28 N´m

(250 in. lbs.) torque.

(5) Connect brake tubes to master cylinder pri-

mary and secondary ports (Fig. 104) and (Fig. 105).

Torque all tube nuts to 17 N´m (145 in. lbs.) torque.

Fig. 111 Lubricating Master Cylinder Push Rod

Fig. 112 Installing Vacuum Seal On Master Cylinder

Push Rod

Fig. 113 Vacuum Seal Positioned For Installing

Master Cinder

PLBRAKES 5 - 43

REMOVAL AND INSTALLATION (Continued)

Page 125 of 1200

VACUUM BOOSTER

REMOVE

CAUTION: On ABS equipped vehicles, vacuum in

power booster must be pumped down before

removing master cylinder to prevent booster from

sucking in any contamination. This can be done

simply by pumping the brake pedal until a firm

pedal is achieved, with the ignition off.

(1) On ABS equipped vehicles, with engine not

running, pump the brake pedal until a firm pedal is

achieved (4-5 strokes).

(2) Remove vehicle wiring harness connector from

brake fluid level sensor located in master cylinder

brake fluid reservoir (Fig. 114).

(3) Disconnect the primary and secondary brake

tubes from the master cylinder (Fig. 115) and (Fig.

116). Install plugs at all open brake tube outlets on

master cylinder assembly.(4) On vehicles equipped with ABS, clean area

where master cylinder attaches to booster using a

suitable brake cleaner such as Mopar Brake Parts

Cleaner or an equivalent.

(5) Remove the 2 nuts (Fig. 117) attaching master

cylinder housing to power brake vacuum booster.

(6) Slide master cylinder assembly straight out of

the power brake vacuum booster.

CAUTION: On vehicles equipped with ABS, the

master cylinder is used to create the seal for hold-

ing vacuum in the power brake vacuum booster.

The vacuum seal in the front of the power brake

vacuum booster (Fig. 118) MUST be replaced when-

ever the master cylinder is removed from the power

brake vacuum booster.

(7) If vehicle is equipped with ABS, remove vac-

uum seal (Fig. 118) located in the front of the power

Fig. 114 Master Cylinder Fluid Level Sensor

Fig. 115 Primary And Secondary Brake Tubes W/O

ABS Brakes

Fig. 116 Primary And Secondary Brake Tubes With

ABS Brakes

Fig. 117 Master Cylinder Mounting To Vacuum

Booster

5 - 44 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 127 of 1200

INSTALL

(1) Position power brake booster onto dash panel.

(2) Install and torque the 4 power brake vacuum

booster mounting nuts (Fig. 121) to 29 N´m (250 in.

lbs.) torque.

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake vacuum booster input rod.

(4) Connect power brake vacuum booster input rod

to brake pedal pin and install a NEW retaining clip.

Use only a new retainer clip DO NOT USE the

old clip.

(5) Connect all previously removed vacuum hoses

onto power brake vacuum booster check valve (Fig.

119).

(6) If vehicle is equipped with ABS, install HCU.

Refer to Antilock Brake System Hydraulic Control

Unit in the Removal And Installation Section of the

Antilock Brake System Section of this service manual

for the required procedure.

CAUTION: When replacing the power brake vac-

uum booster on a vehicle equipped with ABS, a

NEW vacuum seal MUST be installed in the power

brake vacuum booster. Use only the procedure

detailed below for installing vacuum seal into power

brake vacuum booster. If old vacuum seal came out

with master cylinder when it was removed from

power brake vacuum booster, be sure it is removed

from master cylinder before attempting to install

master cylinder into power brake vacuum booster.

CAUTION: When lubricating master cylinder push

rod, use only Mopar Silicone Dielectric Compound.

Using any other type of grease or lubricant on the

push rod, will not provide adequate long term lubri-

cation of the push rod.

(7) Lubricate master cylinder push rod as indi-

cated in (Fig. 122) only usingMopar Dielectric

GreaseÐAnd No Substitutes.Refer to the Mopar

Chemicals Catalog to obtain the required lubricant.

(8) Install vacuum seal on master cylinder push

rod as shown with notches on vacuum seal pointing

toward master cylinder housing (Fig. 123). Then slide

vacuum seal onto master push rod until seal is

seated against master cylinder housing (Fig. 124)

before installing master cylinder on power brake vac-

uum booster.

CAUTION: If vehicle is equipped with ABS, be sure

the old vacuum seal is removed from power brake

vacuum booster before attempting to install master

cylinder and NEW vacuum seal. If vacuum seal is

not removed, refer to Master Cylinder Removal in

this section of the service manual for required vac-

uum seal removal procedure.

Fig. 122 Lubricating Master Cylinder Push Rod

Fig. 123 Installing Vacuum Seal On Master Cylinder

Push Rod

Fig. 124 Vacuum Seal Positioned For Installing

Master Cylinder

5 - 46 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 129 of 1200

PARK BRAKE LEVER ASSEMBLY

WARNING: THE AUTO ADJUSTING FEATURE OF

THIS PARKING BRAKE LEVER ASSEMBLY CON-

TAINS A CLOCK SPRING LOADED TO APPROXI-

MATELY 20 POUNDS. DO NOT RELEASE THE AUTO

ADJUSTER LOCKOUT DEVICE BEFORE INSTALL-

ING CABLES INTO THE EQUALIZER. KEEP HANDS

OUT OF AUTO ADJUSTER SECTOR AND PAWL

AREA. FAILURE TO OBSERVE CAUTION IN HAN-

DLING THIS MECHANISM COULD LEAD TO SERI-

OUS INJURY.

REMOVE

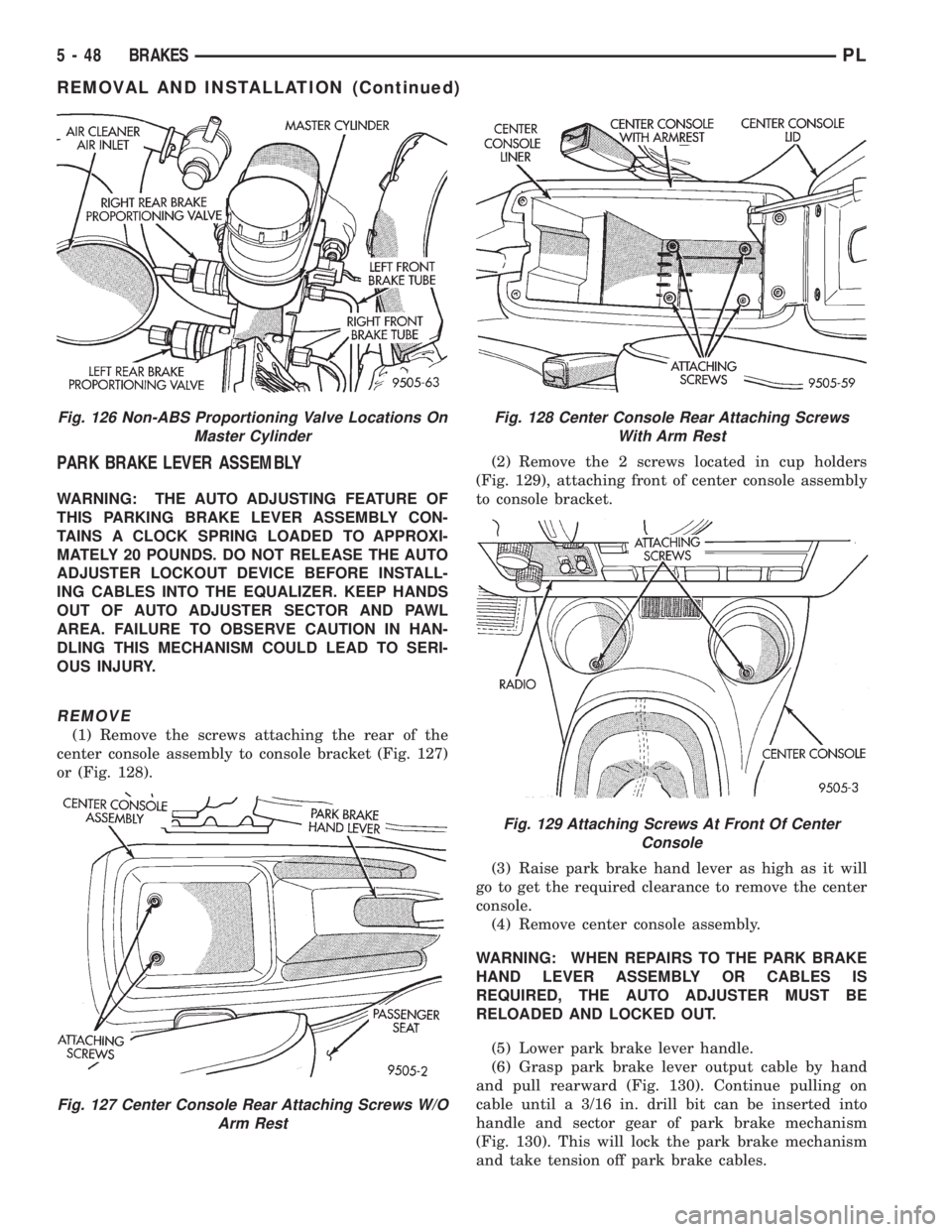

(1) Remove the screws attaching the rear of the

center console assembly to console bracket (Fig. 127)

or (Fig. 128).(2) Remove the 2 screws located in cup holders

(Fig. 129), attaching front of center console assembly

to console bracket.

(3) Raise park brake hand lever as high as it will

go to get the required clearance to remove the center

console.

(4) Remove center console assembly.

WARNING: WHEN REPAIRS TO THE PARK BRAKE

HAND LEVER ASSEMBLY OR CABLES IS

REQUIRED, THE AUTO ADJUSTER MUST BE

RELOADED AND LOCKED OUT.

(5) Lower park brake lever handle.

(6) Grasp park brake lever output cable by hand

and pull rearward (Fig. 130). Continue pulling on

cable until a 3/16 in. drill bit can be inserted into

handle and sector gear of park brake mechanism

(Fig. 130). This will lock the park brake mechanism

and take tension off park brake cables.

Fig. 126 Non-ABS Proportioning Valve Locations On

Master Cylinder

Fig. 127 Center Console Rear Attaching Screws W/O

Arm Rest

Fig. 128 Center Console Rear Attaching Screws

With Arm Rest

Fig. 129 Attaching Screws At Front Of Center

Console

5 - 48 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 132 of 1200

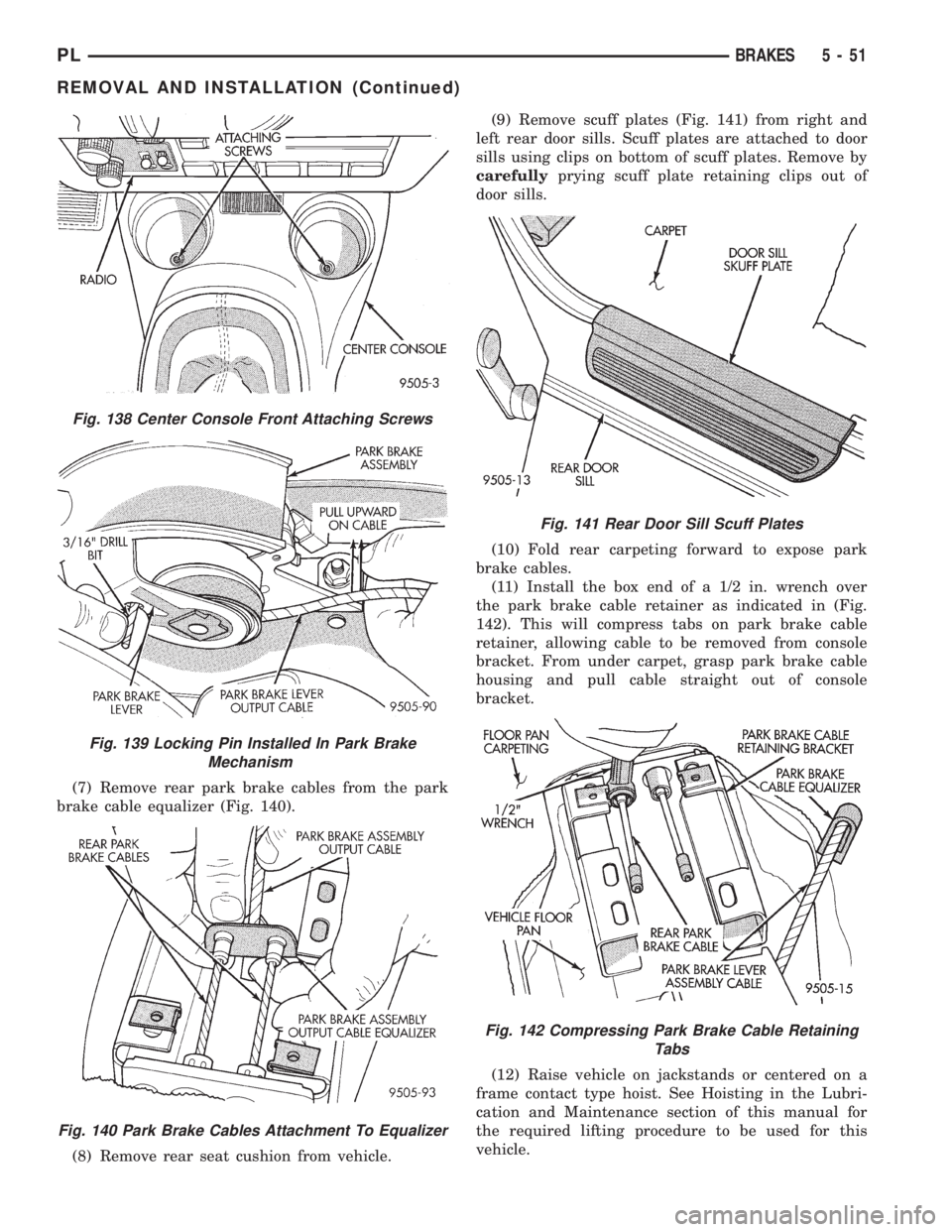

(7) Remove rear park brake cables from the park

brake cable equalizer (Fig. 140).

(8) Remove rear seat cushion from vehicle.(9) Remove scuff plates (Fig. 141) from right and

left rear door sills. Scuff plates are attached to door

sills using clips on bottom of scuff plates. Remove by

carefullyprying scuff plate retaining clips out of

door sills.

(10) Fold rear carpeting forward to expose park

brake cables.

(11) Install the box end of a 1/2 in. wrench over

the park brake cable retainer as indicated in (Fig.

142). This will compress tabs on park brake cable

retainer, allowing cable to be removed from console

bracket. From under carpet, grasp park brake cable

housing and pull cable straight out of console

bracket.

(12) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual for

the required lifting procedure to be used for this

vehicle.

Fig. 138 Center Console Front Attaching Screws

Fig. 139 Locking Pin Installed In Park Brake

Mechanism

Fig. 140 Park Brake Cables Attachment To Equalizer

Fig. 141 Rear Door Sill Scuff Plates

Fig. 142 Compressing Park Brake Cable Retaining

Tabs

PLBRAKES 5 - 51

REMOVAL AND INSTALLATION (Continued)