fuse DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 694 of 1200

8W-95 SPLICE LOCATIONS

DESCRIPTION AND OPERATION

INTRODUCTION

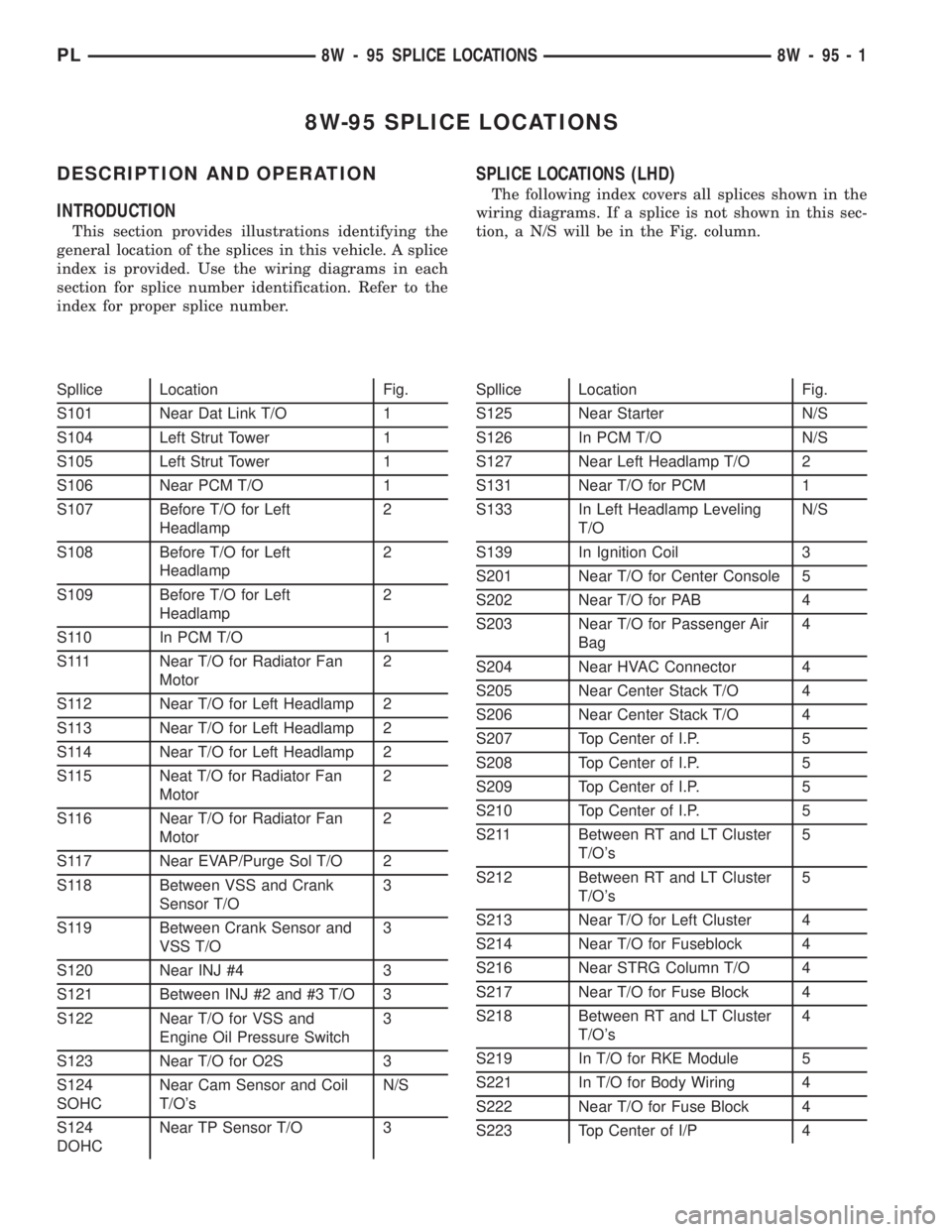

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for proper splice number.

SPLICE LOCATIONS (LHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S101 Near Dat Link T/O 1

S104 Left Strut Tower 1

S105 Left Strut Tower 1

S106 Near PCM T/O 1

S107 Before T/O for Left

Headlamp2

S108 Before T/O for Left

Headlamp2

S109 Before T/O for Left

Headlamp2

S110 In PCM T/O 1

S111 Near T/O for Radiator Fan

Motor2

S112 Near T/O for Left Headlamp 2

S113 Near T/O for Left Headlamp 2

S114 Near T/O for Left Headlamp 2

S115 Neat T/O for Radiator Fan

Motor2

S116 Near T/O for Radiator Fan

Motor2

S117 Near EVAP/Purge Sol T/O 2

S118 Between VSS and Crank

Sensor T/O3

S119 Between Crank Sensor and

VSS T/O3

S120 Near INJ #4 3

S121 Between INJ #2 and #3 T/O 3

S122 Near T/O for VSS and

Engine Oil Pressure Switch3

S123 Near T/O for O2S 3

S124

SOHCNear Cam Sensor and Coil

T/O'sN/S

S124

DOHCNear TP Sensor T/O 3Spllice Location Fig.

S125 Near Starter N/S

S126 In PCM T/O N/S

S127 Near Left Headlamp T/O 2

S131 Near T/O for PCM 1

S133 In Left Headlamp Leveling

T/ON/S

S139 In Ignition Coil 3

S201 Near T/O for Center Console 5

S202 Near T/O for PAB 4

S203 Near T/O for Passenger Air

Bag4

S204 Near HVAC Connector 4

S205 Near Center Stack T/O 4

S206 Near Center Stack T/O 4

S207 Top Center of I.P. 5

S208 Top Center of I.P. 5

S209 Top Center of I.P. 5

S210 Top Center of I.P. 5

S211 Between RT and LT Cluster

T/O's5

S212 Between RT and LT Cluster

T/O's5

S213 Near T/O for Left Cluster 4

S214 Near T/O for Fuseblock 4

S216 Near STRG Column T/O 4

S217 Near T/O for Fuse Block 4

S218 Between RT and LT Cluster

T/O's4

S219 In T/O for RKE Module 5

S221 In T/O for Body Wiring 4

S222 Near T/O for Fuse Block 4

S223 Top Center of I/P 4

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 1

Page 704 of 1200

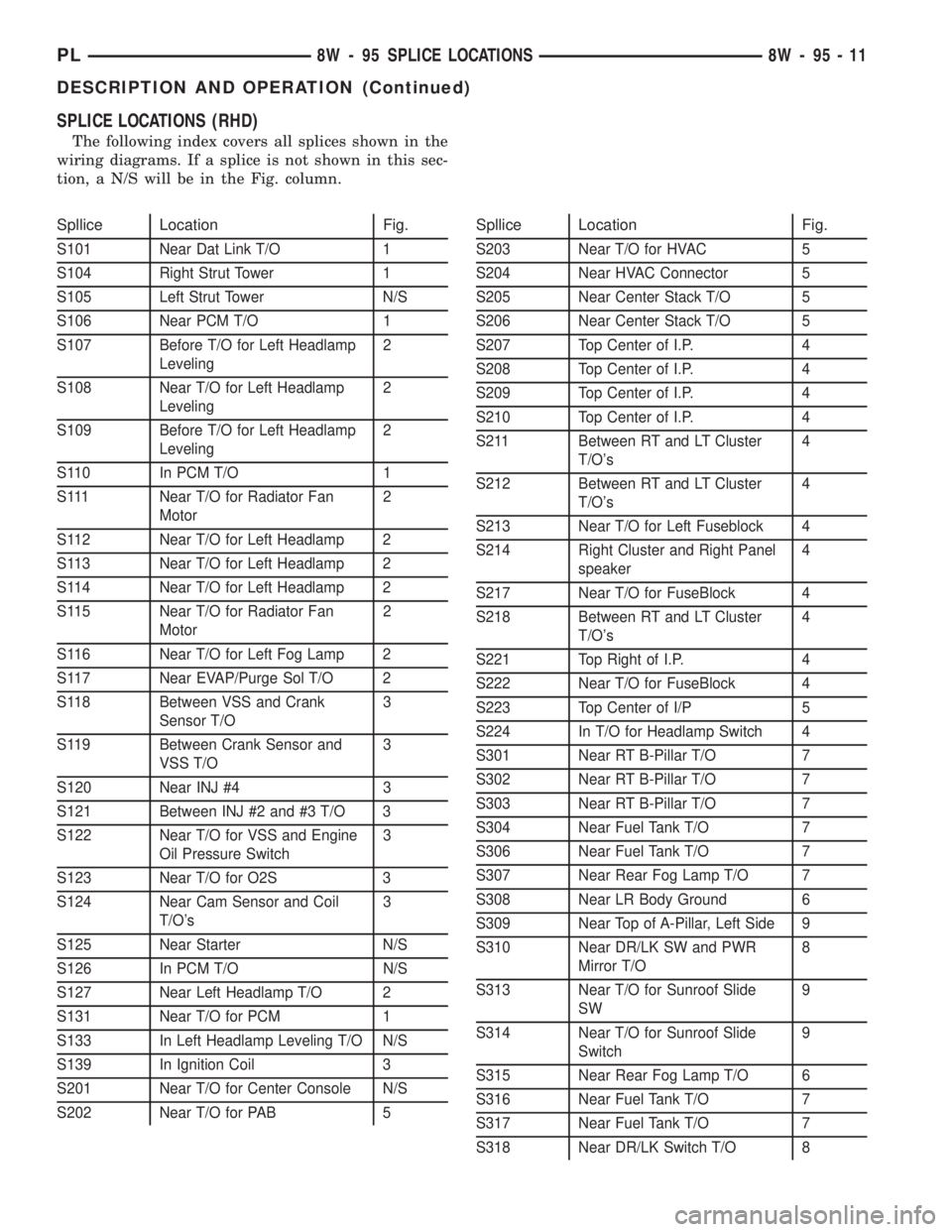

SPLICE LOCATIONS (RHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S101 Near Dat Link T/O 1

S104 Right Strut Tower 1

S105 Left Strut Tower N/S

S106 Near PCM T/O 1

S107 Before T/O for Left Headlamp

Leveling2

S108 Near T/O for Left Headlamp

Leveling2

S109 Before T/O for Left Headlamp

Leveling2

S110 In PCM T/O 1

S111 Near T/O for Radiator Fan

Motor2

S112 Near T/O for Left Headlamp 2

S113 Near T/O for Left Headlamp 2

S114 Near T/O for Left Headlamp 2

S115 Near T/O for Radiator Fan

Motor2

S116 Near T/O for Left Fog Lamp 2

S117 Near EVAP/Purge Sol T/O 2

S118 Between VSS and Crank

Sensor T/O3

S119 Between Crank Sensor and

VSS T/O3

S120 Near INJ #4 3

S121 Between INJ #2 and #3 T/O 3

S122 Near T/O for VSS and Engine

Oil Pressure Switch3

S123 Near T/O for O2S 3

S124 Near Cam Sensor and Coil

T/O's3

S125 Near Starter N/S

S126 In PCM T/O N/S

S127 Near Left Headlamp T/O 2

S131 Near T/O for PCM 1

S133 In Left Headlamp Leveling T/O N/S

S139 In Ignition Coil 3

S201 Near T/O for Center Console N/S

S202 Near T/O for PAB 5

Spllice Location Fig.

S203 Near T/O for HVAC 5

S204 Near HVAC Connector 5

S205 Near Center Stack T/O 5

S206 Near Center Stack T/O 5

S207 Top Center of I.P. 4

S208 Top Center of I.P. 4

S209 Top Center of I.P. 4

S210 Top Center of I.P. 4

S211 Between RT and LT Cluster

T/O's4

S212 Between RT and LT Cluster

T/O's4

S213 Near T/O for Left Fuseblock 4

S214 Right Cluster and Right Panel

speaker4

S217 Near T/O for FuseBlock 4

S218 Between RT and LT Cluster

T/O's4

S221 Top Right of I.P. 4

S222 Near T/O for FuseBlock 4

S223 Top Center of I/P 5

S224 In T/O for Headlamp Switch 4

S301 Near RT B-Pillar T/O 7

S302 Near RT B-Pillar T/O 7

S303 Near RT B-Pillar T/O 7

S304 Near Fuel Tank T/O 7

S306 Near Fuel Tank T/O 7

S307 Near Rear Fog Lamp T/O 7

S308 Near LR Body Ground 6

S309 Near Top of A-Pillar, Left Side 9

S310 Near DR/LK SW and PWR

Mirror T/O8

S313 Near T/O for Sunroof Slide

SW9

S314 Near T/O for Sunroof Slide

Switch9

S315 Near Rear Fog Lamp T/O 6

S316 Near Fuel Tank T/O 7

S317 Near Fuel Tank T/O 7

S318 Near DR/LK Switch T/O 8

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 11

DESCRIPTION AND OPERATION (Continued)

Page 852 of 1200

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

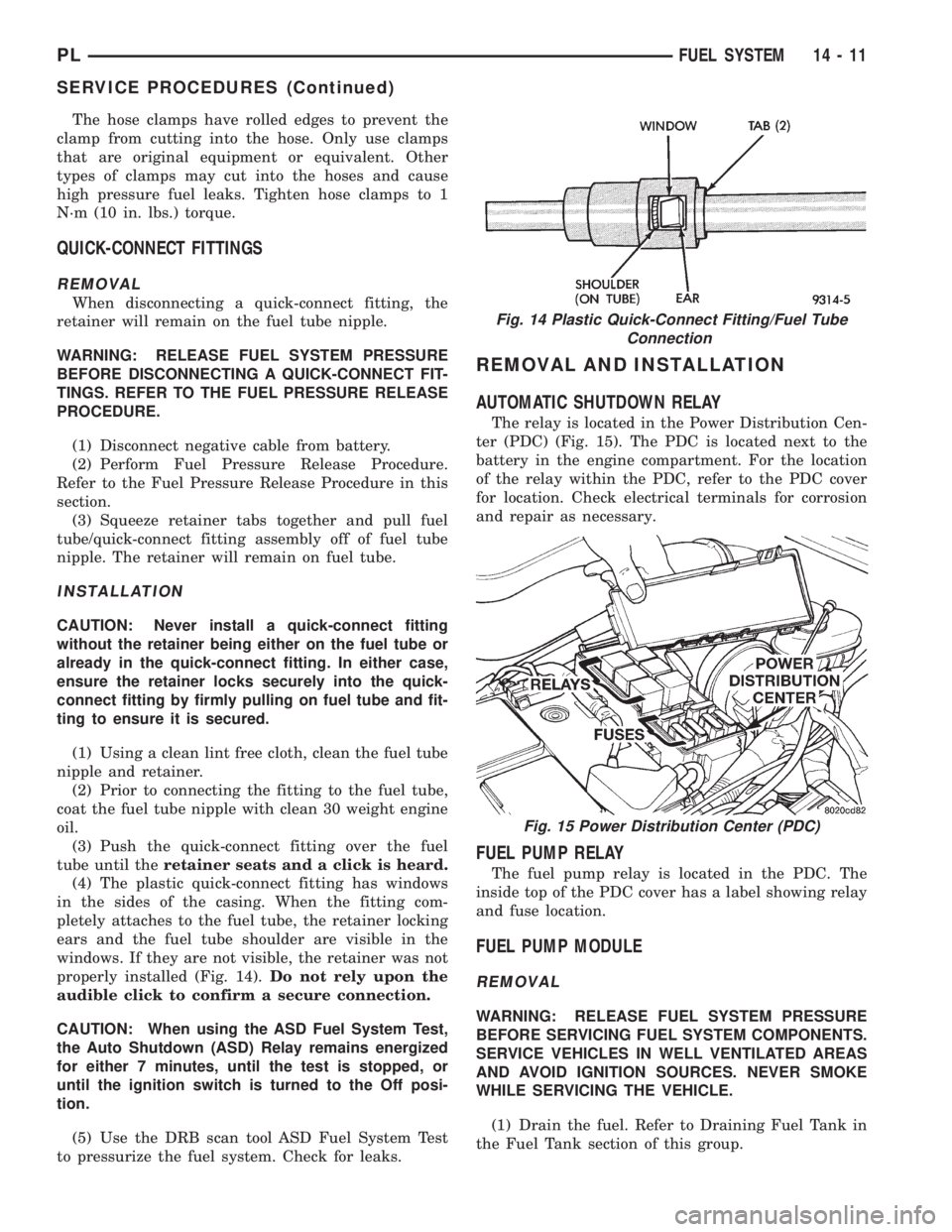

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 14).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY

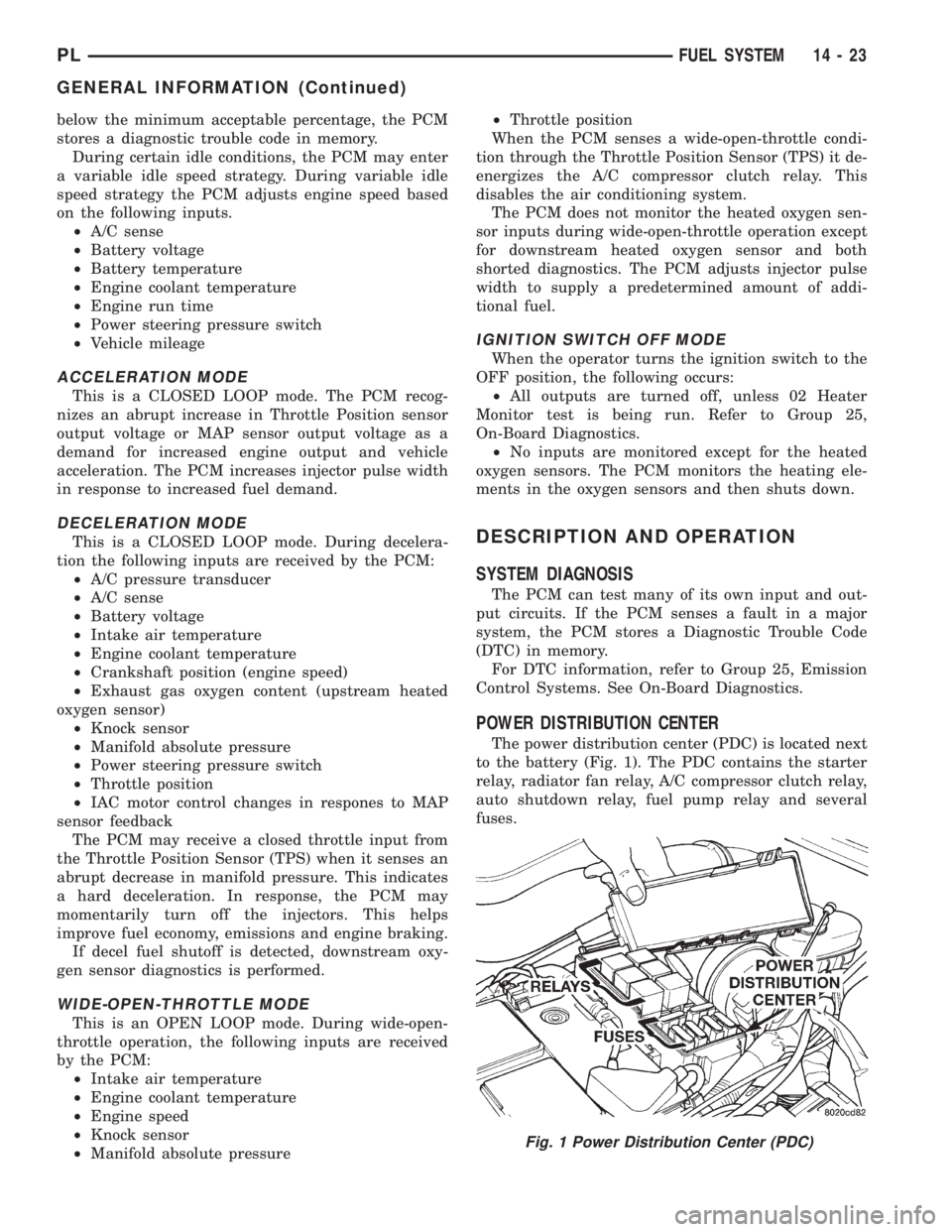

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 15). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

Fig. 14 Plastic Quick-Connect Fitting/Fuel Tube

Connection

Fig. 15 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 864 of 1200

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in respones to MAP

sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to Group 25,

On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

DESCRIPTION AND OPERATION

SYSTEM DIAGNOSIS

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information, refer to Group 25, Emission

Control Systems. See On-Board Diagnostics.

POWER DISTRIBUTION CENTER

The power distribution center (PDC) is located next

to the battery (Fig. 1). The PDC contains the starter

relay, radiator fan relay, A/C compressor clutch relay,

auto shutdown relay, fuel pump relay and several

fuses.

Fig. 1 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 23

GENERAL INFORMATION (Continued)

Page 872 of 1200

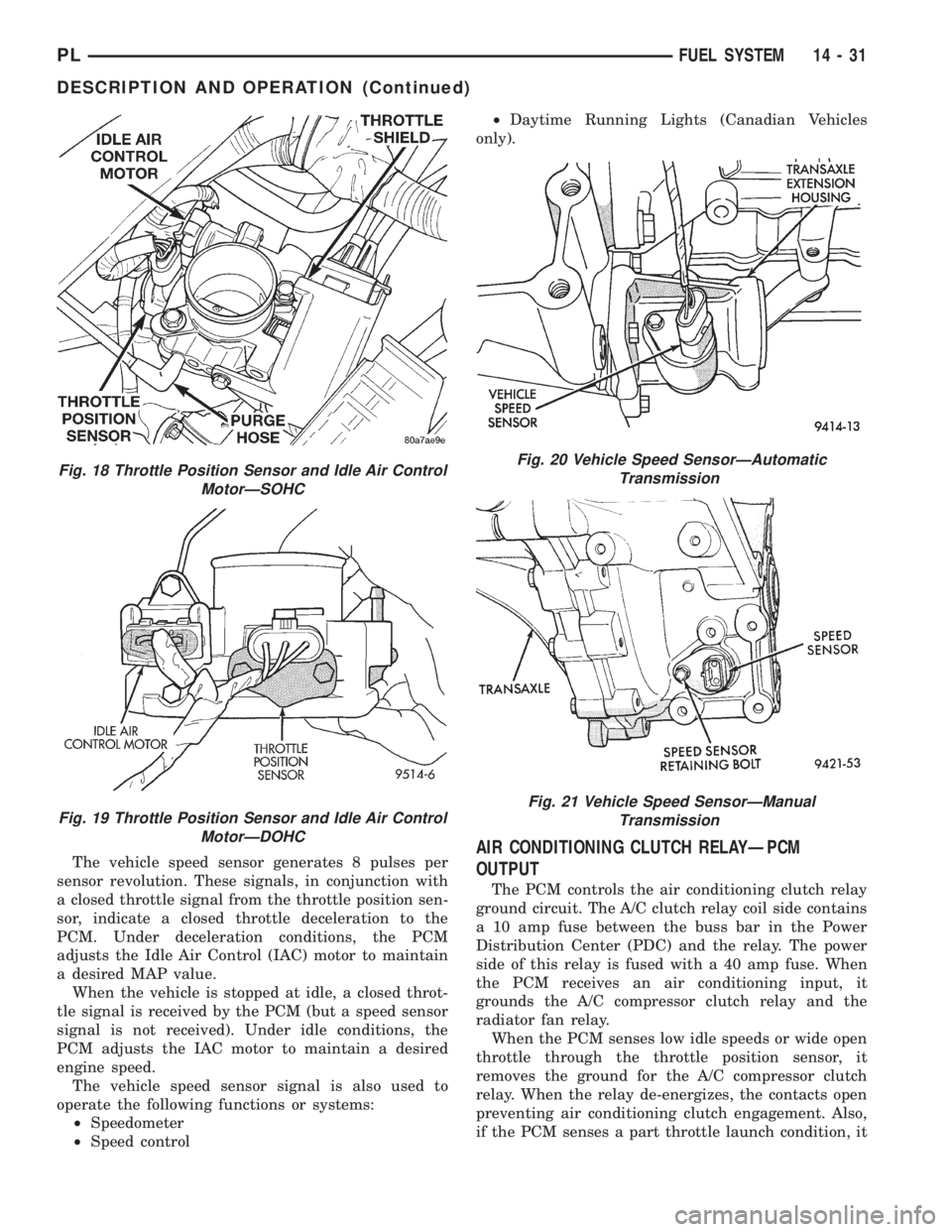

The vehicle speed sensor generates 8 pulses per

sensor revolution. These signals, in conjunction with

a closed throttle signal from the throttle position sen-

sor, indicate a closed throttle deceleration to the

PCM. Under deceleration conditions, the PCM

adjusts the Idle Air Control (IAC) motor to maintain

a desired MAP value.

When the vehicle is stopped at idle, a closed throt-

tle signal is received by the PCM (but a speed sensor

signal is not received). Under idle conditions, the

PCM adjusts the IAC motor to maintain a desired

engine speed.

The vehicle speed sensor signal is also used to

operate the following functions or systems:

²Speedometer

²Speed control²Daytime Running Lights (Canadian Vehicles

only).AIR CONDITIONING CLUTCH RELAYÐPCM

OUTPUT

The PCM controls the air conditioning clutch relay

ground circuit. The A/C clutch relay coil side contains

a 10 amp fuse between the buss bar in the Power

Distribution Center (PDC) and the relay. The power

side of this relay is fused with a 40 amp fuse. When

the PCM receives an air conditioning input, it

grounds the A/C compressor clutch relay and the

radiator fan relay.

When the PCM senses low idle speeds or wide open

throttle through the throttle position sensor, it

removes the ground for the A/C compressor clutch

relay. When the relay de-energizes, the contacts open

preventing air conditioning clutch engagement. Also,

if the PCM senses a part throttle launch condition, it

Fig. 18 Throttle Position Sensor and Idle Air Control

MotorÐSOHC

Fig. 19 Throttle Position Sensor and Idle Air Control

MotorÐDOHC

Fig. 20 Vehicle Speed SensorÐAutomatic

Transmission

Fig. 21 Vehicle Speed SensorÐManual

Transmission

PLFUEL SYSTEM 14 - 31

DESCRIPTION AND OPERATION (Continued)

Page 873 of 1200

disables the A/C compressor clutch for several sec-

onds.

The air conditioning clutch relay is located in the

PDC. The inside top of the PDC cover has a label

showing relay and fuse location.

AUTOMATIC SHUTDOWN RELAYÐPCM OUTPUT

The automatic shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors.

A buss bar in the power distribution center (PDC)

supplies voltage to the solenoid side and contact side

of the relay. The ASD relay power circuit contains a

20 amp fuse between the buss bar in the PDC and

the relay. The fuse also protects the power circuit for

the fuel pump relay and pump. The fuse is located in

the PDC. Refer to Group 8W, Wiring Diagrams for

circuit information.

The PCM controls the relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position unless the 02

Heater Monitor test is being run. Refer to Group 25,

On-Board Diagnostics. When the ignition switch is in

the On or Crank position, the PCM monitors the

crankshaft position sensor and camshaft position sen-

sor signals to determine engine speed and ignition

timing (coil dwell). If the PCM does not receive the

crankshaft position sensor and camshaft position sen-

sor signals when the ignition switch is in the Run

position, it will de- energize the ASD relay.

The ASD relay is located in the PDC. The inside

top of the PDC cover has a label showing relay and

fuse location.

CHARGING SYSTEM INDICATOR LAMPÐPCM

OUTPUT

The PCM turns the instrument panel Charging

System Lamp on. Refer to Group 8C for charging sys-

tem information.

FUEL PUMP RELAYÐPCM OUTPUT

The fuel pump relay supplies battery voltage to the

fuel pump. A buss bar in the Power Distribution Cen-

ter (PDC) supplies voltage to the solenoid side and

contact side of the relay. The fuel pump relay power

circuit contains a 20 amp fuse between the buss bar

in the PDC and the relay. The fuse also protects the

power circuit for the Automatic Shutdown (ASD)

relay. The fuse is located in the PDC. Refer to Group

8W, Wiring Diagrams for circuit information.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

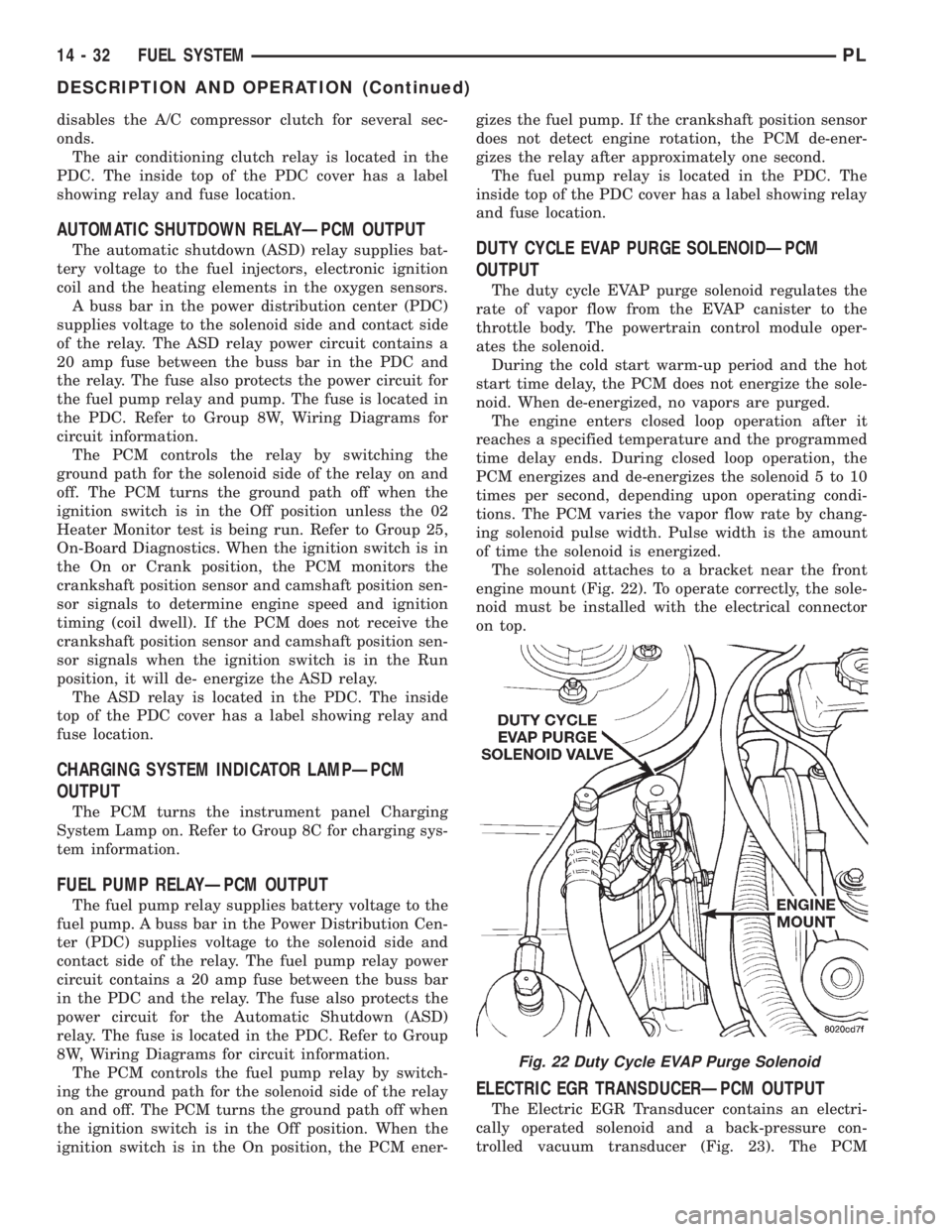

DUTY CYCLE EVAP PURGE SOLENOIDÐPCM

OUTPUT

The duty cycle EVAP purge solenoid regulates the

rate of vapor flow from the EVAP canister to the

throttle body. The powertrain control module oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The engine enters closed loop operation after it

reaches a specified temperature and the programmed

time delay ends. During closed loop operation, the

PCM energizes and de-energizes the solenoid 5 to 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time the solenoid is energized.

The solenoid attaches to a bracket near the front

engine mount (Fig. 22). To operate correctly, the sole-

noid must be installed with the electrical connector

on top.

ELECTRIC EGR TRANSDUCERÐPCM OUTPUT

The Electric EGR Transducer contains an electri-

cally operated solenoid and a back-pressure con-

trolled vacuum transducer (Fig. 23). The PCM

Fig. 22 Duty Cycle EVAP Purge Solenoid

14 - 32 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 877 of 1200

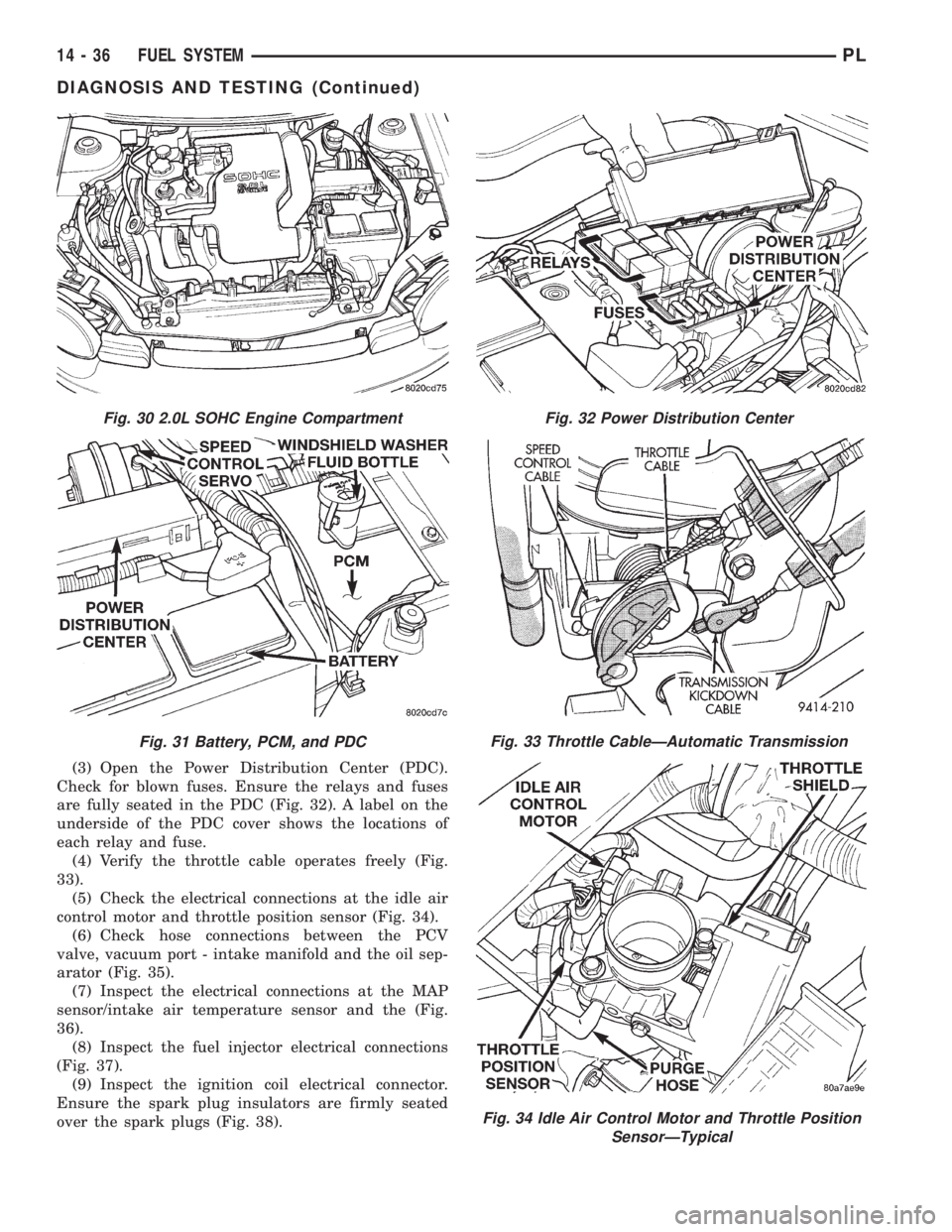

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC (Fig. 32). A label on the

underside of the PDC cover shows the locations of

each relay and fuse.

(4) Verify the throttle cable operates freely (Fig.

33).

(5) Check the electrical connections at the idle air

control motor and throttle position sensor (Fig. 34).

(6) Check hose connections between the PCV

valve, vacuum port - intake manifold and the oil sep-

arator (Fig. 35).

(7) Inspect the electrical connections at the MAP

sensor/intake air temperature sensor and the (Fig.

36).

(8) Inspect the fuel injector electrical connections

(Fig. 37).

(9) Inspect the ignition coil electrical connector.

Ensure the spark plug insulators are firmly seated

over the spark plugs (Fig. 38).

Fig. 30 2.0L SOHC Engine Compartment

Fig. 31 Battery, PCM, and PDC

Fig. 32 Power Distribution Center

Fig. 33 Throttle CableÐAutomatic Transmission

Fig. 34 Idle Air Control Motor and Throttle Position

SensorÐTypical

14 - 36 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 882 of 1200

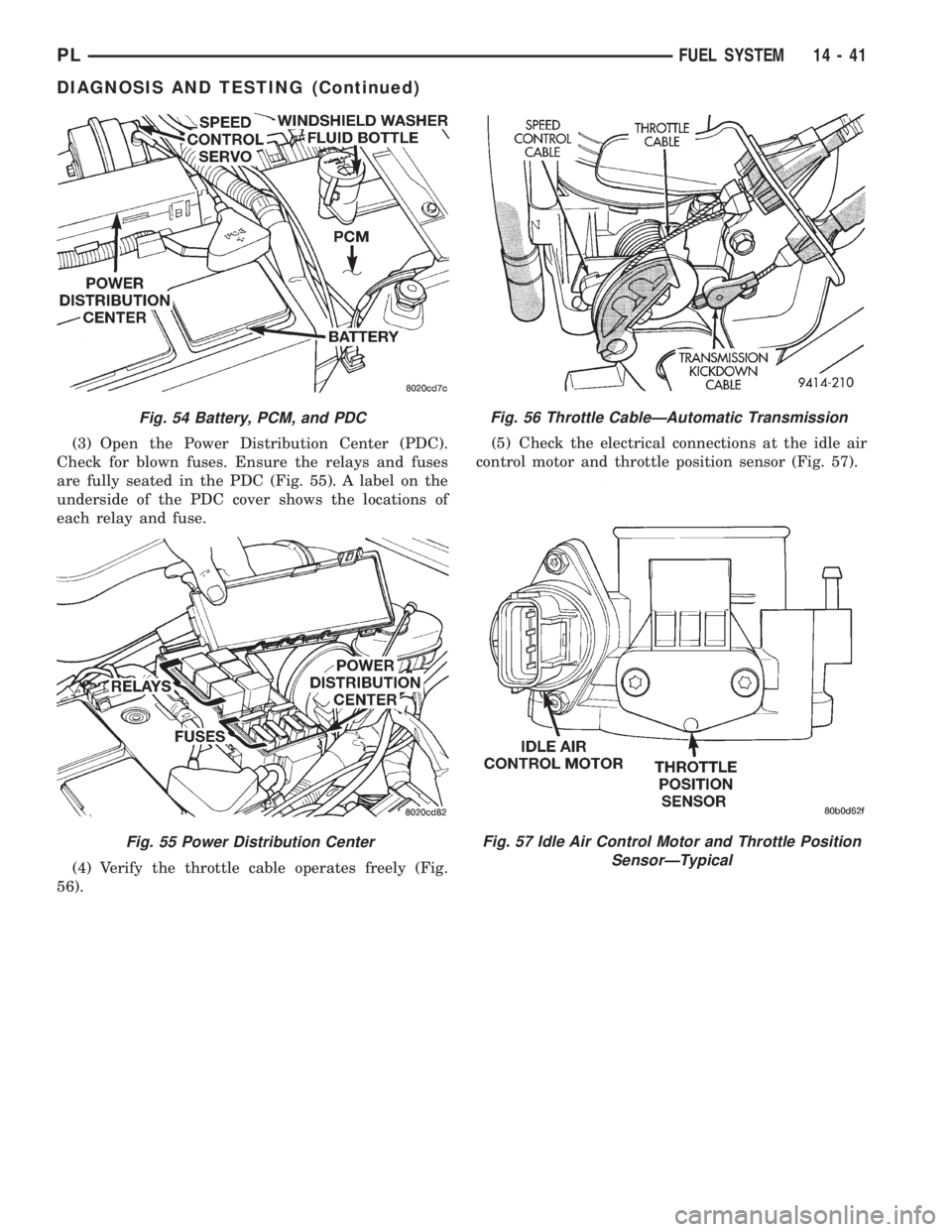

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC (Fig. 55). A label on the

underside of the PDC cover shows the locations of

each relay and fuse.

(4) Verify the throttle cable operates freely (Fig.

56).(5) Check the electrical connections at the idle air

control motor and throttle position sensor (Fig. 57).

Fig. 54 Battery, PCM, and PDC

Fig. 55 Power Distribution Center

Fig. 56 Throttle CableÐAutomatic Transmission

Fig. 57 Idle Air Control Motor and Throttle Position

SensorÐTypical

PLFUEL SYSTEM 14 - 41

DIAGNOSIS AND TESTING (Continued)

Page 1128 of 1200

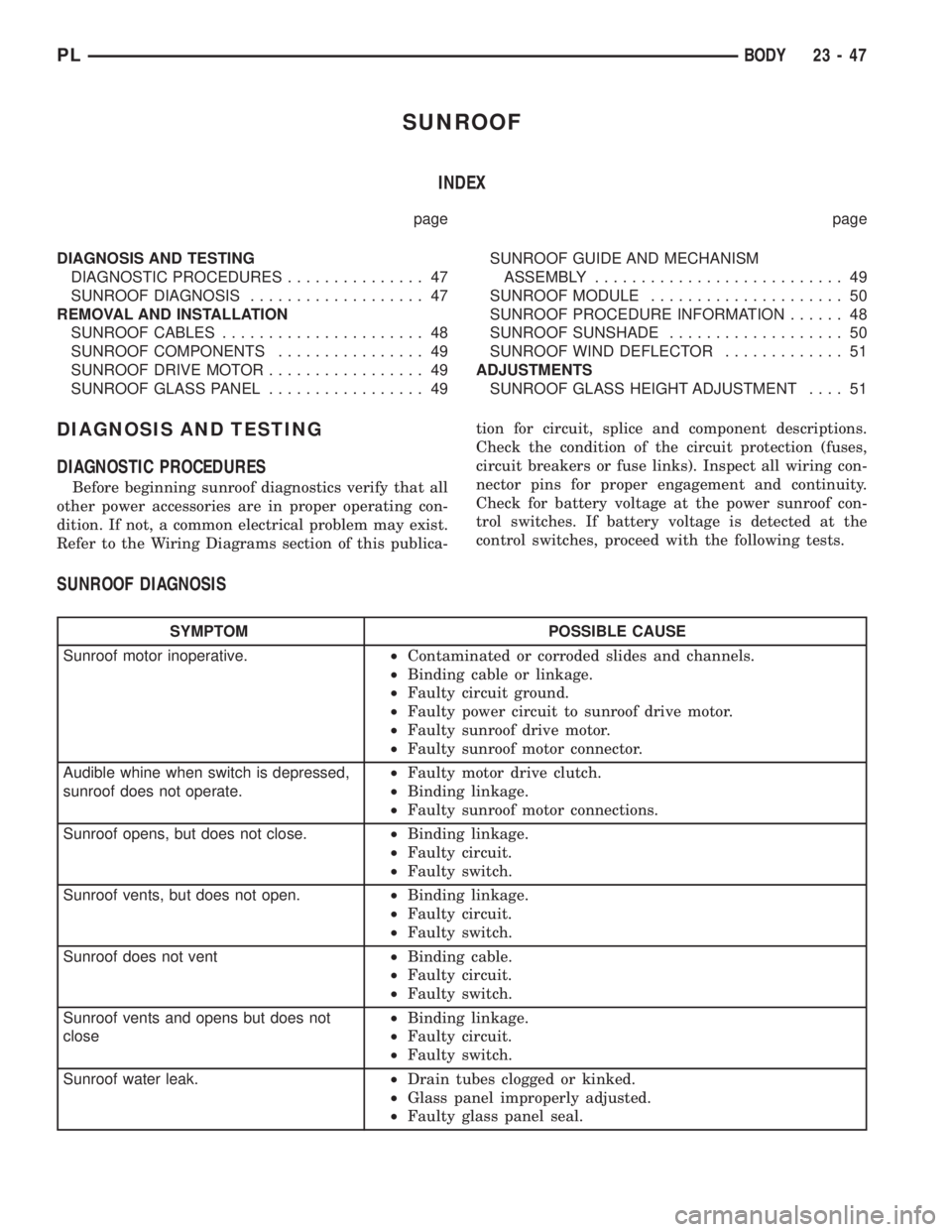

SUNROOF

INDEX

page page

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES............... 47

SUNROOF DIAGNOSIS................... 47

REMOVAL AND INSTALLATION

SUNROOF CABLES...................... 48

SUNROOF COMPONENTS................ 49

SUNROOF DRIVE MOTOR................. 49

SUNROOF GLASS PANEL................. 49SUNROOF GUIDE AND MECHANISM

ASSEMBLY........................... 49

SUNROOF MODULE..................... 50

SUNROOF PROCEDURE INFORMATION...... 48

SUNROOF SUNSHADE................... 50

SUNROOF WIND DEFLECTOR............. 51

ADJUSTMENTS

SUNROOF GLASS HEIGHT ADJUSTMENT.... 51

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

Before beginning sunroof diagnostics verify that all

other power accessories are in proper operating con-

dition. If not, a common electrical problem may exist.

Refer to the Wiring Diagrams section of this publica-tion for circuit, splice and component descriptions.

Check the condition of the circuit protection (fuses,

circuit breakers or fuse links). Inspect all wiring con-

nector pins for proper engagement and continuity.

Check for battery voltage at the power sunroof con-

trol switches. If battery voltage is detected at the

control switches, proceed with the following tests.

SUNROOF DIAGNOSIS

SYMPTOM POSSIBLE CAUSE

Sunroof motor inoperative.²Contaminated or corroded slides and channels.

²Binding cable or linkage.

²Faulty circuit ground.

²Faulty power circuit to sunroof drive motor.

²Faulty sunroof drive motor.

²Faulty sunroof motor connector.

Audible whine when switch is depressed,

sunroof does not operate.²Faulty motor drive clutch.

²Binding linkage.

²Faulty sunroof motor connections.

Sunroof opens, but does not close.²Binding linkage.

²Faulty circuit.

²Faulty switch.

Sunroof vents, but does not open.²Binding linkage.

²Faulty circuit.

²Faulty switch.

Sunroof does not vent²Binding cable.

²Faulty circuit.

²Faulty switch.

Sunroof vents and opens but does not

close²Binding linkage.

²Faulty circuit.

²Faulty switch.

Sunroof water leak.²Drain tubes clogged or kinked.

²Glass panel improperly adjusted.

²Faulty glass panel seal.

PLBODY 23 - 47

Page 1141 of 1200

(3) Close all doors, windows and vents to the pas-

senger compartment.

(4) Set Heater-A/C control to A/C, full heat, floor,

RECIRC. and high blower.

(5) Start the engine and hold the idle speed (1000

rpm). After the engine has reached running temper-

ature, allow the passenger compartment to heat up.

This will create the need for maximum refrigerant

flow into the evaporator.

(6) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 2620 kPa

(140 to 380 psi). Suction (low pressure) gauge should

read 103 to 2417 kPa (15 to 35 psi). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(7) If suction side low pressure is within specified

range, freeze the expansion valve control head (Fig.

10) for 30 seconds. Use a super cold substance (liquid

CO2).Do not spray refrigerant on the expansion

valve for this test.Suction side low pressure should

drop to 34.5 kPa (5 psi) If not, replace expansion

valve.

(8) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 103 to 241

kPa (15 to 35 psi). If not, replace expansion valve.

(9) When expansion valve test is complete, test

A/C overall performance. Refer to the Heater and A/C

Performance Test in this section. Remove all test

equipment before returning vehicle to use.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical System Diag-

nosis chart in this section. Also refer to Group 8W,

Wiring Diagrams for more information.

BLOWER MOTOR VIBRATION AND/OR NOISE

DIAGNOSIS

The resistor block supplies the blower motor with

varied voltage (low and middle speeds) or battery

voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing.

Refer to the Blower Motor Vibration/Noise chart

for diagnosis.

EVAPORATOR PROBE TEST

The work area and vehicle must be between 16É C

(60É F) and 32É C (90É F) when testing the switch.(1) Disconnect the three wire connector from the

evaporator probe lead located behind the glove box.

(2) Start engine and set A/C to low blower motor

speed, panel, full cool, and RECIRC.

(3) Using a voltmeter, check for battery voltage

between Pin 1 and 2. If no voltage is detected, there

is no power to the switch. Check wiring and fuses.

Refer to Group 8W, Wiring Diagrams for circuit diag-

nosis.

(4) Using a voltmeter, check for battery voltage

between Pin 1 and Pin 3. If no voltage is detected,

there is no voltage from the Powertrain Control Mod-

ule. Refer to Group 8W, Wiring Diagrams. If voltage

is OK, connect a jumper wire between Pin 1 and Pin

3. The compressor clutch should engage. If the clutch

engages, remove the jumper wire immediately and go

to Step 5. If the compressor clutch does not engage,

check the operation of the clutch and repair as nec-

essary.

(5) If compressor clutch engages, connect the evap-

orator probe 3-way connector. The compressor clutch

should engage or cycle depending on evaporator tem-

perature. If OK, go to Step 6. If not OK, replace the

clutch cycling switch.

(6) The engine running and the A/C set to:

²Blower motor on low speed

²Panel position

²Full cool

²RECIRC.

Close all doors and windows. Place a thermometer

in the center discharge vent.

(7) If the clutch does not begin to cycle off between

2É C to 7É C (35É F to 45É F), verify that the evapo-

rator probe is fully installed and not loose in evapo-

rator. If it is not properly installed, install probe and

retest outlet temperature. If the evaporator probe is

properly installed, replace the clutch cycling switch.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

24 - 8 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)