wheel alignment DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 12 of 1200

SUSPENSION

CONTENTS

page page

FRONT SUSPENSION..................... 10

REAR SUSPENSION...................... 39WHEEL ALIGNMENT....................... 1

WHEEL ALIGNMENT

INDEX

page page

DESCRIPTION AND OPERATION

COMPETITION PACKAGE ALIGNMENT........ 2

WHEEL ALIGNMENT GENERAL

INFORMATION......................... 1

DIAGNOSIS AND TESTING

PRE-ALIGNMENT VEHICLE INSPECTION...... 5

SUSPENSION AND STEERING DIAGNOSIS.... 3SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND

ADJUSTMENT PROCEDURE.............. 5

SPECIFICATIONS

VEHICLE ALIGNMENT SPECIFICATIONS AT

CURB HEIGHT......................... 9

DESCRIPTION AND OPERATION

WHEEL ALIGNMENT GENERAL INFORMATION

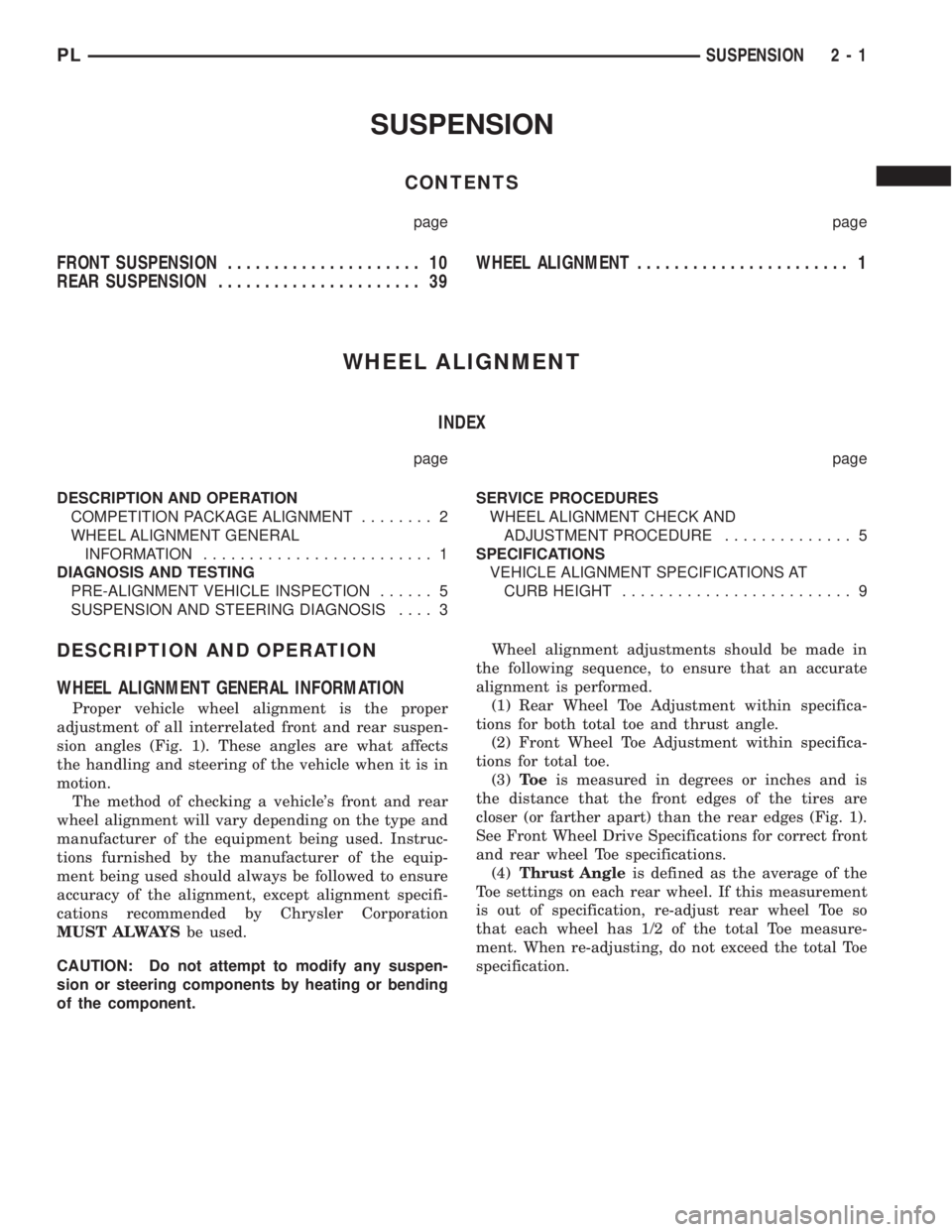

Proper vehicle wheel alignment is the proper

adjustment of all interrelated front and rear suspen-

sion angles (Fig. 1). These angles are what affects

the handling and steering of the vehicle when it is in

motion.

The method of checking a vehicle's front and rear

wheel alignment will vary depending on the type and

manufacturer of the equipment being used. Instruc-

tions furnished by the manufacturer of the equip-

ment being used should always be followed to ensure

accuracy of the alignment, except alignment specifi-

cations recommended by Chrysler Corporation

MUST ALWAYSbe used.

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating or bending

of the component.Wheel alignment adjustments should be made in

the following sequence, to ensure that an accurate

alignment is performed.

(1) Rear Wheel Toe Adjustment within specifica-

tions for both total toe and thrust angle.

(2) Front Wheel Toe Adjustment within specifica-

tions for total toe.

(3)To eis measured in degrees or inches and is

the distance that the front edges of the tires are

closer (or farther apart) than the rear edges (Fig. 1).

See Front Wheel Drive Specifications for correct front

and rear wheel Toe specifications.

(4)Thrust Angleis defined as the average of the

Toe settings on each rear wheel. If this measurement

is out of specification, re-adjust rear wheel Toe so

that each wheel has 1/2 of the total Toe measure-

ment. When re-adjusting, do not exceed the total Toe

specification.

PLSUSPENSION 2 - 1

Page 13 of 1200

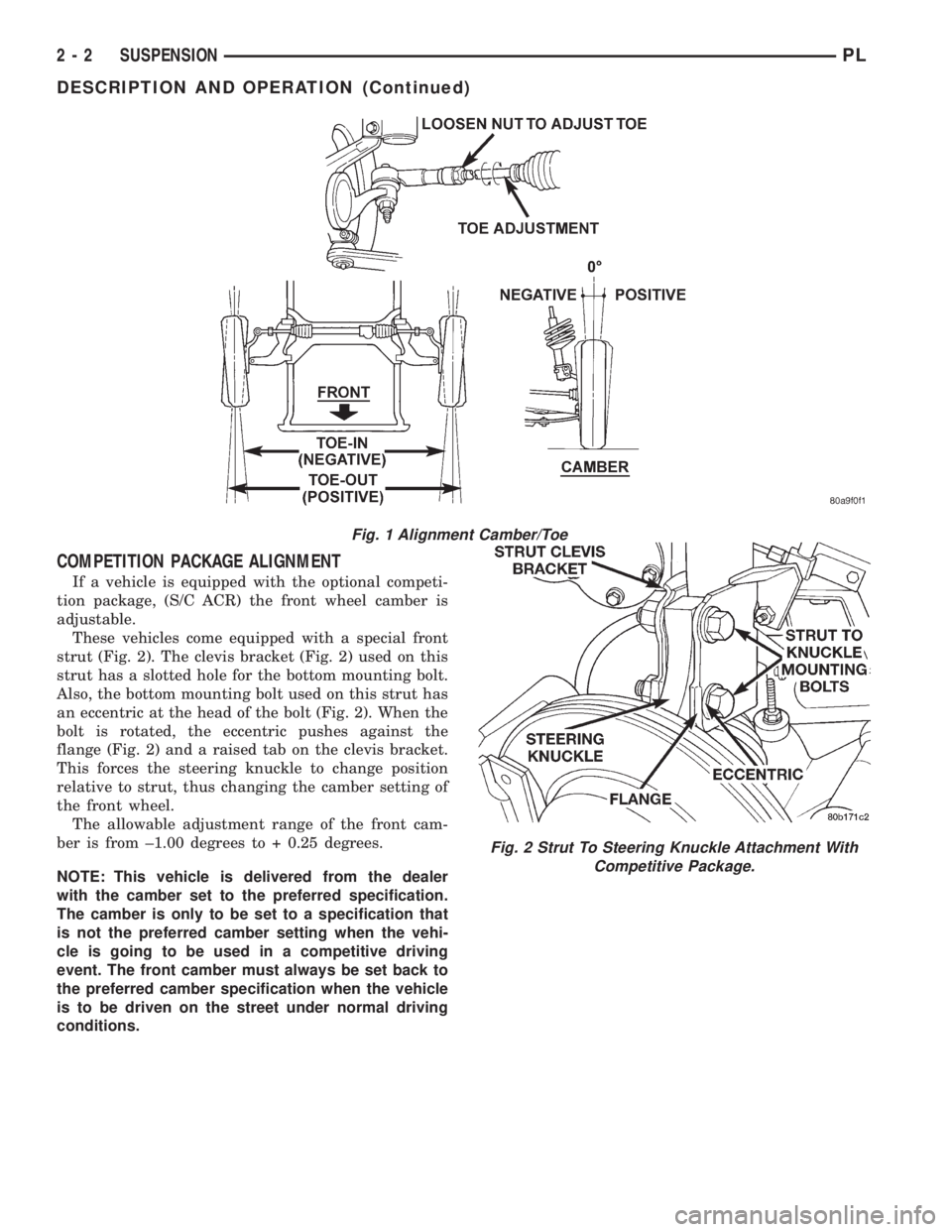

COMPETITION PACKAGE ALIGNMENT

If a vehicle is equipped with the optional competi-

tion package, (S/C ACR) the front wheel camber is

adjustable.

These vehicles come equipped with a special front

strut (Fig. 2). The clevis bracket (Fig. 2) used on this

strut has a slotted hole for the bottom mounting bolt.

Also, the bottom mounting bolt used on this strut has

an eccentric at the head of the bolt (Fig. 2). When the

bolt is rotated, the eccentric pushes against the

flange (Fig. 2) and a raised tab on the clevis bracket.

This forces the steering knuckle to change position

relative to strut, thus changing the camber setting of

the front wheel.

The allowable adjustment range of the front cam-

ber is from ±1.00 degrees to + 0.25 degrees.

NOTE: This vehicle is delivered from the dealer

with the camber set to the preferred specification.

The camber is only to be set to a specification that

is not the preferred camber setting when the vehi-

cle is going to be used in a competitive driving

event. The front camber must always be set back to

the preferred camber specification when the vehicle

is to be driven on the street under normal driving

conditions.

Fig. 1 Alignment Camber/Toe

Fig. 2 Strut To Steering Knuckle Attachment With

Competitive Package.

2 - 2 SUSPENSIONPL

DESCRIPTION AND OPERATION (Continued)

Page 14 of 1200

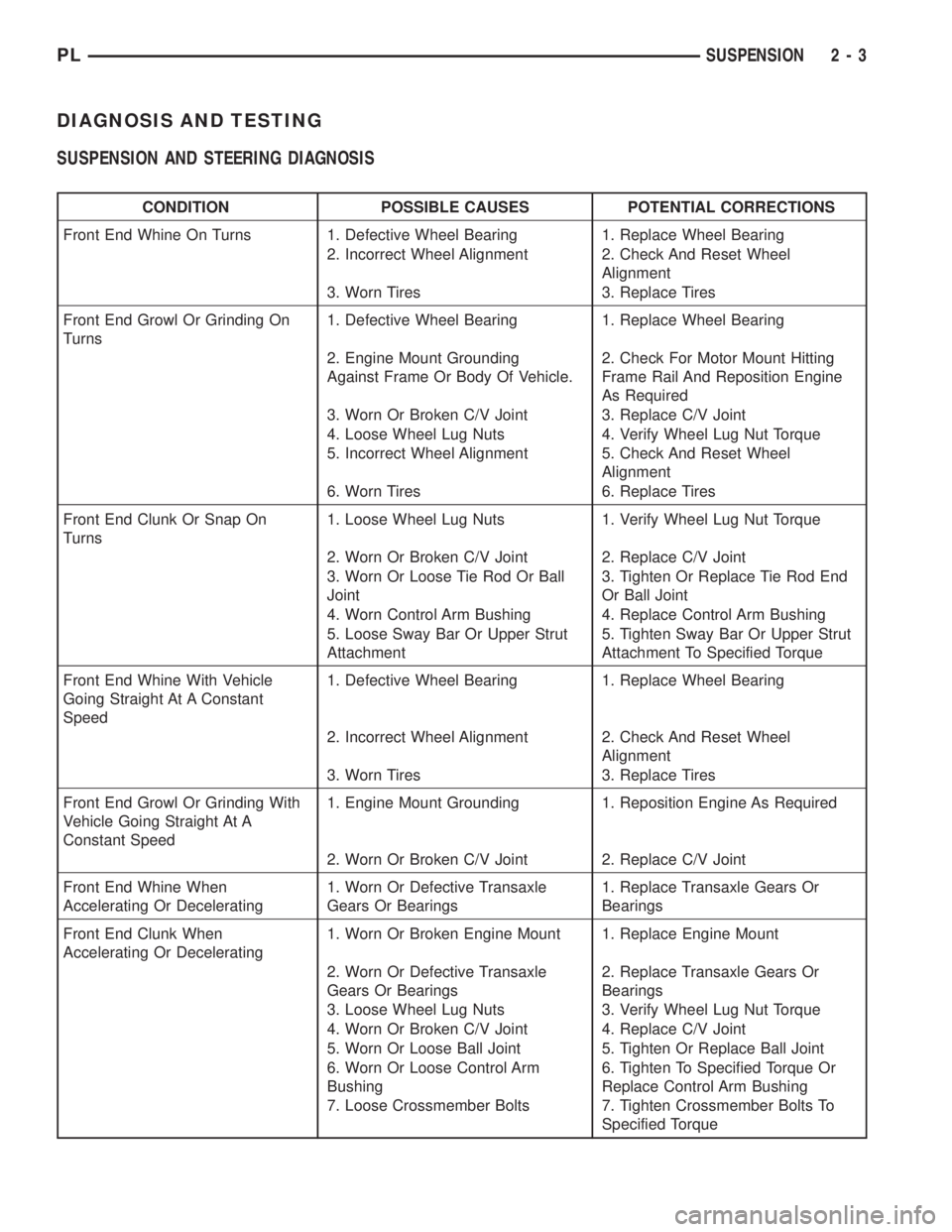

DIAGNOSIS AND TESTING

SUSPENSION AND STEERING DIAGNOSIS

CONDITION POSSIBLE CAUSES POTENTIAL CORRECTIONS

Front End Whine On Turns 1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Incorrect Wheel Alignment 2. Check And Reset Wheel

Alignment

3. Worn Tires 3. Replace Tires

Front End Growl Or Grinding On

Turns1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Engine Mount Grounding

Against Frame Or Body Of Vehicle.2. Check For Motor Mount Hitting

Frame Rail And Reposition Engine

As Required

3. Worn Or Broken C/V Joint 3. Replace C/V Joint

4. Loose Wheel Lug Nuts 4. Verify Wheel Lug Nut Torque

5. Incorrect Wheel Alignment 5. Check And Reset Wheel

Alignment

6. Worn Tires 6. Replace Tires

Front End Clunk Or Snap On

Turns1. Loose Wheel Lug Nuts 1. Verify Wheel Lug Nut Torque

2. Worn Or Broken C/V Joint 2. Replace C/V Joint

3. Worn Or Loose Tie Rod Or Ball

Joint3. Tighten Or Replace Tie Rod End

Or Ball Joint

4. Worn Control Arm Bushing 4. Replace Control Arm Bushing

5. Loose Sway Bar Or Upper Strut

Attachment5. Tighten Sway Bar Or Upper Strut

Attachment To Specified Torque

Front End Whine With Vehicle

Going Straight At A Constant

Speed1. Defective Wheel Bearing 1. Replace Wheel Bearing

2. Incorrect Wheel Alignment 2. Check And Reset Wheel

Alignment

3. Worn Tires 3. Replace Tires

Front End Growl Or Grinding With

Vehicle Going Straight At A

Constant Speed1. Engine Mount Grounding 1. Reposition Engine As Required

2. Worn Or Broken C/V Joint 2. Replace C/V Joint

Front End Whine When

Accelerating Or Decelerating1. Worn Or Defective Transaxle

Gears Or Bearings1. Replace Transaxle Gears Or

Bearings

Front End Clunk When

Accelerating Or Decelerating1. Worn Or Broken Engine Mount 1. Replace Engine Mount

2. Worn Or Defective Transaxle

Gears Or Bearings2. Replace Transaxle Gears Or

Bearings

3. Loose Wheel Lug Nuts 3. Verify Wheel Lug Nut Torque

4. Worn Or Broken C/V Joint 4. Replace C/V Joint

5. Worn Or Loose Ball Joint 5. Tighten Or Replace Ball Joint

6. Worn Or Loose Control Arm

Bushing6. Tighten To Specified Torque Or

Replace Control Arm Bushing

7. Loose Crossmember Bolts 7. Tighten Crossmember Bolts To

Specified Torque

PLSUSPENSION 2 - 3

Page 16 of 1200

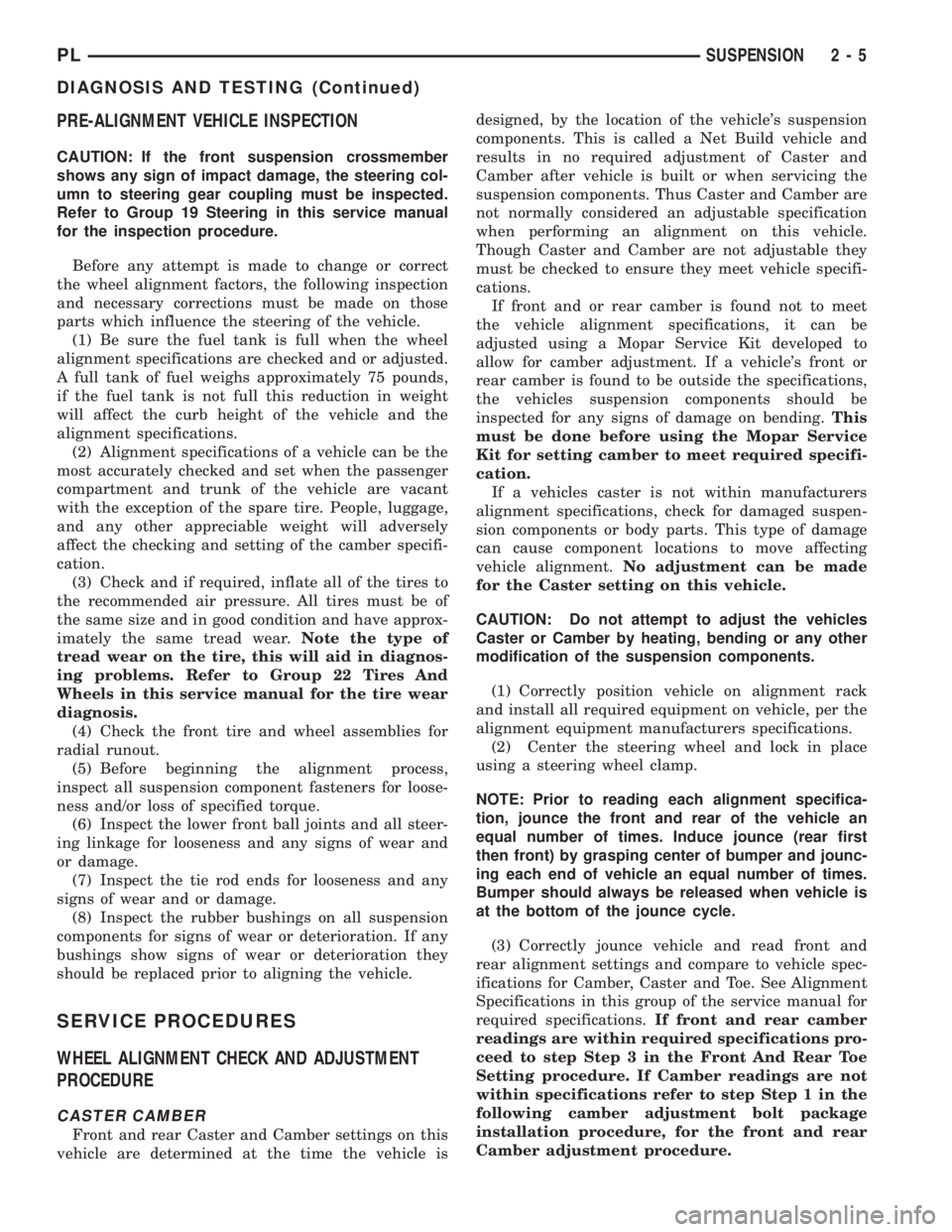

PRE-ALIGNMENT VEHICLE INSPECTION

CAUTION: If the front suspension crossmember

shows any sign of impact damage, the steering col-

umn to steering gear coupling must be inspected.

Refer to Group 19 Steering in this service manual

for the inspection procedure.

Before any attempt is made to change or correct

the wheel alignment factors, the following inspection

and necessary corrections must be made on those

parts which influence the steering of the vehicle.

(1) Be sure the fuel tank is full when the wheel

alignment specifications are checked and or adjusted.

A full tank of fuel weighs approximately 75 pounds,

if the fuel tank is not full this reduction in weight

will affect the curb height of the vehicle and the

alignment specifications.

(2) Alignment specifications of a vehicle can be the

most accurately checked and set when the passenger

compartment and trunk of the vehicle are vacant

with the exception of the spare tire. People, luggage,

and any other appreciable weight will adversely

affect the checking and setting of the camber specifi-

cation.

(3) Check and if required, inflate all of the tires to

the recommended air pressure. All tires must be of

the same size and in good condition and have approx-

imately the same tread wear.Note the type of

tread wear on the tire, this will aid in diagnos-

ing problems. Refer to Group 22 Tires And

Wheels in this service manual for the tire wear

diagnosis.

(4) Check the front tire and wheel assemblies for

radial runout.

(5) Before beginning the alignment process,

inspect all suspension component fasteners for loose-

ness and/or loss of specified torque.

(6) Inspect the lower front ball joints and all steer-

ing linkage for looseness and any signs of wear and

or damage.

(7) Inspect the tie rod ends for looseness and any

signs of wear and or damage.

(8) Inspect the rubber bushings on all suspension

components for signs of wear or deterioration. If any

bushings show signs of wear or deterioration they

should be replaced prior to aligning the vehicle.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER CAMBER

Front and rear Caster and Camber settings on this

vehicle are determined at the time the vehicle isdesigned, by the location of the vehicle's suspension

components. This is called a Net Build vehicle and

results in no required adjustment of Caster and

Camber after vehicle is built or when servicing the

suspension components. Thus Caster and Camber are

not normally considered an adjustable specification

when performing an alignment on this vehicle.

Though Caster and Camber are not adjustable they

must be checked to ensure they meet vehicle specifi-

cations.

If front and or rear camber is found not to meet

the vehicle alignment specifications, it can be

adjusted using a Mopar Service Kit developed to

allow for camber adjustment. If a vehicle's front or

rear camber is found to be outside the specifications,

the vehicles suspension components should be

inspected for any signs of damage on bending.This

must be done before using the Mopar Service

Kit for setting camber to meet required specifi-

cation.

If a vehicles caster is not within manufacturers

alignment specifications, check for damaged suspen-

sion components or body parts. This type of damage

can cause component locations to move affecting

vehicle alignment.No adjustment can be made

for the Caster setting on this vehicle.

CAUTION: Do not attempt to adjust the vehicles

Caster or Camber by heating, bending or any other

modification of the suspension components.

(1) Correctly position vehicle on alignment rack

and install all required equipment on vehicle, per the

alignment equipment manufacturers specifications.

(2) Center the steering wheel and lock in place

using a steering wheel clamp.

NOTE: Prior to reading each alignment specifica-

tion, jounce the front and rear of the vehicle an

equal number of times. Induce jounce (rear first

then front) by grasping center of bumper and jounc-

ing each end of vehicle an equal number of times.

Bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Correctly jounce vehicle and read front and

rear alignment settings and compare to vehicle spec-

ifications for Camber, Caster and Toe. See Alignment

Specifications in this group of the service manual for

required specifications.If front and rear camber

readings are within required specifications pro-

ceed to step Step 3 in the Front And Rear Toe

Setting procedure. If Camber readings are not

within specifications refer to step Step 1 in the

following camber adjustment bolt package

installation procedure, for the front and rear

Camber adjustment procedure.

PLSUSPENSION 2 - 5

DIAGNOSIS AND TESTING (Continued)

Page 18 of 1200

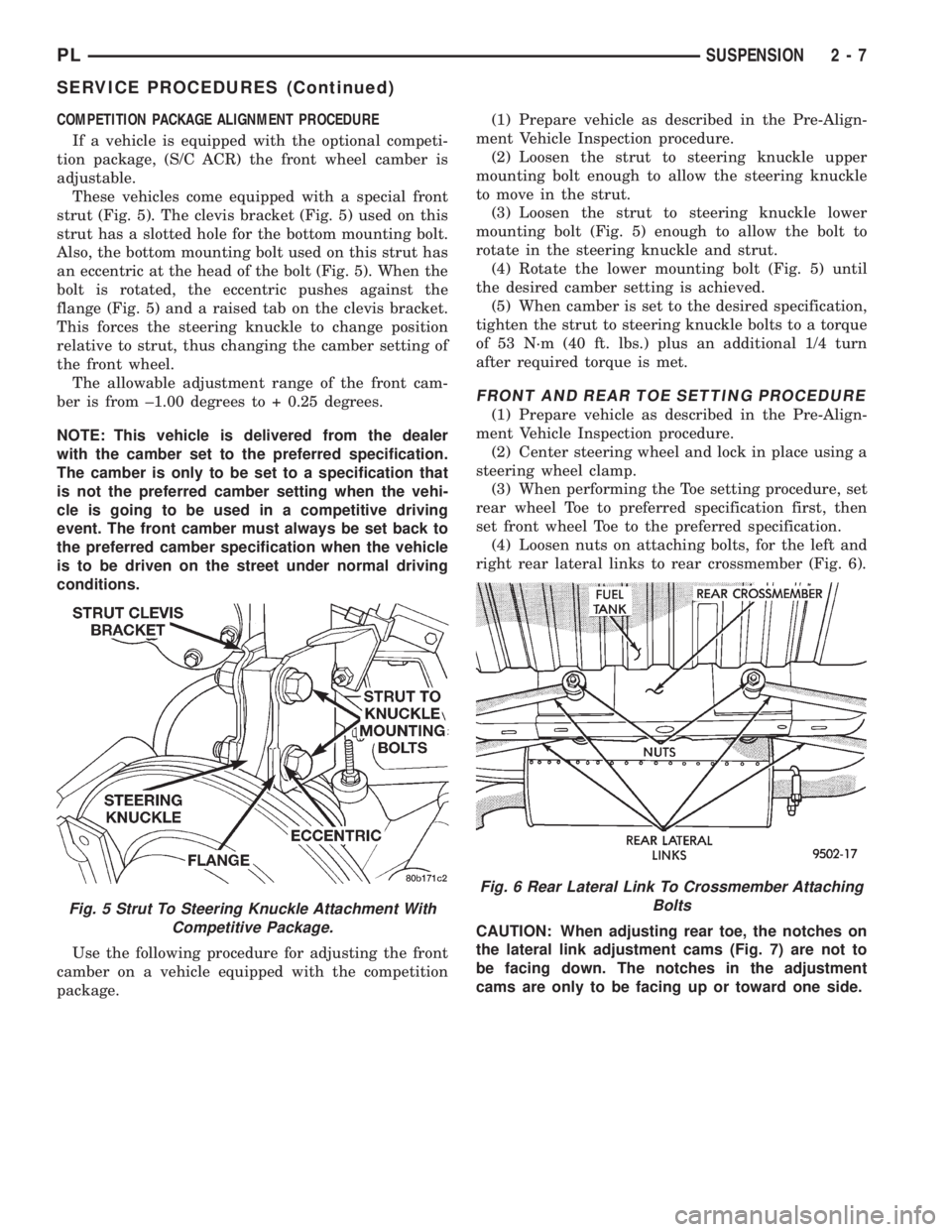

COMPETITION PACKAGE ALIGNMENT PROCEDURE

If a vehicle is equipped with the optional competi-

tion package, (S/C ACR) the front wheel camber is

adjustable.

These vehicles come equipped with a special front

strut (Fig. 5). The clevis bracket (Fig. 5) used on this

strut has a slotted hole for the bottom mounting bolt.

Also, the bottom mounting bolt used on this strut has

an eccentric at the head of the bolt (Fig. 5). When the

bolt is rotated, the eccentric pushes against the

flange (Fig. 5) and a raised tab on the clevis bracket.

This forces the steering knuckle to change position

relative to strut, thus changing the camber setting of

the front wheel.

The allowable adjustment range of the front cam-

ber is from ±1.00 degrees to + 0.25 degrees.

NOTE: This vehicle is delivered from the dealer

with the camber set to the preferred specification.

The camber is only to be set to a specification that

is not the preferred camber setting when the vehi-

cle is going to be used in a competitive driving

event. The front camber must always be set back to

the preferred camber specification when the vehicle

is to be driven on the street under normal driving

conditions.

Use the following procedure for adjusting the front

camber on a vehicle equipped with the competition

package.(1) Prepare vehicle as described in the Pre-Align-

ment Vehicle Inspection procedure.

(2) Loosen the strut to steering knuckle upper

mounting bolt enough to allow the steering knuckle

to move in the strut.

(3) Loosen the strut to steering knuckle lower

mounting bolt (Fig. 5) enough to allow the bolt to

rotate in the steering knuckle and strut.

(4) Rotate the lower mounting bolt (Fig. 5) until

the desired camber setting is achieved.

(5) When camber is set to the desired specification,

tighten the strut to steering knuckle bolts to a torque

of 53 N´m (40 ft. lbs.) plus an additional 1/4 turn

after required torque is met.

FRONT AND REAR TOE SETTING PROCEDURE

(1) Prepare vehicle as described in the Pre-Align-

ment Vehicle Inspection procedure.

(2) Center steering wheel and lock in place using a

steering wheel clamp.

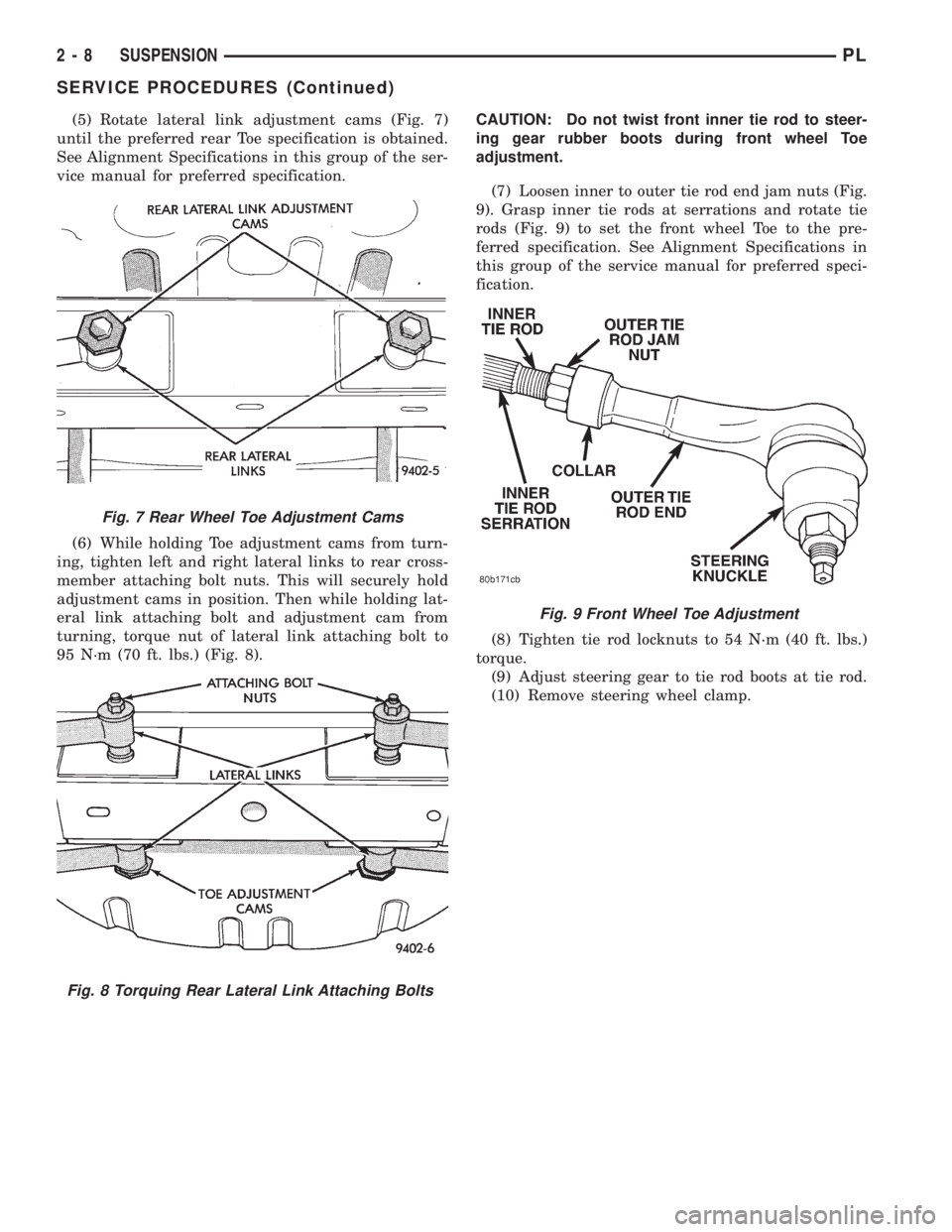

(3) When performing the Toe setting procedure, set

rear wheel Toe to preferred specification first, then

set front wheel Toe to the preferred specification.

(4) Loosen nuts on attaching bolts, for the left and

right rear lateral links to rear crossmember (Fig. 6).

CAUTION: When adjusting rear toe, the notches on

the lateral link adjustment cams (Fig. 7) are not to

be facing down. The notches in the adjustment

cams are only to be facing up or toward one side.

Fig. 5 Strut To Steering Knuckle Attachment With

Competitive Package.

Fig. 6 Rear Lateral Link To Crossmember Attaching

Bolts

PLSUSPENSION 2 - 7

SERVICE PROCEDURES (Continued)

Page 19 of 1200

(5) Rotate lateral link adjustment cams (Fig. 7)

until the preferred rear Toe specification is obtained.

See Alignment Specifications in this group of the ser-

vice manual for preferred specification.

(6) While holding Toe adjustment cams from turn-

ing, tighten left and right lateral links to rear cross-

member attaching bolt nuts. This will securely hold

adjustment cams in position. Then while holding lat-

eral link attaching bolt and adjustment cam from

turning, torque nut of lateral link attaching bolt to

95 N´m (70 ft. lbs.) (Fig. 8).CAUTION: Do not twist front inner tie rod to steer-

ing gear rubber boots during front wheel Toe

adjustment.

(7) Loosen inner to outer tie rod end jam nuts (Fig.

9). Grasp inner tie rods at serrations and rotate tie

rods (Fig. 9) to set the front wheel Toe to the pre-

ferred specification. See Alignment Specifications in

this group of the service manual for preferred speci-

fication.

(8) Tighten tie rod locknuts to 54 N´m (40 ft. lbs.)

torque.

(9) Adjust steering gear to tie rod boots at tie rod.

(10) Remove steering wheel clamp.

Fig. 7 Rear Wheel Toe Adjustment Cams

Fig. 8 Torquing Rear Lateral Link Attaching Bolts

Fig. 9 Front Wheel Toe Adjustment

2 - 8 SUSPENSIONPL

SERVICE PROCEDURES (Continued)

Page 20 of 1200

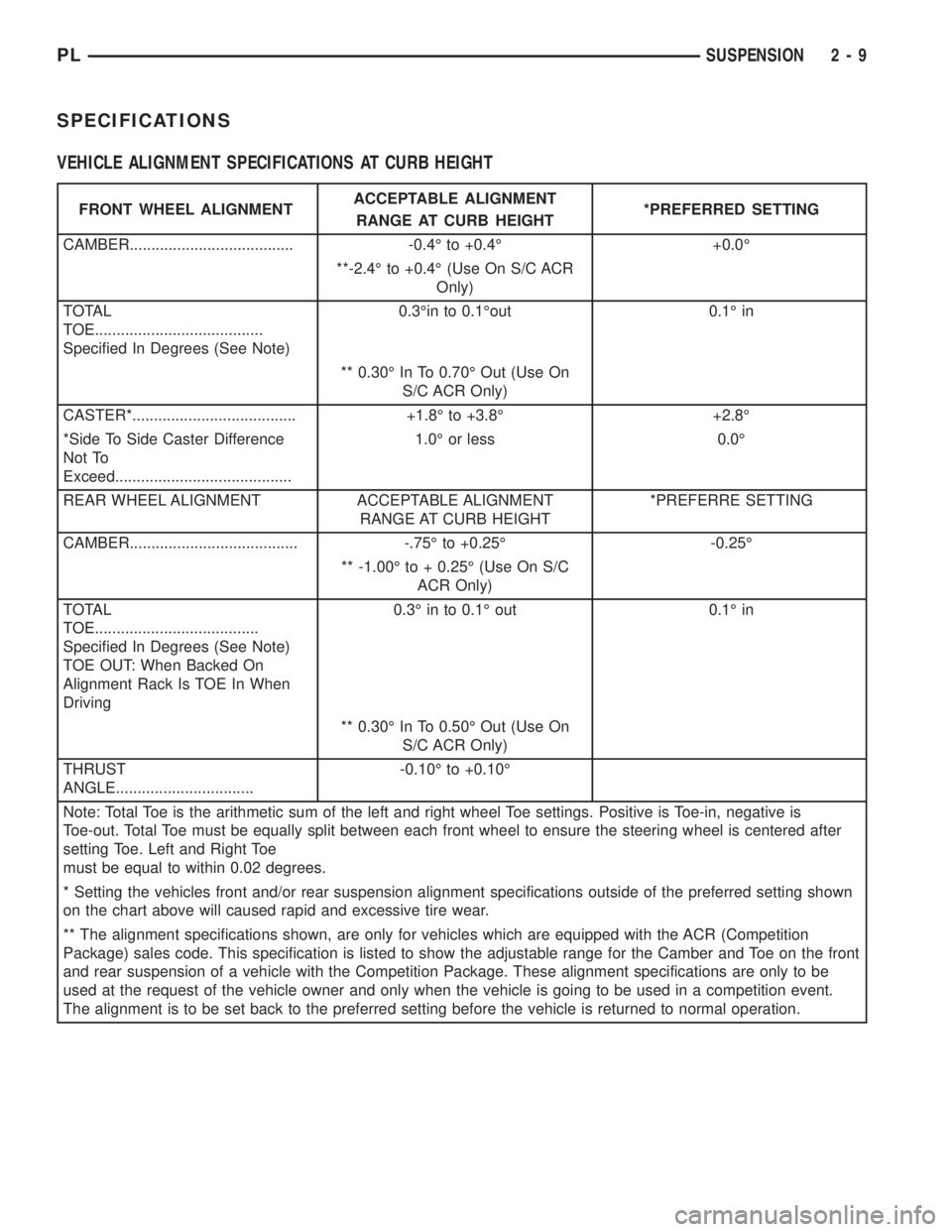

SPECIFICATIONS

VEHICLE ALIGNMENT SPECIFICATIONS AT CURB HEIGHT

FRONT WHEEL ALIGNMENTACCEPTABLE ALIGNMENT

RANGE AT CURB HEIGHT*PREFERRED SETTING

CAMBER...................................... -0.4É to +0.4É +0.0É

**-2.4É to +0.4É (Use On S/C ACR

Only)

TOTAL

TOE.......................................

Specified In Degrees (See Note)0.3Éin to 0.1Éout 0.1É in

** 0.30É In To 0.70É Out (Use On

S/C ACR Only)

CASTER*...................................... +1.8É to +3.8É +2.8É

*Side To Side Caster Difference

Not To

Exceed.........................................1.0É or less 0.0É

REAR WHEEL ALIGNMENT ACCEPTABLE ALIGNMENT

RANGE AT CURB HEIGHT*PREFERRE SETTING

CAMBER....................................... -.75É to +0.25É -0.25É

** -1.00É to + 0.25É (Use On S/C

ACR Only)

TOTAL

TOE......................................

Specified In Degrees (See Note)

TOE OUT: When Backed On

Alignment Rack Is TOE In When

Driving0.3É in to 0.1É out 0.1É in

** 0.30É In To 0.50É Out (Use On

S/C ACR Only)

THRUST

ANGLE................................-0.10É to +0.10É

Note: Total Toe is the arithmetic sum of the left and right wheel Toe settings. Positive is Toe-in, negative is

Toe-out. Total Toe must be equally split between each front wheel to ensure the steering wheel is centered after

setting Toe. Left and Right Toe

must be equal to within 0.02 degrees.

* Setting the vehicles front and/or rear suspension alignment specifications outside of the preferred setting shown

on the chart above will caused rapid and excessive tire wear.

** The alignment specifications shown, are only for vehicles which are equipped with the ACR (Competition

Package) sales code. This specification is listed to show the adjustable range for the Camber and Toe on the front

and rear suspension of a vehicle with the Competition Package. These alignment specifications are only to be

used at the request of the vehicle owner and only when the vehicle is going to be used in a competition event.

The alignment is to be set back to the preferred setting before the vehicle is returned to normal operation.

PLSUSPENSION 2 - 9

Page 32 of 1200

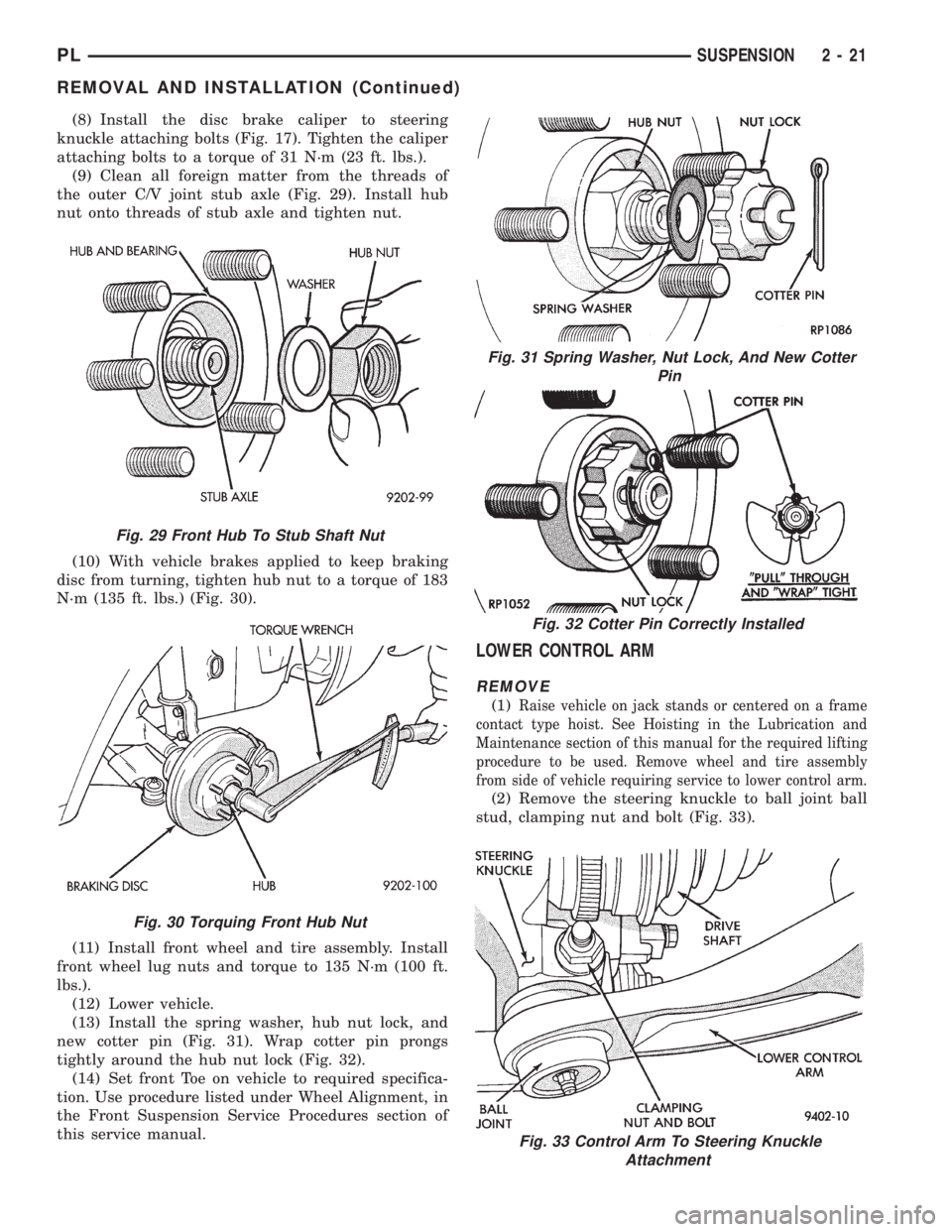

(8) Install the disc brake caliper to steering

knuckle attaching bolts (Fig. 17). Tighten the caliper

attaching bolts to a torque of 31 N´m (23 ft. lbs.).

(9) Clean all foreign matter from the threads of

the outer C/V joint stub axle (Fig. 29). Install hub

nut onto threads of stub axle and tighten nut.

(10) With vehicle brakes applied to keep braking

disc from turning, tighten hub nut to a torque of 183

N´m (135 ft. lbs.) (Fig. 30).

(11) Install front wheel and tire assembly. Install

front wheel lug nuts and torque to 135 N´m (100 ft.

lbs.).

(12) Lower vehicle.

(13) Install the spring washer, hub nut lock, and

new cotter pin (Fig. 31). Wrap cotter pin prongs

tightly around the hub nut lock (Fig. 32).

(14) Set front Toe on vehicle to required specifica-

tion. Use procedure listed under Wheel Alignment, in

the Front Suspension Service Procedures section of

this service manual.

LOWER CONTROL ARM

REMOVE

(1)Raise vehicle on jack stands or centered on a frame

contact type hoist. See Hoisting in the Lubrication and

Maintenance section of this manual for the required lifting

procedure to be used. Remove wheel and tire assembly

from side of vehicle requiring service to lower control arm.

(2) Remove the steering knuckle to ball joint ball

stud, clamping nut and bolt (Fig. 33).

Fig. 29 Front Hub To Stub Shaft Nut

Fig. 30 Torquing Front Hub Nut

Fig. 31 Spring Washer, Nut Lock, And New Cotter

Pin

Fig. 32 Cotter Pin Correctly Installed

Fig. 33 Control Arm To Steering Knuckle

Attachment

PLSUSPENSION 2 - 21

REMOVAL AND INSTALLATION (Continued)

Page 39 of 1200

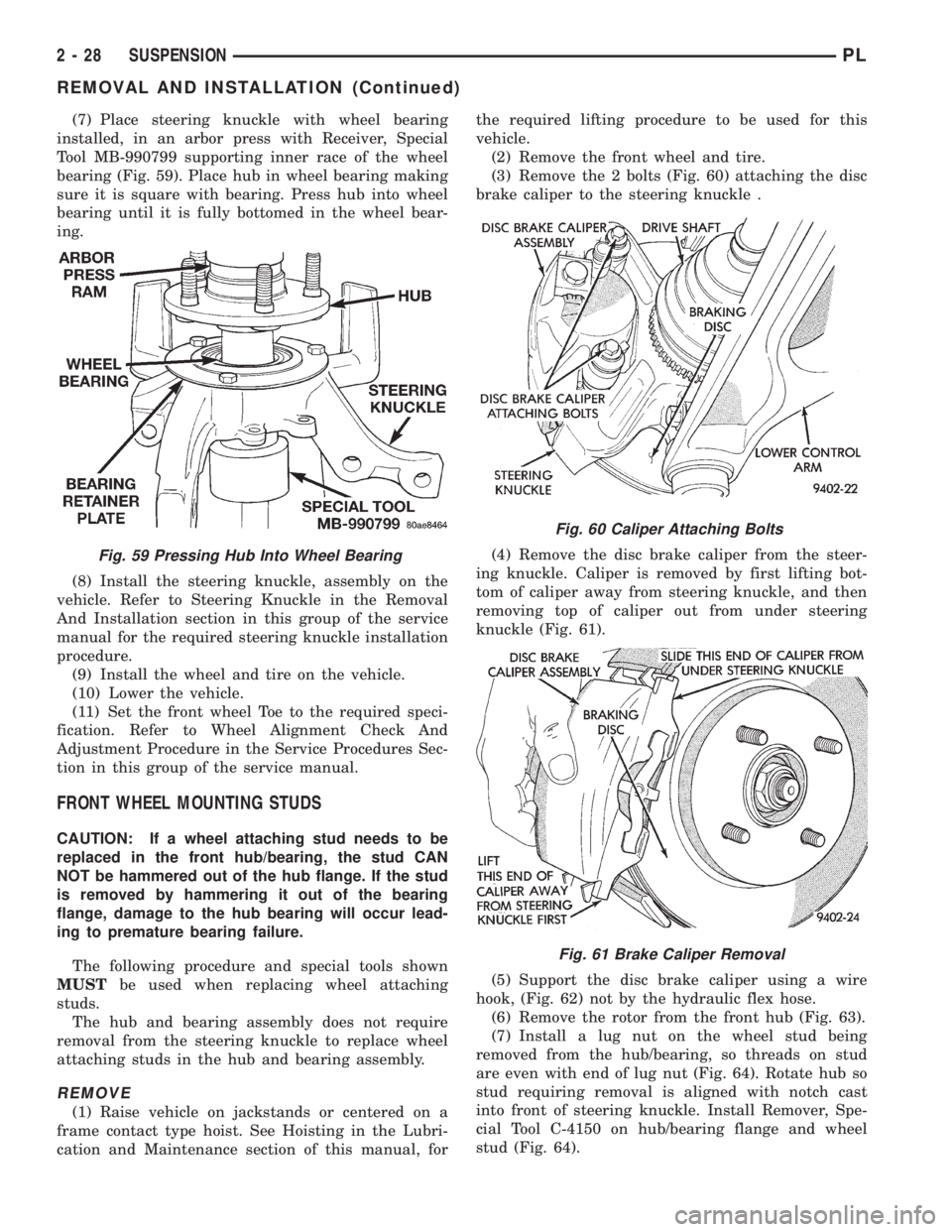

(7) Place steering knuckle with wheel bearing

installed, in an arbor press with Receiver, Special

Tool MB-990799 supporting inner race of the wheel

bearing (Fig. 59). Place hub in wheel bearing making

sure it is square with bearing. Press hub into wheel

bearing until it is fully bottomed in the wheel bear-

ing.

(8) Install the steering knuckle, assembly on the

vehicle. Refer to Steering Knuckle in the Removal

And Installation section in this group of the service

manual for the required steering knuckle installation

procedure.

(9) Install the wheel and tire on the vehicle.

(10) Lower the vehicle.

(11) Set the front wheel Toe to the required speci-

fication. Refer to Wheel Alignment Check And

Adjustment Procedure in the Service Procedures Sec-

tion in this group of the service manual.

FRONT WHEEL MOUNTING STUDS

CAUTION: If a wheel attaching stud needs to be

replaced in the front hub/bearing, the stud CAN

NOT be hammered out of the hub flange. If the stud

is removed by hammering it out of the bearing

flange, damage to the hub bearing will occur lead-

ing to premature bearing failure.

The following procedure and special tools shown

MUSTbe used when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, forthe required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire.

(3) Remove the 2 bolts (Fig. 60) attaching the disc

brake caliper to the steering knuckle .

(4) Remove the disc brake caliper from the steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle (Fig. 61).

(5) Support the disc brake caliper using a wire

hook, (Fig. 62) not by the hydraulic flex hose.

(6) Remove the rotor from the front hub (Fig. 63).

(7) Install a lug nut on the wheel stud being

removed from the hub/bearing, so threads on stud

are even with end of lug nut (Fig. 64). Rotate hub so

stud requiring removal is aligned with notch cast

into front of steering knuckle. Install Remover, Spe-

cial Tool C-4150 on hub/bearing flange and wheel

stud (Fig. 64).

Fig. 59 Pressing Hub Into Wheel Bearing

Fig. 60 Caliper Attaching Bolts

Fig. 61 Brake Caliper Removal

2 - 28 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 50 of 1200

REAR SUSPENSION

INDEX

page page

GENERAL INFORMATION

GENERAL INFORMATION................. 39

DESCRIPTION AND OPERATION

COIL SPRING........................... 41

COMPETITION PACKAGE SUSPENSION...... 41

KNUCKLE............................. 41

LATERAL LINKS AND TENSION STRUTS...... 41

REAR SUSPENSION..................... 39

STABILIZER BAR........................ 41

STRUT................................ 41

DIAGNOSIS AND TESTING

KNUCKLE............................. 42

LATERAL LINKS......................... 42

STABILIZER BAR AND BUSHINGS........... 43

STABILIZER BAR ATTACHING LINKS......... 43

STRUT INSPECTION (ON VEHICLE)......... 42

TENSION STRUT........................ 42

SERVICE PROCEDURES

REAR WHEEL ALIGNMENT................ 43REMOVAL AND INSTALLATION

COIL SPRING........................... 44

KNUCKLE............................. 46

LATERAL LINKS......................... 48

STABILIZER BAR........................ 45

STRUT ASSEMBLY...................... 43

DISASSEMBLY AND ASSEMBLY

STABILIZER BAR BUSHINGS............... 53

STRUT ASSEMBLY...................... 50

ADJUSTMENTS

STRUT ADJUSTMENT COMPETITION

PACKAGE SUSPENSION................ 53

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUE

SPECIFICATIONS...................... 54

SPECIAL TOOLS

REAR SUSPENSION..................... 54

GENERAL INFORMATION

GENERAL INFORMATION

CAUTION: Only frame contact or wheel lift hoisting

equipment can be used on vehicles having a fully

independent rear suspension. Vehicles with inde-

pendent rear suspension can not be hoisted using

equipment designed to lift a vehicle by the rear

axle. If this type of hoisting equipment is used dam-

age to rear suspension components will occur.

NOTE: If a rear suspension component becomes

bent, damaged or fails, no attempt should be made

to straighten or repair it. Always replace with a new

component.

DESCRIPTION AND OPERATION

REAR SUSPENSION

The rear suspension system used on this vehicle is

a fully independent type rear suspension system (Fig.

1).A forged rear knuckle is bolted to each rear strut.

The movement of the rear knuckle is controlled lat-

erally using lateral links going from the front and

rear of the knuckle to the rear crossmember. Fore

and aft movement of the knuckle is controlled by a

tension strut.

The lateral links and tension strut have rubber iso-

lator bushings at each end. The lateral links are

attached to the rear crossmember and knuckle, using

a common bolt and nut assembly at each end. The

tension strut bolts to the bottom of the knuckle and

to a bracket attached to the floor pan of the vehicle.

The lateral links, tension strut and spindle are

normally replaced only when the part has been dam-

aged or when the vehicle has been involved in an

accident. If a suspension part has been damaged, be

sure to check the underbody dimensions of the car. If

the underbody dimensions are not correct, the frame

of the vehicle must be straightened, before replace-

ment suspension components are installed.

PLSUSPENSION 2 - 39