ignition DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1164 of 1200

EMISSION CONTROL SYSTEMS

CONTENTS

page page

EVAPORATIVE EMISSION CONTROLS........ 11

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM.............................. 18ON-BOARD DIAGNOSTICS.................. 1

ON-BOARD DIAGNOSTICS

INDEX

page page

GENERAL INFORMATION

SYSTEM DESCRIPTION................... 1

DESCRIPTION AND OPERATION

CIRCUIT ACTUATION TEST MODE........... 2

COMPONENT MONITORS.................. 9

DIAGNOSTIC TROUBLE CODES............. 2

HIGH AND LOW LIMITS................... 10LOAD VALUE........................... 10

MALFUNCTION INDICATOR LAMP (MIL)....... 1

MONITORED SYSTEMS.................... 6

NON-MONITORED CIRCUITS............... 9

STATE DISPLAY TEST MODE............... 2

TRIP DEFINITION........................ 9

GENERAL INFORMATION

SYSTEM DESCRIPTION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor'soutput circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRB scan tool to

erase all DTC's and extinguish the MIL.

Technicians can display stored DTC's by using the

DRB scan tool. Refer to Diagnostic Trouble Codes in

this section. For DTC information, refer to charts in

this section.

DESCRIPTION AND OPERATION

MALFUNCTION INDICATOR LAMP (MIL)

As a functional test, the Malfunction Indicator

Lamp (MIL) illuminates at key-on before engine

PLEMISSION CONTROL SYSTEMS 25 - 1

Page 1165 of 1200

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the CCD Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.

Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

CIRCUIT ACTUATION TEST MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

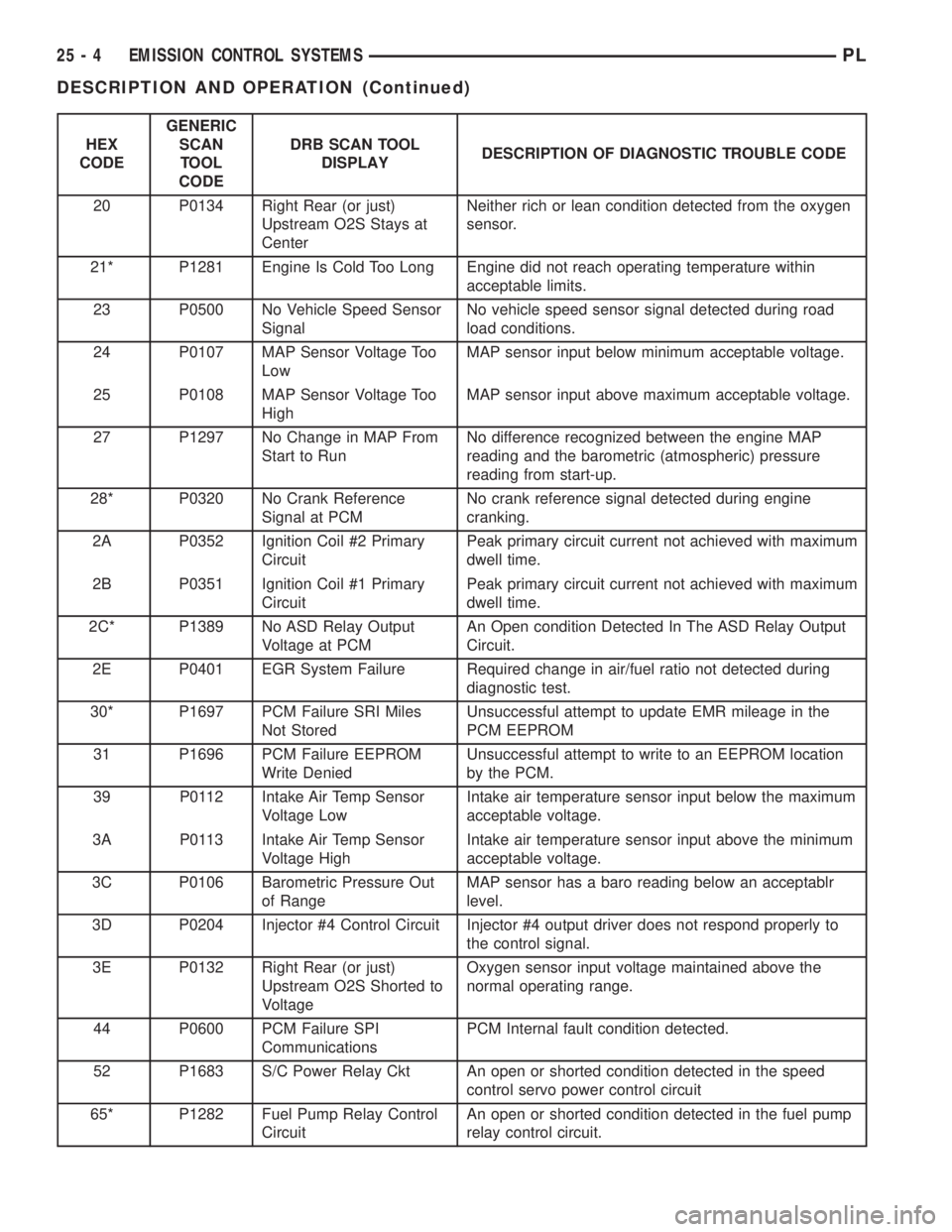

DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

²The preferred and most accurate method of

retrieving a DTC is by using the DRB scan tool. The

scan tool supplies detailed diagnostic information

which can be used to more accurately diagnose

causes for a DTC.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

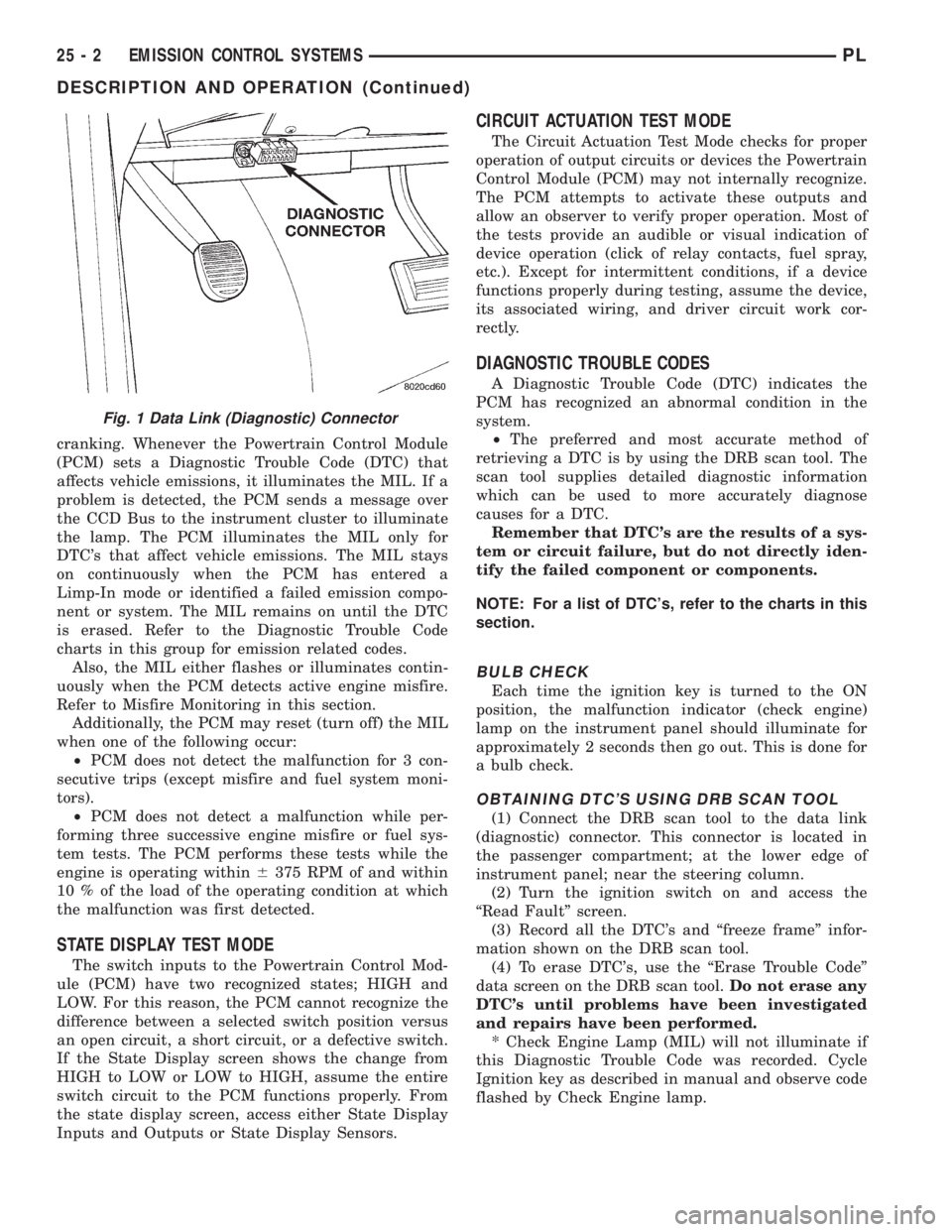

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

* Check Engine Lamp (MIL) will not illuminate if

this Diagnostic Trouble Code was recorded. Cycle

Ignition key as described in manual and observe code

flashed by Check Engine lamp.

Fig. 1 Data Link (Diagnostic) Connector

25 - 2 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1167 of 1200

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC TROUBLE CODE

20 P0134 Right Rear (or just)

Upstream O2S Stays at

CenterNeither rich or lean condition detected from the oxygen

sensor.

21* P1281 Engine Is Cold Too Long Engine did not reach operating temperature within

acceptable limits.

23 P0500 No Vehicle Speed Sensor

SignalNo vehicle speed sensor signal detected during road

load conditions.

24 P0107 MAP Sensor Voltage Too

LowMAP sensor input below minimum acceptable voltage.

25 P0108 MAP Sensor Voltage Too

HighMAP sensor input above maximum acceptable voltage.

27 P1297 No Change in MAP From

Start to RunNo difference recognized between the engine MAP

reading and the barometric (atmospheric) pressure

reading from start-up.

28* P0320 No Crank Reference

Signal at PCMNo crank reference signal detected during engine

cranking.

2A P0352 Ignition Coil #2 Primary

CircuitPeak primary circuit current not achieved with maximum

dwell time.

2B P0351 Ignition Coil #1 Primary

CircuitPeak primary circuit current not achieved with maximum

dwell time.

2C* P1389 No ASD Relay Output

Voltage at PCMAn Open condition Detected In The ASD Relay Output

Circuit.

2E P0401 EGR System Failure Required change in air/fuel ratio not detected during

diagnostic test.

30* P1697 PCM Failure SRI Miles

Not StoredUnsuccessful attempt to update EMR mileage in the

PCM EEPROM

31 P1696 PCM Failure EEPROM

Write DeniedUnsuccessful attempt to write to an EEPROM location

by the PCM.

39 P0112 Intake Air Temp Sensor

Voltage LowIntake air temperature sensor input below the maximum

acceptable voltage.

3A P0113 Intake Air Temp Sensor

Voltage HighIntake air temperature sensor input above the minimum

acceptable voltage.

3C P0106 Barometric Pressure Out

of RangeMAP sensor has a baro reading below an acceptablr

level.

3D P0204 Injector #4 Control Circuit Injector #4 output driver does not respond properly to

the control signal.

3E P0132 Right Rear (or just)

Upstream O2S Shorted to

VoltageOxygen sensor input voltage maintained above the

normal operating range.

44 P0600 PCM Failure SPI

CommunicationsPCM Internal fault condition detected.

52 P1683 S/C Power Relay Ckt An open or shorted condition detected in the speed

control servo power control circuit

65* P1282 Fuel Pump Relay Control

CircuitAn open or shorted condition detected in the fuel pump

relay control circuit.

25 - 4 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1169 of 1200

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC TROUBLE CODE

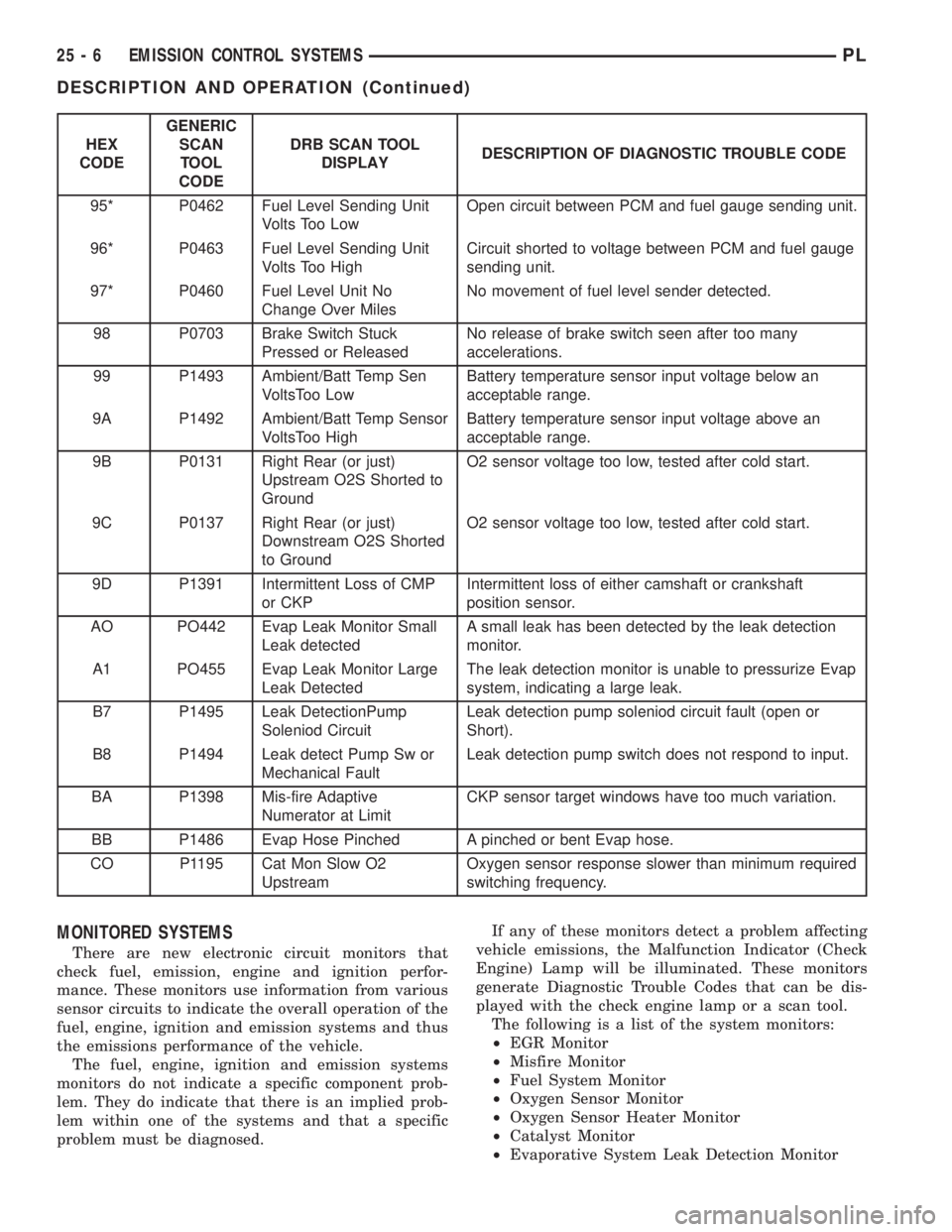

95* P0462 Fuel Level Sending Unit

Volts Too LowOpen circuit between PCM and fuel gauge sending unit.

96* P0463 Fuel Level Sending Unit

Volts Too HighCircuit shorted to voltage between PCM and fuel gauge

sending unit.

97* P0460 Fuel Level Unit No

Change Over MilesNo movement of fuel level sender detected.

98 P0703 Brake Switch Stuck

Pressed or ReleasedNo release of brake switch seen after too many

accelerations.

99 P1493 Ambient/Batt Temp Sen

VoltsToo LowBattery temperature sensor input voltage below an

acceptable range.

9A P1492 Ambient/Batt Temp Sensor

VoltsToo HighBattery temperature sensor input voltage above an

acceptable range.

9B P0131 Right Rear (or just)

Upstream O2S Shorted to

GroundO2 sensor voltage too low, tested after cold start.

9C P0137 Right Rear (or just)

Downstream O2S Shorted

to GroundO2 sensor voltage too low, tested after cold start.

9D P1391 Intermittent Loss of CMP

or CKPIntermittent loss of either camshaft or crankshaft

position sensor.

AO PO442 Evap Leak Monitor Small

Leak detectedA small leak has been detected by the leak detection

monitor.

A1 PO455 Evap Leak Monitor Large

Leak DetectedThe leak detection monitor is unable to pressurize Evap

system, indicating a large leak.

B7 P1495 Leak DetectionPump

Soleniod CircuitLeak detection pump soleniod circuit fault (open or

Short).

B8 P1494 Leak detect Pump Sw or

Mechanical FaultLeak detection pump switch does not respond to input.

BA P1398 Mis-fire Adaptive

Numerator at LimitCKP sensor target windows have too much variation.

BB P1486 Evap Hose Pinched A pinched or bent Evap hose.

CO P1195 Cat Mon Slow O2

UpstreamOxygen sensor response slower than minimum required

switching frequency.

MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the system monitors:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor

25 - 6 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1173 of 1200

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL

MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

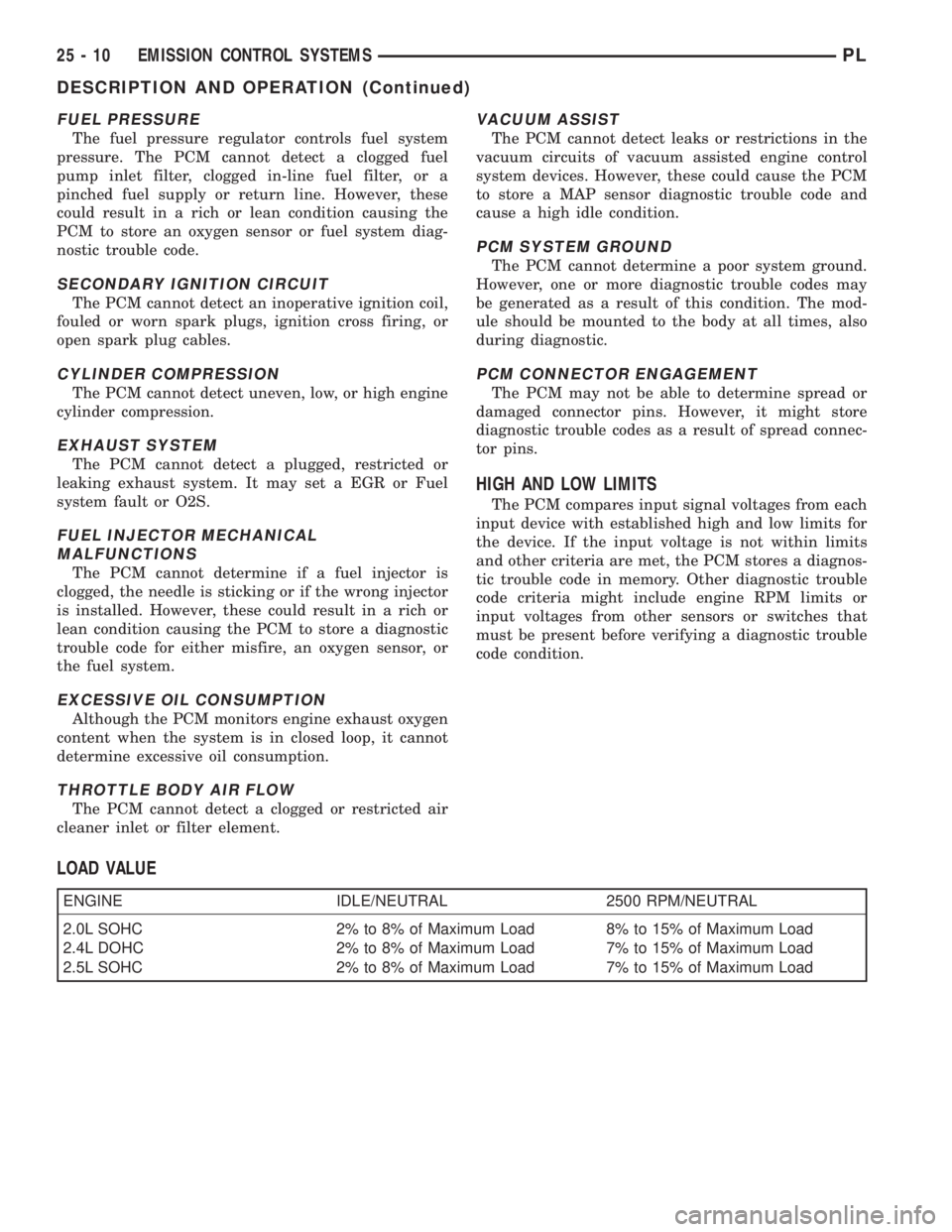

LOAD VALUE

ENGINE IDLE/NEUTRAL 2500 RPM/NEUTRAL

2.0L SOHC 2% to 8% of Maximum Load 8% to 15% of Maximum Load

2.4L DOHC 2% to 8% of Maximum Load 7% to 15% of Maximum Load

2.5L SOHC 2% to 8% of Maximum Load 7% to 15% of Maximum Load

25 - 10 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1200 of 1200

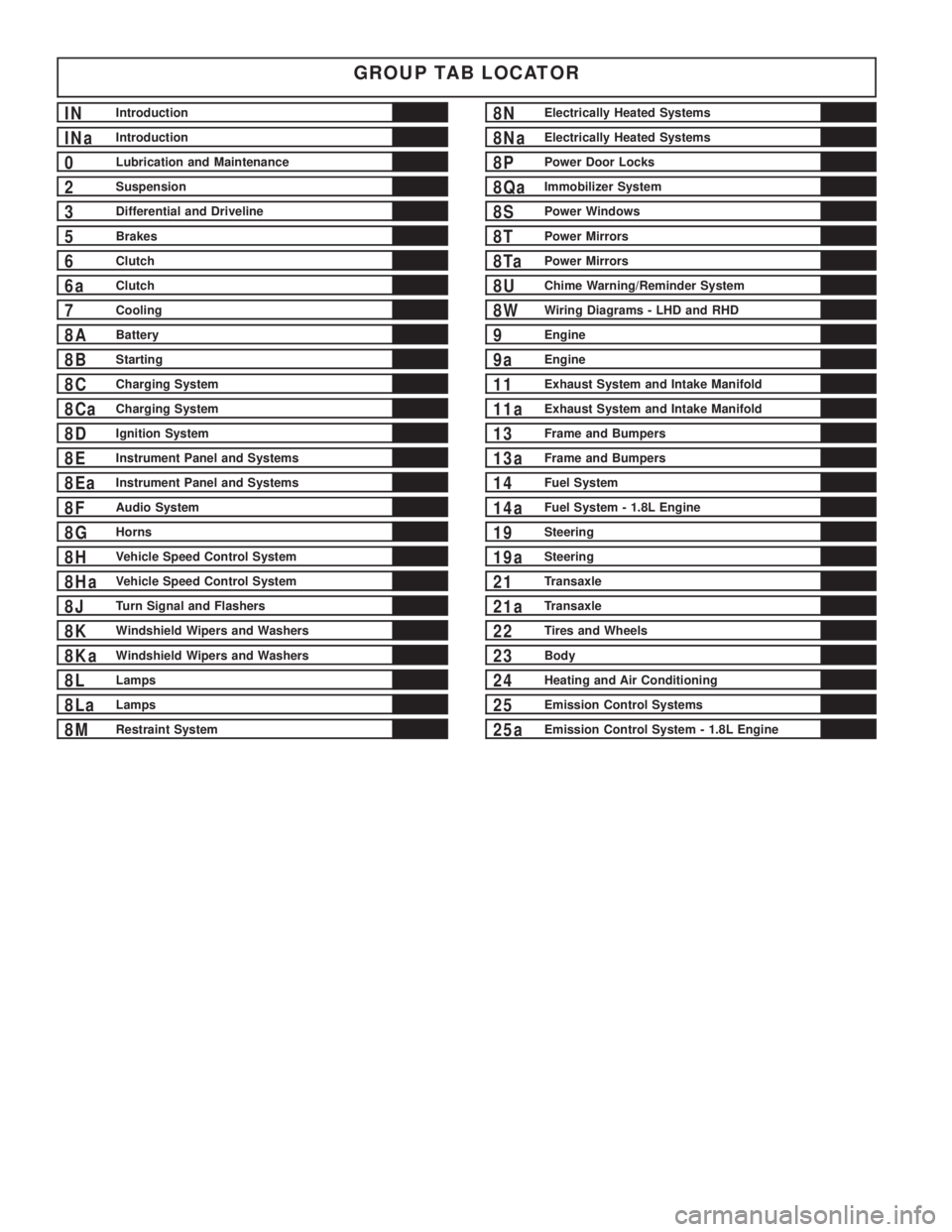

GROUP TAB LOCATOR

INIntroduction

INaIntroduction

0Lubrication and Maintenance

2Suspension

3Differential and Driveline

5Brakes

6Clutch

6aClutch

7Cooling

8ABattery

8BStarting

8CCharging System

8CaCharging System

8DIgnition System

8EInstrument Panel and Systems

8EaInstrument Panel and Systems

8FAudio System

8GHorns

8HVehicle Speed Control System

8HaVehicle Speed Control System

8JTurn Signal and Flashers

8KWindshield Wipers and Washers

8KaWindshield Wipers and Washers

8LLamps

8LaLamps

8MRestraint System

8NElectrically Heated Systems

8NaElectrically Heated Systems

8PPower Door Locks

8QaImmobilizer System

8SPower Windows

8TPower Mirrors

8TaPower Mirrors

8UChime Warning/Reminder System

8WWiring Diagrams - LHD and RHD

9Engine

9aEngine

11Exhaust System and Intake Manifold

11aExhaust System and Intake Manifold

13Frame and Bumpers

13aFrame and Bumpers

14Fuel System

14aFuel System - 1.8L Engine

19Steering

19aSteering

21Transaxle

21aTransaxle

22Tires and Wheels

23Body

24Heating and Air Conditioning

25Emission Control Systems

25aEmission Control System - 1.8L Engine