ignition DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1003 of 1200

(18) Carefully remove the cable from the under-

body by unfolding the cable retainer clip as you go

along.

INSTALLATION

(1) To install gearshift cable, reverse removal pro-

cedure.

(2) Adjust gearshift cable using the adjustment

procedure in this Group.

GEARSHIFT MECHANISM

REMOVAL

(1) Disconnect battery negative cable and isolate.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

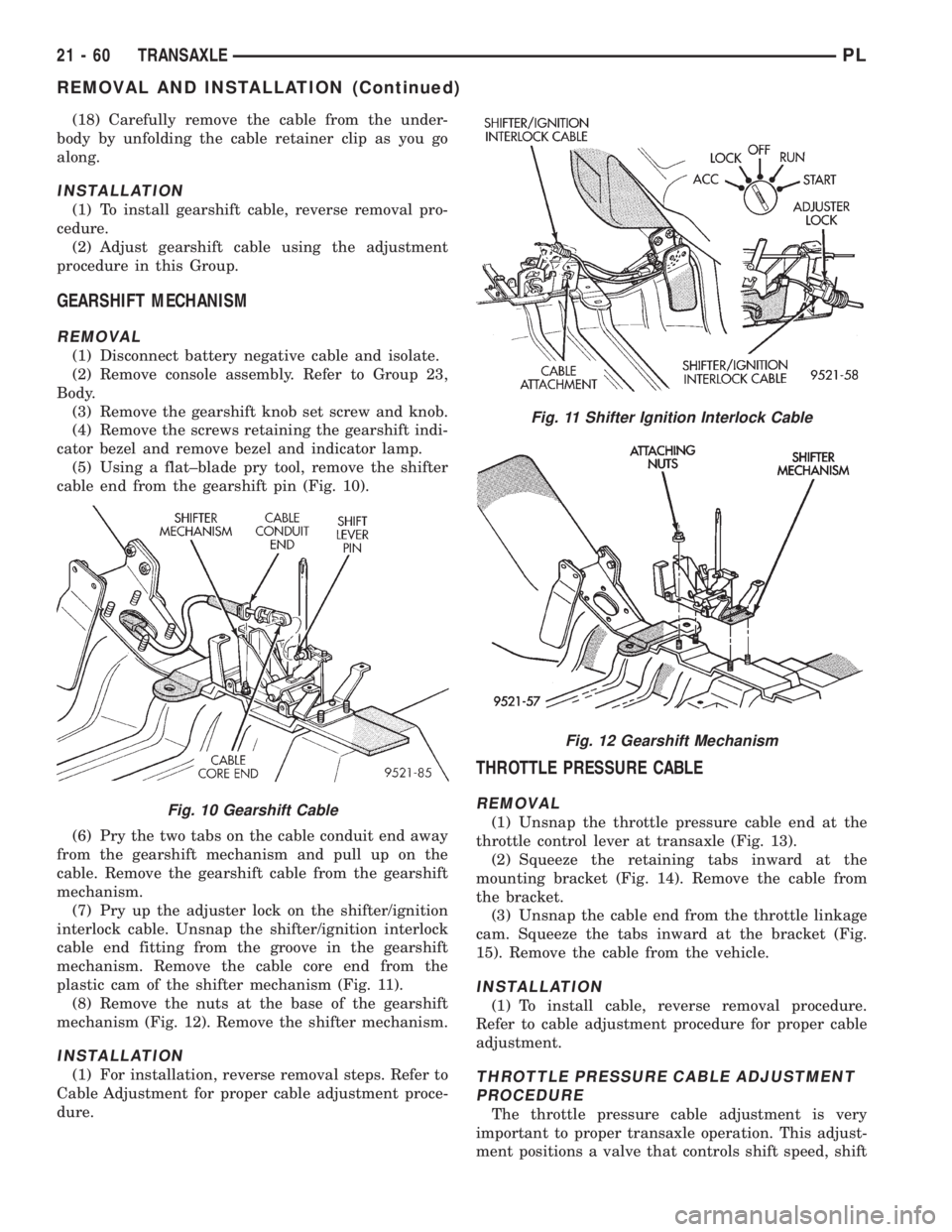

(5) Using a flat±blade pry tool, remove the shifter

cable end from the gearshift pin (Fig. 10).

(6) Pry the two tabs on the cable conduit end away

from the gearshift mechanism and pull up on the

cable. Remove the gearshift cable from the gearshift

mechanism.

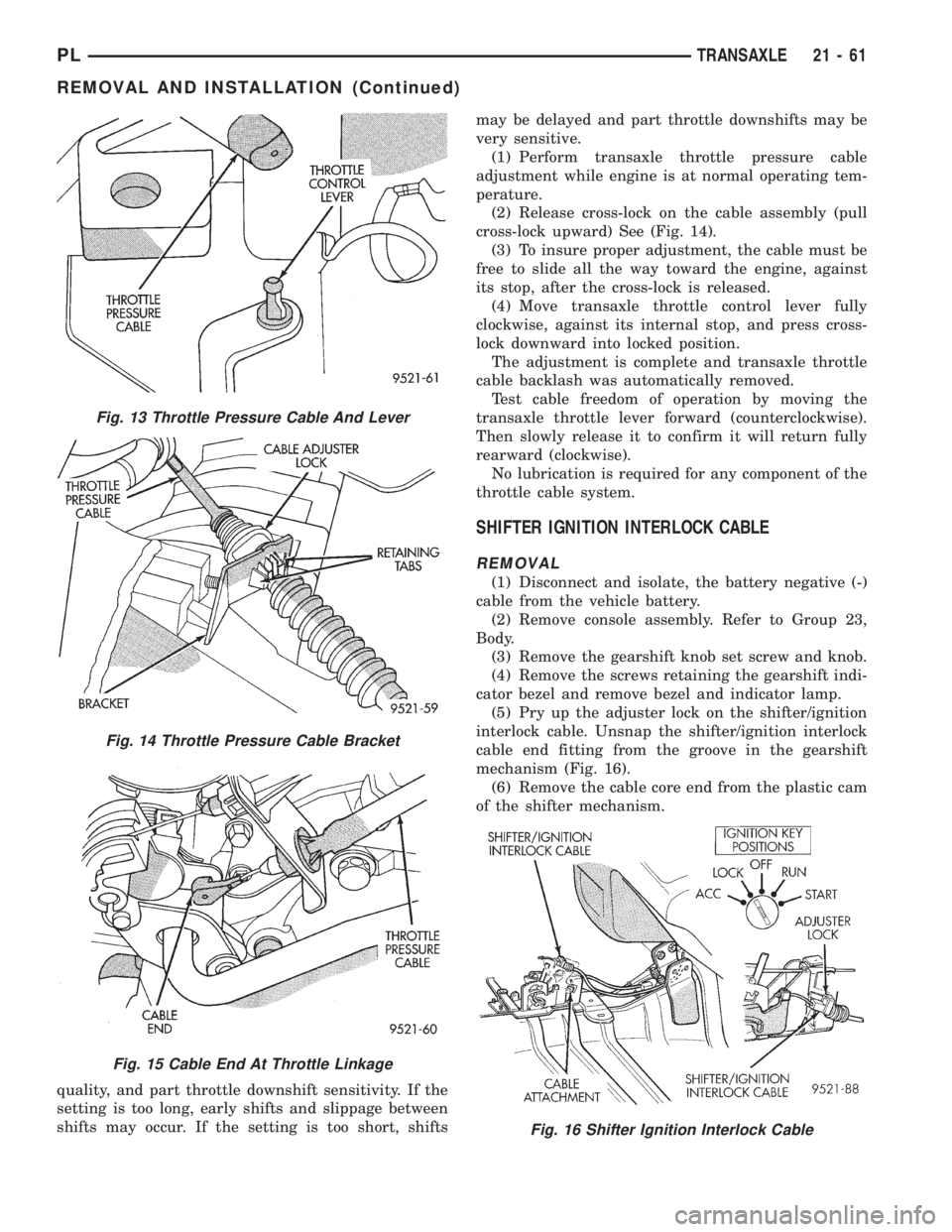

(7) Pry up the adjuster lock on the shifter/ignition

interlock cable. Unsnap the shifter/ignition interlock

cable end fitting from the groove in the gearshift

mechanism. Remove the cable core end from the

plastic cam of the shifter mechanism (Fig. 11).

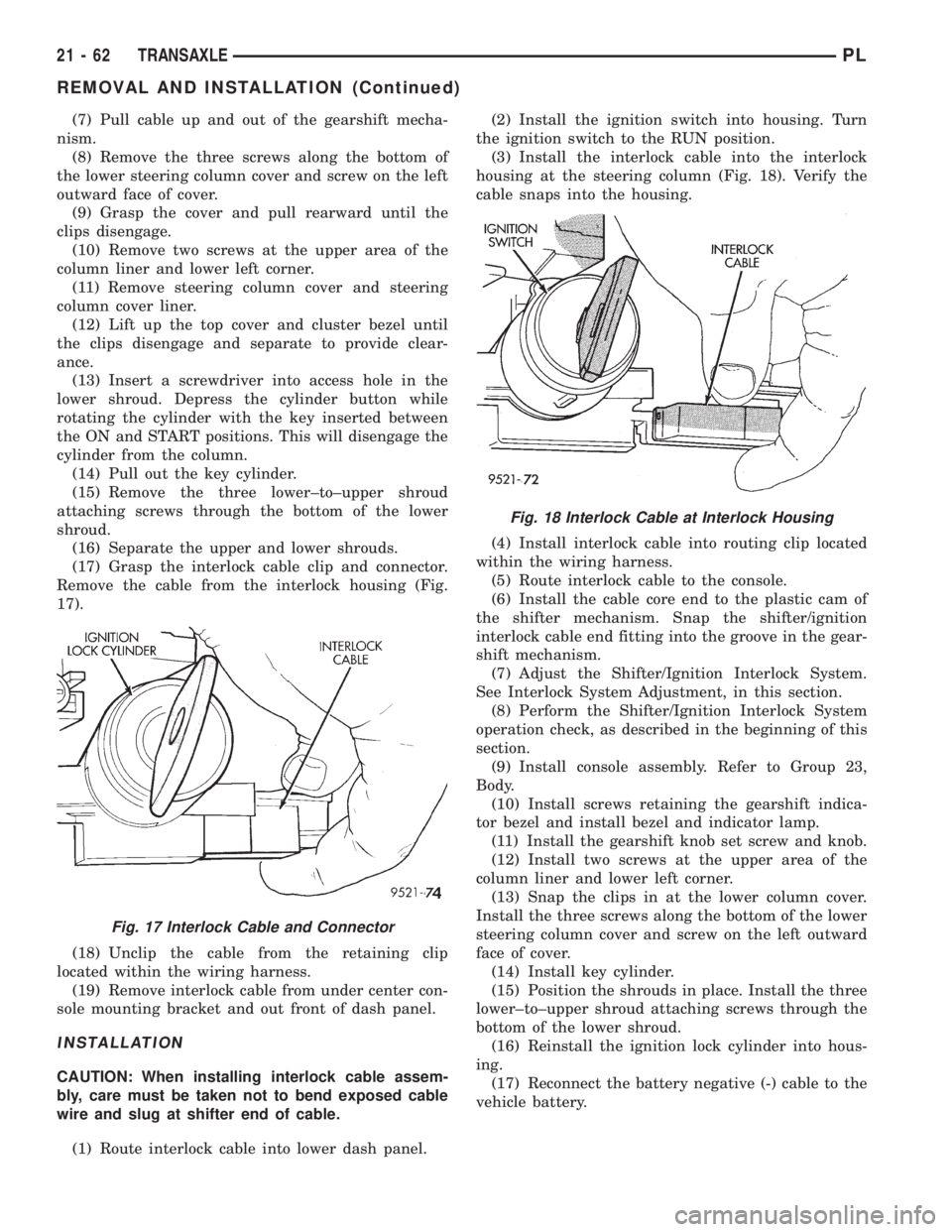

(8) Remove the nuts at the base of the gearshift

mechanism (Fig. 12). Remove the shifter mechanism.

INSTALLATION

(1) For installation, reverse removal steps. Refer to

Cable Adjustment for proper cable adjustment proce-

dure.

THROTTLE PRESSURE CABLE

REMOVAL

(1) Unsnap the throttle pressure cable end at the

throttle control lever at transaxle (Fig. 13).

(2) Squeeze the retaining tabs inward at the

mounting bracket (Fig. 14). Remove the cable from

the bracket.

(3) Unsnap the cable end from the throttle linkage

cam. Squeeze the tabs inward at the bracket (Fig.

15). Remove the cable from the vehicle.

INSTALLATION

(1) To install cable, reverse removal procedure.

Refer to cable adjustment procedure for proper cable

adjustment.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve that controls shift speed, shift

Fig. 10 Gearshift Cable

Fig. 11 Shifter Ignition Interlock Cable

Fig. 12 Gearshift Mechanism

21 - 60 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1004 of 1200

quality, and part throttle downshift sensitivity. If the

setting is too long, early shifts and slippage between

shifts may occur. If the setting is too short, shiftsmay be delayed and part throttle downshifts may be

very sensitive.

(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) See (Fig. 14).

(3) To insure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER IGNITION INTERLOCK CABLE

REMOVAL

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Pry up the adjuster lock on the shifter/ignition

interlock cable. Unsnap the shifter/ignition interlock

cable end fitting from the groove in the gearshift

mechanism (Fig. 16).

(6) Remove the cable core end from the plastic cam

of the shifter mechanism.

Fig. 13 Throttle Pressure Cable And Lever

Fig. 14 Throttle Pressure Cable Bracket

Fig. 15 Cable End At Throttle Linkage

Fig. 16 Shifter Ignition Interlock Cable

PLTRANSAXLE 21 - 61

REMOVAL AND INSTALLATION (Continued)

Page 1005 of 1200

(7) Pull cable up and out of the gearshift mecha-

nism.

(8) Remove the three screws along the bottom of

the lower steering column cover and screw on the left

outward face of cover.

(9) Grasp the cover and pull rearward until the

clips disengage.

(10) Remove two screws at the upper area of the

column liner and lower left corner.

(11) Remove steering column cover and steering

column cover liner.

(12) Lift up the top cover and cluster bezel until

the clips disengage and separate to provide clear-

ance.

(13) Insert a screwdriver into access hole in the

lower shroud. Depress the cylinder button while

rotating the cylinder with the key inserted between

the ON and START positions. This will disengage the

cylinder from the column.

(14) Pull out the key cylinder.

(15) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud.

(16) Separate the upper and lower shrouds.

(17) Grasp the interlock cable clip and connector.

Remove the cable from the interlock housing (Fig.

17).

(18) Unclip the cable from the retaining clip

located within the wiring harness.

(19) Remove interlock cable from under center con-

sole mounting bracket and out front of dash panel.

INSTALLATION

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.

(1) Route interlock cable into lower dash panel.(2) Install the ignition switch into housing. Turn

the ignition switch to the RUN position.

(3) Install the interlock cable into the interlock

housing at the steering column (Fig. 18). Verify the

cable snaps into the housing.

(4) Install interlock cable into routing clip located

within the wiring harness.

(5) Route interlock cable to the console.

(6) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism.

(7) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section.

(8) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section.

(9) Install console assembly. Refer to Group 23,

Body.

(10) Install screws retaining the gearshift indica-

tor bezel and install bezel and indicator lamp.

(11) Install the gearshift knob set screw and knob.

(12) Install two screws at the upper area of the

column liner and lower left corner.

(13) Snap the clips in at the lower column cover.

Install the three screws along the bottom of the lower

steering column cover and screw on the left outward

face of cover.

(14) Install key cylinder.

(15) Position the shrouds in place. Install the three

lower±to±upper shroud attaching screws through the

bottom of the lower shroud.

(16) Reinstall the ignition lock cylinder into hous-

ing.

(17) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 17 Interlock Cable and Connector

Fig. 18 Interlock Cable at Interlock Housing

21 - 62 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1006 of 1200

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

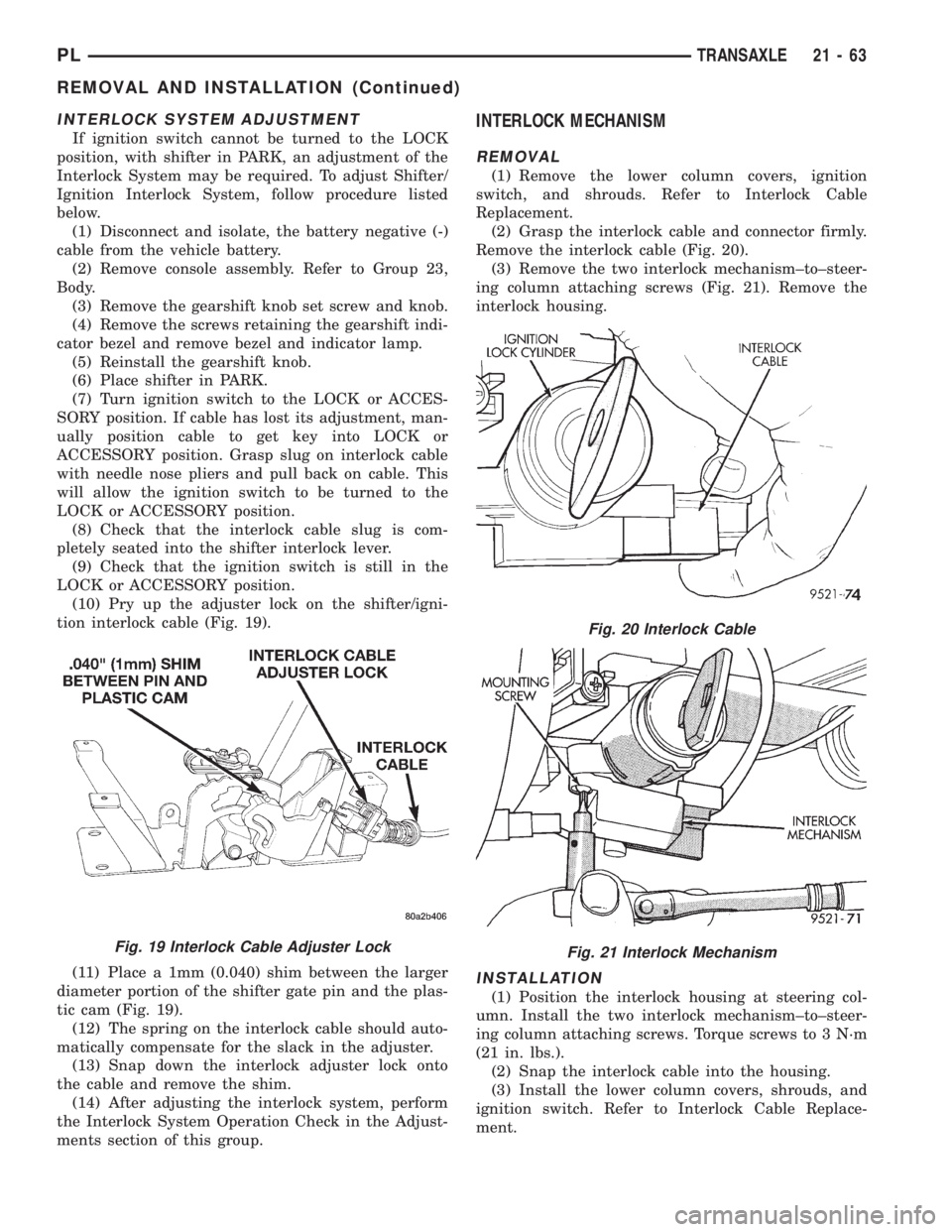

(10) Pry up the adjuster lock on the shifter/igni-

tion interlock cable (Fig. 19).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 19).

(12) The spring on the interlock cable should auto-

matically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the interlock system, perform

the Interlock System Operation Check in the Adjust-

ments section of this group.

INTERLOCK MECHANISM

REMOVAL

(1) Remove the lower column covers, ignition

switch, and shrouds. Refer to Interlock Cable

Replacement.

(2) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 20).

(3) Remove the two interlock mechanism±to±steer-

ing column attaching screws (Fig. 21). Remove the

interlock housing.

INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism±to±steer-

ing column attaching screws. Torque screws to 3 N´m

(21 in. lbs.).

(2) Snap the interlock cable into the housing.

(3) Install the lower column covers, shrouds, and

ignition switch. Refer to Interlock Cable Replace-

ment.

Fig. 19 Interlock Cable Adjuster Lock

Fig. 20 Interlock Cable

Fig. 21 Interlock Mechanism

PLTRANSAXLE 21 - 63

REMOVAL AND INSTALLATION (Continued)

Page 1043 of 1200

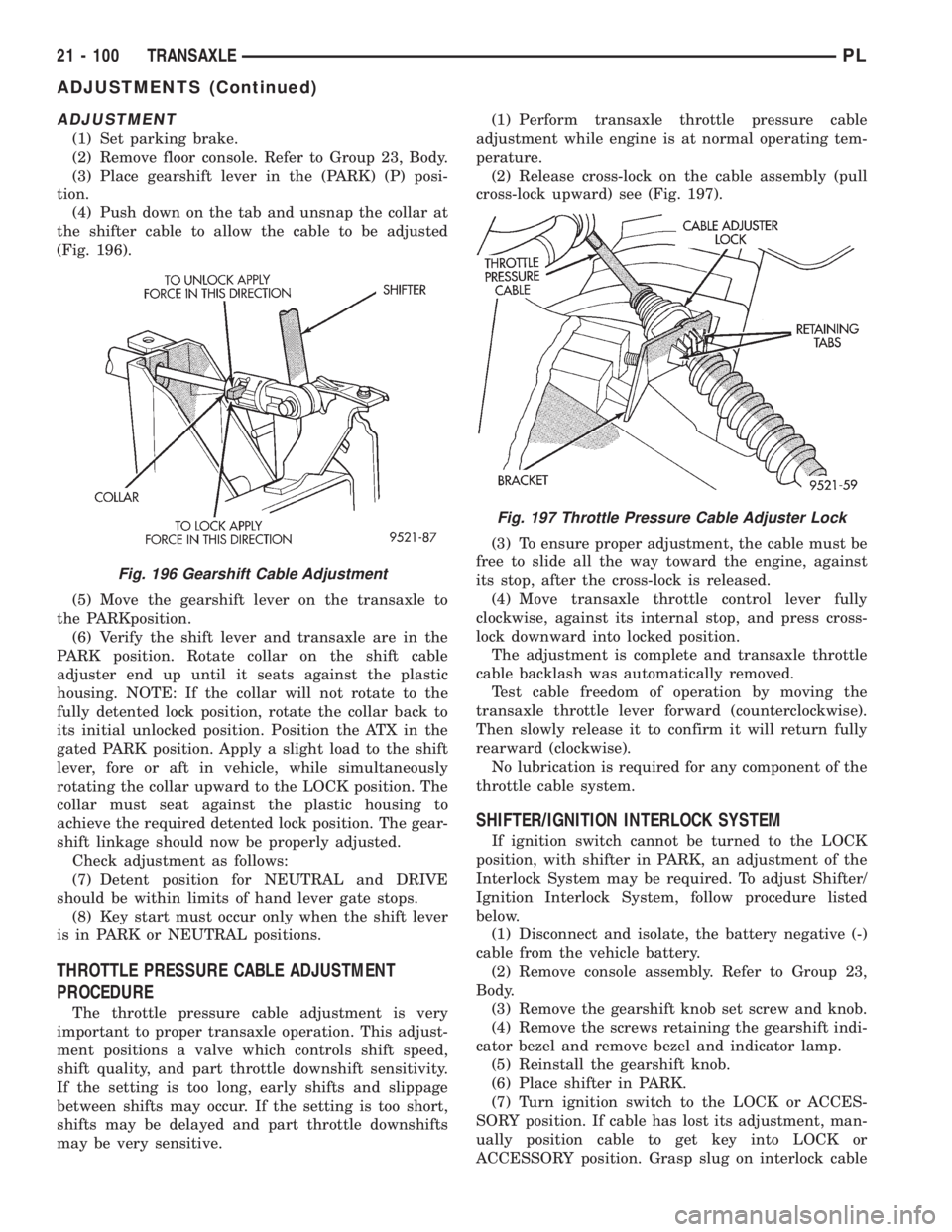

ADJUSTMENT

(1) Set parking brake.

(2) Remove floor console. Refer to Group 23, Body.

(3) Place gearshift lever in the (PARK) (P) posi-

tion.

(4) Push down on the tab and unsnap the collar at

the shifter cable to allow the cable to be adjusted

(Fig. 196).

(5) Move the gearshift lever on the transaxle to

the PARKposition.

(6) Verify the shift lever and transaxle are in the

PARK position. Rotate collar on the shift cable

adjuster end up until it seats against the plastic

housing. NOTE: If the collar will not rotate to the

fully detented lock position, rotate the collar back to

its initial unlocked position. Position the ATX in the

gated PARK position. Apply a slight load to the shift

lever, fore or aft in vehicle, while simultaneously

rotating the collar upward to the LOCK position. The

collar must seat against the plastic housing to

achieve the required detented lock position. The gear-

shift linkage should now be properly adjusted.

Check adjustment as follows:

(7) Detent position for NEUTRAL and DRIVE

should be within limits of hand lever gate stops.

(8) Key start must occur only when the shift lever

is in PARK or NEUTRAL positions.

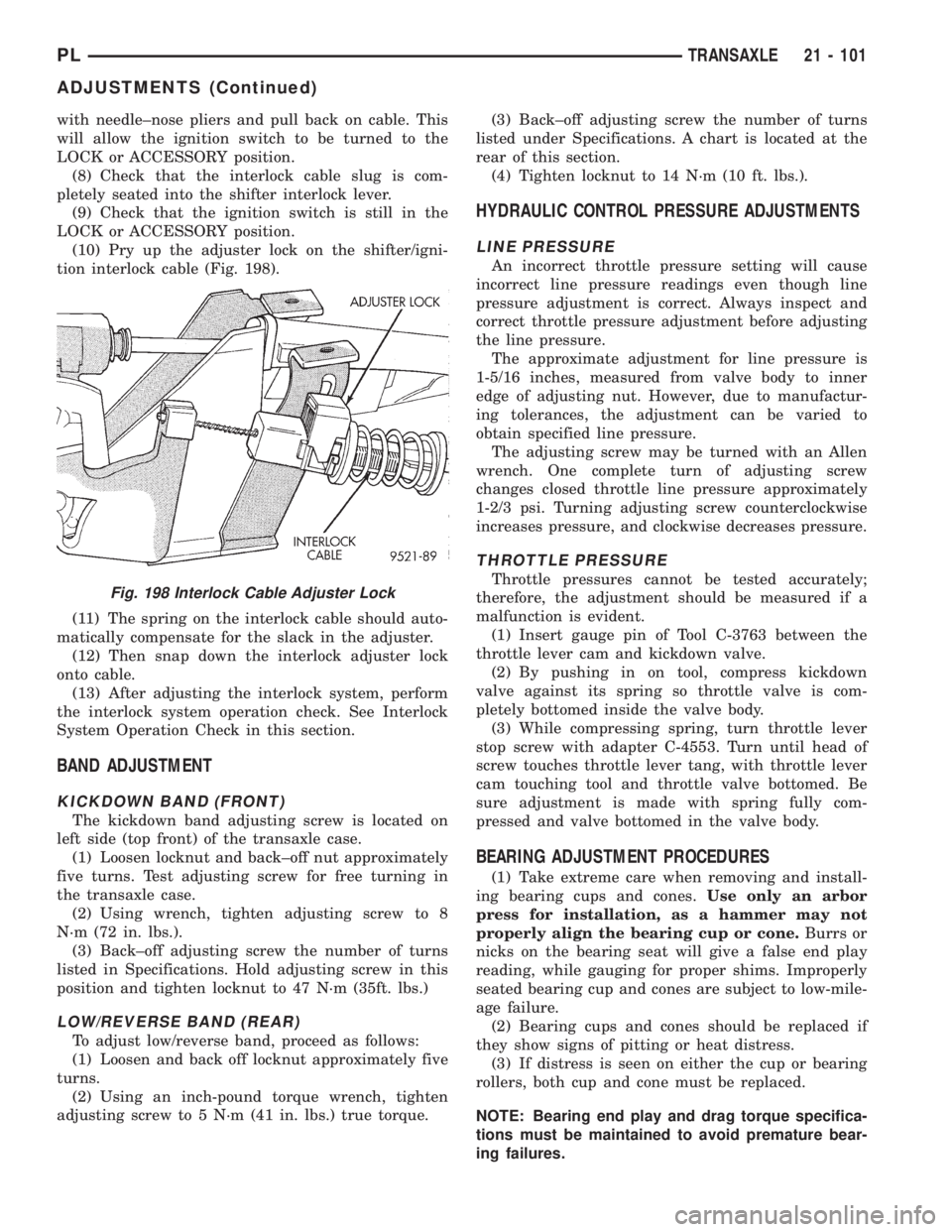

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage

between shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) see (Fig. 197).

(3) To ensure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER/IGNITION INTERLOCK SYSTEM

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

Fig. 196 Gearshift Cable Adjustment

Fig. 197 Throttle Pressure Cable Adjuster Lock

21 - 100 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1044 of 1200

with needle±nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

(10) Pry up the adjuster lock on the shifter/igni-

tion interlock cable (Fig. 198).

(11) The spring on the interlock cable should auto-

matically compensate for the slack in the adjuster.

(12) Then snap down the interlock adjuster lock

onto cable.

(13) After adjusting the interlock system, perform

the interlock system operation check. See Interlock

System Operation Check in this section.

BAND ADJUSTMENT

KICKDOWN BAND (FRONT)

The kickdown band adjusting screw is located on

left side (top front) of the transaxle case.

(1) Loosen locknut and back±off nut approximately

five turns. Test adjusting screw for free turning in

the transaxle case.

(2) Using wrench, tighten adjusting screw to 8

N´m (72 in. lbs.).

(3) Back±off adjusting screw the number of turns

listed in Specifications. Hold adjusting screw in this

position and tighten locknut to 47 N´m (35ft. lbs.)

LOW/REVERSE BAND (REAR)

To adjust low/reverse band, proceed as follows:

(1) Loosen and back off locknut approximately five

turns.

(2) Using an inch-pound torque wrench, tighten

adjusting screw to 5 N´m (41 in. lbs.) true torque.(3) Back±off adjusting screw the number of turns

listed under Specifications. A chart is located at the

rear of this section.

(4) Tighten locknut to 14 N´m (10 ft. lbs.).

HYDRAULIC CONTROL PRESSURE ADJUSTMENTS

LINE PRESSURE

An incorrect throttle pressure setting will cause

incorrect line pressure readings even though line

pressure adjustment is correct. Always inspect and

correct throttle pressure adjustment before adjusting

the line pressure.

The approximate adjustment for line pressure is

1-5/16 inches, measured from valve body to inner

edge of adjusting nut. However, due to manufactur-

ing tolerances, the adjustment can be varied to

obtain specified line pressure.

The adjusting screw may be turned with an Allen

wrench. One complete turn of adjusting screw

changes closed throttle line pressure approximately

1-2/3 psi. Turning adjusting screw counterclockwise

increases pressure, and clockwise decreases pressure.

THROTTLE PRESSURE

Throttle pressures cannot be tested accurately;

therefore, the adjustment should be measured if a

malfunction is evident.

(1) Insert gauge pin of Tool C-3763 between the

throttle lever cam and kickdown valve.

(2) By pushing in on tool, compress kickdown

valve against its spring so throttle valve is com-

pletely bottomed inside the valve body.

(3) While compressing spring, turn throttle lever

stop screw with adapter C-4553. Turn until head of

screw touches throttle lever tang, with throttle lever

cam touching tool and throttle valve bottomed. Be

sure adjustment is made with spring fully com-

pressed and valve bottomed in the valve body.

BEARING ADJUSTMENT PROCEDURES

(1) Take extreme care when removing and install-

ing bearing cups and cones.Use only an arbor

press for installation, as a hammer may not

properly align the bearing cup or cone.Burrs or

nicks on the bearing seat will give a false end play

reading, while gauging for proper shims. Improperly

seated bearing cup and cones are subject to low-mile-

age failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress.

(3) If distress is seen on either the cup or bearing

rollers, both cup and cone must be replaced.

NOTE: Bearing end play and drag torque specifica-

tions must be maintained to avoid premature bear-

ing failures.

Fig. 198 Interlock Cable Adjuster Lock

PLTRANSAXLE 21 - 101

ADJUSTMENTS (Continued)

Page 1064 of 1200

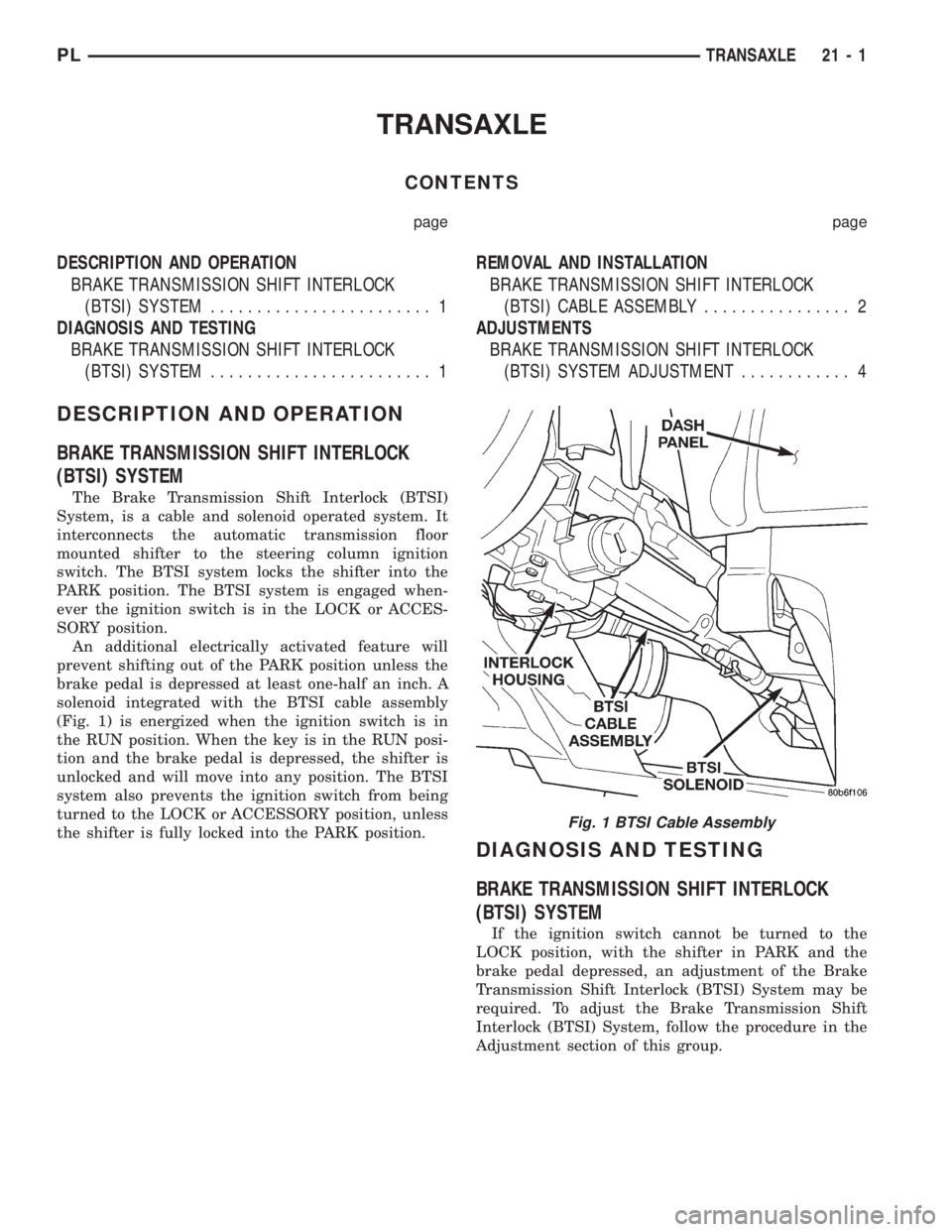

TRANSAXLE

CONTENTS

page page

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY................ 2

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT............ 4

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

The Brake Transmission Shift Interlock (BTSI)

System, is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The BTSI system locks the shifter into the

PARK position. The BTSI system is engaged when-

ever the ignition switch is in the LOCK or ACCES-

SORY position.

An additional electrically activated feature will

prevent shifting out of the PARK position unless the

brake pedal is depressed at least one-half an inch. A

solenoid integrated with the BTSI cable assembly

(Fig. 1) is energized when the ignition switch is in

the RUN position. When the key is in the RUN posi-

tion and the brake pedal is depressed, the shifter is

unlocked and will move into any position. The BTSI

system also prevents the ignition switch from being

turned to the LOCK or ACCESSORY position, unless

the shifter is fully locked into the PARK position.

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

If the ignition switch cannot be turned to the

LOCK position, with the shifter in PARK and the

brake pedal depressed, an adjustment of the Brake

Transmission Shift Interlock (BTSI) System may be

required. To adjust the Brake Transmission Shift

Interlock (BTSI) System, follow the procedure in the

Adjustment section of this group.

Fig. 1 BTSI Cable Assembly

PLTRANSAXLE 21 - 1

Page 1065 of 1200

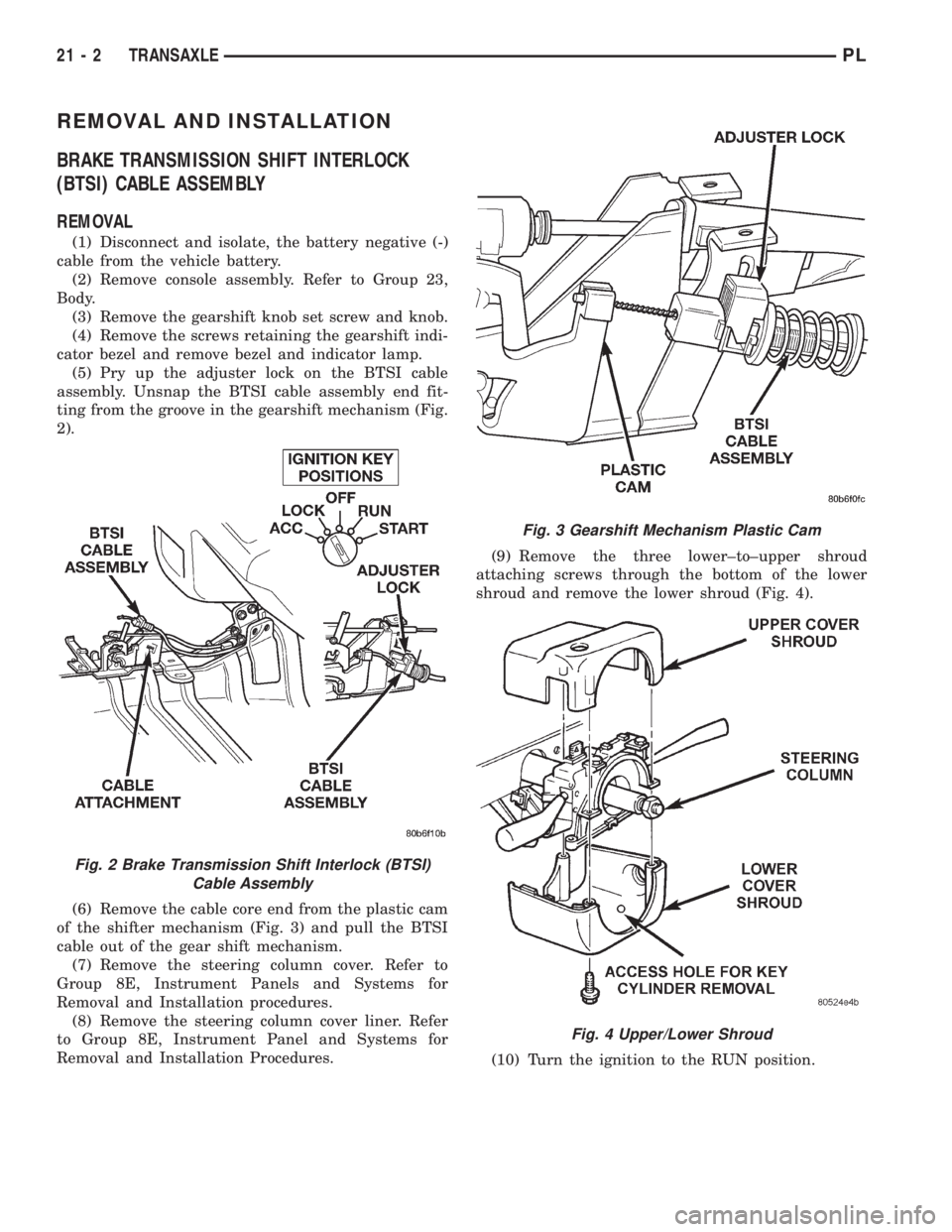

REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY

REMOVAL

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Pry up the adjuster lock on the BTSI cable

assembly. Unsnap the BTSI cable assembly end fit-

ting from the groove in the gearshift mechanism (Fig.

2).

(6) Remove the cable core end from the plastic cam

of the shifter mechanism (Fig. 3) and pull the BTSI

cable out of the gear shift mechanism.

(7) Remove the steering column cover. Refer to

Group 8E, Instrument Panels and Systems for

Removal and Installation procedures.

(8) Remove the steering column cover liner. Refer

to Group 8E, Instrument Panel and Systems for

Removal and Installation Procedures.(9) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud and remove the lower shroud (Fig. 4).

(10) Turn the ignition to the RUN position.

Fig. 2 Brake Transmission Shift Interlock (BTSI)

Cable Assembly

Fig. 3 Gearshift Mechanism Plastic Cam

Fig. 4 Upper/Lower Shroud

21 - 2 TRANSAXLEPL

Page 1067 of 1200

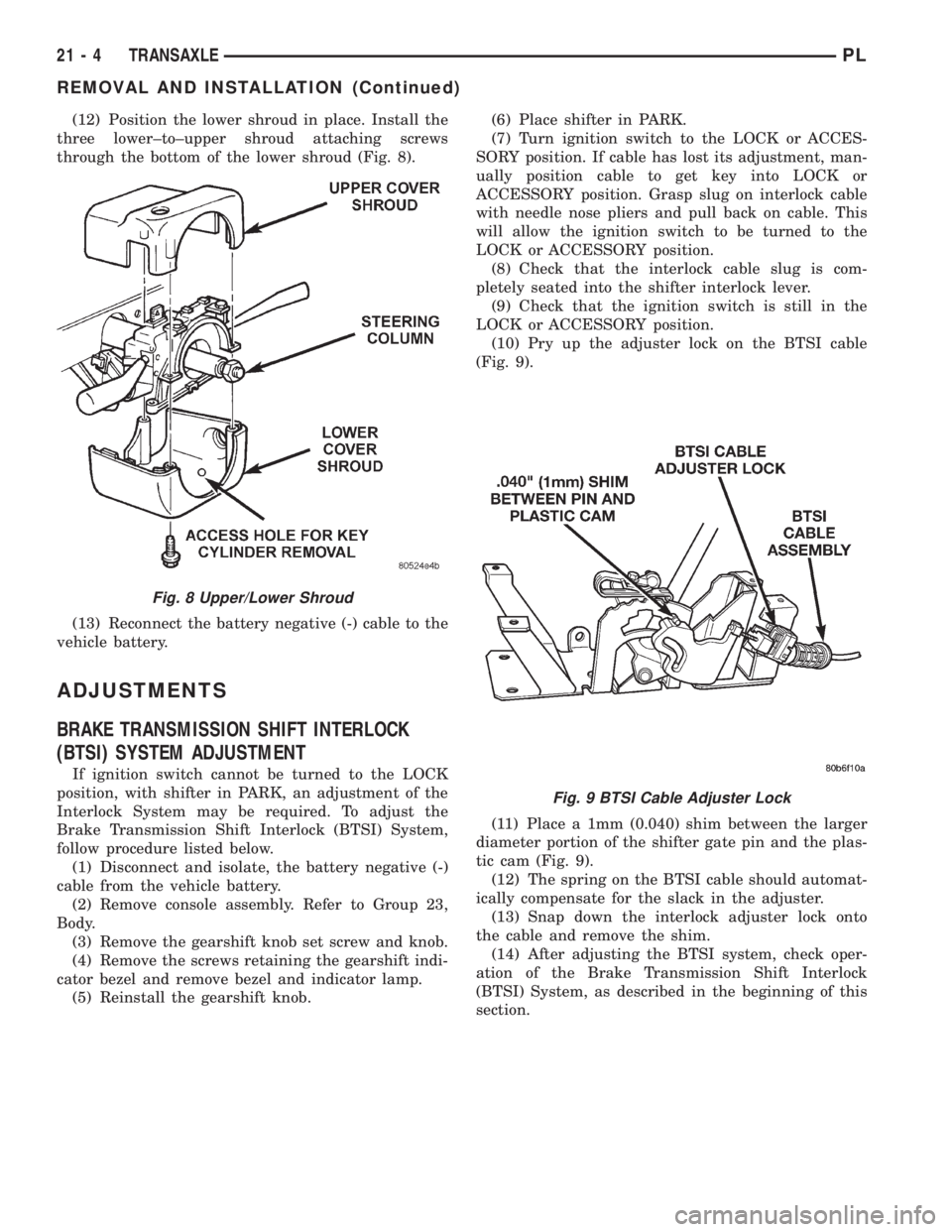

(12) Position the lower shroud in place. Install the

three lower±to±upper shroud attaching screws

through the bottom of the lower shroud (Fig. 8).

(13) Reconnect the battery negative (-) cable to the

vehicle battery.

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust the

Brake Transmission Shift Interlock (BTSI) System,

follow procedure listed below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

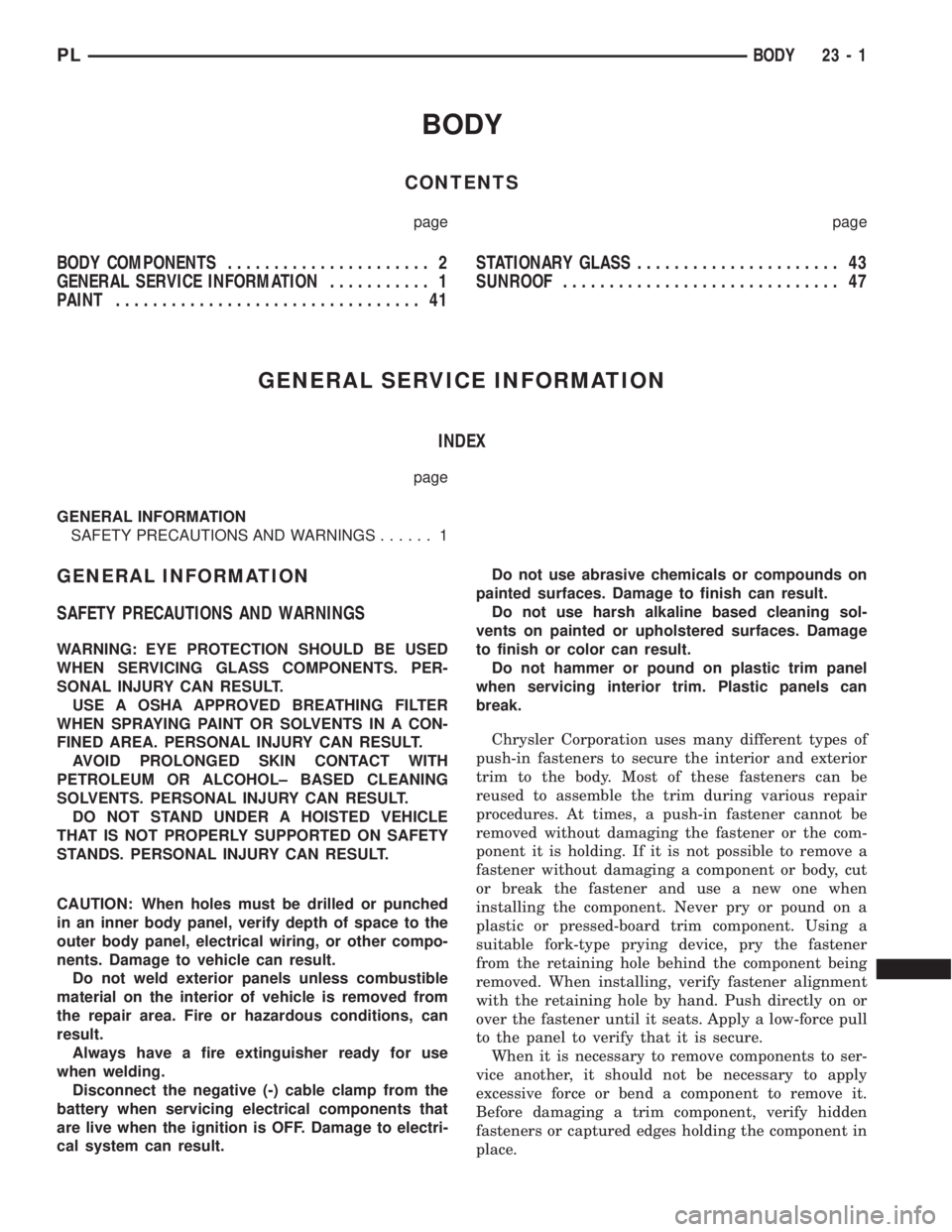

(10) Pry up the adjuster lock on the BTSI cable

(Fig. 9).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 9).

(12) The spring on the BTSI cable should automat-

ically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the BTSI system, check oper-

ation of the Brake Transmission Shift Interlock

(BTSI) System, as described in the beginning of this

section.

Fig. 8 Upper/Lower Shroud

Fig. 9 BTSI Cable Adjuster Lock

21 - 4 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1082 of 1200

BODY

CONTENTS

page page

BODY COMPONENTS...................... 2

GENERAL SERVICE INFORMATION........... 1

PAINT................................. 41STATIONARY GLASS...................... 43

SUNROOF.............................. 47

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

PLBODY 23 - 1