wheel alignment DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 177 of 1200

DRIVE PLATE MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder

²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

CLUTCH COVER AND DISC RUNOUT

Check condition of the clutch cover before installa-

tion. A warped cover or diaphragm spring will cause

grab and/or incomplete release or engagement. Use

care when handling the clutch assembly. Impact can

distort the cover, diaphragm spring, and release fin-

gers.

CLUTCH CHATTER COMPLAINTS

For all clutch chatter complaints, do the following:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further. If

chatter persists:

(2) Check to see if clutch cable routing is correct

and operates smoothly.

(3) Check for loose connections in drive train. Cor-

rect any problems and determine if clutch chatter

complaints have been satisfied. If not:

(4) Remove transaxle. See Group 21, Manual Tran-

saxle for procedure.

(5) Check to see if the release bearing is sticky or

binding. Replace bearing, if needed.

(6) Check linkage for excessive wear on the pivot

stud and fork fingers. Replace all worn parts.

(7) Check clutch assembly for contamination (dirt,

oil). Replace clutch assembly, if required.

(8) Check to see if the clutch disc hub splines are

damaged. Replace with new clutch assembly, if nec-

essary.

(9) Check input shaft splines for damage. Replace,

if necessary.

(10) Check for uneven wear on clutch fingers.

(11) Check for broken clutch cover diaphragm

spring fingers. Replace with new clutch assembly, if

necessary.

CLASH±INTO±REVERSE COMPLAINTS

Certain NV T350 (A-578) manual transaxles are

equipped with a reverse brake. It prevents clash

when shifting into reverse, but only if the vehicle is

not moving. See Group 21, Transaxle for further

diagnosis.

(1) Depress clutch pedal to floor and hold. After

three seconds, shift to reverse. If clash is present,

clutch has excessive spin time, and the reverse brake

may not be functioning.

(2) Remove transaxle. See Group 21, Manual Tran-

saxle for procedure.

(3) Check the input shaft spline, clutch disc

splines, and release bearing for dry rust. If present,

clean rust off and apply a light coat of bearing grease

to the input shaft splines. Apply grease on the input

shaft splines only where the clutch disc slides. Verify

that the clutch disc slides freely along the input shaft

spline.

(4) Check to see if the clutch disc hub splines are

damaged, and replace with new clutch assembly if

required.

(5) Check the input shaft for damaged splines.

Replace as necessary.

(6) Check for broken clutch cover diaphragm

spring fingers.

(7) Install clutch assembly and transaxle.

REMOVAL AND INSTALLATION

CLUTCH CABLE

REMOVAL

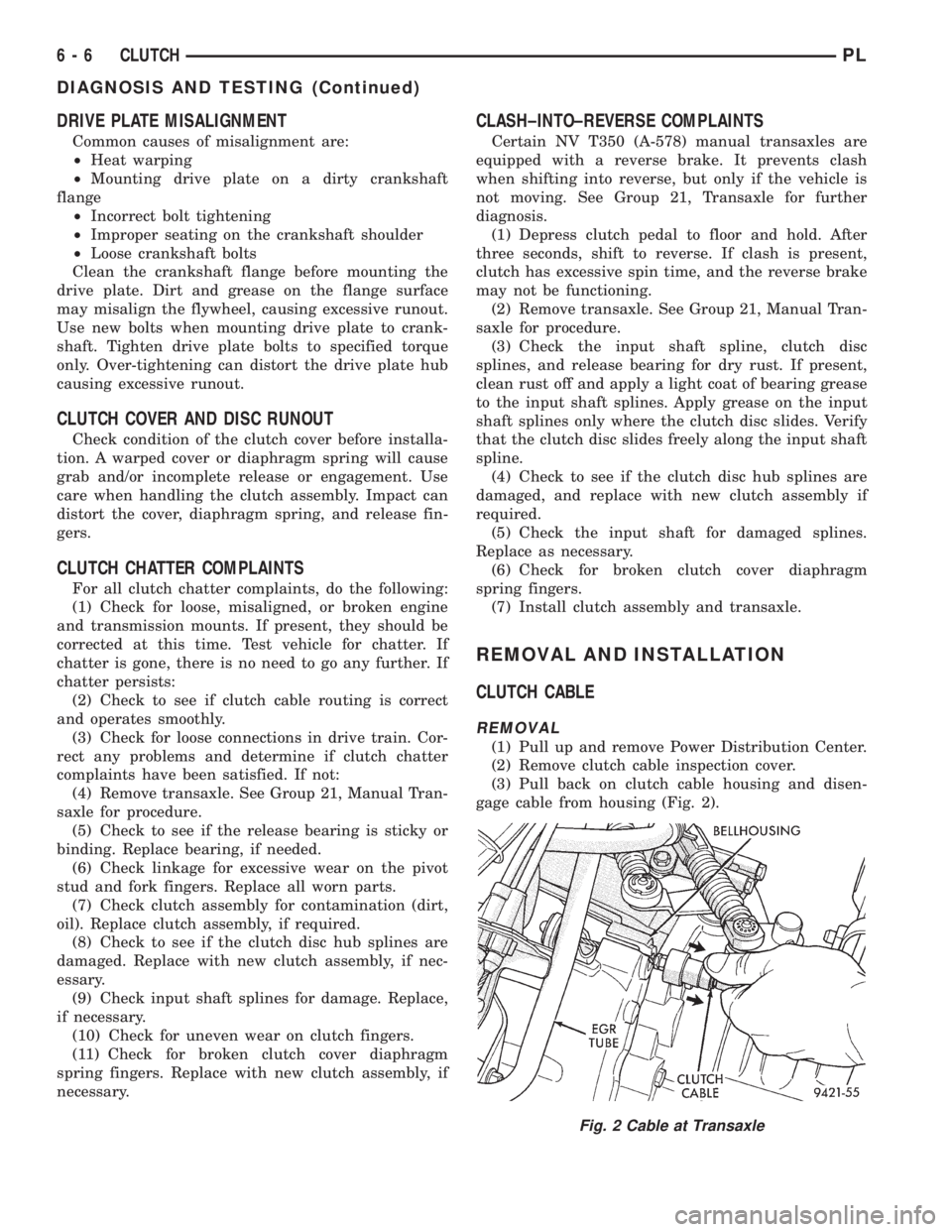

(1) Pull up and remove Power Distribution Center.

(2) Remove clutch cable inspection cover.

(3) Pull back on clutch cable housing and disen-

gage cable from housing (Fig. 2).

Fig. 2 Cable at Transaxle

6 - 6 CLUTCHPL

DIAGNOSIS AND TESTING (Continued)

Page 179 of 1200

REMOVAL

(1) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure.

(2) Mark clutch cover and flywheel, to maintain

their same relative positions when installing clutch

assembly.

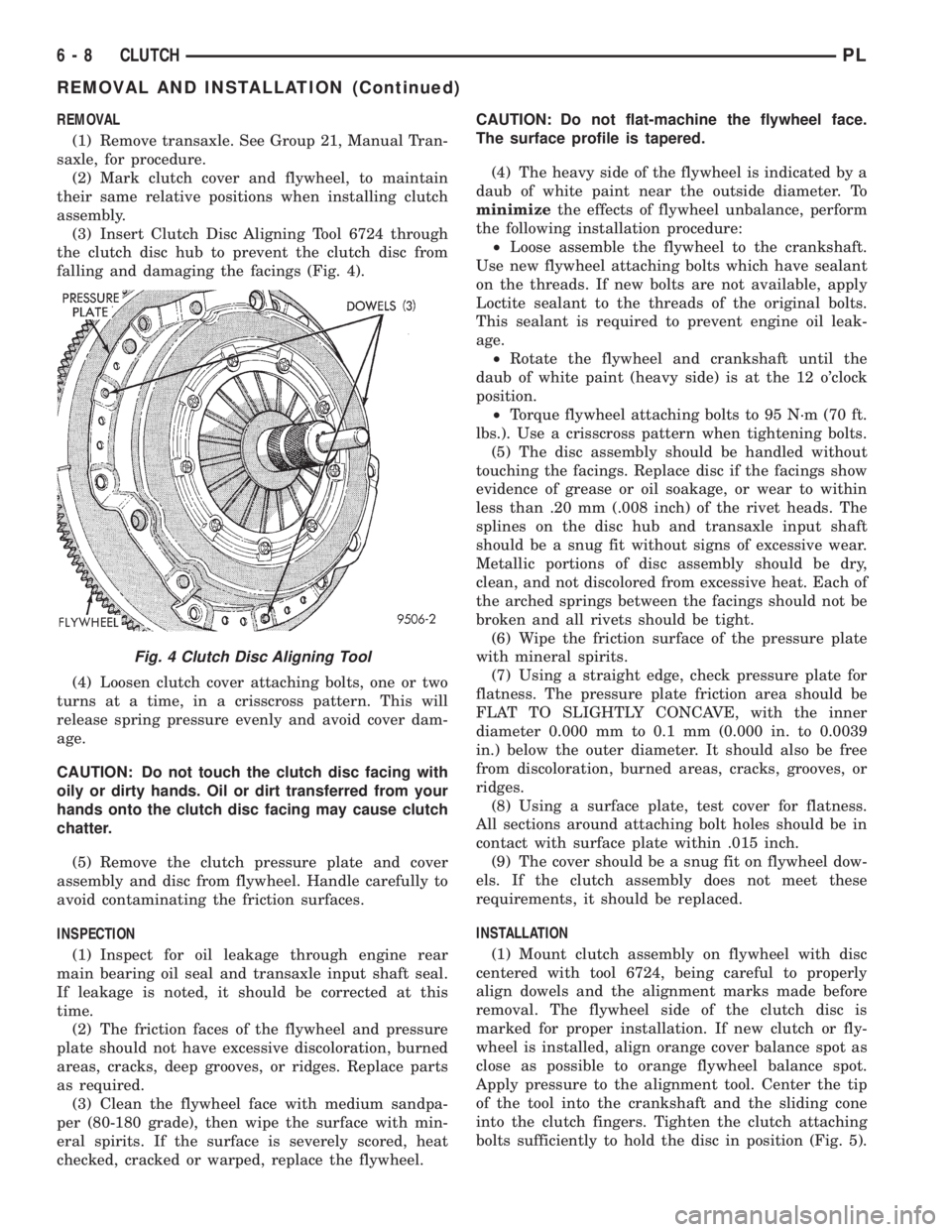

(3) Insert Clutch Disc Aligning Tool 6724 through

the clutch disc hub to prevent the clutch disc from

falling and damaging the facings (Fig. 4).

(4) Loosen clutch cover attaching bolts, one or two

turns at a time, in a crisscross pattern. This will

release spring pressure evenly and avoid cover dam-

age.

CAUTION: Do not touch the clutch disc facing with

oily or dirty hands. Oil or dirt transferred from your

hands onto the clutch disc facing may cause clutch

chatter.

(5) Remove the clutch pressure plate and cover

assembly and disc from flywheel. Handle carefully to

avoid contaminating the friction surfaces.

INSPECTION

(1) Inspect for oil leakage through engine rear

main bearing oil seal and transaxle input shaft seal.

If leakage is noted, it should be corrected at this

time.

(2) The friction faces of the flywheel and pressure

plate should not have excessive discoloration, burned

areas, cracks, deep grooves, or ridges. Replace parts

as required.

(3) Clean the flywheel face with medium sandpa-

per (80-180 grade), then wipe the surface with min-

eral spirits. If the surface is severely scored, heat

checked, cracked or warped, replace the flywheel.CAUTION: Do not flat-machine the flywheel face.

The surface profile is tapered.

(4) The heavy side of the flywheel is indicated by a

daub of white paint near the outside diameter. To

minimizethe effects of flywheel unbalance, perform

the following installation procedure:

²Loose assemble the flywheel to the crankshaft.

Use new flywheel attaching bolts which have sealant

on the threads. If new bolts are not available, apply

Loctite sealant to the threads of the original bolts.

This sealant is required to prevent engine oil leak-

age.

²Rotate the flywheel and crankshaft until the

daub of white paint (heavy side) is at the 12 o'clock

position.

²Torque flywheel attaching bolts to 95 N´m (70 ft.

lbs.). Use a crisscross pattern when tightening bolts.

(5) The disc assembly should be handled without

touching the facings. Replace disc if the facings show

evidence of grease or oil soakage, or wear to within

less than .20 mm (.008 inch) of the rivet heads. The

splines on the disc hub and transaxle input shaft

should be a snug fit without signs of excessive wear.

Metallic portions of disc assembly should be dry,

clean, and not discolored from excessive heat. Each of

the arched springs between the facings should not be

broken and all rivets should be tight.

(6) Wipe the friction surface of the pressure plate

with mineral spirits.

(7) Using a straight edge, check pressure plate for

flatness. The pressure plate friction area should be

FLAT TO SLIGHTLY CONCAVE, with the inner

diameter 0.000 mm to 0.1 mm (0.000 in. to 0.0039

in.) below the outer diameter. It should also be free

from discoloration, burned areas, cracks, grooves, or

ridges.

(8) Using a surface plate, test cover for flatness.

All sections around attaching bolt holes should be in

contact with surface plate within .015 inch.

(9) The cover should be a snug fit on flywheel dow-

els. If the clutch assembly does not meet these

requirements, it should be replaced.

INSTALLATION

(1) Mount clutch assembly on flywheel with disc

centered with tool 6724, being careful to properly

align dowels and the alignment marks made before

removal. The flywheel side of the clutch disc is

marked for proper installation. If new clutch or fly-

wheel is installed, align orange cover balance spot as

close as possible to orange flywheel balance spot.

Apply pressure to the alignment tool. Center the tip

of the tool into the crankshaft and the sliding cone

into the clutch fingers. Tighten the clutch attaching

bolts sufficiently to hold the disc in position (Fig. 5).

Fig. 4 Clutch Disc Aligning Tool

6 - 8 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 186 of 1200

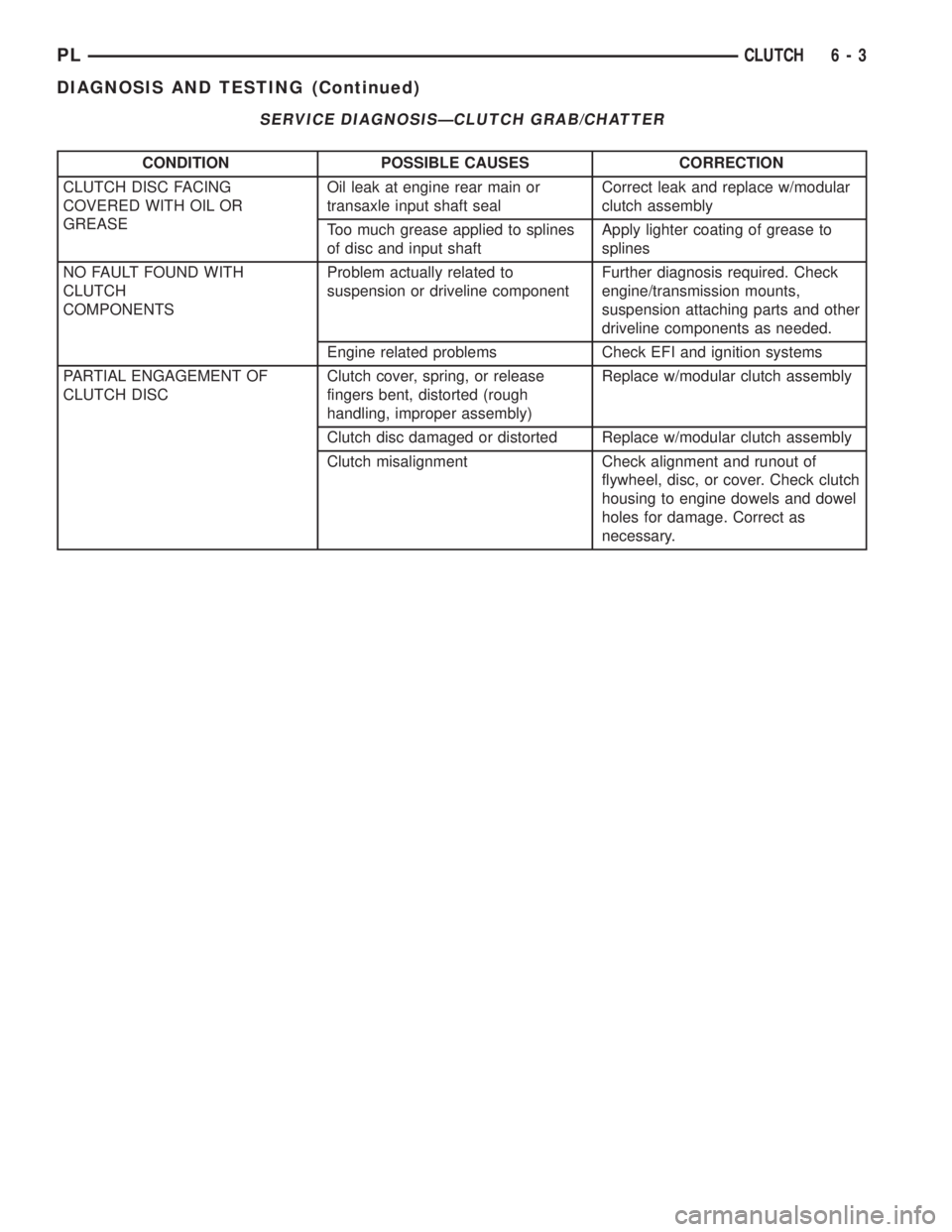

SERVICE DIAGNOSISÐCLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or

transaxle input shaft sealCorrect leak and replace w/modular

clutch assembly

Too much grease applied to splines

of disc and input shaftApply lighter coating of grease to

splines

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to

suspension or driveline componentFurther diagnosis required. Check

engine/transmission mounts,

suspension attaching parts and other

driveline components as needed.

Engine related problems Check EFI and ignition systems

PARTIAL ENGAGEMENT OF

CLUTCH DISCClutch cover, spring, or release

fingers bent, distorted (rough

handling, improper assembly)Replace w/modular clutch assembly

Clutch disc damaged or distorted Replace w/modular clutch assembly

Clutch misalignment Check alignment and runout of

flywheel, disc, or cover. Check clutch

housing to engine dowels and dowel

holes for damage. Correct as

necessary.

PLCLUTCH 6 - 3

DIAGNOSIS AND TESTING (Continued)

Page 727 of 1200

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

der head. The rocker shafts route oil to the rocker

arms/hydraulic lash adjuster assemblies.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A partial open deck is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4 mm. The bedplate

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket trans-

mits crankshaft movement, via timing belt to the

camshaft sprocket providing timed valve actuation.

PISTONS:The SOHC EngineDOES NOThave

provision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hex

head cap screw are used to provide alignment and

durability in the assembly. Pistons And Connecting

rods are serviced as an assembly.

PISTON RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package consist of 2 steel rails and a expander

spacer.

CYLINDER HEADÐSOHC:It features a Single

Over Head Camshaft, four-valves per cylinder cross

flow design. The valves are arranged in two inlinebanks, with the two intake per cylinder facing

toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFTÐSOHC:The nodular iron camshaft

has five bearing journals and 3 cam lobes per cylin-

der. Provision for cam position sensor on the cam at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVESÐSOHC:Four valves per cylinder are

actuated by roller rocker arms/hydraulic lash adjust-

ers assemblies which pivot on rocker arm shafts. All

valves have 6 mm diameter chrome plated valve

stems. The valve train has 33 mm (1.299 inch) diam-

eter intake valves and 28 mm (1.10 inch) diameter

exhaust valves. Viton rubber valve stem seals are

integral with spring seats. Valve springs, spring

retainers, and locks are conventional design.

INTAKE MANIFOLD:The intake manifold is a

molded plastic composition, attached to the cylinder

head with ten fasteners. This long branch design

enhances low and mid-range torque.

EXHAUST MANIFOLD:The exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 3). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

9 - 14 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 773 of 1200

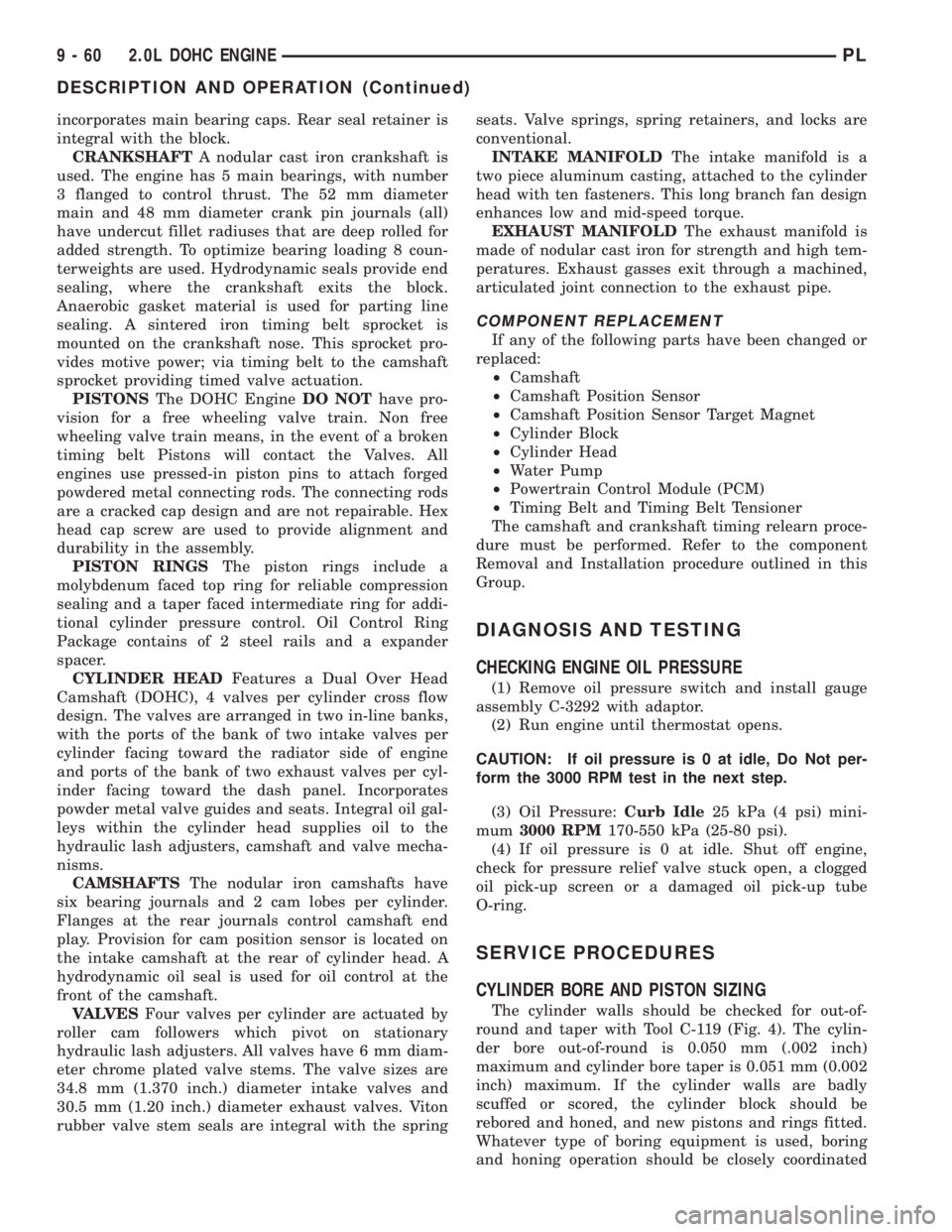

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFTA nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket pro-

vides motive power; via timing belt to the camshaft

sprocket providing timed valve actuation.

PISTONSThe DOHC EngineDO NOThave pro-

vision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hex

head cap screw are used to provide alignment and

durability in the assembly.

PISTON RINGSThe piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package contains of 2 steel rails and a expander

spacer.

CYLINDER HEADFeatures a Dual Over Head

Camshaft (DOHC), 4 valves per cylinder cross flow

design. The valves are arranged in two in-line banks,

with the ports of the bank of two intake valves per

cylinder facing toward the radiator side of engine

and ports of the bank of two exhaust valves per cyl-

inder facing toward the dash panel. Incorporates

powder metal valve guides and seats. Integral oil gal-

leys within the cylinder head supplies oil to the

hydraulic lash adjusters, camshaft and valve mecha-

nisms.

CAMSHAFTSThe nodular iron camshafts have

six bearing journals and 2 cam lobes per cylinder.

Flanges at the rear journals control camshaft end

play. Provision for cam position sensor is located on

the intake camshaft at the rear of cylinder head. A

hydrodynamic oil seal is used for oil control at the

front of the camshaft.

VA LV E SFour valves per cylinder are actuated by

roller cam followers which pivot on stationary

hydraulic lash adjusters. All valves have 6 mm diam-

eter chrome plated valve stems. The valve sizes are

34.8 mm (1.370 inch.) diameter intake valves and

30.5 mm (1.20 inch.) diameter exhaust valves. Viton

rubber valve stem seals are integral with the springseats. Valve springs, spring retainers, and locks are

conventional.

INTAKE MANIFOLDThe intake manifold is a

two piece aluminum casting, attached to the cylinder

head with ten fasteners. This long branch fan design

enhances low and mid-speed torque.

EXHAUST MANIFOLDThe exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure outlined in this

Group.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 4). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

9 - 60 2.0L DOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 832 of 1200

FRAMES

INDEX

page page

REMOVAL AND INSTALLATION

FRONT SUSPENSION CROSSMEMBER....... 3

SPECIFICATIONS

STRUCTURAL DIMENSIONS................ 4TORQUE SPECIFICATIONS................ 10

REMOVAL AND INSTALLATION

FRONT SUSPENSION CROSSMEMBER

WARNING: IF SUSPENSION CROSSMEMBER IS

REPLACED DUE TO COLLISION DAMAGE, INSPECT

THE STEERING COLUMN TO STEERING GEAR

COUPLING FOR DAMAGE. REFER TO GROUP 19,

STEERING FOR INSTRUCTIONS.

Before removing front suspension crossmem-

ber, index mark location of crossmember on

frame to aid installation.

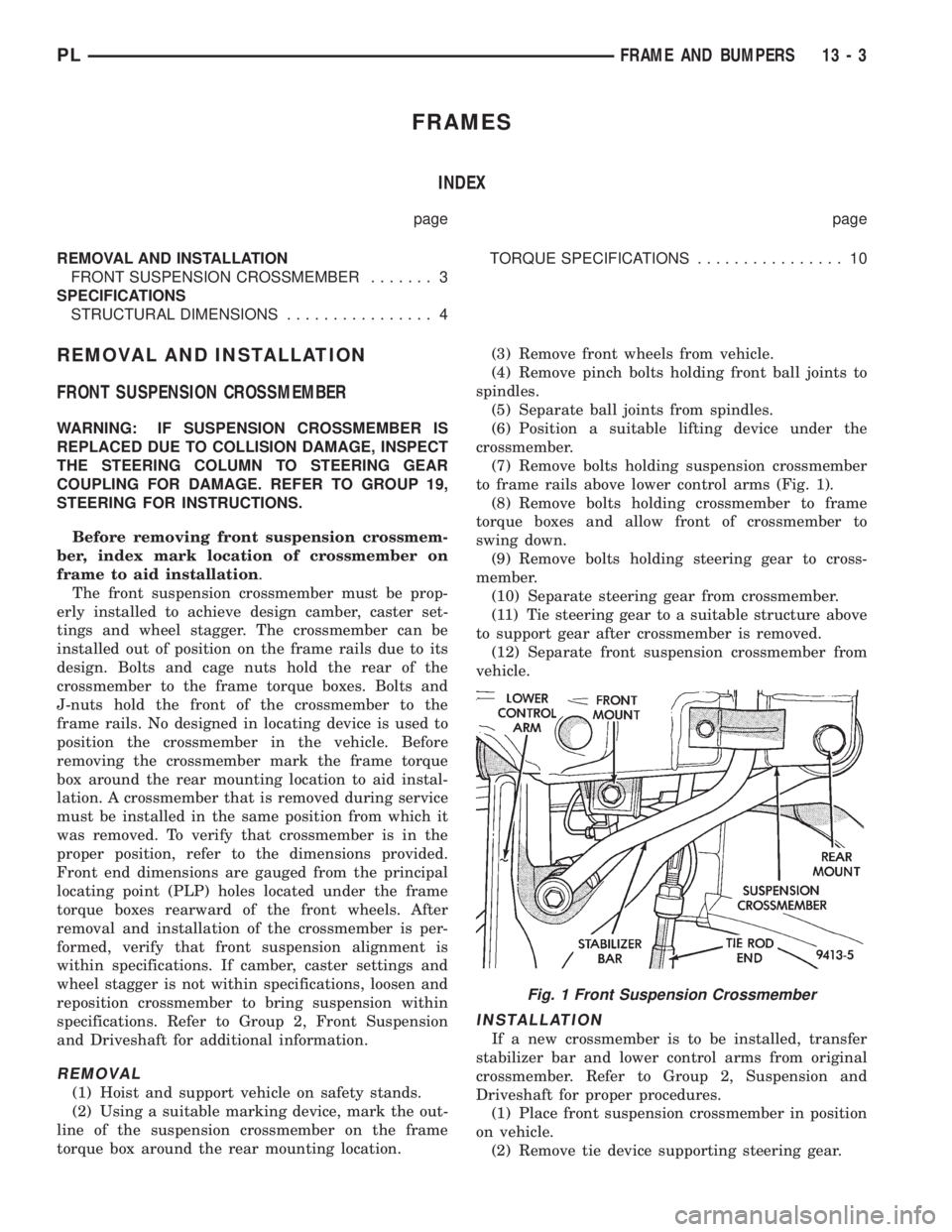

The front suspension crossmember must be prop-

erly installed to achieve design camber, caster set-

tings and wheel stagger. The crossmember can be

installed out of position on the frame rails due to its

design. Bolts and cage nuts hold the rear of the

crossmember to the frame torque boxes. Bolts and

J-nuts hold the front of the crossmember to the

frame rails. No designed in locating device is used to

position the crossmember in the vehicle. Before

removing the crossmember mark the frame torque

box around the rear mounting location to aid instal-

lation. A crossmember that is removed during service

must be installed in the same position from which it

was removed. To verify that crossmember is in the

proper position, refer to the dimensions provided.

Front end dimensions are gauged from the principal

locating point (PLP) holes located under the frame

torque boxes rearward of the front wheels. After

removal and installation of the crossmember is per-

formed, verify that front suspension alignment is

within specifications. If camber, caster settings and

wheel stagger is not within specifications, loosen and

reposition crossmember to bring suspension within

specifications. Refer to Group 2, Front Suspension

and Driveshaft for additional information.

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Using a suitable marking device, mark the out-

line of the suspension crossmember on the frame

torque box around the rear mounting location.(3) Remove front wheels from vehicle.

(4) Remove pinch bolts holding front ball joints to

spindles.

(5) Separate ball joints from spindles.

(6) Position a suitable lifting device under the

crossmember.

(7) Remove bolts holding suspension crossmember

to frame rails above lower control arms (Fig. 1).

(8) Remove bolts holding crossmember to frame

torque boxes and allow front of crossmember to

swing down.

(9) Remove bolts holding steering gear to cross-

member.

(10) Separate steering gear from crossmember.

(11) Tie steering gear to a suitable structure above

to support gear after crossmember is removed.

(12) Separate front suspension crossmember from

vehicle.

INSTALLATION

If a new crossmember is to be installed, transfer

stabilizer bar and lower control arms from original

crossmember. Refer to Group 2, Suspension and

Driveshaft for proper procedures.

(1) Place front suspension crossmember in position

on vehicle.

(2) Remove tie device supporting steering gear.

Fig. 1 Front Suspension Crossmember

PLFRAME AND BUMPERS 13 - 3

Page 833 of 1200

(3) Place steering gear in position on crossmember.

(4) Install bolts to hold steering gear to crossmem-

ber.

(5) Position lifting device under the crossmember.

(6) Lift crossmember to frame rails.

(7) Engage bolts to hold crossmember rear mounts

into cage nuts in the frame torque boxes. Do not

tighten bolts.

(8) Install bolts to hold crossmember to frame rails

above lower control arms.

(9) Lower and remove lifting device.

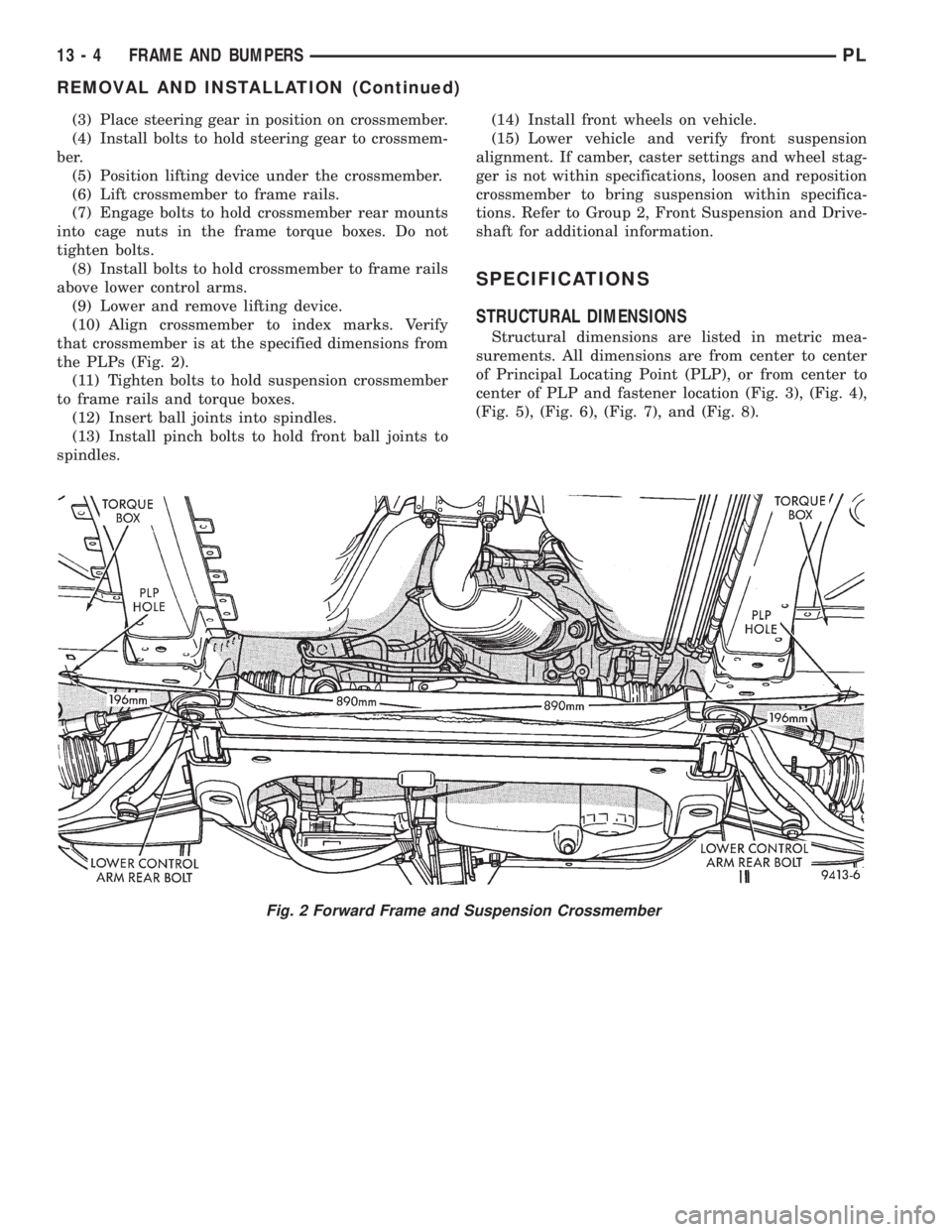

(10) Align crossmember to index marks. Verify

that crossmember is at the specified dimensions from

the PLPs (Fig. 2).

(11) Tighten bolts to hold suspension crossmember

to frame rails and torque boxes.

(12) Insert ball joints into spindles.

(13) Install pinch bolts to hold front ball joints to

spindles.(14) Install front wheels on vehicle.

(15) Lower vehicle and verify front suspension

alignment. If camber, caster settings and wheel stag-

ger is not within specifications, loosen and reposition

crossmember to bring suspension within specifica-

tions. Refer to Group 2, Front Suspension and Drive-

shaft for additional information.

SPECIFICATIONS

STRUCTURAL DIMENSIONS

Structural dimensions are listed in metric mea-

surements. All dimensions are from center to center

of Principal Locating Point (PLP), or from center to

center of PLP and fastener location (Fig. 3), (Fig. 4),

(Fig. 5), (Fig. 6), (Fig. 7), and (Fig. 8).

Fig. 2 Forward Frame and Suspension Crossmember

13 - 4 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)

Page 907 of 1200

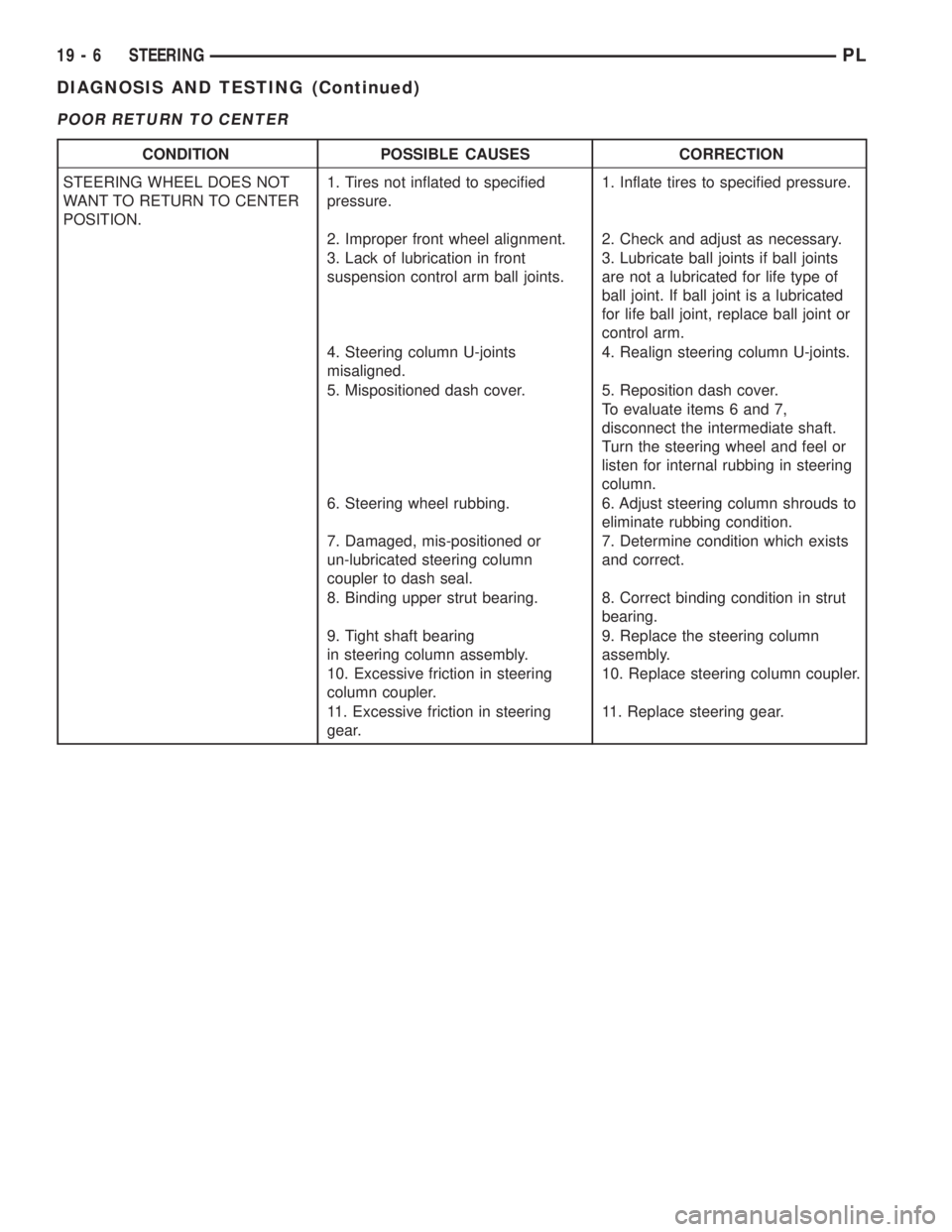

POOR RETURN TO CENTER

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES NOT

WANT TO RETURN TO CENTER

POSITION.1. Tires not inflated to specified

pressure.1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust as necessary.

3. Lack of lubrication in front

suspension control arm ball joints.3. Lubricate ball joints if ball joints

are not a lubricated for life type of

ball joint. If ball joint is a lubricated

for life ball joint, replace ball joint or

control arm.

4. Steering column U-joints

misaligned.4. Realign steering column U-joints.

5. Mispositioned dash cover. 5. Reposition dash cover.

To evaluate items 6 and 7,

disconnect the intermediate shaft.

Turn the steering wheel and feel or

listen for internal rubbing in steering

column.

6. Steering wheel rubbing. 6. Adjust steering column shrouds to

eliminate rubbing condition.

7. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.7. Determine condition which exists

and correct.

8. Binding upper strut bearing. 8. Correct binding condition in strut

bearing.

9. Tight shaft bearing

in steering column assembly.9. Replace the steering column

assembly.

10. Excessive friction in steering

column coupler.10. Replace steering column coupler.

11. Excessive friction in steering

gear.11. Replace steering gear.

19 - 6 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 908 of 1200

LOOSE STEERING

VEHICLE LEADS TO THE SIDE

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE STEERING WHEEL

KICKBACK OR TO MUCH

STEERING WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Fill power steering fluid reservoir

to the specified level. Perform

procedure to bleed the air out of the

power steering system. Perform

leakage diagnosis.

2. Steering gear loose on front

suspension crossmember.2. Check steering rear to front

suspension crossmember mounting

bolts. Tighten to specified torque if

found to be loose.

3. Worn, broken or loose steering

column to steering gear coupler.3. Check for worn universal joint,

broken isolator or loose fasteners.

4. Free play in steering column.

4.Check components of the steering

system and repair or replace as required.

5. Loose front suspension control

arm ball joints.5. Check and or replace the ball joint

or control arm as required.

6. Loose steering knuckle to ball

joint stud pinch bolt.6. Check pinch bolts and tighten if

required to specified torque.

7. Front wheel bearings loose or

worn.7. Tighten hub nut to specified

torque or replace with new parts as

necessary.

8. Loose outer tie rod ends. 8. Check free play of outer tie rod

ends and replace if required.

9. Loose inner tie rod ends. 9. Replace steering gear assembly.

10 Defective steering gear rotary

valve.10. Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES NOT

WANT RETURN TO CENTER

POSITION.1. Radial tire lead. 1.Rotate tires as recommended in

the Tire And Wheel Group of this

service manual.

2. Front suspension misaligned. 2. Align the front suspension as

required. Refer to the Wheel

Alignment Procedure in the

Suspension Group of this service

manual for the required wheel

alignment procedure.

3. Wheel braking. 3. Check for dragging brakes. Refer

to the procedures in the Brake

Group of this service manual.

4. Unbalanced steering gear valve. (If

this is the cause, the steering efforts will

be very light in direction of lead and

heavier in the opposite direction.4. Replace steering gear.

STEERING WHEEL HAS FORE

AND AFT LOOSENESS.1. Steering wheel to steering column

shaft retaining nut not properly

tightened and torqued.1. Tighten the retaining nut to its

specified torque specification.

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

PLSTEERING 19 - 7

DIAGNOSIS AND TESTING (Continued)

Page 932 of 1200

Torque the 4 steering gear mounting bolts to 68 N´m

(50 ft. lbs.).

(2) Using the transmission jack, raise front sus-

pension crossmember and steering gear against body

and frame rails of vehicle. Start the 2 rear bolts into

tapping plates, attaching front suspension crossmem-

ber to body of vehicle (Fig. 13). Then install the 2

front bolts, attaching front suspension crossmember

to frame rails of vehicle (Fig. 13). Tighten the 4

mounting bolts, until front suspension crossmember

is against body of vehicle at the 4 mounting points.

Then torque the 4 mounting bolts to 2 N´m (20 in.

lbs.) to hold front suspension crossmember in posi-

tion.

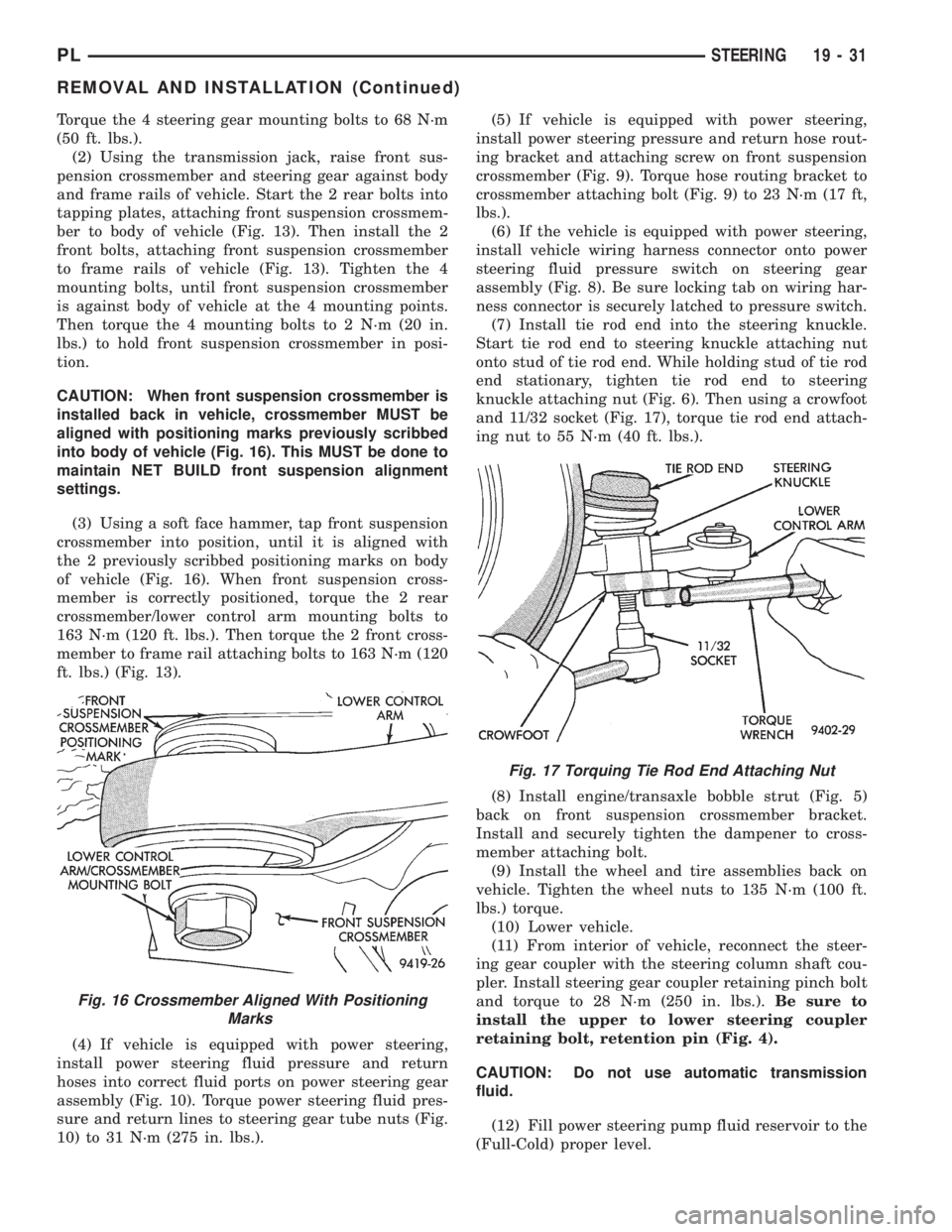

CAUTION: When front suspension crossmember is

installed back in vehicle, crossmember MUST be

aligned with positioning marks previously scribbed

into body of vehicle (Fig. 16). This MUST be done to

maintain NET BUILD front suspension alignment

settings.

(3) Using a soft face hammer, tap front suspension

crossmember into position, until it is aligned with

the 2 previously scribbed positioning marks on body

of vehicle (Fig. 16). When front suspension cross-

member is correctly positioned, torque the 2 rear

crossmember/lower control arm mounting bolts to

163 N´m (120 ft. lbs.). Then torque the 2 front cross-

member to frame rail attaching bolts to 163 N´m (120

ft. lbs.) (Fig. 13).

(4) If vehicle is equipped with power steering,

install power steering fluid pressure and return

hoses into correct fluid ports on power steering gear

assembly (Fig. 10). Torque power steering fluid pres-

sure and return lines to steering gear tube nuts (Fig.

10) to 31 N´m (275 in. lbs.).(5) If vehicle is equipped with power steering,

install power steering pressure and return hose rout-

ing bracket and attaching screw on front suspension

crossmember (Fig. 9). Torque hose routing bracket to

crossmember attaching bolt (Fig. 9) to 23 N´m (17 ft,

lbs.).

(6) If the vehicle is equipped with power steering,

install vehicle wiring harness connector onto power

steering fluid pressure switch on steering gear

assembly (Fig. 8). Be sure locking tab on wiring har-

ness connector is securely latched to pressure switch.

(7) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 6). Then using a crowfoot

and 11/32 socket (Fig. 17), torque tie rod end attach-

ing nut to 55 N´m (40 ft. lbs.).

(8) Install engine/transaxle bobble strut (Fig. 5)

back on front suspension crossmember bracket.

Install and securely tighten the dampener to cross-

member attaching bolt.

(9) Install the wheel and tire assemblies back on

vehicle. Tighten the wheel nuts to 135 N´m (100 ft.

lbs.) torque.

(10) Lower vehicle.

(11) From interior of vehicle, reconnect the steer-

ing gear coupler with the steering column shaft cou-

pler. Install steering gear coupler retaining pinch bolt

and torque to 28 N´m (250 in. lbs.).Be sure to

install the upper to lower steering coupler

retaining bolt, retention pin (Fig. 4).

CAUTION: Do not use automatic transmission

fluid.

(12) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level.

Fig. 16 Crossmember Aligned With Positioning

Marks

Fig. 17 Torquing Tie Rod End Attaching Nut

PLSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)