ESP DODGE NEON 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 300 of 1200

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

STOP LAMP SWITCH

Vehicles equipped with the speed control option use

a dual function stop lamp switch. The switch is

mounted on the brake pedal mounting bracket under

the instrument panel. The PCM monitors the state of

the dual function stop lamp switch. Refer to Group 5,

Brakes for more information on stop lamp switch ser-

vice and adjustment procedures.

SERVO CABLE

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage. This cable causes the

throttle control linkage to open or close the throttle

valve in response to movement of the vacuum servo

diaphragm.

POWERTRAIN CONTROL MODULE

The speed control electronic control circuitry is

integrated into the Powertrain Control Module

(PCM). The PCM is located in the engine compart-

ment. The PCM speed control functions are moni-

tored by the On-Board Diagnostics (OBD). All OBD-

sensed systems are monitored by the PCM. Each

monitored circuit is assigned a Diagnostic Trouble

Code (DTC). The PCM will store a DTC in electronic

memory for any failure it detects. See On-Board

Diagnostic Tests in this group for more information.

The PCM cannot be repaired and must be replaced if

faulty.

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE ORIGINAL VEHICLES MILEAGE. IF THIS

STEP IS NOT DONE A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

VACUUM RESERVOIR

The reservoir contains a one-way check valve to

trap engine vacuum in the reservoir. When engine

vacuum drops, as in climbing a grade while driving,

the reservoir supplies the vacuum needed to main-

tain proper speed control operation. The vacuum res-

ervoir cannot be repaired and must be replaced if

faulty.

VEHICLE SPEED AND DISTANCE

The 4 speed automatic Transmission Control Mod-

ule (TCM) supplies the speed input to the PCM. The

PCM determines acceleration rates. The speed con-

trol software in the PCM uses vehicle speed and

acceleration to control to the set speed.Vehicles with a 3 speed automatic or manual trans-

mission have a vehicle speed sensor (VSS) mounted

to an adapter near the transmission output shaft.

The sensor is driven through the adapter by a speed-

ometer pinion gear. The VSS pulse signal is moni-

tored by the PCM to determine vehicle speed and to

maintain speed control set speed. Refer to the appro-

priate Powertrain Diagnostic Procedures manual for

diagnosis and testing of this component. Refer to

group 14, Fuel System for Removal/Installation

DIAGNOSIS AND TESTING

ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8E,

Instrument Panel and Gauges for speedometer diag-

nosis.

If a road test verifies a surge following a set and

the speedometer operates properly see ªOvershoot/

Undershoot on speed control setº.

If a road test verifies an inoperative system, and

the speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose or corroded electrical connections at the

servo. Corrosion should be removed from electrical

terminals and a light coating of Mopar Multipurpose

Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment at both ends of the speed

control servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Conduct electrical test at PCM.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

PLVEHICLE SPEED CONTROL SYSTEM 8H - 3

DESCRIPTION AND OPERATION (Continued)

Page 370 of 1200

POWER DOOR LOCKS

CONTENTS

page page

POWER DOOR LOCKS..................... 1REMOTE KEYLESS ENTRY.................. 3

POWER DOOR LOCKS

INDEX

page page

DESCRIPTION AND OPERATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

DOOR LOCK MOTOR..................... 1

DOOR LOCK SWITCH..................... 1WIRING................................ 1

REMOVAL AND INSTALLATION

DOOR LOCK MOTOR..................... 2

DOOR LOCK SWITCH..................... 2

DESCRIPTION AND OPERATION

INTRODUCTION

All doors can be locked or unlocked electrically by

operating the switch on either front door panels.

The rear doors can be locked or unlocked by actu-

ation of the front door switch, or can be locked or

unlocked mechanically and independently with their

respective locking knobs.

The front doors can be locked or unlocked mechan-

ically with the locking knob regardless of electrical

locking and unlocking actuation with the front door

knobs.

The right and left front door can be locked or

unlocked mechanically from the outside with the key

or electrically as described above.

CHILD PROTECTION LOCK

The child protection lock is on the rear door only.

The lock will disable the inside door handle from

opening the door when engaged. The lock is part of

the latch/lock assembly. The lock is engaged by mov-

ing a lever that is located on the rearward inside

edge of the door.

DIAGNOSIS AND TESTING

DOOR LOCK MOTOR

Make certain battery is in normal condition before

circuits are tested.To determine which motor is faulty, check each

individual door for electrical lock and unlock or dis-

connect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem maybe caused

by a shorted motor, or a bad switch. Disconnecting

the defective motor will allow the others to work.

To test an individual door lock motor, disconnect

the electrical connector from the motor. To lock the

door, connect a 12 volt power source to the positive

pin of the lock motor and a ground wire to the other

pin (Fig. 1) To unlock the door reverse the wire con-

nections at the motor pin terminals. If these results

are NOT obtained, replace the door latch assembly.

DOOR LOCK SWITCH

Remove the switch from its mounting location.

Using an ohmmeter, refer to (Fig. 2) to determine if

continuity is correct in the Lock and Unlock switch

positions. If these results are not obtained, replace

the switch.

WIRING

The following wiring test sequence determines

whether or not voltage is continuous through the

body harness to switch.

(1) Remove left side switch from door trim panel.

(2) Carefully separate multiple terminal block on

wiring harness from switch body.

PLPOWER DOOR LOCKS 8P - 1

Page 376 of 1200

IMMOBILIZER SYSTEM

CONTENTS

page page

DESCRIPTION AND OPERATION

IMMOBILIZER RECEIVER................ 1

IMMOBILIZER SYSTEM.................. 1

IMMOBILIZER TRANSMITTER............. 2

POWER-UP MODE...................... 2

DIAGNOSIS AND TESTING

IMMOBILIZER DIAGNOSIS............... 2SERVICE PROCEDURES

VEHICLE IMMOBILIZER SYSTEM.......... 3

REMOVAL AND INSTALLATION

IMMOBILIZER RECEIVER................ 3

DESCRIPTION AND OPERATION

IMMOBILIZER SYSTEM

The Immobilizer system includes the following

unique items:

²An immobilizer module receiver that controls

system operation and also controls the RKE and Illu-

minated entry systems, if equipped.

²An encoded Crankshaft Position Sensor for the

ignition system. The Immobilizer module decodes the

signal from the crankshaft so the PCM can recognize

it as a valid Crankshaft Position Sensor signal, and

allow the engine to run.

²A wiring harness that interconnects the crank-

shaft sensor, the immobilizer receiver, and the PCM.

²Two key fob transmitters.

The Immobilizer System prevents unauthorized

operation of the vehicle by disabling the engine and

starter. The system will NOT allow the vehicle to

start unless the UNLOCK button on the RKE trans-

mitter is pressed. The system will be activated after

turning the ignition switch to the OFF position and

using one of the following methods.

(1) Press the LOCK button on the RKE transmit-

ter.

(2) LOCK the doors by pressing a power lock but-

ton switch.

(3) LOCK the driver or passenger door using the

key.

²The Security light will flash, for about 16 sec-

onds, indicating that the engine and starter will be

disabled.

²The Security light remaining on, indicates the

system is not operational.

²The Immobilizer will activate automatically

within 10 minutes of the ignition switch being in the

OFF position, whether the vehicle has been locked or

unlocked.²An attempt to start the vehicle without pressing

the UNLOCK button on the RKE transmitter will

result in a warning chime and the Security light

flashing.

NOTE: The ignition switch must be in the OFF posi-

tion in order for the system to be activated, whether

the doors are closed or not.

IMMOBILIZER RECEIVER

The immobilizer receiver is programmed to

respond to the Lock and Unlock radio signals issued

by the immobilizer transmitters. The receiver will

only respond to the radio signals of transmitters (up

to four) whose vehicle access codes have been stored

in the receiver's electronic memory. The receiver is

programmed at the assembly plant with the vehicle

access codes of the two transmitters that are shipped

with the vehicle.

The immobilizer receiver also has a central pro-

cessing unit, which contains the immobilizer system

logic. The programming in the immobilizer receiver

allows the system to learn and retain transmitter

vehicle access codes, as well as to communicate with

the Powertrain Control Module (PCM) and/or the

DRB scan tool on the Chrysler Collision Detection

(CCD) data bus network.

The CCD data bus network allows the sharing of

sensor information. This helps to reduce wiring har-

ness complexity, reduce internal controller hardware,

and reduce component sensor current loads. At the

same time, the CCD data bus network provides

increased reliability and enhanced diagnostic capabil-

ities.

Each immobilizer transmitter has a different vehi-

cle access code, which must be programmed into the

memory of the immobilizer receiver in the vehicle in

order to operate the immobilizer system. A DRB scan

tool must be used to program new or additional

PLIMMOBILIZER SYSTEM 8Q - 1

Page 385 of 1200

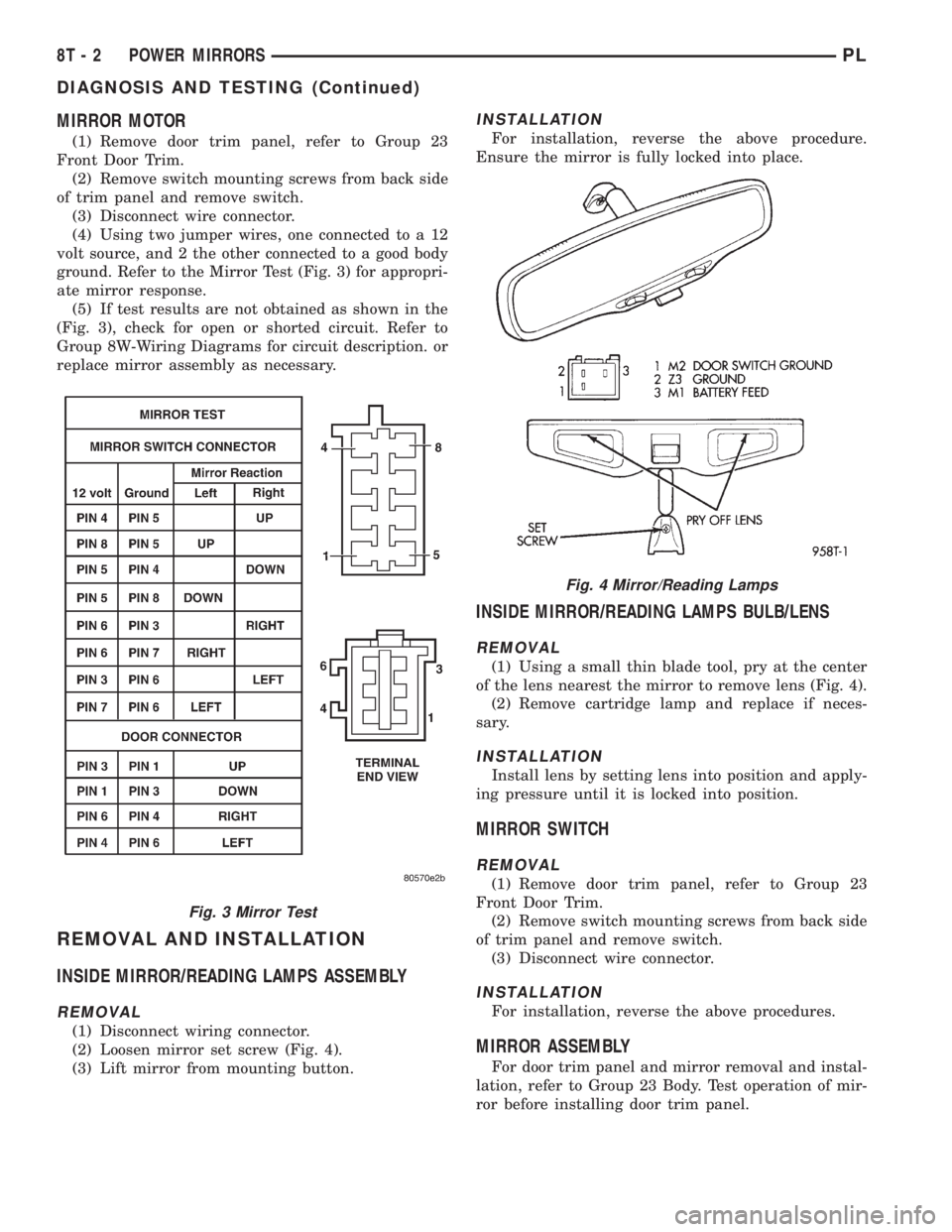

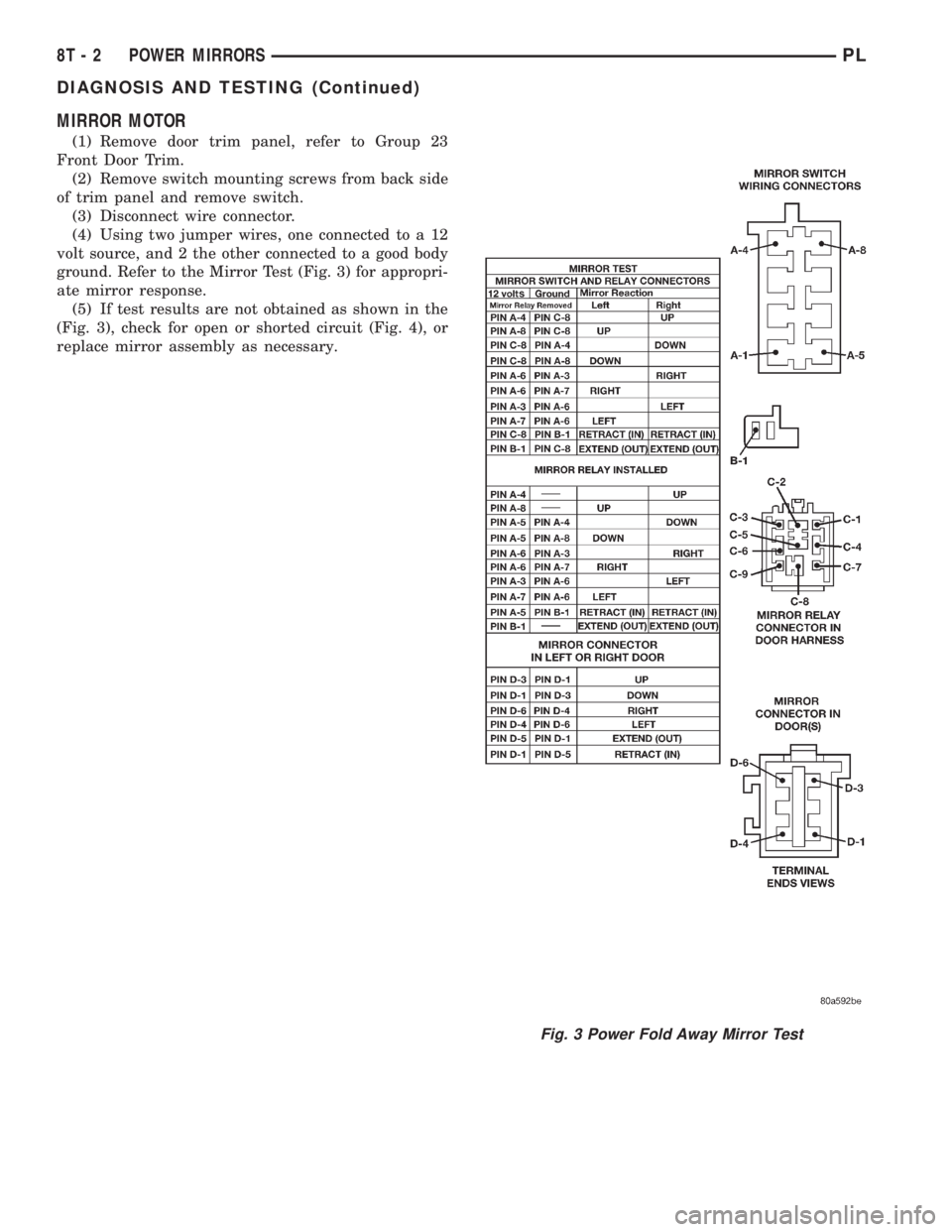

MIRROR MOTOR

(1) Remove door trim panel, refer to Group 23

Front Door Trim.

(2) Remove switch mounting screws from back side

of trim panel and remove switch.

(3) Disconnect wire connector.

(4) Using two jumper wires, one connected to a 12

volt source, and 2 the other connected to a good body

ground. Refer to the Mirror Test (Fig. 3) for appropri-

ate mirror response.

(5) If test results are not obtained as shown in the

(Fig. 3), check for open or shorted circuit. Refer to

Group 8W-Wiring Diagrams for circuit description. or

replace mirror assembly as necessary.

REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS ASSEMBLY

REMOVAL

(1) Disconnect wiring connector.

(2) Loosen mirror set screw (Fig. 4).

(3) Lift mirror from mounting button.

INSTALLATION

For installation, reverse the above procedure.

Ensure the mirror is fully locked into place.

INSIDE MIRROR/READING LAMPS BULB/LENS

REMOVAL

(1) Using a small thin blade tool, pry at the center

of the lens nearest the mirror to remove lens (Fig. 4).

(2) Remove cartridge lamp and replace if neces-

sary.

INSTALLATION

Install lens by setting lens into position and apply-

ing pressure until it is locked into position.

MIRROR SWITCH

REMOVAL

(1) Remove door trim panel, refer to Group 23

Front Door Trim.

(2) Remove switch mounting screws from back side

of trim panel and remove switch.

(3) Disconnect wire connector.

INSTALLATION

For installation, reverse the above procedures.

MIRROR ASSEMBLY

For door trim panel and mirror removal and instal-

lation, refer to Group 23 Body. Test operation of mir-

ror before installing door trim panel.

Fig. 3 Mirror Test

Fig. 4 Mirror/Reading Lamps

8T - 2 POWER MIRRORSPL

DIAGNOSIS AND TESTING (Continued)

Page 387 of 1200

MIRROR MOTOR

(1) Remove door trim panel, refer to Group 23

Front Door Trim.

(2) Remove switch mounting screws from back side

of trim panel and remove switch.

(3) Disconnect wire connector.

(4) Using two jumper wires, one connected to a 12

volt source, and 2 the other connected to a good body

ground. Refer to the Mirror Test (Fig. 3) for appropri-

ate mirror response.

(5) If test results are not obtained as shown in the

(Fig. 3), check for open or shorted circuit (Fig. 4), or

replace mirror assembly as necessary.

Fig. 3 Power Fold Away Mirror Test

8T - 2 POWER MIRRORSPL

DIAGNOSIS AND TESTING (Continued)

Page 401 of 1200

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER, AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY, AND LOOSE CLOTH-

ING.

TAKE OUTS

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component.

ELECTROSTATIC DISCHARGE (ESD) SENSITIVE

DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 4) is used to indicate this. When han-

dling any component with this symbol comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part from its protective

packing until it is time to install the part.

(5) Before removing the part from its package,

ground the package to a known good ground on the

vehicle.

DIAGNOSIS AND TESTING

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicle are solid state. When checking

voltages in these circuits use a meter with a 10-me-

gohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: - Most of the electrical components used

in today's vehicle are Solid State. When checking

resistance in these circuits use a meter with a 10-

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle

electrical system can cause damage to the equip-

ment and provide false readings.

Fig. 4 Electrostatic Discharge Symbol

8W - 01 - 8 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 491 of 1200

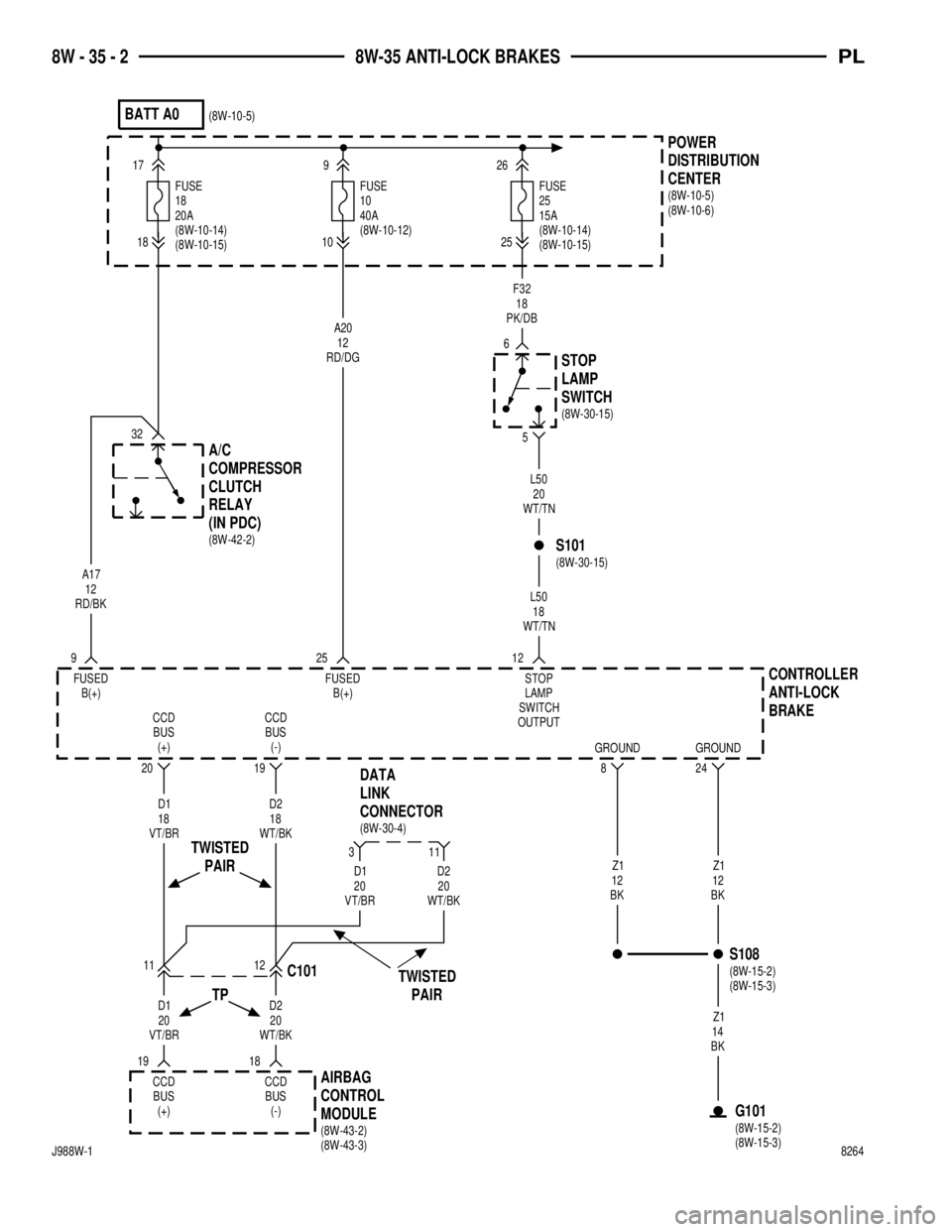

POWER

DISTRIBUTION

CENTER

18 17

20A

FUSE

18

9

CONTROLLER

ANTI-LOCK

BRAKE

A17

12

RD/BK

32

BATT A0

D2

18

WT/BK D1

18

VT/BR

2019

1819

1112C101

D1

20

VT/BRD2

20

WT/BK

PAIR TWISTED

25 26

15A

FUSE

25

824

Z1

12

BK BK12Z1

Z1

14

BK

G101 S108

6

5

L50

20

WT/TN

12

L50

18

WT/TN

S101

F32

18

PK/DB

STOP

LAMP

SWITCH

OUTPUT

GROUND GROUND FUSED

B(+) B(+)FUSED

25

RD/DG12 A20 109

40A

FUSE

10

(IN PDC) RELAY

CLUTCH

COMPRESSOR

A/C

DATA

LINK

CONNECTOR

AIRBAG

CONTROL

MODULE

D1

20

VT/BRD2

20

WT/BK

11 3

STOP

LAMP

SWITCH

CCD

BUS

(+) (-)BUS CCD

CCD

BUS

(-) (+) BUS CCD

TPPAIR TWISTED

(8W-10-5)

(8W-10-6)

(8W-10-14)

(8W-10-15)(8W-10-5)

(8W-10-14)

(8W-10-15)

(8W-15-2)

(8W-15-3) (8W-15-2)

(8W-15-3) (8W-30-15) (8W-10-12)

(8W-42-2)

(8W-30-4)

(8W-43-2)

(8W-43-3)(8W-30-15)

8W - 35 - 2 8W-35 ANTI-LOCK BRAKESPL

J988W-18264

Page 493 of 1200

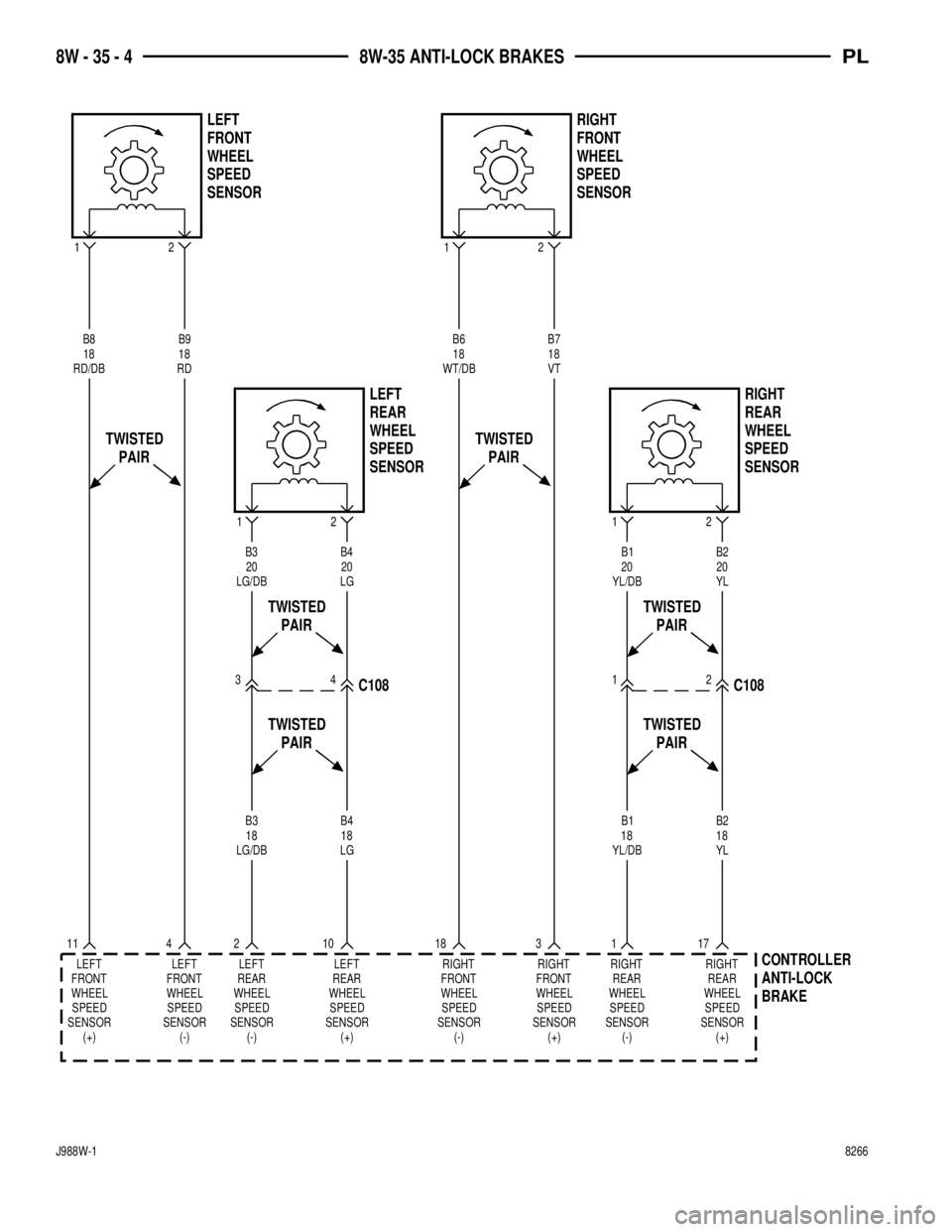

SENSOR SPEED

WHEEL

FRONT

LEFT

LEFT

REAR

WHEEL

SPEED

SENSORRIGHT

FRONT

WHEEL

SPEED

SENSOR

RIGHT

REAR

WHEEL

SPEED

SENSOR

LEFT

FRONT

WHEEL

SPEED

SENSOR

(+)LEFT

FRONT

WHEEL

SPEED

SENSOR

(-) (+)SENSORSPEED WHEELREARLEFT

(-) SENSORSPEED WHEELREARLEFT RIGHT

FRONT

WHEEL

SPEED

SENSOR

(-)RIGHT

FRONT

WHEEL

SPEED

SENSOR

(+) (+)SENSORSPEED WHEELREAR RIGHT

(-) SENSORSPEED WHEELREAR RIGHT

114210183117 B8

18

RD/DB

B9

18

RDB6

18

WT/DBB7

18

VT

B2

20

YL B1

20

YL/DB B3

20

LG/DBB4

20

LG

21

21

21

21

CONTROLLER

ANTI-LOCK

BRAKE

PAIR TWISTED

TWISTED

PAIR

TWISTED

PAIR

PAIR TWISTED

2C10813C1084

B3

18

LG/DBB4

18

LGB1

18

YL/DBB2

18

YL

TWISTED

PAIR

PAIR TWISTED

8W - 35 - 4 8W-35 ANTI-LOCK BRAKESPL

J988W-18266

Page 722 of 1200

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

(6) Disconnect the fresh air hose (makeup air) at

the cylinder head cover and plug or cap the nipple on

the cover.

(7) Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. Thefollowing steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil galley cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified. Refer to Rear

Crankshaft Seals, for proper replacement procedures.

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 728 of 1200

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

with the fitting of pistons and rings in order that

specified clearances may be maintained.Refer to

Honing Cylinder Bores outlined in the Stan-

dard Service Procedures for specification and

procedures.

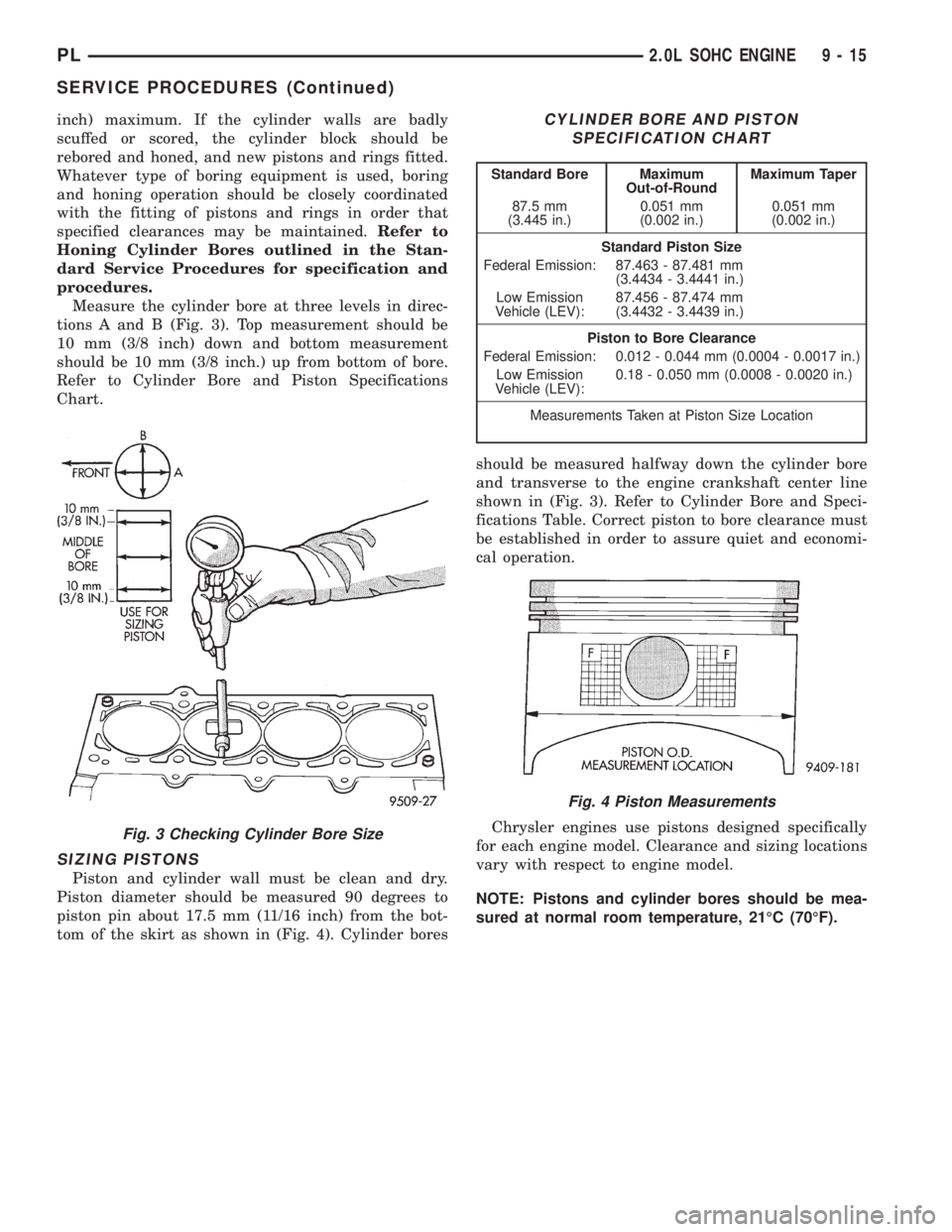

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 3). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Cylinder Bore and Piston Specifications

Chart.

SIZING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 17.5 mm (11/16 inch) from the bot-

tom of the skirt as shown in (Fig. 4). Cylinder boresshould be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 3). Refer to Cylinder Bore and Speci-

fications Table. Correct piston to bore clearance must

be established in order to assure quiet and economi-

cal operation.

Chrysler engines use pistons designed specifically

for each engine model. Clearance and sizing locations

vary with respect to engine model.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21ÉC (70ÉF).

Fig. 3 Checking Cylinder Bore Size

CYLINDER BORE AND PISTON

SPECIFICATION CHART

Standard Bore Maximum

Out-of-RoundMaximum Taper

87.5 mm

(3.445 in.)0.051 mm

(0.002 in.)0.051 mm

(0.002 in.)

Standard Piston Size

Federal Emission: 87.463 - 87.481 mm

(3.4434 - 3.4441 in.)

Low Emission

Vehicle (LEV):87.456 - 87.474 mm

(3.4432 - 3.4439 in.)

Piston to Bore Clearance

Federal Emission: 0.012 - 0.044 mm (0.0004 - 0.0017 in.)

Low Emission

Vehicle (LEV):0.18 - 0.050 mm (0.0008 - 0.0020 in.)

Measurements Taken at Piston Size Location

Fig. 4 Piston Measurements

PL2.0L SOHC ENGINE 9 - 15

SERVICE PROCEDURES (Continued)