ESP DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 735 of 1200

(4) Apply MopartStud and Bearing Mount or

equivalent to a new tube approximately 1 mm from

theendina3mmwide area.

(5) Install sealer end of tube into the cylinder

head. Then carefully install the tube using a hard-

wood block and mallet until the tube is seated into

the bottom of the bore.

(6) Install cylinder head cover. Refer to procedure

outlined in this section.

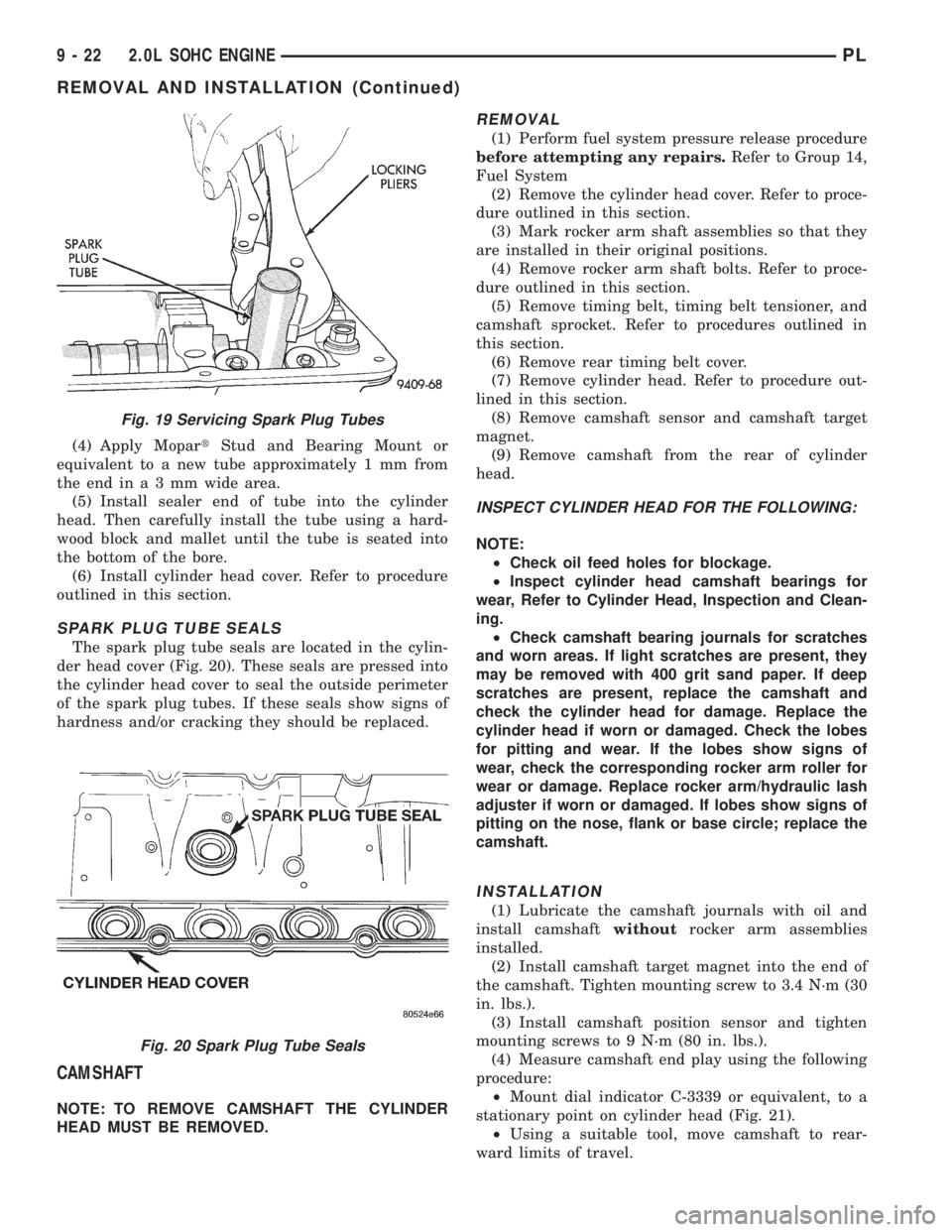

SPARK PLUG TUBE SEALS

The spark plug tube seals are located in the cylin-

der head cover (Fig. 20). These seals are pressed into

the cylinder head cover to seal the outside perimeter

of the spark plug tubes. If these seals show signs of

hardness and/or cracking they should be replaced.

CAMSHAFT

NOTE: TO REMOVE CAMSHAFT THE CYLINDER

HEAD MUST BE REMOVED.

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Remove the cylinder head cover. Refer to proce-

dure outlined in this section.

(3) Mark rocker arm shaft assemblies so that they

are installed in their original positions.

(4) Remove rocker arm shaft bolts. Refer to proce-

dure outlined in this section.

(5) Remove timing belt, timing belt tensioner, and

camshaft sprocket. Refer to procedures outlined in

this section.

(6) Remove rear timing belt cover.

(7) Remove cylinder head. Refer to procedure out-

lined in this section.

(8) Remove camshaft sensor and camshaft target

magnet.

(9) Remove camshaft from the rear of cylinder

head.

INSPECT CYLINDER HEAD FOR THE FOLLOWING:

NOTE:

²Check oil feed holes for blockage.

²Inspect cylinder head camshaft bearings for

wear, Refer to Cylinder Head, Inspection and Clean-

ing.

²Check camshaft bearing journals for scratches

and worn areas. If light scratches are present, they

may be removed with 400 grit sand paper. If deep

scratches are present, replace the camshaft and

check the cylinder head for damage. Replace the

cylinder head if worn or damaged. Check the lobes

for pitting and wear. If the lobes show signs of

wear, check the corresponding rocker arm roller for

wear or damage. Replace rocker arm/hydraulic lash

adjuster if worn or damaged. If lobes show signs of

pitting on the nose, flank or base circle; replace the

camshaft.

INSTALLATION

(1) Lubricate the camshaft journals with oil and

install camshaftwithoutrocker arm assemblies

installed.

(2) Install camshaft target magnet into the end of

the camshaft. Tighten mounting screw to 3.4 N´m (30

in. lbs.).

(3) Install camshaft position sensor and tighten

mounting screws to 9 N´m (80 in. lbs.).

(4) Measure camshaft end play using the following

procedure:

²Mount dial indicator C-3339 or equivalent, to a

stationary point on cylinder head (Fig. 21).

²Using a suitable tool, move camshaft to rear-

ward limits of travel.

Fig. 19 Servicing Spark Plug Tubes

Fig. 20 Spark Plug Tube Seals

9 - 22 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 763 of 1200

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 108). Make sure

measurements are taken from top of spring seat to

the bottom surface of spring retainer. If height is

greater than 40.18 mm (1.58 in.), install a 0.762 mm

(0.030 in.) spacer under the valve spring seat to

bring spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster/s to bleed down before rotating

cam.

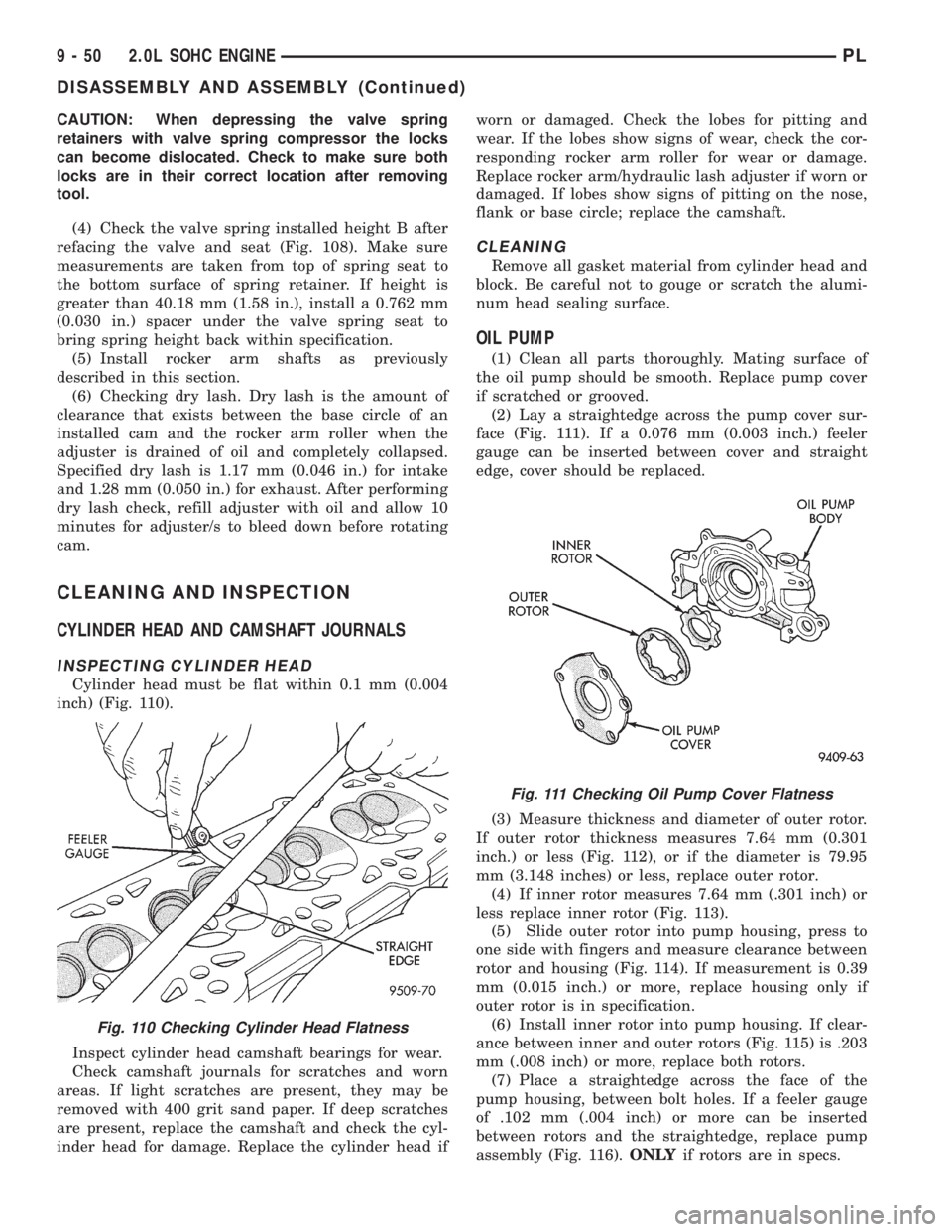

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

INSPECTING CYLINDER HEAD

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 110).

Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head ifworn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 111). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 112), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (.301 inch) or

less replace inner rotor (Fig. 113).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 114). If measurement is 0.39

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

(6) Install inner rotor into pump housing. If clear-

ance between inner and outer rotors (Fig. 115) is .203

mm (.008 inch) or more, replace both rotors.

(7) Place a straightedge across the face of the

pump housing, between bolt holes. If a feeler gauge

of .102 mm (.004 inch) or more can be inserted

between rotors and the straightedge, replace pump

assembly (Fig. 116).ONLYif rotors are in specs.

Fig. 110 Checking Cylinder Head Flatness

Fig. 111 Checking Oil Pump Cover Flatness

9 - 50 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 774 of 1200

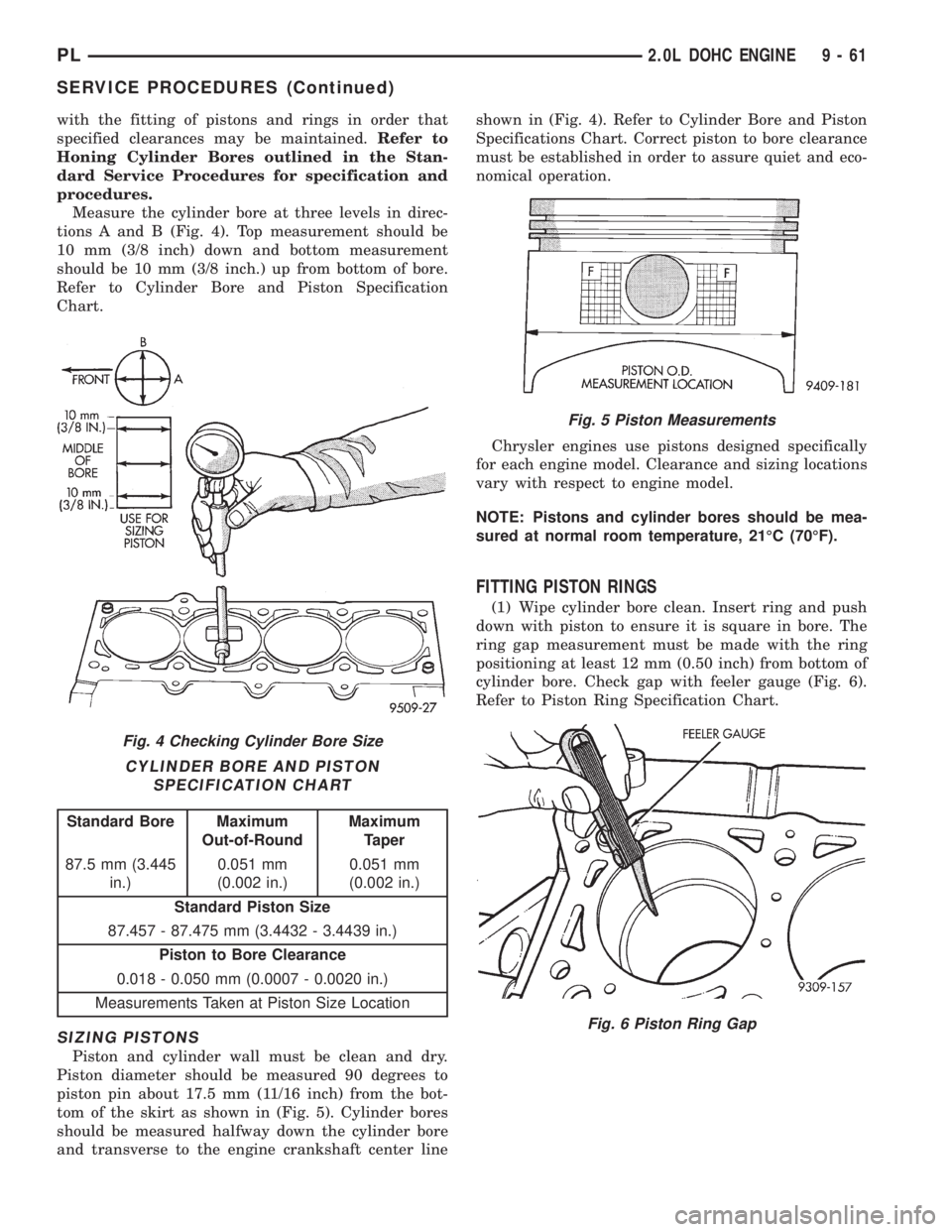

with the fitting of pistons and rings in order that

specified clearances may be maintained.Refer to

Honing Cylinder Bores outlined in the Stan-

dard Service Procedures for specification and

procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 4). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Cylinder Bore and Piston Specification

Chart.

SIZING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 17.5 mm (11/16 inch) from the bot-

tom of the skirt as shown in (Fig. 5). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center lineshown in (Fig. 4). Refer to Cylinder Bore and Piston

Specifications Chart. Correct piston to bore clearance

must be established in order to assure quiet and eco-

nomical operation.

Chrysler engines use pistons designed specifically

for each engine model. Clearance and sizing locations

vary with respect to engine model.

NOTE: Pistons and cylinder bores should be mea-

sured at normal room temperature, 21ÉC (70ÉF).

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 6).

Refer to Piston Ring Specification Chart.

Fig. 4 Checking Cylinder Bore Size

CYLINDER BORE AND PISTON

SPECIFICATION CHART

Standard Bore Maximum

Out-of-RoundMaximum

Taper

87.5 mm (3.445

in.)0.051 mm

(0.002 in.)0.051 mm

(0.002 in.)

Standard Piston Size

87.457 - 87.475 mm (3.4432 - 3.4439 in.)

Piston to Bore Clearance

0.018 - 0.050 mm (0.0007 - 0.0020 in.)

Measurements Taken at Piston Size Location

Fig. 5 Piston Measurements

Fig. 6 Piston Ring Gap

PL2.0L DOHC ENGINE 9 - 61

SERVICE PROCEDURES (Continued)

Page 807 of 1200

CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 100). Make sure

measurements are taken from top of spring seat to

the bottom surface of spring retainer. If height is

greater than 38.75 mm (1.525 in.), install a 7.620

mm (0.030 inch.) spacer under the valve spring seat

to bring spring height back within specification.

(5) Install cam followers and camshaft as previ-

ously described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster or adjusters to bleed down

before rotating cam.

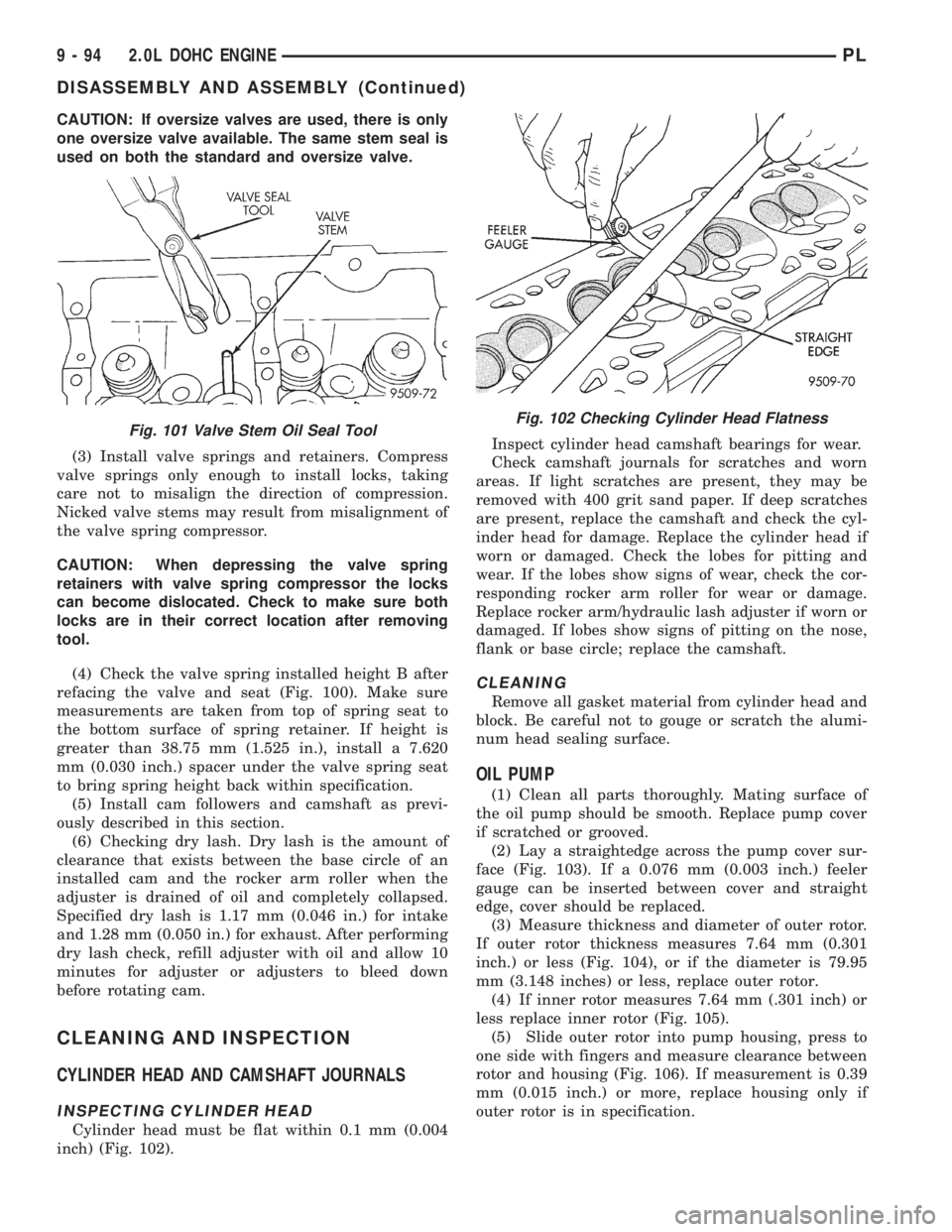

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

INSPECTING CYLINDER HEAD

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 102).Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head if

worn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 103). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 104), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (.301 inch) or

less replace inner rotor (Fig. 105).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 106). If measurement is 0.39

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

Fig. 101 Valve Stem Oil Seal ToolFig. 102 Checking Cylinder Head Flatness

9 - 94 2.0L DOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 843 of 1200

oline and up to 17 percent ETBE. Gasoline blended

with MTBE or ETBE may be used in your vehicle.

Methanol- Methanol (Methyl or Wood Alcohol) is

used in a variety of concentrations blended with

unleaded gasoline. You may encounter fuels contain-

ing 3 percent or more methanol along with other

alcohols called cosolvents.

DO NOT USE GASOLINES CONTAINING

METHANOL.

Use of methanol/gasoline blends may result in

starting and driveability problems and damage criti-

cal fuel system components.

Problems that are the result of using methanol/

gasoline blends are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty.

Reformulated Gasoline

Many areas of the country are requiring the use of

cleaner-burning fuel referred to asReformulatedGasoline. Reformulated gasolines are specially

blended to reduce vehicle emissions and improve air

quality.

Chrysler Corporation strongly supports the use of

reformulated gasolines whenever available. Although

your vehicle was designed to provide optimum perfor-

mance and lowest emissions operating on high qual-

ity unleaded gasoline, it will perform equally well

and produce even lower emissions when operating on

reformulated gasoline.

Materials Added to Fuel

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain active sol-

vents of similar ingredients that can be harmful to

fuel system gasket and diaphragm materials.

14 - 2 FUEL SYSTEMPL

GENERAL INFORMATION (Continued)

Page 862 of 1200

GENERAL INFORMATION

INTRODUCTION

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygen

sensor diagnostics (they are checked for shorted con-

ditions at all times).During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than .745

volts or less than .1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

PLFUEL SYSTEM 14 - 21

Page 864 of 1200

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in respones to MAP

sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to Group 25,

On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

DESCRIPTION AND OPERATION

SYSTEM DIAGNOSIS

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information, refer to Group 25, Emission

Control Systems. See On-Board Diagnostics.

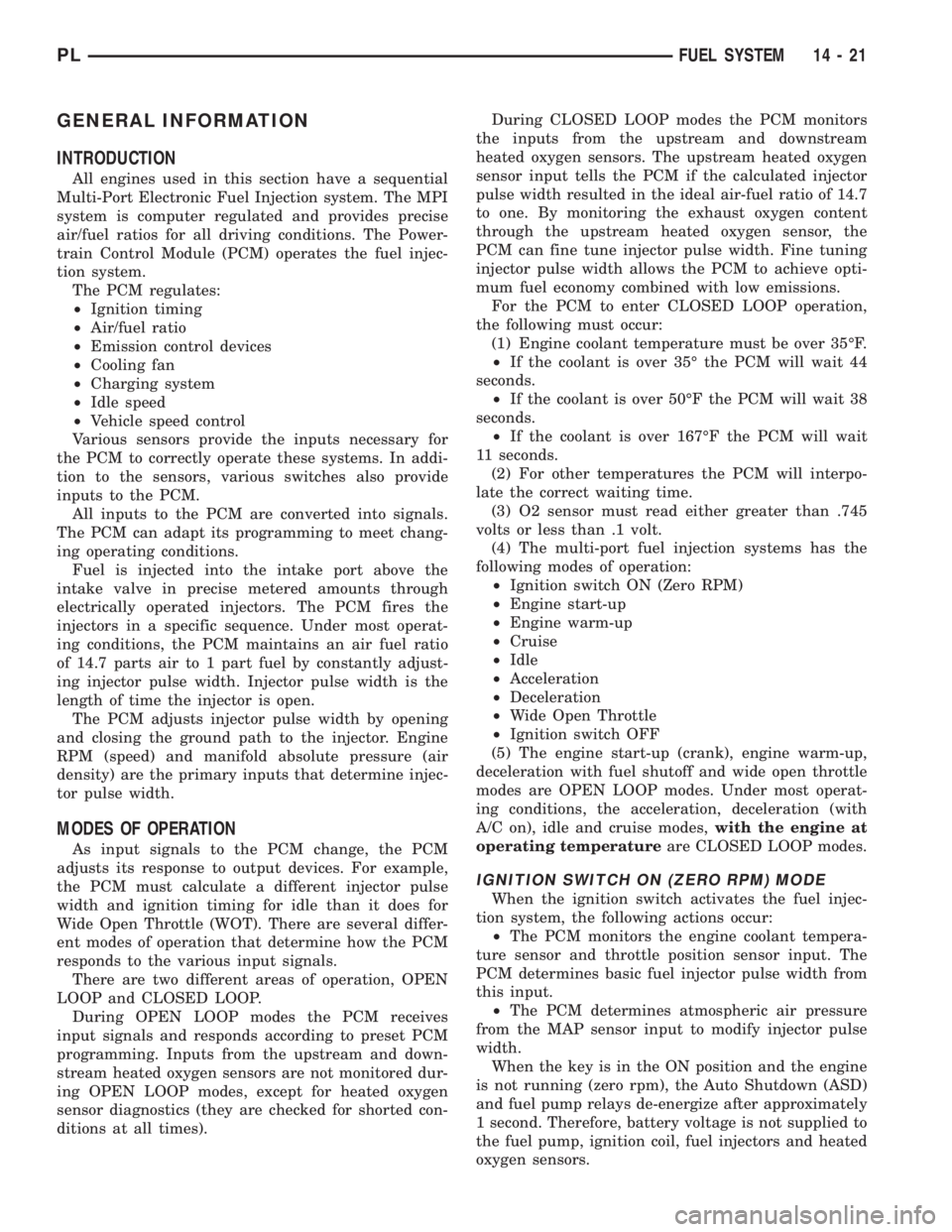

POWER DISTRIBUTION CENTER

The power distribution center (PDC) is located next

to the battery (Fig. 1). The PDC contains the starter

relay, radiator fan relay, A/C compressor clutch relay,

auto shutdown relay, fuel pump relay and several

fuses.

Fig. 1 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 23

GENERAL INFORMATION (Continued)

Page 870 of 1200

As Intake Air temperature varies the Intake Air

Temperature sensors resistance changes resulting in

a different input voltage to the PCM.

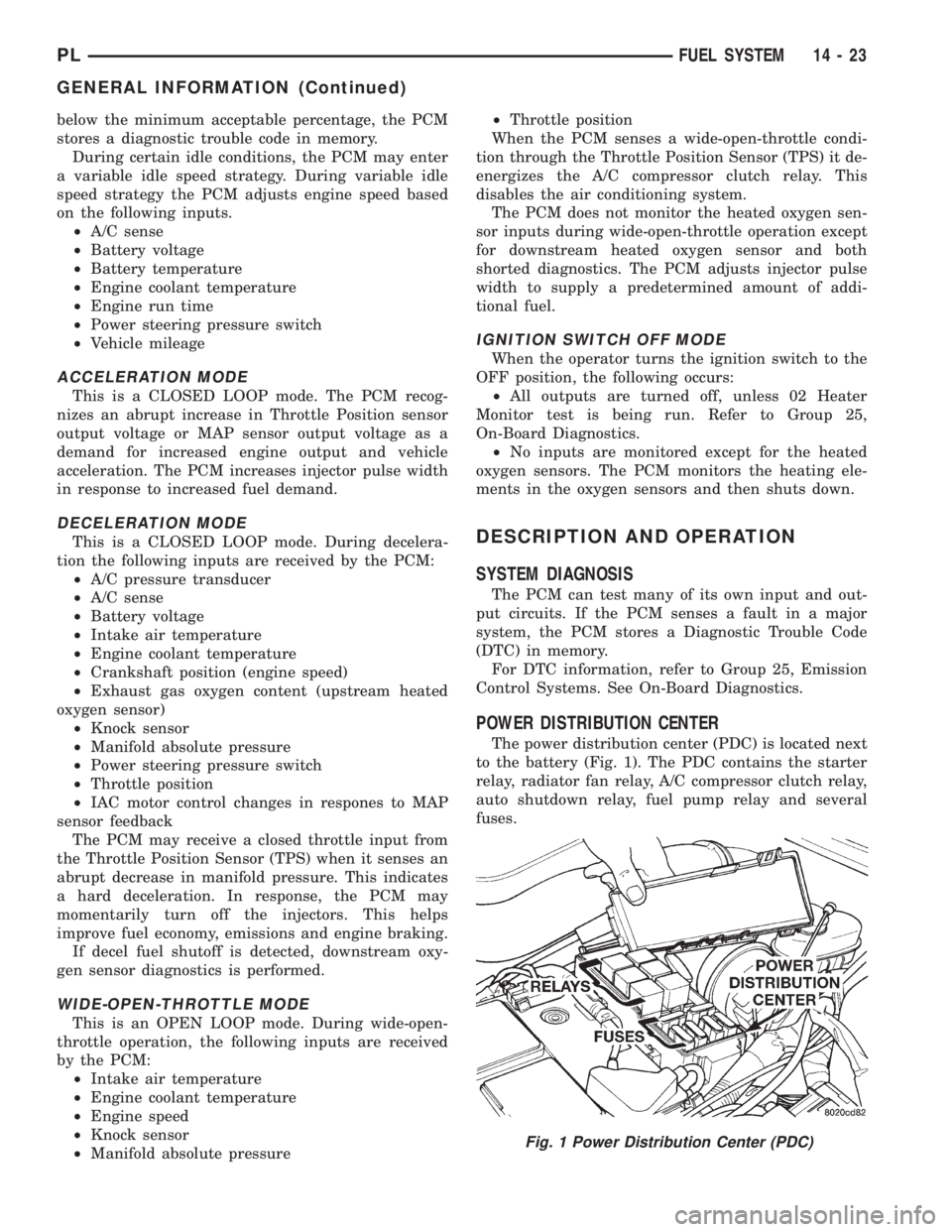

The IAT sensor and Manifold Absolute Pressure

(MAP) switch are a combined into a single sensor

that attachs to the intake manifold (Fig. 13) or (Fig.

14).

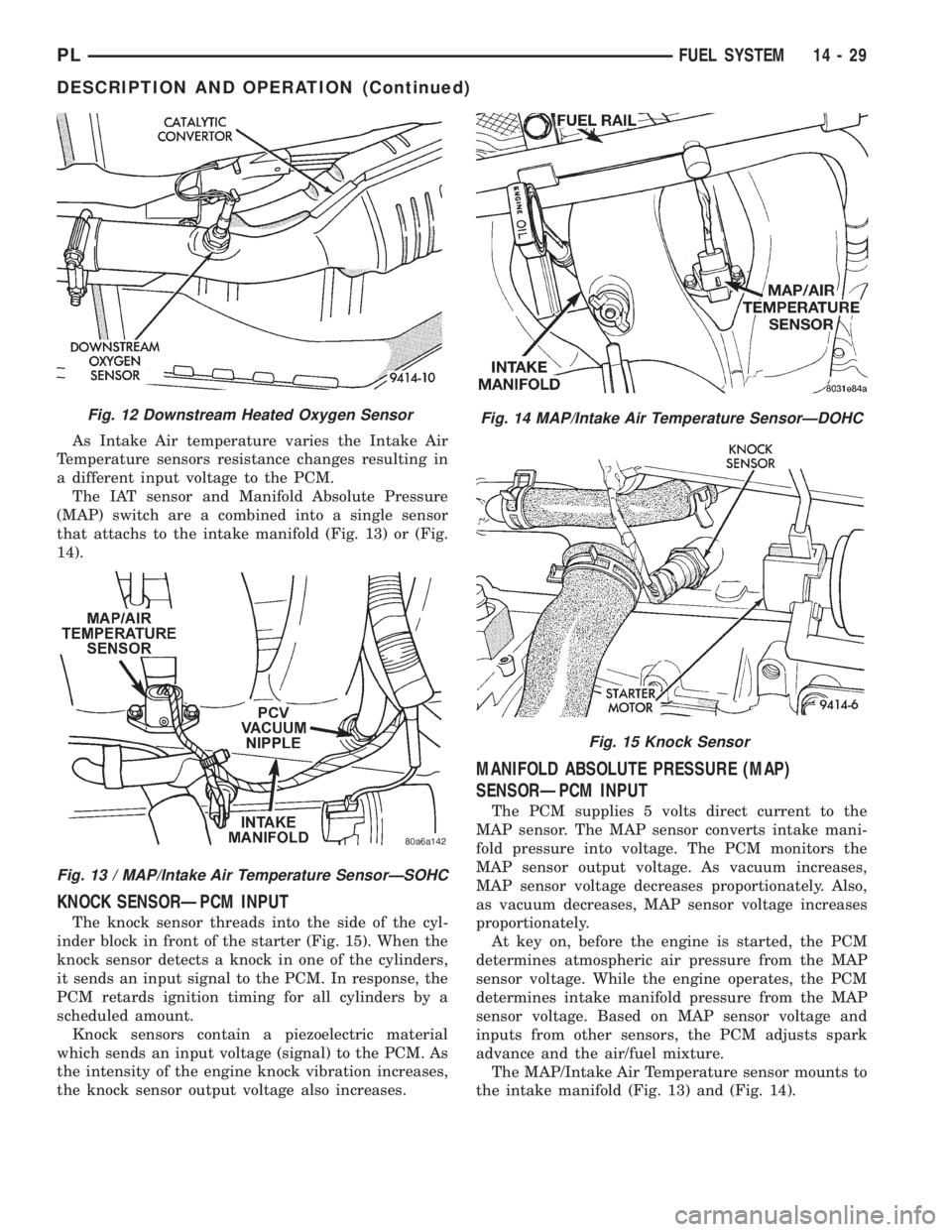

KNOCK SENSORÐPCM INPUT

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 15). When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which sends an input voltage (signal) to the PCM. As

the intensity of the engine knock vibration increases,

the knock sensor output voltage also increases.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The PCM supplies 5 volts direct current to the

MAP sensor. The MAP sensor converts intake mani-

fold pressure into voltage. The PCM monitors the

MAP sensor output voltage. As vacuum increases,

MAP sensor voltage decreases proportionately. Also,

as vacuum decreases, MAP sensor voltage increases

proportionately.

At key on, before the engine is started, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage and

inputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

The MAP/Intake Air Temperature sensor mounts to

the intake manifold (Fig. 13) and (Fig. 14).

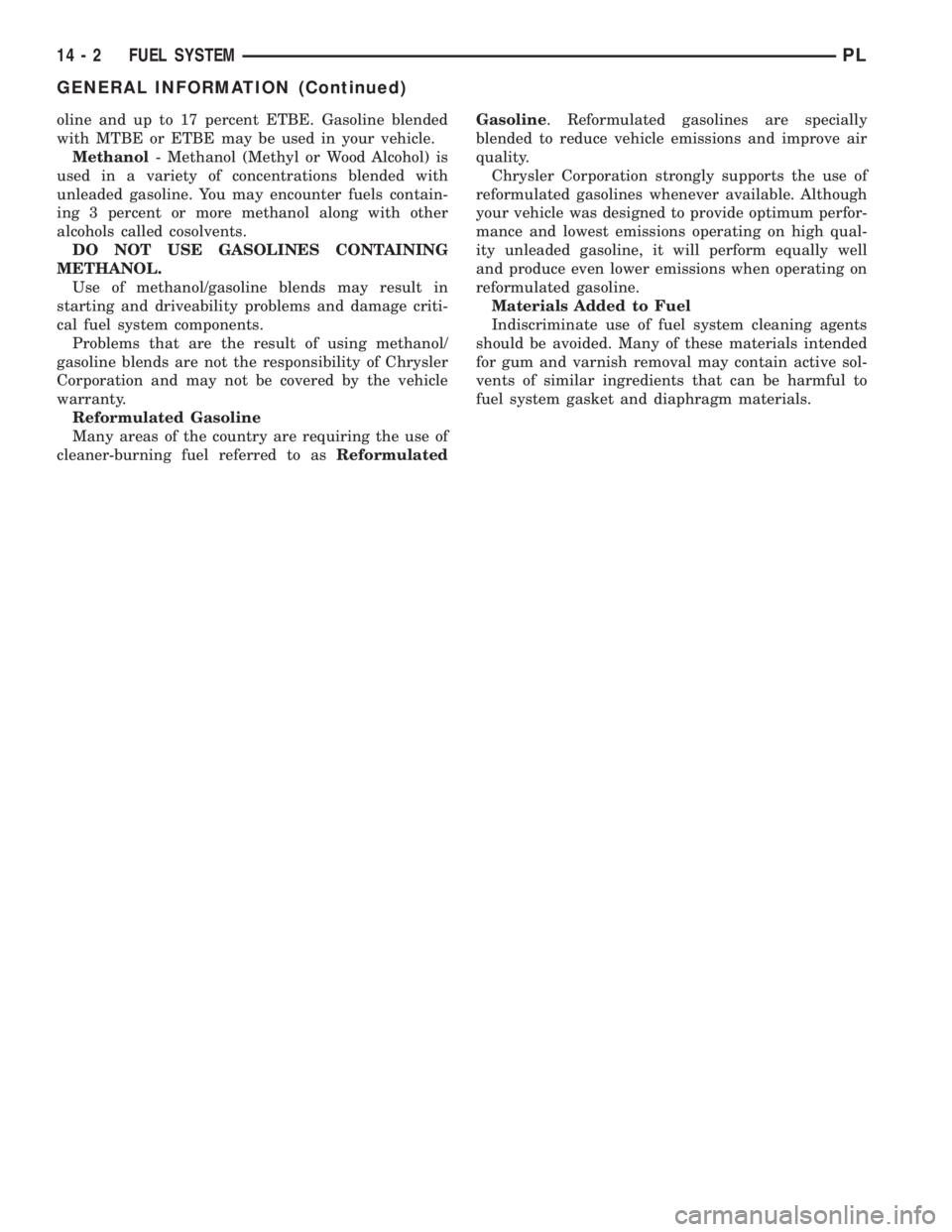

Fig. 12 Downstream Heated Oxygen Sensor

Fig. 13 / MAP/Intake Air Temperature SensorÐSOHC

Fig. 14 MAP/Intake Air Temperature SensorÐDOHC

Fig. 15 Knock Sensor

PLFUEL SYSTEM 14 - 29

DESCRIPTION AND OPERATION (Continued)

Page 876 of 1200

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to Group 25, On-Board

Dianostics.

SOLID STATE FAN RELAYÐPCM OUTPUT

The radiator fan runs when coolant temperature

and A/C system pressure demand cooling. The radia-

tor fan circuit contains a Solid State Fan Relay

(SSFR). Refer to the Group 8W for a circuit sche-

matic.

A 5 volt signal is supplied to the SSFR. The PCM

provides a pulsed ground for the SSFR. Depending

upon the amount of pulse on time, the SSFR puts out

a proportional voltage to the fan motor at the lower

speed. For instance, if the on time is 30 percent, then

the voltage to the fan motor will be 3.6 volts.

When engine coolant reaches approximately 99ÉC

(210ÉF) the PCM grounds the SSFR relay. When the

PCM grounds the relay it operates at a 30% duty

cycle and immediately ramps up to 100% duty cycle.

The PCM de-energizes the SSFR relay when coolant

temperature drops to approximately 93ÉC (199ÉF).

Also, when the air conditioning pressure switch

closes, the PCM grounds the SSFR. The air condi-

tioning switch closes at 285 psi610 psi. When air

conditioning pressure drops approximately 40 psi, the

pressure switch opens and the fan turns off.

The SSFR relay is located on the left front inner

frame just behind the radiator.

SPEED CONTROLÐPCM INPUT

The speed control system provides five separate

voltages (inputs) to the Powertrain Control Module

(PCM). The voltages correspond to the ON/OFF, SET,

RESUME and CANCEL.

The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control OFF voltage tells the PCM that the

speed control system has deactivated. Refer to Group

8H for more speed control information.

SCI RECEIVEÐPCM OUTPUT

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Control Module (PCM) receives data from the DRB

through the SCI Receive circuit.

TACHOMETERÐPCM OUTPUT

The PCM operates the tachometer on the instru-

ment panel. The PCM calculates engine RPM from

the crankshaft position sensor input.

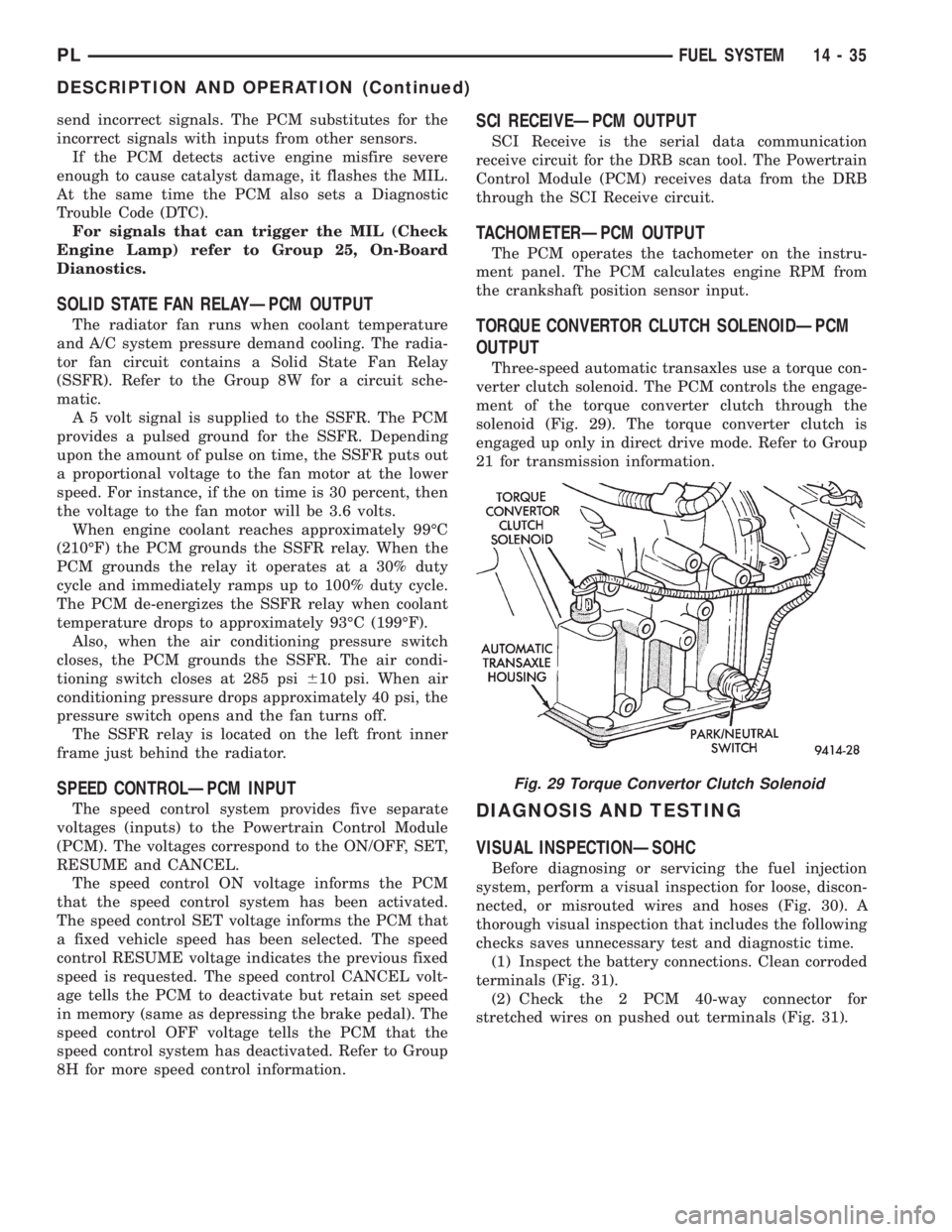

TORQUE CONVERTOR CLUTCH SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a torque con-

verter clutch solenoid. The PCM controls the engage-

ment of the torque converter clutch through the

solenoid (Fig. 29). The torque converter clutch is

engaged up only in direct drive mode. Refer to Group

21 for transmission information.

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐSOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses (Fig. 30). A

thorough visual inspection that includes the following

checks saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals (Fig. 31).

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals (Fig. 31).

Fig. 29 Torque Convertor Clutch Solenoid

PLFUEL SYSTEM 14 - 35

DESCRIPTION AND OPERATION (Continued)

Page 997 of 1200

(3) Move selector lever on transaxle two detents

forward from full rearward position. This is selector

D position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise to the full

counterclockwise position.

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi. as lever is moved counter-

clockwise.

(6) Kickdown release is pressurized only in direct

drive and should be same as line pressure within 3

psi, up to kickdown point.

(7) This tests pump output, pressure regulation,

and condition of rear clutch, front clutch, and

hydraulic circuits.

TEST FOUR (SELECTOR IN REVERSE)

(1) Attach 300 psi gauge to low-reverse port.

(2) Operate engine at 1600 rpm for test.

(3) Move selector lever on transaxle four detents

forward from full rearward position. This is selector

R position.

(4) Low/reverse pressure should read 180 to 220

psi with throttle lever clockwise. Pressure should

gradually increase to 260 to 300 psi. as lever is

moved counterclockwise.

(5) This tests pump output, pressure regulation,

and condition of front clutch and rear servo hydraulic

circuits.

(6) Move selector lever on transaxle to D position

to check that low/reverse pressure drops to zero.

(7) This tests for leakage into rear servo, due to

case porosity, which can cause reverse band burn out.

TEST RESULT INDICATIONS

(1) If proper line pressure, minimum to maximum,

is found in any one test, the pump and pressure reg-

ulator are working properly.

(2) Low pressure in D, 1, and 2 but correct pres-

sure in R, indicates rear clutch circuit leakage.

(3) Low pressure in D and R, but correct pressure

in 1 indicates front clutch circuit leakage.

(4) Low pressure in R and 1, but correct pressure

in 2 indicates rear servo circuit leakage.

(5) Low line pressure in all positions indicates a

defective pump, a clogged filter, or a stuck pressure

regulator valve.

GOVERNOR PRESSURE

Test only if transaxle shifts at wrong vehicle

speeds when throttle cable is correctly adjusted.

(1) Connect a 0-150 psi pressure gauge to governor

pressure take-off point. It is located at lower right

side of case, below differential cover.

(2) Operate transaxle in third gear to read pres-

sures. The governor pressure should respondsmoothly to changes in mph and should return to 0

to 3 psi when vehicle is stopped. High pressure

(above 3 psi) at standstill will prevent the transaxle

from downshifting.

THROTTLE PRESSURE

No gauge port is provided for throttle pressure.

Incorrect throttle pressure should be suspected if

part throttle upshift speeds are either delayed or

occur too early in relation to vehicle speed. Engine

runaway on shifts can also be an indicator of low

throttle pressure setting, or misadjusted throttle

cable.

In no case should throttle pressure be adjusted

until the transaxle throttle cable adjustment has

been verified to be correct.

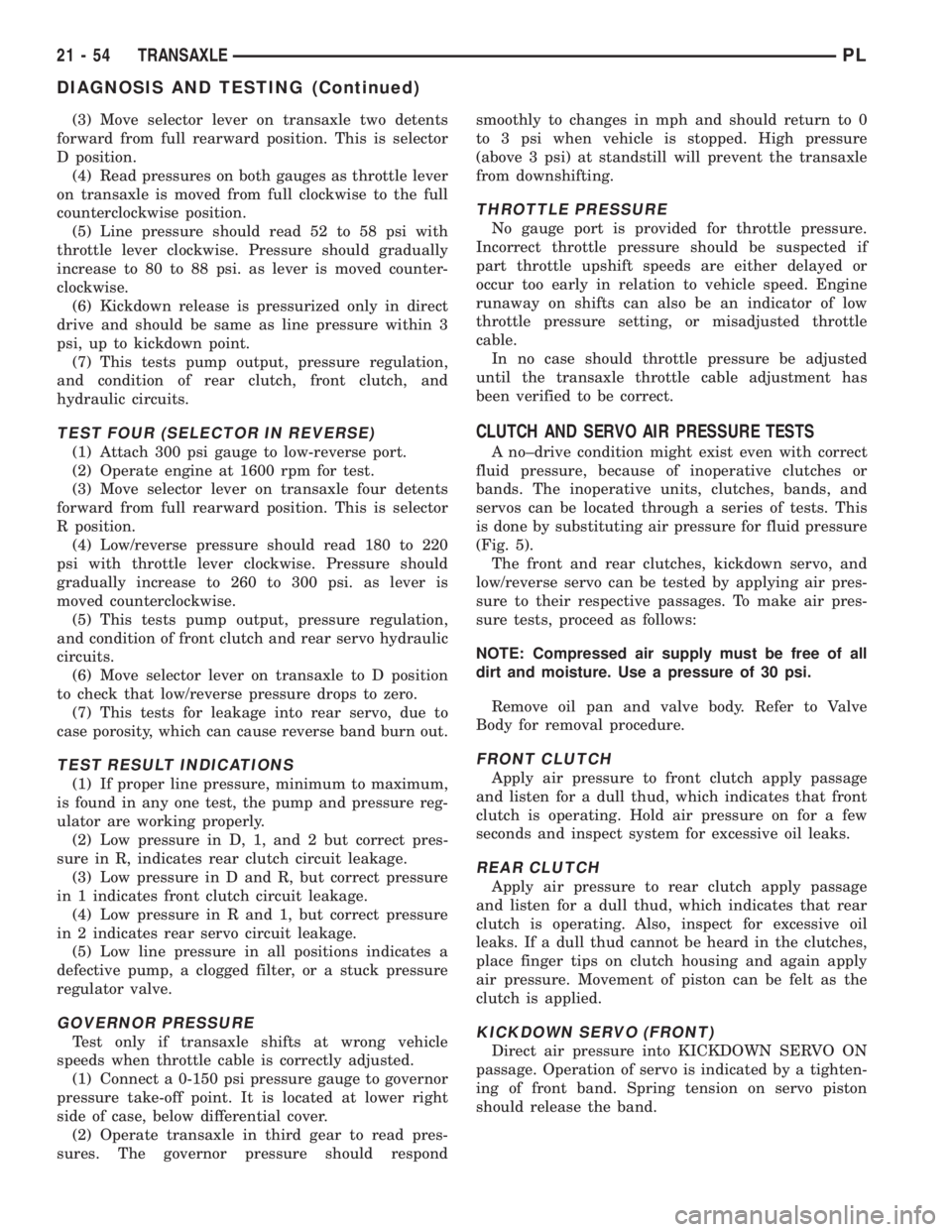

CLUTCH AND SERVO AIR PRESSURE TESTS

A no±drive condition might exist even with correct

fluid pressure, because of inoperative clutches or

bands. The inoperative units, clutches, bands, and

servos can be located through a series of tests. This

is done by substituting air pressure for fluid pressure

(Fig. 5).

The front and rear clutches, kickdown servo, and

low/reverse servo can be tested by applying air pres-

sure to their respective passages. To make air pres-

sure tests, proceed as follows:

NOTE: Compressed air supply must be free of all

dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. Refer to Valve

Body for removal procedure.

FRONT CLUTCH

Apply air pressure to front clutch apply passage

and listen for a dull thud, which indicates that front

clutch is operating. Hold air pressure on for a few

seconds and inspect system for excessive oil leaks.

REAR CLUTCH

Apply air pressure to rear clutch apply passage

and listen for a dull thud, which indicates that rear

clutch is operating. Also, inspect for excessive oil

leaks. If a dull thud cannot be heard in the clutches,

place finger tips on clutch housing and again apply

air pressure. Movement of piston can be felt as the

clutch is applied.

KICKDOWN SERVO (FRONT)

Direct air pressure into KICKDOWN SERVO ON

passage. Operation of servo is indicated by a tighten-

ing of front band. Spring tension on servo piston

should release the band.

21 - 54 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)