ESP DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 119 of 1200

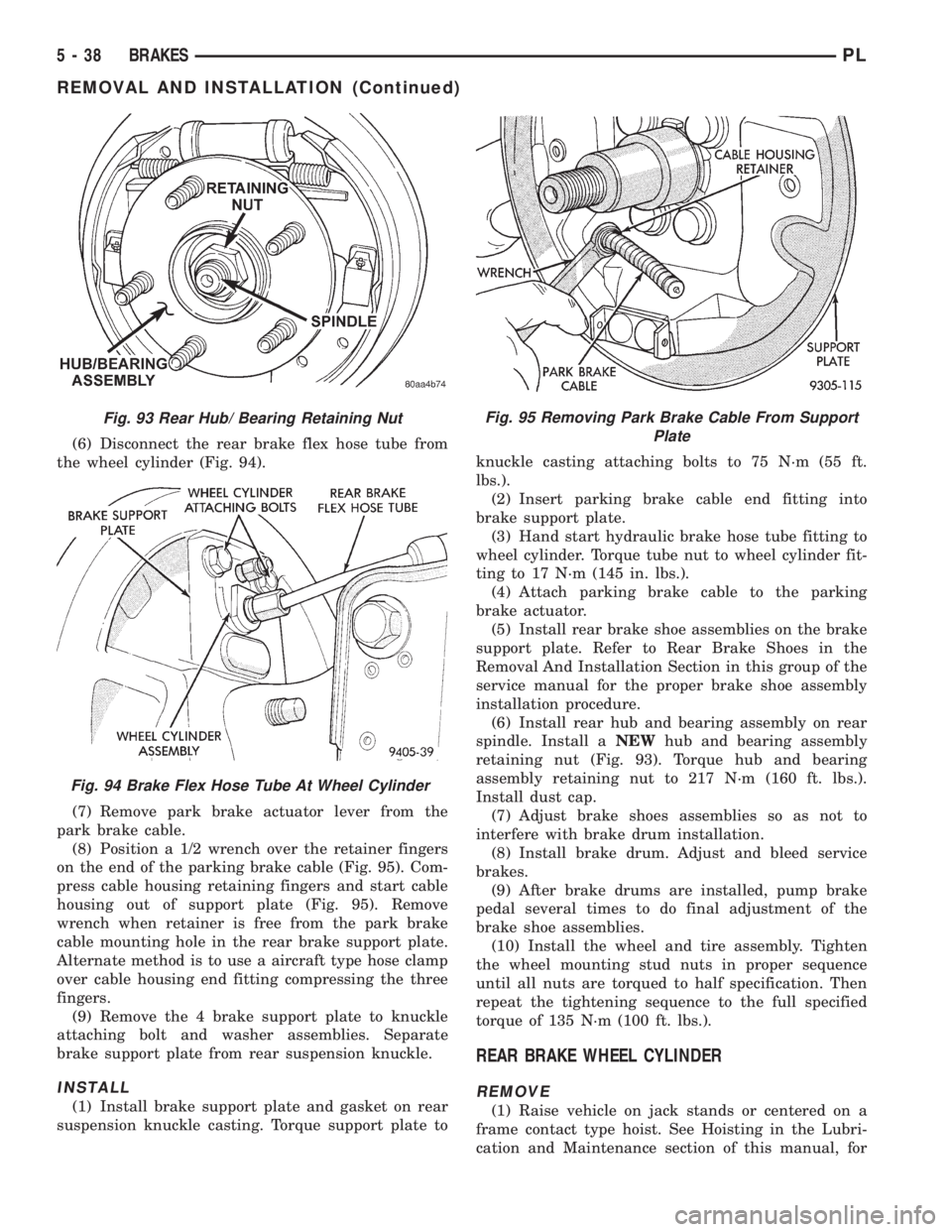

(6) Disconnect the rear brake flex hose tube from

the wheel cylinder (Fig. 94).

(7) Remove park brake actuator lever from the

park brake cable.

(8) Position a 1/2 wrench over the retainer fingers

on the end of the parking brake cable (Fig. 95). Com-

press cable housing retaining fingers and start cable

housing out of support plate (Fig. 95). Remove

wrench when retainer is free from the park brake

cable mounting hole in the rear brake support plate.

Alternate method is to use a aircraft type hose clamp

over cable housing end fitting compressing the three

fingers.

(9) Remove the 4 brake support plate to knuckle

attaching bolt and washer assemblies. Separate

brake support plate from rear suspension knuckle.

INSTALL

(1) Install brake support plate and gasket on rear

suspension knuckle casting. Torque support plate toknuckle casting attaching bolts to 75 N´m (55 ft.

lbs.).

(2) Insert parking brake cable end fitting into

brake support plate.

(3) Hand start hydraulic brake hose tube fitting to

wheel cylinder. Torque tube nut to wheel cylinder fit-

ting to 17 N´m (145 in. lbs.).

(4) Attach parking brake cable to the parking

brake actuator.

(5) Install rear brake shoe assemblies on the brake

support plate. Refer to Rear Brake Shoes in the

Removal And Installation Section in this group of the

service manual for the proper brake shoe assembly

installation procedure.

(6) Install rear hub and bearing assembly on rear

spindle. Install aNEWhub and bearing assembly

retaining nut (Fig. 93). Torque hub and bearing

assembly retaining nut to 217 N´m (160 ft. lbs.).

Install dust cap.

(7) Adjust brake shoes assemblies so as not to

interfere with brake drum installation.

(8) Install brake drum. Adjust and bleed service

brakes.

(9) After brake drums are installed, pump brake

pedal several times to do final adjustment of the

brake shoe assemblies.

(10) Install the wheel and tire assembly. Tighten

the wheel mounting stud nuts in proper sequence

until all nuts are torqued to half specification. Then

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

REAR BRAKE WHEEL CYLINDER

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

Fig. 93 Rear Hub/ Bearing Retaining Nut

Fig. 94 Brake Flex Hose Tube At Wheel Cylinder

Fig. 95 Removing Park Brake Cable From Support

Plate

5 - 38 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 121 of 1200

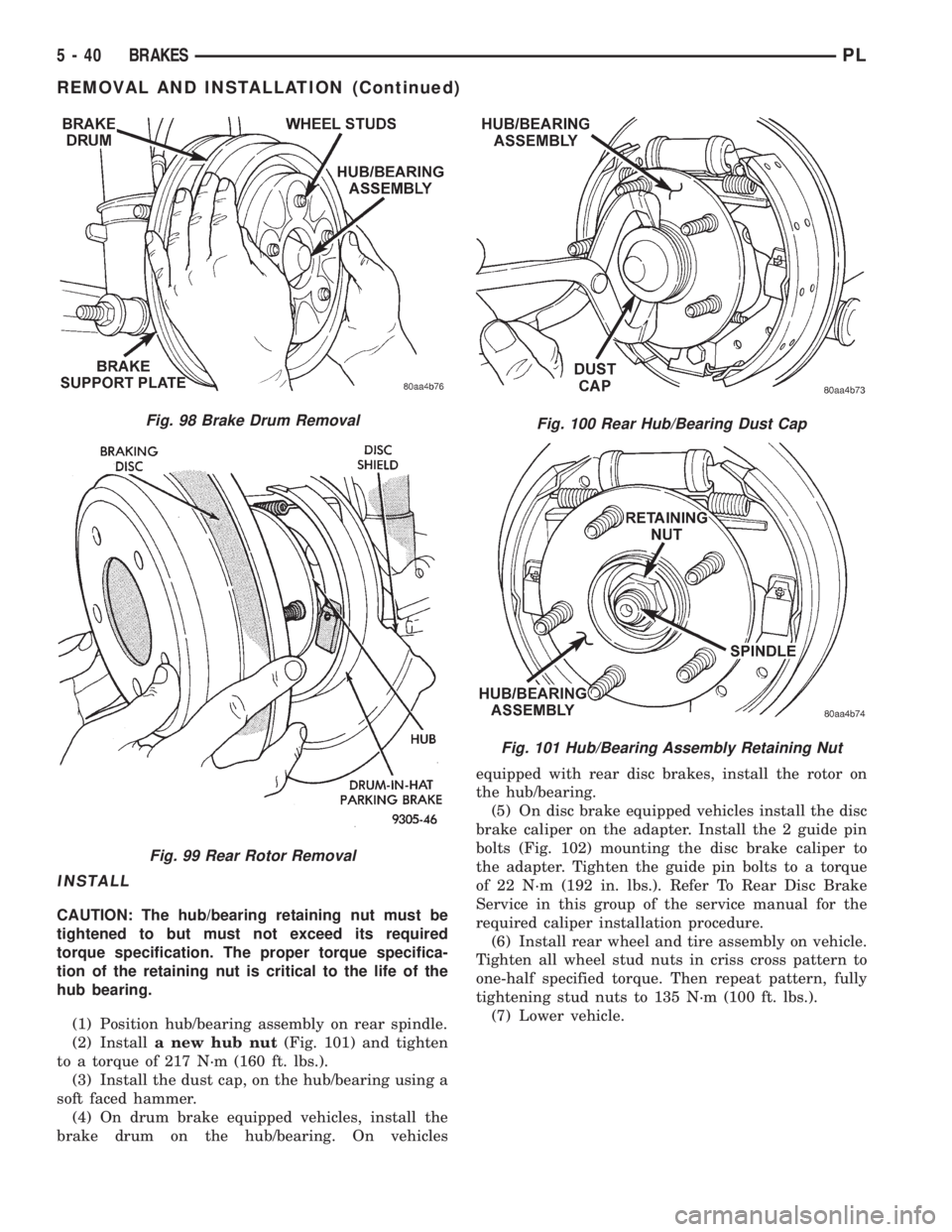

INSTALL

CAUTION: The hub/bearing retaining nut must be

tightened to but must not exceed its required

torque specification. The proper torque specifica-

tion of the retaining nut is critical to the life of the

hub bearing.

(1) Position hub/bearing assembly on rear spindle.

(2) Installa new hub nut(Fig. 101) and tighten

to a torque of 217 N´m (160 ft. lbs.).

(3) Install the dust cap, on the hub/bearing using a

soft faced hammer.

(4) On drum brake equipped vehicles, install the

brake drum on the hub/bearing. On vehiclesequipped with rear disc brakes, install the rotor on

the hub/bearing.

(5) On disc brake equipped vehicles install the disc

brake caliper on the adapter. Install the 2 guide pin

bolts (Fig. 102) mounting the disc brake caliper to

the adapter. Tighten the guide pin bolts to a torque

of 22 N´m (192 in. lbs.). Refer To Rear Disc Brake

Service in this group of the service manual for the

required caliper installation procedure.

(6) Install rear wheel and tire assembly on vehicle.

Tighten all wheel stud nuts in criss cross pattern to

one-half specified torque. Then repeat pattern, fully

tightening stud nuts to 135 N´m (100 ft. lbs.).

(7) Lower vehicle.

Fig. 98 Brake Drum Removal

Fig. 99 Rear Rotor Removal

Fig. 100 Rear Hub/Bearing Dust Cap

Fig. 101 Hub/Bearing Assembly Retaining Nut

5 - 40 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 123 of 1200

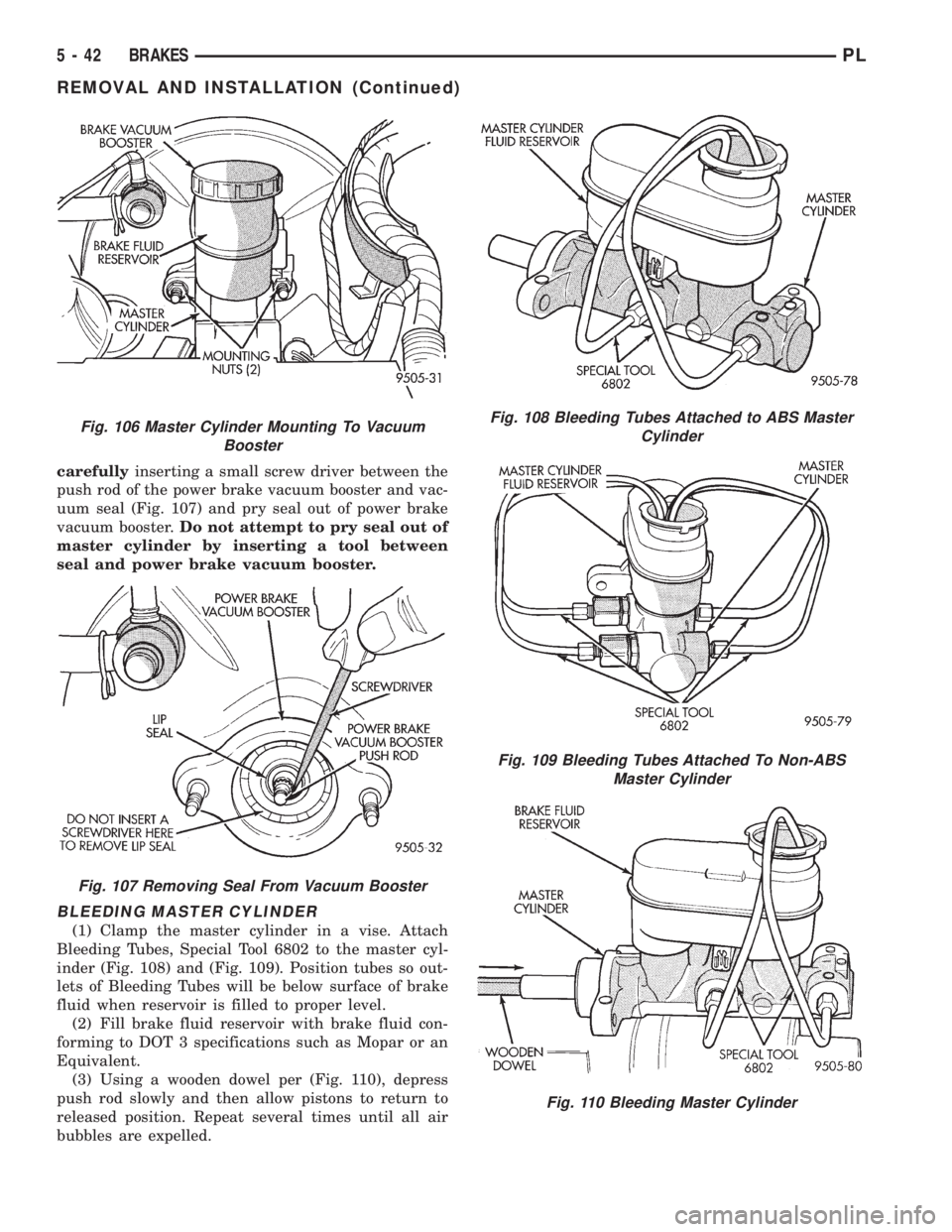

carefullyinserting a small screw driver between the

push rod of the power brake vacuum booster and vac-

uum seal (Fig. 107) and pry seal out of power brake

vacuum booster.Do not attempt to pry seal out of

master cylinder by inserting a tool between

seal and power brake vacuum booster.

BLEEDING MASTER CYLINDER

(1) Clamp the master cylinder in a vise. Attach

Bleeding Tubes, Special Tool 6802 to the master cyl-

inder (Fig. 108) and (Fig. 109). Position tubes so out-

lets of Bleeding Tubes will be below surface of brake

fluid when reservoir is filled to proper level.

(2) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(3) Using a wooden dowel per (Fig. 110), depress

push rod slowly and then allow pistons to return to

released position. Repeat several times until all air

bubbles are expelled.

Fig. 106 Master Cylinder Mounting To Vacuum

Booster

Fig. 107 Removing Seal From Vacuum Booster

Fig. 108 Bleeding Tubes Attached to ABS Master

Cylinder

Fig. 109 Bleeding Tubes Attached To Non-ABS

Master Cylinder

Fig. 110 Bleeding Master Cylinder

5 - 42 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 125 of 1200

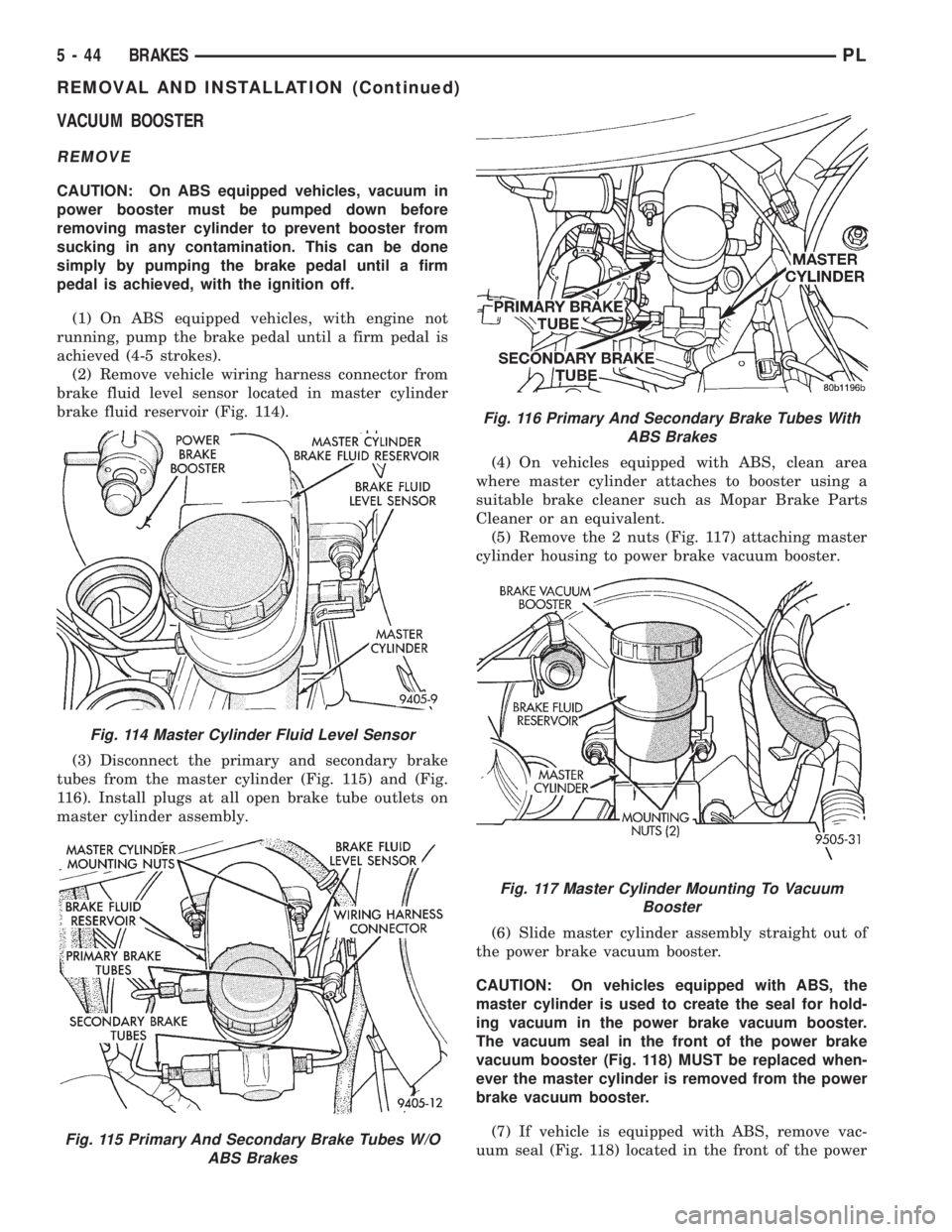

VACUUM BOOSTER

REMOVE

CAUTION: On ABS equipped vehicles, vacuum in

power booster must be pumped down before

removing master cylinder to prevent booster from

sucking in any contamination. This can be done

simply by pumping the brake pedal until a firm

pedal is achieved, with the ignition off.

(1) On ABS equipped vehicles, with engine not

running, pump the brake pedal until a firm pedal is

achieved (4-5 strokes).

(2) Remove vehicle wiring harness connector from

brake fluid level sensor located in master cylinder

brake fluid reservoir (Fig. 114).

(3) Disconnect the primary and secondary brake

tubes from the master cylinder (Fig. 115) and (Fig.

116). Install plugs at all open brake tube outlets on

master cylinder assembly.(4) On vehicles equipped with ABS, clean area

where master cylinder attaches to booster using a

suitable brake cleaner such as Mopar Brake Parts

Cleaner or an equivalent.

(5) Remove the 2 nuts (Fig. 117) attaching master

cylinder housing to power brake vacuum booster.

(6) Slide master cylinder assembly straight out of

the power brake vacuum booster.

CAUTION: On vehicles equipped with ABS, the

master cylinder is used to create the seal for hold-

ing vacuum in the power brake vacuum booster.

The vacuum seal in the front of the power brake

vacuum booster (Fig. 118) MUST be replaced when-

ever the master cylinder is removed from the power

brake vacuum booster.

(7) If vehicle is equipped with ABS, remove vac-

uum seal (Fig. 118) located in the front of the power

Fig. 114 Master Cylinder Fluid Level Sensor

Fig. 115 Primary And Secondary Brake Tubes W/O

ABS Brakes

Fig. 116 Primary And Secondary Brake Tubes With

ABS Brakes

Fig. 117 Master Cylinder Mounting To Vacuum

Booster

5 - 44 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 127 of 1200

INSTALL

(1) Position power brake booster onto dash panel.

(2) Install and torque the 4 power brake vacuum

booster mounting nuts (Fig. 121) to 29 N´m (250 in.

lbs.) torque.

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake vacuum booster input rod.

(4) Connect power brake vacuum booster input rod

to brake pedal pin and install a NEW retaining clip.

Use only a new retainer clip DO NOT USE the

old clip.

(5) Connect all previously removed vacuum hoses

onto power brake vacuum booster check valve (Fig.

119).

(6) If vehicle is equipped with ABS, install HCU.

Refer to Antilock Brake System Hydraulic Control

Unit in the Removal And Installation Section of the

Antilock Brake System Section of this service manual

for the required procedure.

CAUTION: When replacing the power brake vac-

uum booster on a vehicle equipped with ABS, a

NEW vacuum seal MUST be installed in the power

brake vacuum booster. Use only the procedure

detailed below for installing vacuum seal into power

brake vacuum booster. If old vacuum seal came out

with master cylinder when it was removed from

power brake vacuum booster, be sure it is removed

from master cylinder before attempting to install

master cylinder into power brake vacuum booster.

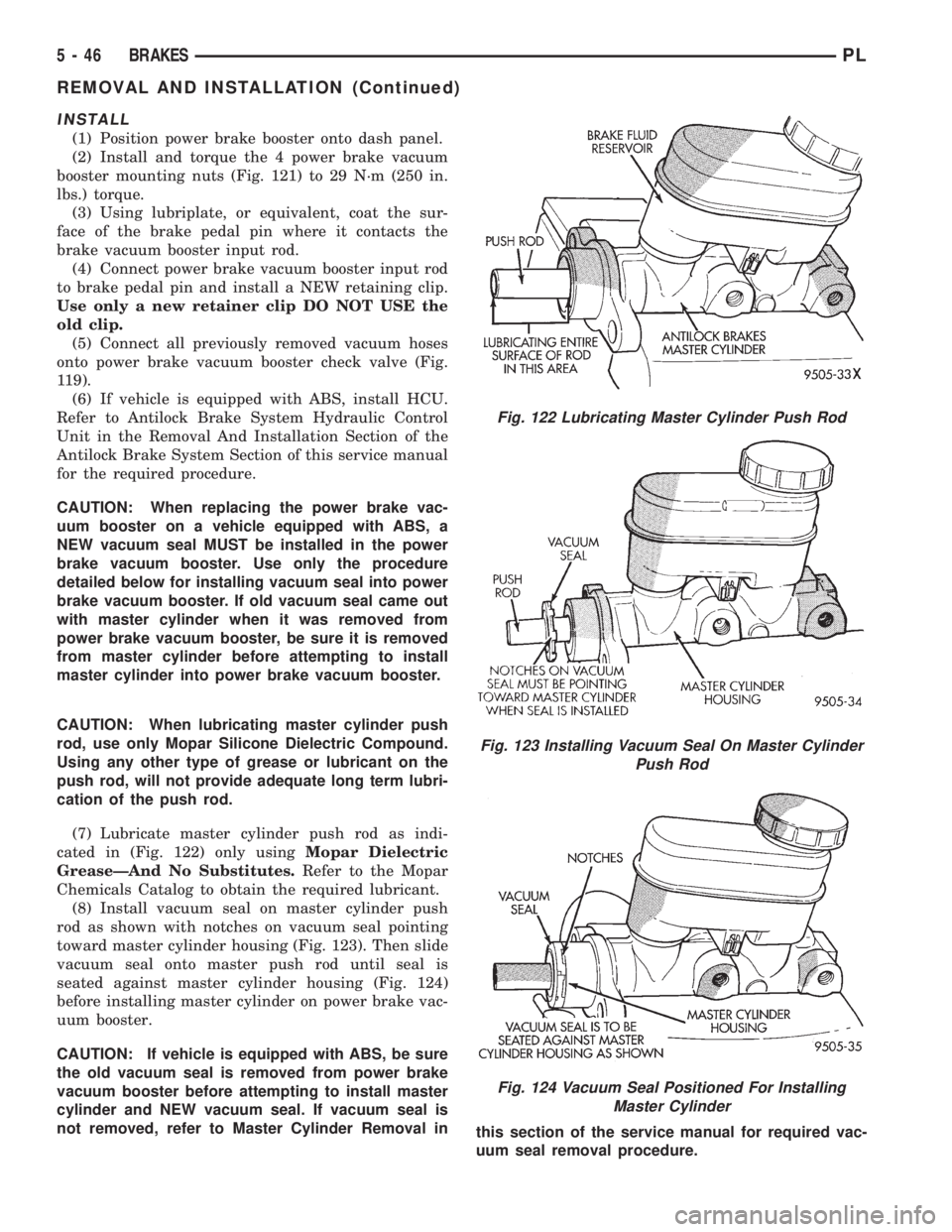

CAUTION: When lubricating master cylinder push

rod, use only Mopar Silicone Dielectric Compound.

Using any other type of grease or lubricant on the

push rod, will not provide adequate long term lubri-

cation of the push rod.

(7) Lubricate master cylinder push rod as indi-

cated in (Fig. 122) only usingMopar Dielectric

GreaseÐAnd No Substitutes.Refer to the Mopar

Chemicals Catalog to obtain the required lubricant.

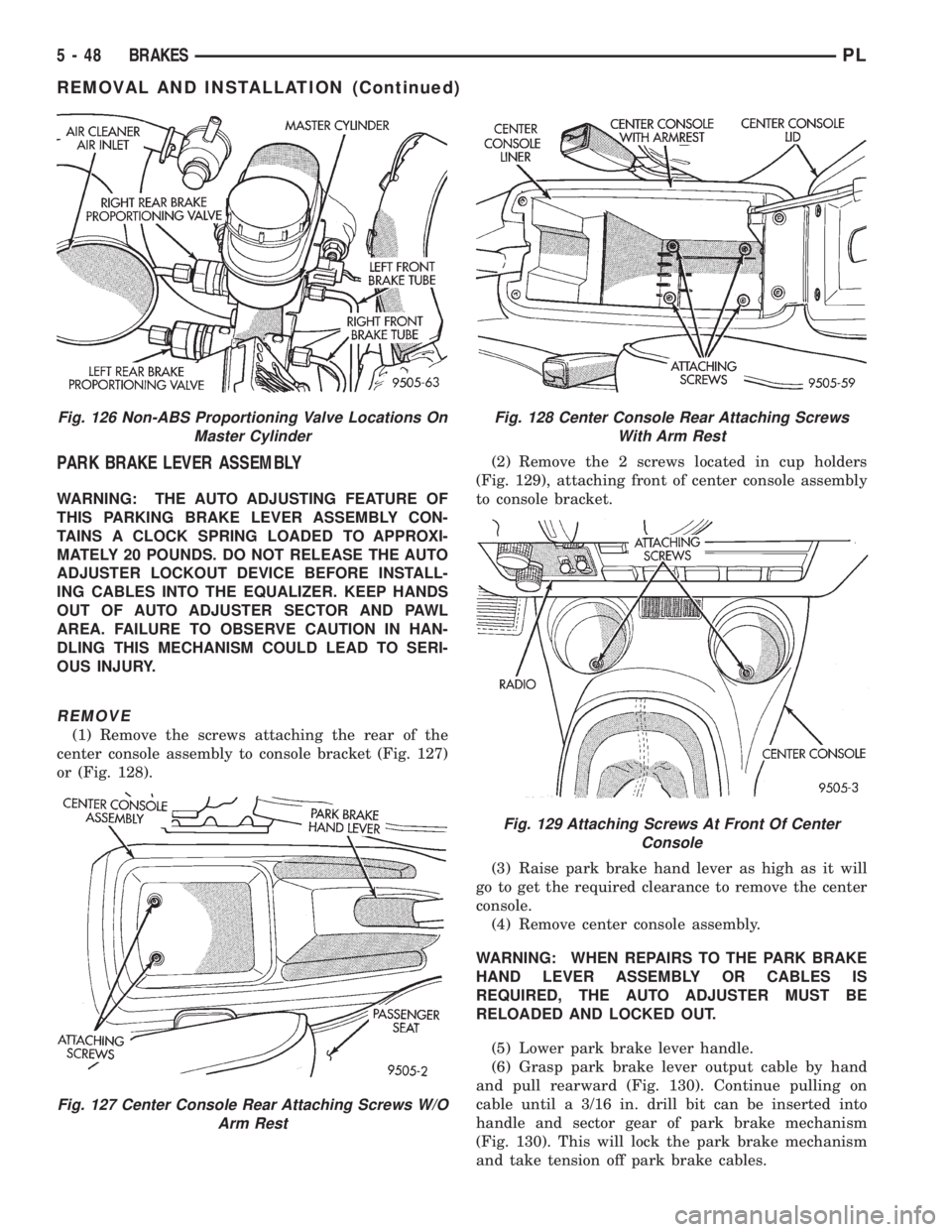

(8) Install vacuum seal on master cylinder push

rod as shown with notches on vacuum seal pointing

toward master cylinder housing (Fig. 123). Then slide

vacuum seal onto master push rod until seal is

seated against master cylinder housing (Fig. 124)

before installing master cylinder on power brake vac-

uum booster.

CAUTION: If vehicle is equipped with ABS, be sure

the old vacuum seal is removed from power brake

vacuum booster before attempting to install master

cylinder and NEW vacuum seal. If vacuum seal is

not removed, refer to Master Cylinder Removal in

this section of the service manual for required vac-

uum seal removal procedure.

Fig. 122 Lubricating Master Cylinder Push Rod

Fig. 123 Installing Vacuum Seal On Master Cylinder

Push Rod

Fig. 124 Vacuum Seal Positioned For Installing

Master Cylinder

5 - 46 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 129 of 1200

PARK BRAKE LEVER ASSEMBLY

WARNING: THE AUTO ADJUSTING FEATURE OF

THIS PARKING BRAKE LEVER ASSEMBLY CON-

TAINS A CLOCK SPRING LOADED TO APPROXI-

MATELY 20 POUNDS. DO NOT RELEASE THE AUTO

ADJUSTER LOCKOUT DEVICE BEFORE INSTALL-

ING CABLES INTO THE EQUALIZER. KEEP HANDS

OUT OF AUTO ADJUSTER SECTOR AND PAWL

AREA. FAILURE TO OBSERVE CAUTION IN HAN-

DLING THIS MECHANISM COULD LEAD TO SERI-

OUS INJURY.

REMOVE

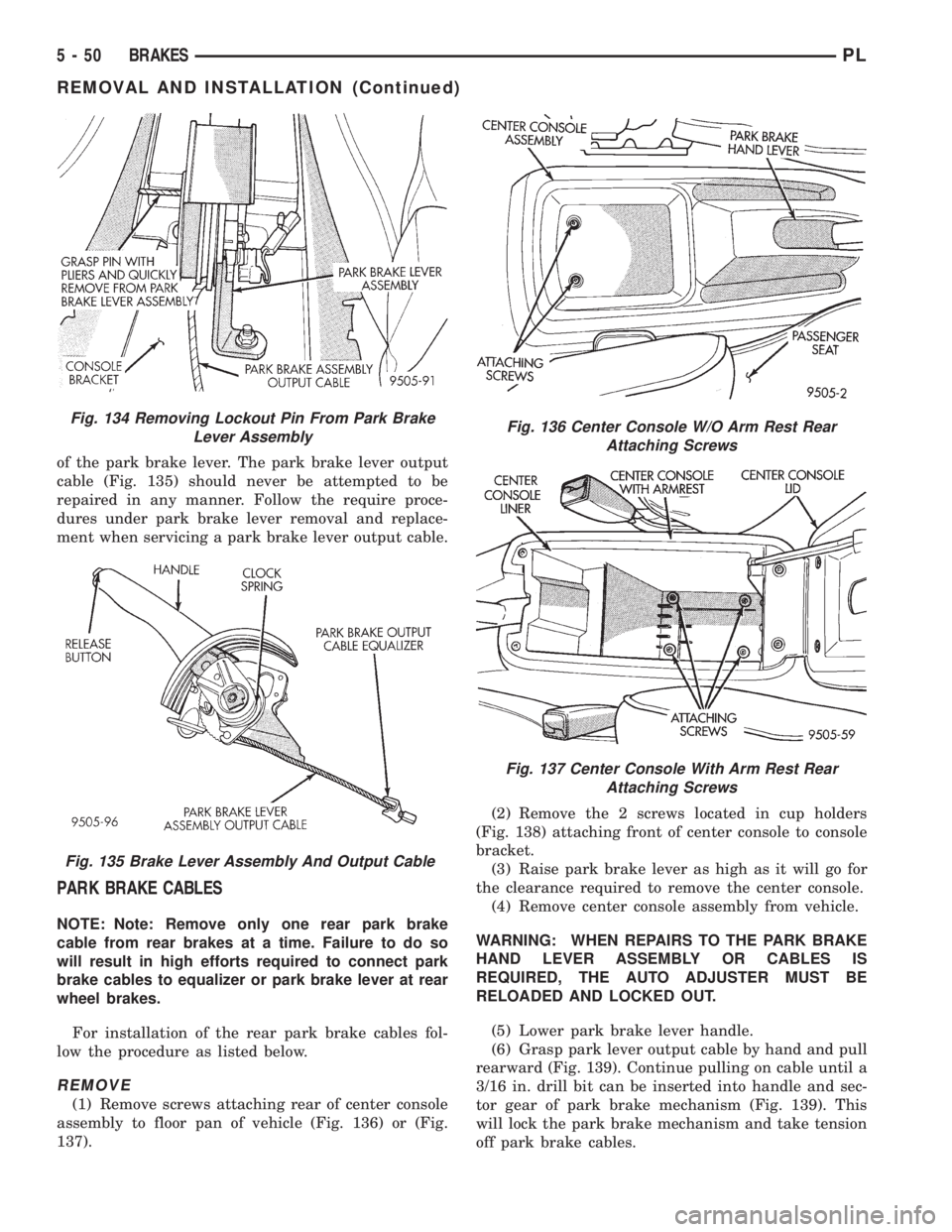

(1) Remove the screws attaching the rear of the

center console assembly to console bracket (Fig. 127)

or (Fig. 128).(2) Remove the 2 screws located in cup holders

(Fig. 129), attaching front of center console assembly

to console bracket.

(3) Raise park brake hand lever as high as it will

go to get the required clearance to remove the center

console.

(4) Remove center console assembly.

WARNING: WHEN REPAIRS TO THE PARK BRAKE

HAND LEVER ASSEMBLY OR CABLES IS

REQUIRED, THE AUTO ADJUSTER MUST BE

RELOADED AND LOCKED OUT.

(5) Lower park brake lever handle.

(6) Grasp park brake lever output cable by hand

and pull rearward (Fig. 130). Continue pulling on

cable until a 3/16 in. drill bit can be inserted into

handle and sector gear of park brake mechanism

(Fig. 130). This will lock the park brake mechanism

and take tension off park brake cables.

Fig. 126 Non-ABS Proportioning Valve Locations On

Master Cylinder

Fig. 127 Center Console Rear Attaching Screws W/O

Arm Rest

Fig. 128 Center Console Rear Attaching Screws

With Arm Rest

Fig. 129 Attaching Screws At Front Of Center

Console

5 - 48 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 131 of 1200

of the park brake lever. The park brake lever output

cable (Fig. 135) should never be attempted to be

repaired in any manner. Follow the require proce-

dures under park brake lever removal and replace-

ment when servicing a park brake lever output cable.

PARK BRAKE CABLES

NOTE: Note: Remove only one rear park brake

cable from rear brakes at a time. Failure to do so

will result in high efforts required to connect park

brake cables to equalizer or park brake lever at rear

wheel brakes.

For installation of the rear park brake cables fol-

low the procedure as listed below.

REMOVE

(1) Remove screws attaching rear of center console

assembly to floor pan of vehicle (Fig. 136) or (Fig.

137).(2) Remove the 2 screws located in cup holders

(Fig. 138) attaching front of center console to console

bracket.

(3) Raise park brake lever as high as it will go for

the clearance required to remove the center console.

(4) Remove center console assembly from vehicle.

WARNING: WHEN REPAIRS TO THE PARK BRAKE

HAND LEVER ASSEMBLY OR CABLES IS

REQUIRED, THE AUTO ADJUSTER MUST BE

RELOADED AND LOCKED OUT.

(5) Lower park brake lever handle.

(6) Grasp park lever output cable by hand and pull

rearward (Fig. 139). Continue pulling on cable until a

3/16 in. drill bit can be inserted into handle and sec-

tor gear of park brake mechanism (Fig. 139). This

will lock the park brake mechanism and take tension

off park brake cables.

Fig. 134 Removing Lockout Pin From Park Brake

Lever Assembly

Fig. 135 Brake Lever Assembly And Output Cable

Fig. 136 Center Console W/O Arm Rest Rear

Attaching Screws

Fig. 137 Center Console With Arm Rest Rear

Attaching Screws

5 - 50 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 133 of 1200

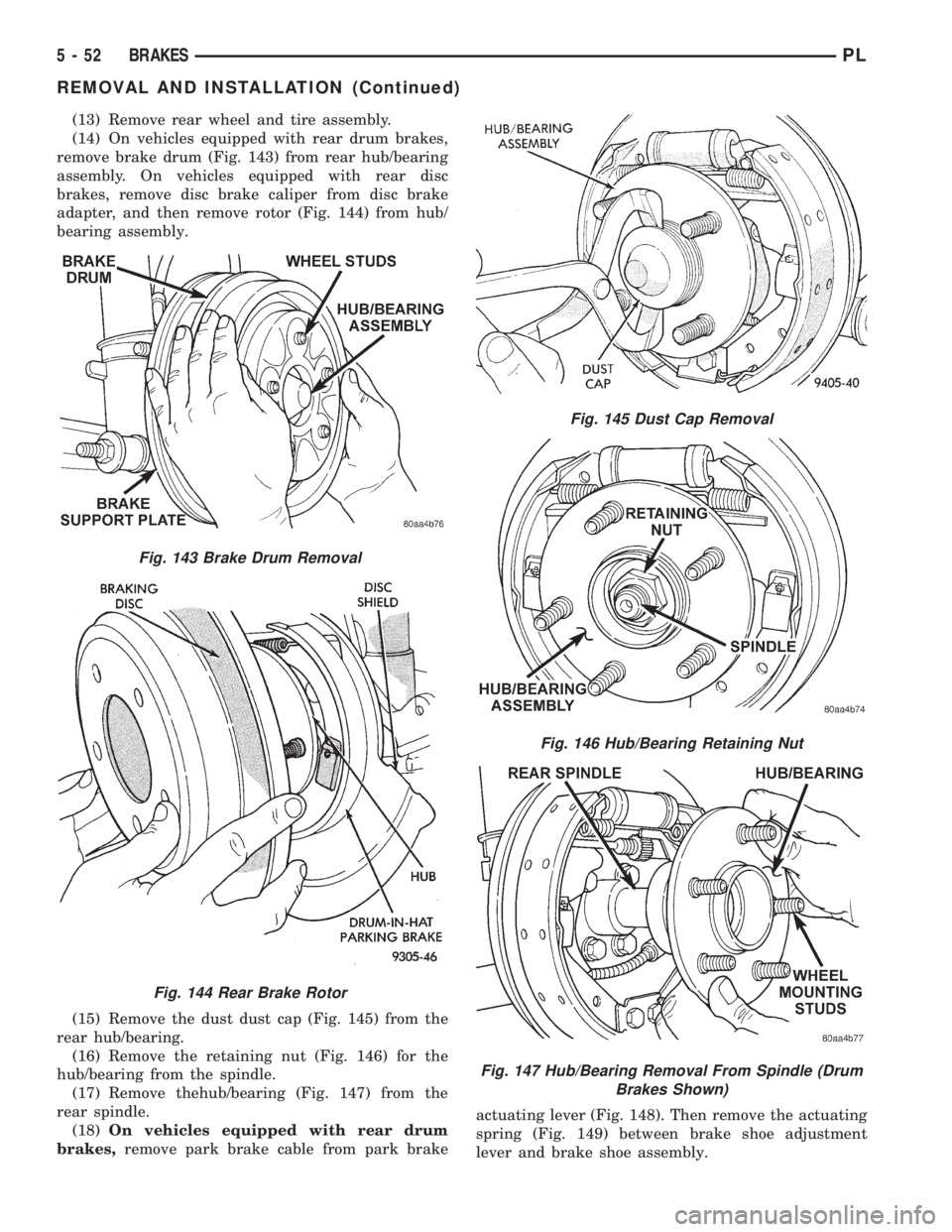

(13) Remove rear wheel and tire assembly.

(14) On vehicles equipped with rear drum brakes,

remove brake drum (Fig. 143) from rear hub/bearing

assembly. On vehicles equipped with rear disc

brakes, remove disc brake caliper from disc brake

adapter, and then remove rotor (Fig. 144) from hub/

bearing assembly.

(15) Remove the dust dust cap (Fig. 145) from the

rear hub/bearing.

(16) Remove the retaining nut (Fig. 146) for the

hub/bearing from the spindle.

(17) Remove thehub/bearing (Fig. 147) from the

rear spindle.

(18)On vehicles equipped with rear drum

brakes,remove park brake cable from park brakeactuating lever (Fig. 148). Then remove the actuating

spring (Fig. 149) between brake shoe adjustment

lever and brake shoe assembly.

Fig. 143 Brake Drum Removal

Fig. 144 Rear Brake Rotor

Fig. 145 Dust Cap Removal

Fig. 146 Hub/Bearing Retaining Nut

Fig. 147 Hub/Bearing Removal From Spindle (Drum

Brakes Shown)

5 - 52 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 135 of 1200

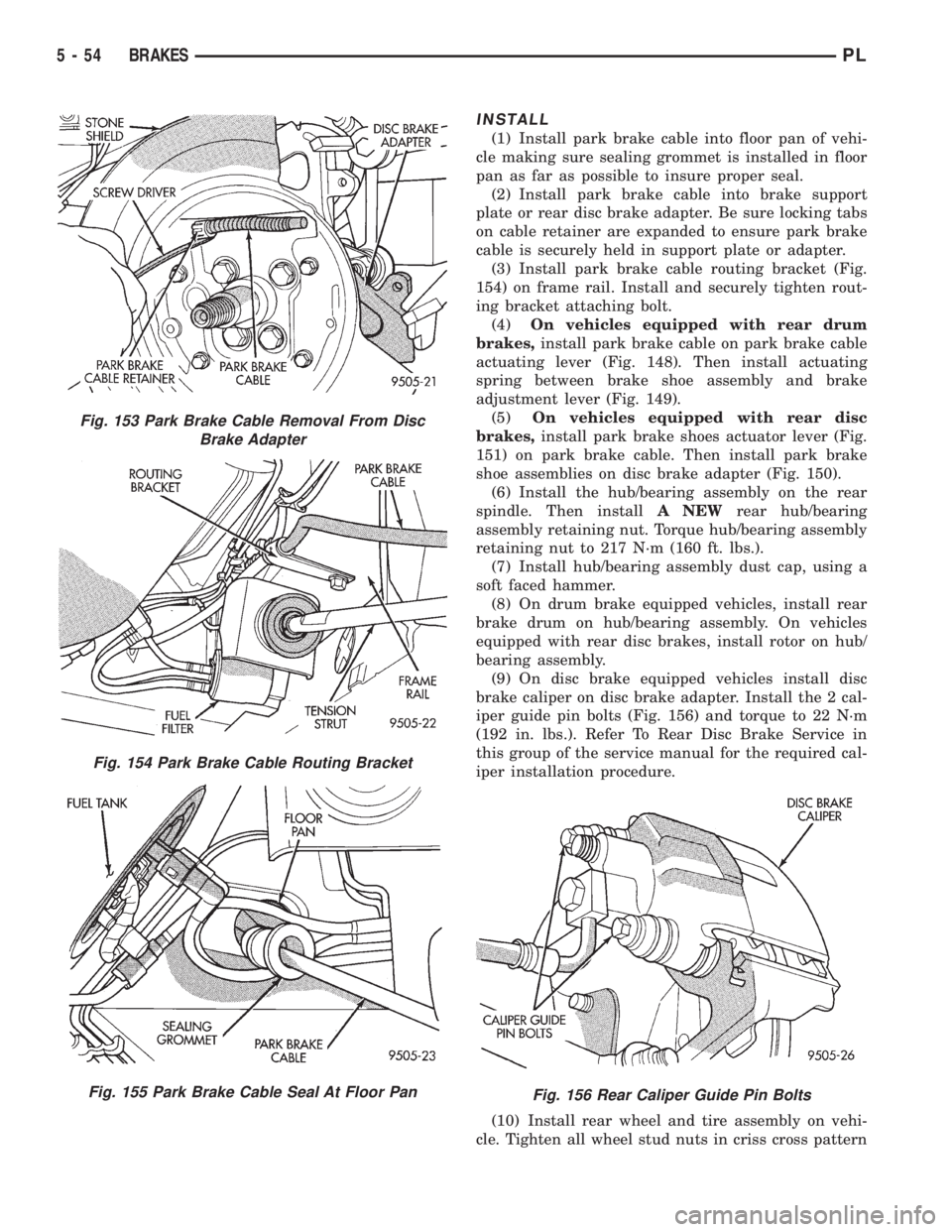

INSTALL

(1) Install park brake cable into floor pan of vehi-

cle making sure sealing grommet is installed in floor

pan as far as possible to insure proper seal.

(2) Install park brake cable into brake support

plate or rear disc brake adapter. Be sure locking tabs

on cable retainer are expanded to ensure park brake

cable is securely held in support plate or adapter.

(3) Install park brake cable routing bracket (Fig.

154) on frame rail. Install and securely tighten rout-

ing bracket attaching bolt.

(4)On vehicles equipped with rear drum

brakes,install park brake cable on park brake cable

actuating lever (Fig. 148). Then install actuating

spring between brake shoe assembly and brake

adjustment lever (Fig. 149).

(5)On vehicles equipped with rear disc

brakes,install park brake shoes actuator lever (Fig.

151) on park brake cable. Then install park brake

shoe assemblies on disc brake adapter (Fig. 150).

(6) Install the hub/bearing assembly on the rear

spindle. Then installA NEWrear hub/bearing

assembly retaining nut. Torque hub/bearing assembly

retaining nut to 217 N´m (160 ft. lbs.).

(7) Install hub/bearing assembly dust cap, using a

soft faced hammer.

(8) On drum brake equipped vehicles, install rear

brake drum on hub/bearing assembly. On vehicles

equipped with rear disc brakes, install rotor on hub/

bearing assembly.

(9) On disc brake equipped vehicles install disc

brake caliper on disc brake adapter. Install the 2 cal-

iper guide pin bolts (Fig. 156) and torque to 22 N´m

(192 in. lbs.). Refer To Rear Disc Brake Service in

this group of the service manual for the required cal-

iper installation procedure.

(10) Install rear wheel and tire assembly on vehi-

cle. Tighten all wheel stud nuts in criss cross pattern

Fig. 153 Park Brake Cable Removal From Disc

Brake Adapter

Fig. 154 Park Brake Cable Routing Bracket

Fig. 155 Park Brake Cable Seal At Floor PanFig. 156 Rear Caliper Guide Pin Bolts

5 - 54 BRAKESPL

Page 137 of 1200

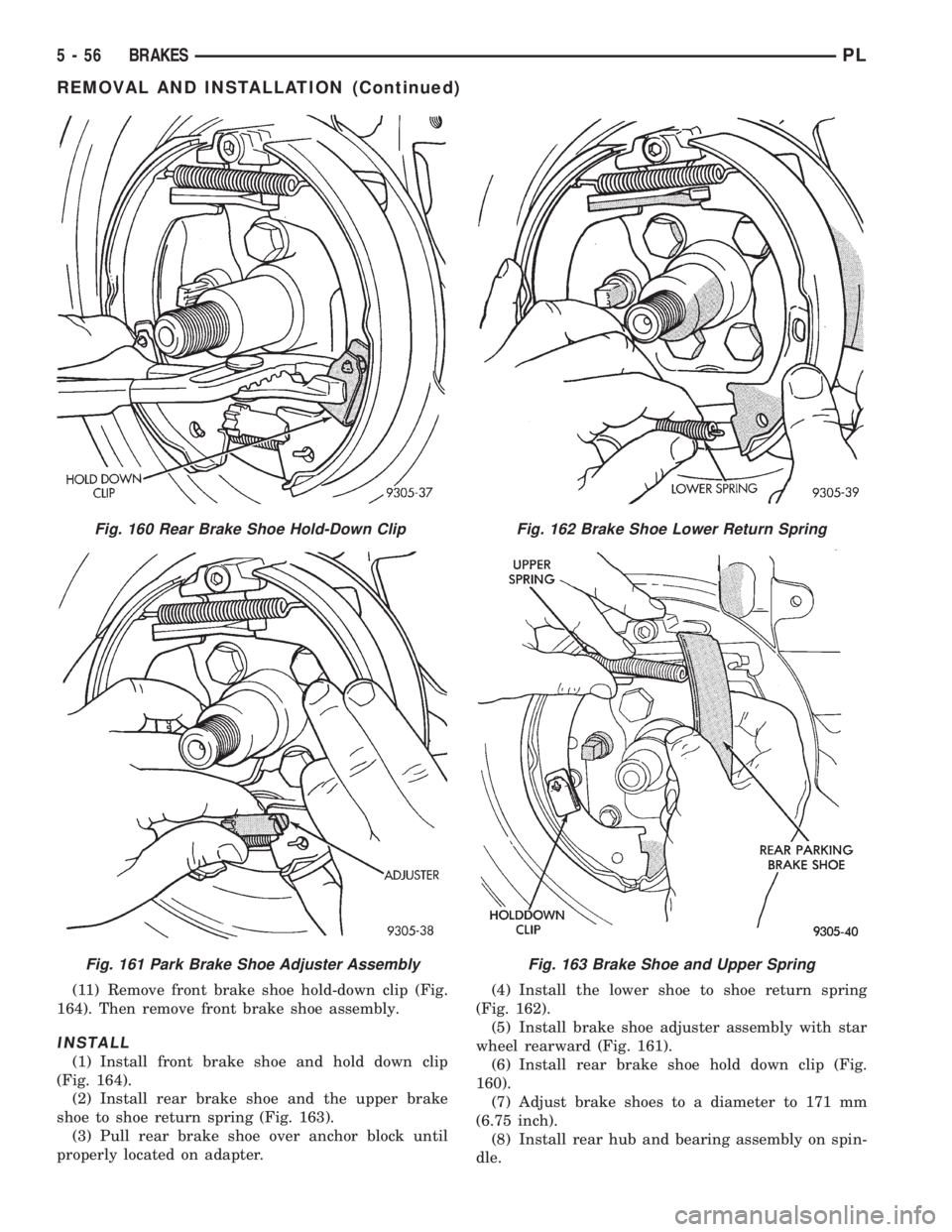

(11) Remove front brake shoe hold-down clip (Fig.

164). Then remove front brake shoe assembly.

INSTALL

(1) Install front brake shoe and hold down clip

(Fig. 164).

(2) Install rear brake shoe and the upper brake

shoe to shoe return spring (Fig. 163).

(3) Pull rear brake shoe over anchor block until

properly located on adapter.(4) Install the lower shoe to shoe return spring

(Fig. 162).

(5) Install brake shoe adjuster assembly with star

wheel rearward (Fig. 161).

(6) Install rear brake shoe hold down clip (Fig.

160).

(7) Adjust brake shoes to a diameter to 171 mm

(6.75 inch).

(8) Install rear hub and bearing assembly on spin-

dle.

Fig. 160 Rear Brake Shoe Hold-Down Clip

Fig. 161 Park Brake Shoe Adjuster Assembly

Fig. 162 Brake Shoe Lower Return Spring

Fig. 163 Brake Shoe and Upper Spring

5 - 56 BRAKESPL

REMOVAL AND INSTALLATION (Continued)