brake fluid DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 4 of 1200

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to. Use the schedule that best

describes these conditions.

Schedule ±A, lists maintenance recommended for

vehicles used for general transportation.

Schedule ±B, lists maintenance recommended for

vehicles used under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Frequent trailer towing

²Extensive idling

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90ÉF (32ÉC)

Where time and mileage are listed, follow the

interval that occurs first.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery, clean, and tighten terminals as

required.

²Check fluid levels of coolant reservoir, power

steering and automatic transmission and add as

required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on schedule ± B (6,000 miles).

²Check coolant level, hoses and clamps.

²Check the manual transaxle fluid level.

²If the mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Replace engine oil filter.

²Lubricate front suspension ball joints.

²Adjust drive belt tension.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 5 of 1200

²Replace air cleaner element.

²Replace spark plugs.

²Change automatic transmission fluid.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil.

45,000 Miles (72 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

²Inspect front brake pads and rear brake linings.

²Adjust drive belt tension.

²Flush and replace engine coolant at 36 months,

regardless of mileage.

52,500 Miles (84 000 km) or at 42 months

²Change engine oil.

²Flush and replace engine coolant if not done at

36 months.

60,000 Miles (96 000 km) or at 48 months

²Change engine oil.

²Replace engine oil filter.

²Check and replace, if necessary***, the PCV

valve.**

²Lubricate front suspension upper ball joints.

²Replace drive belts.

²Replace air cleaner element.

²Replace ignition cables.

²Replace spark plugs.

²Change automatic transmission fluid.

67,500 Miles (108 000 km) or at 54 months

²Change engine oil.

²Inspect front brake pads and rear brake linings.

75,000 Miles (120 000 km) or at 60 months

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

82,500 Miles (132 000 km) or at 66 months

²Change engine oil.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

90,000 Miles (144 000 km) or at 72 months

²Change engine oil.

²Replace engine oil filter.

²Check and replace, if necessary***, the PCV

valve.**

²Lubricate front suspension upper ball joints.

²Inspect front brake pads and rear brake linings.²Adjust drive belt tension.

²Replace air cleaner air cleaner element.

²Replace spark plugs.

²Change automatic transmission fluid.

97,500 Miles (156 000 km) or at 78 months

²Change engine oil.

105,000 Miles (168 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace engine timing belt

²Adjust drive belt tension.

SCHEDULE ± B

NOTE: * Follow this schedule if you usually operate

your vehicle under one or more of the following

conditions. Change the automatic transmission

fluid and filter every 15,000 miles (24 000 km) if you

usually operate your vehicle under one of the con-

ditions marked with an *.

3,000 Miles (5 000 km)

²Change engine oil

6,000 Miles (10 000 km)

²Change engine oil

²Replace engine oil filter.

9,000 Miles (14 000 km)

²Change engine oil

²Inspect front brake pads and rear brake lining.

12,000 Miles (19 000 km)

²Change engine oil

²Replace engine oil filter.

15,000 Miles (24 000 km)

²Change engine oil

²Adjust drive belt tension.

²Inspect and replace, if required, the air

cleaner element.

²Change automatic transaxle fluid and filter.

Adjust the bands.*

18,000 Miles (29 000 km)

²Change engine oil

²Replace engine oil filter.

²Inspect front brake pads and rear brake linings.

21,000 Miles (34 000 km)

²Change engine oil

0 - 4 LUBRICATION AND MAINTENANCEPL

GENERAL INFORMATION (Continued)

Page 6 of 1200

24,000 Miles (38 000 km)

²Change engine oil

²Replace engine oil filter.

27,000 Miles (43 000 km)

²Change engine oil

²Inspect front brake pads and rear brake linings.

30,000 Miles (48 000 km)

²Change engine oil

²Replace engine oil filter.

²Check and replace, if necessary, the PCV

valve.**

²Lubricate front suspension upper ball joints.

²Adjust drive belt tension.

²Replace air cleaner element.

²Replace spark plugs.

²Change automatic transmission fluid and filter.

Adjust the bands.*

33,000 Miles (53 000 km)

²Change engine oil.

36,000 Miles (58 000 km)

²Change engine oil.

²Replace engine oil filter.

²Flush and replace engine coolant.

²Inspect front brake pads and rear brake linings.

39,000 Miles (62 000 km)

²Change engine oil.

42,000 Miles (67 000 km)

²Change engine oil.

²Replace engine oil filter.

45,000 Miles (72 000 km)

²Change engine oil.

²Inspect front brake pads and rear brake linings.

²Inspect and replace, if necessary, the air

cleaner element.

²Adjust drive belt tension.

²Change automatic transaxle fluid and filter.

Adjust the bands.*

48,000 Miles (77 000 km)

²Change engine oil.

²Replace engine oil filter.

51,000 Miles (82 000 km)

²Change engine oil.

²Flush and replace engine coolant.

54,000 Miles (86 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect front brake pads and rear brake linings.

57,000 Miles (91 000 km)

²Change engine oil.

60,000 Miles (96 000 km)

²Change engine oil.

²Replace engine oil filter.

²Check and replace, if necessary***, the PCV

valve.**

²Lubricate front suspension upper ball joints.

²Replace drive belts.

²Replace air cleaner element.

²Replace ignition cables.

²Replace spark plugs.

²Change automatic transaxle fluid and filter.

Adjust the bands.*

63,000 Miles (101 000 km)

²Change engine oil.

²Inspect front brake pads and rear brake linings.

66,000 Miles (106 000 km)

²Change engine oil.

²Replace engine oil filter.

69,000 Miles (110 000 km)

²Change engine oil.

72,000 Miles (115 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect front brake pads and rear brake linings.

75,000 Miles (120 000 km)

²Change engine oil.

²Adjust drive belt tension.

²Inspect and replace, if necessary, the air

cleaner element.

²Change automatic transaxle fluid and filter.

Adjust the bands.*

78,000 Miles (125 000 km)

²Change engine oil.

²Replace engine oil filter.

81,000 Miles (130 000 km)

²Change engine oil.

²Flush and replace the engine coolant.

²Inspect front brake pads and rear brake linings.

84,000 Miles (134 000 km)

²Change engine oil.

²Replace engine oil filter.

87,000 Miles (139 000 km)

²Change engine oil.

PLLUBRICATION AND MAINTENANCE 0 - 5

GENERAL INFORMATION (Continued)

Page 7 of 1200

90,000 Miles (144 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect front brake pads and rear brake linings.

²Check and replace, if necessary***, the PCV

valve.**

²Lubricate front suspension upper ball joints.

²Adjust drive belt tension.

²Replace air cleaner element.

²Replace spark plugs.

²Change automatic transaxle fluid and filter.

Adjust the bands.*

93,000 Miles (149 000 km)

²Change engine oil.

96,000 Miles (154 000 km)

²Change engine oil.

²Replace engine oil filter.

99,000 Miles (158 000 km)

²Change engine oil.

²Inspect front brake pads and rear brake linings.

102,000 Miles (163 000km)

²Change engine oil.

²Replace engine oil filter.

105,000 Miles (168 000km)

²Replace the engine timing belt

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

²Inspect and replace, if necessary, the air

cleaner element.

NOTE: **This maintenance is recommended by

Chrysler to the owner but is not required to main-

tain the warranty on the PCV valve.

NOTE: ***This maintenance is not required if the

PCV valve was previously replaced.

0 - 6 LUBRICATION AND MAINTENANCEPL

GENERAL INFORMATION (Continued)

Page 8 of 1200

JUMP STARTING, TOWING AND HOISTING

INDEX

page page

SERVICE PROCEDURES

HOISTING RECOMMENDATIONS............ 9JUMP STARTING PROCEDURE.............. 7

TOWING RECOMMENDATIONS.............. 8

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, placethe automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

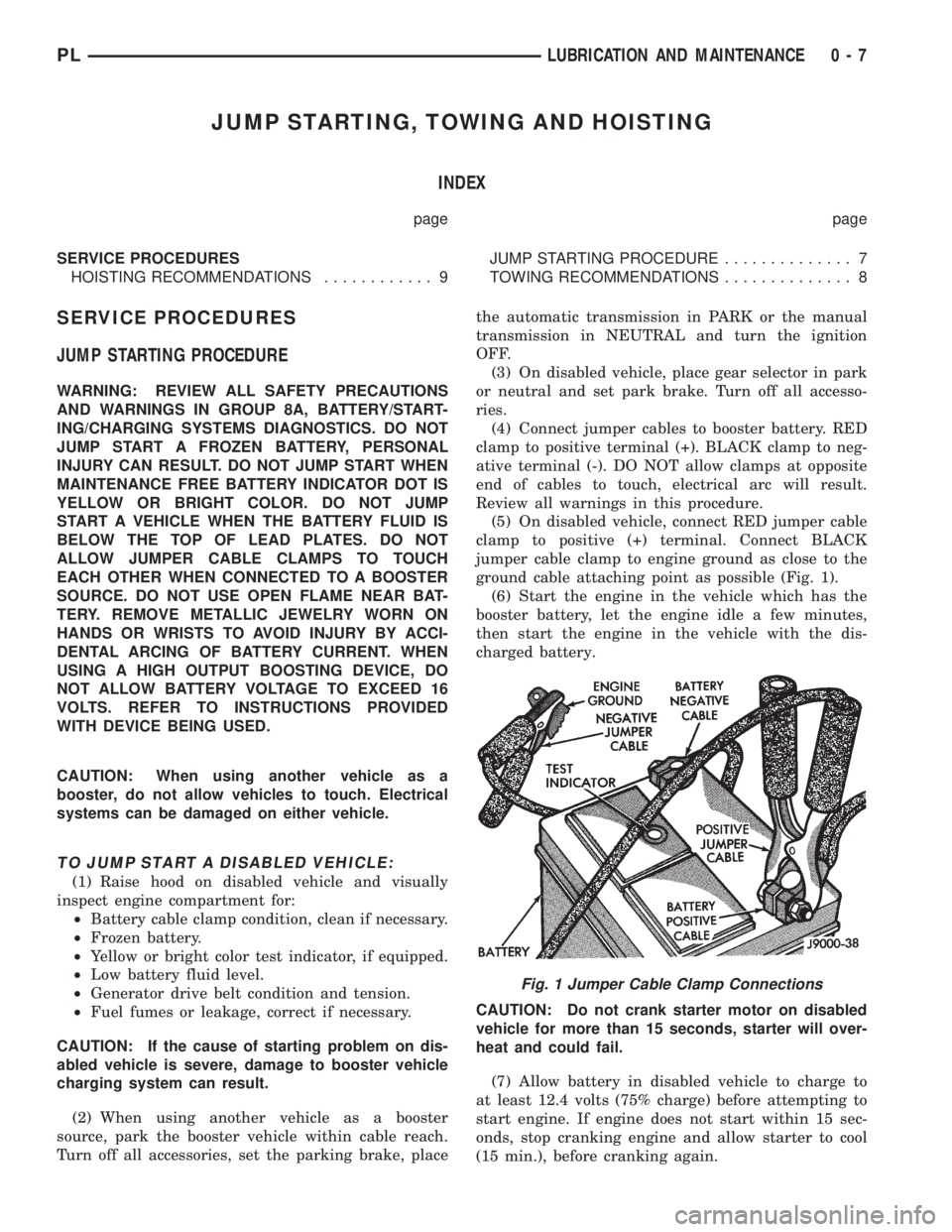

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

Fig. 1 Jumper Cable Clamp Connections

PLLUBRICATION AND MAINTENANCE 0 - 7

Page 71 of 1200

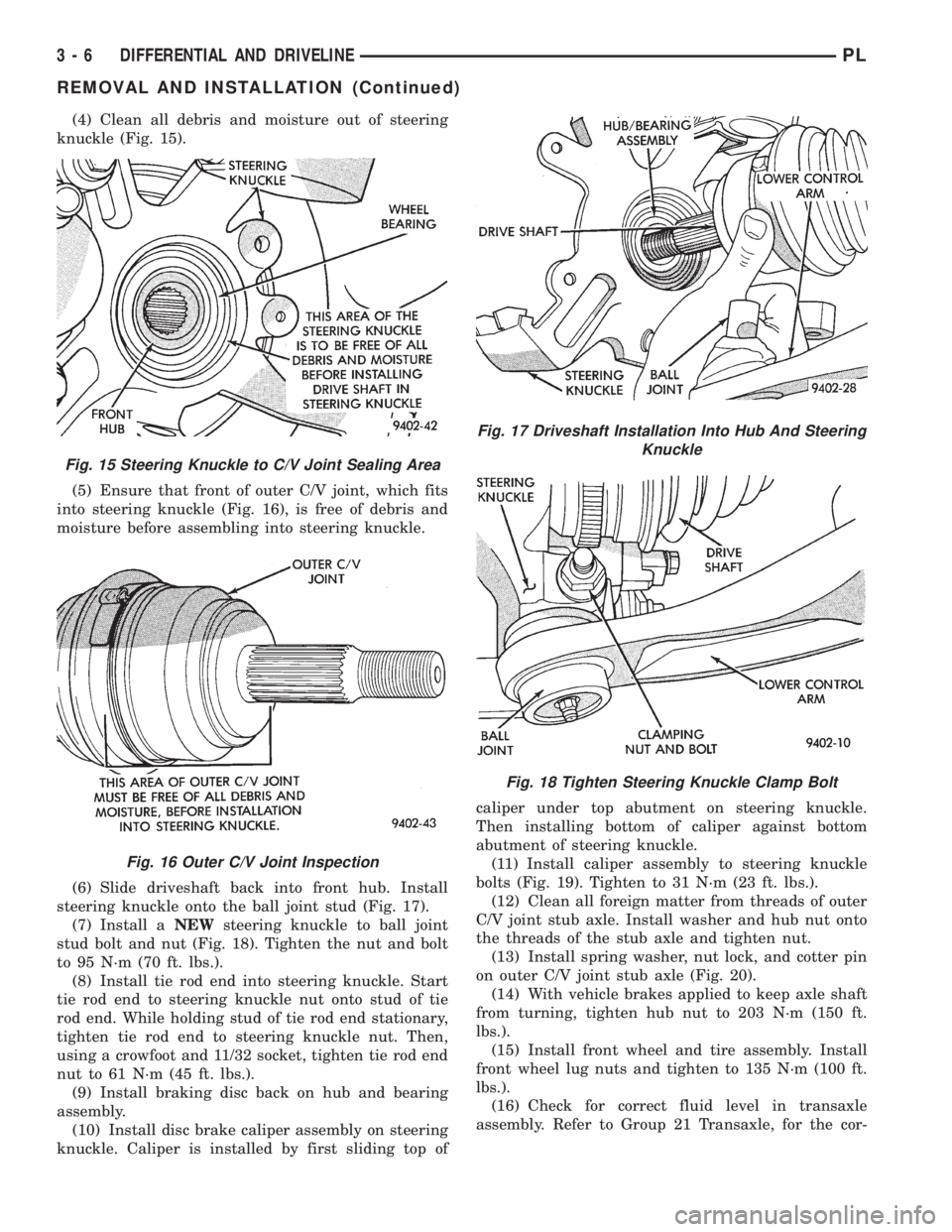

(4) Clean all debris and moisture out of steering

knuckle (Fig. 15).

(5) Ensure that front of outer C/V joint, which fits

into steering knuckle (Fig. 16), is free of debris and

moisture before assembling into steering knuckle.

(6) Slide driveshaft back into front hub. Install

steering knuckle onto the ball joint stud (Fig. 17).

(7) Install aNEWsteering knuckle to ball joint

stud bolt and nut (Fig. 18). Tighten the nut and bolt

to 95 N´m (70 ft. lbs.).

(8) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle nut onto stud of tie

rod end. While holding stud of tie rod end stationary,

tighten tie rod end to steering knuckle nut. Then,

using a crowfoot and 11/32 socket, tighten tie rod end

nut to 61 N´m (45 ft. lbs.).

(9) Install braking disc back on hub and bearing

assembly.

(10) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding top ofcaliper under top abutment on steering knuckle.

Then installing bottom of caliper against bottom

abutment of steering knuckle.

(11) Install caliper assembly to steering knuckle

bolts (Fig. 19). Tighten to 31 N´m (23 ft. lbs.).

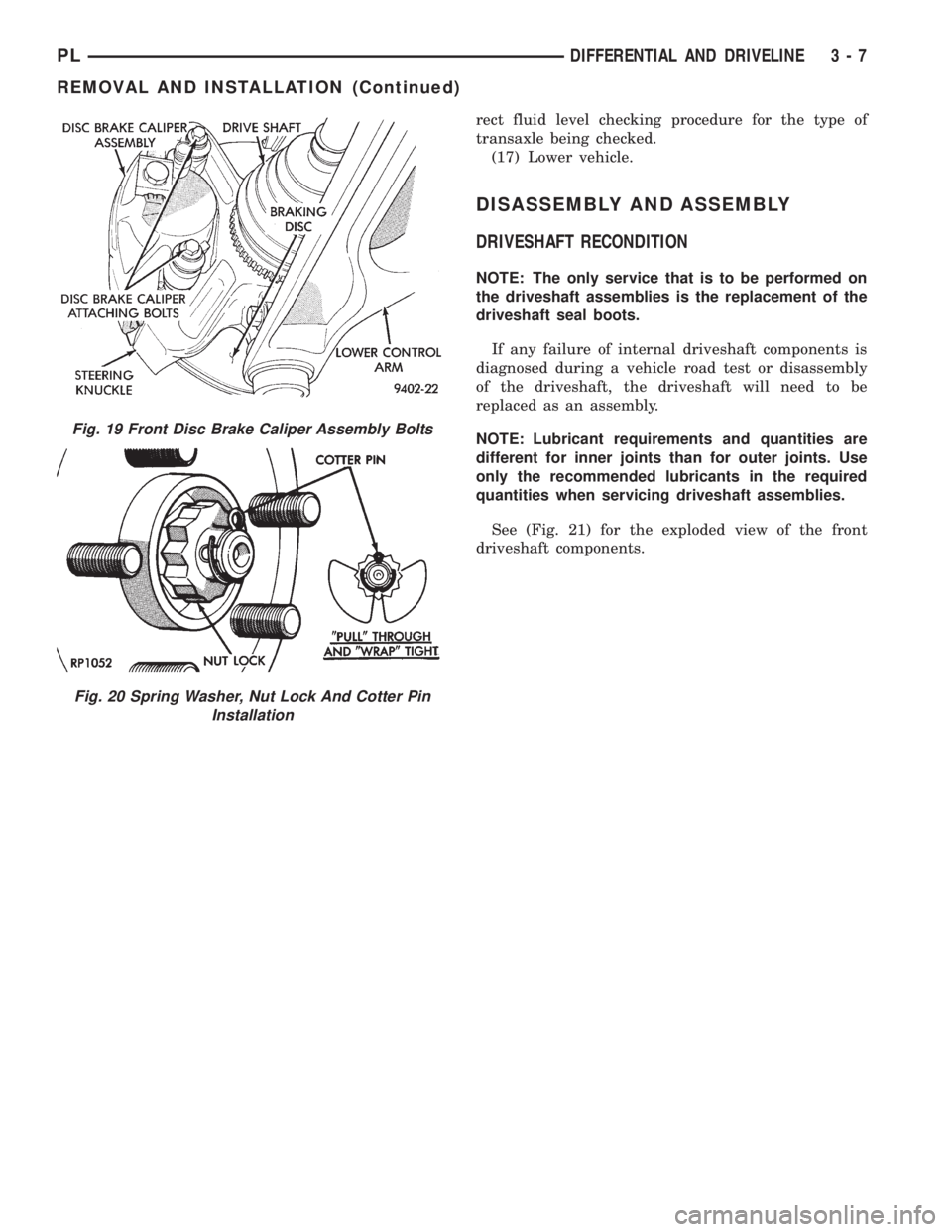

(12) Clean all foreign matter from threads of outer

C/V joint stub axle. Install washer and hub nut onto

the threads of the stub axle and tighten nut.

(13) Install spring washer, nut lock, and cotter pin

on outer C/V joint stub axle (Fig. 20).

(14) With vehicle brakes applied to keep axle shaft

from turning, tighten hub nut to 203 N´m (150 ft.

lbs.).

(15) Install front wheel and tire assembly. Install

front wheel lug nuts and tighten to 135 N´m (100 ft.

lbs.).

(16) Check for correct fluid level in transaxle

assembly. Refer to Group 21 Transaxle, for the cor-

Fig. 15 Steering Knuckle to C/V Joint Sealing Area

Fig. 16 Outer C/V Joint Inspection

Fig. 17 Driveshaft Installation Into Hub And Steering

Knuckle

Fig. 18 Tighten Steering Knuckle Clamp Bolt

3 - 6 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 72 of 1200

rect fluid level checking procedure for the type of

transaxle being checked.

(17) Lower vehicle.

DISASSEMBLY AND ASSEMBLY

DRIVESHAFT RECONDITION

NOTE: The only service that is to be performed on

the driveshaft assemblies is the replacement of the

driveshaft seal boots.

If any failure of internal driveshaft components is

diagnosed during a vehicle road test or disassembly

of the driveshaft, the driveshaft will need to be

replaced as an assembly.

NOTE: Lubricant requirements and quantities are

different for inner joints than for outer joints. Use

only the recommended lubricants in the required

quantities when servicing driveshaft assemblies.

See (Fig. 21) for the exploded view of the front

driveshaft components.

Fig. 19 Front Disc Brake Caliper Assembly Bolts

Fig. 20 Spring Washer, Nut Lock And Cotter Pin

Installation

PLDIFFERENTIAL AND DRIVELINE 3 - 7

REMOVAL AND INSTALLATION (Continued)

Page 82 of 1200

BRAKES

CONTENTS

page page

ANTILOCK BRAKE SYSTEM±TEVES MARK 20 . 69

BASE BRAKE SYSTEM..................... 2GENERAL INFORMATION................... 1

GENERAL INFORMATION

INDEX

page

GENERAL INFORMATION

BASE BRAKE SYSTEM DESCRIPTION........ 1

GENERAL INFORMATION

BASE BRAKE SYSTEM DESCRIPTION

Typical brake equipment consists of:

²Double pin floating caliper disc front brakes.

²Rear automatic adjusting drum brakes.

²Brake Fluid Level Switch.

²Master cylinder.

²Vacuum power booster.

²Double pin floating caliper rear disc brakes are

available on some models.

²Hand operated auto adjust park brake lever.

²Front disc brake pads are semi-metallic.

Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20 and

is supplied by Teves. This system shares the base

brake hardware with vehicles not equipped withABS. A vehicle equipped with ABS does however use

a different vacuum booster, master cylinder and

brake tubes. Also included in the ABS system is an

integrated control unit (ICU), four wheel speed sen-

sors, and an electronic controller referred to as the

controller antilock brakes (CAB). These components

will be described in detail in the Teves Mark 20 ABS

brake section in this group of the service manual.

The hydraulic brake system is diagonally split on

both the Non-ABS and ABS braking system. With the

left front and right rear brakes on one hydraulic sys-

tem and the right front and left rear on the other.

The master cylinder is anodized, lightweight alu-

minum. On vehicles equipped with front disc brakes

and rear drum brakes, the master cylinder bore is

21.0 mm. On vehicles equipped with four wheel disc

brakes, the master cylinder bore is 22.2 mm.

PLBRAKES 5 - 1

Page 83 of 1200

BASE BRAKE SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

CHASSIS TUBES AND HOSES.............. 6

FRONT DISC BRAKES..................... 2

MASTER CYLINDER...................... 6

PARKING BRAKES........................ 4

PROPORTIONING VALVES................. 5

REAR DISC BRAKES...................... 4

REAR DRUM BRAKES..................... 4

REAR WHEEL HUB/BEARING............... 8

RED BRAKE WARNING LAMP............... 7

STOP LAMP SWITCH...................... 8

VACUUM BOOSTER...................... 6

DIAGNOSIS AND TESTING

BRAKE FLUID CONTAMINATION............ 19

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE.... 9

BRAKE SYSTEM DIAGNOSIS CHARTS....... 10

DRUM BRAKE AUTOMATIC ADJUSTER....... 14

PROPORTIONING VALVES................ 16

RED BRAKE WARNING LAMP TEST......... 19

ROTOR THICKNESS AND RUNOUT.......... 14

STOP LAMP SWITCH TEST PROCEDURE..... 19

SERVICE PROCEDURES

BRAKE BLEEDING....................... 20

BRAKE DRUM MACHINING................ 23

BRAKE FLUID LEVEL CHECK.............. 19

BRAKE ROTOR MACHINING............... 22

BRAKE TUBE REPAIR.................... 25

MASTER CYLINDER BLEEDING............ 21

PARK BRAKE LEVER AUTO ADJUSTER

MECHANISM.......................... 23

REMOVAL AND INSTALLATION

CHASSIS TUBES AND HOSES.............. 47

FRONT DISC BRAKE CALIPER............. 26

FRONT DISC BRAKE SHOES.............. 28

MASTER CYLINDER..................... 41

PARK BRAKE CABLES.................... 50

PARK BRAKE LEVER ASSEMBLY........... 48PARK BRAKE LEVER OUTPUT CABLE....... 49

PARK BRAKE SHOES WITH REAR DISC

BRAKES............................. 55

PROPORTIONING VALVE (BASE BRAKES).... 47

REAR BRAKE DRUM..................... 34

REAR BRAKE SHOE SUPPORT PLATE....... 37

REAR BRAKE SHOES.................... 35

REAR BRAKE WHEEL CYLINDER........... 38

REAR DISC BRAKE CALIPER.............. 30

REAR DISC BRAKE SHOES................ 32

REAR HUB/BEARING..................... 39

STOP LAMP SWITCH..................... 57

VACUUM BOOSTER..................... 44

WHEEL AND TIRE ASSEMBLY.............. 26

DISASSEMBLY AND ASSEMBLY

BRAKE FLUID LEVEL SWITCH............. 58

BRAKE FLUID RESERVOIR................ 57

FRONT AND REAR DISC BRAKE CALIPER.... 58

WHEEL CYLINDER (REAR DRUM BRAKE).... 63

CLEANING AND INSPECTION

CHASSIS TUBES AND HOSES.............. 65

FRONT DISC BRAKES.................... 63

REAR DISC BRAKES..................... 64

REAR DRUM BRAKE WHEEL CYLINDER...... 65

REAR DRUM BRAKES.................... 64

REAR WHEEL HUB AND BEARING ASSEMBLY . 65

ADJUSTMENTS

PARK BRAKE ADJUSTMENT............... 66

REAR DRUM BRAKE SHOE ADJUSTMENT.... 65

STOP LAMP SWITCH..................... 65

SPECIFICATIONS

BRAKE ACTUATION SYSTEM.............. 67

BRAKE FASTENER TORQUE SPECIFICATIONS . 67

BRAKE FLUID.......................... 67

SPECIAL TOOLS

BASE BRAKE SYSTEM................... 68

DESCRIPTION AND OPERATION

FRONT DISC BRAKES

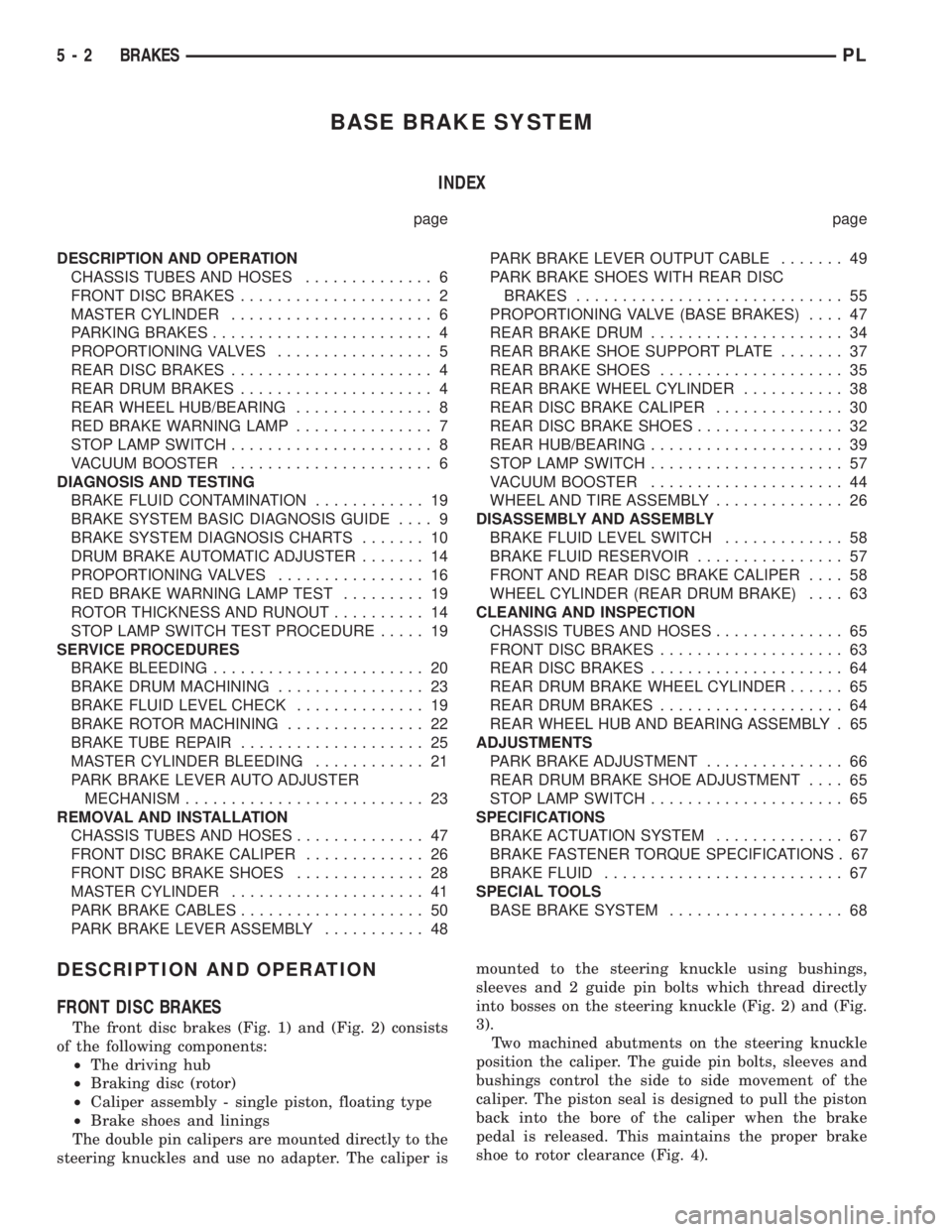

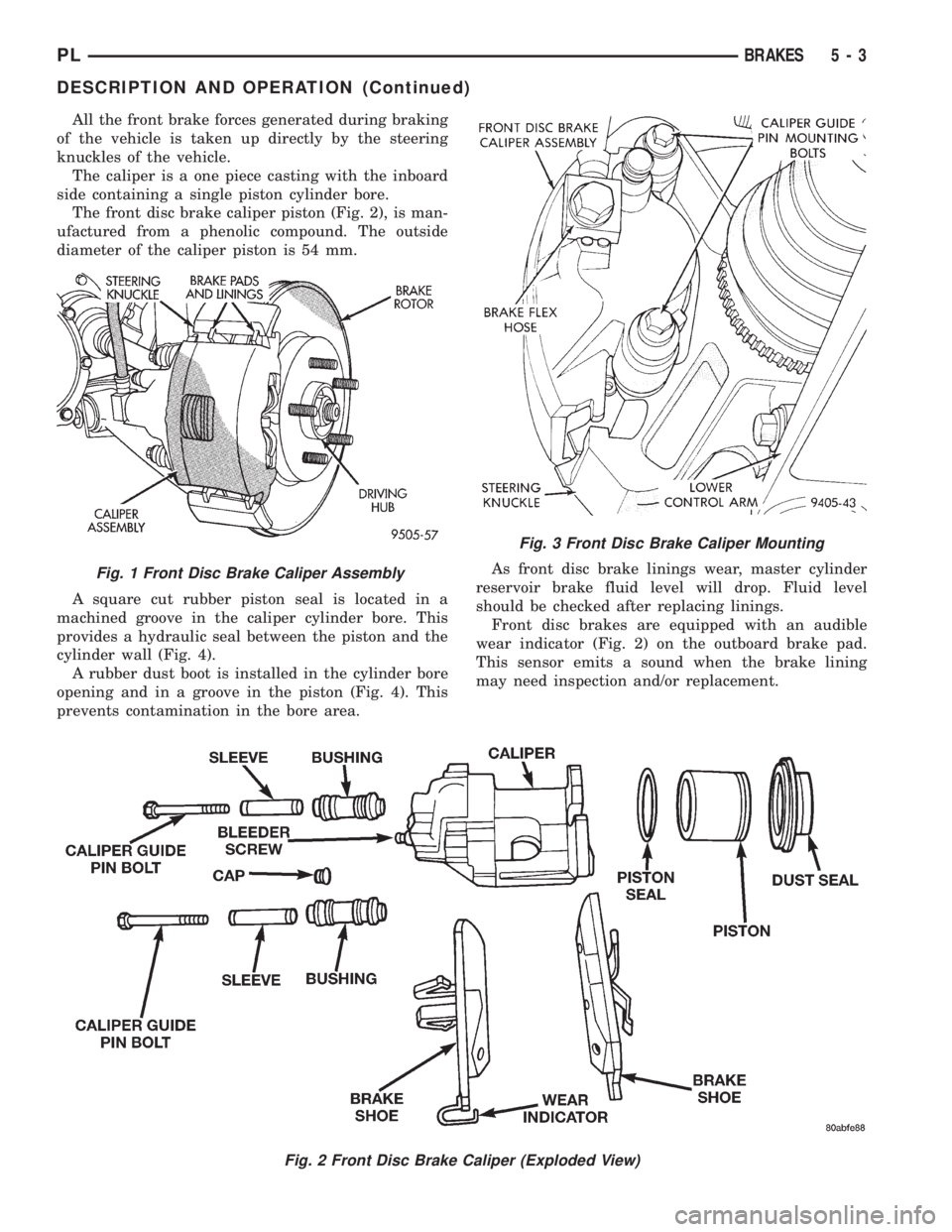

The front disc brakes (Fig. 1) and (Fig. 2) consists

of the following components:

²The driving hub

²Braking disc (rotor)

²Caliper assembly - single piston, floating type

²Brake shoes and linings

The double pin calipers are mounted directly to the

steering knuckles and use no adapter. The caliper ismounted to the steering knuckle using bushings,

sleeves and 2 guide pin bolts which thread directly

into bosses on the steering knuckle (Fig. 2) and (Fig.

3).

Two machined abutments on the steering knuckle

position the caliper. The guide pin bolts, sleeves and

bushings control the side to side movement of the

caliper. The piston seal is designed to pull the piston

back into the bore of the caliper when the brake

pedal is released. This maintains the proper brake

shoe to rotor clearance (Fig. 4).

5 - 2 BRAKESPL

Page 84 of 1200

All the front brake forces generated during braking

of the vehicle is taken up directly by the steering

knuckles of the vehicle.

The caliper is a one piece casting with the inboard

side containing a single piston cylinder bore.

The front disc brake caliper piston (Fig. 2), is man-

ufactured from a phenolic compound. The outside

diameter of the caliper piston is 54 mm.

A square cut rubber piston seal is located in a

machined groove in the caliper cylinder bore. This

provides a hydraulic seal between the piston and the

cylinder wall (Fig. 4).

A rubber dust boot is installed in the cylinder bore

opening and in a groove in the piston (Fig. 4). This

prevents contamination in the bore area.As front disc brake linings wear, master cylinder

reservoir brake fluid level will drop. Fluid level

should be checked after replacing linings.

Front disc brakes are equipped with an audible

wear indicator (Fig. 2) on the outboard brake pad.

This sensor emits a sound when the brake lining

may need inspection and/or replacement.

Fig. 1 Front Disc Brake Caliper Assembly

Fig. 2 Front Disc Brake Caliper (Exploded View)

Fig. 3 Front Disc Brake Caliper Mounting

PLBRAKES 5 - 3

DESCRIPTION AND OPERATION (Continued)