four wheel drive DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 102 of 1200

enough fluid has not passed through the system to

expel all the trapped air. Be sure to monitor the fluid

level in the pressure bleeder. It must stay at the

proper level so air will not be allowed to reenter the

brake system through the master cylinder reservoir.

BLEEDING WITHOUT A PRESSURE BLEEDER

NOTE: Correct bleeding of the brakes hydraulic

system without the use of pressure bleeding equip-

ment will require the aid of a helper.

The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure

adequate removal of all trapped air from the hydrau-

lic system.

²Left rear wheel

²Right front wheel

²Right rear wheel

²Left front wheel

(1) Attach a clear plastic hose to the bleeder screw

starting at the right rear wheel and feed the hose

into a clear jar containing enough fresh brake fluid

to submerge the end of the hose (Fig. 36).

(2) Pump the brake pedal three or four times and

hold it down before the bleeder screw is opened.

(3) Open the bleeder screw at least 1 full turn.

When the bleeder screw opens the brake pedal will

drop.

(4) Close the bleeder screw. Release the brake

pedal onlyafterthe bleeder screw is closed.

(5) Repeat steps 1 through 3, four or five times at

each bleeder screw. Then check the pedal for travel.

If pedal travel is excessive or has not been improved,

enough fluid has not passed through the system to

expel all the trapped air. Be sure to monitor the fluid

level in the master cylinder reservoir. It must stay at

the proper level so air will not be allowed to re-enter

the brake system.(6) Test drive vehicle to be sure brakes are operat-

ing correctly and that pedal is solid.

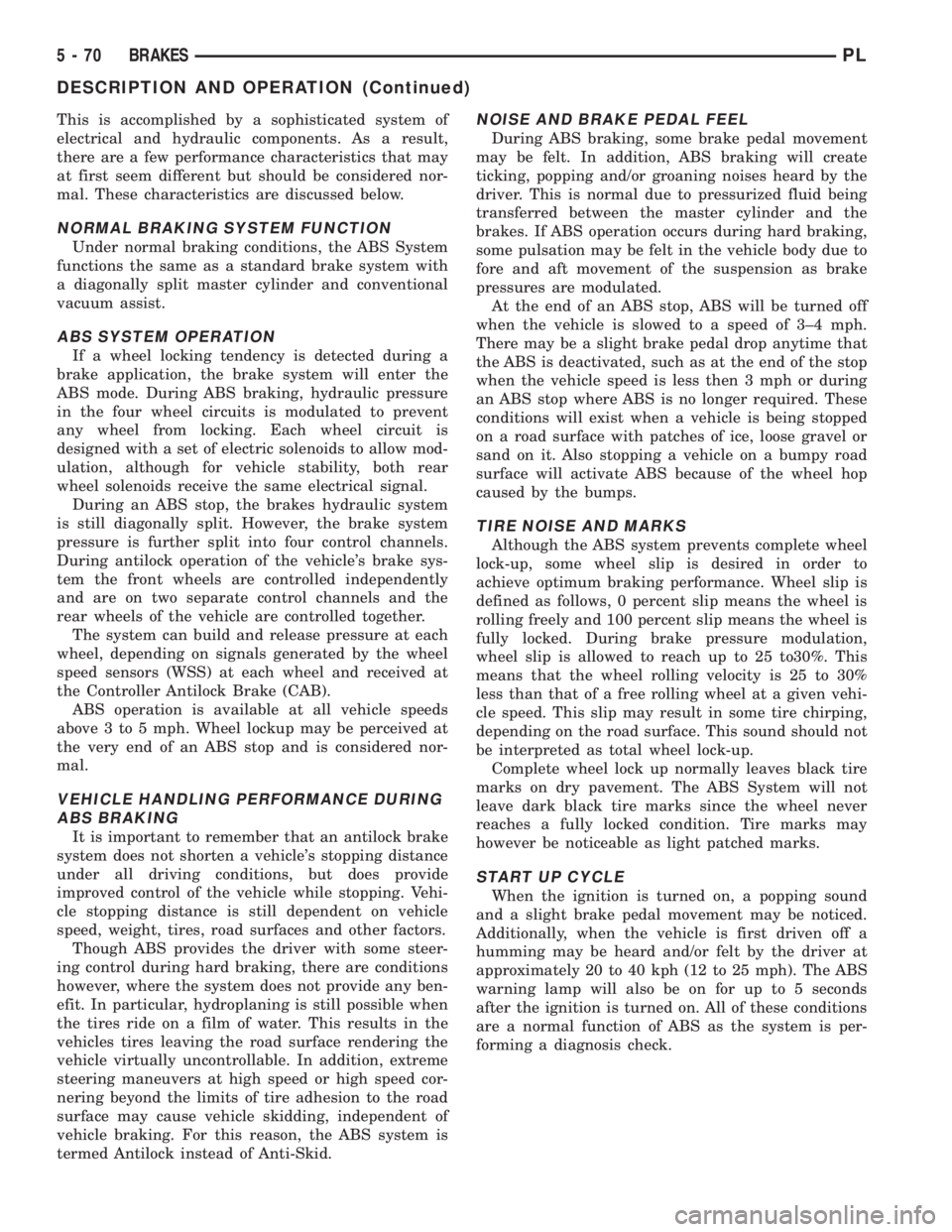

MASTER CYLINDER BLEEDING

(1) Clamp the master cylinder in a vise. Attach

Bleeding Tubes, Special Tool 6802 to the master cyl-

inder (Fig. 38) and (Fig. 39). Position so outlets of

Bleeding Tubes will be below surface of brake fluid

when reservoir is filled to its proper level.

(2) Fill brake fluid reservoir with brake fluid con-

forming to DOT 3 specifications such as Mopar or an

Equivalent.

(3) Using a wooden dowel per (Fig. 40). Depress

push rod slowly, and then allow pistons to return to

released position. Repeat several times until all air

bubbles are expelled.

(4) Remove bleeding tubes from master cylinder

outlet ports, plug outlet ports and install fill cap on

reservoir.

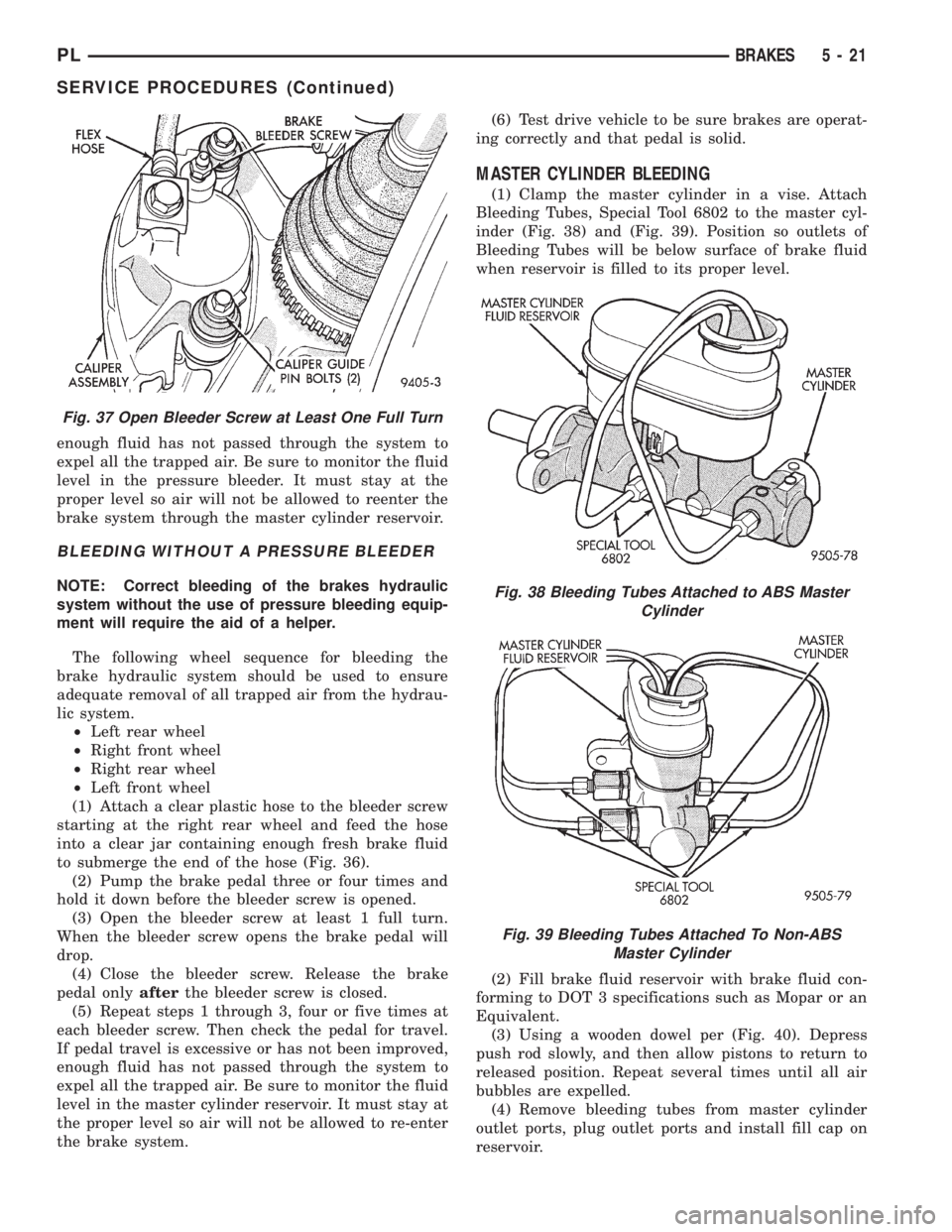

Fig. 37 Open Bleeder Screw at Least One Full Turn

Fig. 38 Bleeding Tubes Attached to ABS Master

Cylinder

Fig. 39 Bleeding Tubes Attached To Non-ABS

Master Cylinder

PLBRAKES 5 - 21

SERVICE PROCEDURES (Continued)

Page 151 of 1200

This is accomplished by a sophisticated system of

electrical and hydraulic components. As a result,

there are a few performance characteristics that may

at first seem different but should be considered nor-

mal. These characteristics are discussed below.

NORMAL BRAKING SYSTEM FUNCTION

Under normal braking conditions, the ABS System

functions the same as a standard brake system with

a diagonally split master cylinder and conventional

vacuum assist.

ABS SYSTEM OPERATION

If a wheel locking tendency is detected during a

brake application, the brake system will enter the

ABS mode. During ABS braking, hydraulic pressure

in the four wheel circuits is modulated to prevent

any wheel from locking. Each wheel circuit is

designed with a set of electric solenoids to allow mod-

ulation, although for vehicle stability, both rear

wheel solenoids receive the same electrical signal.

During an ABS stop, the brakes hydraulic system

is still diagonally split. However, the brake system

pressure is further split into four control channels.

During antilock operation of the vehicle's brake sys-

tem the front wheels are controlled independently

and are on two separate control channels and the

rear wheels of the vehicle are controlled together.

The system can build and release pressure at each

wheel, depending on signals generated by the wheel

speed sensors (WSS) at each wheel and received at

the Controller Antilock Brake (CAB).

ABS operation is available at all vehicle speeds

above 3 to 5 mph. Wheel lockup may be perceived at

the very end of an ABS stop and is considered nor-

mal.

VEHICLE HANDLING PERFORMANCE DURING

ABS BRAKING

It is important to remember that an antilock brake

system does not shorten a vehicle's stopping distance

under all driving conditions, but does provide

improved control of the vehicle while stopping. Vehi-

cle stopping distance is still dependent on vehicle

speed, weight, tires, road surfaces and other factors.

Though ABS provides the driver with some steer-

ing control during hard braking, there are conditions

however, where the system does not provide any ben-

efit. In particular, hydroplaning is still possible when

the tires ride on a film of water. This results in the

vehicles tires leaving the road surface rendering the

vehicle virtually uncontrollable. In addition, extreme

steering maneuvers at high speed or high speed cor-

nering beyond the limits of tire adhesion to the road

surface may cause vehicle skidding, independent of

vehicle braking. For this reason, the ABS system is

termed Antilock instead of Anti-Skid.

NOISE AND BRAKE PEDAL FEEL

During ABS braking, some brake pedal movement

may be felt. In addition, ABS braking will create

ticking, popping and/or groaning noises heard by the

driver. This is normal due to pressurized fluid being

transferred between the master cylinder and the

brakes. If ABS operation occurs during hard braking,

some pulsation may be felt in the vehicle body due to

fore and aft movement of the suspension as brake

pressures are modulated.

At the end of an ABS stop, ABS will be turned off

when the vehicle is slowed to a speed of 3±4 mph.

There may be a slight brake pedal drop anytime that

the ABS is deactivated, such as at the end of the stop

when the vehicle speed is less then 3 mph or during

an ABS stop where ABS is no longer required. These

conditions will exist when a vehicle is being stopped

on a road surface with patches of ice, loose gravel or

sand on it. Also stopping a vehicle on a bumpy road

surface will activate ABS because of the wheel hop

caused by the bumps.

TIRE NOISE AND MARKS

Although the ABS system prevents complete wheel

lock-up, some wheel slip is desired in order to

achieve optimum braking performance. Wheel slip is

defined as follows, 0 percent slip means the wheel is

rolling freely and 100 percent slip means the wheel is

fully locked. During brake pressure modulation,

wheel slip is allowed to reach up to 25 to30%. This

means that the wheel rolling velocity is 25 to 30%

less than that of a free rolling wheel at a given vehi-

cle speed. This slip may result in some tire chirping,

depending on the road surface. This sound should not

be interpreted as total wheel lock-up.

Complete wheel lock up normally leaves black tire

marks on dry pavement. The ABS System will not

leave dark black tire marks since the wheel never

reaches a fully locked condition. Tire marks may

however be noticeable as light patched marks.

START UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

Additionally, when the vehicle is first driven off a

humming may be heard and/or felt by the driver at

approximately 20 to 40 kph (12 to 25 mph). The ABS

warning lamp will also be on for up to 5 seconds

after the ignition is turned on. All of these conditions

are a normal function of ABS as the system is per-

forming a diagnosis check.

5 - 70 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 152 of 1200

PREMATURE ABS CYCLING

NOTE: When working on a vehicle which has a

complaint of premature ABS cycling it may be nec-

essary to use a DRB Scan Tool to detect and verify

the condition.

There is one complaint called Premature ABS

Cycling in which neither the Red Brake Warning

Lamp nor the Amber Antilock Lamp were illumi-

nated and no fault codes were stored in the CAB.

Symptoms of Premature ABS Cycling, include click-

ing sounds from the solenoids valves, pump motor

running and pulsations in the brake pedal. This con-

dition can occur at any braking rate of the vehicle

and on any type of road surface. This creates an

additional condition which needs to be correctly

assessed when diagnosing problems with the antilock

brake system.

The following conditions are common causes that

need to be checked when diagnosing a condition of

Premature ABS Cycling. Damaged tone wheels,

incorrect tone wheels, damage to a wheel speed sen-

sor mounting boss on a steering knuckle, a loose

wheel speed sensor mounting bolt, and excessive tone

wheel runout. Also, an excessively large tone wheel

to wheel speed sensor air gap can lead to the condi-

tion of Premature ABS Cycling. Special attention is

to be given to these components when diagnosing a

vehicle exhibiting the condition of Premature ABS

Cycling. After diagnosing the defective component,

repair or replace as required.

When the component repair or replacement is com-

pleted, test drive the vehicle to verify the condition of

Premature ABS Cycling has been corrected.

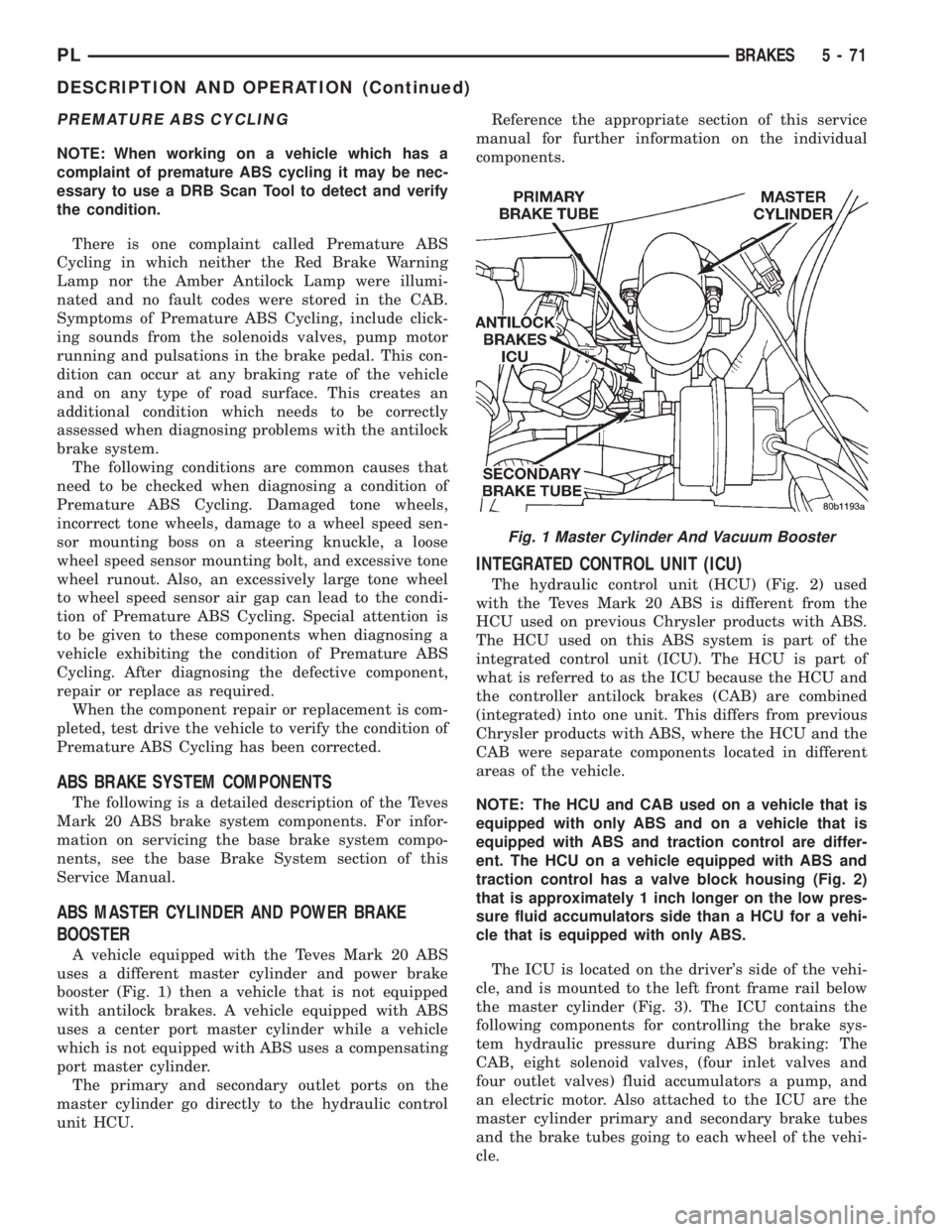

ABS BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Teves

Mark 20 ABS brake system components. For infor-

mation on servicing the base brake system compo-

nents, see the base Brake System section of this

Service Manual.

ABS MASTER CYLINDER AND POWER BRAKE

BOOSTER

A vehicle equipped with the Teves Mark 20 ABS

uses a different master cylinder and power brake

booster (Fig. 1) then a vehicle that is not equipped

with antilock brakes. A vehicle equipped with ABS

uses a center port master cylinder while a vehicle

which is not equipped with ABS uses a compensating

port master cylinder.

The primary and secondary outlet ports on the

master cylinder go directly to the hydraulic control

unit HCU.Reference the appropriate section of this service

manual for further information on the individual

components.

INTEGRATED CONTROL UNIT (ICU)

The hydraulic control unit (HCU) (Fig. 2) used

with the Teves Mark 20 ABS is different from the

HCU used on previous Chrysler products with ABS.

The HCU used on this ABS system is part of the

integrated control unit (ICU). The HCU is part of

what is referred to as the ICU because the HCU and

the controller antilock brakes (CAB) are combined

(integrated) into one unit. This differs from previous

Chrysler products with ABS, where the HCU and the

CAB were separate components located in different

areas of the vehicle.

NOTE: The HCU and CAB used on a vehicle that is

equipped with only ABS and on a vehicle that is

equipped with ABS and traction control are differ-

ent. The HCU on a vehicle equipped with ABS and

traction control has a valve block housing (Fig. 2)

that is approximately 1 inch longer on the low pres-

sure fluid accumulators side than a HCU for a vehi-

cle that is equipped with only ABS.

The ICU is located on the driver's side of the vehi-

cle, and is mounted to the left front frame rail below

the master cylinder (Fig. 3). The ICU contains the

following components for controlling the brake sys-

tem hydraulic pressure during ABS braking: The

CAB, eight solenoid valves, (four inlet valves and

four outlet valves) fluid accumulators a pump, and

an electric motor. Also attached to the ICU are the

master cylinder primary and secondary brake tubes

and the brake tubes going to each wheel of the vehi-

cle.

Fig. 1 Master Cylinder And Vacuum Booster

PLBRAKES 5 - 71

DESCRIPTION AND OPERATION (Continued)

Page 153 of 1200

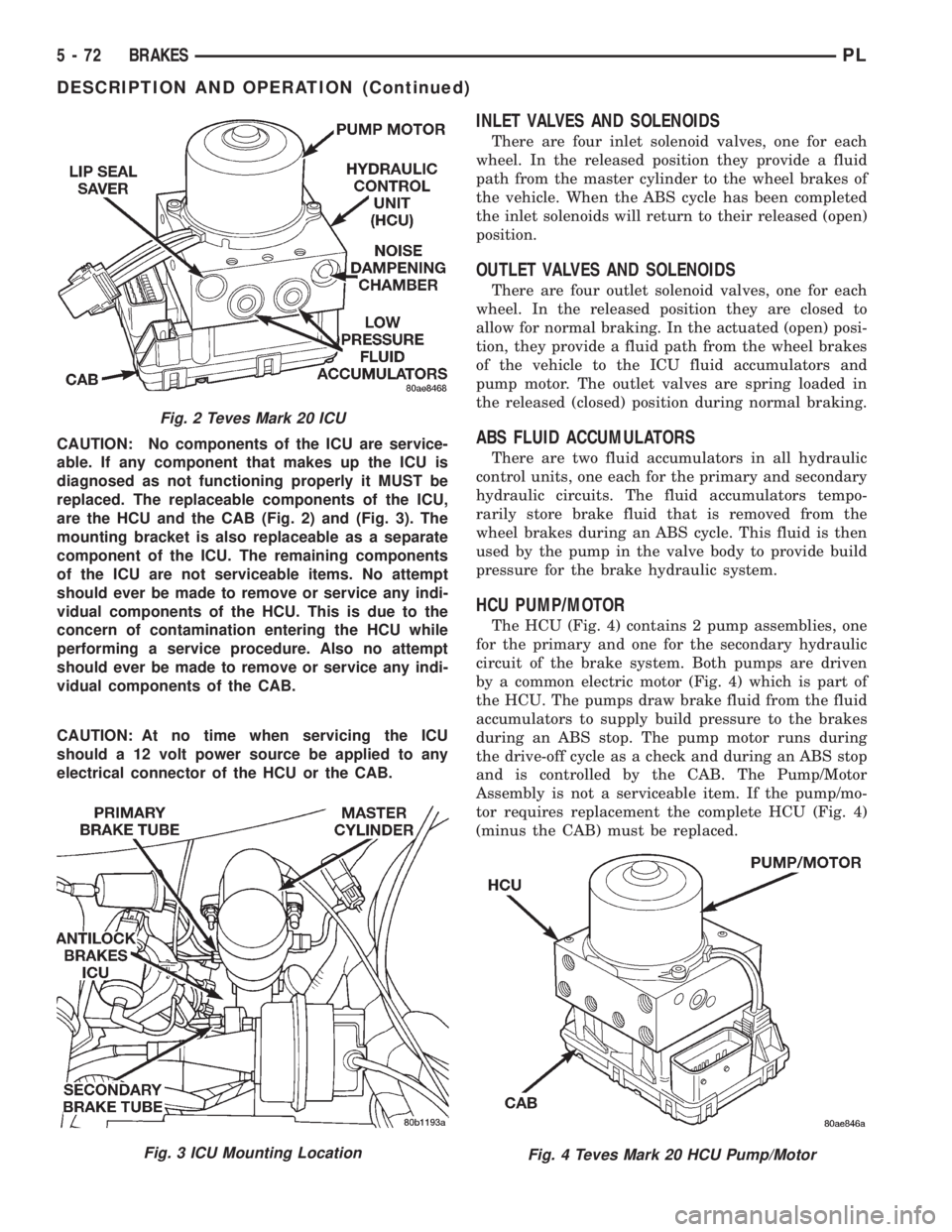

CAUTION: No components of the ICU are service-

able. If any component that makes up the ICU is

diagnosed as not functioning properly it MUST be

replaced. The replaceable components of the ICU,

are the HCU and the CAB (Fig. 2) and (Fig. 3). The

mounting bracket is also replaceable as a separate

component of the ICU. The remaining components

of the ICU are not serviceable items. No attempt

should ever be made to remove or service any indi-

vidual components of the HCU. This is due to the

concern of contamination entering the HCU while

performing a service procedure. Also no attempt

should ever be made to remove or service any indi-

vidual components of the CAB.

CAUTION: At no time when servicing the ICU

should a 12 volt power source be applied to any

electrical connector of the HCU or the CAB.

INLET VALVES AND SOLENOIDS

There are four inlet solenoid valves, one for each

wheel. In the released position they provide a fluid

path from the master cylinder to the wheel brakes of

the vehicle. When the ABS cycle has been completed

the inlet solenoids will return to their released (open)

position.

OUTLET VALVES AND SOLENOIDS

There are four outlet solenoid valves, one for each

wheel. In the released position they are closed to

allow for normal braking. In the actuated (open) posi-

tion, they provide a fluid path from the wheel brakes

of the vehicle to the ICU fluid accumulators and

pump motor. The outlet valves are spring loaded in

the released (closed) position during normal braking.

ABS FLUID ACCUMULATORS

There are two fluid accumulators in all hydraulic

control units, one each for the primary and secondary

hydraulic circuits. The fluid accumulators tempo-

rarily store brake fluid that is removed from the

wheel brakes during an ABS cycle. This fluid is then

used by the pump in the valve body to provide build

pressure for the brake hydraulic system.

HCU PUMP/MOTOR

The HCU (Fig. 4) contains 2 pump assemblies, one

for the primary and one for the secondary hydraulic

circuit of the brake system. Both pumps are driven

by a common electric motor (Fig. 4) which is part of

the HCU. The pumps draw brake fluid from the fluid

accumulators to supply build pressure to the brakes

during an ABS stop. The pump motor runs during

the drive-off cycle as a check and during an ABS stop

and is controlled by the CAB. The Pump/Motor

Assembly is not a serviceable item. If the pump/mo-

tor requires replacement the complete HCU (Fig. 4)

(minus the CAB) must be replaced.

Fig. 2 Teves Mark 20 ICU

Fig. 3 ICU Mounting LocationFig. 4 Teves Mark 20 HCU Pump/Motor

5 - 72 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 156 of 1200

cally cleared from the CAB memory after the identi-

cal fault has not been seen during the next 255 key

cycles of vehicle operation.

CONTROLLER ANTILOCK BRAKE INPUTS

²Four wheel speed sensors.

²Stop lamp switch.

²Ignition switch.

²System relay voltage.

²Ground.

²Diagnostics Communications (CCD)

CONTROLLER ANTILOCK BRAKE OUTPUTS

²ABS warning lamp actuation.

²Diagnostic communication. (CCD)

ABS WARNING LAMP (YELLOW)

The ABS system uses a yellow colored ABS Warn-

ing Lamp. The ABS warning lamp is located on the

lower left side of the instrument pane. The purpose

of the warning lamp is discussed in detail below.

The ABS warning lamp will turn on when the CAB

detects a condition which results in a shutdown of

ABS function. When the ignition key is turned to the

on position, the ABS Warning Lamp is on until the

CAB completes its self tests and turns the lamp off

(approximately 4 seconds after the ignition switch is

turned on). Under most conditions, when the ABS

warning lamp is on, only the ABS function of the

brake system is affected. The standard brake system

and the ability to stop the car will not be affected

when only the ABS warning lamp is on.

The ABS warning lamp is controlled by the CAB.

The CAB turns on the yellow ABS warning lamp by

grounding the circuit.

HYDRAULIC CIRCUITS AND VALVE OPERATION

Through the following operation descriptions the

function of the various hydraulic control valves in the

ABS will be described. The fluid control valves men-

tioned below, control the flow of pressurized brake

fluid to the wheel brakes during the different modes

of ABS braking.

For explanation purposes, all wheel speed sensors

except the right front are sending the same wheel

speed information. The following diagrams show only

the right front wheel in a antilock braking condition.

NORMAL BRAKING HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION

This condition is the normal operation of the vehi-

cles base brake hydraulic system. The hydraulic sys-

tem circuit diagram (Fig. 11) shows a situation where

no wheel spin or slip is occurring relative to the

speed of the vehicle. The driver is applying the brake

pedal to build pressure in the brake hydraulic system

to apply the brakes and stop the vehicle.

TEVES MARK 20 ABS CIRCUIT AND

SOLENOID VALVE FUNCTION

This hydraulic circuit diagram (Fig. 12) shows the

vehicle in the ABS braking mode. This hydraulic cir-

cuit (Fig. 12) shows a situation where one wheel is

slipping because the driver is attempting to stop the

vehicle at a faster rate than the surface the vehicle's

tires are on will allow. The normally open and nor-

mally closed valves modulate the brake hydraulic

pressure as required. The pump/motor is switched on

so that the brake fluid from the low pressure accu-

mulators is returned to the master cylinder circuits.

The brake fluid will then be routed to either the mas-

ter cylinder or the wheel brake depending on the

position of the normally open valve.

TEVES MARK 20 SECONDARY ABS CIRCUIT

AND SOLENOID VALVE FUNCTION

This hydraulic circuit diagram (Fig. 13) shows the

vehicle in the ABS braking mode. This hydraulic cir-

cuit (Fig. 13) shows a situation where one wheel is

slipping because the driver is attempting to stop the

vehicle at a faster rate than the surface the vehicle's

tires are on will allow. The normally open and nor-

mally closed valves modulate the brake hydraulic

pressure as required. The pump/motor is switched on

so that the brake fluid from the low pressure accu-

mulators is returned to the master cylinder circuits.

The brake fluid will then be routed to either the mas-

ter cylinder or the wheel brake depending on the

position of the normally open valve. A volume of 1.2

cc's of brake fluid is taken in by the lip seal saver

(Fig. 13) to protect the lip seals on the piston of the

master cylinder.

DIAGNOSIS AND TESTING

ABS GENERAL DIAGNOSTICS INFORMATION

This section contains the information necessary to

diagnose the ITT Teves Mark 20 ABS Brake System.

Specifically, this section should be used to help diag-

nose conditions which result in any of the following:

(1) ABS Warning Lamp turned on.

(2) Brakes Lock-up on hard application

Diagnosis of base brake conditions which are obvi-

ously mechanical in nature should be directed to

Group 5 Brakes in this service manual. This includes

brake noise, brake pulsation, lack of power assist,

parking brake, Red BRAKE Warning Lamp lighting,

or vehicle vibration during normal braking.

Many conditions that generate customer com-

plaints may be normal operating conditions, but are

judged to be a problem due to not being familiar with

the ABS system. These conditions can be recognized

without performing extensive diagnostic work, given

adequate understanding of the operating principles

PLBRAKES 5 - 75

DESCRIPTION AND OPERATION (Continued)

Page 172 of 1200

CLUTCH

CONTENTS

page page

GENERAL INFORMATION

CLUTCH COMPONENTS................... 1

CLUTCH DISC AND COVER APPLICATION.... 2

CLUTCH REPLACEMENT.................. 2

DESCRIPTION AND OPERATION

CLUTCH CABLE......................... 2

CLUTCH PEDAL POSITION SWITCH......... 2

DIAGNOSIS AND TESTING

CLASH±INTO±REVERSE COMPLAINTS....... 6

CLUTCH CHATTER COMPLAINTS........... 6

CLUTCH COVER AND DISC RUNOUT........ 6

CLUTCH DIAGNOSIS..................... 3

CLUTCH PEDAL POSITION SWITCH......... 2

DRIVE PLATE MISALIGNMENT............. 6

REMOVAL AND INSTALLATION

CLUTCH ASSEMBLY...................... 7CLUTCH CABLE......................... 6

CLUTCH PEDAL POSITION SWITCH......... 7

RELEASE BEARING AND FORK............. 9

CLEANING AND INSPECTION

CLEANING PRECAUTIONS................ 10

CLUTCH CONTAMINATION................ 10

ADJUSTMENTS

CLUTCH CABLE........................ 10

CLUTCH PEDAL POSITION SWITCH........ 11

SPECIFICATIONS

TORQUE.............................. 11

SPECIAL TOOLS

CLUTCH.............................. 11

GENERAL INFORMATION

CLUTCH COMPONENTS

NOTE: Neon vehicles produced at the Toluca

assembly plant, in Mexico, have conventional clutch

and flywheel assemblies. Vehicles produced at Bel-

videre assembly plant have modular clutch assem-

blies.

Before beginning clutch service, check the 11th

character of the V.I.N. to determine where it was

produced. The 11th character is ªDº for vehicles

produced at Belvidere, or ªTº for vehicles produced

at Toluca.

For a vehicle produced at Belvidere assembly,

refer to this manual for service information on the

modular clutch assembly. For a vehicle produced at

Toluca assembly, refer to the following information

to determine proper service procedures.

Service parts stock only a Conventional Clutch

Disc Assembly or a Modular Clutch Service Pack-

age to service Toluca built vehicles. The Modular

Clutch Service Package contains the following

parts:

²One modular clutch assembly

²One drive plate assembly

²One backing plate assembly

²Four drive plate to clutch bolts

²Eight drive plate to crankshaft boltsIf only the clutch disc requires replacement,

obtain the clutch disc. Replace the clutch disc

using the information in the Removal And Installa-

tion section of this manual.

If the clutch pressure plate or flywheel requires

replacement, obtain the Modular Clutch Service

Package. Refer to this manual for service informa-

tion on the modular clutch assembly.

The clutch assembly used in this vehicle consists of

a single, dry-type clutch disc and a diaphragm style

clutch cover.

The clutch disc has cushion springs riveted to the

disc hub assembly. The clutch disc facings are riveted

to the cushion springs. The facings are made from a

non-asbestos material.

The clutch cover pressure plate assembly is a dia-

phragm type unit with a one-piece diaphragm spring

with multiple release fingers. The pressure plate

release fingers are preset during manufacture and

are not adjustable.

A sleeve-type release bearing is used to engage and

disengage the clutch cover pressure plate. The bear-

ing is prelubed during manufacture and is a sealed

unit.

The release bearing is operated by a pivoting

release fork in the clutch housing. The fork pivots on

a ball stud within the housing. The release fork is

actuated by a self-adjusting clutch cable.

PLCLUTCH 6 - 1

Page 173 of 1200

The clutch cable has a unique self-adjuster mecha-

nism built into the cable which compensates for

clutch disc wear. The cable requires no maintenance

or lubrication. There are no serviceable components

on the cable assembly.

The clutch pedal is connected to the cable through

a plastic spacer. The upper end of the clutch pedal

pivots in the pedal bracket on two nylon bushings

and a shaft. These bushings are greased at assembly

and do not require periodic lubrication.

CLUTCH DISC AND COVER APPLICATION

The 2.0 single overhead cam engine uses a 216 mm

(8.5 in.) clutch disc. The manual transaxle is avail-

able only with the 2.0 liter engine.

CLUTCH REPLACEMENT

The transaxle must be removed to service the

clutch disc, pressure plate, flywheel/drive plate,

and/or clutch release bearing and lever.

DESCRIPTION AND OPERATION

CLUTCH CABLE

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

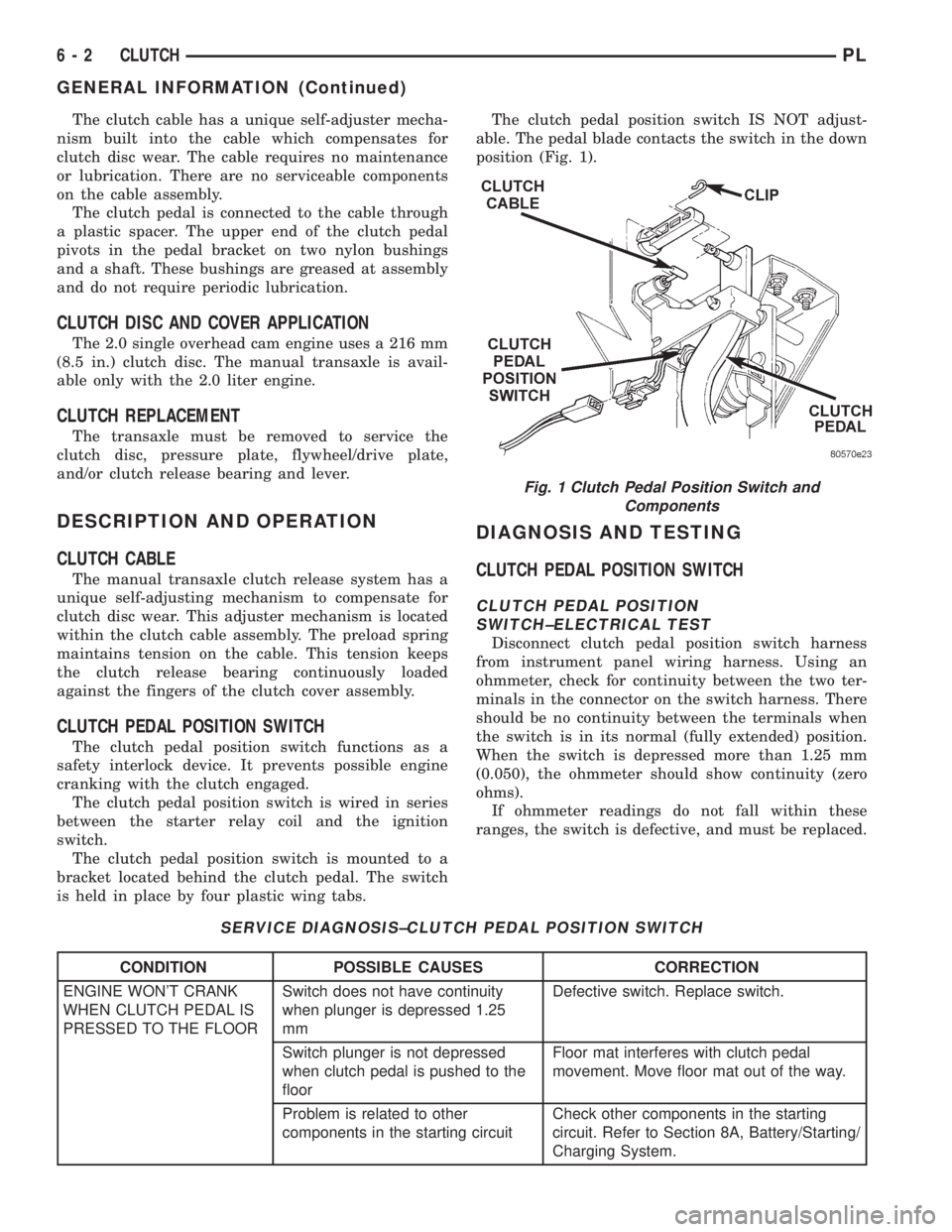

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch functions as a

safety interlock device. It prevents possible engine

cranking with the clutch engaged.

The clutch pedal position switch is wired in series

between the starter relay coil and the ignition

switch.

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 1).

DIAGNOSIS AND TESTING

CLUTCH PEDAL POSITION SWITCH

CLUTCH PEDAL POSITION

SWITCH±ELECTRICAL TEST

Disconnect clutch pedal position switch harness

from instrument panel wiring harness. Using an

ohmmeter, check for continuity between the two ter-

minals in the connector on the switch harness. There

should be no continuity between the terminals when

the switch is in its normal (fully extended) position.

When the switch is depressed more than 1.25 mm

(0.050), the ohmmeter should show continuity (zero

ohms).

If ohmmeter readings do not fall within these

ranges, the switch is defective, and must be replaced.

SERVICE DIAGNOSIS±CLUTCH PEDAL POSITION SWITCH

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WON'T CRANK

WHEN CLUTCH PEDAL IS

PRESSED TO THE FLOORSwitch does not have continuity

when plunger is depressed 1.25

mmDefective switch. Replace switch.

Switch plunger is not depressed

when clutch pedal is pushed to the

floorFloor mat interferes with clutch pedal

movement. Move floor mat out of the way.

Problem is related to other

components in the starting circuitCheck other components in the starting

circuit. Refer to Section 8A, Battery/Starting/

Charging System.

Fig. 1 Clutch Pedal Position Switch and

Components

6 - 2 CLUTCHPL

GENERAL INFORMATION (Continued)

Page 182 of 1200

(4) Reinstall cable inspection cover and air cleaner

assembly. Check clutch pedal position switch opera-

tion.

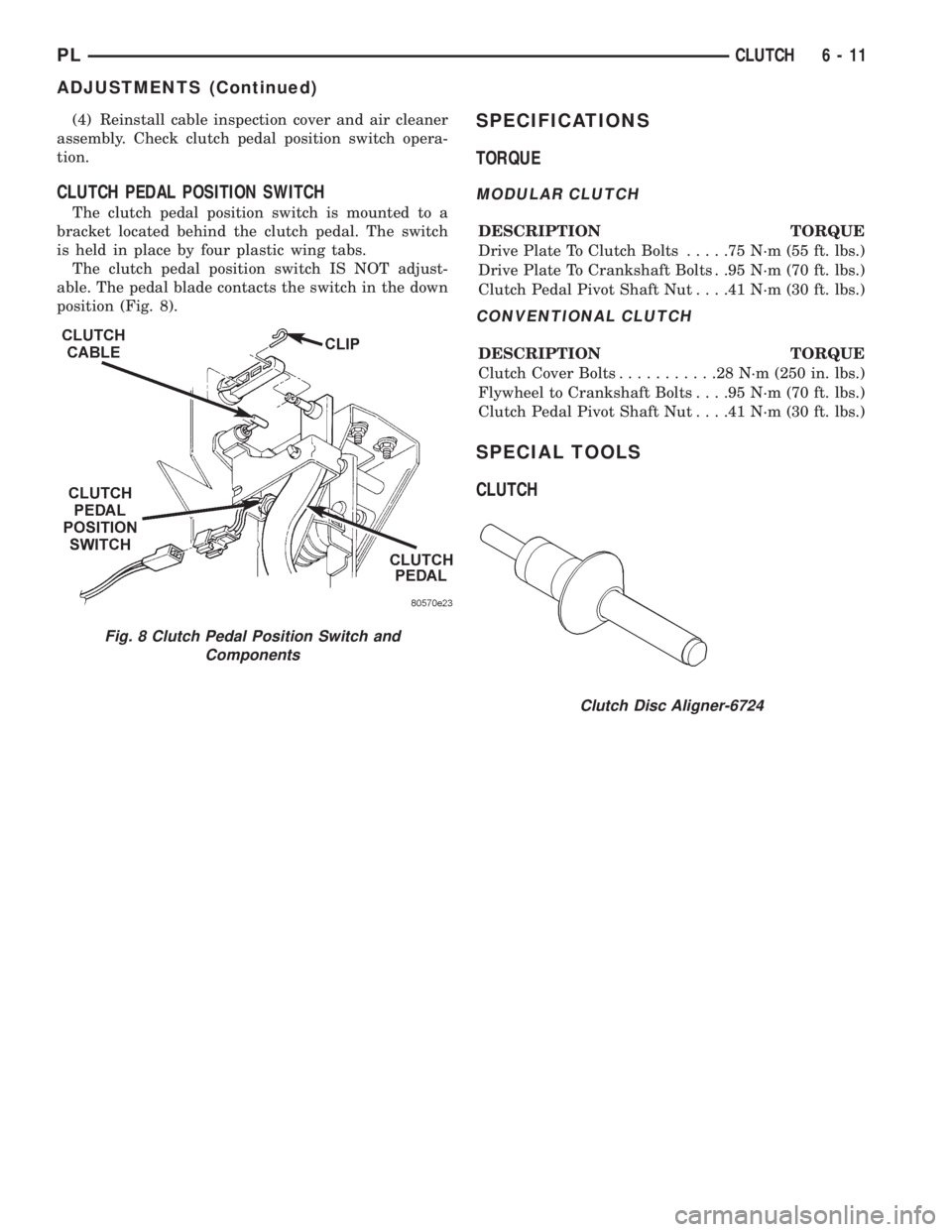

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.

The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 8).

SPECIFICATIONS

TORQUE

MODULAR CLUTCH

DESCRIPTION TORQUE

Drive Plate To Clutch Bolts.....75N´m(55ft.lbs.)

Drive Plate To Crankshaft Bolts . .95 N´m (70 ft. lbs.)

Clutch Pedal Pivot Shaft Nut. . . .41 N´m (30 ft. lbs.)

CONVENTIONAL CLUTCH

DESCRIPTION TORQUE

Clutch Cover Bolts...........28N´m(250 in. lbs.)

Flywheel to Crankshaft Bolts. . . .95 N´m (70 ft. lbs.)

Clutch Pedal Pivot Shaft Nut. . . .41 N´m (30 ft. lbs.)

SPECIAL TOOLS

CLUTCH

Clutch Disc Aligner-6724

Fig. 8 Clutch Pedal Position Switch and

Components

PLCLUTCH 6 - 11

ADJUSTMENTS (Continued)

Page 279 of 1200

HEATER A/C CONTROL BLOWER SWITCH

The switch is not serviced, replace heater A/C con-

trol. Refer to the Heater A/C Control Removal and

Installation.

HEATER A/C CONTROL LAMP

REMOVAL

(1) Remove the Heater A/C Control. Refer to the

Heater A/C Control Removal.

(2) Remove the two center knobs by pulling the

knob rearward.

(3) Replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

HEATER CONTROL BLOWER SWITCH

The switch is not serviced, replace the heater con-

trol. Refer to the A/C Heater Control Removal and

Installation.

IGNITION KEY LAMP

REMOVAL

(1) Remove the steering column cover. Refer to

Steering Column Cover Removal.

(2) Disconnect the lamp hood from the base panel.

(3) Remove the lamp socket from hood and replace

the lamp.

INSTALLATION

For installation, reverse the above procedures.

INSTRUMENT PANEL

REMOVAL

CAUTION: Disconnect battery negative cable, in

engine compartment, before servicing instrument

panel.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the floor console. Refer to Floor Con-

sole Removal.

(3) Remove the right and left cowl side trim pan-

els (Fig. 19).

(4) Remove the steering column cover and liner.

(5) Remove the top cover and cluster bezel assem-

bly.

(6) Remove the right and left trim panel.

(7) Remove the defroster upper duct by lifting it

up.

(8) Remove the center outlet duct by pulling rear-

ward.(9) Disconnect the Heater A/C Control, by remov-

ing the control cables clips with a screwdriver and

remove the wire connector.

CAUTION: Lock the steering wheel in the straight

ahead position. This will prevent clockspring dam-

age when the steering wheel rotates freely.

(10) Disconnect the steering column at the bottom

slap together joint.

(11) Disconnect the ATX shifter interlock cable at

the shifter, if equipped.

(12) Disconnect the instrument panel wiring as

required.

(13) Remove the four attaching screws at the cen-

ter floor pan bracket (Fig. 20).

(14) Remove the four attaching screws at steering

column.

(15) Remove the four cowl top nuts.

(16) Remove the attaching screws from the left

and right lower cowl side bracket (Fig. 21).

(17) Remove the two attaching screws from the left

upper cowl side and one from the right upper cowl

side.

(18) Pull the instrument panel rearward away

from the dash/plenum.

(19) Remove the instrument panel from vehicle.

INSTALLATION

For installation, reverse the above procedures.

LEFT TRIM PANEL

REMOVAL

(1) Remove the top cover and cluster bezel (Fig.

19).

(2) Remove the steering column cover.

(3) Remove the two attaching screws along the

bottom and the one at the top of the trim panel and

pull rearward to remove.

INSTALLATION

For installation, reverse the above procedures.

ODOMETER

REMOVAL

(1) Remove the instrument panel top cover and

cluster bezel.

(2) Remove the four screws attaching cluster to

instrument panel (Fig. 22).

(3) Remove the cluster.

(4) Remove the screws attaching PC board cover to

cluster.

(5) Disconnect the odometer connector from the

printed circuit board.

8E - 10 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 360 of 1200

DRIVER AIRBAG MODULE

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

When removing a deployed module, rubber gloves,

eye protection and long sleeved shirt should be worn,

as there may be deposits on the surface which could

irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

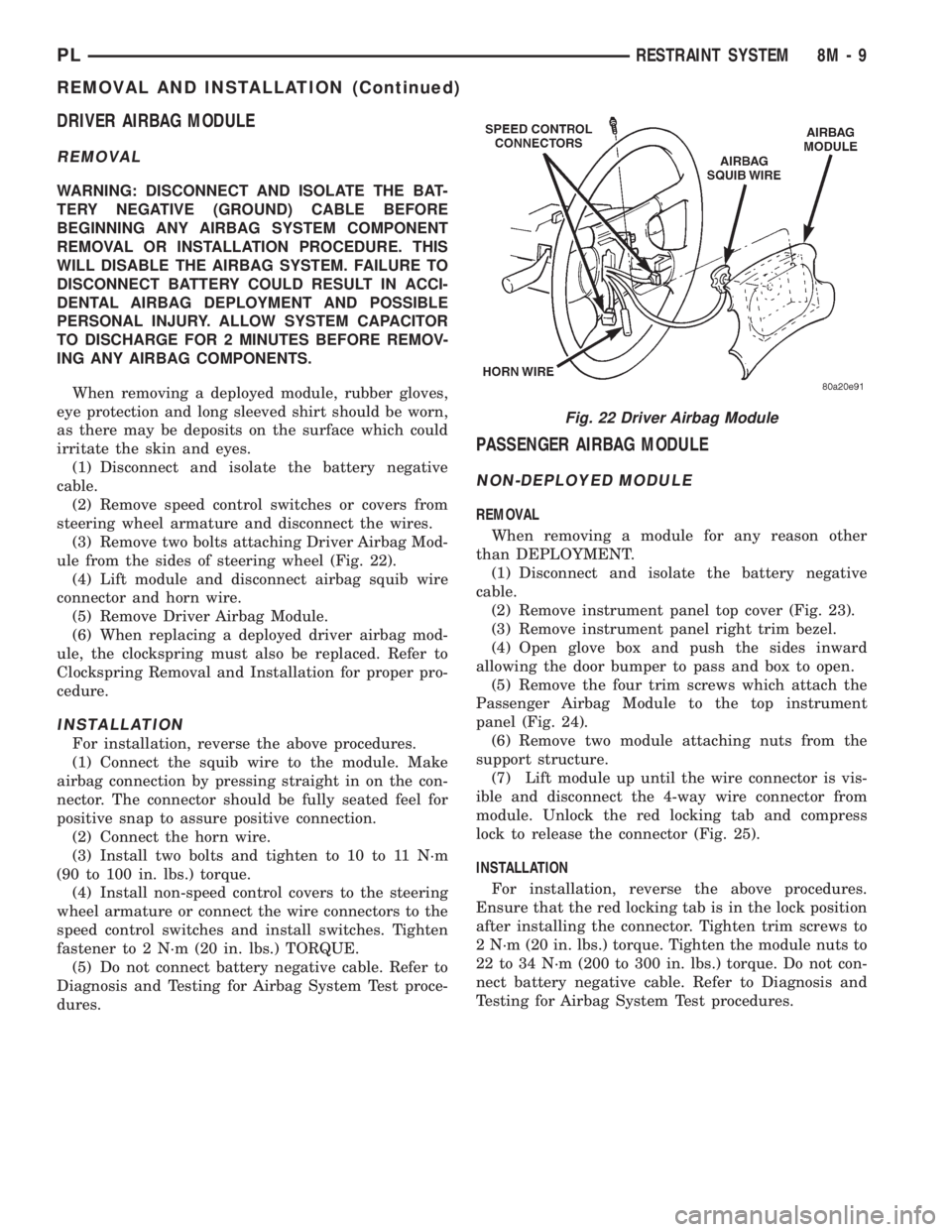

(2) Remove speed control switches or covers from

steering wheel armature and disconnect the wires.

(3) Remove two bolts attaching Driver Airbag Mod-

ule from the sides of steering wheel (Fig. 22).

(4) Lift module and disconnect airbag squib wire

connector and horn wire.

(5) Remove Driver Airbag Module.

(6) When replacing a deployed driver airbag mod-

ule, the clockspring must also be replaced. Refer to

Clockspring Removal and Installation for proper pro-

cedure.

INSTALLATION

For installation, reverse the above procedures.

(1) Connect the squib wire to the module. Make

airbag connection by pressing straight in on the con-

nector. The connector should be fully seated feel for

positive snap to assure positive connection.

(2) Connect the horn wire.

(3) Install two bolts and tighten to 10 to 11 N´m

(90 to 100 in. lbs.) torque.

(4) Install non-speed control covers to the steering

wheel armature or connect the wire connectors to the

speed control switches and install switches. Tighten

fastener to 2 N´m (20 in. lbs.) TORQUE.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test proce-

dures.

PASSENGER AIRBAG MODULE

NON-DEPLOYED MODULE

REMOVAL

When removing a module for any reason other

than DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel top cover (Fig. 23).

(3) Remove instrument panel right trim bezel.

(4) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(5) Remove the four trim screws which attach the

Passenger Airbag Module to the top instrument

panel (Fig. 24).

(6) Remove two module attaching nuts from the

support structure.

(7) Lift module up until the wire connector is vis-

ible and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector (Fig. 25).

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

Fig. 22 Driver Airbag Module

PLRESTRAINT SYSTEM 8M - 9

REMOVAL AND INSTALLATION (Continued)