fuel additives DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 259 of 1200

Connect the DVM between the center and sensor

ground terminal. Refer to Group 8W - Wiring Dia-

grams for correct pinout.

With the ignition switch in the ON position, check

the output voltage at the center terminal wire of the

connector. Check the output voltage at idle and at

Wide-Open-Throttle (WOT). At idle, TPS output volt-

age should be approximately 0.38 volts to 1.2 volts.

At wide open throttle, TPS output voltage should be

approximately 3.1 volts to 4.4 volts. The output volt-

age should gradually increase as the throttle plate

moves slowly from idle to WOT.

Check for spread terminals at the sensor and PCM

connections before replacing the TPS.

SPARK PLUG CONDITION

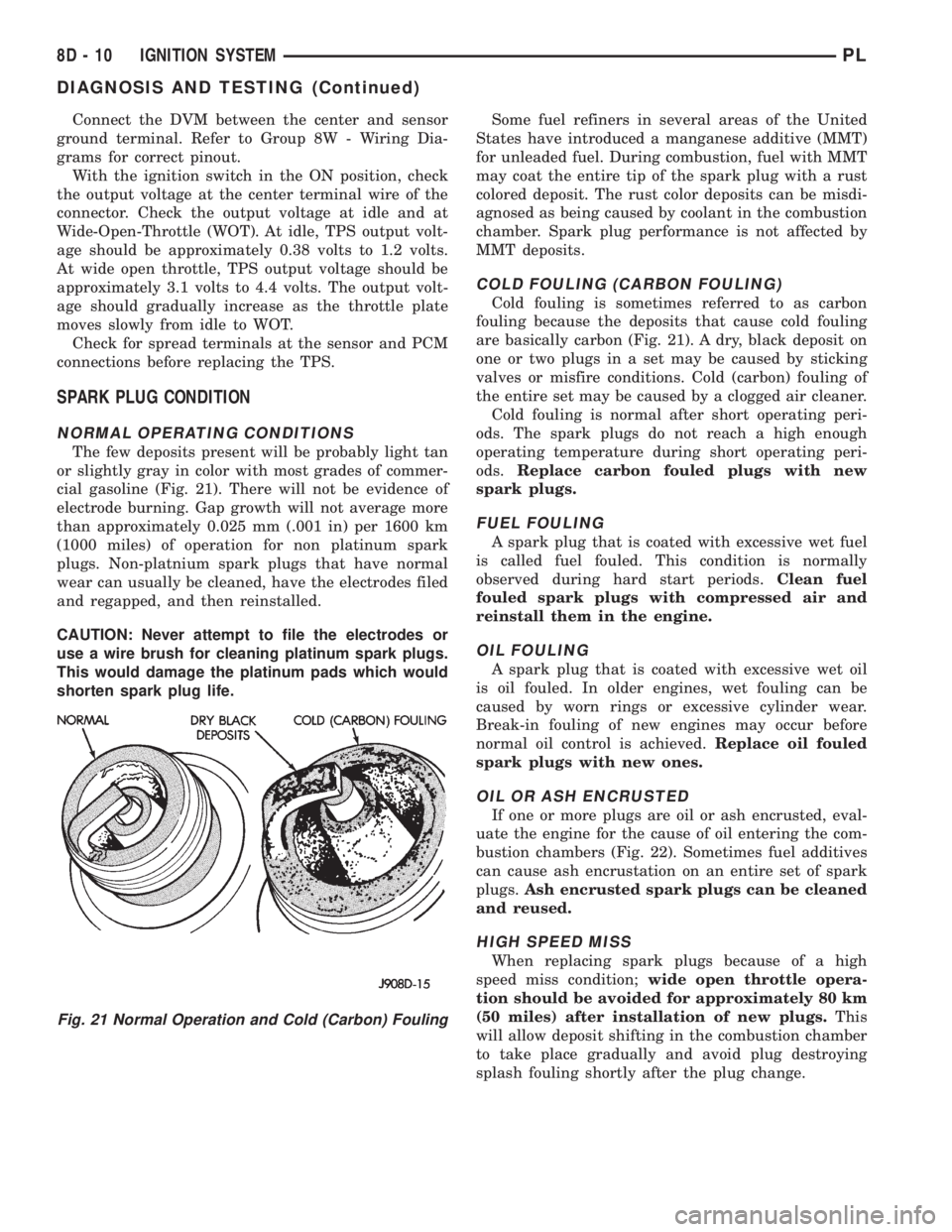

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 21). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation for non platinum spark

plugs. Non-platnium spark plugs that have normal

wear can usually be cleaned, have the electrodes filed

and regapped, and then reinstalled.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum spark plugs.

This would damage the platinum pads which would

shorten spark plug life.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling

are basically carbon (Fig. 21). A dry, black deposit on

one or two plugs in a set may be caused by sticking

valves or misfire conditions. Cold (carbon) fouling of

the entire set may be caused by a clogged air cleaner.

Cold fouling is normal after short operating peri-

ods. The spark plugs do not reach a high enough

operating temperature during short operating peri-

ods.Replace carbon fouled plugs with new

spark plugs.

FUEL FOULING

A spark plug that is coated with excessive wet fuel

is called fuel fouled. This condition is normally

observed during hard start periods.Clean fuel

fouled spark plugs with compressed air and

reinstall them in the engine.

OIL FOULING

A spark plug that is coated with excessive wet oil

is oil fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur before

normal oil control is achieved.Replace oil fouled

spark plugs with new ones.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or ash encrusted, eval-

uate the engine for the cause of oil entering the com-

bustion chambers (Fig. 22). Sometimes fuel additives

can cause ash encrustation on an entire set of spark

plugs.Ash encrusted spark plugs can be cleaned

and reused.

HIGH SPEED MISS

When replacing spark plugs because of a high

speed miss condition;wide open throttle opera-

tion should be avoided for approximately 80 km

(50 miles) after installation of new plugs.This

will allow deposit shifting in the combustion chamber

to take place gradually and avoid plug destroying

splash fouling shortly after the plug change.

Fig. 21 Normal Operation and Cold (Carbon) Fouling

8D - 10 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 260 of 1200

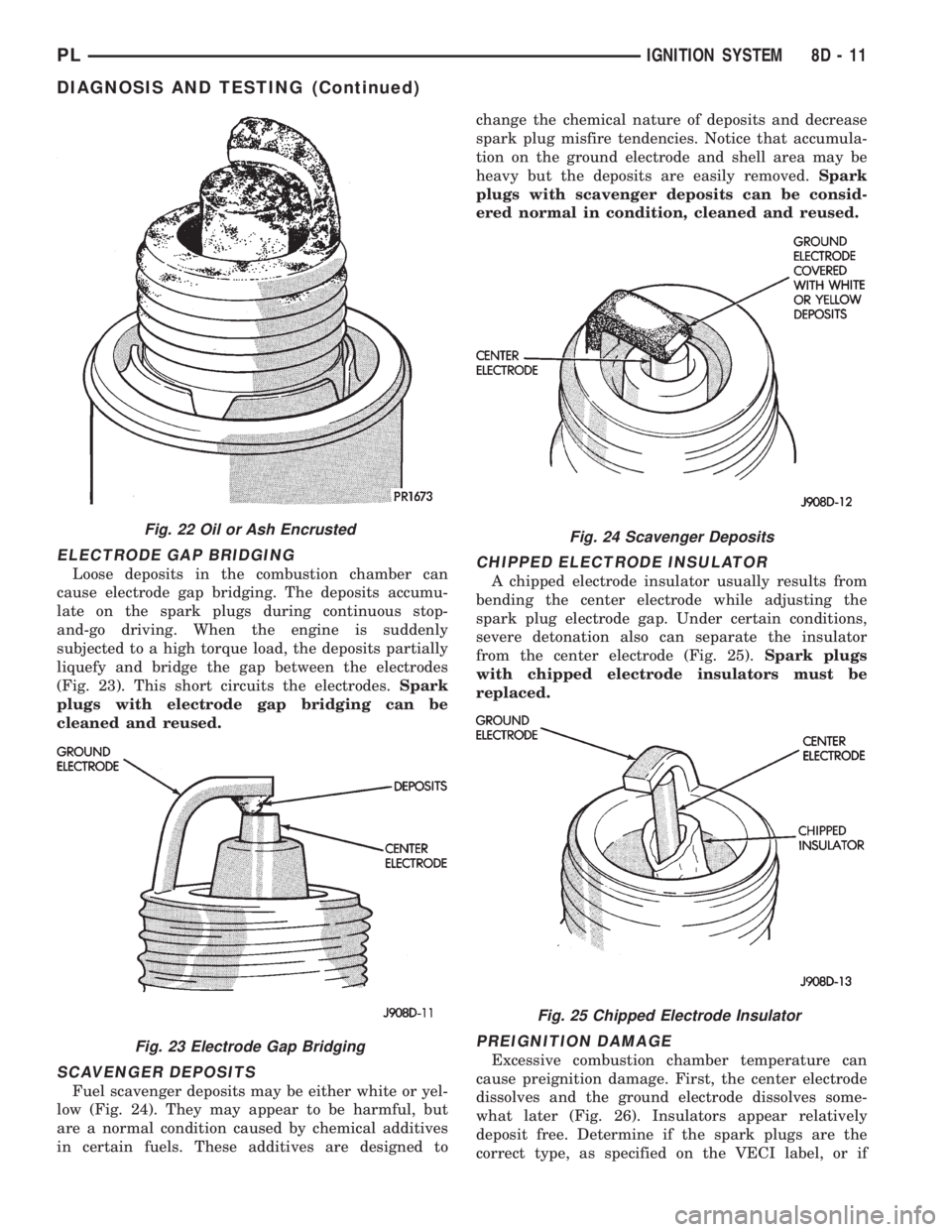

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can

cause electrode gap bridging. The deposits accumu-

late on the spark plugs during continuous stop-

and-go driving. When the engine is suddenly

subjected to a high torque load, the deposits partially

liquefy and bridge the gap between the electrodes

(Fig. 23). This short circuits the electrodes.Spark

plugs with electrode gap bridging can be

cleaned and reused.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 24). They may appear to be harmful, but

are a normal condition caused by chemical additives

in certain fuels. These additives are designed tochange the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy but the deposits are easily removed.Spark

plugs with scavenger deposits can be consid-

ered normal in condition, cleaned and reused.

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation also can separate the insulator

from the center electrode (Fig. 25).Spark plugs

with chipped electrode insulators must be

replaced.

PREIGNITION DAMAGE

Excessive combustion chamber temperature can

cause preignition damage. First, the center electrode

dissolves and the ground electrode dissolves some-

what later (Fig. 26). Insulators appear relatively

deposit free. Determine if the spark plugs are the

correct type, as specified on the VECI label, or if

Fig. 22 Oil or Ash Encrusted

Fig. 23 Electrode Gap Bridging

Fig. 24 Scavenger Deposits

Fig. 25 Chipped Electrode Insulator

PLIGNITION SYSTEM 8D - 11

DIAGNOSIS AND TESTING (Continued)

Page 842 of 1200

FUEL SYSTEM

CONTENTS

page page

FUEL DELIVERY SYSTEM................... 3

FUEL INJECTION SYSTEM................. 20GENERAL INFORMATION................... 1

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

FUEL REQUIREMENTS.................... 1

GASOLINE/OXYGENATE BLENDS............ 1INTRODUCTION......................... 1

PCM REPLACEMENT..................... 1

GENERAL INFORMATION

INTRODUCTION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

The Evaporation Control System, is also considered

part of the fuel system. The system reduces the emis-

sion of fuel vapor into the atmosphere.

The description and function of the Evaporation

Control System is found in Group 25 of this manual.

PCM REPLACEMENT

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

FUEL REQUIREMENTS

Your vehicle was designed to meet all emission reg-

ulations and provide excellent fuel economy when

using high quality unleaded gasoline.

Use unleaded gasolines having a minimum posted

octane of 87.

If your vehicle develops occasional light spark

knock (ping) at low engine speeds this is not harm-

ful. However; continued heavy knock at high speeds

can cause damage and should be reported to yourdealer immediately. Engine damage as a result of

heavy knock operation may not be covered by the

new vehicle warranty.

In addition to using unleaded gasoline with the

proper octane rating, those that contain detergents,

corrosion and stability additives are recommended.

Using gasolines that have these additives will help

improve fuel economy, reduce emissions, and main-

tain vehicle performance.

Poor quality gasoline can cause problems such as

hard starting, stalling, and stumble. If you experi-

ence these problems, try another brand of gasoline

before considering service for the vehicle.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

carbon monoxide emissions. The type and amount of

oxygenate used in the blend is important.

The following are generally used in gasoline

blends:

Ethanol- (Ethyl or Grain Alcohol) properly

blended, is used as a mixture of 10 percent ethanol

and 90 percent gasoline. Gasoline blended with etha-

nol may be used in your vehicle.

MTBE/ETBE- Gasoline and MTBE (Methyl Ter-

tiary Butyl Ether) blends are a mixture of unleaded

gasoline and up to 15 percent MTBE. Gasoline and

ETBE (Ethyl Tertiary Butyl Ether) are blends of gas-

PLFUEL SYSTEM 14 - 1