horn DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 294 of 1200

HORNS

CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

HORN RELAY........................... 2

HORN SWITCH.......................... 2

HORN................................. 1SYSTEM TEST.......................... 2

REMOVAL AND INSTALLATION

HORN RELAY........................... 4

HORN SWITCHES........................ 4

HORN................................. 4

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

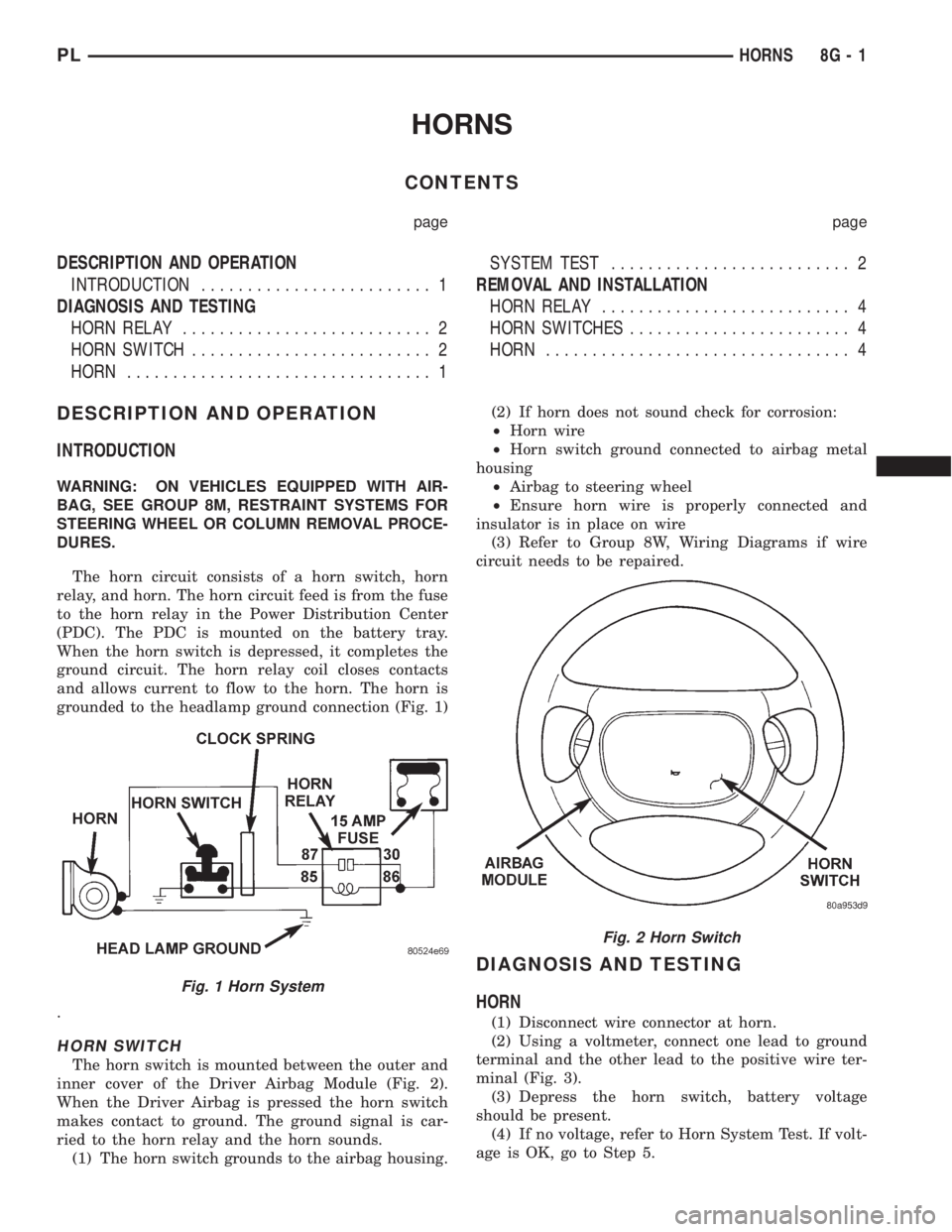

The horn circuit consists of a horn switch, horn

relay, and horn. The horn circuit feed is from the fuse

to the horn relay in the Power Distribution Center

(PDC). The PDC is mounted on the battery tray.

When the horn switch is depressed, it completes the

ground circuit. The horn relay coil closes contacts

and allows current to flow to the horn. The horn is

grounded to the headlamp ground connection (Fig. 1)

.

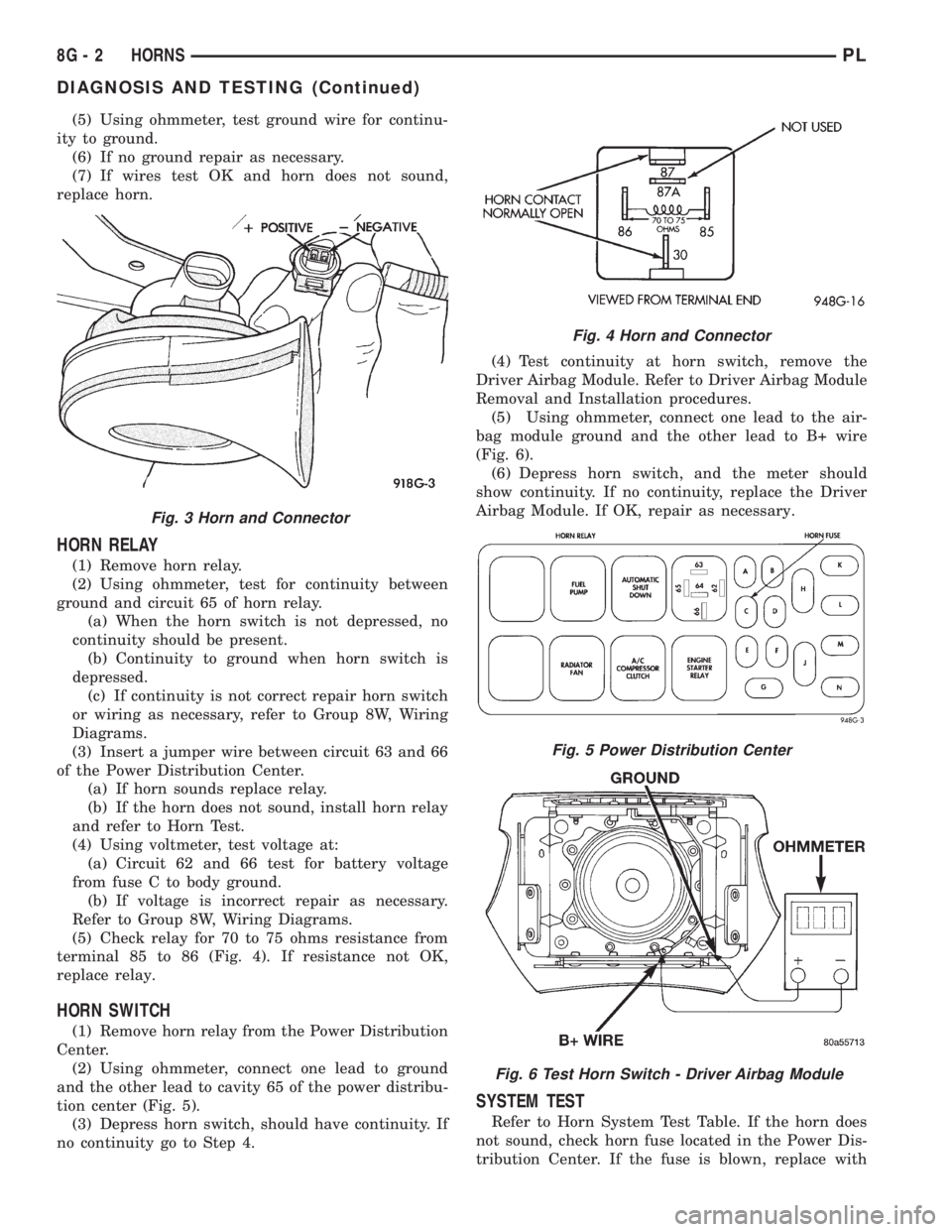

HORN SWITCH

The horn switch is mounted between the outer and

inner cover of the Driver Airbag Module (Fig. 2).

When the Driver Airbag is pressed the horn switch

makes contact to ground. The ground signal is car-

ried to the horn relay and the horn sounds.

(1) The horn switch grounds to the airbag housing.(2) If horn does not sound check for corrosion:

²Horn wire

²Horn switch ground connected to airbag metal

housing

²Airbag to steering wheel

²Ensure horn wire is properly connected and

insulator is in place on wire

(3) Refer to Group 8W, Wiring Diagrams if wire

circuit needs to be repaired.

DIAGNOSIS AND TESTING

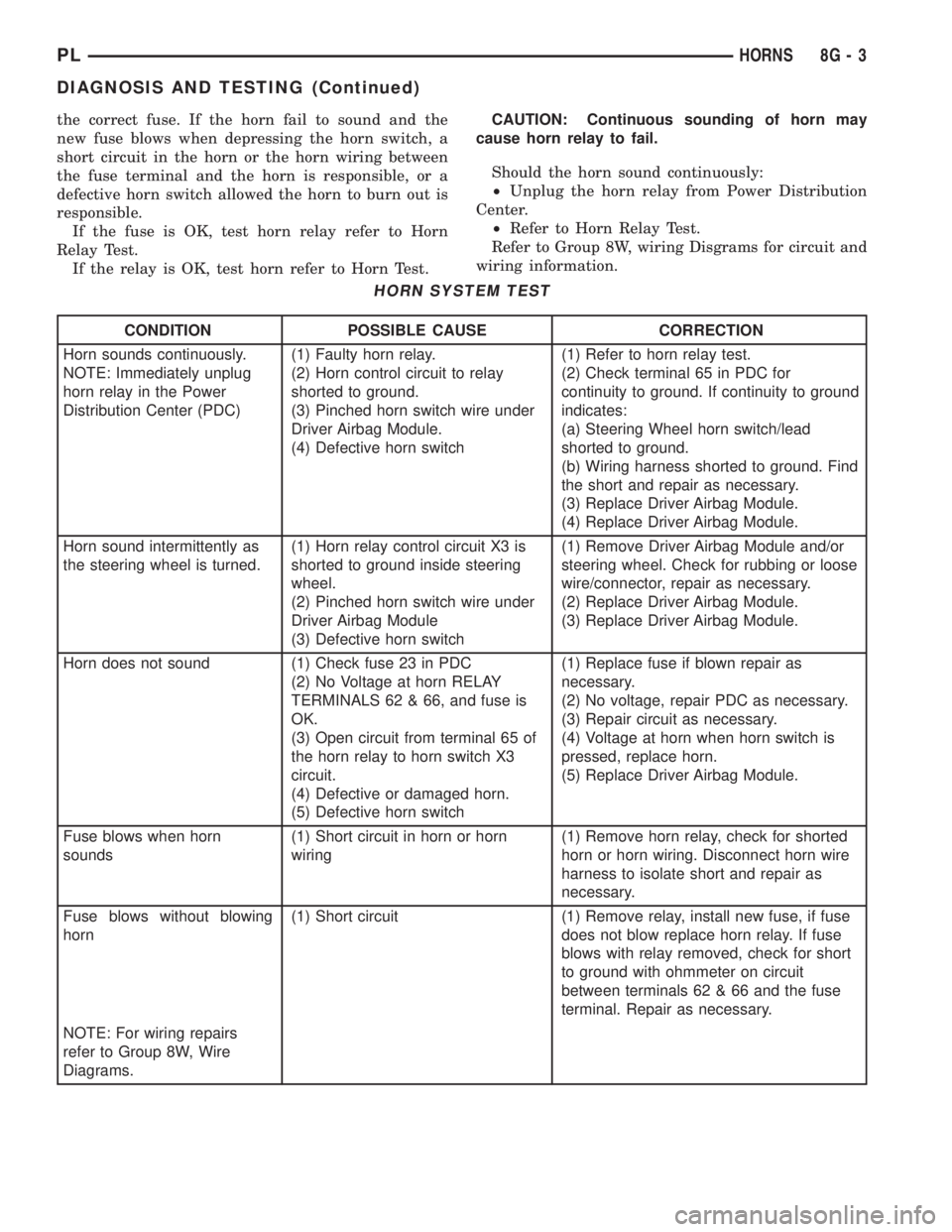

HORN

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 3).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer to Horn System Test. If volt-

age is OK, go to Step 5.

Fig. 1 Horn System

Fig. 2 Horn Switch

PLHORNS 8G - 1

Page 295 of 1200

(5) Using ohmmeter, test ground wire for continu-

ity to ground.

(6) If no ground repair as necessary.

(7) If wires test OK and horn does not sound,

replace horn.

HORN RELAY

(1) Remove horn relay.

(2) Using ohmmeter, test for continuity between

ground and circuit 65 of horn relay.

(a) When the horn switch is not depressed, no

continuity should be present.

(b) Continuity to ground when horn switch is

depressed.

(c) If continuity is not correct repair horn switch

or wiring as necessary, refer to Group 8W, Wiring

Diagrams.

(3) Insert a jumper wire between circuit 63 and 66

of the Power Distribution Center.

(a) If horn sounds replace relay.

(b) If the horn does not sound, install horn relay

and refer to Horn Test.

(4) Using voltmeter, test voltage at:

(a) Circuit 62 and 66 test for battery voltage

from fuse C to body ground.

(b) If voltage is incorrect repair as necessary.

Refer to Group 8W, Wiring Diagrams.

(5) Check relay for 70 to 75 ohms resistance from

terminal 85 to 86 (Fig. 4). If resistance not OK,

replace relay.

HORN SWITCH

(1) Remove horn relay from the Power Distribution

Center.

(2) Using ohmmeter, connect one lead to ground

and the other lead to cavity 65 of the power distribu-

tion center (Fig. 5).

(3) Depress horn switch, should have continuity. If

no continuity go to Step 4.(4) Test continuity at horn switch, remove the

Driver Airbag Module. Refer to Driver Airbag Module

Removal and Installation procedures.

(5) Using ohmmeter, connect one lead to the air-

bag module ground and the other lead to B+ wire

(Fig. 6).

(6) Depress horn switch, and the meter should

show continuity. If no continuity, replace the Driver

Airbag Module. If OK, repair as necessary.

SYSTEM TEST

Refer to Horn System Test Table. If the horn does

not sound, check horn fuse located in the Power Dis-

tribution Center. If the fuse is blown, replace with

Fig. 3 Horn and Connector

Fig. 4 Horn and Connector

Fig. 5 Power Distribution Center

Fig. 6 Test Horn Switch - Driver Airbag Module

8G - 2 HORNSPL

DIAGNOSIS AND TESTING (Continued)

Page 296 of 1200

the correct fuse. If the horn fail to sound and the

new fuse blows when depressing the horn switch, a

short circuit in the horn or the horn wiring between

the fuse terminal and the horn is responsible, or a

defective horn switch allowed the horn to burn out is

responsible.

If the fuse is OK, test horn relay refer to Horn

Relay Test.

If the relay is OK, test horn refer to Horn Test.CAUTION: Continuous sounding of horn may

cause horn relay to fail.

Should the horn sound continuously:

²Unplug the horn relay from Power Distribution

Center.

²Refer to Horn Relay Test.

Refer to Group 8W, wiring Disgrams for circuit and

wiring information.

HORN SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

Horn sounds continuously.

NOTE: Immediately unplug

horn relay in the Power

Distribution Center (PDC)(1) Faulty horn relay.

(2) Horn control circuit to relay

shorted to ground.

(3) Pinched horn switch wire under

Driver Airbag Module.

(4) Defective horn switch(1) Refer to horn relay test.

(2) Check terminal 65 in PDC for

continuity to ground. If continuity to ground

indicates:

(a) Steering Wheel horn switch/lead

shorted to ground.

(b) Wiring harness shorted to ground. Find

the short and repair as necessary.

(3) Replace Driver Airbag Module.

(4) Replace Driver Airbag Module.

Horn sound intermittently as

the steering wheel is turned.(1) Horn relay control circuit X3 is

shorted to ground inside steering

wheel.

(2) Pinched horn switch wire under

Driver Airbag Module

(3) Defective horn switch(1) Remove Driver Airbag Module and/or

steering wheel. Check for rubbing or loose

wire/connector, repair as necessary.

(2) Replace Driver Airbag Module.

(3) Replace Driver Airbag Module.

Horn does not sound (1) Check fuse 23 in PDC

(2) No Voltage at horn RELAY

TERMINALS 62 & 66, and fuse is

OK.

(3) Open circuit from terminal 65 of

the horn relay to horn switch X3

circuit.

(4) Defective or damaged horn.

(5) Defective horn switch(1) Replace fuse if blown repair as

necessary.

(2) No voltage, repair PDC as necessary.

(3) Repair circuit as necessary.

(4) Voltage at horn when horn switch is

pressed, replace horn.

(5) Replace Driver Airbag Module.

Fuse blows when horn

sounds(1) Short circuit in horn or horn

wiring(1) Remove horn relay, check for shorted

horn or horn wiring. Disconnect horn wire

harness to isolate short and repair as

necessary.

Fuse blows without blowing

horn(1) Short circuit (1) Remove relay, install new fuse, if fuse

does not blow replace horn relay. If fuse

blows with relay removed, check for short

to ground with ohmmeter on circuit

between terminals 62 & 66 and the fuse

terminal. Repair as necessary.

NOTE: For wiring repairs

refer to Group 8W, Wire

Diagrams.

PLHORNS 8G - 3

DIAGNOSIS AND TESTING (Continued)

Page 297 of 1200

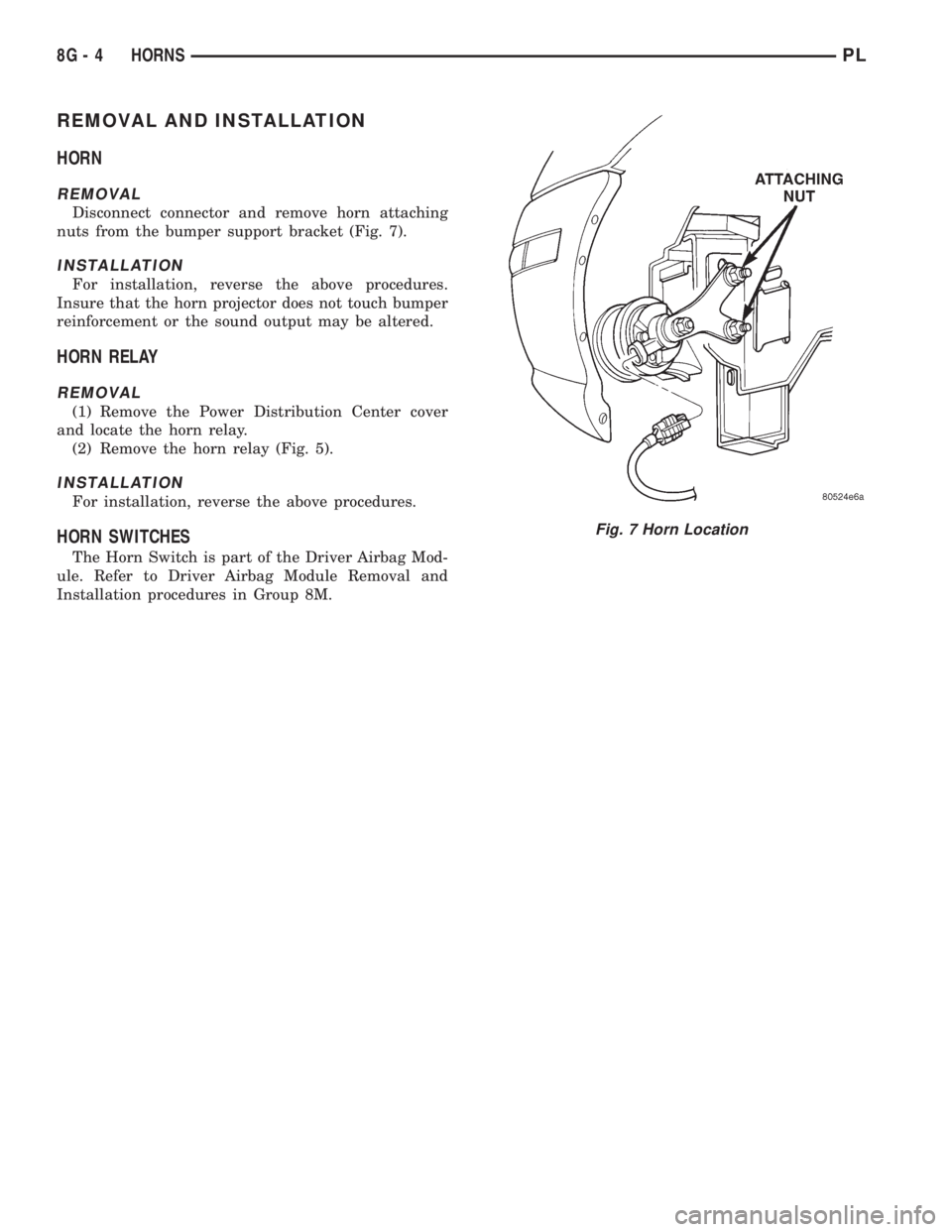

REMOVAL AND INSTALLATION

HORN

REMOVAL

Disconnect connector and remove horn attaching

nuts from the bumper support bracket (Fig. 7).

INSTALLATION

For installation, reverse the above procedures.

Insure that the horn projector does not touch bumper

reinforcement or the sound output may be altered.

HORN RELAY

REMOVAL

(1) Remove the Power Distribution Center cover

and locate the horn relay.

(2) Remove the horn relay (Fig. 5).

INSTALLATION

For installation, reverse the above procedures.

HORN SWITCHES

The Horn Switch is part of the Driver Airbag Mod-

ule. Refer to Driver Airbag Module Removal and

Installation procedures in Group 8M.

Fig. 7 Horn Location

8G - 4 HORNSPL

Page 310 of 1200

TURN SIGNAL AND FLASHERS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

COMBINATION FLASHER.................. 1

HAZARD WARNING SYSTEM............... 1DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH................ 2

MULTI-FUNCTION SWITCH TEST............ 2

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH................ 4

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG REMOVAL PROCEDURES.

The turn signals are part of the multi-function

switch. Which contains:

²Electrical circuitry for turn signals

²Hazard warning switch

²Headlamp beam select switch

²Headlamp optical horn

The integrated switch assembly is mounted to the

left hand side of the steering column. When the

driver wishes to signal his intentions to change direc-

tion of travel, he moves the lever upward to cause

the right signals to flash and downward to cause the

left signals to flash. After completion of a turn the

system is deactivated automatically. As the steering

wheel returns to the straight ahead position, a can-

celing cam molded to the clockspring mechanism

comes in contact with the cancel actuator on the turn

signal multi-function switch assembly. The cam lobe,

pushing on the cancel actuator, returns the switch to

the off position.

If only momentary signaling such as indication of a

lane change is desired, the switch is actuated to a

left or right intermediate detent position. In this

position the signal lamps flash as described above,

but the switch returns to the OFF position as soon as

the lever is released.

When the system is activated, one of two indicator

lamps mounted in the instrument cluster flashes in

unison with the turn signal lamps, indicating to the

driver that the system is operating.

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM

The hazard warning system is actuated by a slide

button located on the top of the steering column

between the steering wheel and the instrument

panel. The hazard switch is identified with a double

triangle on front of the button.

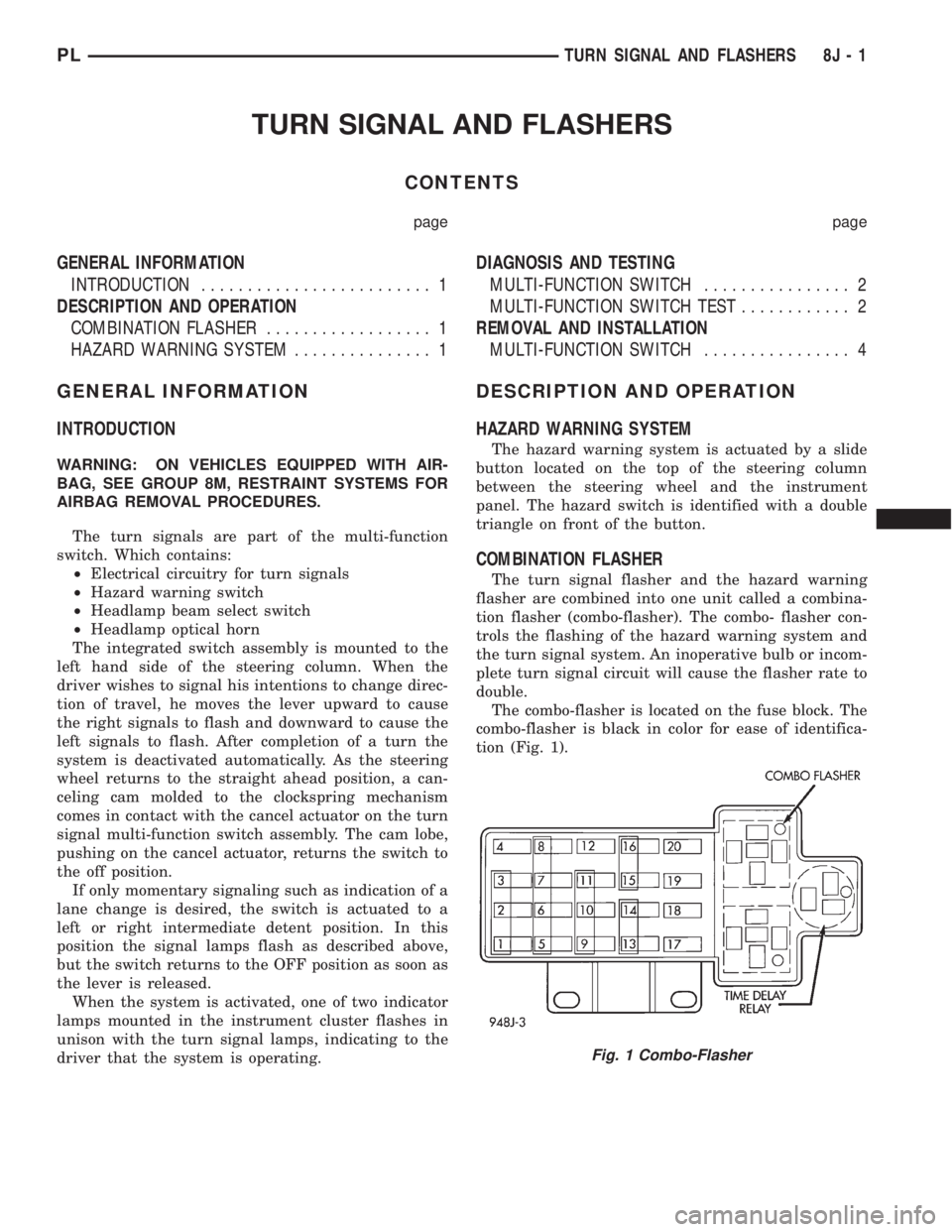

COMBINATION FLASHER

The turn signal flasher and the hazard warning

flasher are combined into one unit called a combina-

tion flasher (combo-flasher). The combo- flasher con-

trols the flashing of the hazard warning system and

the turn signal system. An inoperative bulb or incom-

plete turn signal circuit will cause the flasher rate to

double.

The combo-flasher is located on the fuse block. The

combo-flasher is black in color for ease of identifica-

tion (Fig. 1).

Fig. 1 Combo-Flasher

PLTURN SIGNAL AND FLASHERS 8J - 1

Page 311 of 1200

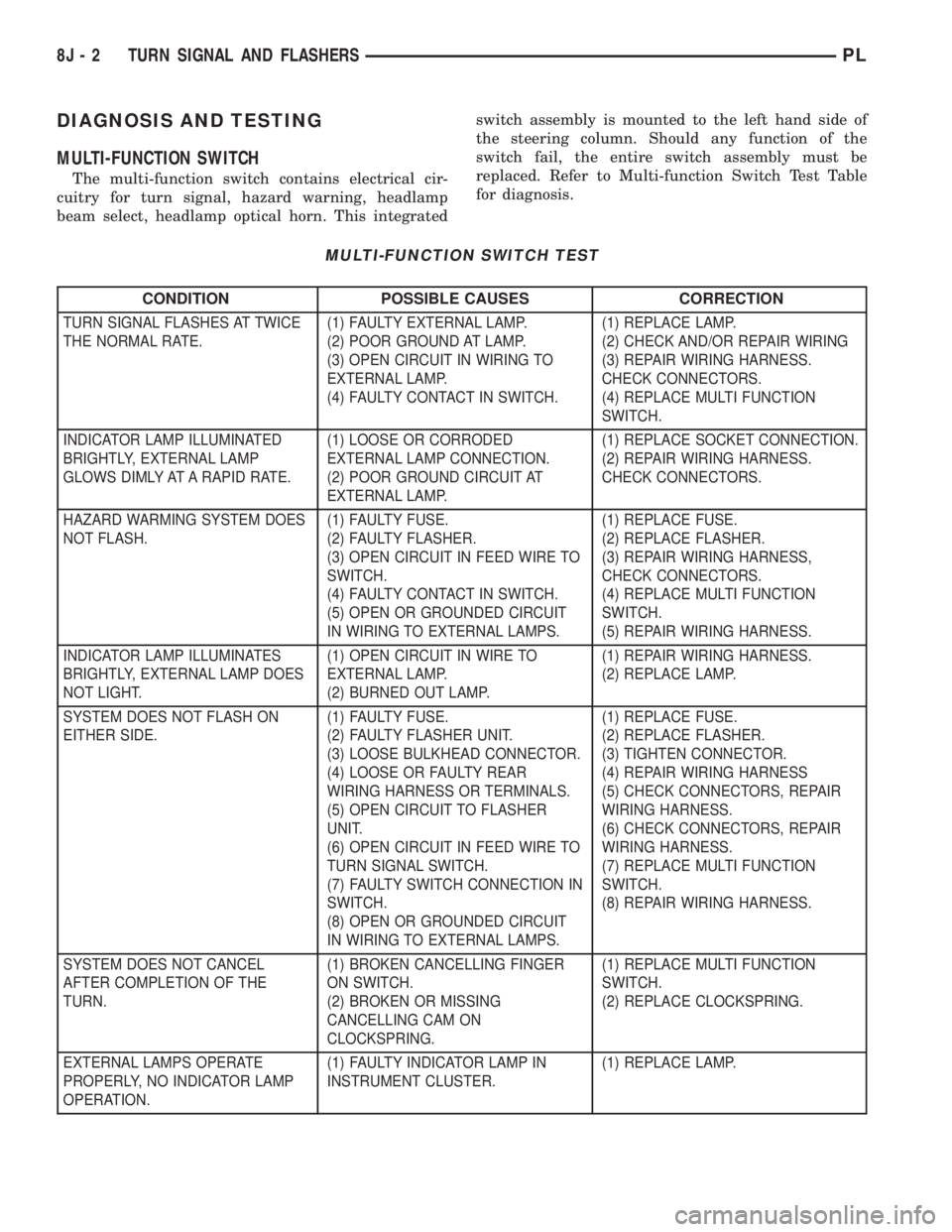

DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH

The multi-function switch contains electrical cir-

cuitry for turn signal, hazard warning, headlamp

beam select, headlamp optical horn. This integratedswitch assembly is mounted to the left hand side of

the steering column. Should any function of the

switch fail, the entire switch assembly must be

replaced. Refer to Multi-function Switch Test Table

for diagnosis.

MULTI-FUNCTION SWITCH TEST

CONDITION POSSIBLE CAUSES CORRECTION

TURN SIGNAL FLASHES AT TWICE

THE NORMAL RATE.(1) FAULTY EXTERNAL LAMP.

(2) POOR GROUND AT LAMP.

(3) OPEN CIRCUIT IN WIRING TO

EXTERNAL LAMP.

(4) FAULTY CONTACT IN SWITCH.(1) REPLACE LAMP.

(2) CHECK AND/OR REPAIR WIRING

(3) REPAIR WIRING HARNESS.

CHECK CONNECTORS.

(4) REPLACE MULTI FUNCTION

SWITCH.

INDICATOR LAMP ILLUMINATED

BRIGHTLY, EXTERNAL LAMP

GLOWS DIMLY AT A RAPID RATE.(1) LOOSE OR CORRODED

EXTERNAL LAMP CONNECTION.

(2) POOR GROUND CIRCUIT AT

EXTERNAL LAMP.(1) REPLACE SOCKET CONNECTION.

(2) REPAIR WIRING HARNESS.

CHECK CONNECTORS.

HAZARD WARMING SYSTEM DOES

NOT FLASH.(1) FAULTY FUSE.

(2) FAULTY FLASHER.

(3) OPEN CIRCUIT IN FEED WIRE TO

SWITCH.

(4) FAULTY CONTACT IN SWITCH.

(5) OPEN OR GROUNDED CIRCUIT

IN WIRING TO EXTERNAL LAMPS.(1) REPLACE FUSE.

(2) REPLACE FLASHER.

(3) REPAIR WIRING HARNESS,

CHECK CONNECTORS.

(4) REPLACE MULTI FUNCTION

SWITCH.

(5) REPAIR WIRING HARNESS.

INDICATOR LAMP ILLUMINATES

BRIGHTLY, EXTERNAL LAMP DOES

NOT LIGHT.(1) OPEN CIRCUIT IN WIRE TO

EXTERNAL LAMP.

(2) BURNED OUT LAMP.(1) REPAIR WIRING HARNESS.

(2) REPLACE LAMP.

SYSTEM DOES NOT FLASH ON

EITHER SIDE.(1) FAULTY FUSE.

(2) FAULTY FLASHER UNIT.

(3) LOOSE BULKHEAD CONNECTOR.

(4) LOOSE OR FAULTY REAR

WIRING HARNESS OR TERMINALS.

(5) OPEN CIRCUIT TO FLASHER

UNIT.

(6) OPEN CIRCUIT IN FEED WIRE TO

TURN SIGNAL SWITCH.

(7) FAULTY SWITCH CONNECTION IN

SWITCH.

(8) OPEN OR GROUNDED CIRCUIT

IN WIRING TO EXTERNAL LAMPS.(1) REPLACE FUSE.

(2) REPLACE FLASHER.

(3) TIGHTEN CONNECTOR.

(4) REPAIR WIRING HARNESS

(5) CHECK CONNECTORS, REPAIR

WIRING HARNESS.

(6) CHECK CONNECTORS, REPAIR

WIRING HARNESS.

(7) REPLACE MULTI FUNCTION

SWITCH.

(8) REPAIR WIRING HARNESS.

SYSTEM DOES NOT CANCEL

AFTER COMPLETION OF THE

TURN.(1) BROKEN CANCELLING FINGER

ON SWITCH.

(2) BROKEN OR MISSING

CANCELLING CAM ON

CLOCKSPRING.(1) REPLACE MULTI FUNCTION

SWITCH.

(2) REPLACE CLOCKSPRING.

EXTERNAL LAMPS OPERATE

PROPERLY, NO INDICATOR LAMP

OPERATION.(1) FAULTY INDICATOR LAMP IN

INSTRUMENT CLUSTER.(1) REPLACE LAMP.

8J - 2 TURN SIGNAL AND FLASHERSPL

Page 353 of 1200

shift lever and the park brake lever (Fig. 1). The saf-

ing sensor provides confirmation of a crash, but does

not discriminate severity. The ACM monitors the sys-

tem to determine the system readiness. The ACM

contains on-board diagnostics, and will illuminate the

AIRBAG warning lamp in the cluster when a fault

occurs. The warning equipment is tested for six to

eight seconds every time the vehicle is started.

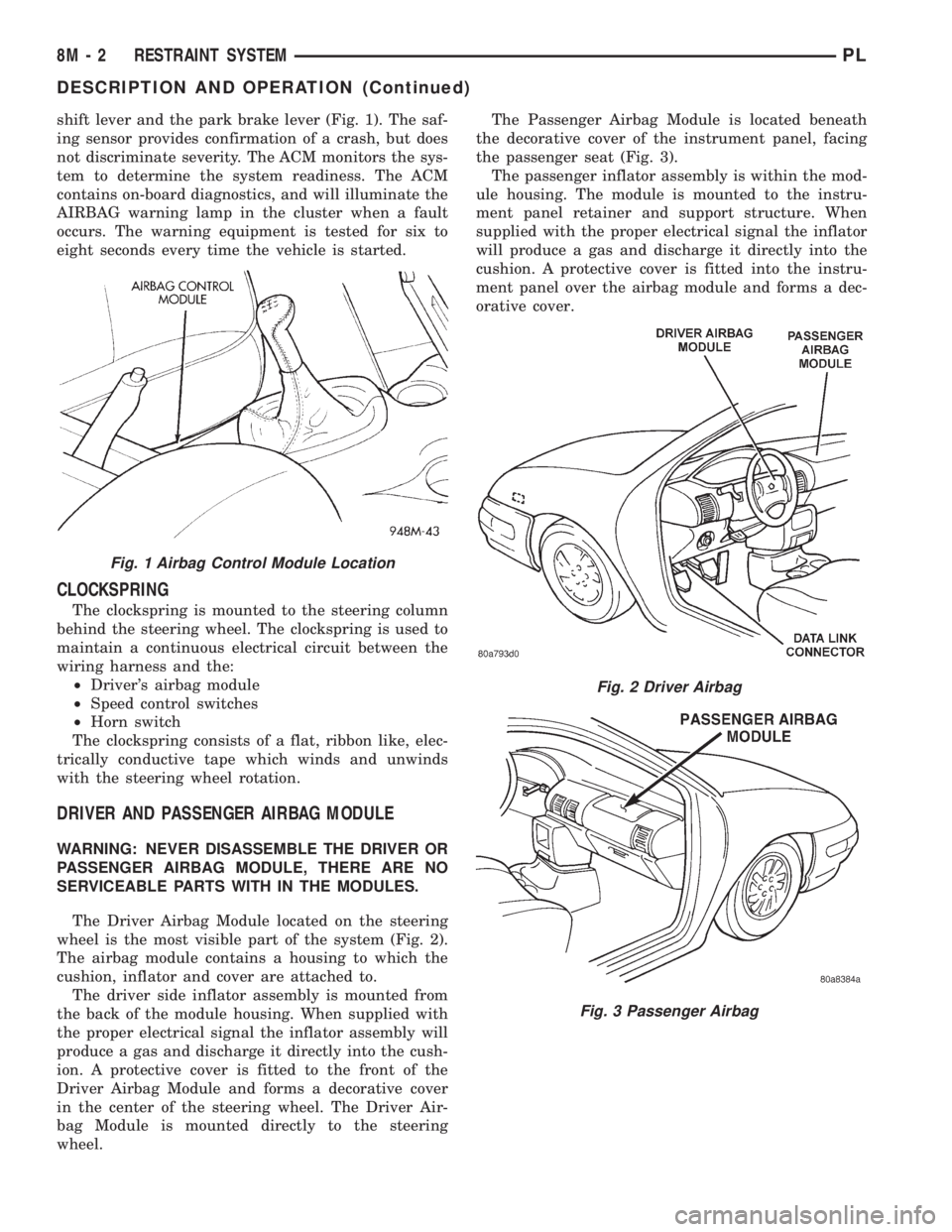

CLOCKSPRING

The clockspring is mounted to the steering column

behind the steering wheel. The clockspring is used to

maintain a continuous electrical circuit between the

wiring harness and the:

²Driver's airbag module

²Speed control switches

²Horn switch

The clockspring consists of a flat, ribbon like, elec-

trically conductive tape which winds and unwinds

with the steering wheel rotation.

DRIVER AND PASSENGER AIRBAG MODULE

WARNING: NEVER DISASSEMBLE THE DRIVER OR

PASSENGER AIRBAG MODULE, THERE ARE NO

SERVICEABLE PARTS WITH IN THE MODULES.

The Driver Airbag Module located on the steering

wheel is the most visible part of the system (Fig. 2).

The airbag module contains a housing to which the

cushion, inflator and cover are attached to.

The driver side inflator assembly is mounted from

the back of the module housing. When supplied with

the proper electrical signal the inflator assembly will

produce a gas and discharge it directly into the cush-

ion. A protective cover is fitted to the front of the

Driver Airbag Module and forms a decorative cover

in the center of the steering wheel. The Driver Air-

bag Module is mounted directly to the steering

wheel.The Passenger Airbag Module is located beneath

the decorative cover of the instrument panel, facing

the passenger seat (Fig. 3).

The passenger inflator assembly is within the mod-

ule housing. The module is mounted to the instru-

ment panel retainer and support structure. When

supplied with the proper electrical signal the inflator

will produce a gas and discharge it directly into the

cushion. A protective cover is fitted into the instru-

ment panel over the airbag module and forms a dec-

orative cover.

Fig. 1 Airbag Control Module Location

Fig. 2 Driver Airbag

Fig. 3 Passenger Airbag

8M - 2 RESTRAINT SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 359 of 1200

CLOCKSPRING

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

(1) Place the front road wheels in the straight

ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with ignition lock cylinder.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the reserve capacitor to

discharge before removing non-deployed module.

(4) Remove speed control switch mounting screws,

switches and disconnect the wire connectors or

remove covers.

(5) Remove the Driver Airbag Module attaching

bolts from under the speed control switches or covers.

(6) Lift module and disconnect the airbag and horn

wire connectors.

(7) Remove the steering wheel, refer to Steering

Wheel removal procedures.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring.

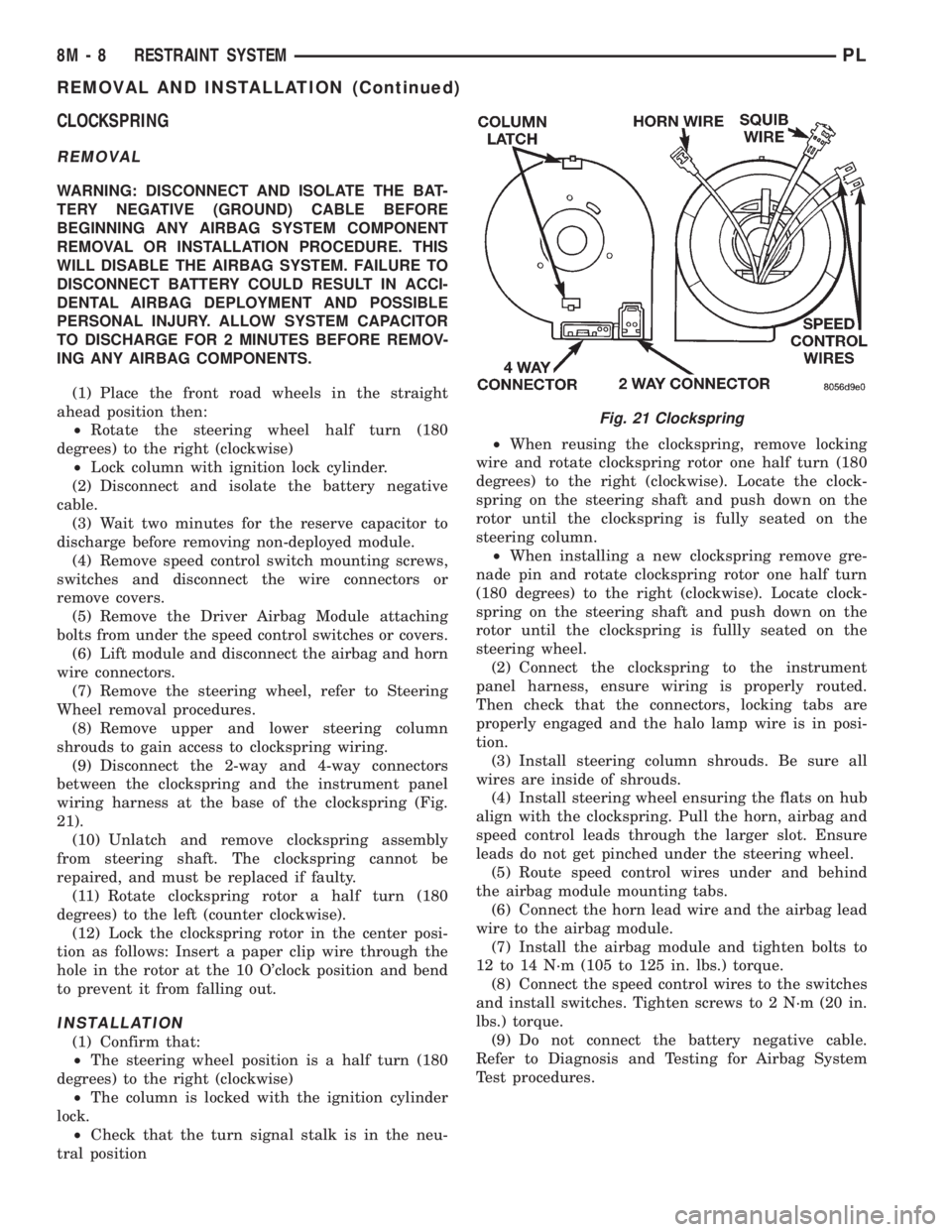

(9) Disconnect the 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness at the base of the clockspring (Fig.

21).

(10) Unlatch and remove clockspring assembly

from steering shaft. The clockspring cannot be

repaired, and must be replaced if faulty.

(11) Rotate clockspring rotor a half turn (180

degrees) to the left (counter clockwise).

(12) Lock the clockspring rotor in the center posi-

tion as follows: Insert a paper clip wire through the

hole in the rotor at the 10 O'clock position and bend

to prevent it from falling out.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position²When reusing the clockspring, remove locking

wire and rotate clockspring rotor one half turn (180

degrees) to the right (clockwise). Locate the clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fully seated on the

steering column.

²When installing a new clockspring remove gre-

nade pin and rotate clockspring rotor one half turn

(180 degrees) to the right (clockwise). Locate clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fullly seated on the

steering wheel.

(2) Connect the clockspring to the instrument

panel harness, ensure wiring is properly routed.

Then check that the connectors, locking tabs are

properly engaged and the halo lamp wire is in posi-

tion.

(3) Install steering column shrouds. Be sure all

wires are inside of shrouds.

(4) Install steering wheel ensuring the flats on hub

align with the clockspring. Pull the horn, airbag and

speed control leads through the larger slot. Ensure

leads do not get pinched under the steering wheel.

(5) Route speed control wires under and behind

the airbag module mounting tabs.

(6) Connect the horn lead wire and the airbag lead

wire to the airbag module.

(7) Install the airbag module and tighten bolts to

12 to 14 N´m (105 to 125 in. lbs.) torque.

(8) Connect the speed control wires to the switches

and install switches. Tighten screws to 2 N´m (20 in.

lbs.) torque.

(9) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

Fig. 21 Clockspring

8M - 8 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 360 of 1200

DRIVER AIRBAG MODULE

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

When removing a deployed module, rubber gloves,

eye protection and long sleeved shirt should be worn,

as there may be deposits on the surface which could

irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove speed control switches or covers from

steering wheel armature and disconnect the wires.

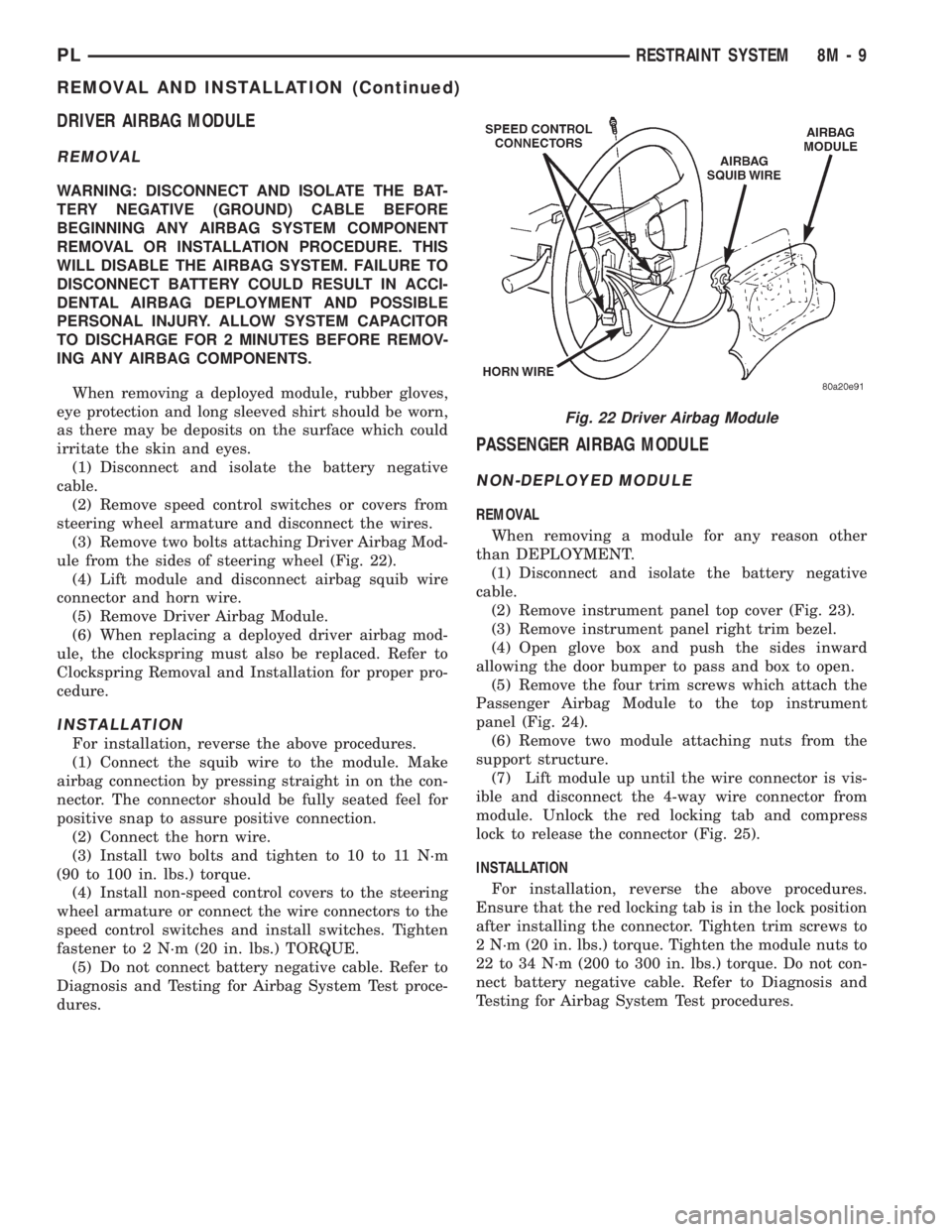

(3) Remove two bolts attaching Driver Airbag Mod-

ule from the sides of steering wheel (Fig. 22).

(4) Lift module and disconnect airbag squib wire

connector and horn wire.

(5) Remove Driver Airbag Module.

(6) When replacing a deployed driver airbag mod-

ule, the clockspring must also be replaced. Refer to

Clockspring Removal and Installation for proper pro-

cedure.

INSTALLATION

For installation, reverse the above procedures.

(1) Connect the squib wire to the module. Make

airbag connection by pressing straight in on the con-

nector. The connector should be fully seated feel for

positive snap to assure positive connection.

(2) Connect the horn wire.

(3) Install two bolts and tighten to 10 to 11 N´m

(90 to 100 in. lbs.) torque.

(4) Install non-speed control covers to the steering

wheel armature or connect the wire connectors to the

speed control switches and install switches. Tighten

fastener to 2 N´m (20 in. lbs.) TORQUE.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test proce-

dures.

PASSENGER AIRBAG MODULE

NON-DEPLOYED MODULE

REMOVAL

When removing a module for any reason other

than DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel top cover (Fig. 23).

(3) Remove instrument panel right trim bezel.

(4) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(5) Remove the four trim screws which attach the

Passenger Airbag Module to the top instrument

panel (Fig. 24).

(6) Remove two module attaching nuts from the

support structure.

(7) Lift module up until the wire connector is vis-

ible and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector (Fig. 25).

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

Fig. 22 Driver Airbag Module

PLRESTRAINT SYSTEM 8M - 9

REMOVAL AND INSTALLATION (Continued)

Page 362 of 1200

(5) Lift module and disconnect the airbag and horn

wire connectors.

(6) Remove steering wheel retaining nut.

(7) Remove the steering wheel with a steering

wheel puller. While removing the steering wheel take

care to feed the wires gently through the holes in the

clockspring armature.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position

(2) Install the steering wheel ensuring the flats on

hub align with the clockspring. Pull the horn lead,

airbag and speed control leads through the larger

slot. Ensure leads do not get pinched under the steer-

ing wheel.

(3) Install the steering wheel retaining nut, and

tighten it to 61 N´m (45 ft. lbs.) torque.

(4) Install the airbag module. Refer to Driver Air-

bag Module Removal and Installation for proper pro-

cedures.

(5) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE

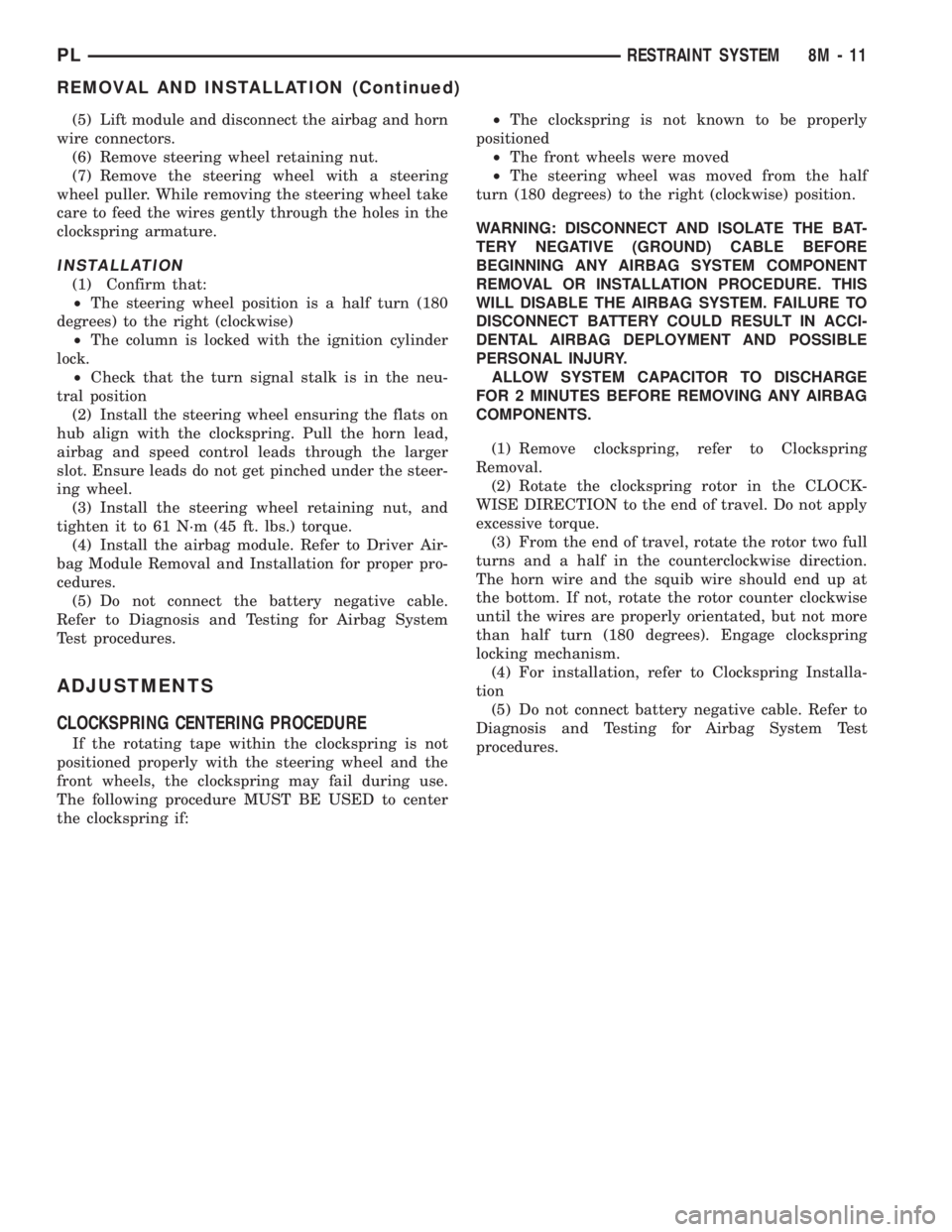

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedure MUST BE USED to center

the clockspring if:²The clockspring is not known to be properly

positioned

²The front wheels were moved

²The steering wheel was moved from the half

turn (180 degrees) to the right (clockwise) position.

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

(1) Remove clockspring, refer to Clockspring

Removal.

(2) Rotate the clockspring rotor in the CLOCK-

WISE DIRECTION to the end of travel. Do not apply

excessive torque.

(3) From the end of travel, rotate the rotor two full

turns and a half in the counterclockwise direction.

The horn wire and the squib wire should end up at

the bottom. If not, rotate the rotor counter clockwise

until the wires are properly orientated, but not more

than half turn (180 degrees). Engage clockspring

locking mechanism.

(4) For installation, refer to Clockspring Installa-

tion

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test

procedures.

PLRESTRAINT SYSTEM 8M - 11

REMOVAL AND INSTALLATION (Continued)