tire size DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 16 of 1200

PRE-ALIGNMENT VEHICLE INSPECTION

CAUTION: If the front suspension crossmember

shows any sign of impact damage, the steering col-

umn to steering gear coupling must be inspected.

Refer to Group 19 Steering in this service manual

for the inspection procedure.

Before any attempt is made to change or correct

the wheel alignment factors, the following inspection

and necessary corrections must be made on those

parts which influence the steering of the vehicle.

(1) Be sure the fuel tank is full when the wheel

alignment specifications are checked and or adjusted.

A full tank of fuel weighs approximately 75 pounds,

if the fuel tank is not full this reduction in weight

will affect the curb height of the vehicle and the

alignment specifications.

(2) Alignment specifications of a vehicle can be the

most accurately checked and set when the passenger

compartment and trunk of the vehicle are vacant

with the exception of the spare tire. People, luggage,

and any other appreciable weight will adversely

affect the checking and setting of the camber specifi-

cation.

(3) Check and if required, inflate all of the tires to

the recommended air pressure. All tires must be of

the same size and in good condition and have approx-

imately the same tread wear.Note the type of

tread wear on the tire, this will aid in diagnos-

ing problems. Refer to Group 22 Tires And

Wheels in this service manual for the tire wear

diagnosis.

(4) Check the front tire and wheel assemblies for

radial runout.

(5) Before beginning the alignment process,

inspect all suspension component fasteners for loose-

ness and/or loss of specified torque.

(6) Inspect the lower front ball joints and all steer-

ing linkage for looseness and any signs of wear and

or damage.

(7) Inspect the tie rod ends for looseness and any

signs of wear and or damage.

(8) Inspect the rubber bushings on all suspension

components for signs of wear or deterioration. If any

bushings show signs of wear or deterioration they

should be replaced prior to aligning the vehicle.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER CAMBER

Front and rear Caster and Camber settings on this

vehicle are determined at the time the vehicle isdesigned, by the location of the vehicle's suspension

components. This is called a Net Build vehicle and

results in no required adjustment of Caster and

Camber after vehicle is built or when servicing the

suspension components. Thus Caster and Camber are

not normally considered an adjustable specification

when performing an alignment on this vehicle.

Though Caster and Camber are not adjustable they

must be checked to ensure they meet vehicle specifi-

cations.

If front and or rear camber is found not to meet

the vehicle alignment specifications, it can be

adjusted using a Mopar Service Kit developed to

allow for camber adjustment. If a vehicle's front or

rear camber is found to be outside the specifications,

the vehicles suspension components should be

inspected for any signs of damage on bending.This

must be done before using the Mopar Service

Kit for setting camber to meet required specifi-

cation.

If a vehicles caster is not within manufacturers

alignment specifications, check for damaged suspen-

sion components or body parts. This type of damage

can cause component locations to move affecting

vehicle alignment.No adjustment can be made

for the Caster setting on this vehicle.

CAUTION: Do not attempt to adjust the vehicles

Caster or Camber by heating, bending or any other

modification of the suspension components.

(1) Correctly position vehicle on alignment rack

and install all required equipment on vehicle, per the

alignment equipment manufacturers specifications.

(2) Center the steering wheel and lock in place

using a steering wheel clamp.

NOTE: Prior to reading each alignment specifica-

tion, jounce the front and rear of the vehicle an

equal number of times. Induce jounce (rear first

then front) by grasping center of bumper and jounc-

ing each end of vehicle an equal number of times.

Bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Correctly jounce vehicle and read front and

rear alignment settings and compare to vehicle spec-

ifications for Camber, Caster and Toe. See Alignment

Specifications in this group of the service manual for

required specifications.If front and rear camber

readings are within required specifications pro-

ceed to step Step 3 in the Front And Rear Toe

Setting procedure. If Camber readings are not

within specifications refer to step Step 1 in the

following camber adjustment bolt package

installation procedure, for the front and rear

Camber adjustment procedure.

PLSUSPENSION 2 - 5

DIAGNOSIS AND TESTING (Continued)

Page 17 of 1200

CAMBER ADJUSTMENT BOLT PACKAGE INSTALLATION

PROCEDURE

(1) If front and or rear camber readings obtained

are not within the required specification range, a

Mopar Service Kit is available to provide the

required adjustment. The kit contains new bolts and

nuts for the strut clevis bracket to steering knuckle

attachment. The bolts contained in the service kit,

are slightly undersize allowing for movement

between the strut clevis bracket and steering

knuckle. The movement allowed by the undersize

bolts will provide approximately 2 degrees of camber

adjustment per side of vehicle. To install new bolts in

service kit follow the procedure below.

CAUTION: The Mopar Service Kit for allowing

adjustment of front and rear camber are different

for the front and rear of the vehicle. When using the

service kits be sure that the front and rear strut

attaching bolts are always used in the right location

on the vehicle.

(2) Raise front and or rear of vehicle until tires are

not supporting the weight of the vehicle.

CAUTION: The steering knuckle and rear knuckle

to strut assembly attaching bolts are serrated and

must not be turned during removal. Remove nuts

while holding bolts stationary in the steering knuck-

les.

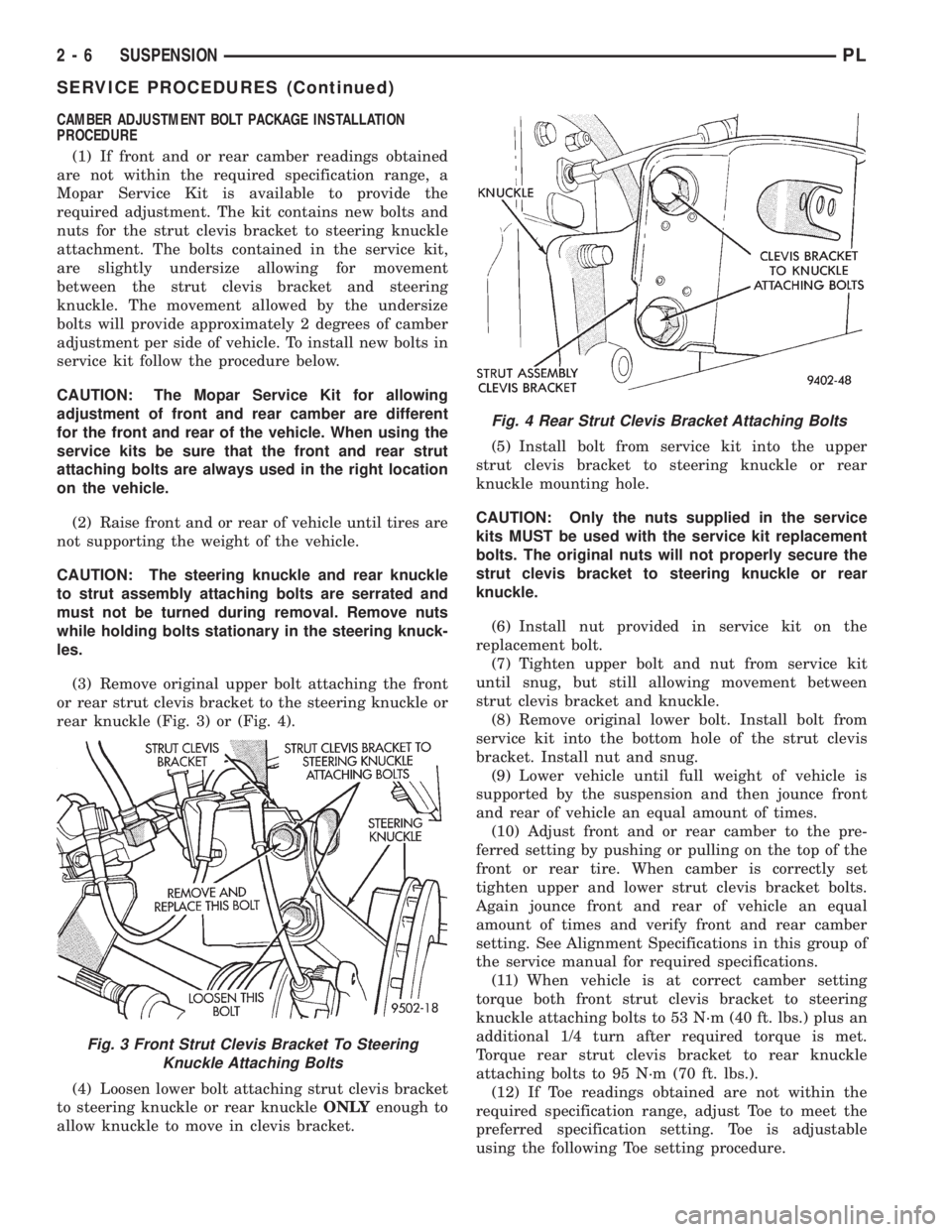

(3) Remove original upper bolt attaching the front

or rear strut clevis bracket to the steering knuckle or

rear knuckle (Fig. 3) or (Fig. 4).

(4) Loosen lower bolt attaching strut clevis bracket

to steering knuckle or rear knuckleONLYenough to

allow knuckle to move in clevis bracket.(5) Install bolt from service kit into the upper

strut clevis bracket to steering knuckle or rear

knuckle mounting hole.

CAUTION: Only the nuts supplied in the service

kits MUST be used with the service kit replacement

bolts. The original nuts will not properly secure the

strut clevis bracket to steering knuckle or rear

knuckle.

(6) Install nut provided in service kit on the

replacement bolt.

(7) Tighten upper bolt and nut from service kit

until snug, but still allowing movement between

strut clevis bracket and knuckle.

(8) Remove original lower bolt. Install bolt from

service kit into the bottom hole of the strut clevis

bracket. Install nut and snug.

(9) Lower vehicle until full weight of vehicle is

supported by the suspension and then jounce front

and rear of vehicle an equal amount of times.

(10) Adjust front and or rear camber to the pre-

ferred setting by pushing or pulling on the top of the

front or rear tire. When camber is correctly set

tighten upper and lower strut clevis bracket bolts.

Again jounce front and rear of vehicle an equal

amount of times and verify front and rear camber

setting. See Alignment Specifications in this group of

the service manual for required specifications.

(11) When vehicle is at correct camber setting

torque both front strut clevis bracket to steering

knuckle attaching bolts to 53 N´m (40 ft. lbs.) plus an

additional 1/4 turn after required torque is met.

Torque rear strut clevis bracket to rear knuckle

attaching bolts to 95 N´m (70 ft. lbs.).

(12) If Toe readings obtained are not within the

required specification range, adjust Toe to meet the

preferred specification setting. Toe is adjustable

using the following Toe setting procedure.

Fig. 3 Front Strut Clevis Bracket To Steering

Knuckle Attaching Bolts

Fig. 4 Rear Strut Clevis Bracket Attaching Bolts

2 - 6 SUSPENSIONPL

SERVICE PROCEDURES (Continued)

Page 59 of 1200

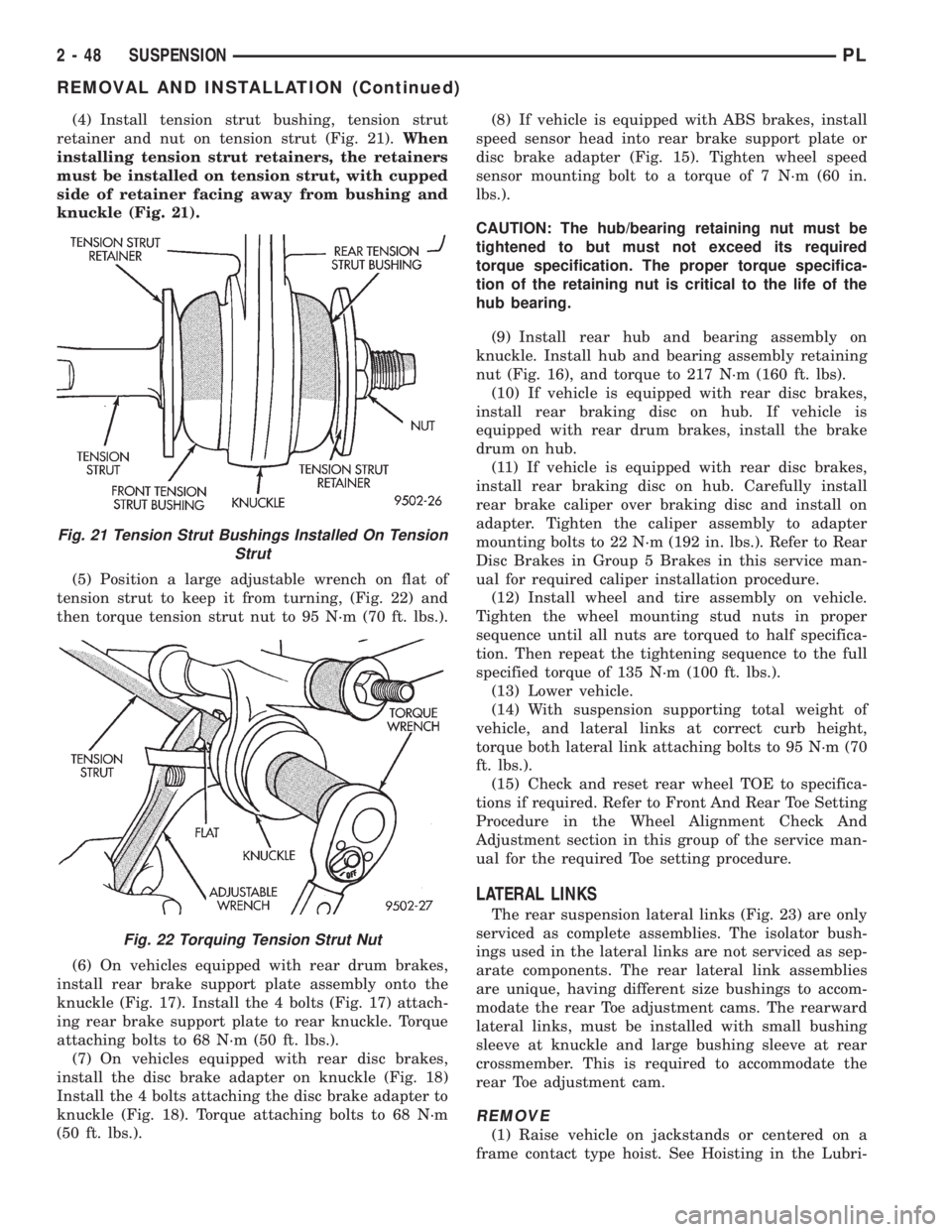

(4) Install tension strut bushing, tension strut

retainer and nut on tension strut (Fig. 21).When

installing tension strut retainers, the retainers

must be installed on tension strut, with cupped

side of retainer facing away from bushing and

knuckle (Fig. 21).

(5) Position a large adjustable wrench on flat of

tension strut to keep it from turning, (Fig. 22) and

then torque tension strut nut to 95 N´m (70 ft. lbs.).

(6) On vehicles equipped with rear drum brakes,

install rear brake support plate assembly onto the

knuckle (Fig. 17). Install the 4 bolts (Fig. 17) attach-

ing rear brake support plate to rear knuckle. Torque

attaching bolts to 68 N´m (50 ft. lbs.).

(7) On vehicles equipped with rear disc brakes,

install the disc brake adapter on knuckle (Fig. 18)

Install the 4 bolts attaching the disc brake adapter to

knuckle (Fig. 18). Torque attaching bolts to 68 N´m

(50 ft. lbs.).(8) If vehicle is equipped with ABS brakes, install

speed sensor head into rear brake support plate or

disc brake adapter (Fig. 15). Tighten wheel speed

sensor mounting bolt to a torque of 7 N´m (60 in.

lbs.).

CAUTION: The hub/bearing retaining nut must be

tightened to but must not exceed its required

torque specification. The proper torque specifica-

tion of the retaining nut is critical to the life of the

hub bearing.

(9) Install rear hub and bearing assembly on

knuckle. Install hub and bearing assembly retaining

nut (Fig. 16), and torque to 217 N´m (160 ft. lbs).

(10) If vehicle is equipped with rear disc brakes,

install rear braking disc on hub. If vehicle is

equipped with rear drum brakes, install the brake

drum on hub.

(11) If vehicle is equipped with rear disc brakes,

install rear braking disc on hub. Carefully install

rear brake caliper over braking disc and install on

adapter. Tighten the caliper assembly to adapter

mounting bolts to 22 N´m (192 in. lbs.). Refer to Rear

Disc Brakes in Group 5 Brakes in this service man-

ual for required caliper installation procedure.

(12) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(13) Lower vehicle.

(14) With suspension supporting total weight of

vehicle, and lateral links at correct curb height,

torque both lateral link attaching bolts to 95 N´m (70

ft. lbs.).

(15) Check and reset rear wheel TOE to specifica-

tions if required. Refer to Front And Rear Toe Setting

Procedure in the Wheel Alignment Check And

Adjustment section in this group of the service man-

ual for the required Toe setting procedure.

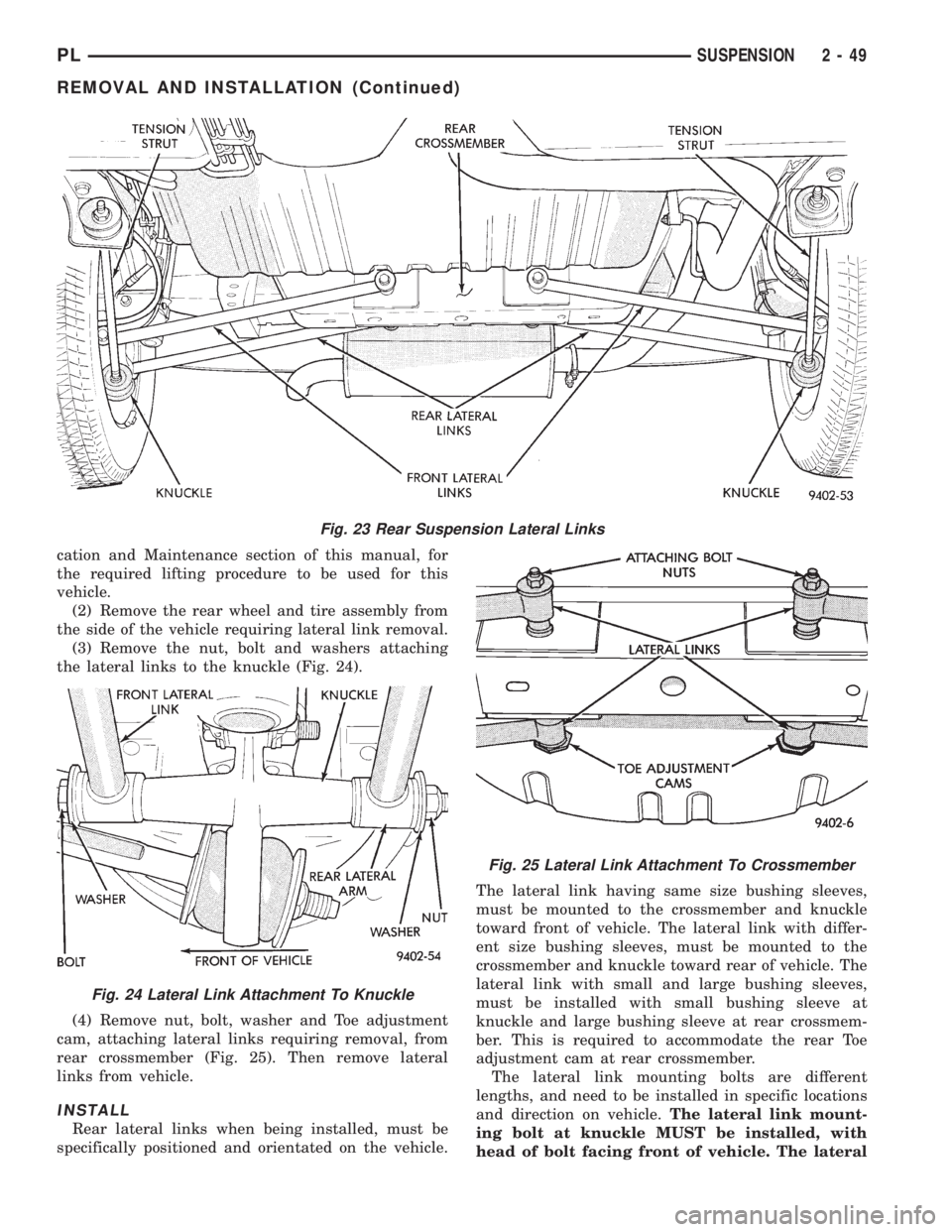

LATERAL LINKS

The rear suspension lateral links (Fig. 23) are only

serviced as complete assemblies. The isolator bush-

ings used in the lateral links are not serviced as sep-

arate components. The rear lateral link assemblies

are unique, having different size bushings to accom-

modate the rear Toe adjustment cams. The rearward

lateral links, must be installed with small bushing

sleeve at knuckle and large bushing sleeve at rear

crossmember. This is required to accommodate the

rear Toe adjustment cam.

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

Fig. 21 Tension Strut Bushings Installed On Tension

Strut

Fig. 22 Torquing Tension Strut Nut

2 - 48 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 60 of 1200

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly from

the side of the vehicle requiring lateral link removal.

(3) Remove the nut, bolt and washers attaching

the lateral links to the knuckle (Fig. 24).

(4) Remove nut, bolt, washer and Toe adjustment

cam, attaching lateral links requiring removal, from

rear crossmember (Fig. 25). Then remove lateral

links from vehicle.

INSTALL

Rear lateral links when being installed, must be

specifically positioned and orientated on the vehicle.The lateral link having same size bushing sleeves,

must be mounted to the crossmember and knuckle

toward front of vehicle. The lateral link with differ-

ent size bushing sleeves, must be mounted to the

crossmember and knuckle toward rear of vehicle. The

lateral link with small and large bushing sleeves,

must be installed with small bushing sleeve at

knuckle and large bushing sleeve at rear crossmem-

ber. This is required to accommodate the rear Toe

adjustment cam at rear crossmember.

The lateral link mounting bolts are different

lengths, and need to be installed in specific locations

and direction on vehicle.The lateral link mount-

ing bolt at knuckle MUST be installed, with

head of bolt facing front of vehicle. The lateral

Fig. 23 Rear Suspension Lateral Links

Fig. 24 Lateral Link Attachment To Knuckle

Fig. 25 Lateral Link Attachment To Crossmember

PLSUSPENSION 2 - 49

REMOVAL AND INSTALLATION (Continued)

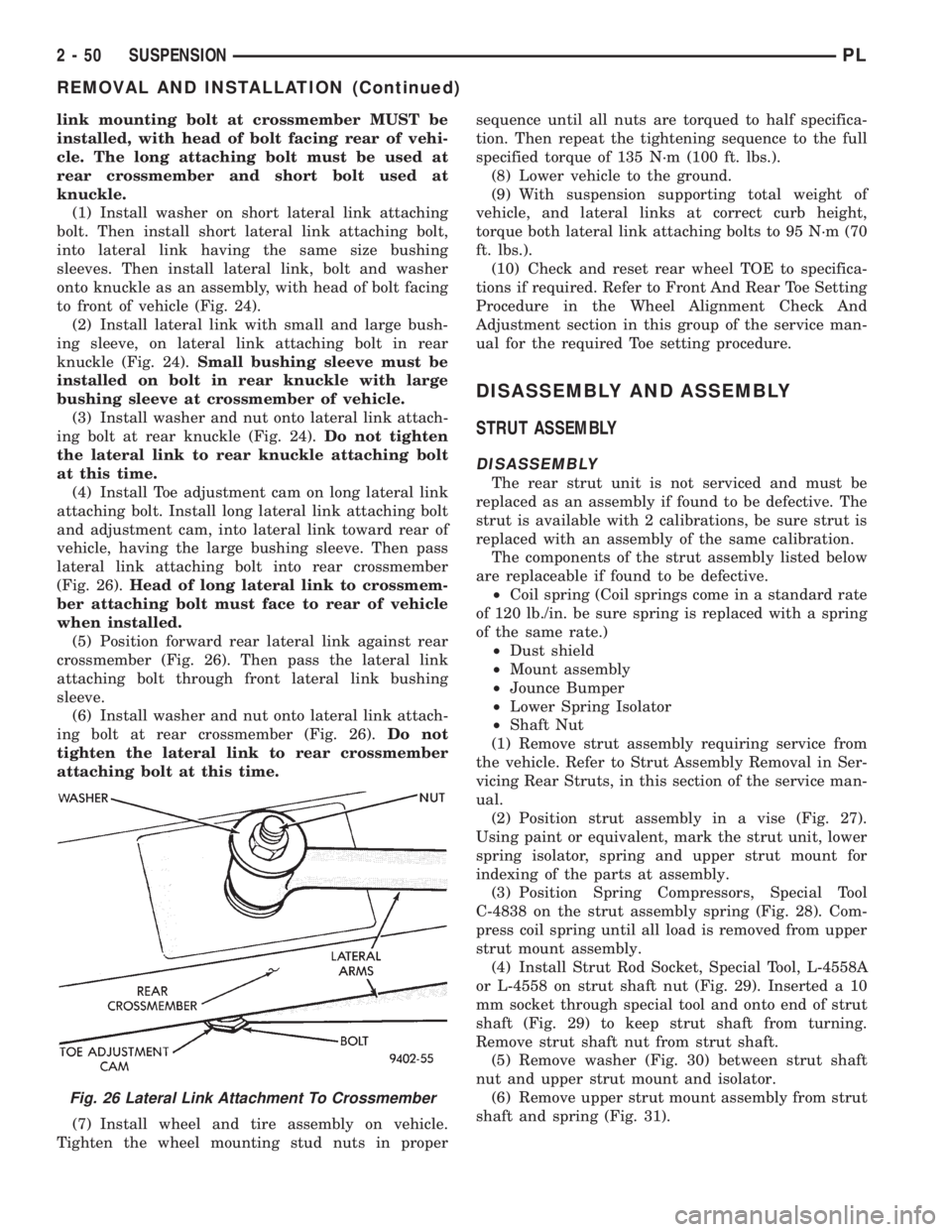

Page 61 of 1200

link mounting bolt at crossmember MUST be

installed, with head of bolt facing rear of vehi-

cle. The long attaching bolt must be used at

rear crossmember and short bolt used at

knuckle.

(1) Install washer on short lateral link attaching

bolt. Then install short lateral link attaching bolt,

into lateral link having the same size bushing

sleeves. Then install lateral link, bolt and washer

onto knuckle as an assembly, with head of bolt facing

to front of vehicle (Fig. 24).

(2) Install lateral link with small and large bush-

ing sleeve, on lateral link attaching bolt in rear

knuckle (Fig. 24).Small bushing sleeve must be

installed on bolt in rear knuckle with large

bushing sleeve at crossmember of vehicle.

(3) Install washer and nut onto lateral link attach-

ing bolt at rear knuckle (Fig. 24).Do not tighten

the lateral link to rear knuckle attaching bolt

at this time.

(4) Install Toe adjustment cam on long lateral link

attaching bolt. Install long lateral link attaching bolt

and adjustment cam, into lateral link toward rear of

vehicle, having the large bushing sleeve. Then pass

lateral link attaching bolt into rear crossmember

(Fig. 26).Head of long lateral link to crossmem-

ber attaching bolt must face to rear of vehicle

when installed.

(5) Position forward rear lateral link against rear

crossmember (Fig. 26). Then pass the lateral link

attaching bolt through front lateral link bushing

sleeve.

(6) Install washer and nut onto lateral link attach-

ing bolt at rear crossmember (Fig. 26).Do not

tighten the lateral link to rear crossmember

attaching bolt at this time.

(7) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in propersequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(8) Lower vehicle to the ground.

(9) With suspension supporting total weight of

vehicle, and lateral links at correct curb height,

torque both lateral link attaching bolts to 95 N´m (70

ft. lbs.).

(10) Check and reset rear wheel TOE to specifica-

tions if required. Refer to Front And Rear Toe Setting

Procedure in the Wheel Alignment Check And

Adjustment section in this group of the service man-

ual for the required Toe setting procedure.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY

DISASSEMBLY

The rear strut unit is not serviced and must be

replaced as an assembly if found to be defective. The

strut is available with 2 calibrations, be sure strut is

replaced with an assembly of the same calibration.

The components of the strut assembly listed below

are replaceable if found to be defective.

²Coil spring (Coil springs come in a standard rate

of 120 lb./in. be sure spring is replaced with a spring

of the same rate.)

²Dust shield

²Mount assembly

²Jounce Bumper

²Lower Spring Isolator

²Shaft Nut

(1) Remove strut assembly requiring service from

the vehicle. Refer to Strut Assembly Removal in Ser-

vicing Rear Struts, in this section of the service man-

ual.

(2) Position strut assembly in a vise (Fig. 27).

Using paint or equivalent, mark the strut unit, lower

spring isolator, spring and upper strut mount for

indexing of the parts at assembly.

(3) Position Spring Compressors, Special Tool

C-4838 on the strut assembly spring (Fig. 28). Com-

press coil spring until all load is removed from upper

strut mount assembly.

(4) Install Strut Rod Socket, Special Tool, L-4558A

or L-4558 on strut shaft nut (Fig. 29). Inserted a 10

mm socket through special tool and onto end of strut

shaft (Fig. 29) to keep strut shaft from turning.

Remove strut shaft nut from strut shaft.

(5) Remove washer (Fig. 30) between strut shaft

nut and upper strut mount and isolator.

(6) Remove upper strut mount assembly from strut

shaft and spring (Fig. 31).

Fig. 26 Lateral Link Attachment To Crossmember

2 - 50 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 67 of 1200

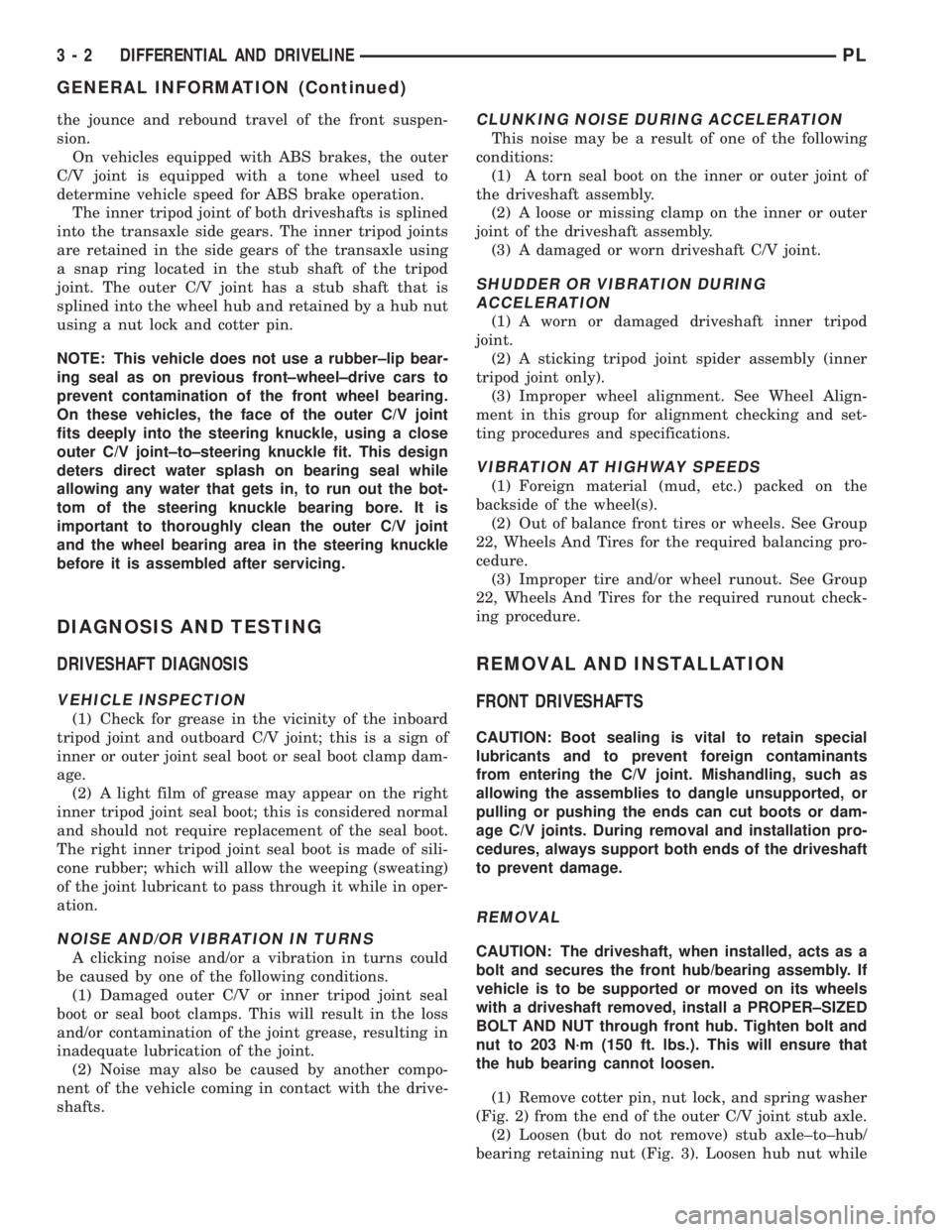

the jounce and rebound travel of the front suspen-

sion.

On vehicles equipped with ABS brakes, the outer

C/V joint is equipped with a tone wheel used to

determine vehicle speed for ABS brake operation.

The inner tripod joint of both driveshafts is splined

into the transaxle side gears. The inner tripod joints

are retained in the side gears of the transaxle using

a snap ring located in the stub shaft of the tripod

joint. The outer C/V joint has a stub shaft that is

splined into the wheel hub and retained by a hub nut

using a nut lock and cotter pin.

NOTE: This vehicle does not use a rubber±lip bear-

ing seal as on previous front±wheel±drive cars to

prevent contamination of the front wheel bearing.

On these vehicles, the face of the outer C/V joint

fits deeply into the steering knuckle, using a close

outer C/V joint±to±steering knuckle fit. This design

deters direct water splash on bearing seal while

allowing any water that gets in, to run out the bot-

tom of the steering knuckle bearing bore. It is

important to thoroughly clean the outer C/V joint

and the wheel bearing area in the steering knuckle

before it is assembled after servicing.

DIAGNOSIS AND TESTING

DRIVESHAFT DIAGNOSIS

VEHICLE INSPECTION

(1) Check for grease in the vicinity of the inboard

tripod joint and outboard C/V joint; this is a sign of

inner or outer joint seal boot or seal boot clamp dam-

age.

(2) A light film of grease may appear on the right

inner tripod joint seal boot; this is considered normal

and should not require replacement of the seal boot.

The right inner tripod joint seal boot is made of sili-

cone rubber; which will allow the weeping (sweating)

of the joint lubricant to pass through it while in oper-

ation.

NOISE AND/OR VIBRATION IN TURNS

A clicking noise and/or a vibration in turns could

be caused by one of the following conditions.

(1) Damaged outer C/V or inner tripod joint seal

boot or seal boot clamps. This will result in the loss

and/or contamination of the joint grease, resulting in

inadequate lubrication of the joint.

(2) Noise may also be caused by another compo-

nent of the vehicle coming in contact with the drive-

shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of one of the following

conditions:

(1) A torn seal boot on the inner or outer joint of

the driveshaft assembly.

(2) A loose or missing clamp on the inner or outer

joint of the driveshaft assembly.

(3) A damaged or worn driveshaft C/V joint.

SHUDDER OR VIBRATION DURING

ACCELERATION

(1) A worn or damaged driveshaft inner tripod

joint.

(2) A sticking tripod joint spider assembly (inner

tripod joint only).

(3) Improper wheel alignment. See Wheel Align-

ment in this group for alignment checking and set-

ting procedures and specifications.

VIBRATION AT HIGHWAY SPEEDS

(1) Foreign material (mud, etc.) packed on the

backside of the wheel(s).

(2) Out of balance front tires or wheels. See Group

22, Wheels And Tires for the required balancing pro-

cedure.

(3) Improper tire and/or wheel runout. See Group

22, Wheels And Tires for the required runout check-

ing procedure.

REMOVAL AND INSTALLATION

FRONT DRIVESHAFTS

CAUTION: Boot sealing is vital to retain special

lubricants and to prevent foreign contaminants

from entering the C/V joint. Mishandling, such as

allowing the assemblies to dangle unsupported, or

pulling or pushing the ends can cut boots or dam-

age C/V joints. During removal and installation pro-

cedures, always support both ends of the driveshaft

to prevent damage.

REMOVAL

CAUTION: The driveshaft, when installed, acts as a

bolt and secures the front hub/bearing assembly. If

vehicle is to be supported or moved on its wheels

with a driveshaft removed, install a PROPER±SIZED

BOLT AND NUT through front hub. Tighten bolt and

nut to 203 N´m (150 ft. lbs.). This will ensure that

the hub bearing cannot loosen.

(1) Remove cotter pin, nut lock, and spring washer

(Fig. 2) from the end of the outer C/V joint stub axle.

(2) Loosen (but do not remove) stub axle±to±hub/

bearing retaining nut (Fig. 3). Loosen hub nut while

3 - 2 DIFFERENTIAL AND DRIVELINEPL

GENERAL INFORMATION (Continued)

Page 107 of 1200

Place gauge (Form A) on edge over end of brake

tubing. Push tubing through jaws until end of tubing

contacts the recessed notch in gauge matching the

tubing size. Squeeze handles of flaring tool and lock

tubing in place. Place 3/16 inch plug of gauge (A)

down in end of tubing. Swing compression disc over

gauge and center tapered flaring screw in recess of

disc. Screw in until plug gauge has seated on jaws of

flaring tool. This action has started to invert the

extended end of the tubing. Remove gauge and con-

tinue to screw down until tool is firmly seated in tub-

ing. Remove tubing from flaring tool and inspect

seat. Refer to tube routing diagrams for proper brake

tube routing and clip locations. Replace any damaged

tube routing clips.

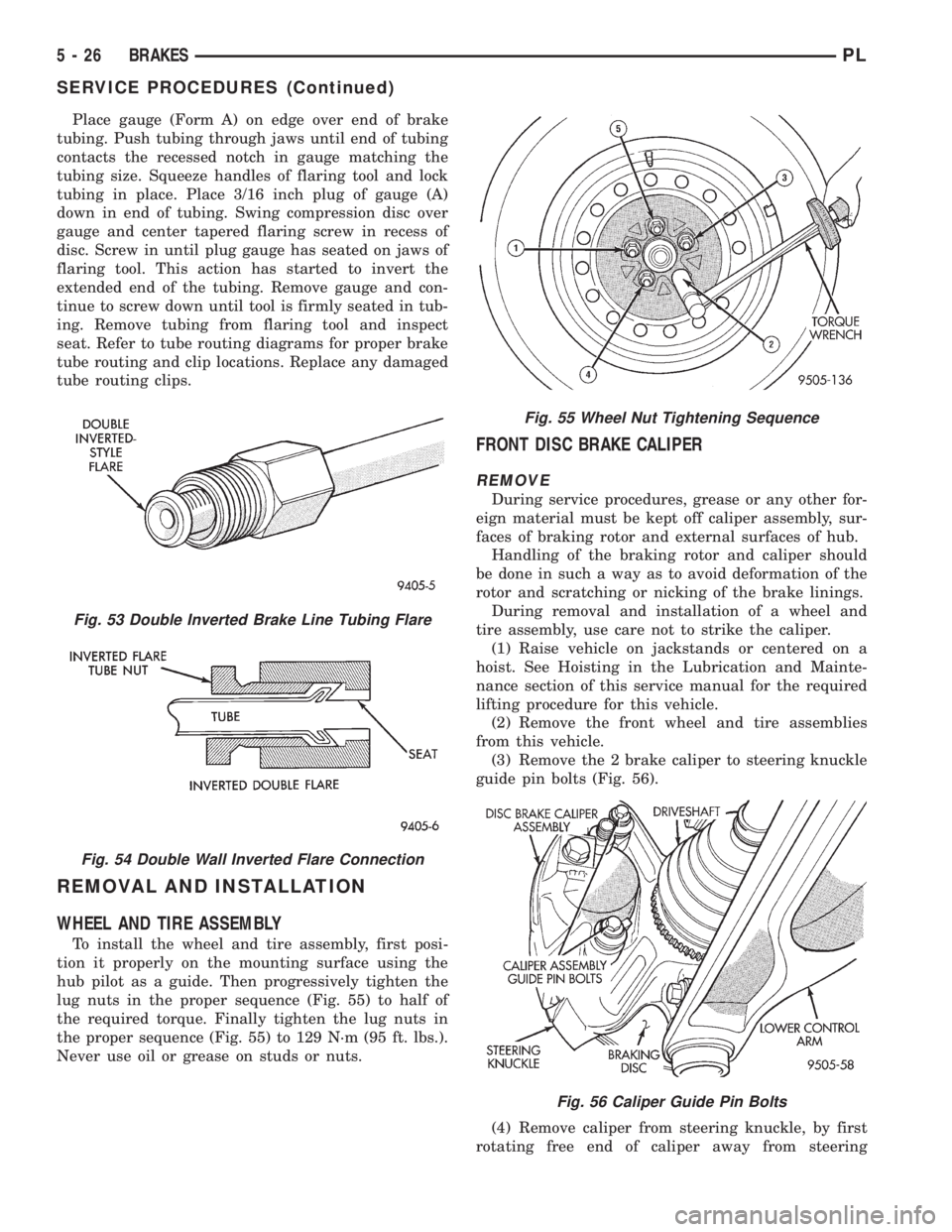

REMOVAL AND INSTALLATION

WHEEL AND TIRE ASSEMBLY

To install the wheel and tire assembly, first posi-

tion it properly on the mounting surface using the

hub pilot as a guide. Then progressively tighten the

lug nuts in the proper sequence (Fig. 55) to half of

the required torque. Finally tighten the lug nuts in

the proper sequence (Fig. 55) to 129 N´m (95 ft. lbs.).

Never use oil or grease on studs or nuts.

FRONT DISC BRAKE CALIPER

REMOVE

During service procedures, grease or any other for-

eign material must be kept off caliper assembly, sur-

faces of braking rotor and external surfaces of hub.

Handling of the braking rotor and caliper should

be done in such a way as to avoid deformation of the

rotor and scratching or nicking of the brake linings.

During removal and installation of a wheel and

tire assembly, use care not to strike the caliper.

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this service manual for the required

lifting procedure for this vehicle.

(2) Remove the front wheel and tire assemblies

from this vehicle.

(3) Remove the 2 brake caliper to steering knuckle

guide pin bolts (Fig. 56).

(4) Remove caliper from steering knuckle, by first

rotating free end of caliper away from steering

Fig. 53 Double Inverted Brake Line Tubing Flare

Fig. 54 Double Wall Inverted Flare Connection

Fig. 55 Wheel Nut Tightening Sequence

Fig. 56 Caliper Guide Pin Bolts

5 - 26 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 115 of 1200

or fluid leak is visible, disassemble caliper and

install a new seal and boot, (and piston if scored).

Refer to Caliper Disassembly And Re-Assembly Pro-

cedures in Disc Brake Caliper Service in this section

of the service manual.

Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition.

Replace if they are damaged, dry, or found to be brit-

tle. Refer to Guide Pin Bushing Service in Disc

Brake Caliper Service in this section of the service

manual.

INSTALL

(1) Completely retract the caliper piston back into

the piston bore of the caliper assembly. This is

required for caliper installation when new brake pad

assemblies are installed on caliper.

(2) Lubricate both adapter abutments with a lib-

eral amount of MopartMultipurpose Lubricant, or

equivalent.

(3) Install rear rotor on the hub making sure it is

squarely seated on face of hub (Fig. 77).

(4) Remove protective paper from noise suppres-

sion gasket on both inner and outer brake pad

assemblies (if equipped).

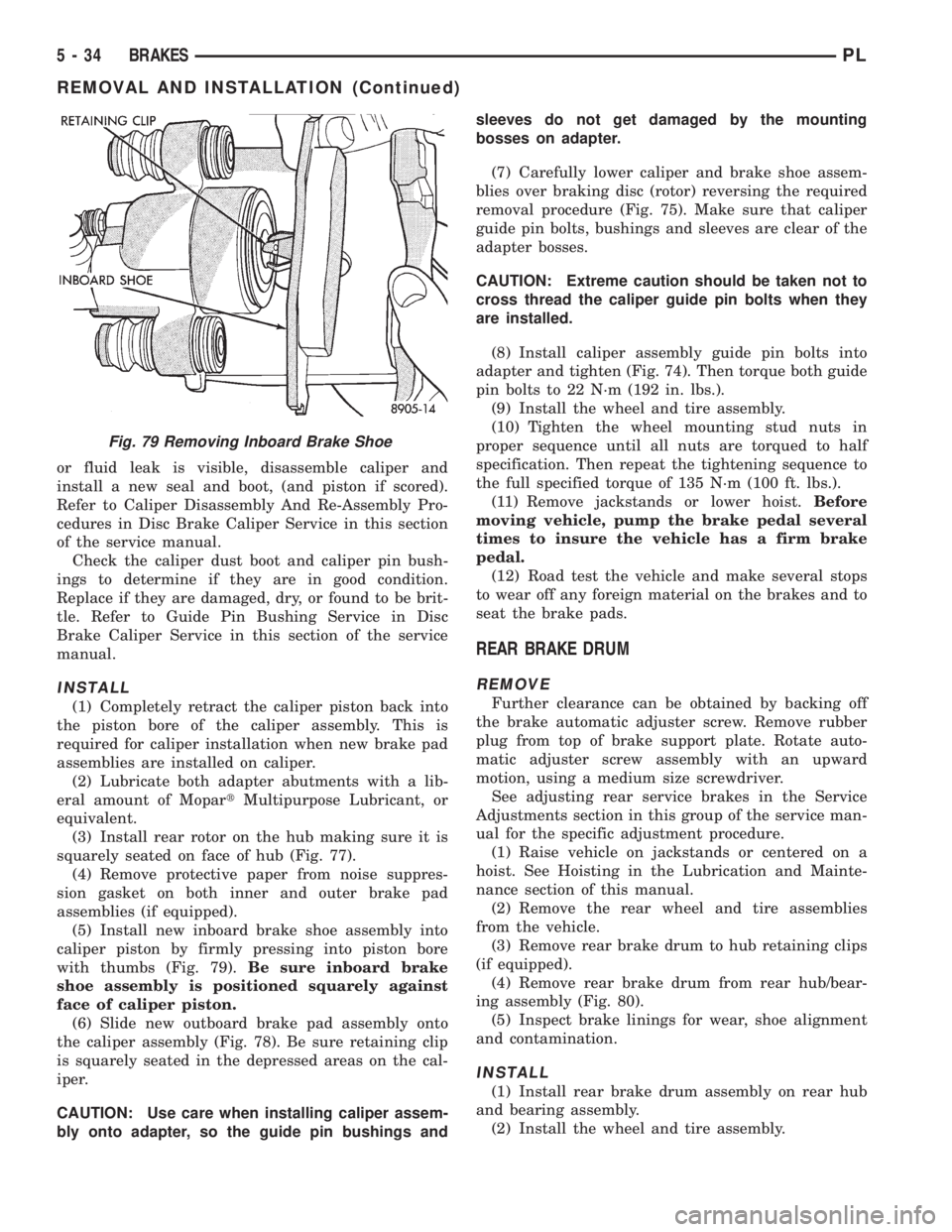

(5) Install new inboard brake shoe assembly into

caliper piston by firmly pressing into piston bore

with thumbs (Fig. 79).Be sure inboard brake

shoe assembly is positioned squarely against

face of caliper piston.

(6) Slide new outboard brake pad assembly onto

the caliper assembly (Fig. 78). Be sure retaining clip

is squarely seated in the depressed areas on the cal-

iper.

CAUTION: Use care when installing caliper assem-

bly onto adapter, so the guide pin bushings andsleeves do not get damaged by the mounting

bosses on adapter.

(7) Carefully lower caliper and brake shoe assem-

blies over braking disc (rotor) reversing the required

removal procedure (Fig. 75). Make sure that caliper

guide pin bolts, bushings and sleeves are clear of the

adapter bosses.

CAUTION: Extreme caution should be taken not to

cross thread the caliper guide pin bolts when they

are installed.

(8) Install caliper assembly guide pin bolts into

adapter and tighten (Fig. 74). Then torque both guide

pin bolts to 22 N´m (192 in. lbs.).

(9) Install the wheel and tire assembly.

(10) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(11) Remove jackstands or lower hoist.Before

moving vehicle, pump the brake pedal several

times to insure the vehicle has a firm brake

pedal.

(12) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake pads.

REAR BRAKE DRUM

REMOVE

Further clearance can be obtained by backing off

the brake automatic adjuster screw. Remove rubber

plug from top of brake support plate. Rotate auto-

matic adjuster screw assembly with an upward

motion, using a medium size screwdriver.

See adjusting rear service brakes in the Service

Adjustments section in this group of the service man-

ual for the specific adjustment procedure.

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this manual.

(2) Remove the rear wheel and tire assemblies

from the vehicle.

(3) Remove rear brake drum to hub retaining clips

(if equipped).

(4) Remove rear brake drum from rear hub/bear-

ing assembly (Fig. 80).

(5) Inspect brake linings for wear, shoe alignment

and contamination.

INSTALL

(1) Install rear brake drum assembly on rear hub

and bearing assembly.

(2) Install the wheel and tire assembly.

Fig. 79 Removing Inboard Brake Shoe

5 - 34 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 148 of 1200

(3) Remove the rubber plug from the adjusting

hole in the brake shoe backing plate on both sides of

the vehicle.

(4)Driver (left) side park brake shoe adjust-

ment procedure.Insert a medium size screwdriver

through adjustment hole in backing plate. Position

the srewdriver against the starwheel on the park

brake shoe adjuster mechanism. Using the screw-

driver rotate the starwheeldownwarduntil a slight

drag is felt when turning the rear tire and wheel.

Then, using the screwdriver rotate the starwheel

upwardjust until the rear tire and wheel can be

rotated with no park brake shoe drag. From the

point where there is no more park brake drag rotate

the starwheelupwarda maximum of two additional

clicks. The park brake shoe to drum clearance is

know properly adjusted.

(5)Passenger (right) side park brake shoe

adjustment procedure.Insert a medium size

screwdriver through adjustment hole in backing

plate. Position the srewdriver against the starwheel

on the park brake shoe adjuster mechanism. Using

the screwdriver rotate the starwheelupwarduntil a

slight drag is felt when turning the rear tire and

wheel. Then, using the screwdriver rotate the star-

wheeldownwardjust until the rear tire and wheel

can be rotated with no park brake shoe drag. From

the point where there is no more park brake drag

rotate the starwheeldownwarda maximum of two

additional clicks. The park brake shoe to drum clear-

ance is know properly adjusted.

(6) Install the rubber plug in the adjusting hole on

the brake shoe backing plate on both sides of the

vehicle.

(7) Lower vehicle far enough to allow access the

park brake lever. The rear tires must not be on the

ground.

(8) Fully apply and release the park brakes two

times after adjusting the park brake shoes. Then

rotate both rear wheels to ensure that the park

brake shoes do not drag on the brake drum following

the application and release of the park brakes.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. Anopen container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid ect.

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.........Standard

Hydraulic System...........Dual-Diagonally Split

MASTER CYLINDER ASSEMBLY:

Type ...........................Dual Tandem

Body Material...............Anodized Aluminum

Reservoir Material................Polypropelene

MASTER CYLINDER BORE / STROKE

AND SPLIT:

NonABS ....21mmx32.6 mm (.875 in. x 1.28 in.)

ABS........21mmx32.7 mm (.874 in. x 1.29 in.)

Displacement Split.....................50/50

MASTER CYLINDER FLUID OUTLET PORTS:

ABS ..........Primary 3/8±24 Secondary 7/16±24

Non ABS . . .Primary Inboard And Outboard 7/16±24

Non ABS . . .Secondary Inboard And Outboard 3/8±23

Outlet Fitting Type.......SAE 45 É Inverted Flare

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting Type.SAE 45 É Inverted Flare

BOOSTER:

Make/Type.........Bendix Vacuum W/&W/O ABS

Mounting Studs.....................M8x1.25

Type ..........................230 mm Single

Boost At 20 inches Of Manifold Vacuum. . . .4690 All

PROPORTIONING VALVE:

Material...........................Aluminum

Function........Hydraulic Pressure Proportioning

BRAKE PEDAL

Pedal Ratio.............................3.28

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components Except HCU. . . . 17 N´m (145 in. lbs.)

From Master Cylinder To

HCU At HCU Ports........21N´m(185 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

PLBRAKES 5 - 67

ADJUSTMENTS (Continued)

Page 155 of 1200

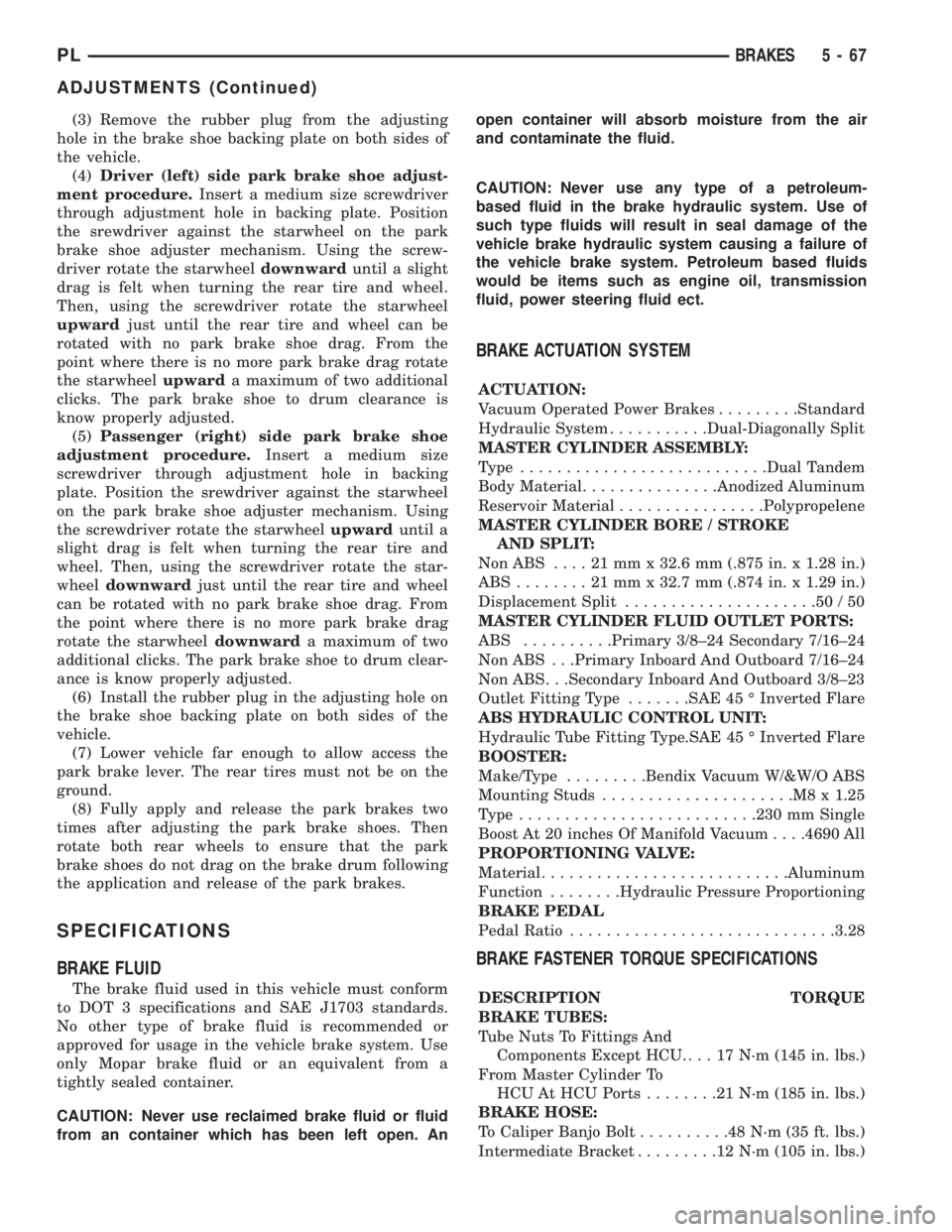

integral part of the rear wheel hub and bearing

assembly. The speed sensor air gap on both applica-

tions is NOT adjustable.

The four Wheel Speed Sensors are serviced individ-

ually. The front Tone Wheels are serviced as an

assembly with the outboard constant velocity joint.

The rear Tone Wheels are serviced as an assembly

with the rear hub and bearing assembly.

Correct ABS system operation is dependent on

accurate wheel speed signals. The vehicle's wheels

and tires must all be the same size and type to gen-

erate accurate signals. Variations in wheel and tire

size can produce inaccurate wheel speed signals.

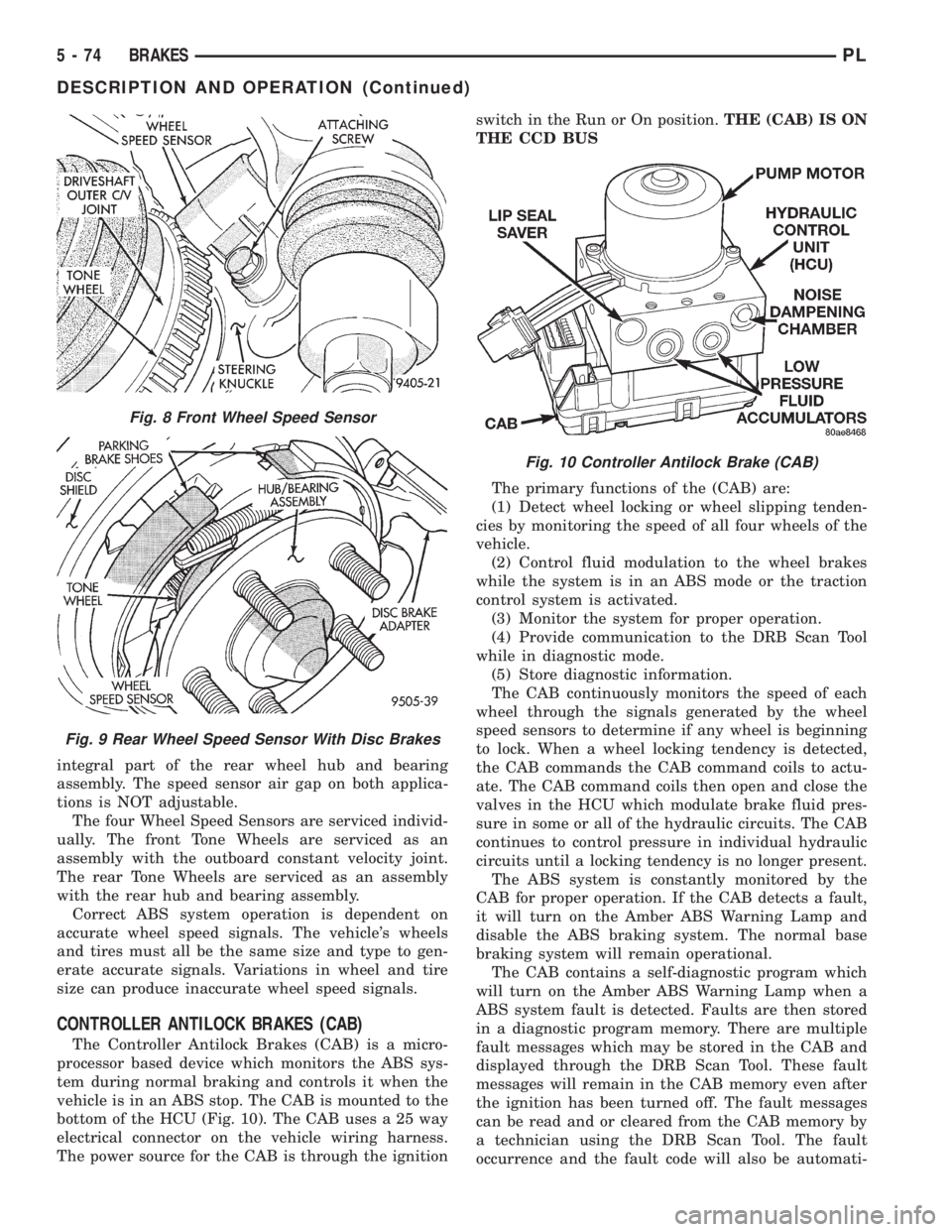

CONTROLLER ANTILOCK BRAKES (CAB)

The Controller Antilock Brakes (CAB) is a micro-

processor based device which monitors the ABS sys-

tem during normal braking and controls it when the

vehicle is in an ABS stop. The CAB is mounted to the

bottom of the HCU (Fig. 10). The CAB uses a 25 way

electrical connector on the vehicle wiring harness.

The power source for the CAB is through the ignitionswitch in the Run or On position.THE (CAB) IS ON

THE CCD BUS

The primary functions of the (CAB) are:

(1) Detect wheel locking or wheel slipping tenden-

cies by monitoring the speed of all four wheels of the

vehicle.

(2) Control fluid modulation to the wheel brakes

while the system is in an ABS mode or the traction

control system is activated.

(3) Monitor the system for proper operation.

(4) Provide communication to the DRB Scan Tool

while in diagnostic mode.

(5) Store diagnostic information.

The CAB continuously monitors the speed of each

wheel through the signals generated by the wheel

speed sensors to determine if any wheel is beginning

to lock. When a wheel locking tendency is detected,

the CAB commands the CAB command coils to actu-

ate. The CAB command coils then open and close the

valves in the HCU which modulate brake fluid pres-

sure in some or all of the hydraulic circuits. The CAB

continues to control pressure in individual hydraulic

circuits until a locking tendency is no longer present.

The ABS system is constantly monitored by the

CAB for proper operation. If the CAB detects a fault,

it will turn on the Amber ABS Warning Lamp and

disable the ABS braking system. The normal base

braking system will remain operational.

The CAB contains a self-diagnostic program which

will turn on the Amber ABS Warning Lamp when a

ABS system fault is detected. Faults are then stored

in a diagnostic program memory. There are multiple

fault messages which may be stored in the CAB and

displayed through the DRB Scan Tool. These fault

messages will remain in the CAB memory even after

the ignition has been turned off. The fault messages

can be read and or cleared from the CAB memory by

a technician using the DRB Scan Tool. The fault

occurrence and the fault code will also be automati-

Fig. 8 Front Wheel Speed Sensor

Fig. 9 Rear Wheel Speed Sensor With Disc Brakes

Fig. 10 Controller Antilock Brake (CAB)

5 - 74 BRAKESPL

DESCRIPTION AND OPERATION (Continued)