warning DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 8 of 1200

JUMP STARTING, TOWING AND HOISTING

INDEX

page page

SERVICE PROCEDURES

HOISTING RECOMMENDATIONS............ 9JUMP STARTING PROCEDURE.............. 7

TOWING RECOMMENDATIONS.............. 8

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, placethe automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

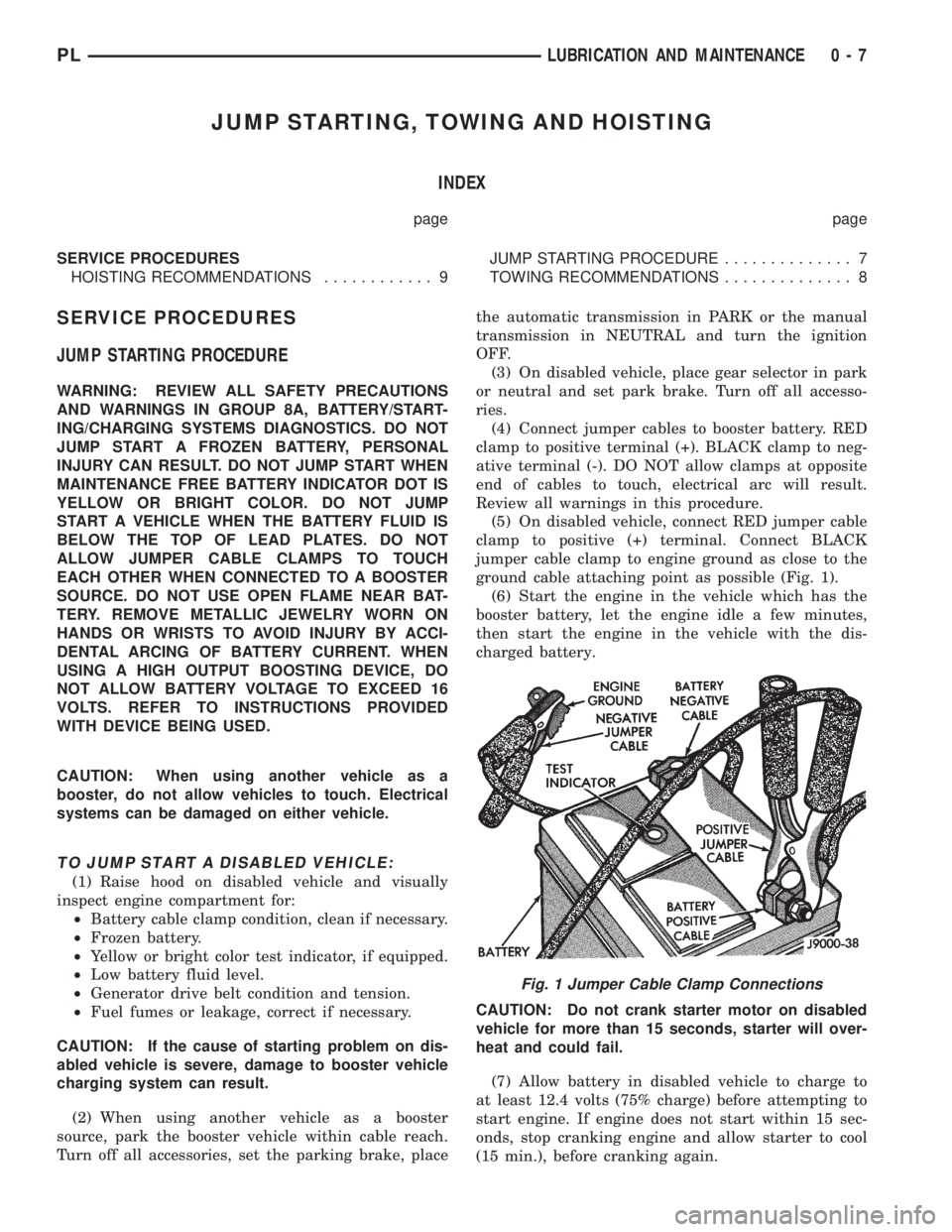

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

Fig. 1 Jumper Cable Clamp Connections

PLLUBRICATION AND MAINTENANCE 0 - 7

Page 9 of 1200

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING RECOMMENDATIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT. DO NOT LIFT OR

TOW VEHICLE BY FRONT OR REAR BUMPER, OR

BUMPER ENERGY ABSORBER UNITS. DO NOT

VENTURE UNDER A LIFTED VEHICLE IF NOT SUP-

PORTED PROPERLY ON SAFETY STANDS. DO NOT

ALLOW PASSENGERS TO RIDE IN A TOWED VEHI-

CLE. USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust

system, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle. Do not attach towing device to

front or rear suspension components. Do not

secure vehicle to towing device by the use of front

or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing. Refer to state and

local rules and regulations before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

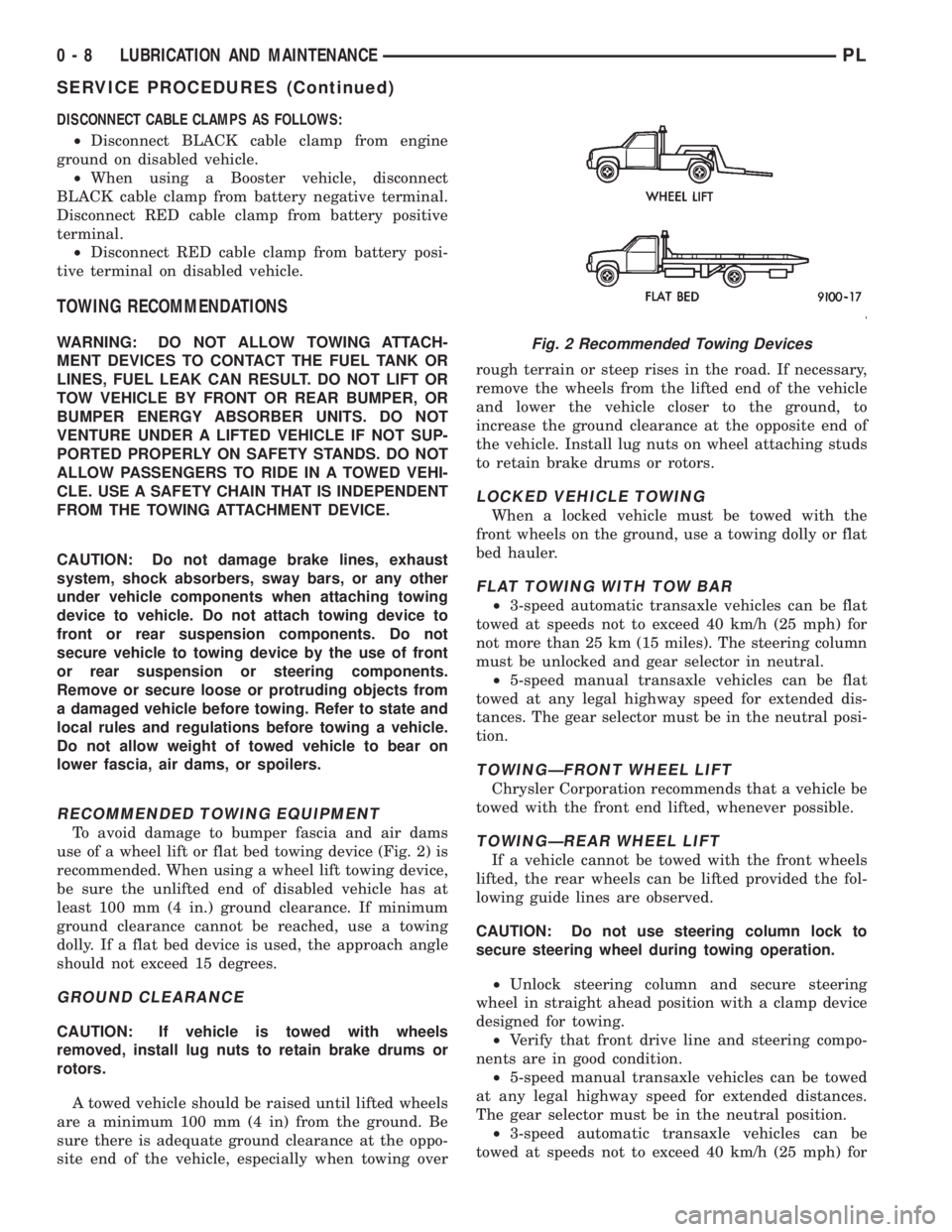

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use of a wheel lift or flat bed towing device (Fig. 2) is

recommended. When using a wheel lift towing device,

be sure the unlifted end of disabled vehicle has at

least 100 mm (4 in.) ground clearance. If minimum

ground clearance cannot be reached, use a towing

dolly. If a flat bed device is used, the approach angle

should not exceed 15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing overrough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²5-speed manual transaxle vehicles can be flat

towed at any legal highway speed for extended dis-

tances. The gear selector must be in the neutral posi-

tion.

TOWINGÐFRONT WHEEL LIFT

Chrysler Corporation recommends that a vehicle be

towed with the front end lifted, whenever possible.

TOWINGÐREAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Verify that front drive line and steering compo-

nents are in good condition.

²5-speed manual transaxle vehicles can be towed

at any legal highway speed for extended distances.

The gear selector must be in the neutral position.

²3-speed automatic transaxle vehicles can be

towed at speeds not to exceed 40 km/h (25 mph) for

Fig. 2 Recommended Towing Devices

0 - 8 LUBRICATION AND MAINTENANCEPL

SERVICE PROCEDURES (Continued)

Page 10 of 1200

not more than 25 km (15 miles). The gear selector

must be in the neutral position.

HOISTING RECOMMENDATIONS

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on sus-

pension components, damage to vehicle can result.

Do not attempt to raise one entire side of the

vehicle by placing a floor jack midway between the

front and rear wheels. This practice may result in

permanent damage to the body.

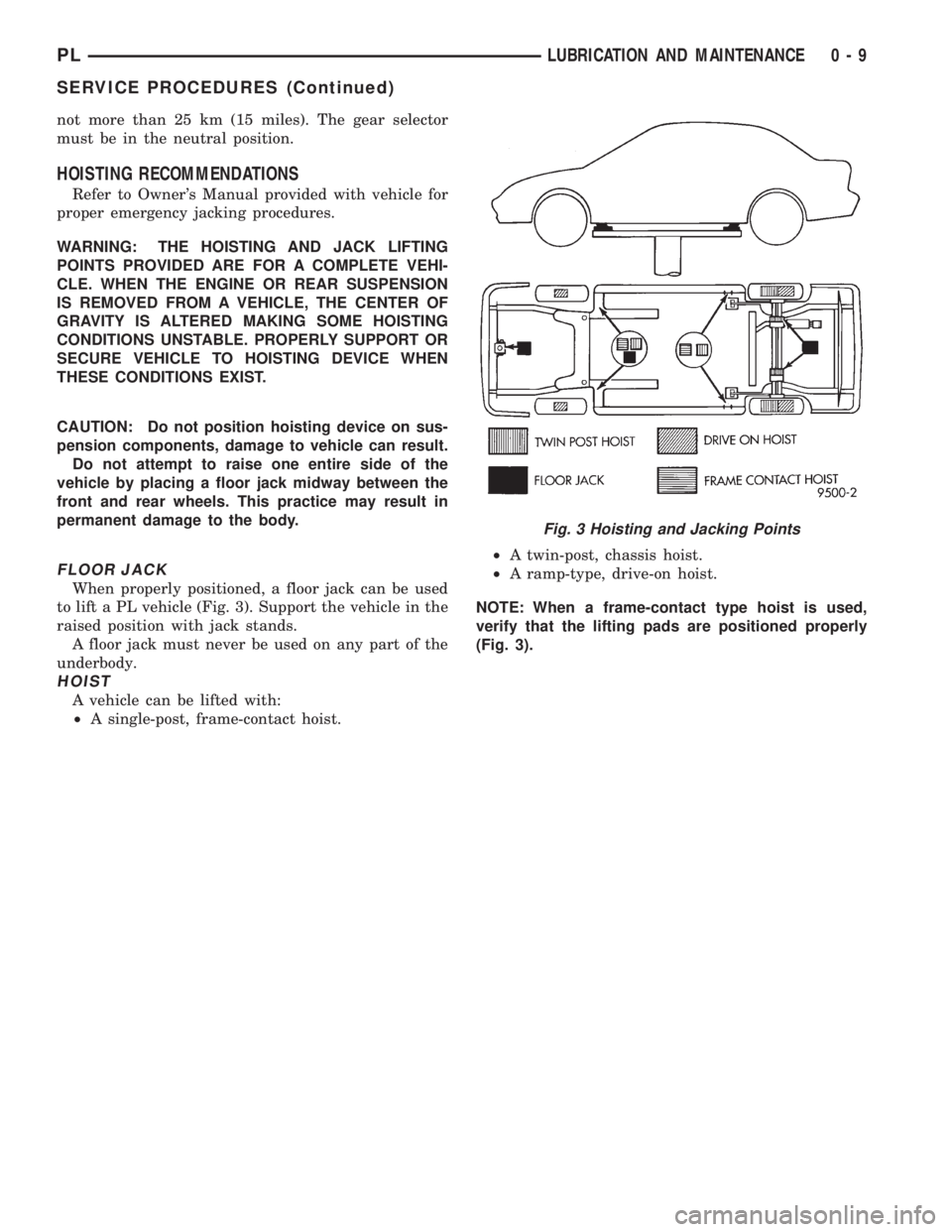

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a PL vehicle (Fig. 3). Support the vehicle in the

raised position with jack stands.

A floor jack must never be used on any part of the

underbody.

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 3).

Fig. 3 Hoisting and Jacking Points

PLLUBRICATION AND MAINTENANCE 0 - 9

SERVICE PROCEDURES (Continued)

Page 27 of 1200

nent removal and installation sections in this group

of the service manual.

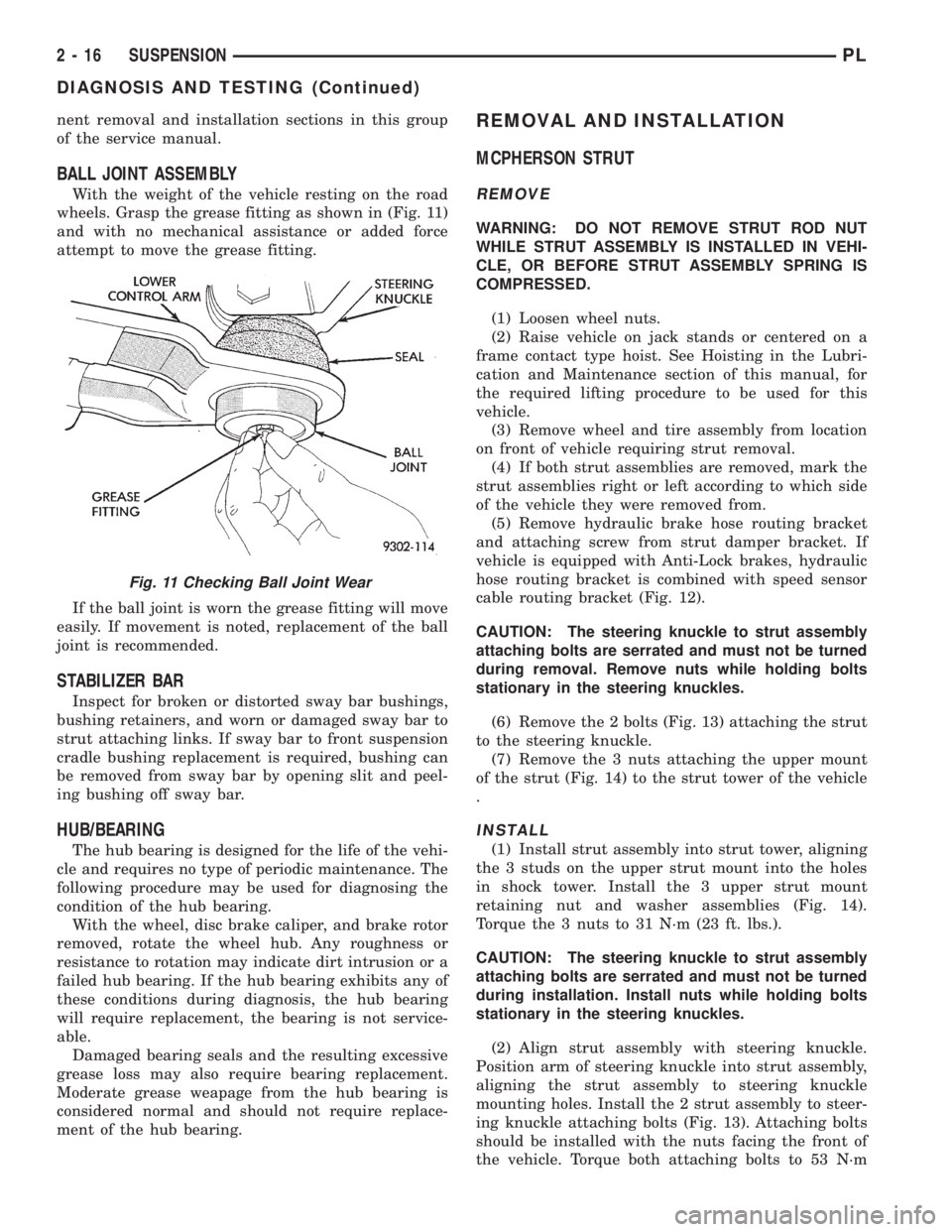

BALL JOINT ASSEMBLY

With the weight of the vehicle resting on the road

wheels. Grasp the grease fitting as shown in (Fig. 11)

and with no mechanical assistance or added force

attempt to move the grease fitting.

If the ball joint is worn the grease fitting will move

easily. If movement is noted, replacement of the ball

joint is recommended.

STABILIZER BAR

Inspect for broken or distorted sway bar bushings,

bushing retainers, and worn or damaged sway bar to

strut attaching links. If sway bar to front suspension

cradle bushing replacement is required, bushing can

be removed from sway bar by opening slit and peel-

ing bushing off sway bar.

HUB/BEARING

The hub bearing is designed for the life of the vehi-

cle and requires no type of periodic maintenance. The

following procedure may be used for diagnosing the

condition of the hub bearing.

With the wheel, disc brake caliper, and brake rotor

removed, rotate the wheel hub. Any roughness or

resistance to rotation may indicate dirt intrusion or a

failed hub bearing. If the hub bearing exhibits any of

these conditions during diagnosis, the hub bearing

will require replacement, the bearing is not service-

able.

Damaged bearing seals and the resulting excessive

grease loss may also require bearing replacement.

Moderate grease weapage from the hub bearing is

considered normal and should not require replace-

ment of the hub bearing.

REMOVAL AND INSTALLATION

MCPHERSON STRUT

REMOVE

WARNING: DO NOT REMOVE STRUT ROD NUT

WHILE STRUT ASSEMBLY IS INSTALLED IN VEHI-

CLE, OR BEFORE STRUT ASSEMBLY SPRING IS

COMPRESSED.

(1) Loosen wheel nuts.

(2) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(3) Remove wheel and tire assembly from location

on front of vehicle requiring strut removal.

(4) If both strut assemblies are removed, mark the

strut assemblies right or left according to which side

of the vehicle they were removed from.

(5) Remove hydraulic brake hose routing bracket

and attaching screw from strut damper bracket. If

vehicle is equipped with Anti-Lock brakes, hydraulic

hose routing bracket is combined with speed sensor

cable routing bracket (Fig. 12).

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during removal. Remove nuts while holding bolts

stationary in the steering knuckles.

(6) Remove the 2 bolts (Fig. 13) attaching the strut

to the steering knuckle.

(7) Remove the 3 nuts attaching the upper mount

of the strut (Fig. 14) to the strut tower of the vehicle

.

INSTALL

(1) Install strut assembly into strut tower, aligning

the 3 studs on the upper strut mount into the holes

in shock tower. Install the 3 upper strut mount

retaining nut and washer assemblies (Fig. 14).

Torque the 3 nuts to 31 N´m (23 ft. lbs.).

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckles.

(2) Align strut assembly with steering knuckle.

Position arm of steering knuckle into strut assembly,

aligning the strut assembly to steering knuckle

mounting holes. Install the 2 strut assembly to steer-

ing knuckle attaching bolts (Fig. 13). Attaching bolts

should be installed with the nuts facing the front of

the vehicle. Torque both attaching bolts to 53 N´m

Fig. 11 Checking Ball Joint Wear

2 - 16 SUSPENSIONPL

DIAGNOSIS AND TESTING (Continued)

Page 41 of 1200

(5) Install the disc brake caliper to steering

knuckle attaching bolts (Fig. 61). Tighten the attach-

ing bolts to a torque of 31 N´m (23 ft. lbs.).

(6) Install front wheel and tire. Install front wheel

lug nuts and torque to 135 N´m

(7) (100 ft. lbs.).

(8) Lower vehicle.

DISASSEMBLY AND ASSEMBLY

McPHERSON STRUT

DISASSEMBLY

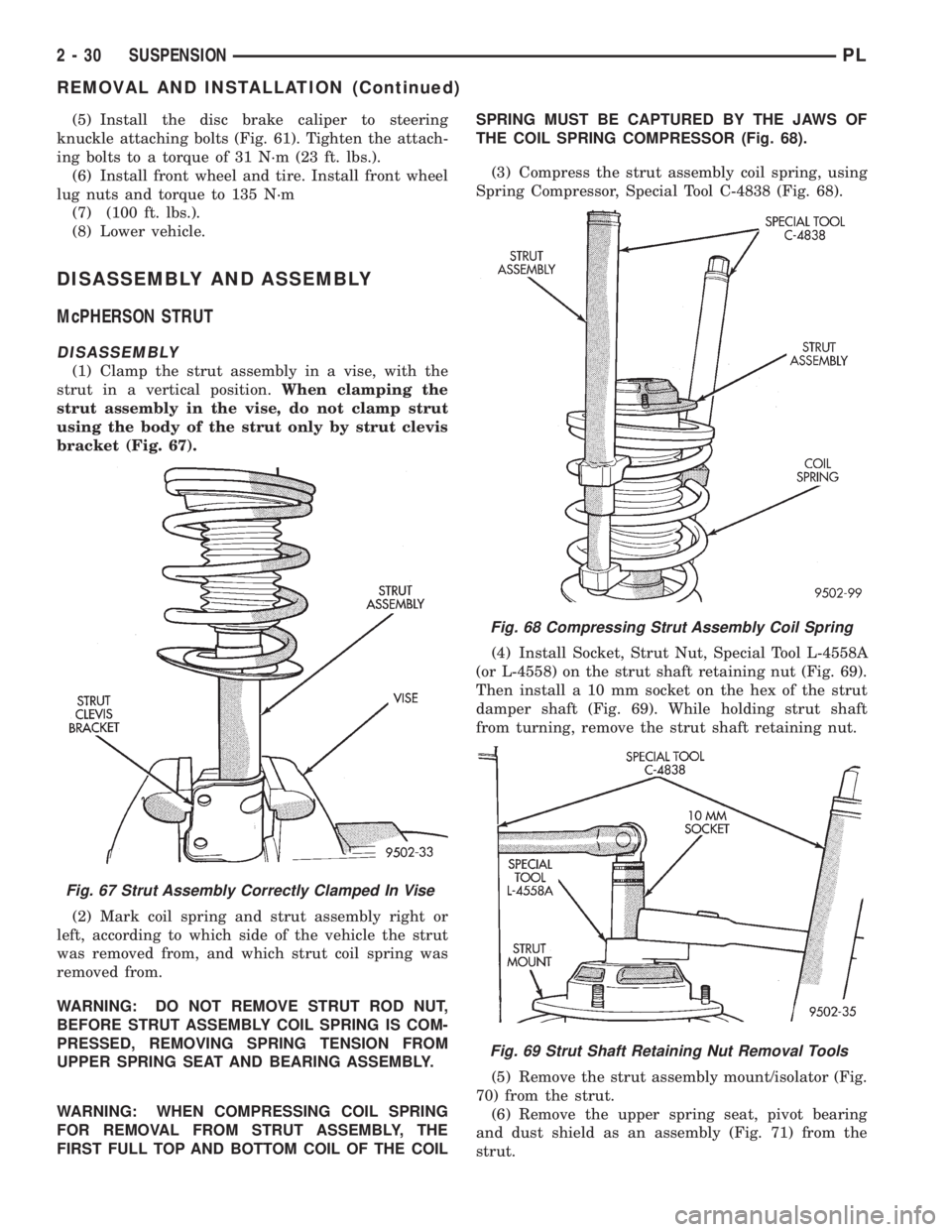

(1) Clamp the strut assembly in a vise, with the

strut in a vertical position.When clamping the

strut assembly in the vise, do not clamp strut

using the body of the strut only by strut clevis

bracket (Fig. 67).

(2) Mark coil spring and strut assembly right or

left, according to which side of the vehicle the strut

was removed from, and which strut coil spring was

removed from.

WARNING: DO NOT REMOVE STRUT ROD NUT,

BEFORE STRUT ASSEMBLY COIL SPRING IS COM-

PRESSED, REMOVING SPRING TENSION FROM

UPPER SPRING SEAT AND BEARING ASSEMBLY.

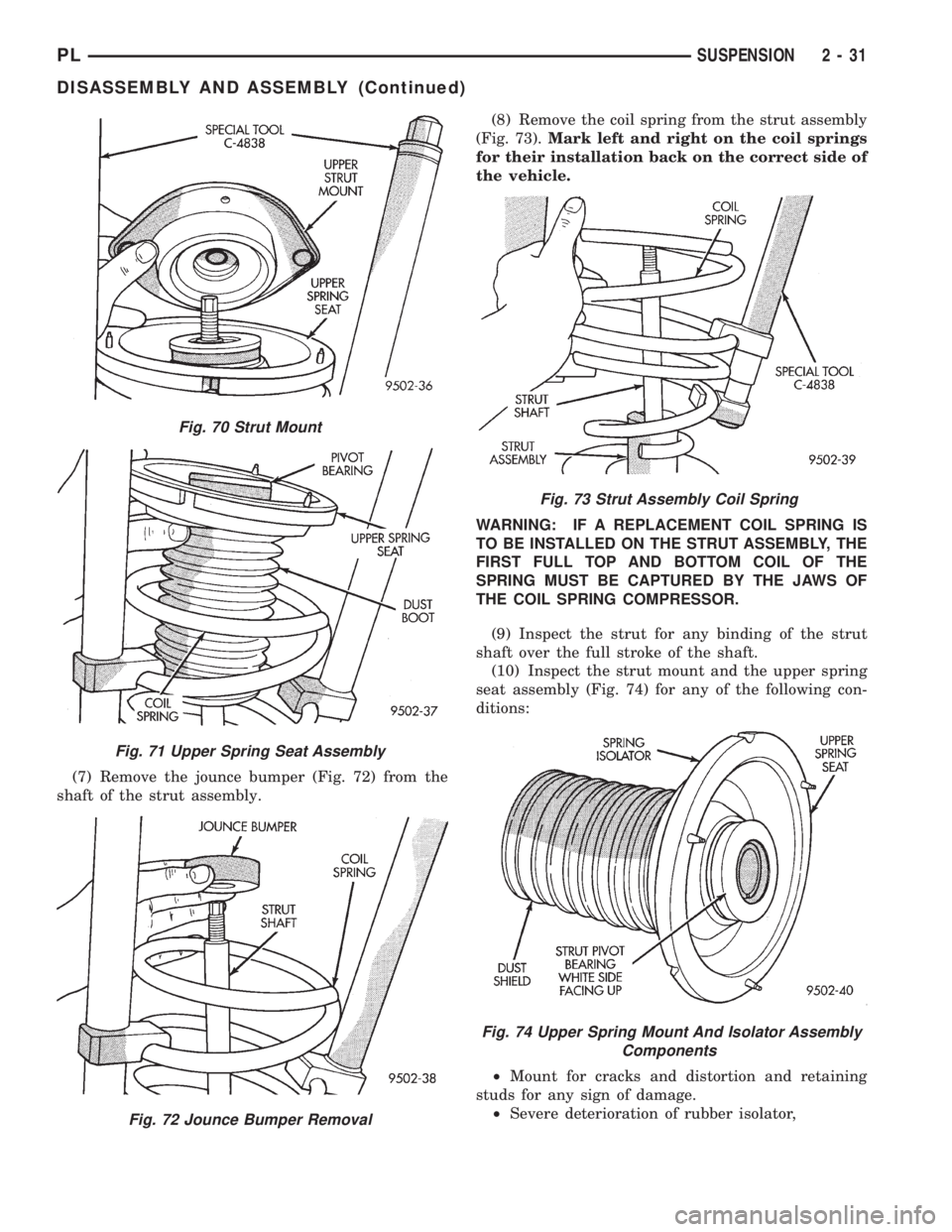

WARNING: WHEN COMPRESSING COIL SPRING

FOR REMOVAL FROM STRUT ASSEMBLY, THE

FIRST FULL TOP AND BOTTOM COIL OF THE COILSPRING MUST BE CAPTURED BY THE JAWS OF

THE COIL SPRING COMPRESSOR (Fig. 68).

(3) Compress the strut assembly coil spring, using

Spring Compressor, Special Tool C-4838 (Fig. 68).

(4) Install Socket, Strut Nut, Special Tool L-4558A

(or L-4558) on the strut shaft retaining nut (Fig. 69).

Then install a 10 mm socket on the hex of the strut

damper shaft (Fig. 69). While holding strut shaft

from turning, remove the strut shaft retaining nut.

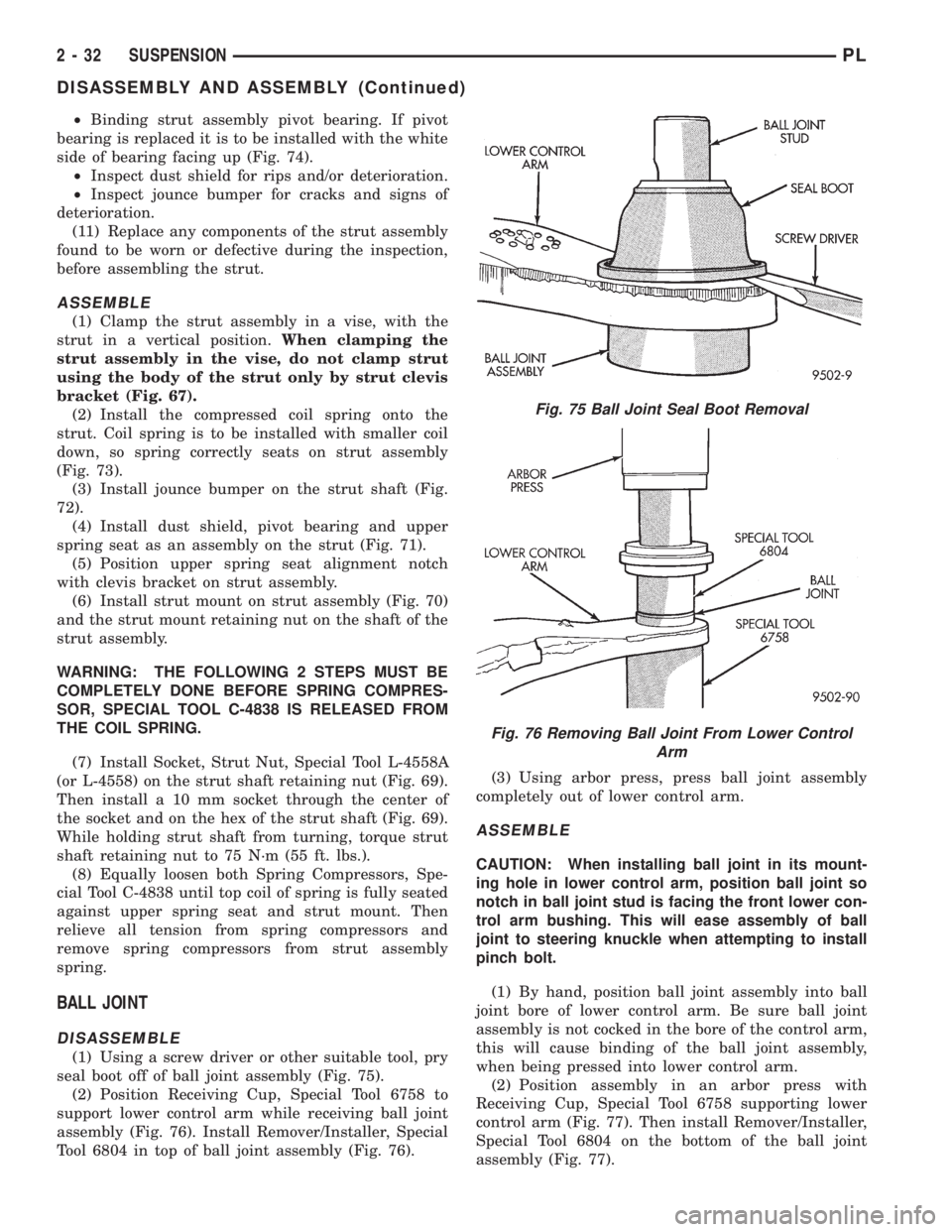

(5) Remove the strut assembly mount/isolator (Fig.

70) from the strut.

(6) Remove the upper spring seat, pivot bearing

and dust shield as an assembly (Fig. 71) from the

strut.

Fig. 67 Strut Assembly Correctly Clamped In Vise

Fig. 68 Compressing Strut Assembly Coil Spring

Fig. 69 Strut Shaft Retaining Nut Removal Tools

2 - 30 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 42 of 1200

(7) Remove the jounce bumper (Fig. 72) from the

shaft of the strut assembly.(8) Remove the coil spring from the strut assembly

(Fig. 73).Mark left and right on the coil springs

for their installation back on the correct side of

the vehicle.

WARNING: IF A REPLACEMENT COIL SPRING IS

TO BE INSTALLED ON THE STRUT ASSEMBLY, THE

FIRST FULL TOP AND BOTTOM COIL OF THE

SPRING MUST BE CAPTURED BY THE JAWS OF

THE COIL SPRING COMPRESSOR.

(9) Inspect the strut for any binding of the strut

shaft over the full stroke of the shaft.

(10) Inspect the strut mount and the upper spring

seat assembly (Fig. 74) for any of the following con-

ditions:

²Mount for cracks and distortion and retaining

studs for any sign of damage.

²Severe deterioration of rubber isolator,

Fig. 70 Strut Mount

Fig. 71 Upper Spring Seat Assembly

Fig. 72 Jounce Bumper Removal

Fig. 73 Strut Assembly Coil Spring

Fig. 74 Upper Spring Mount And Isolator Assembly

Components

PLSUSPENSION 2 - 31

DISASSEMBLY AND ASSEMBLY (Continued)

Page 43 of 1200

²Binding strut assembly pivot bearing. If pivot

bearing is replaced it is to be installed with the white

side of bearing facing up (Fig. 74).

²Inspect dust shield for rips and/or deterioration.

²Inspect jounce bumper for cracks and signs of

deterioration.

(11) Replace any components of the strut assembly

found to be worn or defective during the inspection,

before assembling the strut.

ASSEMBLE

(1) Clamp the strut assembly in a vise, with the

strut in a vertical position.When clamping the

strut assembly in the vise, do not clamp strut

using the body of the strut only by strut clevis

bracket (Fig. 67).

(2) Install the compressed coil spring onto the

strut. Coil spring is to be installed with smaller coil

down, so spring correctly seats on strut assembly

(Fig. 73).

(3) Install jounce bumper on the strut shaft (Fig.

72).

(4) Install dust shield, pivot bearing and upper

spring seat as an assembly on the strut (Fig. 71).

(5) Position upper spring seat alignment notch

with clevis bracket on strut assembly.

(6) Install strut mount on strut assembly (Fig. 70)

and the strut mount retaining nut on the shaft of the

strut assembly.

WARNING: THE FOLLOWING 2 STEPS MUST BE

COMPLETELY DONE BEFORE SPRING COMPRES-

SOR, SPECIAL TOOL C-4838 IS RELEASED FROM

THE COIL SPRING.

(7) Install Socket, Strut Nut, Special Tool L-4558A

(or L-4558) on the strut shaft retaining nut (Fig. 69).

Then install a 10 mm socket through the center of

the socket and on the hex of the strut shaft (Fig. 69).

While holding strut shaft from turning, torque strut

shaft retaining nut to 75 N´m (55 ft. lbs.).

(8) Equally loosen both Spring Compressors, Spe-

cial Tool C-4838 until top coil of spring is fully seated

against upper spring seat and strut mount. Then

relieve all tension from spring compressors and

remove spring compressors from strut assembly

spring.

BALL JOINT

DISASSEMBLE

(1) Using a screw driver or other suitable tool, pry

seal boot off of ball joint assembly (Fig. 75).

(2) Position Receiving Cup, Special Tool 6758 to

support lower control arm while receiving ball joint

assembly (Fig. 76). Install Remover/Installer, Special

Tool 6804 in top of ball joint assembly (Fig. 76).(3) Using arbor press, press ball joint assembly

completely out of lower control arm.

ASSEMBLE

CAUTION: When installing ball joint in its mount-

ing hole in lower control arm, position ball joint so

notch in ball joint stud is facing the front lower con-

trol arm bushing. This will ease assembly of ball

joint to steering knuckle when attempting to install

pinch bolt.

(1) By hand, position ball joint assembly into ball

joint bore of lower control arm. Be sure ball joint

assembly is not cocked in the bore of the control arm,

this will cause binding of the ball joint assembly,

when being pressed into lower control arm.

(2) Position assembly in an arbor press with

Receiving Cup, Special Tool 6758 supporting lower

control arm (Fig. 77). Then install Remover/Installer,

Special Tool 6804 on the bottom of the ball joint

assembly (Fig. 77).

Fig. 75 Ball Joint Seal Boot Removal

Fig. 76 Removing Ball Joint From Lower Control

Arm

2 - 32 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 83 of 1200

BASE BRAKE SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

CHASSIS TUBES AND HOSES.............. 6

FRONT DISC BRAKES..................... 2

MASTER CYLINDER...................... 6

PARKING BRAKES........................ 4

PROPORTIONING VALVES................. 5

REAR DISC BRAKES...................... 4

REAR DRUM BRAKES..................... 4

REAR WHEEL HUB/BEARING............... 8

RED BRAKE WARNING LAMP............... 7

STOP LAMP SWITCH...................... 8

VACUUM BOOSTER...................... 6

DIAGNOSIS AND TESTING

BRAKE FLUID CONTAMINATION............ 19

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE.... 9

BRAKE SYSTEM DIAGNOSIS CHARTS....... 10

DRUM BRAKE AUTOMATIC ADJUSTER....... 14

PROPORTIONING VALVES................ 16

RED BRAKE WARNING LAMP TEST......... 19

ROTOR THICKNESS AND RUNOUT.......... 14

STOP LAMP SWITCH TEST PROCEDURE..... 19

SERVICE PROCEDURES

BRAKE BLEEDING....................... 20

BRAKE DRUM MACHINING................ 23

BRAKE FLUID LEVEL CHECK.............. 19

BRAKE ROTOR MACHINING............... 22

BRAKE TUBE REPAIR.................... 25

MASTER CYLINDER BLEEDING............ 21

PARK BRAKE LEVER AUTO ADJUSTER

MECHANISM.......................... 23

REMOVAL AND INSTALLATION

CHASSIS TUBES AND HOSES.............. 47

FRONT DISC BRAKE CALIPER............. 26

FRONT DISC BRAKE SHOES.............. 28

MASTER CYLINDER..................... 41

PARK BRAKE CABLES.................... 50

PARK BRAKE LEVER ASSEMBLY........... 48PARK BRAKE LEVER OUTPUT CABLE....... 49

PARK BRAKE SHOES WITH REAR DISC

BRAKES............................. 55

PROPORTIONING VALVE (BASE BRAKES).... 47

REAR BRAKE DRUM..................... 34

REAR BRAKE SHOE SUPPORT PLATE....... 37

REAR BRAKE SHOES.................... 35

REAR BRAKE WHEEL CYLINDER........... 38

REAR DISC BRAKE CALIPER.............. 30

REAR DISC BRAKE SHOES................ 32

REAR HUB/BEARING..................... 39

STOP LAMP SWITCH..................... 57

VACUUM BOOSTER..................... 44

WHEEL AND TIRE ASSEMBLY.............. 26

DISASSEMBLY AND ASSEMBLY

BRAKE FLUID LEVEL SWITCH............. 58

BRAKE FLUID RESERVOIR................ 57

FRONT AND REAR DISC BRAKE CALIPER.... 58

WHEEL CYLINDER (REAR DRUM BRAKE).... 63

CLEANING AND INSPECTION

CHASSIS TUBES AND HOSES.............. 65

FRONT DISC BRAKES.................... 63

REAR DISC BRAKES..................... 64

REAR DRUM BRAKE WHEEL CYLINDER...... 65

REAR DRUM BRAKES.................... 64

REAR WHEEL HUB AND BEARING ASSEMBLY . 65

ADJUSTMENTS

PARK BRAKE ADJUSTMENT............... 66

REAR DRUM BRAKE SHOE ADJUSTMENT.... 65

STOP LAMP SWITCH..................... 65

SPECIFICATIONS

BRAKE ACTUATION SYSTEM.............. 67

BRAKE FASTENER TORQUE SPECIFICATIONS . 67

BRAKE FLUID.......................... 67

SPECIAL TOOLS

BASE BRAKE SYSTEM................... 68

DESCRIPTION AND OPERATION

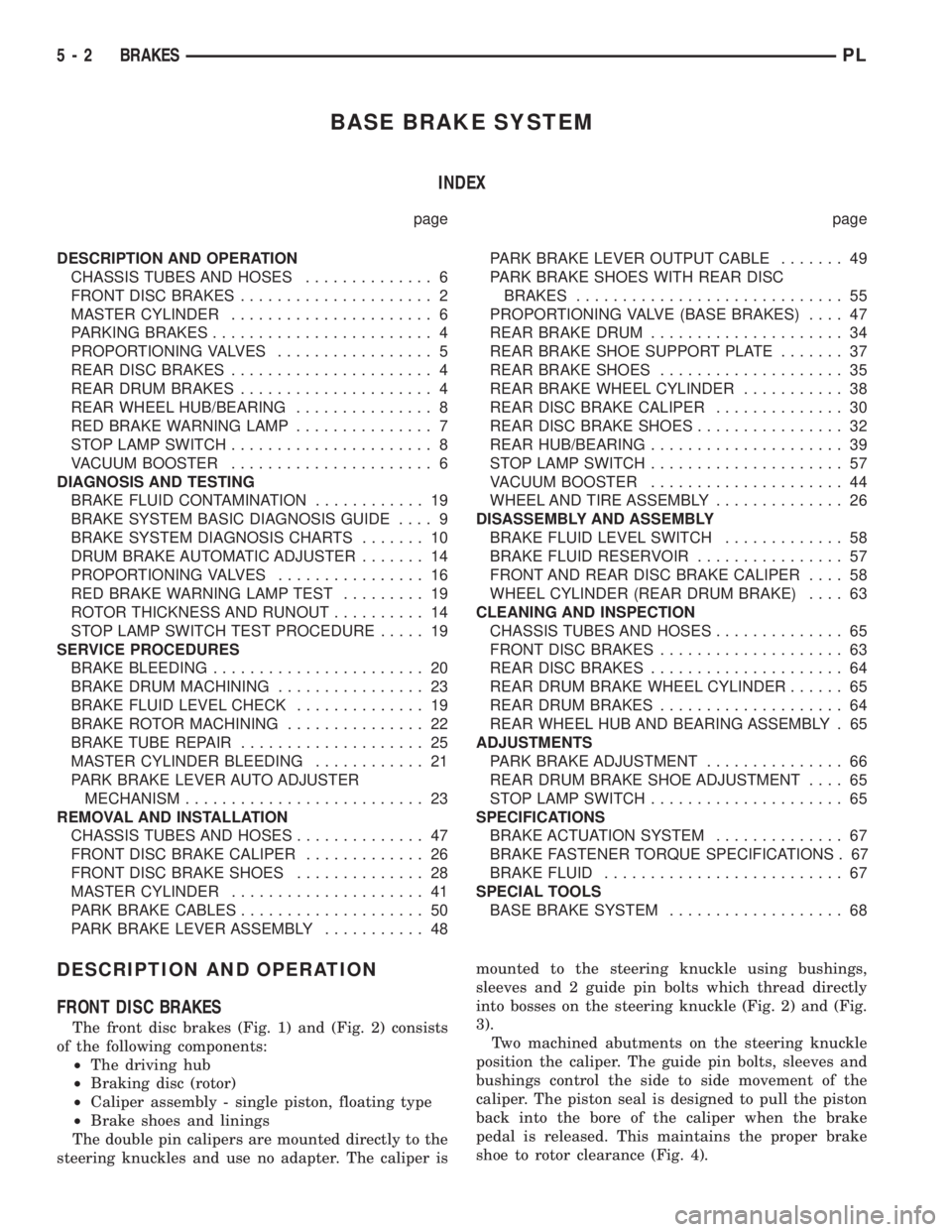

FRONT DISC BRAKES

The front disc brakes (Fig. 1) and (Fig. 2) consists

of the following components:

²The driving hub

²Braking disc (rotor)

²Caliper assembly - single piston, floating type

²Brake shoes and linings

The double pin calipers are mounted directly to the

steering knuckles and use no adapter. The caliper ismounted to the steering knuckle using bushings,

sleeves and 2 guide pin bolts which thread directly

into bosses on the steering knuckle (Fig. 2) and (Fig.

3).

Two machined abutments on the steering knuckle

position the caliper. The guide pin bolts, sleeves and

bushings control the side to side movement of the

caliper. The piston seal is designed to pull the piston

back into the bore of the caliper when the brake

pedal is released. This maintains the proper brake

shoe to rotor clearance (Fig. 4).

5 - 2 BRAKESPL

Page 88 of 1200

boosters differ at the interface to the master cylinder.

If the power brake booster requires replacement be

sure it is replaced with the correct part.

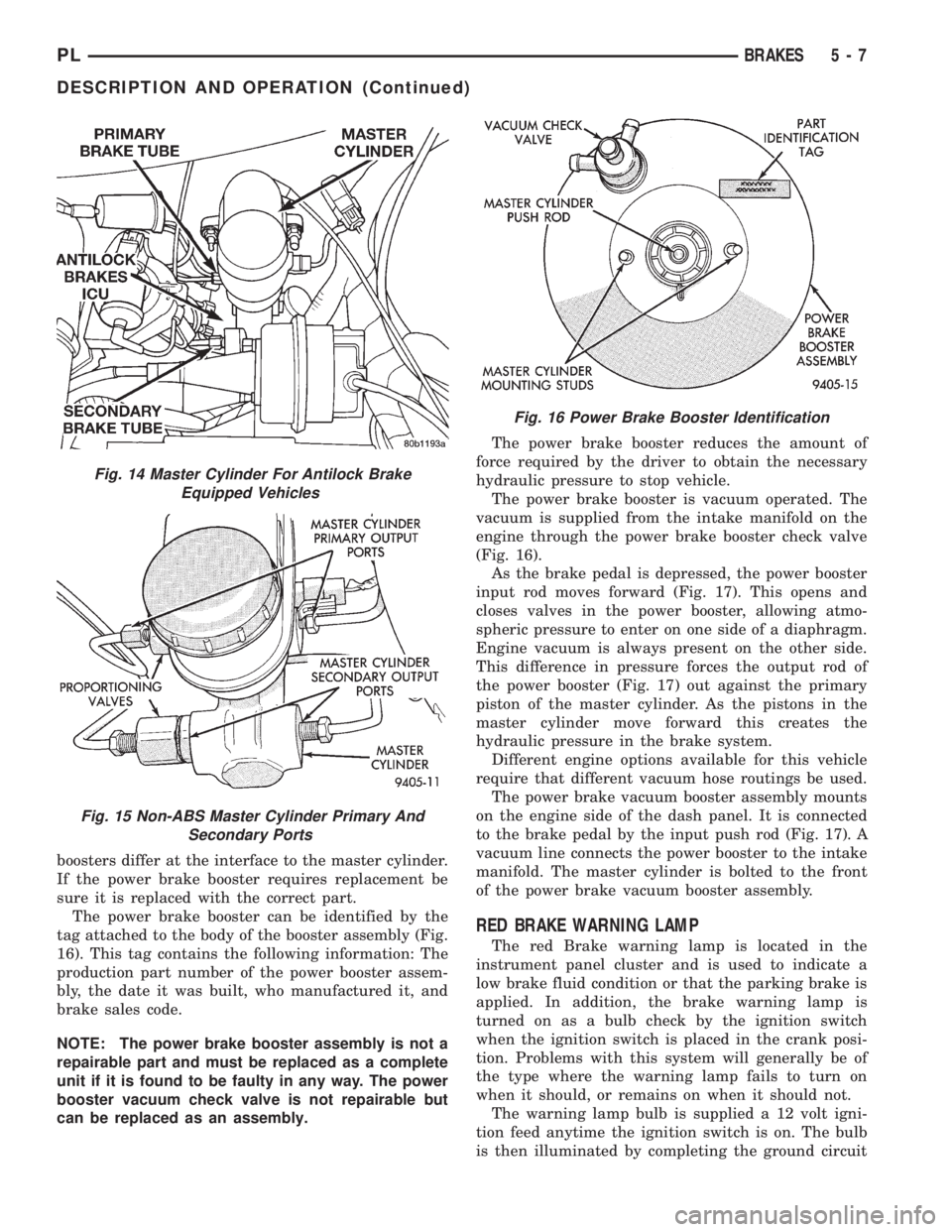

The power brake booster can be identified by the

tag attached to the body of the booster assembly (Fig.

16). This tag contains the following information: The

production part number of the power booster assem-

bly, the date it was built, who manufactured it, and

brake sales code.

NOTE: The power brake booster assembly is not a

repairable part and must be replaced as a complete

unit if it is found to be faulty in any way. The power

booster vacuum check valve is not repairable but

can be replaced as an assembly.The power brake booster reduces the amount of

force required by the driver to obtain the necessary

hydraulic pressure to stop vehicle.

The power brake booster is vacuum operated. The

vacuum is supplied from the intake manifold on the

engine through the power brake booster check valve

(Fig. 16).

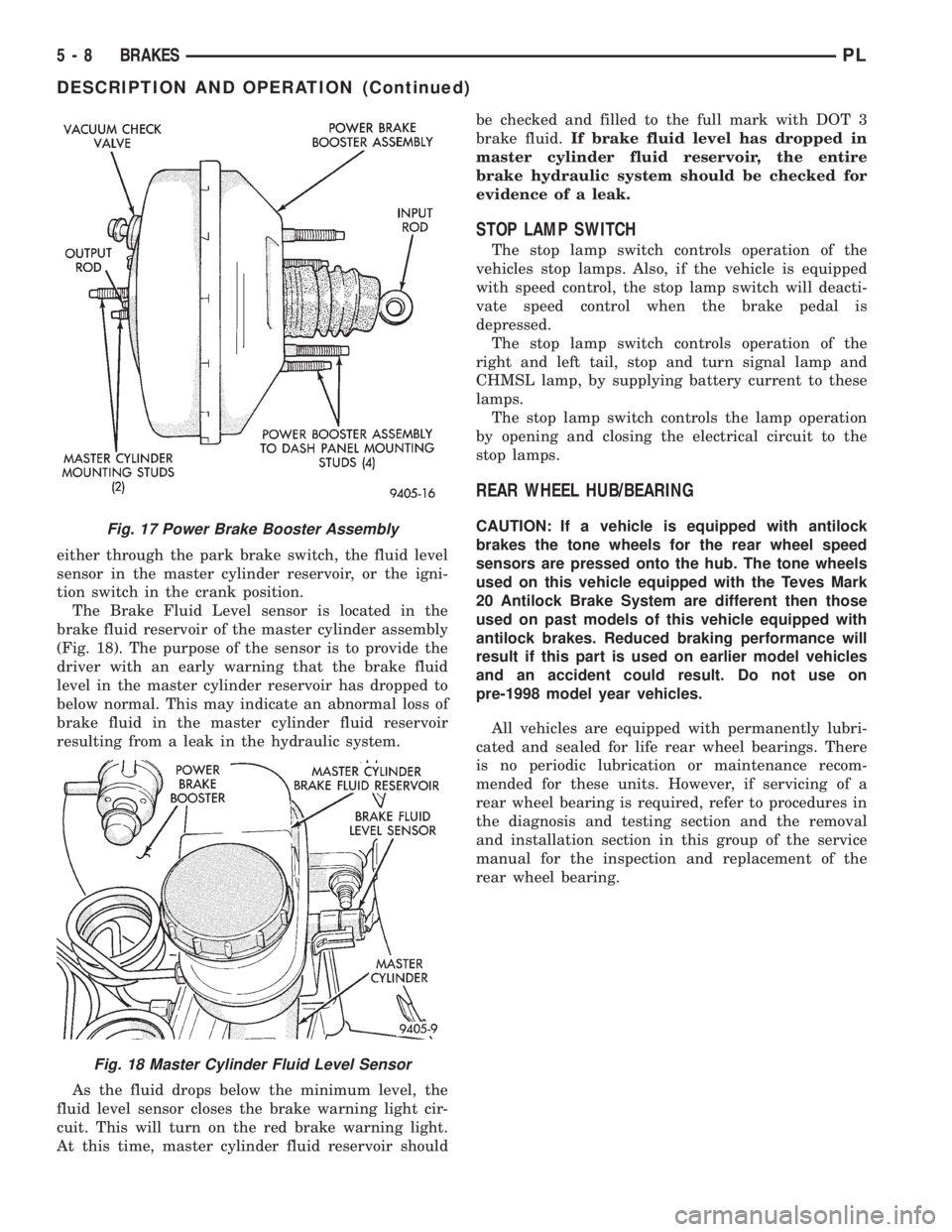

As the brake pedal is depressed, the power booster

input rod moves forward (Fig. 17). This opens and

closes valves in the power booster, allowing atmo-

spheric pressure to enter on one side of a diaphragm.

Engine vacuum is always present on the other side.

This difference in pressure forces the output rod of

the power booster (Fig. 17) out against the primary

piston of the master cylinder. As the pistons in the

master cylinder move forward this creates the

hydraulic pressure in the brake system.

Different engine options available for this vehicle

require that different vacuum hose routings be used.

The power brake vacuum booster assembly mounts

on the engine side of the dash panel. It is connected

to the brake pedal by the input push rod (Fig. 17). A

vacuum line connects the power booster to the intake

manifold. The master cylinder is bolted to the front

of the power brake vacuum booster assembly.

RED BRAKE WARNING LAMP

The red Brake warning lamp is located in the

instrument panel cluster and is used to indicate a

low brake fluid condition or that the parking brake is

applied. In addition, the brake warning lamp is

turned on as a bulb check by the ignition switch

when the ignition switch is placed in the crank posi-

tion. Problems with this system will generally be of

the type where the warning lamp fails to turn on

when it should, or remains on when it should not.

The warning lamp bulb is supplied a 12 volt igni-

tion feed anytime the ignition switch is on. The bulb

is then illuminated by completing the ground circuit

Fig. 14 Master Cylinder For Antilock Brake

Equipped Vehicles

Fig. 15 Non-ABS Master Cylinder Primary And

Secondary Ports

Fig. 16 Power Brake Booster Identification

PLBRAKES 5 - 7

DESCRIPTION AND OPERATION (Continued)

Page 89 of 1200

either through the park brake switch, the fluid level

sensor in the master cylinder reservoir, or the igni-

tion switch in the crank position.

The Brake Fluid Level sensor is located in the

brake fluid reservoir of the master cylinder assembly

(Fig. 18). The purpose of the sensor is to provide the

driver with an early warning that the brake fluid

level in the master cylinder reservoir has dropped to

below normal. This may indicate an abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.

As the fluid drops below the minimum level, the

fluid level sensor closes the brake warning light cir-

cuit. This will turn on the red brake warning light.

At this time, master cylinder fluid reservoir shouldbe checked and filled to the full mark with DOT 3

brake fluid.If brake fluid level has dropped in

master cylinder fluid reservoir, the entire

brake hydraulic system should be checked for

evidence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equipped

with speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

REAR WHEEL HUB/BEARING

CAUTION: If a vehicle is equipped with antilock

brakes the tone wheels for the rear wheel speed

sensors are pressed onto the hub. The tone wheels

used on this vehicle equipped with the Teves Mark

20 Antilock Brake System are different then those

used on past models of this vehicle equipped with

antilock brakes. Reduced braking performance will

result if this part is used on earlier model vehicles

and an accident could result. Do not use on

pre-1998 model year vehicles.

All vehicles are equipped with permanently lubri-

cated and sealed for life rear wheel bearings. There

is no periodic lubrication or maintenance recom-

mended for these units. However, if servicing of a

rear wheel bearing is required, refer to procedures in

the diagnosis and testing section and the removal

and installation section in this group of the service

manual for the inspection and replacement of the

rear wheel bearing.Fig. 17 Power Brake Booster Assembly

Fig. 18 Master Cylinder Fluid Level Sensor

5 - 8 BRAKESPL

DESCRIPTION AND OPERATION (Continued)