height DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 12 of 1200

SUSPENSION

CONTENTS

page page

FRONT SUSPENSION..................... 10

REAR SUSPENSION...................... 39WHEEL ALIGNMENT....................... 1

WHEEL ALIGNMENT

INDEX

page page

DESCRIPTION AND OPERATION

COMPETITION PACKAGE ALIGNMENT........ 2

WHEEL ALIGNMENT GENERAL

INFORMATION......................... 1

DIAGNOSIS AND TESTING

PRE-ALIGNMENT VEHICLE INSPECTION...... 5

SUSPENSION AND STEERING DIAGNOSIS.... 3SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND

ADJUSTMENT PROCEDURE.............. 5

SPECIFICATIONS

VEHICLE ALIGNMENT SPECIFICATIONS AT

CURB HEIGHT......................... 9

DESCRIPTION AND OPERATION

WHEEL ALIGNMENT GENERAL INFORMATION

Proper vehicle wheel alignment is the proper

adjustment of all interrelated front and rear suspen-

sion angles (Fig. 1). These angles are what affects

the handling and steering of the vehicle when it is in

motion.

The method of checking a vehicle's front and rear

wheel alignment will vary depending on the type and

manufacturer of the equipment being used. Instruc-

tions furnished by the manufacturer of the equip-

ment being used should always be followed to ensure

accuracy of the alignment, except alignment specifi-

cations recommended by Chrysler Corporation

MUST ALWAYSbe used.

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating or bending

of the component.Wheel alignment adjustments should be made in

the following sequence, to ensure that an accurate

alignment is performed.

(1) Rear Wheel Toe Adjustment within specifica-

tions for both total toe and thrust angle.

(2) Front Wheel Toe Adjustment within specifica-

tions for total toe.

(3)To eis measured in degrees or inches and is

the distance that the front edges of the tires are

closer (or farther apart) than the rear edges (Fig. 1).

See Front Wheel Drive Specifications for correct front

and rear wheel Toe specifications.

(4)Thrust Angleis defined as the average of the

Toe settings on each rear wheel. If this measurement

is out of specification, re-adjust rear wheel Toe so

that each wheel has 1/2 of the total Toe measure-

ment. When re-adjusting, do not exceed the total Toe

specification.

PLSUSPENSION 2 - 1

Page 16 of 1200

PRE-ALIGNMENT VEHICLE INSPECTION

CAUTION: If the front suspension crossmember

shows any sign of impact damage, the steering col-

umn to steering gear coupling must be inspected.

Refer to Group 19 Steering in this service manual

for the inspection procedure.

Before any attempt is made to change or correct

the wheel alignment factors, the following inspection

and necessary corrections must be made on those

parts which influence the steering of the vehicle.

(1) Be sure the fuel tank is full when the wheel

alignment specifications are checked and or adjusted.

A full tank of fuel weighs approximately 75 pounds,

if the fuel tank is not full this reduction in weight

will affect the curb height of the vehicle and the

alignment specifications.

(2) Alignment specifications of a vehicle can be the

most accurately checked and set when the passenger

compartment and trunk of the vehicle are vacant

with the exception of the spare tire. People, luggage,

and any other appreciable weight will adversely

affect the checking and setting of the camber specifi-

cation.

(3) Check and if required, inflate all of the tires to

the recommended air pressure. All tires must be of

the same size and in good condition and have approx-

imately the same tread wear.Note the type of

tread wear on the tire, this will aid in diagnos-

ing problems. Refer to Group 22 Tires And

Wheels in this service manual for the tire wear

diagnosis.

(4) Check the front tire and wheel assemblies for

radial runout.

(5) Before beginning the alignment process,

inspect all suspension component fasteners for loose-

ness and/or loss of specified torque.

(6) Inspect the lower front ball joints and all steer-

ing linkage for looseness and any signs of wear and

or damage.

(7) Inspect the tie rod ends for looseness and any

signs of wear and or damage.

(8) Inspect the rubber bushings on all suspension

components for signs of wear or deterioration. If any

bushings show signs of wear or deterioration they

should be replaced prior to aligning the vehicle.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER CAMBER

Front and rear Caster and Camber settings on this

vehicle are determined at the time the vehicle isdesigned, by the location of the vehicle's suspension

components. This is called a Net Build vehicle and

results in no required adjustment of Caster and

Camber after vehicle is built or when servicing the

suspension components. Thus Caster and Camber are

not normally considered an adjustable specification

when performing an alignment on this vehicle.

Though Caster and Camber are not adjustable they

must be checked to ensure they meet vehicle specifi-

cations.

If front and or rear camber is found not to meet

the vehicle alignment specifications, it can be

adjusted using a Mopar Service Kit developed to

allow for camber adjustment. If a vehicle's front or

rear camber is found to be outside the specifications,

the vehicles suspension components should be

inspected for any signs of damage on bending.This

must be done before using the Mopar Service

Kit for setting camber to meet required specifi-

cation.

If a vehicles caster is not within manufacturers

alignment specifications, check for damaged suspen-

sion components or body parts. This type of damage

can cause component locations to move affecting

vehicle alignment.No adjustment can be made

for the Caster setting on this vehicle.

CAUTION: Do not attempt to adjust the vehicles

Caster or Camber by heating, bending or any other

modification of the suspension components.

(1) Correctly position vehicle on alignment rack

and install all required equipment on vehicle, per the

alignment equipment manufacturers specifications.

(2) Center the steering wheel and lock in place

using a steering wheel clamp.

NOTE: Prior to reading each alignment specifica-

tion, jounce the front and rear of the vehicle an

equal number of times. Induce jounce (rear first

then front) by grasping center of bumper and jounc-

ing each end of vehicle an equal number of times.

Bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Correctly jounce vehicle and read front and

rear alignment settings and compare to vehicle spec-

ifications for Camber, Caster and Toe. See Alignment

Specifications in this group of the service manual for

required specifications.If front and rear camber

readings are within required specifications pro-

ceed to step Step 3 in the Front And Rear Toe

Setting procedure. If Camber readings are not

within specifications refer to step Step 1 in the

following camber adjustment bolt package

installation procedure, for the front and rear

Camber adjustment procedure.

PLSUSPENSION 2 - 5

DIAGNOSIS AND TESTING (Continued)

Page 20 of 1200

SPECIFICATIONS

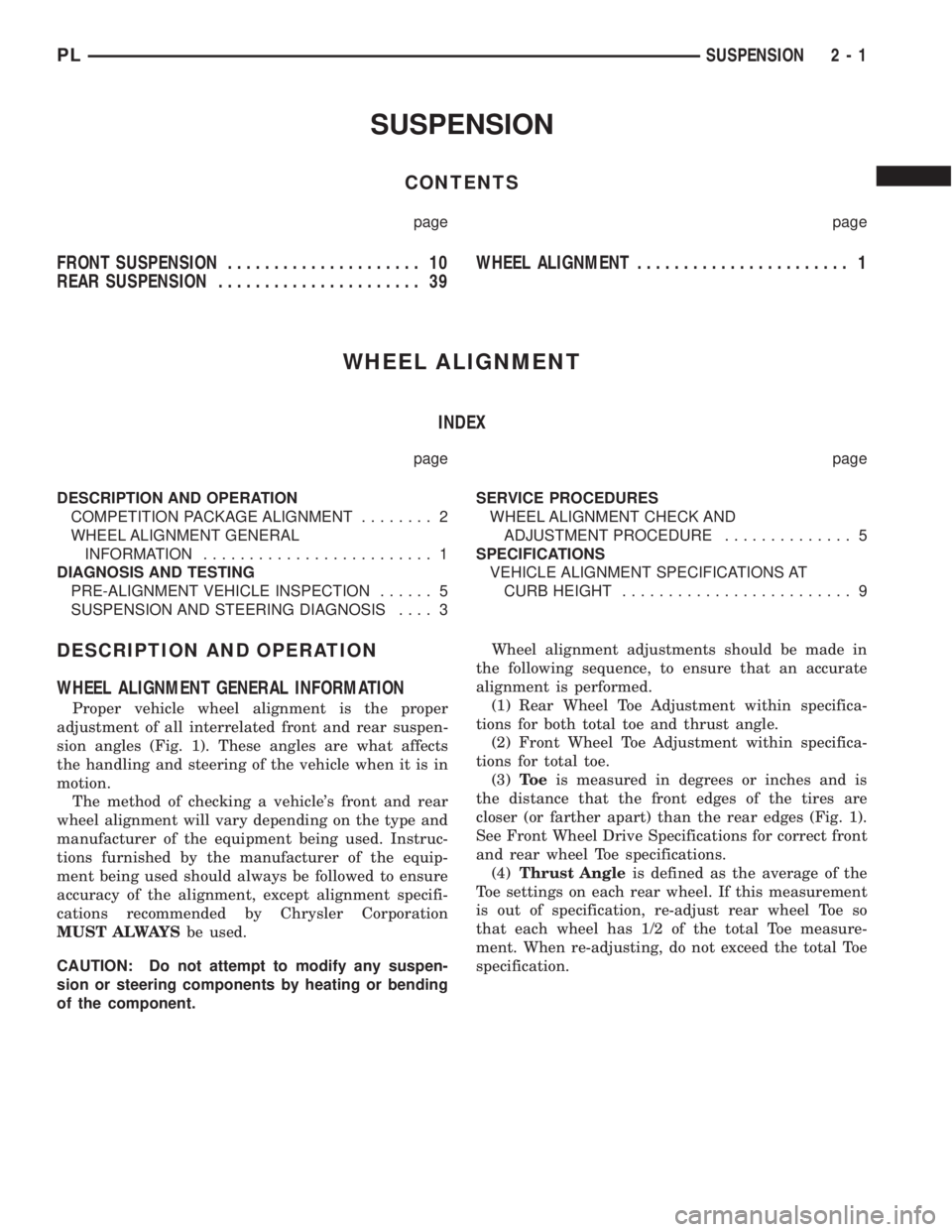

VEHICLE ALIGNMENT SPECIFICATIONS AT CURB HEIGHT

FRONT WHEEL ALIGNMENTACCEPTABLE ALIGNMENT

RANGE AT CURB HEIGHT*PREFERRED SETTING

CAMBER...................................... -0.4É to +0.4É +0.0É

**-2.4É to +0.4É (Use On S/C ACR

Only)

TOTAL

TOE.......................................

Specified In Degrees (See Note)0.3Éin to 0.1Éout 0.1É in

** 0.30É In To 0.70É Out (Use On

S/C ACR Only)

CASTER*...................................... +1.8É to +3.8É +2.8É

*Side To Side Caster Difference

Not To

Exceed.........................................1.0É or less 0.0É

REAR WHEEL ALIGNMENT ACCEPTABLE ALIGNMENT

RANGE AT CURB HEIGHT*PREFERRE SETTING

CAMBER....................................... -.75É to +0.25É -0.25É

** -1.00É to + 0.25É (Use On S/C

ACR Only)

TOTAL

TOE......................................

Specified In Degrees (See Note)

TOE OUT: When Backed On

Alignment Rack Is TOE In When

Driving0.3É in to 0.1É out 0.1É in

** 0.30É In To 0.50É Out (Use On

S/C ACR Only)

THRUST

ANGLE................................-0.10É to +0.10É

Note: Total Toe is the arithmetic sum of the left and right wheel Toe settings. Positive is Toe-in, negative is

Toe-out. Total Toe must be equally split between each front wheel to ensure the steering wheel is centered after

setting Toe. Left and Right Toe

must be equal to within 0.02 degrees.

* Setting the vehicles front and/or rear suspension alignment specifications outside of the preferred setting shown

on the chart above will caused rapid and excessive tire wear.

** The alignment specifications shown, are only for vehicles which are equipped with the ACR (Competition

Package) sales code. This specification is listed to show the adjustable range for the Camber and Toe on the front

and rear suspension of a vehicle with the Competition Package. These alignment specifications are only to be

used at the request of the vehicle owner and only when the vehicle is going to be used in a competition event.

The alignment is to be set back to the preferred setting before the vehicle is returned to normal operation.

PLSUSPENSION 2 - 9

Page 35 of 1200

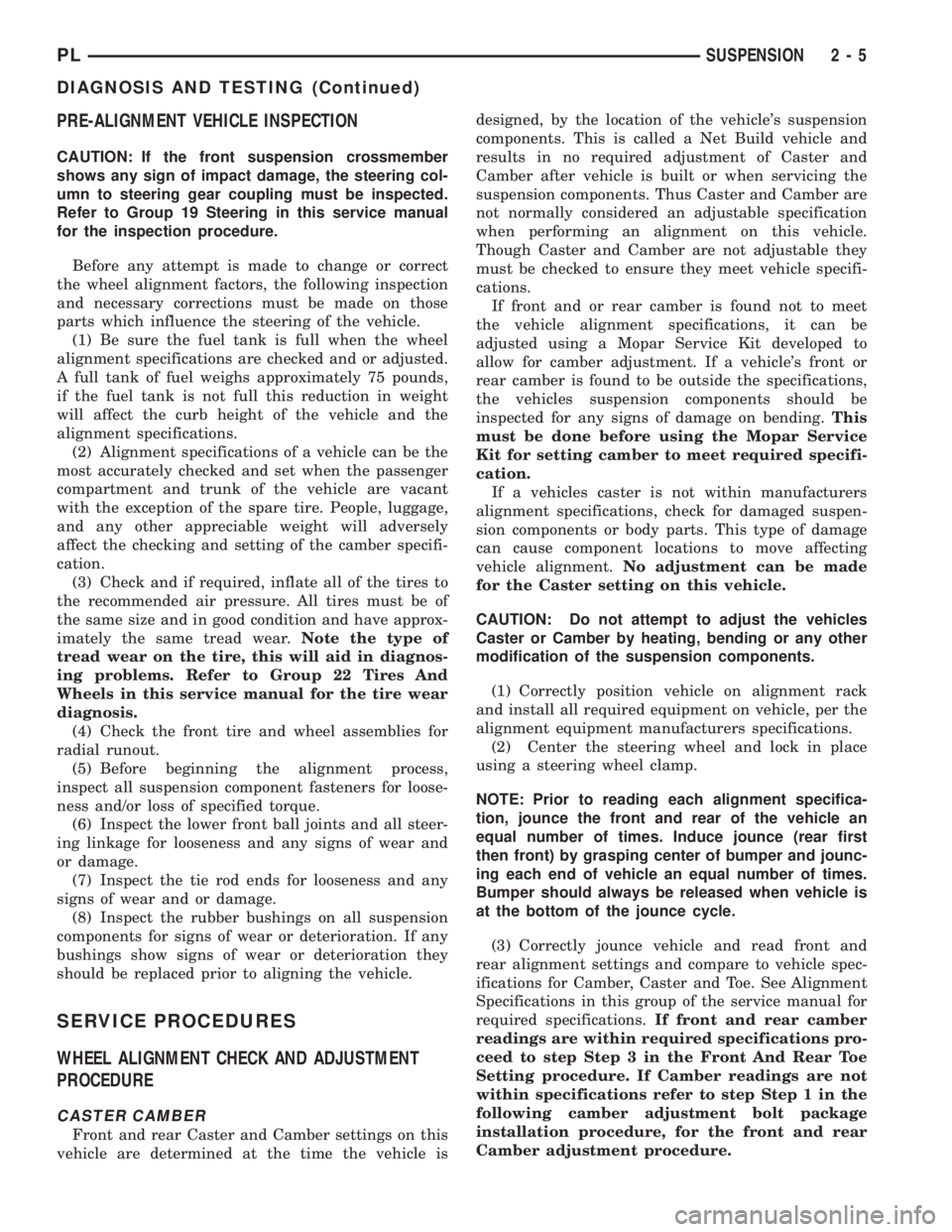

INSTALL

(1) If inspection determines replacement of stabi-

lizer bar to lower control arm attachment link bush-

ings is required, replace bushings before installing

stabilizer bar. Refer to (Fig. 42) for proper orientation

of attaching link bushing components.

(2) If stabilizer bar to front crossmember bushings

require replacement at time of inspection, install new

bushings before installing stabilizer bar. Bushings

are replaced by opening slit on bushings and peeling

them off stabilizer bar. Install new bushings on sta-

bilizer bar, by spreading bushing at slit and forcing

them on stabilizer bar.Bushings must be installed

on stabilizer bar with slit in bushing facing

front of vehicle when stabilizer bar is installed

(Fig. 43).

(3) Position stabilizer bar into front crossmember,

so cutouts in stabilizer bar bushings are aligned with

raised bead in crossmember. Install stabilizer bar

bushing retainers onto crossmember aligning raised

bead on retainer with cutouts in bushings (Fig. 44).Do not tighten stabilizer bar bushing retainers

at this time.

(4) Align stabilizer bar attaching link and bushing

assemblies with attaching link mounting holes in the

lower control arms (Fig. 45). Install stabilizer bar

attaching links into both lower control arms. Install

the attaching link to stabilizer bar bushing and

retaining nut. Torque the stabilizer bar attaching

link nut (Fig. 45) to 28 N´m (21 ft. lbs.).

(5) Lower vehicle so the suspension is supporting

the total weight of the vehicle.

(6) With lower control arms of the vehicle at curb

height, tighten stabilizer bar bushing to crossmember

retainer attaching bolts to 28 N´m (21 ft. lbs.) torque.

Fig. 42 Stabilizer Bar Attaching Link Assembly

Bushing Orientation

Fig. 43 Correct Stabilizer Bar To Crossmember

Bushing Installation

Fig. 44 Stabilizer Bar To Crossmember Bushing

Position

Fig. 45 Stabilizer Bar Link To Control Arm

Attachment

2 - 24 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 58 of 1200

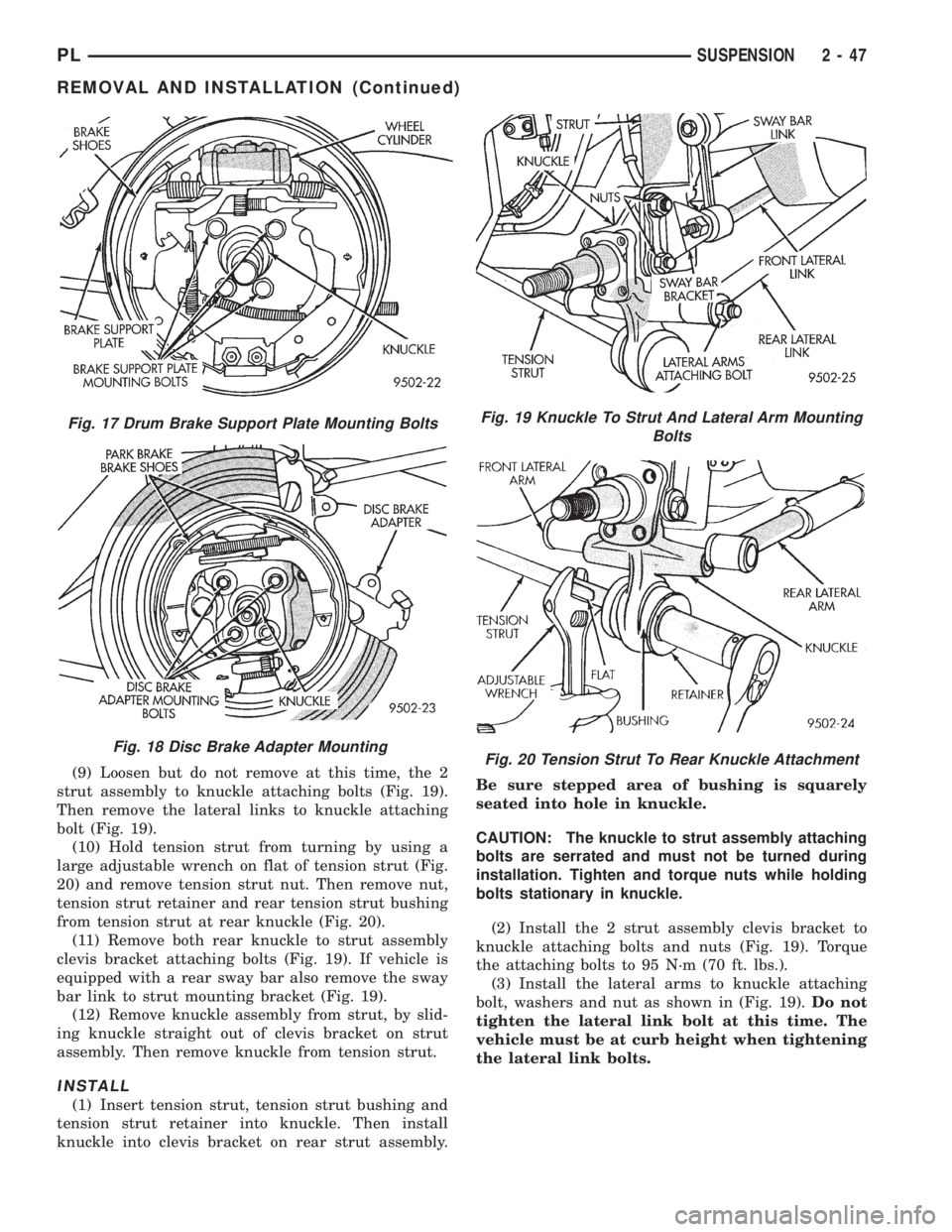

(9) Loosen but do not remove at this time, the 2

strut assembly to knuckle attaching bolts (Fig. 19).

Then remove the lateral links to knuckle attaching

bolt (Fig. 19).

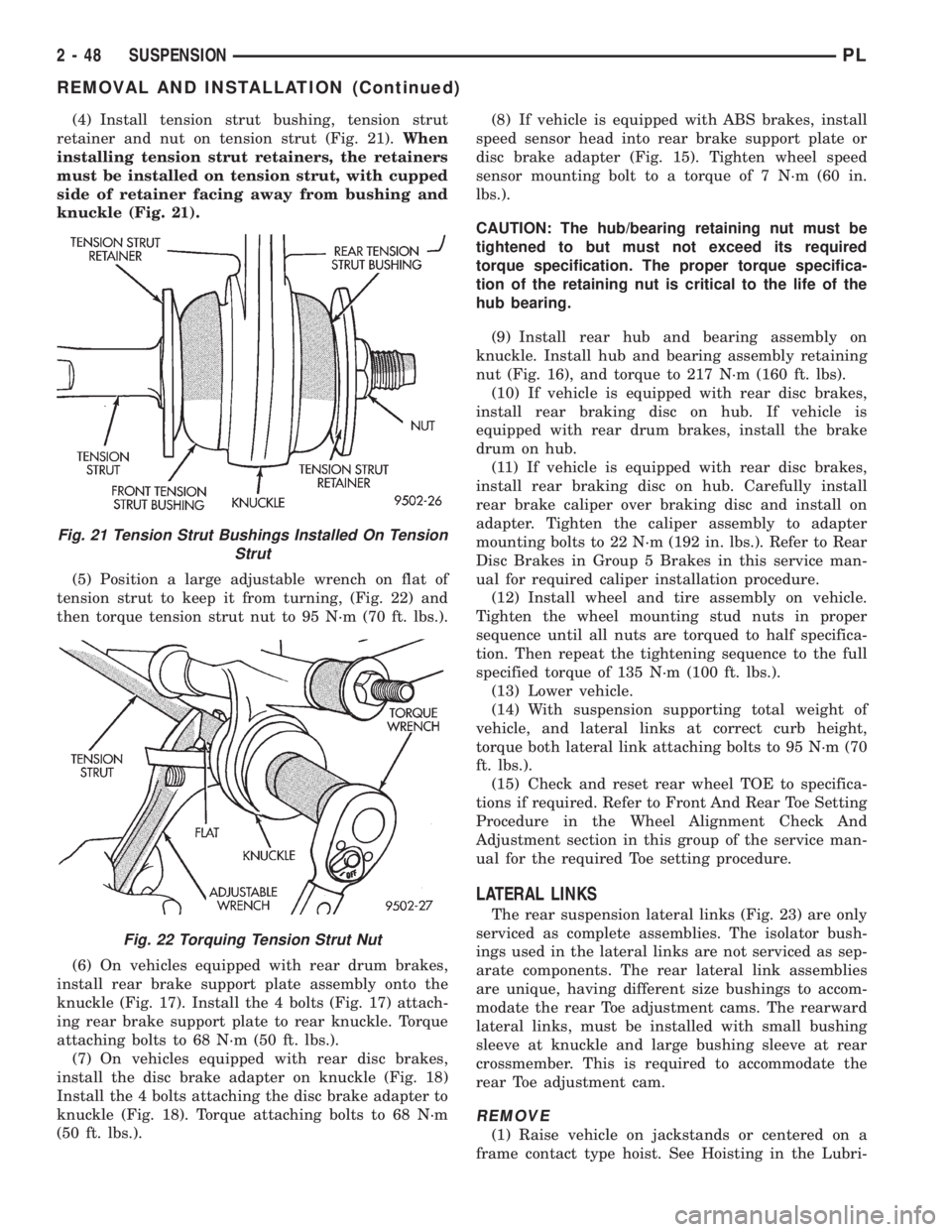

(10) Hold tension strut from turning by using a

large adjustable wrench on flat of tension strut (Fig.

20) and remove tension strut nut. Then remove nut,

tension strut retainer and rear tension strut bushing

from tension strut at rear knuckle (Fig. 20).

(11) Remove both rear knuckle to strut assembly

clevis bracket attaching bolts (Fig. 19). If vehicle is

equipped with a rear sway bar also remove the sway

bar link to strut mounting bracket (Fig. 19).

(12) Remove knuckle assembly from strut, by slid-

ing knuckle straight out of clevis bracket on strut

assembly. Then remove knuckle from tension strut.

INSTALL

(1) Insert tension strut, tension strut bushing and

tension strut retainer into knuckle. Then install

knuckle into clevis bracket on rear strut assembly.Be sure stepped area of bushing is squarely

seated into hole in knuckle.

CAUTION: The knuckle to strut assembly attaching

bolts are serrated and must not be turned during

installation. Tighten and torque nuts while holding

bolts stationary in knuckle.

(2) Install the 2 strut assembly clevis bracket to

knuckle attaching bolts and nuts (Fig. 19). Torque

the attaching bolts to 95 N´m (70 ft. lbs.).

(3) Install the lateral arms to knuckle attaching

bolt, washers and nut as shown in (Fig. 19).Do not

tighten the lateral link bolt at this time. The

vehicle must be at curb height when tightening

the lateral link bolts.

Fig. 17 Drum Brake Support Plate Mounting Bolts

Fig. 18 Disc Brake Adapter Mounting

Fig. 19 Knuckle To Strut And Lateral Arm Mounting

Bolts

Fig. 20 Tension Strut To Rear Knuckle Attachment

PLSUSPENSION 2 - 47

REMOVAL AND INSTALLATION (Continued)

Page 59 of 1200

(4) Install tension strut bushing, tension strut

retainer and nut on tension strut (Fig. 21).When

installing tension strut retainers, the retainers

must be installed on tension strut, with cupped

side of retainer facing away from bushing and

knuckle (Fig. 21).

(5) Position a large adjustable wrench on flat of

tension strut to keep it from turning, (Fig. 22) and

then torque tension strut nut to 95 N´m (70 ft. lbs.).

(6) On vehicles equipped with rear drum brakes,

install rear brake support plate assembly onto the

knuckle (Fig. 17). Install the 4 bolts (Fig. 17) attach-

ing rear brake support plate to rear knuckle. Torque

attaching bolts to 68 N´m (50 ft. lbs.).

(7) On vehicles equipped with rear disc brakes,

install the disc brake adapter on knuckle (Fig. 18)

Install the 4 bolts attaching the disc brake adapter to

knuckle (Fig. 18). Torque attaching bolts to 68 N´m

(50 ft. lbs.).(8) If vehicle is equipped with ABS brakes, install

speed sensor head into rear brake support plate or

disc brake adapter (Fig. 15). Tighten wheel speed

sensor mounting bolt to a torque of 7 N´m (60 in.

lbs.).

CAUTION: The hub/bearing retaining nut must be

tightened to but must not exceed its required

torque specification. The proper torque specifica-

tion of the retaining nut is critical to the life of the

hub bearing.

(9) Install rear hub and bearing assembly on

knuckle. Install hub and bearing assembly retaining

nut (Fig. 16), and torque to 217 N´m (160 ft. lbs).

(10) If vehicle is equipped with rear disc brakes,

install rear braking disc on hub. If vehicle is

equipped with rear drum brakes, install the brake

drum on hub.

(11) If vehicle is equipped with rear disc brakes,

install rear braking disc on hub. Carefully install

rear brake caliper over braking disc and install on

adapter. Tighten the caliper assembly to adapter

mounting bolts to 22 N´m (192 in. lbs.). Refer to Rear

Disc Brakes in Group 5 Brakes in this service man-

ual for required caliper installation procedure.

(12) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(13) Lower vehicle.

(14) With suspension supporting total weight of

vehicle, and lateral links at correct curb height,

torque both lateral link attaching bolts to 95 N´m (70

ft. lbs.).

(15) Check and reset rear wheel TOE to specifica-

tions if required. Refer to Front And Rear Toe Setting

Procedure in the Wheel Alignment Check And

Adjustment section in this group of the service man-

ual for the required Toe setting procedure.

LATERAL LINKS

The rear suspension lateral links (Fig. 23) are only

serviced as complete assemblies. The isolator bush-

ings used in the lateral links are not serviced as sep-

arate components. The rear lateral link assemblies

are unique, having different size bushings to accom-

modate the rear Toe adjustment cams. The rearward

lateral links, must be installed with small bushing

sleeve at knuckle and large bushing sleeve at rear

crossmember. This is required to accommodate the

rear Toe adjustment cam.

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

Fig. 21 Tension Strut Bushings Installed On Tension

Strut

Fig. 22 Torquing Tension Strut Nut

2 - 48 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 61 of 1200

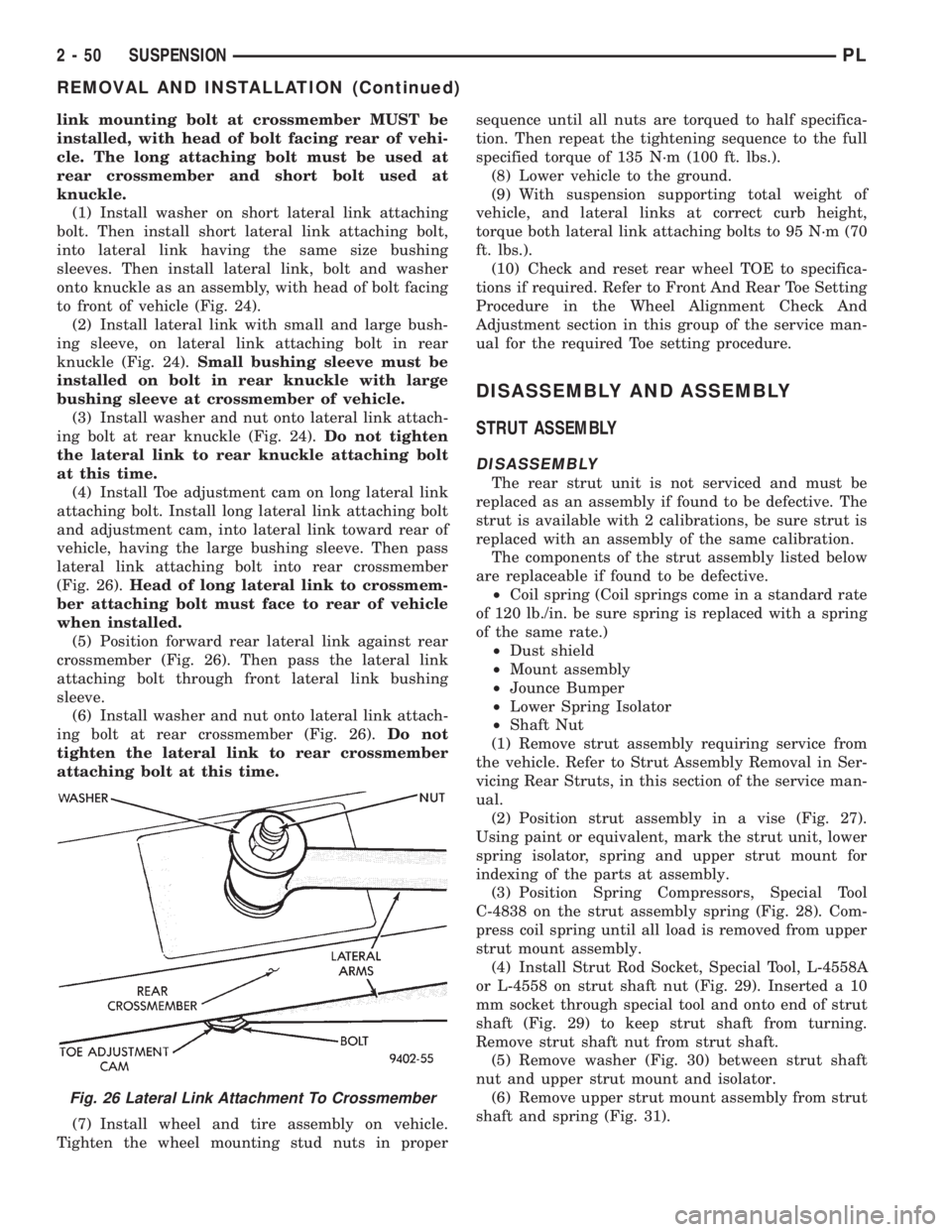

link mounting bolt at crossmember MUST be

installed, with head of bolt facing rear of vehi-

cle. The long attaching bolt must be used at

rear crossmember and short bolt used at

knuckle.

(1) Install washer on short lateral link attaching

bolt. Then install short lateral link attaching bolt,

into lateral link having the same size bushing

sleeves. Then install lateral link, bolt and washer

onto knuckle as an assembly, with head of bolt facing

to front of vehicle (Fig. 24).

(2) Install lateral link with small and large bush-

ing sleeve, on lateral link attaching bolt in rear

knuckle (Fig. 24).Small bushing sleeve must be

installed on bolt in rear knuckle with large

bushing sleeve at crossmember of vehicle.

(3) Install washer and nut onto lateral link attach-

ing bolt at rear knuckle (Fig. 24).Do not tighten

the lateral link to rear knuckle attaching bolt

at this time.

(4) Install Toe adjustment cam on long lateral link

attaching bolt. Install long lateral link attaching bolt

and adjustment cam, into lateral link toward rear of

vehicle, having the large bushing sleeve. Then pass

lateral link attaching bolt into rear crossmember

(Fig. 26).Head of long lateral link to crossmem-

ber attaching bolt must face to rear of vehicle

when installed.

(5) Position forward rear lateral link against rear

crossmember (Fig. 26). Then pass the lateral link

attaching bolt through front lateral link bushing

sleeve.

(6) Install washer and nut onto lateral link attach-

ing bolt at rear crossmember (Fig. 26).Do not

tighten the lateral link to rear crossmember

attaching bolt at this time.

(7) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in propersequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(8) Lower vehicle to the ground.

(9) With suspension supporting total weight of

vehicle, and lateral links at correct curb height,

torque both lateral link attaching bolts to 95 N´m (70

ft. lbs.).

(10) Check and reset rear wheel TOE to specifica-

tions if required. Refer to Front And Rear Toe Setting

Procedure in the Wheel Alignment Check And

Adjustment section in this group of the service man-

ual for the required Toe setting procedure.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY

DISASSEMBLY

The rear strut unit is not serviced and must be

replaced as an assembly if found to be defective. The

strut is available with 2 calibrations, be sure strut is

replaced with an assembly of the same calibration.

The components of the strut assembly listed below

are replaceable if found to be defective.

²Coil spring (Coil springs come in a standard rate

of 120 lb./in. be sure spring is replaced with a spring

of the same rate.)

²Dust shield

²Mount assembly

²Jounce Bumper

²Lower Spring Isolator

²Shaft Nut

(1) Remove strut assembly requiring service from

the vehicle. Refer to Strut Assembly Removal in Ser-

vicing Rear Struts, in this section of the service man-

ual.

(2) Position strut assembly in a vise (Fig. 27).

Using paint or equivalent, mark the strut unit, lower

spring isolator, spring and upper strut mount for

indexing of the parts at assembly.

(3) Position Spring Compressors, Special Tool

C-4838 on the strut assembly spring (Fig. 28). Com-

press coil spring until all load is removed from upper

strut mount assembly.

(4) Install Strut Rod Socket, Special Tool, L-4558A

or L-4558 on strut shaft nut (Fig. 29). Inserted a 10

mm socket through special tool and onto end of strut

shaft (Fig. 29) to keep strut shaft from turning.

Remove strut shaft nut from strut shaft.

(5) Remove washer (Fig. 30) between strut shaft

nut and upper strut mount and isolator.

(6) Remove upper strut mount assembly from strut

shaft and spring (Fig. 31).

Fig. 26 Lateral Link Attachment To Crossmember

2 - 50 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 760 of 1200

DISASSEMBLY AND ASSEMBLY

OIL PUMP

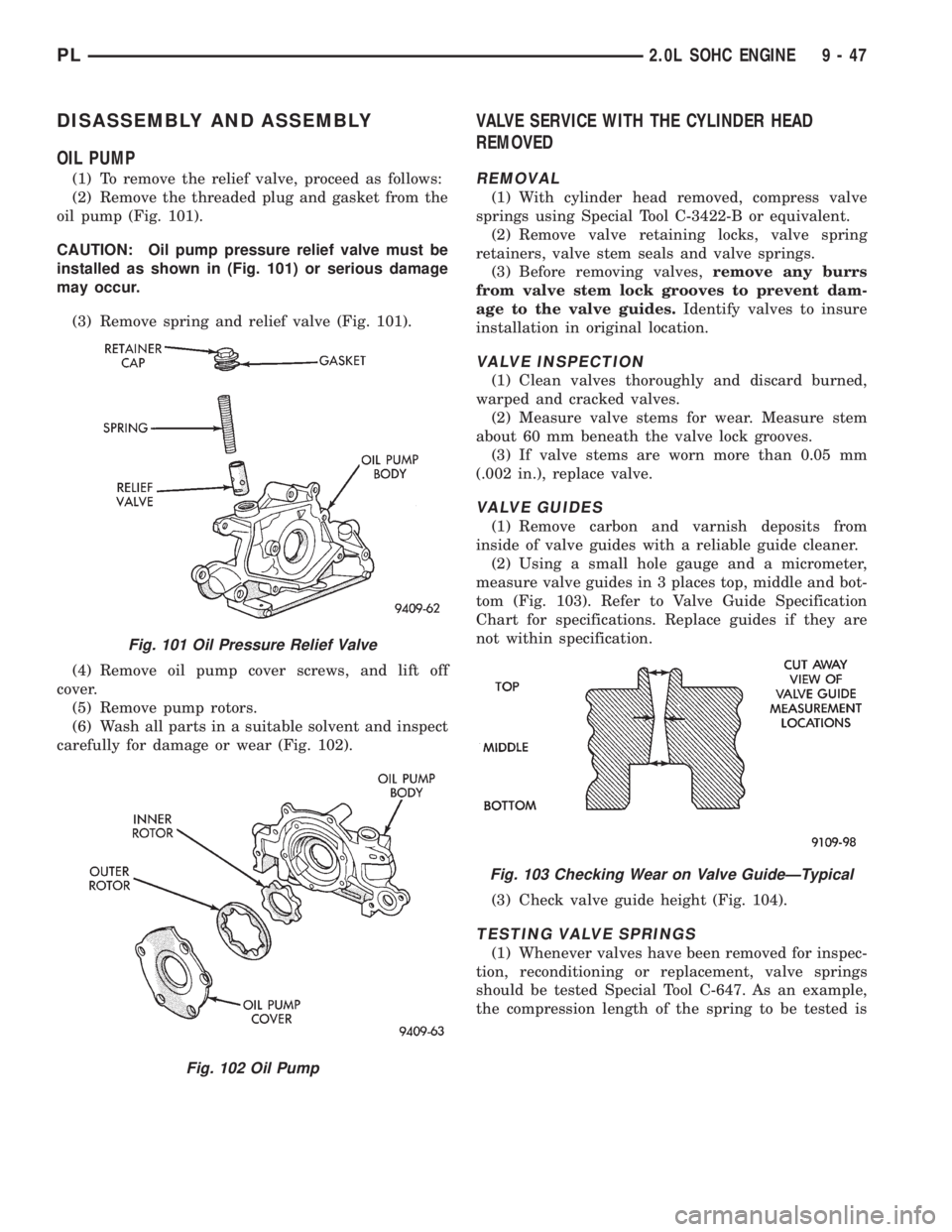

(1) To remove the relief valve, proceed as follows:

(2) Remove the threaded plug and gasket from the

oil pump (Fig. 101).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 101) or serious damage

may occur.

(3) Remove spring and relief valve (Fig. 101).

(4) Remove oil pump cover screws, and lift off

cover.

(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 102).

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED

REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool C-3422-B or equivalent.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

(3) If valve stems are worn more than 0.05 mm

(.002 in.), replace valve.

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 103). Refer to Valve Guide Specification

Chart for specifications. Replace guides if they are

not within specification.

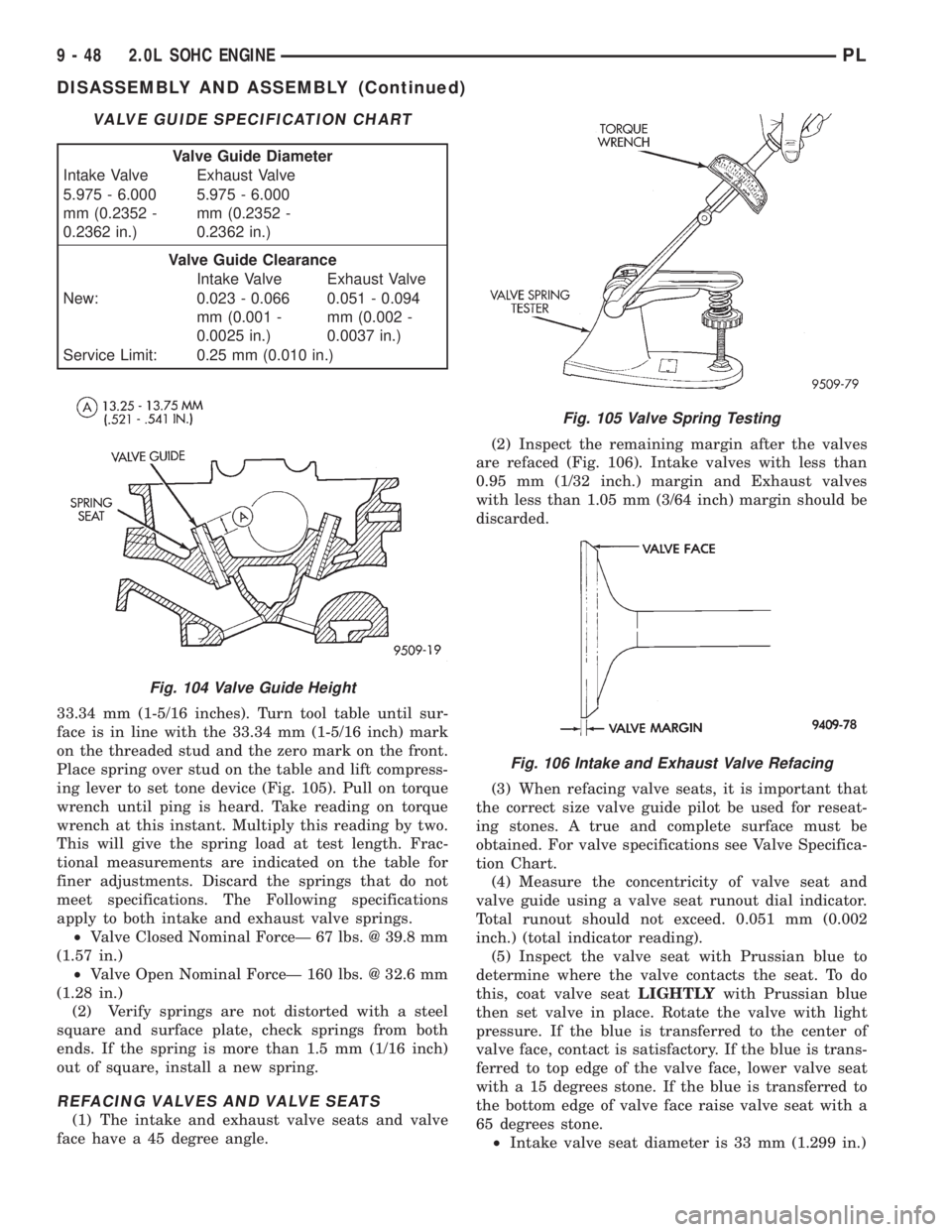

(3) Check valve guide height (Fig. 104).

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested Special Tool C-647. As an example,

the compression length of the spring to be tested is

Fig. 101 Oil Pressure Relief Valve

Fig. 102 Oil Pump

Fig. 103 Checking Wear on Valve GuideÐTypical

PL2.0L SOHC ENGINE 9 - 47

Page 761 of 1200

33.34 mm (1-5/16 inches). Turn tool table until sur-

face is in line with the 33.34 mm (1-5/16 inch) mark

on the threaded stud and the zero mark on the front.

Place spring over stud on the table and lift compress-

ing lever to set tone device (Fig. 105). Pull on torque

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The Following specifications

apply to both intake and exhaust valve springs.

²Valve Closed Nominal ForceÐ 67 lbs. @ 39.8 mm

(1.57 in.)

²Valve Open Nominal ForceÐ 160 lbs. @ 32.6 mm

(1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

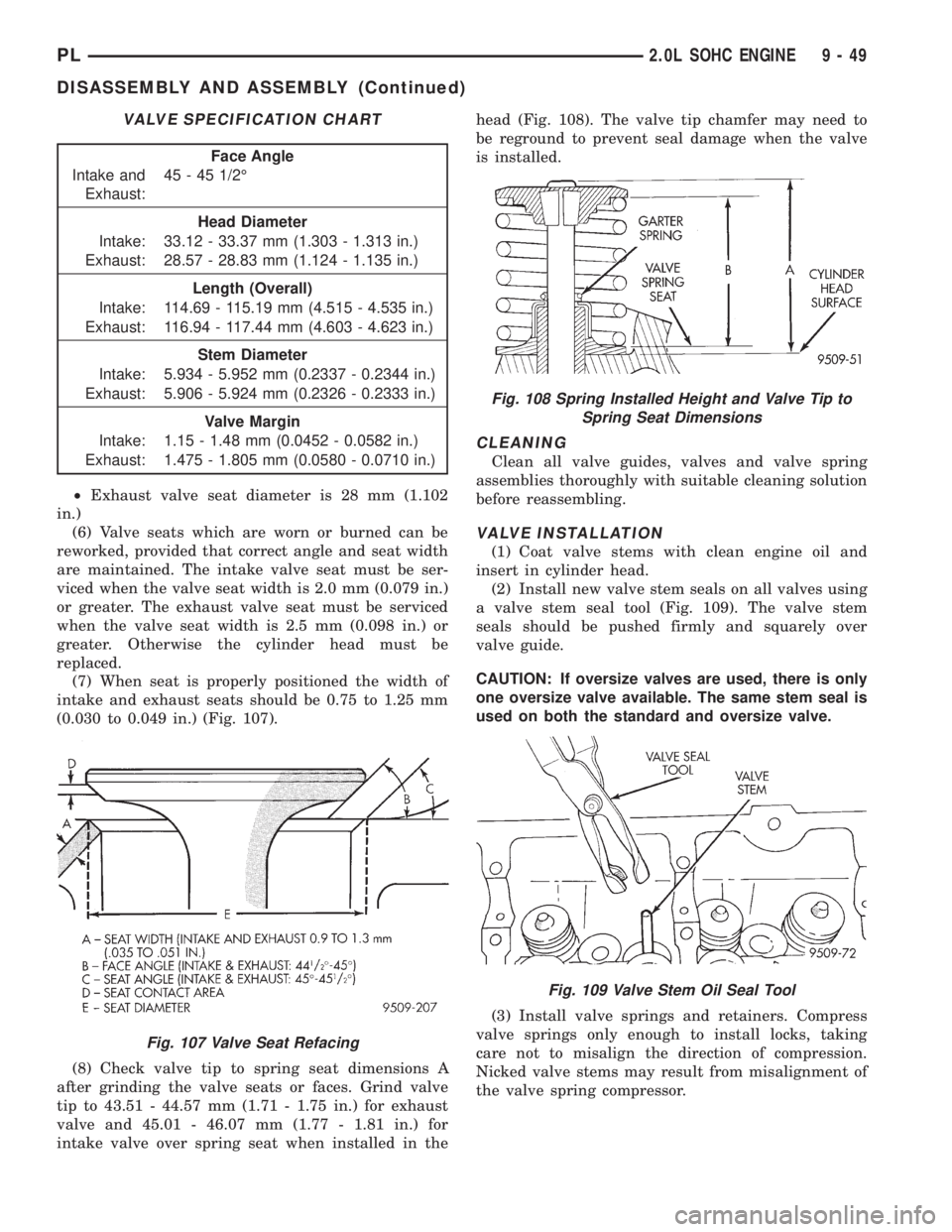

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.(2) Inspect the remaining margin after the valves

are refaced (Fig. 106). Intake valves with less than

0.95 mm (1/32 inch.) margin and Exhaust valves

with less than 1.05 mm (3/64 inch) margin should be

discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For valve specifications see Valve Specifica-

tion Chart.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

²Intake valve seat diameter is 33 mm (1.299 in.)

VALVE GUIDE SPECIFICATION CHART

Valve Guide Diameter

Intake Valve Exhaust Valve

5.975 - 6.000

mm (0.2352 -

0.2362 in.)5.975 - 6.000

mm (0.2352 -

0.2362 in.)

Valve Guide Clearance

Intake Valve Exhaust Valve

New: 0.023 - 0.066

mm (0.001 -

0.0025 in.)0.051 - 0.094

mm (0.002 -

0.0037 in.)

Service Limit: 0.25 mm (0.010 in.)

Fig. 104 Valve Guide Height

Fig. 105 Valve Spring Testing

Fig. 106 Intake and Exhaust Valve Refacing

9 - 48 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 762 of 1200

²Exhaust valve seat diameter is 28 mm (1.102

in.)

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. The intake valve seat must be ser-

viced when the valve seat width is 2.0 mm (0.079 in.)

or greater. The exhaust valve seat must be serviced

when the valve seat width is 2.5 mm (0.098 in.) or

greater. Otherwise the cylinder head must be

replaced.

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.75 to 1.25 mm

(0.030 to 0.049 in.) (Fig. 107).

(8) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip to 43.51 - 44.57 mm (1.71 - 1.75 in.) for exhaust

valve and 45.01 - 46.07 mm (1.77 - 1.81 in.) for

intake valve over spring seat when installed in thehead (Fig. 108). The valve tip chamfer may need to

be reground to prevent seal damage when the valve

is installed.

CLEANING

Clean all valve guides, valves and valve spring

assemblies thoroughly with suitable cleaning solution

before reassembling.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 109). The valve stem

seals should be pushed firmly and squarely over

valve guide.

CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

VALVE SPECIFICATION CHART

Face Angle

Intake and

Exhaust:45 - 45 1/2É

Head Diameter

Intake: 33.12 - 33.37 mm (1.303 - 1.313 in.)

Exhaust: 28.57 - 28.83 mm (1.124 - 1.135 in.)

Length (Overall)

Intake: 114.69 - 115.19 mm (4.515 - 4.535 in.)

Exhaust: 116.94 - 117.44 mm (4.603 - 4.623 in.)

Stem Diameter

Intake: 5.934 - 5.952 mm (0.2337 - 0.2344 in.)

Exhaust: 5.906 - 5.924 mm (0.2326 - 0.2333 in.)

Valve Margin

Intake: 1.15 - 1.48 mm (0.0452 - 0.0582 in.)

Exhaust: 1.475 - 1.805 mm (0.0580 - 0.0710 in.)

Fig. 107 Valve Seat Refacing

Fig. 108 Spring Installed Height and Valve Tip to

Spring Seat Dimensions

Fig. 109 Valve Stem Oil Seal Tool

PL2.0L SOHC ENGINE 9 - 49

DISASSEMBLY AND ASSEMBLY (Continued)