No start DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 845 of 1285

²All inputs monitored for proper voltage range.

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in response to MAP

sensor feedback.

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

SYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information see On-Board Diagnostics.

POWER DISTRIBUTION CENTER

The Power Distribution Center (PDC) is located

next to the battery (Fig. 1). The PDC contains the

starter relay, radiator fan relay, A/C compressor

clutch relay, auto shutdown relay, fuel pump relay

and several fuses.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various

engine and vehicle operations through devices that

are referred to as PCM Outputs.

PCM Inputs:

14 - 24 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 848 of 1285

As the engine enters one of these cells the PCM

looks at the amount of short term correction being

used. Because the goal is to keep short term at 0 (O2

Sensor switching at 0.5 volt), long term will update

in the same direction as short term correction was

moving to bring the short term back to 0. Once short

term is back at 0, this long term correction factor is

stored in memory.

The values stored in long term adaptive memory

are used for all operating conditions, including open

loop. However, the updating of the long term memoryoccurs after the engine has exceeded approximately

17É F, with fuel control in closed loop and two min-

utes of engine run time. This is done to prevent any

transitional temperature or start-up compensations

from corrupting long term fuel correction.

Long term adaptive memory can change the pulse-

width by as much as 25%, which means it can correct

for all of short term. It is possible to have a problem

that would drive long term to 25% and short term to

another 25% for a total change of 50% away from

base pulse-width calculation.

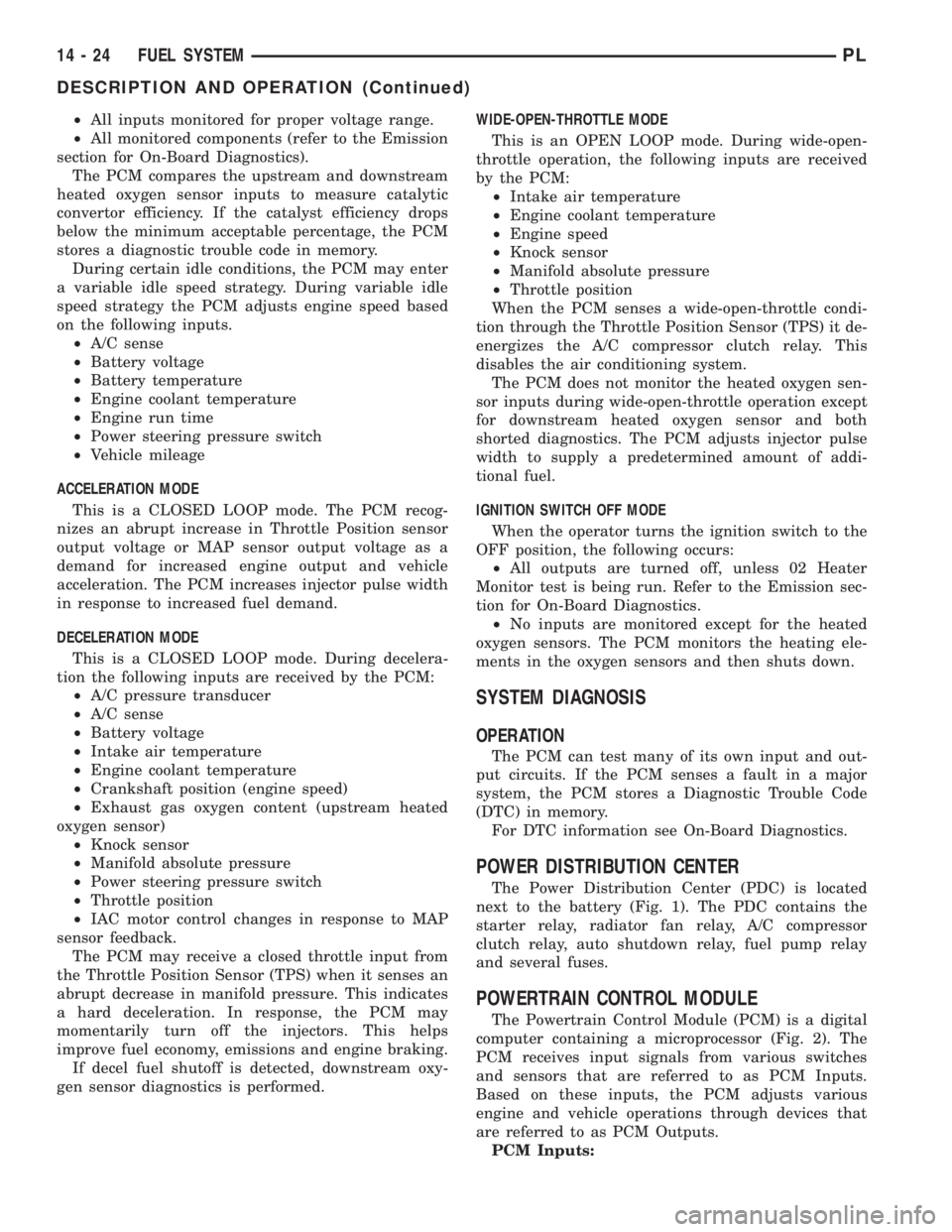

TYPICAL ADAPTIVE MEMORY FUEL CELLS

Open

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

Throttle Idle Decel

Vacuum 20 17 13 9 5 0

Above 1,984

rpm1 3 5 7 9 11 13 Drive 15

Below 1,984

rpm02 4 6 8 1012

Neutral14

MAP volt =0 1.4 2.0 2.6 3.3 3.9

Fuel Correction Diagnostics

There are two fuel correction diagnostic routines:

²Fuel System Rich

²Fuel System Lean

A DTC is set and the MIL is illuminated if the

PCM detects either of these conditions.

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS

OPERATION

Various modules exchange information through a

communications port called the PCI Bus. The Power-

train Control Module (PCM) transmits the Malfunc-

tion Indicator Lamp (Check Engine) On/Off signal

and engine RPM on the PCI Bus. The PCM receives

the Air Conditioning select input, transaxle gear

position inputs over the PCI Bus. The PCM also

receives the air conditioning evaporator temperature

signal from the PCI Bus.

The following components access or send informa-

tion on the PCI Bus.

²Instrument Panel

²Body Control Module

²Air Bag System Diagnostic Module

²Full ATC Display Head

²ABS Module

²Transmission Control Module

²Powertrain Control Module

²Overhead Travel Module

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT

OPERATION

The Powertrain Control Module (PCM) monitors

the A/C compressor discharge (high side) pressure

through the air conditioning pressure transducer.

The transducer supplies an input to the PCM. The

PCM engages the A/C compressor clutch if pressure

is sufficient for A/C system operation.

AUTOMATIC SHUTDOWN (ASD) SENSEÐPCM

INPUT

OPERATION

The ASD sense circuit informs the PCM when the

ASD relay energizes. A 12 volt signal at this input

indicates to the PCM that the ASD has been acti-

vated. This input is used only to sense that the ASD

relay is energized.

When energized, the ASD relay supplies battery

voltage to the fuel injectors, ignition coils and the

heating element in each oxygen sensor. If the PCM

does not receive 12 volts from this input after

grounding the ASD relay, it sets a Diagnostic Trouble

Code (DTC).

PLFUEL SYSTEM 14 - 27

DESCRIPTION AND OPERATION (Continued)

Page 849 of 1285

BATTERY VOLTAGEÐPCM INPUT

OPERATION

In order for the PCM to operate, it must be sup-

plied with battery voltage and ground. The PCM

monitors the direct battery feed input to determine

battery charging rate and to control the injector ini-

tial opening point. It also has back-up RAM memory

used to store Diagnostic Trouble Codes (supply work-

ing DTCs). Direct battery feed is also used to perform

key-OFF diagnostics and to supply working voltage

to the controller for OBDII.

The five and eight volt regulators are protected

from shorts to ground. This protection allows diag-

nostics to be performed should the five volt power

supply become shorted to ground at any of the sen-

sors. A short to ground in the five volt power supply

will cause a ªno-startº situation. There is a Diagnos-

tic Trouble Code (DTC) if the five-volt power supply

becomes shorted to ground. Refer to the Diagnostic

Procedures Manual for more details on any on-board

diagnostic information.

If battery voltage is low the PCM will increase

injector pulse width (period of time that the injector

is energized).

The direct battery feed to the PCM is used as a

reference point to sense battery voltage.

Effect on Fuel Injectors

Fuel injectors are rated for operation at a specific

voltage. If the voltage increases, the plunger will

open faster and further (more efficient) and con-

versely, if voltage is low the injector will be slow to

open and will not open as far. Therefore, if sensed

battery voltage drops, the PCM increases injector

pulse-width to maintain the same volume of fuel

through the injector.

Charging

The PCM uses sensed battery voltage to verify that

target charging voltage (determined by Battery Tem-

perature Sensor) is being reached. To maintain the

target charging voltage, the PCM will full field the

generator to 0.5 volt above target then turn OFF to

0.5 volt below target. This will continue to occur up

to a 100 Hz frequency, 100 times per second.

BRAKE SWITCHÐPCM INPUT

OPERATION

When the brake switch is activated, the PCM

receives an input indicating that the brakes are

being applied. The brake switch is mounted on the

brake pedal support bracket.

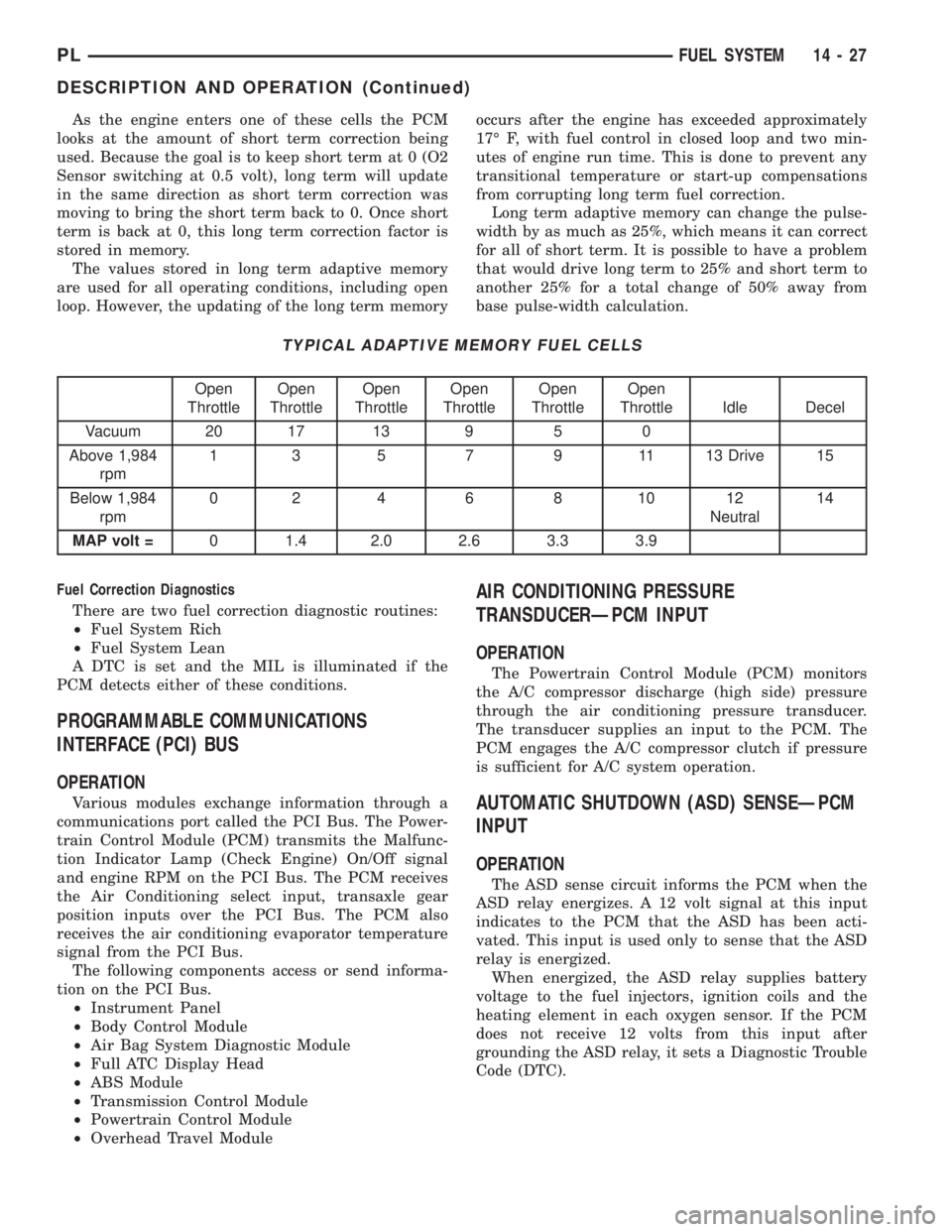

CAMSHAFT POSITION SENSORÐPCM INPUT

DESCRIPTION

The camshaft position sensor attaches to the rear

of the cylinder head. The PCM determines fuel injec-

tion synchronization and cylinder identification from

inputs provided by the camshaft position sensor (Fig.

3) and crankshaft position sensor. From the two

inputs, the PCM determines crankshaft position.

OPERATION

The PCM sends approximately 8 volts to the hall

affect sensor. This voltage is required to operate the

hall effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

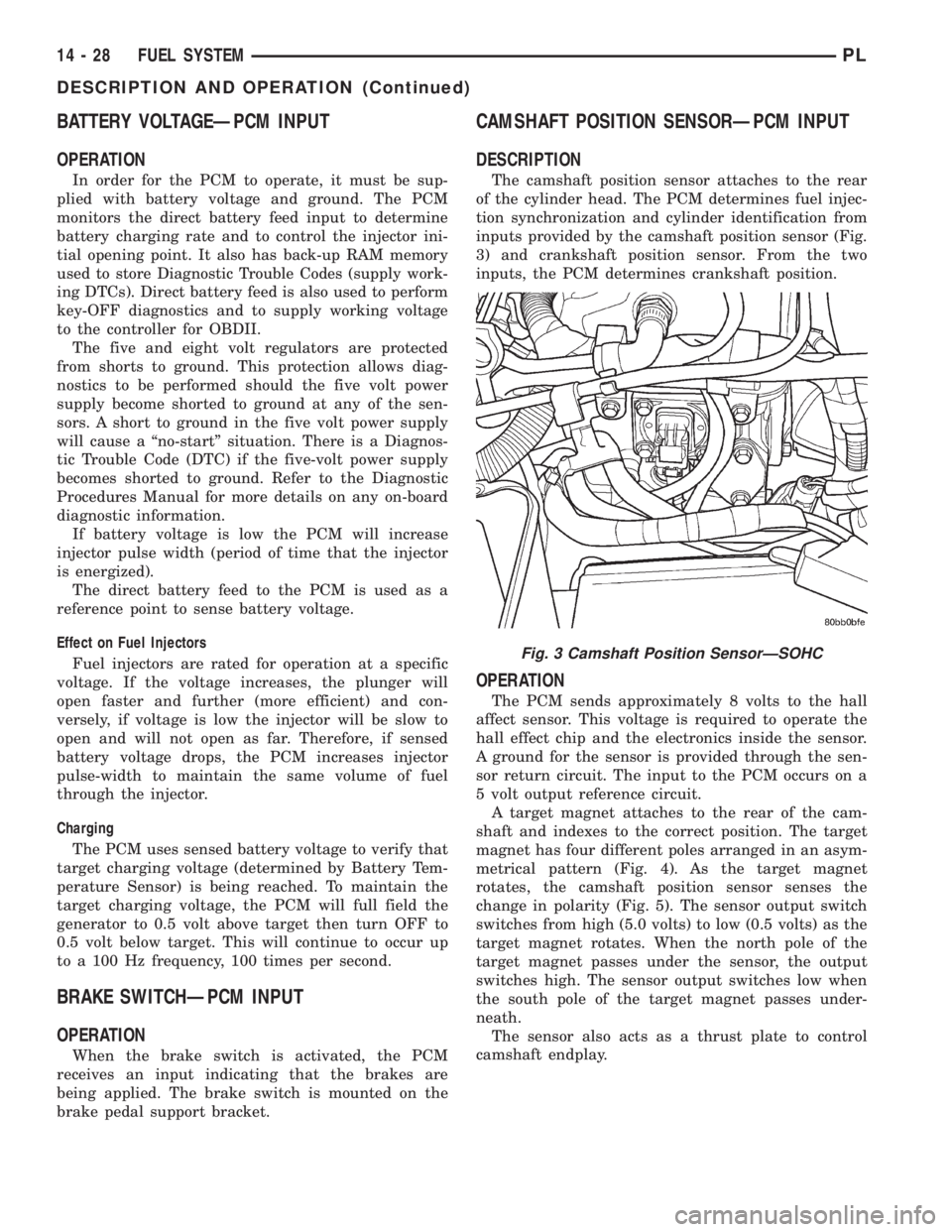

A target magnet attaches to the rear of the cam-

shaft and indexes to the correct position. The target

magnet has four different poles arranged in an asym-

metrical pattern (Fig. 4). As the target magnet

rotates, the camshaft position sensor senses the

change in polarity (Fig. 5). The sensor output switch

switches from high (5.0 volts) to low (0.5 volts) as the

target magnet rotates. When the north pole of the

target magnet passes under the sensor, the output

switches high. The sensor output switches low when

the south pole of the target magnet passes under-

neath.

The sensor also acts as a thrust plate to control

camshaft endplay.

Fig. 3 Camshaft Position SensorÐSOHC

14 - 28 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 850 of 1285

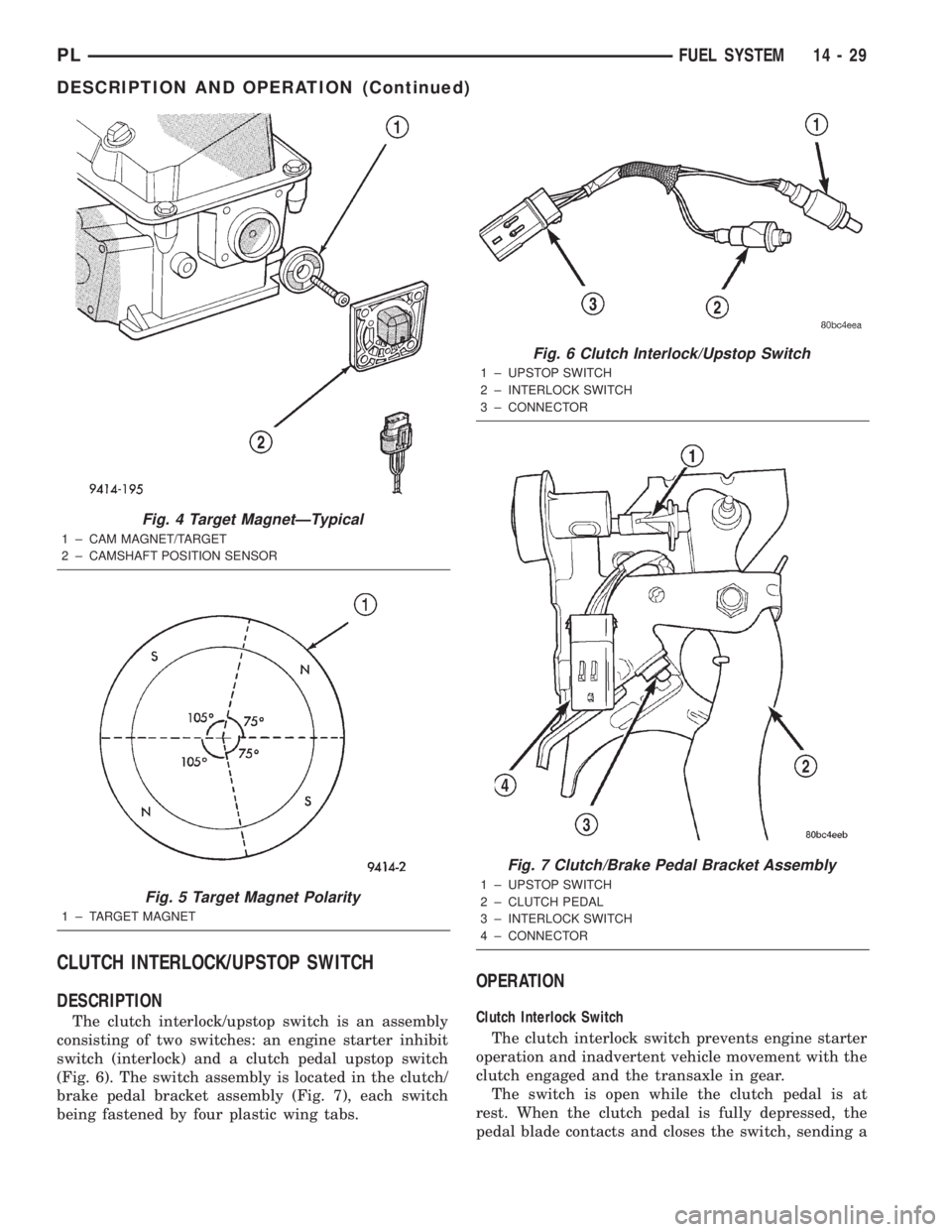

CLUTCH INTERLOCK/UPSTOP SWITCH

DESCRIPTION

The clutch interlock/upstop switch is an assembly

consisting of two switches: an engine starter inhibit

switch (interlock) and a clutch pedal upstop switch

(Fig. 6). The switch assembly is located in the clutch/

brake pedal bracket assembly (Fig. 7), each switch

being fastened by four plastic wing tabs.

OPERATION

Clutch Interlock Switch

The clutch interlock switch prevents engine starter

operation and inadvertent vehicle movement with the

clutch engaged and the transaxle in gear.

The switch is open while the clutch pedal is at

rest. When the clutch pedal is fully depressed, the

pedal blade contacts and closes the switch, sending a

Fig. 4 Target MagnetÐTypical

1 ± CAM MAGNET/TARGET

2 ± CAMSHAFT POSITION SENSOR

Fig. 5 Target Magnet Polarity

1 ± TARGET MAGNET

Fig. 6 Clutch Interlock/Upstop Switch

1 ± UPSTOP SWITCH

2 ± INTERLOCK SWITCH

3 ± CONNECTOR

Fig. 7 Clutch/Brake Pedal Bracket Assembly

1 ± UPSTOP SWITCH

2 ± CLUTCH PEDAL

3 ± INTERLOCK SWITCH

4 ± CONNECTOR

PLFUEL SYSTEM 14 - 29

DESCRIPTION AND OPERATION (Continued)

Page 851 of 1285

signal to the PCM, allowing engine starter operation.

The interlock switch is not adjustable.

Clutch Pedal Upstop Switch

With the clutch pedal at rest, the clutch pedal

upstop switch is closed, allowing speed control oper-

ation. When the clutch pedal is depressed, the upstop

switch opens and signals the PCM to cancel speed

control operation, and enter a modified engine cali-

bration schedule to improve driveability during gear-

to-gear shifts. The upstop switch is not adjustable.

CRANKSHAFT POSITION SENSORÐPCM

INPUT

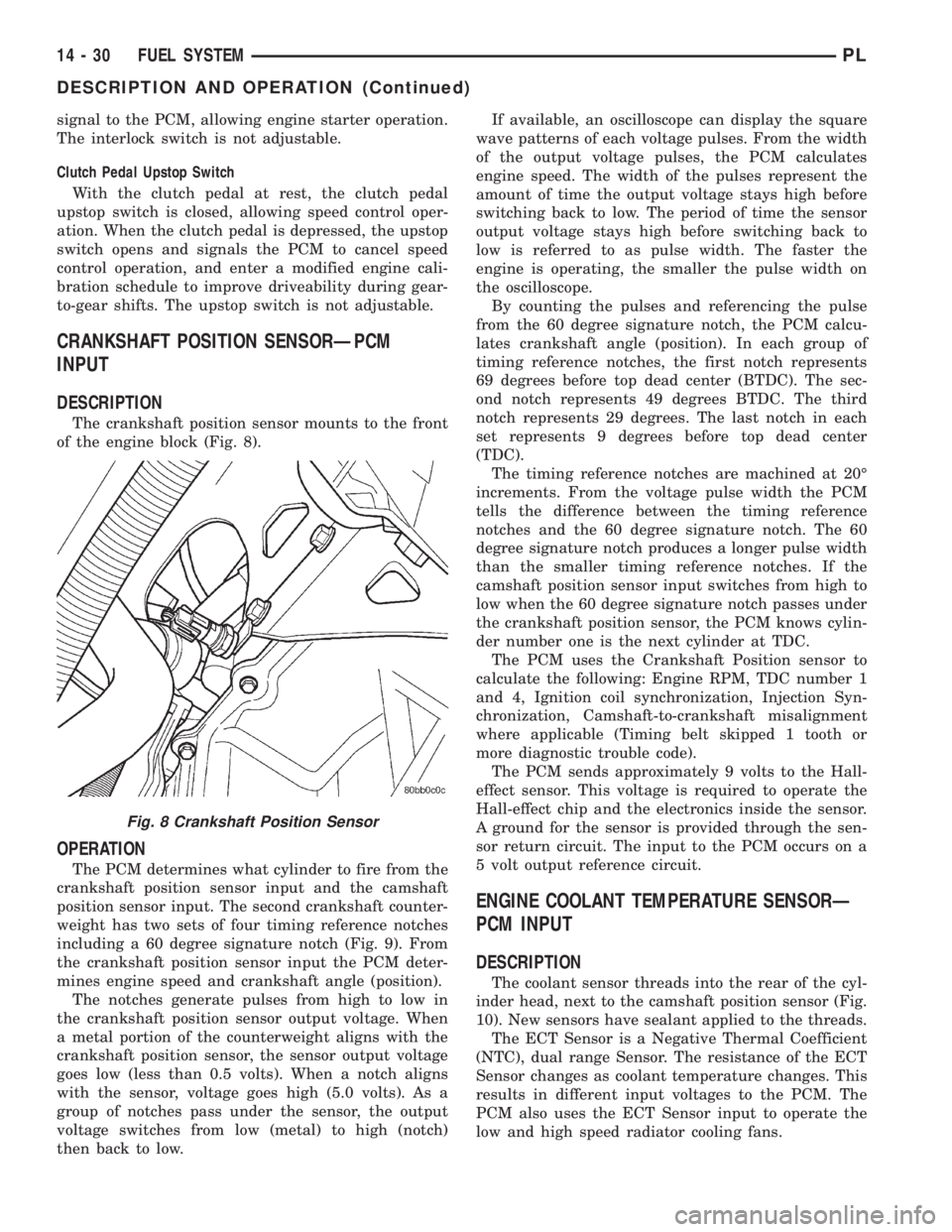

DESCRIPTION

The crankshaft position sensor mounts to the front

of the engine block (Fig. 8).

OPERATION

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 9). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The PCM uses the Crankshaft Position sensor to

calculate the following: Engine RPM, TDC number 1

and 4, Ignition coil synchronization, Injection Syn-

chronization, Camshaft-to-crankshaft misalignment

where applicable (Timing belt skipped 1 tooth or

more diagnostic trouble code).

The PCM sends approximately 9 volts to the Hall-

effect sensor. This voltage is required to operate the

Hall-effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT

DESCRIPTION

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

10). New sensors have sealant applied to the threads.

The ECT Sensor is a Negative Thermal Coefficient

(NTC), dual range Sensor. The resistance of the ECT

Sensor changes as coolant temperature changes. This

results in different input voltages to the PCM. The

PCM also uses the ECT Sensor input to operate the

low and high speed radiator cooling fans.

Fig. 8 Crankshaft Position Sensor

14 - 30 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 855 of 1285

IGNITION CIRCUIT SENSEÐPCM INPUT

OPERATION

The ignition circuit sense input tells the Power-

train Control Module (PCM) the ignition switch has

energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the Ignition Switch when the ignition is in

the RUN or START position. This is called the9igni-

tion senseº circuit and is used to ªwake upº the PCM.

Voltage on the ignition input can be as low as 6 volts

and the PCM will still function. Voltage is supplied to

this circuit to power the 8-volt regulator and to allow

the PCM to perform fuel, ignition and emissions con-

trol functions. The battery voltage on this line is sup-

plied to the 8-volt regulator which then passes on a

power-up supply to the 5-volt regulator.

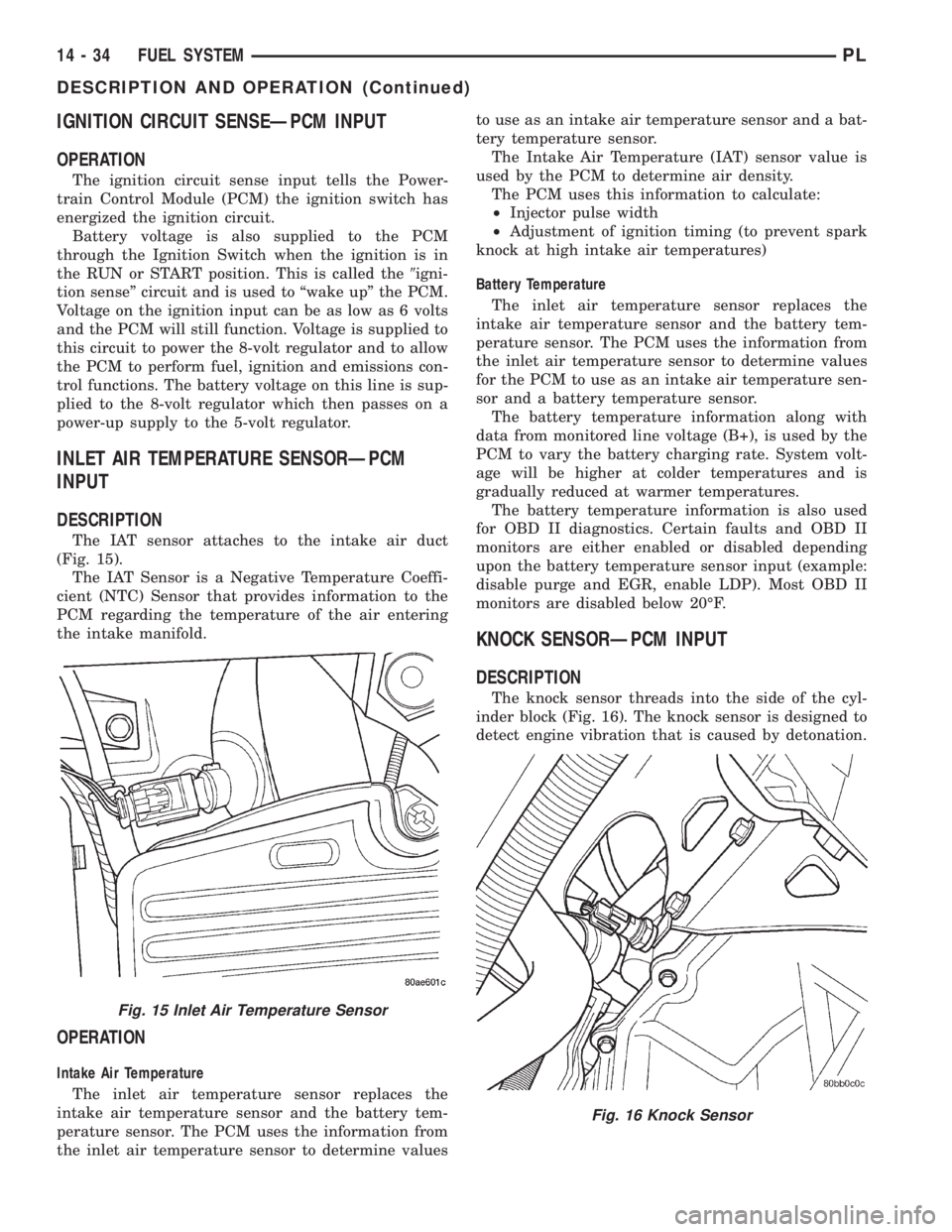

INLET AIR TEMPERATURE SENSORÐPCM

INPUT

DESCRIPTION

The IAT sensor attaches to the intake air duct

(Fig. 15).

The IAT Sensor is a Negative Temperature Coeffi-

cient (NTC) Sensor that provides information to the

PCM regarding the temperature of the air entering

the intake manifold.

OPERATION

Intake Air Temperature

The inlet air temperature sensor replaces the

intake air temperature sensor and the battery tem-

perature sensor. The PCM uses the information from

the inlet air temperature sensor to determine valuesto use as an intake air temperature sensor and a bat-

tery temperature sensor.

The Intake Air Temperature (IAT) sensor value is

used by the PCM to determine air density.

The PCM uses this information to calculate:

²Injector pulse width

²Adjustment of ignition timing (to prevent spark

knock at high intake air temperatures)

Battery Temperature

The inlet air temperature sensor replaces the

intake air temperature sensor and the battery tem-

perature sensor. The PCM uses the information from

the inlet air temperature sensor to determine values

for the PCM to use as an intake air temperature sen-

sor and a battery temperature sensor.

The battery temperature information along with

data from monitored line voltage (B+), is used by the

PCM to vary the battery charging rate. System volt-

age will be higher at colder temperatures and is

gradually reduced at warmer temperatures.

The battery temperature information is also used

for OBD II diagnostics. Certain faults and OBD II

monitors are either enabled or disabled depending

upon the battery temperature sensor input (example:

disable purge and EGR, enable LDP). Most OBD II

monitors are disabled below 20ÉF.

KNOCK SENSORÐPCM INPUT

DESCRIPTION

The knock sensor threads into the side of the cyl-

inder block (Fig. 16). The knock sensor is designed to

detect engine vibration that is caused by detonation.

Fig. 15 Inlet Air Temperature Sensor

Fig. 16 Knock Sensor

14 - 34 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 856 of 1285

OPERATION

When the knock sensor detects a knock in one of

the cylinders, it sends an input signal to the PCM. In

response, the PCM retards ignition timing for all cyl-

inders by a scheduled amount.

Knock sensors contain a piezoelectric material

which sends an input voltage (signal) to the PCM. As

the intensity of the engine knock vibration increases,

the knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives as an input the knock sensor voltage signal.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except WOT.

The PCM, using short term memory, can respond

quickly to retard timing when engine knock is

detected. Short term memory is lost any time the

ignition key is turned off.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

DESCRIPTION

The MAP sensor mounts to the intake manifold

(Fig. 17).

OPERATION

The PCM supplies 5 volts direct current to the

MAP sensor. The MAP sensor converts intake mani-

fold pressure into voltage. The PCM monitors the

MAP sensor output voltage. As vacuum increases,

MAP sensor voltage decreases proportionately. Also,

as vacuum decreases, MAP sensor voltage increases

proportionately.

At key on, before the engine is started, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage andinputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

If the PCM considers the MAP Sensor information

inaccurate, the PCM moves into ªlimp-inº mode.

When the MAP Sensor is in limp-in, the PCM limits

the engine speed as a function of the Throttle Posi-

tion Sensor (TPS) to between 1500 and 4000 rpm. If

the MAP Sensor sends realistic signals once again,

the PCM moves out of limp-in and resumes using the

MAP values.

During limp-in a DTC is set and the MIL illumi-

nates.

POWER STEERING PRESSURE SWITCHÐPCM

INPUT

DESCRIPTION

A pressure sensing switch is located on the power

steering gear.

OPERATION

The switch (Fig. 18) provides an input to the PCM

during periods of high pump load and low engine

RPM; such as during parking maneuvers.

When power steering pump pressure exceeds 2758

kPa (400 psi), the switch is open. The PCM increases

idle air flow through the IAC motor to prevent

engine stalling. The PCM sends 12 volts through a

resister to the sensor circuit to ground. When pump

pressure is low, the switch is closed.

SENSOR RETURNÐPCM INPUT

OPERATION

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

Fig. 17 Manifold Absolute Pressure Sensor

PLFUEL SYSTEM 14 - 35

DESCRIPTION AND OPERATION (Continued)

Page 860 of 1285

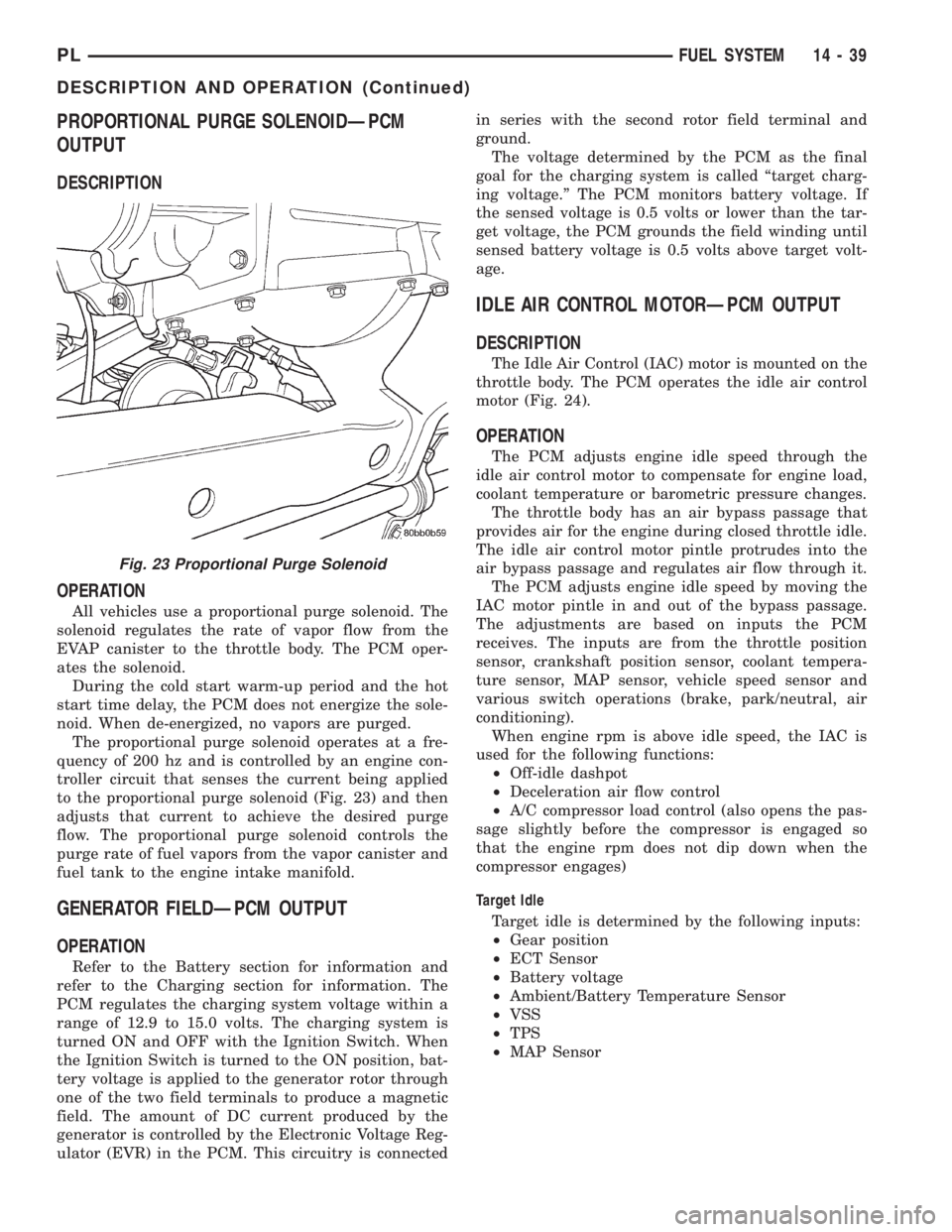

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT

DESCRIPTION

OPERATION

All vehicles use a proportional purge solenoid. The

solenoid regulates the rate of vapor flow from the

EVAP canister to the throttle body. The PCM oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid (Fig. 23) and then

adjusts that current to achieve the desired purge

flow. The proportional purge solenoid controls the

purge rate of fuel vapors from the vapor canister and

fuel tank to the engine intake manifold.

GENERATOR FIELDÐPCM OUTPUT

OPERATION

Refer to the Battery section for information and

refer to the Charging section for information. The

PCM regulates the charging system voltage within a

range of 12.9 to 15.0 volts. The charging system is

turned ON and OFF with the Ignition Switch. When

the Ignition Switch is turned to the ON position, bat-

tery voltage is applied to the generator rotor through

one of the two field terminals to produce a magnetic

field. The amount of DC current produced by the

generator is controlled by the Electronic Voltage Reg-

ulator (EVR) in the PCM. This circuitry is connectedin series with the second rotor field terminal and

ground.

The voltage determined by the PCM as the final

goal for the charging system is called ªtarget charg-

ing voltage.º The PCM monitors battery voltage. If

the sensed voltage is 0.5 volts or lower than the tar-

get voltage, the PCM grounds the field winding until

sensed battery voltage is 0.5 volts above target volt-

age.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

DESCRIPTION

The Idle Air Control (IAC) motor is mounted on the

throttle body. The PCM operates the idle air control

motor (Fig. 24).

OPERATION

The PCM adjusts engine idle speed through the

idle air control motor to compensate for engine load,

coolant temperature or barometric pressure changes.

The throttle body has an air bypass passage that

provides air for the engine during closed throttle idle.

The idle air control motor pintle protrudes into the

air bypass passage and regulates air flow through it.

The PCM adjusts engine idle speed by moving the

IAC motor pintle in and out of the bypass passage.

The adjustments are based on inputs the PCM

receives. The inputs are from the throttle position

sensor, crankshaft position sensor, coolant tempera-

ture sensor, MAP sensor, vehicle speed sensor and

various switch operations (brake, park/neutral, air

conditioning).

When engine rpm is above idle speed, the IAC is

used for the following functions:

²Off-idle dashpot

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

Target Idle

Target idle is determined by the following inputs:

²Gear position

²ECT Sensor

²Battery voltage

²Ambient/Battery Temperature Sensor

²VSS

²TPS

²MAP Sensor

Fig. 23 Proportional Purge Solenoid

PLFUEL SYSTEM 14 - 39

DESCRIPTION AND OPERATION (Continued)

Page 861 of 1285

DATA LINK CONNECTOR

DESCRIPTION

The data link connector is located inside the vehi-

cle, under the instrument panel, left of the steering

column (Fig. 25).

OPERATION

The data link connector (diagnostic connector)

links the DRB scan tool with the powertrain control

module (PCM). Refer to On-Board Diagnostics in the

General Diagnosis section of this group.

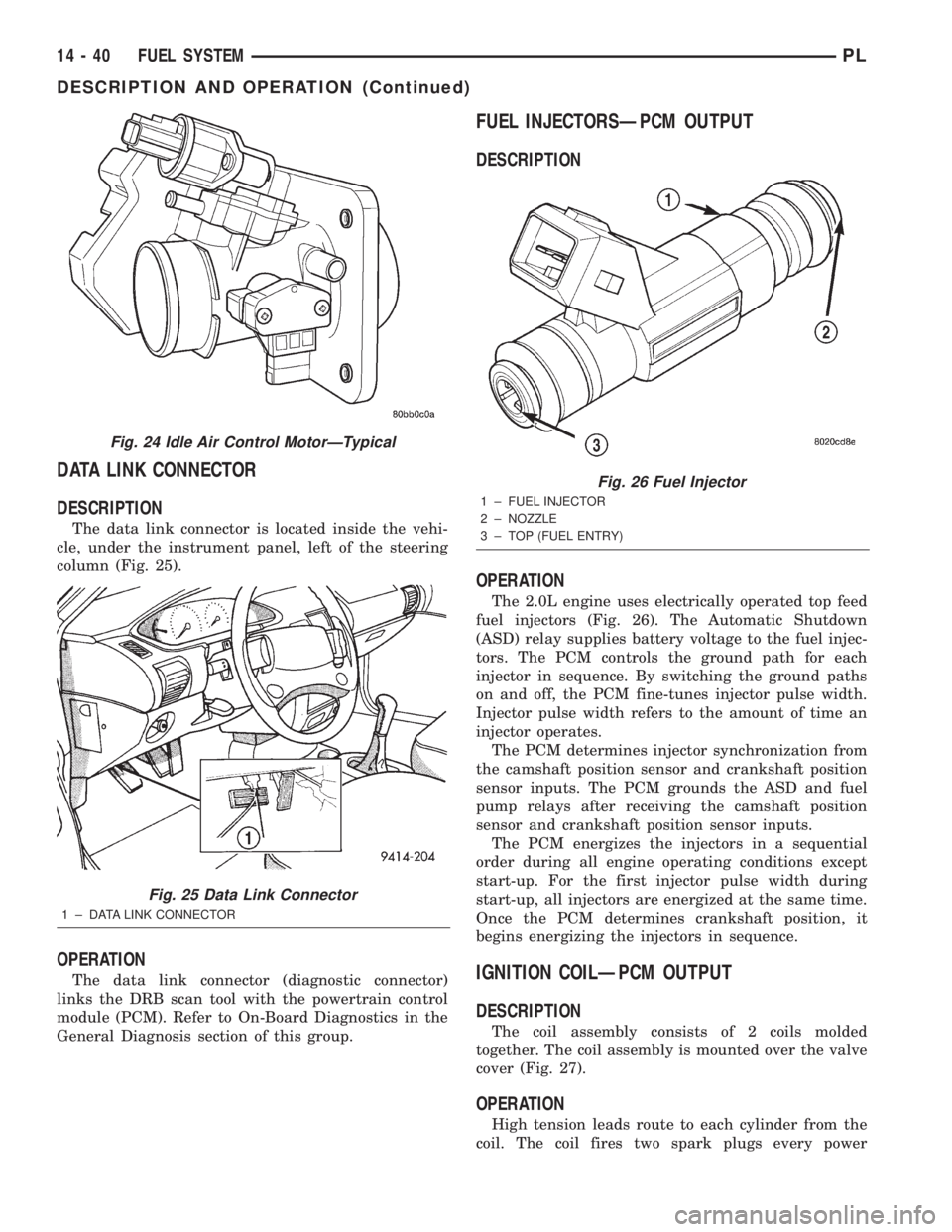

FUEL INJECTORSÐPCM OUTPUT

DESCRIPTION

OPERATION

The 2.0L engine uses electrically operated top feed

fuel injectors (Fig. 26). The Automatic Shutdown

(ASD) relay supplies battery voltage to the fuel injec-

tors. The PCM controls the ground path for each

injector in sequence. By switching the ground paths

on and off, the PCM fine-tunes injector pulse width.

Injector pulse width refers to the amount of time an

injector operates.

The PCM determines injector synchronization from

the camshaft position sensor and crankshaft position

sensor inputs. The PCM grounds the ASD and fuel

pump relays after receiving the camshaft position

sensor and crankshaft position sensor inputs.

The PCM energizes the injectors in a sequential

order during all engine operating conditions except

start-up. For the first injector pulse width during

start-up, all injectors are energized at the same time.

Once the PCM determines crankshaft position, it

begins energizing the injectors in sequence.

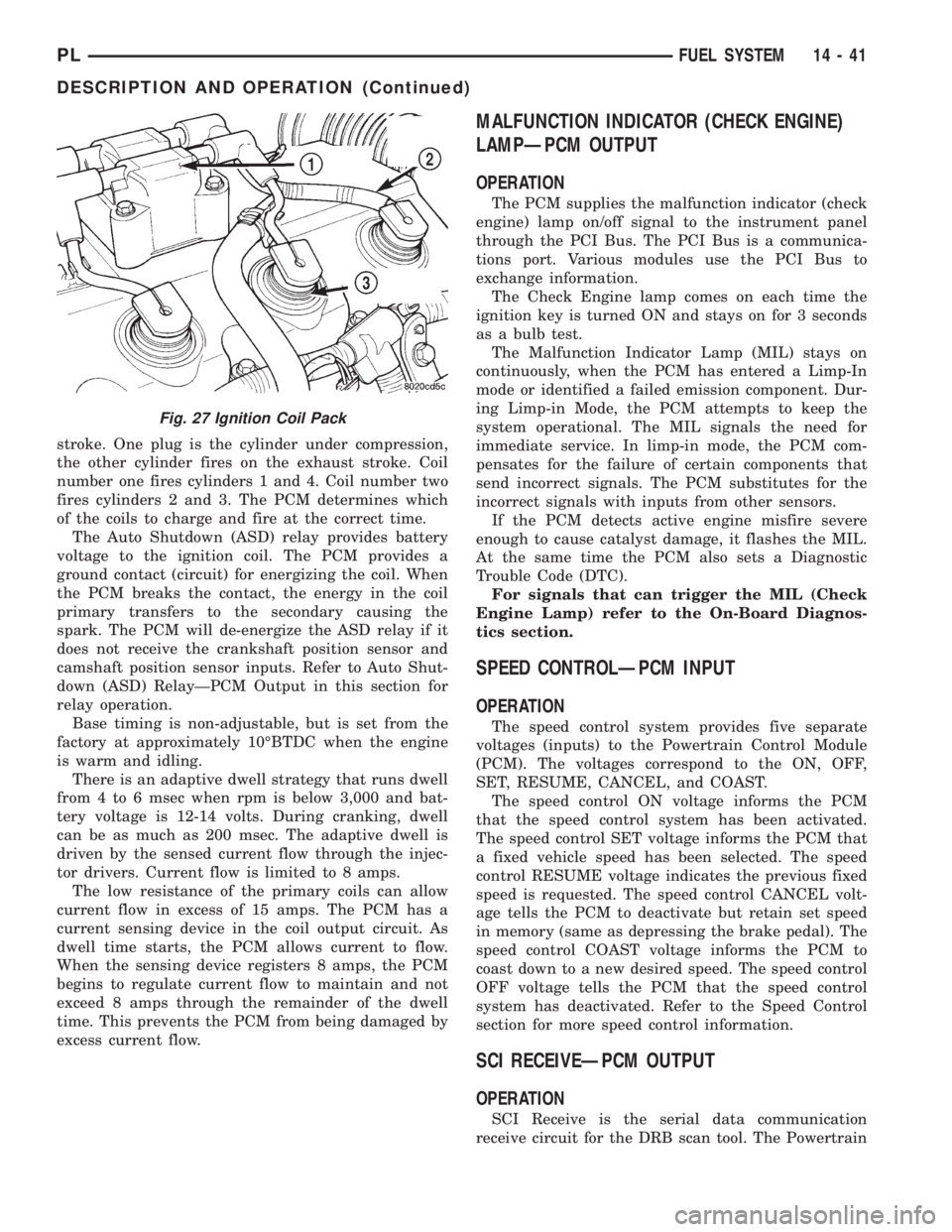

IGNITION COILÐPCM OUTPUT

DESCRIPTION

The coil assembly consists of 2 coils molded

together. The coil assembly is mounted over the valve

cover (Fig. 27).

OPERATION

High tension leads route to each cylinder from the

coil. The coil fires two spark plugs every power

Fig. 24 Idle Air Control MotorÐTypical

Fig. 25 Data Link Connector

1 ± DATA LINK CONNECTOR

Fig. 26 Fuel Injector

1 ± FUEL INJECTOR

2 ± NOZZLE

3 ± TOP (FUEL ENTRY)

14 - 40 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 862 of 1285

stroke. One plug is the cylinder under compression,

the other cylinder fires on the exhaust stroke. Coil

number one fires cylinders 1 and 4. Coil number two

fires cylinders 2 and 3. The PCM determines which

of the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output in this section for

relay operation.

Base timing is non-adjustable, but is set from the

factory at approximately 10ÉBTDC when the engine

is warm and idling.

There is an adaptive dwell strategy that runs dwell

from 4 to 6 msec when rpm is below 3,000 and bat-

tery voltage is 12-14 volts. During cranking, dwell

can be as much as 200 msec. The adaptive dwell is

driven by the sensed current flow through the injec-

tor drivers. Current flow is limited to 8 amps.

The low resistance of the primary coils can allow

current flow in excess of 15 amps. The PCM has a

current sensing device in the coil output circuit. As

dwell time starts, the PCM allows current to flow.

When the sensing device registers 8 amps, the PCM

begins to regulate current flow to maintain and not

exceed 8 amps through the remainder of the dwell

time. This prevents the PCM from being damaged by

excess current flow.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

OPERATION

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the PCI Bus. The PCI Bus is a communica-

tions port. Various modules use the PCI Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to the On-Board Diagnos-

tics section.

SPEED CONTROLÐPCM INPUT

OPERATION

The speed control system provides five separate

voltages (inputs) to the Powertrain Control Module

(PCM). The voltages correspond to the ON, OFF,

SET, RESUME, CANCEL, and COAST.

The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control COAST voltage informs the PCM to

coast down to a new desired speed. The speed control

OFF voltage tells the PCM that the speed control

system has deactivated. Refer to the Speed Control

section for more speed control information.

SCI RECEIVEÐPCM OUTPUT

OPERATION

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Fig. 27 Ignition Coil Pack

PLFUEL SYSTEM 14 - 41

DESCRIPTION AND OPERATION (Continued)