wheel DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 293 of 1285

The integrated switch assembly is mounted to the

left hand side of the steering column. When the

driver wishes to signal his intentions to change direc-

tion of travel, he moves the lever upward to cause

the right signals to flash and downward to cause the

left signals to flash. After completion of a turn the

system is deactivated automatically. As the steering

wheel returns to the straight ahead position, a can-

celing cam molded to the clockspring mechanism

comes in contact with the cancel actuator on the turn

signal multi-function switch assembly. The cam lobe,

pushing on the cancel actuator, returns the switch to

the off position.

If only momentary signaling such as indication of a

lane change is desired, the switch is actuated to a

left or right intermediate detent position. In this

position the signal lamps flash as described above,

but the switch returns to the OFF position as soon as

the lever is released.

When the system is activated, one of two indicator

lamps mounted in the instrument cluster flashes in

unison with the turn signal lamps, indicating to the

driver that the system is operating.

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM

The hazard warning system is actuated by a push

button located in the muti-function switch (Fig. 1) on

the top of the steering column between the steering

wheel and the instrument panel. The hazard switch

is identified with a double triangle on front of the

button.

HEADLAMP SWITCH

The headlamp switch is part of the Multi-Function

Switch (Fig. 1). Refer to Multi-Function Switch Diag-

nosis and Testing, Turn Signal and Hazard Warning

Flasher Diagnosis table in this section.

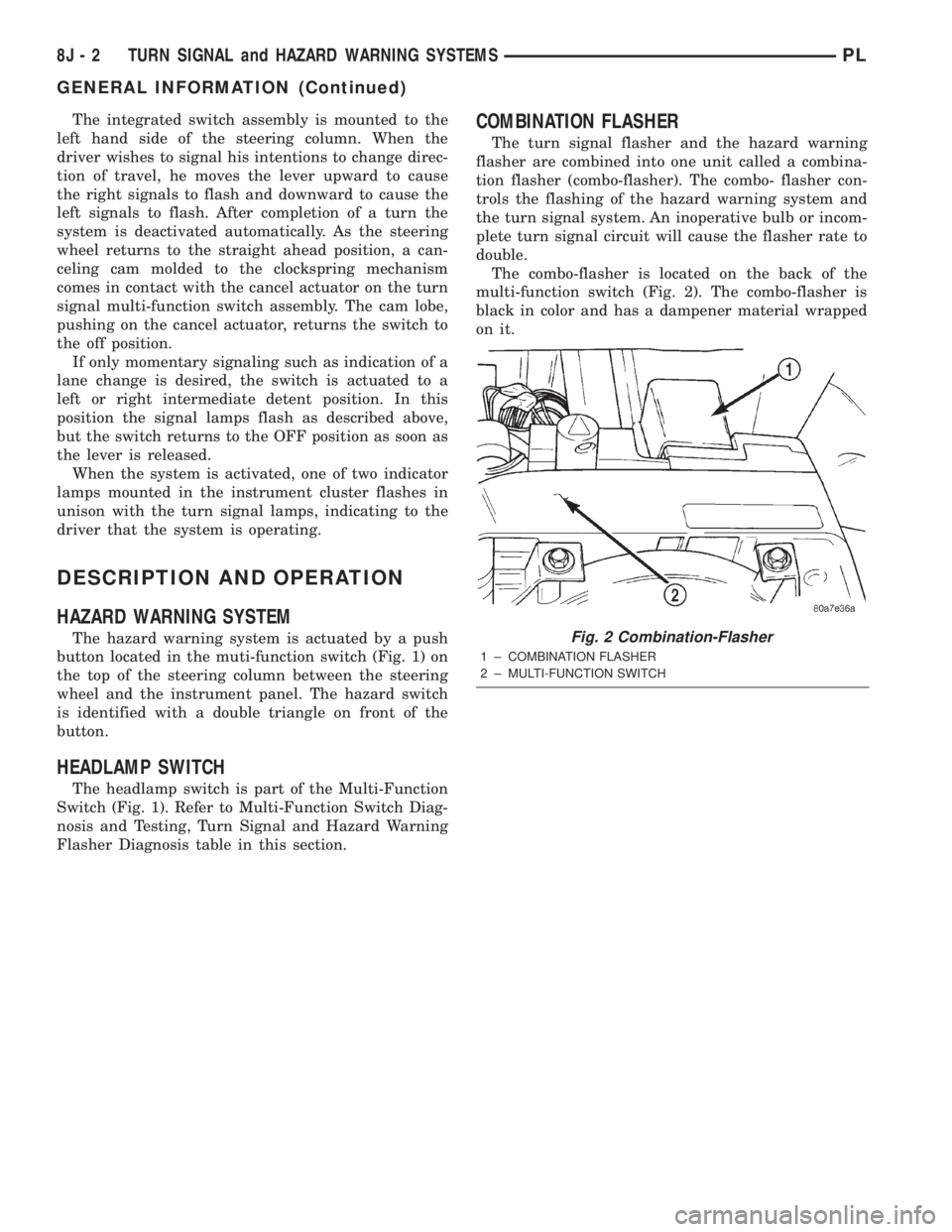

COMBINATION FLASHER

The turn signal flasher and the hazard warning

flasher are combined into one unit called a combina-

tion flasher (combo-flasher). The combo- flasher con-

trols the flashing of the hazard warning system and

the turn signal system. An inoperative bulb or incom-

plete turn signal circuit will cause the flasher rate to

double.

The combo-flasher is located on the back of the

multi-function switch (Fig. 2). The combo-flasher is

black in color and has a dampener material wrapped

on it.

Fig. 2 Combination-Flasher

1 ± COMBINATION FLASHER

2 ± MULTI-FUNCTION SWITCH

8J - 2 TURN SIGNAL and HAZARD WARNING SYSTEMSPL

GENERAL INFORMATION (Continued)

Page 298 of 1285

WINDSHIELD WIPER and WASHER SYSTEMS

TABLE OF CONTENTS

page page

WINDSHIELD WIPER SYSTEM................ 1WINDSHIELD WASHER SYSTEM.............. 8

WINDSHIELD WIPER SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

WIPER BLADES...........................1

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS............2

WINDSHIELD WIPER MOTOR................3

WINDSHIELD WIPER/WASHER SWITCH........5

REMOVAL AND INSTALLATION

WINDSHIELD WIPER ARM(S)................5WINDSHIELD WIPER BLADE(S)..............5

WINDSHIELD WIPER BLADE ELEMENT........5

WINDSHIELD WIPER LINKAGE...............5

WINDSHIELD WIPER MODULE...............6

WINDSHIELD WIPER MOTOR................6

WINDSHIELD WIPER/WASHER SWITCH........6

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)..............6

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)................6

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The windshield wipers will only operate with the

ignition switch in the ACCESSORY or IGNITION

RUN position. The wiper circuit is protected against

over loads by a fuse in the fuse block and a circuit

breaker within the wiper motor. This protects the cir-

cuitry of the wiper system and the vehicle. The wiper

motor has permanent magnet fields.

The intermittent wiper system, in addition to low

and high speed, has a delay mode and a pulse wipe

mode. The delay mode has a range of 1 to 15 seconds.

Pulse wipe is accomplished by momentarily moving

the stalk lever into the WASH position while the

wiper switch is in either OFF or DELAY position.

The wiper blades then sweep once or twice and

return to the previous wiper switch mode, OFF or

DELAY.The intermittent wiper function is integral to the

wiper switch. All electronics and relay are inside the

switch assembly.

The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

The wiper switch also includes the MIST feature

which provides a single wipe when actuated.

DESCRIPTION AND OPERATION

WIPER BLADES

Wiper blades, exposed to the weather for a long

period of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the blades continue to

streak or smear, they should be replaced. The right

and left wipers are different blade lengths. The

driver side length is 550 mm and the passenger side

length is 475 mm. The blades should not be inter-

changed.

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 1

Page 299 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken.

Whatever the problem, disconnect motor wire har-

ness and clean the terminals, then connect motor

wire harness and test.

Refer to Group 8W Wiring Diagrams for circuit

information and connector call-outs.

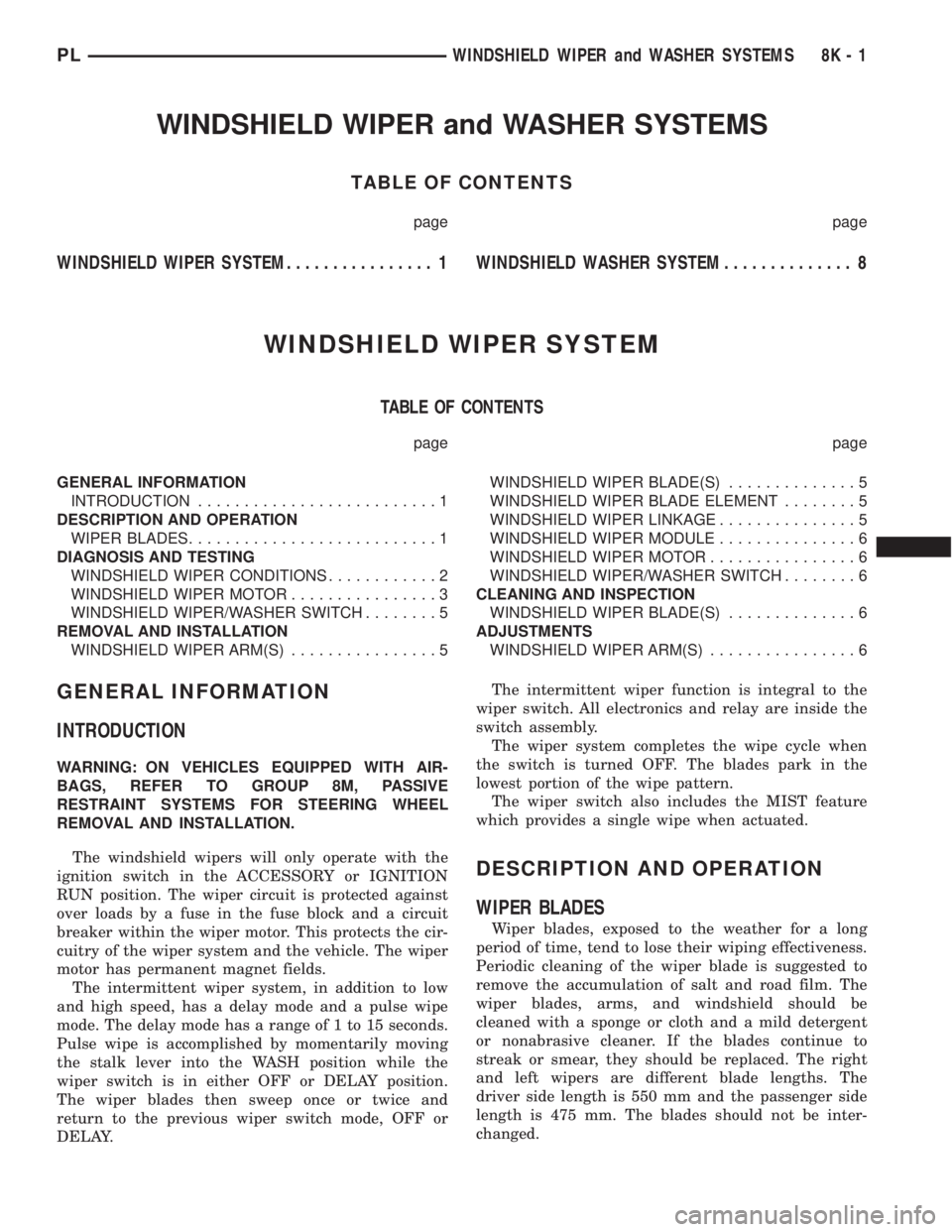

MOTOR WILL NOT OPERATE IN SOME OR ALL

SWITCH POSITIONS

(1) Check fuse 1, in the fuse block (Fig. 1).

(a) If fuse is OK, go to Step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions.

(c) If motor is still inoperative and the fuse does

not blow, go to Step 2.

(d) If replacement fuse blows, go to Step 6.

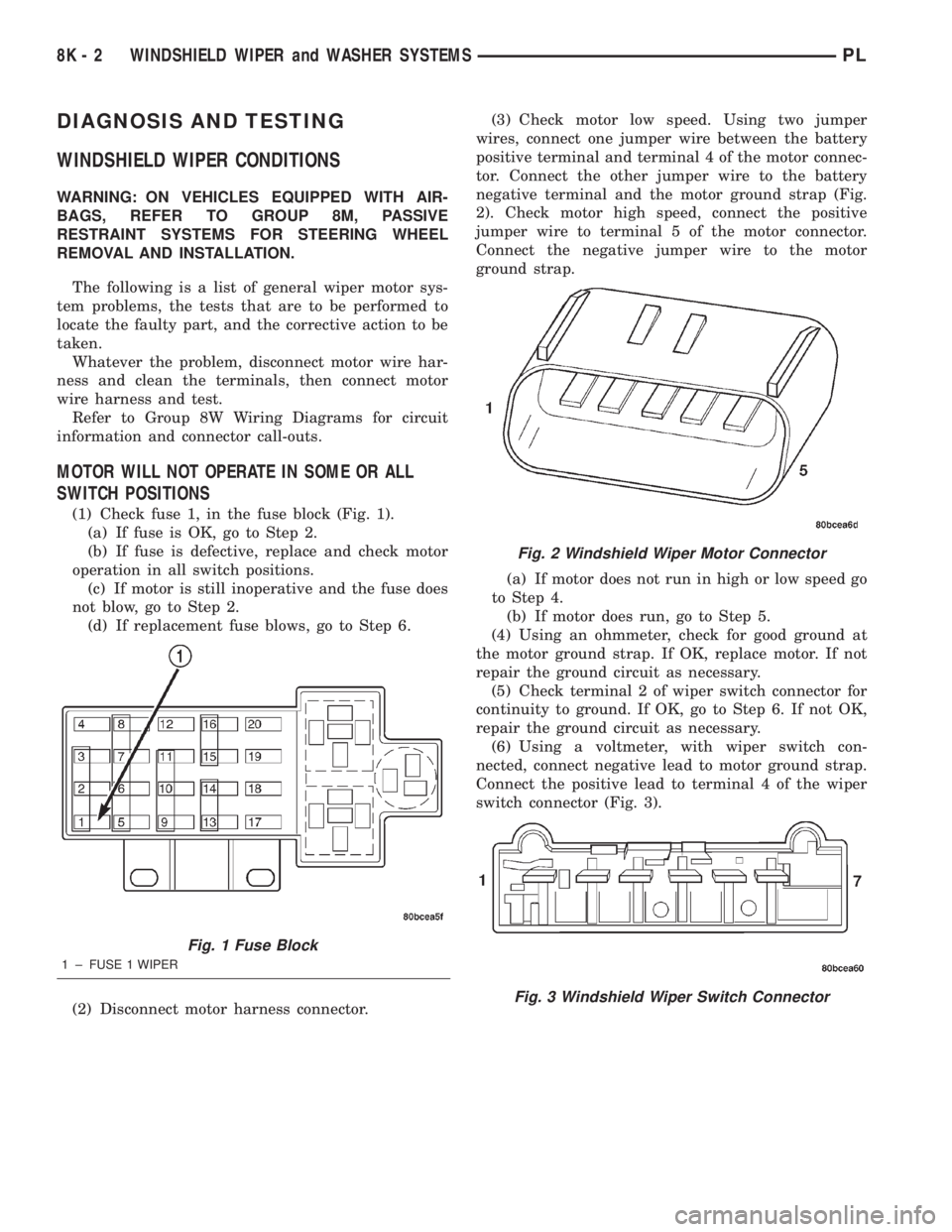

(2) Disconnect motor harness connector.(3) Check motor low speed. Using two jumper

wires, connect one jumper wire between the battery

positive terminal and terminal 4 of the motor connec-

tor. Connect the other jumper wire to the battery

negative terminal and the motor ground strap (Fig.

2). Check motor high speed, connect the positive

jumper wire to terminal 5 of the motor connector.

Connect the negative jumper wire to the motor

ground strap.

(a) If motor does not run in high or low speed go

to Step 4.

(b) If motor does run, go to Step 5.

(4) Using an ohmmeter, check for good ground at

the motor ground strap. If OK, replace motor. If not

repair the ground circuit as necessary.

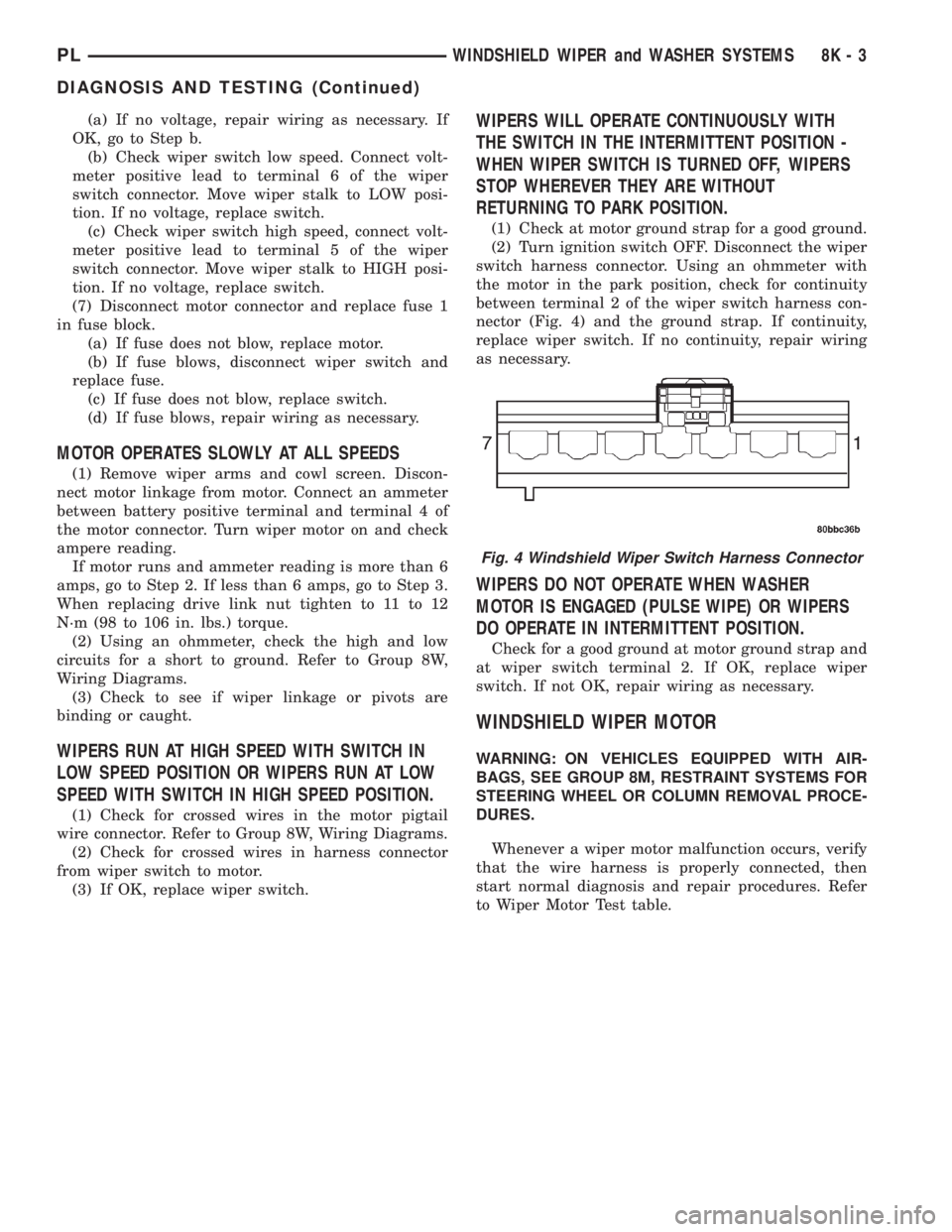

(5) Check terminal 2 of wiper switch connector for

continuity to ground. If OK, go to Step 6. If not OK,

repair the ground circuit as necessary.

(6) Using a voltmeter, with wiper switch con-

nected, connect negative lead to motor ground strap.

Connect the positive lead to terminal 4 of the wiper

switch connector (Fig. 3).

Fig. 1 Fuse Block

1 ± FUSE 1 WIPER

Fig. 2 Windshield Wiper Motor Connector

Fig. 3 Windshield Wiper Switch Connector

8K - 2 WINDSHIELD WIPER and WASHER SYSTEMSPL

Page 300 of 1285

(a) If no voltage, repair wiring as necessary. If

OK, go to Step b.

(b) Check wiper switch low speed. Connect volt-

meter positive lead to terminal 6 of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal 5 of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 1

in fuse block.

(a) If fuse does not blow, replace motor.

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector. Turn wiper motor on and check

ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.

(2) Using an ohmmeter, check the high and low

circuits for a short to ground. Refer to Group 8W,

Wiring Diagrams.

(3) Check to see if wiper linkage or pivots are

binding or caught.

WIPERS RUN AT HIGH SPEED WITH SWITCH IN

LOW SPEED POSITION OR WIPERS RUN AT LOW

SPEED WITH SWITCH IN HIGH SPEED POSITION.

(1) Check for crossed wires in the motor pigtail

wire connector. Refer to Group 8W, Wiring Diagrams.

(2) Check for crossed wires in harness connector

from wiper switch to motor.

(3) If OK, replace wiper switch.

WIPERS WILL OPERATE CONTINUOUSLY WITH

THE SWITCH IN THE INTERMITTENT POSITION -

WHEN WIPER SWITCH IS TURNED OFF, WIPERS

STOP WHEREVER THEY ARE WITHOUT

RETURNING TO PARK POSITION.

(1) Check at motor ground strap for a good ground.

(2) Turn ignition switch OFF. Disconnect the wiper

switch harness connector. Using an ohmmeter with

the motor in the park position, check for continuity

between terminal 2 of the wiper switch harness con-

nector (Fig. 4) and the ground strap. If continuity,

replace wiper switch. If no continuity, repair wiring

as necessary.

WIPERS DO NOT OPERATE WHEN WASHER

MOTOR IS ENGAGED (PULSE WIPE) OR WIPERS

DO OPERATE IN INTERMITTENT POSITION.

Check for a good ground at motor ground strap and

at wiper switch terminal 2. If OK, replace wiper

switch. If not OK, repair wiring as necessary.

WINDSHIELD WIPER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, verify

that the wire harness is properly connected, then

start normal diagnosis and repair procedures. Refer

to Wiper Motor Test table.

Fig. 4 Windshield Wiper Switch Harness Connector

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 3

DIAGNOSIS AND TESTING (Continued)

Page 316 of 1285

FRONT SIDE MARKER LAMP BULB

REMOVAL

(1) Reach behind front bumper fascia forward of

front wheel and remove attaching clip from the front

side marker lamp.

(2) Remove bulb from socket (Fig. 2).

INSTALLATION

(1) Install bulb into socket.

(2) Install attaching clip to the front side marker

lamp.

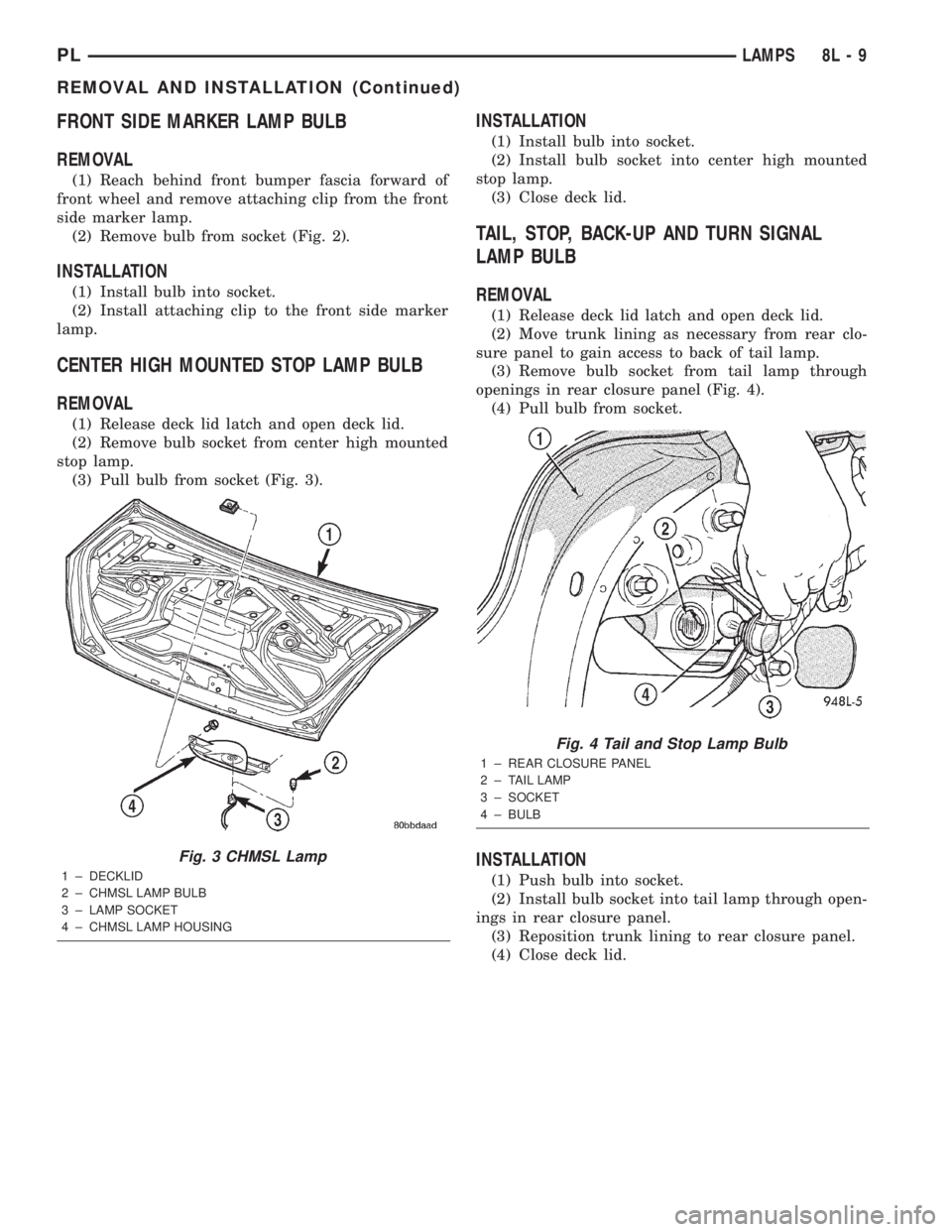

CENTER HIGH MOUNTED STOP LAMP BULB

REMOVAL

(1) Release deck lid latch and open deck lid.

(2) Remove bulb socket from center high mounted

stop lamp.

(3) Pull bulb from socket (Fig. 3).

INSTALLATION

(1) Install bulb into socket.

(2) Install bulb socket into center high mounted

stop lamp.

(3) Close deck lid.

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULB

REMOVAL

(1) Release deck lid latch and open deck lid.

(2) Move trunk lining as necessary from rear clo-

sure panel to gain access to back of tail lamp.

(3) Remove bulb socket from tail lamp through

openings in rear closure panel (Fig. 4).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install bulb socket into tail lamp through open-

ings in rear closure panel.

(3) Reposition trunk lining to rear closure panel.

(4) Close deck lid.

Fig. 3 CHMSL Lamp

1 ± DECKLID

2 ± CHMSL LAMP BULB

3 ± LAMP SOCKET

4 ± CHMSL LAMP HOUSING

Fig. 4 Tail and Stop Lamp Bulb

1 ± REAR CLOSURE PANEL

2 ± TAIL LAMP

3 ± SOCKET

4 ± BULB

PLLAMPS 8L - 9

REMOVAL AND INSTALLATION (Continued)

Page 320 of 1285

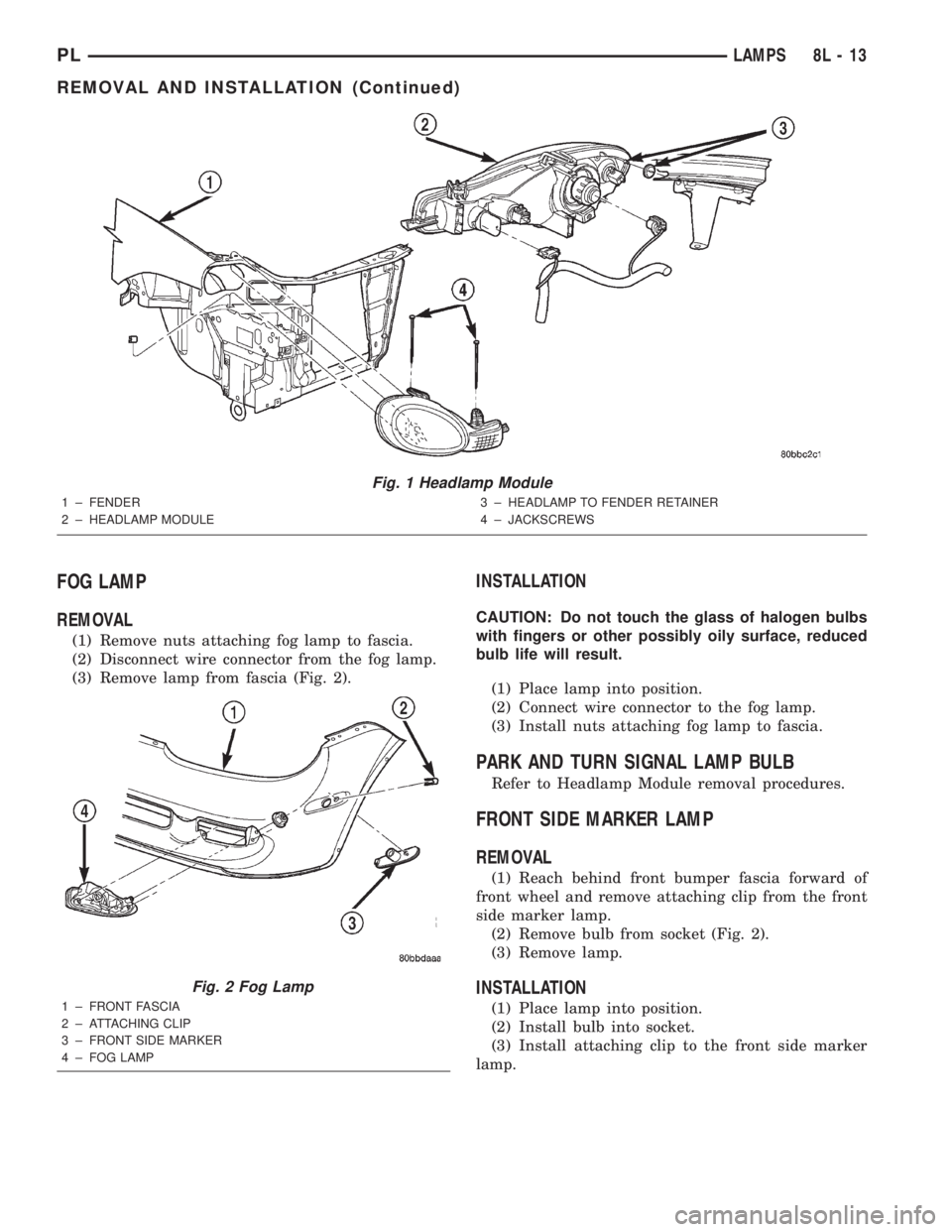

FOG LAMP

REMOVAL

(1) Remove nuts attaching fog lamp to fascia.

(2) Disconnect wire connector from the fog lamp.

(3) Remove lamp from fascia (Fig. 2).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Place lamp into position.

(2) Connect wire connector to the fog lamp.

(3) Install nuts attaching fog lamp to fascia.

PARK AND TURN SIGNAL LAMP BULB

Refer to Headlamp Module removal procedures.

FRONT SIDE MARKER LAMP

REMOVAL

(1) Reach behind front bumper fascia forward of

front wheel and remove attaching clip from the front

side marker lamp.

(2) Remove bulb from socket (Fig. 2).

(3) Remove lamp.

INSTALLATION

(1) Place lamp into position.

(2) Install bulb into socket.

(3) Install attaching clip to the front side marker

lamp.

Fig. 1 Headlamp Module

1 ± FENDER

2 ± HEADLAMP MODULE3 ± HEADLAMP TO FENDER RETAINER

4 ± JACKSCREWS

Fig. 2 Fog Lamp

1 ± FRONT FASCIA

2 ± ATTACHING CLIP

3 ± FRONT SIDE MARKER

4 ± FOG LAMP

PLLAMPS 8L - 13

REMOVAL AND INSTALLATION (Continued)

Page 334 of 1285

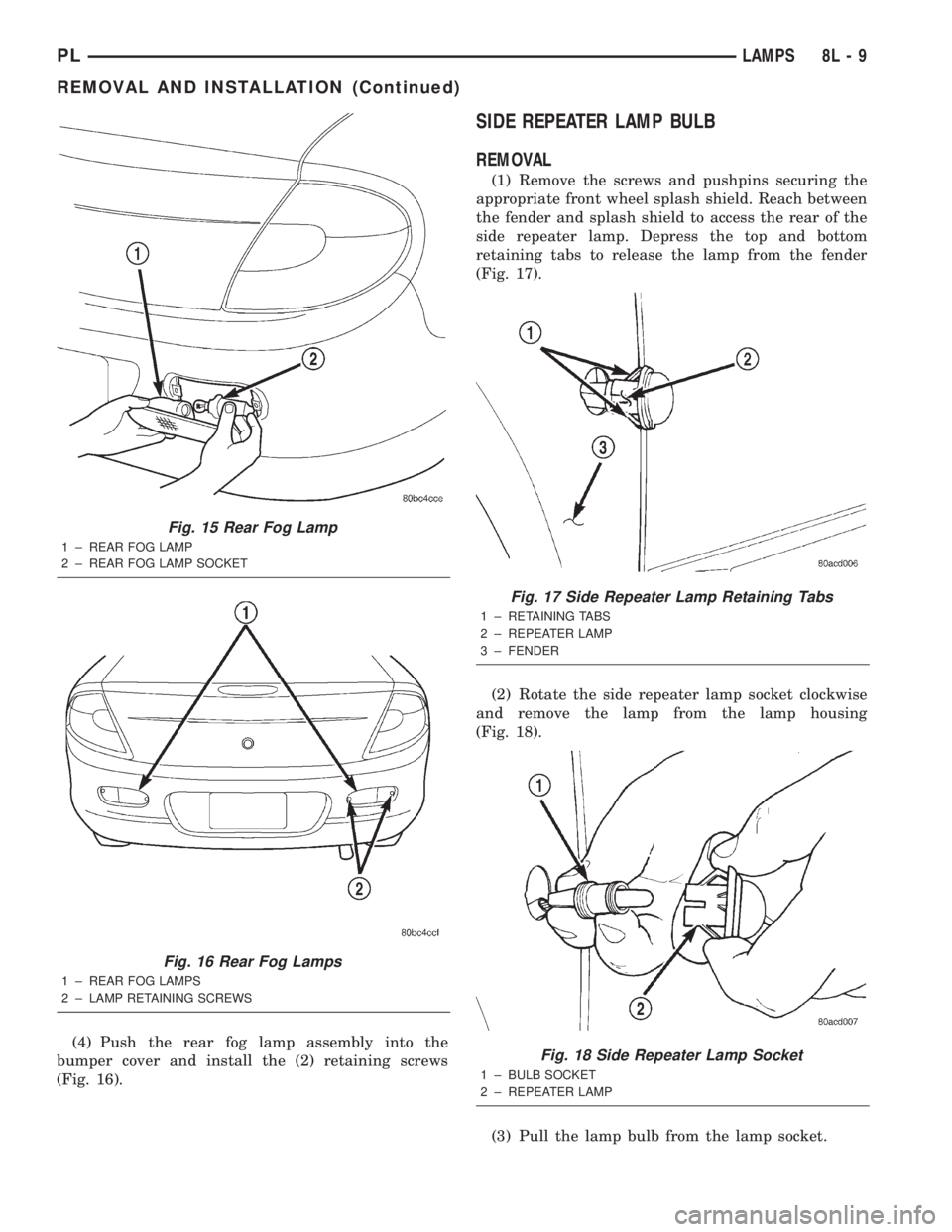

(4) Push the rear fog lamp assembly into the

bumper cover and install the (2) retaining screws

(Fig. 16).

SIDE REPEATER LAMP BULB

REMOVAL

(1) Remove the screws and pushpins securing the

appropriate front wheel splash shield. Reach between

the fender and splash shield to access the rear of the

side repeater lamp. Depress the top and bottom

retaining tabs to release the lamp from the fender

(Fig. 17).

(2) Rotate the side repeater lamp socket clockwise

and remove the lamp from the lamp housing

(Fig. 18).

(3) Pull the lamp bulb from the lamp socket.

Fig. 15 Rear Fog Lamp

1 ± REAR FOG LAMP

2 ± REAR FOG LAMP SOCKET

Fig. 16 Rear Fog Lamps

1 ± REAR FOG LAMPS

2 ± LAMP RETAINING SCREWS

Fig. 17 Side Repeater Lamp Retaining Tabs

1 ± RETAINING TABS

2 ± REPEATER LAMP

3 ± FENDER

Fig. 18 Side Repeater Lamp Socket

1 ± BULB SOCKET

2 ± REPEATER LAMP

PLLAMPS 8L - 9

REMOVAL AND INSTALLATION (Continued)

Page 335 of 1285

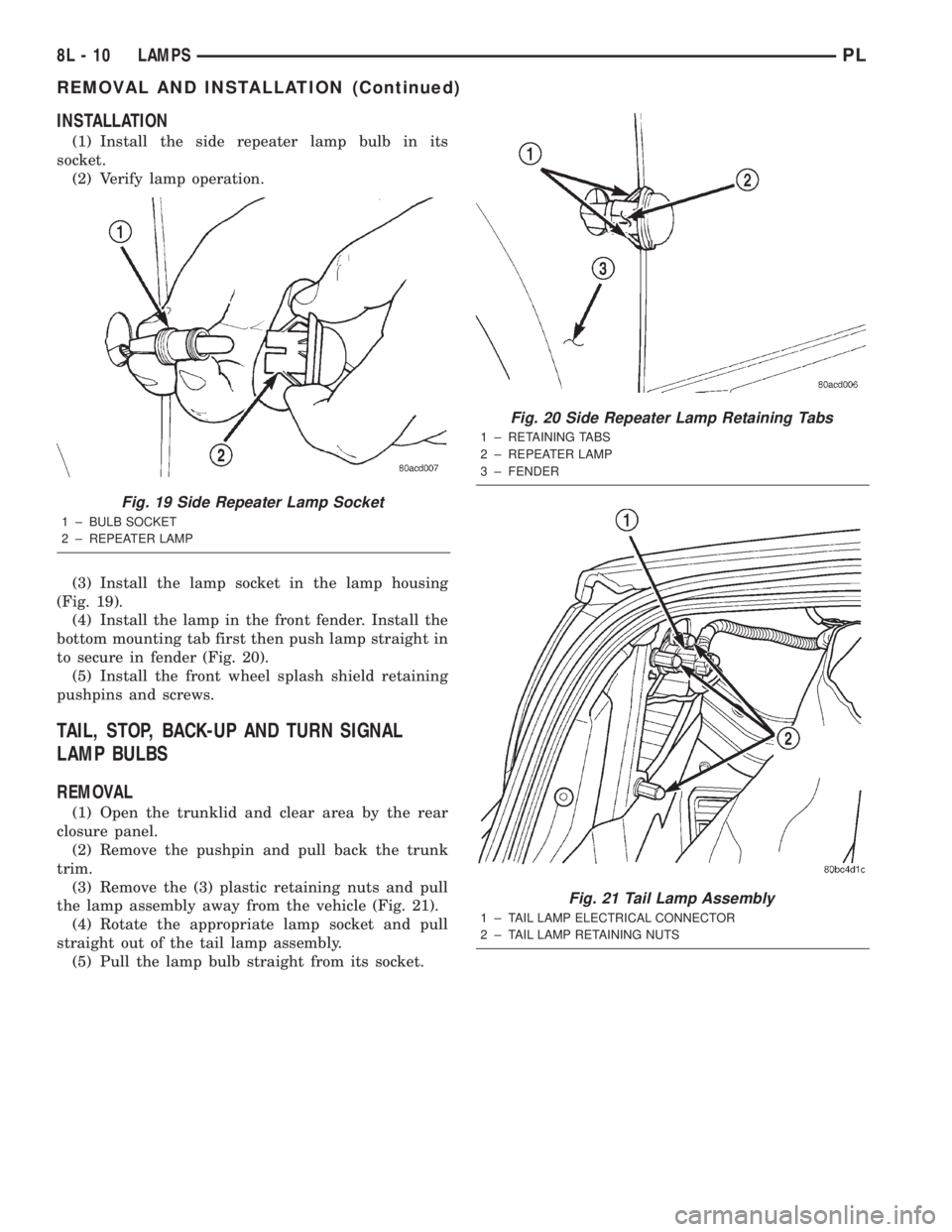

INSTALLATION

(1) Install the side repeater lamp bulb in its

socket.

(2) Verify lamp operation.

(3) Install the lamp socket in the lamp housing

(Fig. 19).

(4) Install the lamp in the front fender. Install the

bottom mounting tab first then push lamp straight in

to secure in fender (Fig. 20).

(5) Install the front wheel splash shield retaining

pushpins and screws.

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULBS

REMOVAL

(1) Open the trunklid and clear area by the rear

closure panel.

(2) Remove the pushpin and pull back the trunk

trim.

(3) Remove the (3) plastic retaining nuts and pull

the lamp assembly away from the vehicle (Fig. 21).

(4) Rotate the appropriate lamp socket and pull

straight out of the tail lamp assembly.

(5) Pull the lamp bulb straight from its socket.

Fig. 19 Side Repeater Lamp Socket

1 ± BULB SOCKET

2 ± REPEATER LAMP

Fig. 20 Side Repeater Lamp Retaining Tabs

1 ± RETAINING TABS

2 ± REPEATER LAMP

3 ± FENDER

Fig. 21 Tail Lamp Assembly

1 ± TAIL LAMP ELECTRICAL CONNECTOR

2 ± TAIL LAMP RETAINING NUTS

8L - 10 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 342 of 1285

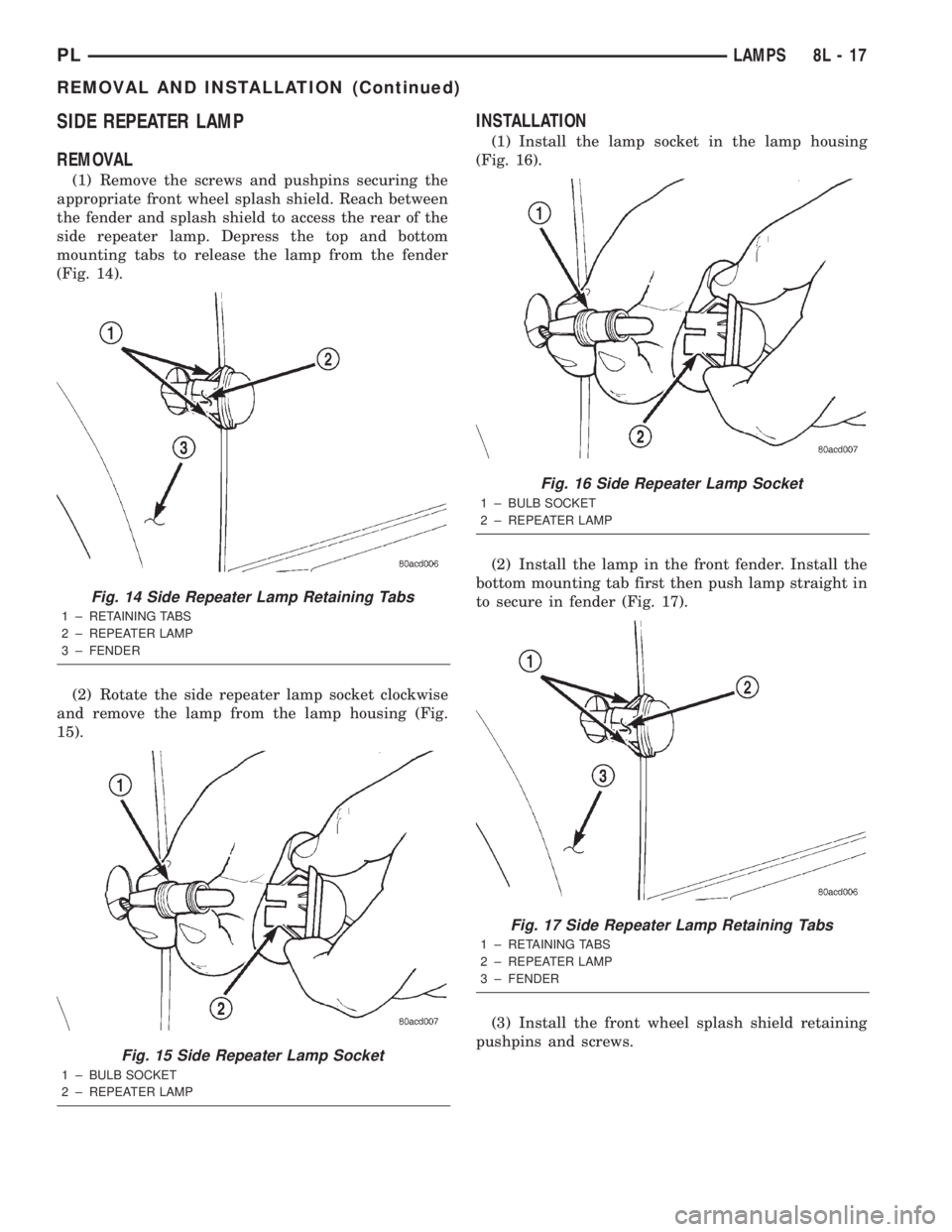

SIDE REPEATER LAMP

REMOVAL

(1) Remove the screws and pushpins securing the

appropriate front wheel splash shield. Reach between

the fender and splash shield to access the rear of the

side repeater lamp. Depress the top and bottom

mounting tabs to release the lamp from the fender

(Fig. 14).

(2) Rotate the side repeater lamp socket clockwise

and remove the lamp from the lamp housing (Fig.

15).

INSTALLATION

(1) Install the lamp socket in the lamp housing

(Fig. 16).

(2) Install the lamp in the front fender. Install the

bottom mounting tab first then push lamp straight in

to secure in fender (Fig. 17).

(3) Install the front wheel splash shield retaining

pushpins and screws.

Fig. 14 Side Repeater Lamp Retaining Tabs

1 ± RETAINING TABS

2 ± REPEATER LAMP

3 ± FENDER

Fig. 15 Side Repeater Lamp Socket

1 ± BULB SOCKET

2 ± REPEATER LAMP

Fig. 16 Side Repeater Lamp Socket

1 ± BULB SOCKET

2 ± REPEATER LAMP

Fig. 17 Side Repeater Lamp Retaining Tabs

1 ± RETAINING TABS

2 ± REPEATER LAMP

3 ± FENDER

PLLAMPS 8L - 17

REMOVAL AND INSTALLATION (Continued)

Page 346 of 1285

PASSIVE RESTRAINT SYSTEMS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS.............1

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)..........1

CLOCKSPRING...........................2

DRIVER and PASSENGER AIRBAG MODULE....2

DIAGNOSIS AND TESTING

AIRBAG SYSTEM.........................3

SERVICE PROCEDURES

CLEAN UP PROCEDURE....................3HANDLING AIRBAG MODULES..............4

MAINTENANCE INSPECTION................4

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE (ACM)..........4

CLOCKSPRING...........................5

DRIVER AIRBAG MODULE..................6

PASSENGER AIRBAG MODULE..............7

STEERING WHEEL........................8

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE......9

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR ONE MINUTE BEFORE REMOVING AIRBAG

COMPONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIRBAG

FACE DOWN ON A SOLID SURFACE, THE AIRBAG

WILL PROPEL INTO THE AIR IF ACCIDENTALLY

DEPLOYED AND COULD RESULT IN PERSONAL

INJURY. WHEN CARRYING OR HANDLING AN UNDE-

PLOYED AIRBAG MODULE, THE TRIM SIDE OF THE

AIRBAG SHOULD BE POINTING AWAY FROM THE

BODY TO MINIMIZE POSSIBILITY OF INJURY IF ACCI-

DENTAL DEPLOYMENT OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES,

AND LONG SLEEVES CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDER

RESIDUE EMITTED FROM A DEPLOYED AIRBAG

CAN CAUSE SKIN IRRITATION. FLUSH AFFECTEDAREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS,

SCREWS AND BOLTS USED TO FASTEN AIRBAG

COMPONENTS HAVE A SPECIAL COATING AND

ARE SPECIFICALLY DESIGNED FOR THE AIRBAG

SYSTEM. DO NOT USE SUBSTITUTE FASTENERS,

USE ONLY ORIGINAL EQUIPMENT FASTENERS

LISTED IN THE PARTS CATALOG WHEN FASTENER

REPLACEMENT IS REQUIRED.

NOTE: Airbags should be stored in a cool dry loca-

tion away from excessive heat and static electrical

activity with the fabric airbag facing UP, or a prema-

ture deployment can result.

If the Driver/Passenger Airbag Module is defective

and not deployed, refer to DaimlerChrysler Corpora-

tion current return list for proper handling proce-

dures.

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)

The Airbag Control Module (ACM) contains the

sensing element, safing sensor, and energy reserve

capacitor. The module is mounted on the tunnel/floor

pan between the gear shift lever and the park brake

PLPASSIVE RESTRAINT SYSTEMS 8M - 1