gasket DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 725 of 1285

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4 oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

ENGINE GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

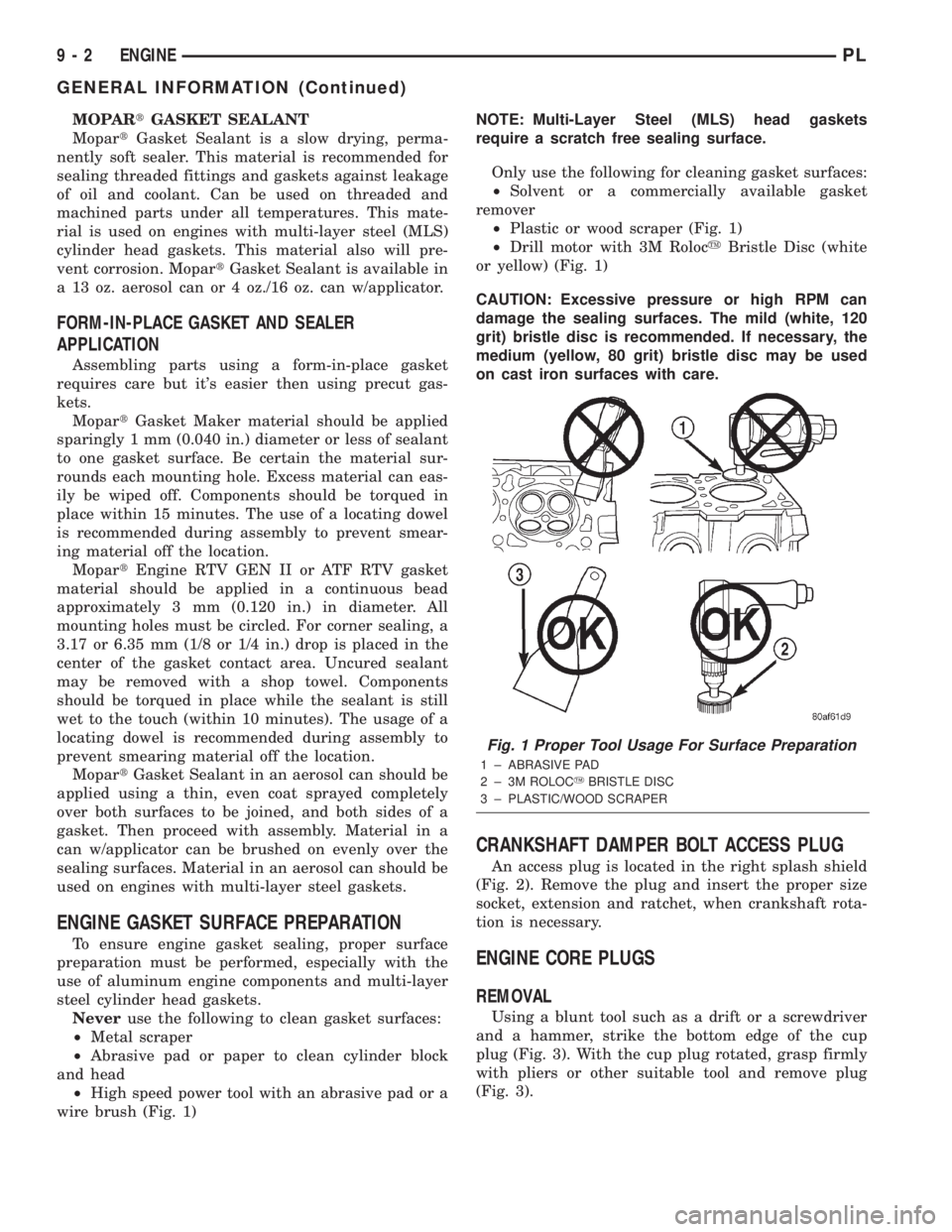

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 1)NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 1)

²Drill motor with 3M RolocyBristle Disc (white

or yellow) (Fig. 1)

CAUTION: Excessive pressure or high RPM can

damage the sealing surfaces. The mild (white, 120

grit) bristle disc is recommended. If necessary, the

medium (yellow, 80 grit) bristle disc may be used

on cast iron surfaces with care.

CRANKSHAFT DAMPER BOLT ACCESS PLUG

An access plug is located in the right splash shield

(Fig. 2). Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 3). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 3).

Fig. 1 Proper Tool Usage For Surface Preparation

1 ± ABRASIVE PAD

2 ± 3M ROLOCYBRISTLE DISC

3 ± PLASTIC/WOOD SCRAPER

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 730 of 1285

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

SAE 5W-30 engine oil is preferred. Select an engine

oil that is best suited to your particular temperature

range and variation (Fig. 9).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of the engine oil

container.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 10).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Group 0, Lubrication and Mainte-

nance.TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Group 0, Lubrication and Maintenance for

Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

Fig. 9 Temperature/Engine Oil Viscosity

Fig. 10 Engine Oil Container Standard Notations

PLENGINE 9 - 7

GENERAL INFORMATION (Continued)

Page 731 of 1285

ENGINE DIAGNOSIS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

GENERAL INFORMATION...................8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS......8

CYLINDER COMPRESSION PRESSURE TEST . . . 8

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.........................9LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS............................9

ENGINE OIL LEAK INSPECTION..............9

ENGINE DIAGNOSISÐPERFORMANCE........11

ENGINE DIAGNOSISÐMECHANICAL.........12

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689 kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

9 - 8 ENGINEPL

Page 734 of 1285

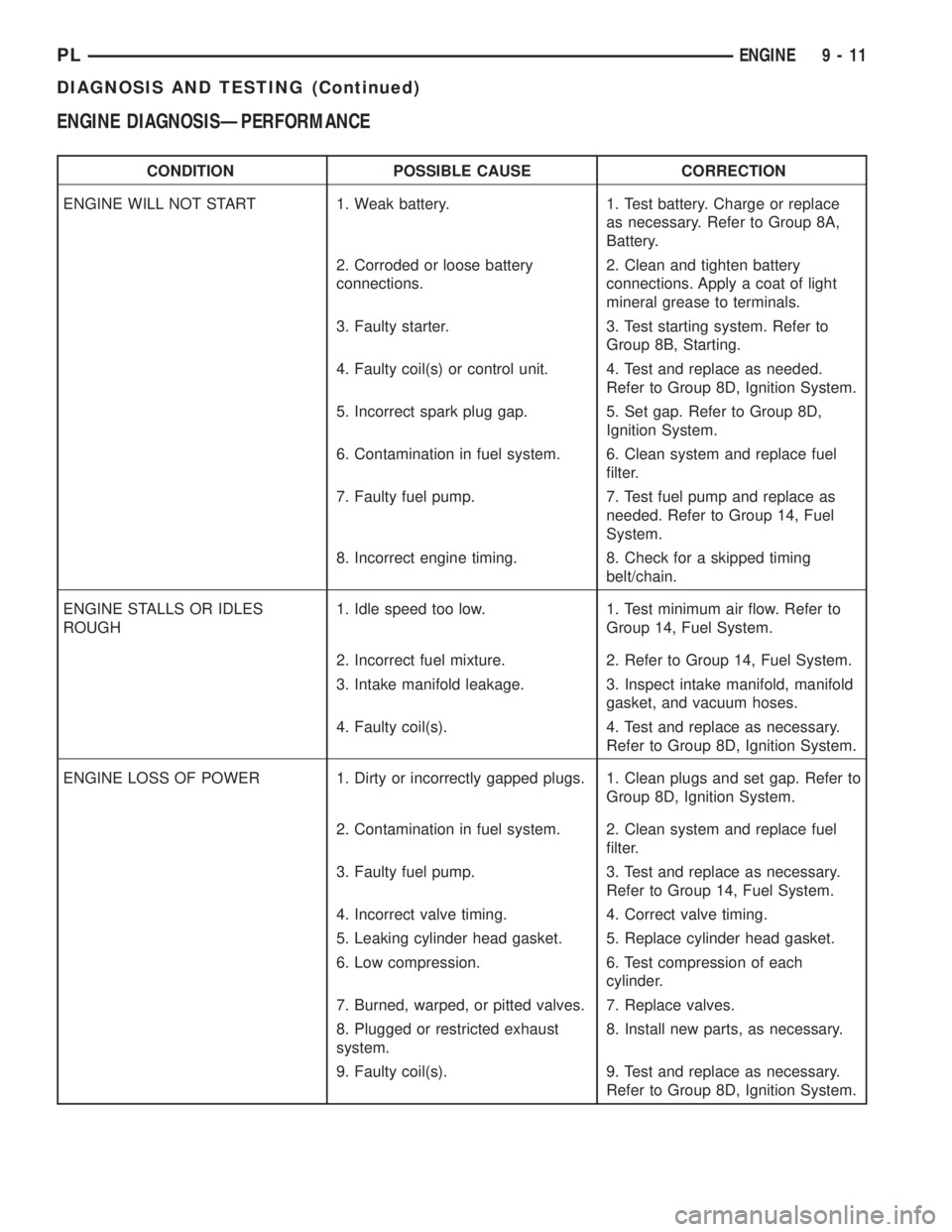

ENGINE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery. 1. Test battery. Charge or replace

as necessary. Refer to Group 8A,

Battery.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Faulty starter. 3. Test starting system. Refer to

Group 8B, Starting.

4. Faulty coil(s) or control unit. 4. Test and replace as needed.

Refer to Group 8D, Ignition System.

5. Incorrect spark plug gap. 5. Set gap. Refer to Group 8D,

Ignition System.

6. Contamination in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as

needed. Refer to Group 14, Fuel

System.

8. Incorrect engine timing. 8. Check for a skipped timing

belt/chain.

ENGINE STALLS OR IDLES

ROUGH1. Idle speed too low. 1. Test minimum air flow. Refer to

Group 14, Fuel System.

2. Incorrect fuel mixture. 2. Refer to Group 14, Fuel System.

3. Intake manifold leakage. 3. Inspect intake manifold, manifold

gasket, and vacuum hoses.

4. Faulty coil(s). 4. Test and replace as necessary.

Refer to Group 8D, Ignition System.

ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped plugs. 1. Clean plugs and set gap. Refer to

Group 8D, Ignition System.

2. Contamination in fuel system. 2. Clean system and replace fuel

filter.

3. Faulty fuel pump. 3. Test and replace as necessary.

Refer to Group 14, Fuel System.

4. Incorrect valve timing. 4. Correct valve timing.

5. Leaking cylinder head gasket. 5. Replace cylinder head gasket.

6. Low compression. 6. Test compression of each

cylinder.

7. Burned, warped, or pitted valves. 7. Replace valves.

8. Plugged or restricted exhaust

system.8. Install new parts, as necessary.

9. Faulty coil(s). 9. Test and replace as necessary.

Refer to Group 8D, Ignition System.

PLENGINE 9 - 11

DIAGNOSIS AND TESTING (Continued)

Page 736 of 1285

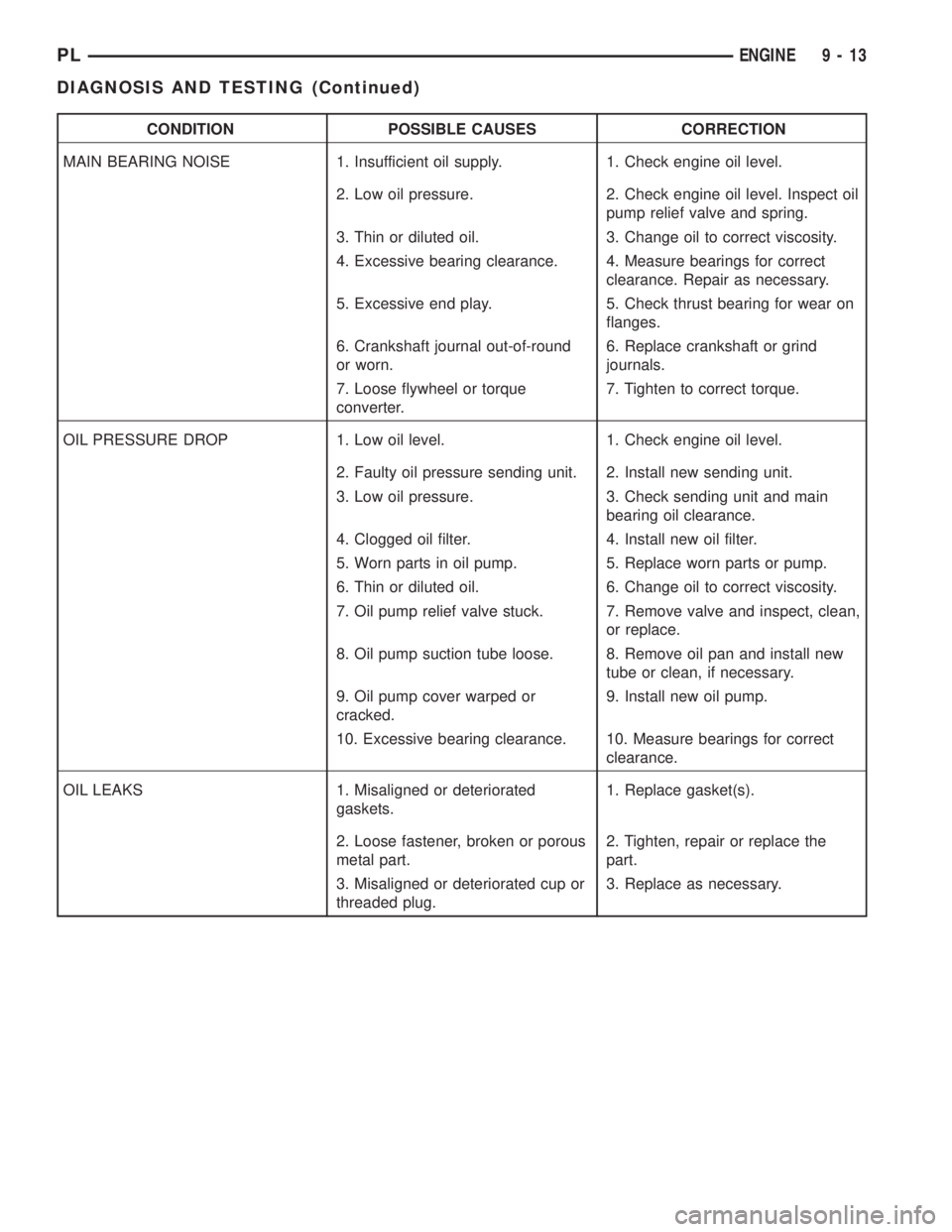

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round

or worn.6. Replace crankshaft or grind

journals.

7. Loose flywheel or torque

converter.7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

PLENGINE 9 - 13

DIAGNOSIS AND TESTING (Continued)

Page 739 of 1285

CRANKSHAFT

A nodular cast iron crankshaft is used. The engine

has five main bearings. The number three main is

flanged to control thrust. The mains and connecting

rod journals have undercut fillet radiuses that are

deep rolled for added strength. To optimize bearing

loading, eight counterweights are used. Hydrody-

namic seals provide end sealing, where the crank-

shaft exits the block. Anaerobic gasket material is

used for parting line sealing. A sintered iron timing

belt sprocket is mounted on the crankshaft nose. This

sprocket transmits crankshaft movement, via timing

belt to the camshaft sprocket providing timed valve

actuation.

PISTONS

The engineDOES NOThave provision for a free

wheeling valve train. Non free wheeling valve train

means, in the event of a broken timing belt pistons

will contact the valves. The engine uses pressed-in

piston pins to attach forged powdered metal connect-

ing rods. The connecting rods are a cracked cap

design and are not repairable. Hex head cap screw

are used to provide alignment and durability in the

assembly. Pistons and connecting rods are serviced as

an assembly.

PISTON RINGS

The piston rings include a molybdenum faced top

ring for reliable compression sealing and a taper

faced intermediate ring for additional cylinder pres-

sure control. Oil Control Ring Package consist of two

steel rails and an expander spacer.

CYLINDER HEAD

The aluminum cylinder head features a Single

Over Head Camshaft (SOHC), four-valves per cylin-

der, cross flow design. The valves are arranged in

two inline banks, with the two intake per cylinder

facing toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFT

The nodular iron camshaft has five bearing jour-

nals and three cam lobes per cylinder. Provision for a

cam position sensor is provided on the camshaft at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVES

Four valves per cylinder are actuated by roller

rocker arms/hydraulic lash adjusters assemblies

which pivot on rocker arm shafts. All valves have

chrome plated valve stems. Viton rubber valve stem

seals are integral with spring seats. Valve springs,

spring retainers, and locks are conventional design.

INTAKE MANIFOLD

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with five fasten-

ers. This long branch design enhances low and mid-

range torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit the manifold into an articulated joint connection

and exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure in this section.

9 - 16 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 740 of 1285

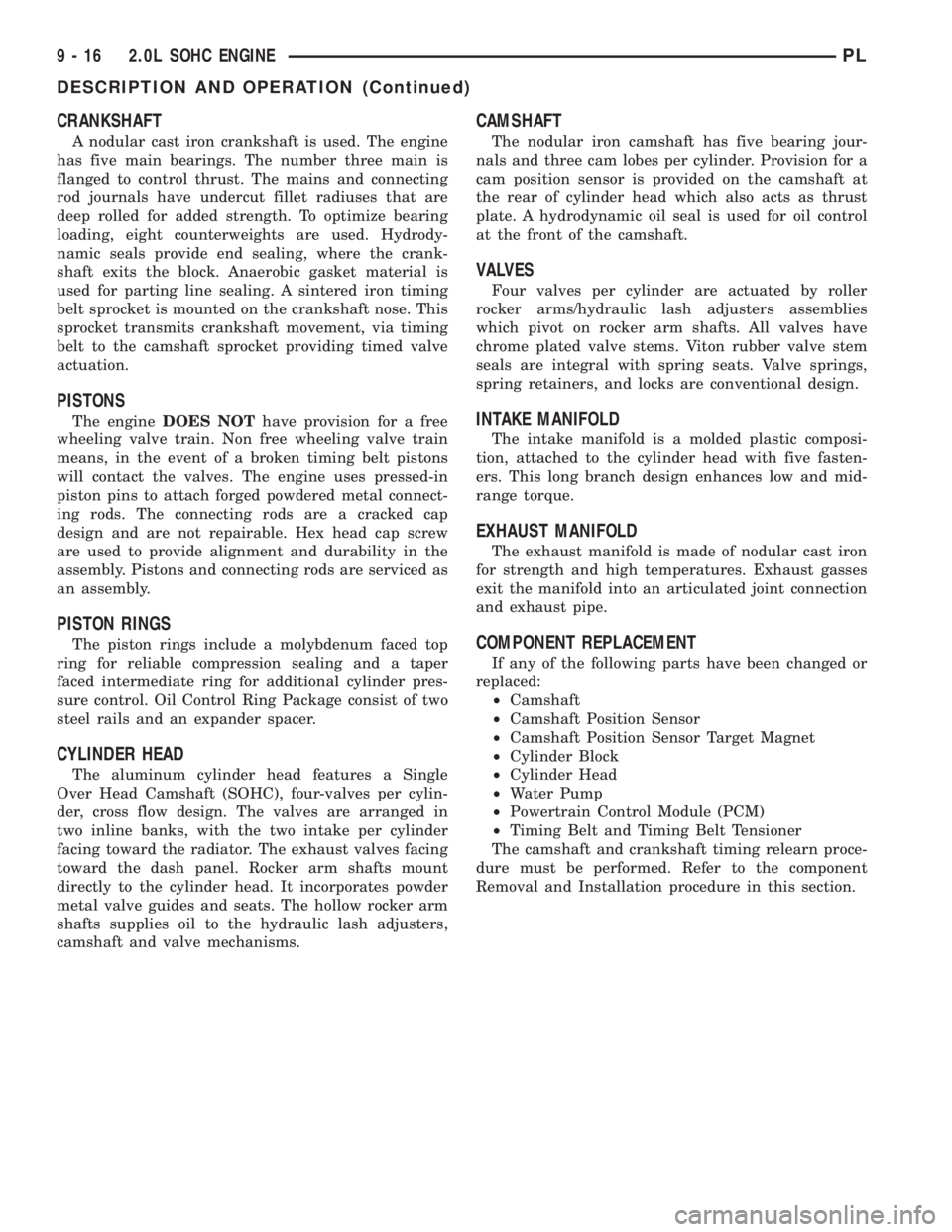

ENGINE LUBRICATION SYSTEM

ENGINE LUBRICATION

Refer to Group 0, Lubrication and Maintenance for

recommended oil capacity to be used in various

engine application. System is full flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

Pressurized oil is then routed through the main oil

gallery, running the length of the cylinder block, sup-

plying main and rod bearings with further routing.

Rod bearing oil throw-off lubricates the pistons from

directed slots on the side of the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full-flow fil-

ter to the main oil gallery running the length of the

cylinder block. A cylinder head restrictor, integral to

the cylinder head gasket, provides increased oil flow

to the main oil gallery (Fig. 2).

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

Engine Lubrication Components

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

PL2.0L SOHC ENGINE 9 - 17

DESCRIPTION AND OPERATION (Continued)

Page 751 of 1285

(27) Start engine and run until operating temper-

ature is reached.

(28) Ensure engine is properly positioned. Refer to

Torque Struts in this section for adjustment proce-

dure.

(29) Adjust transmission linkage, if necessary.

INTAKE MANIFOLD

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove the inlet air duct from intake manifold

to throttle body.

(3) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System for procedures.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSE TO CATCH ANY GASOLINE SPILLAGE

(4) Disconnect fuel supply line quick connect at the

fuel tube assembly. Refer to Group 14, Fuel System

for procedures.

(5) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

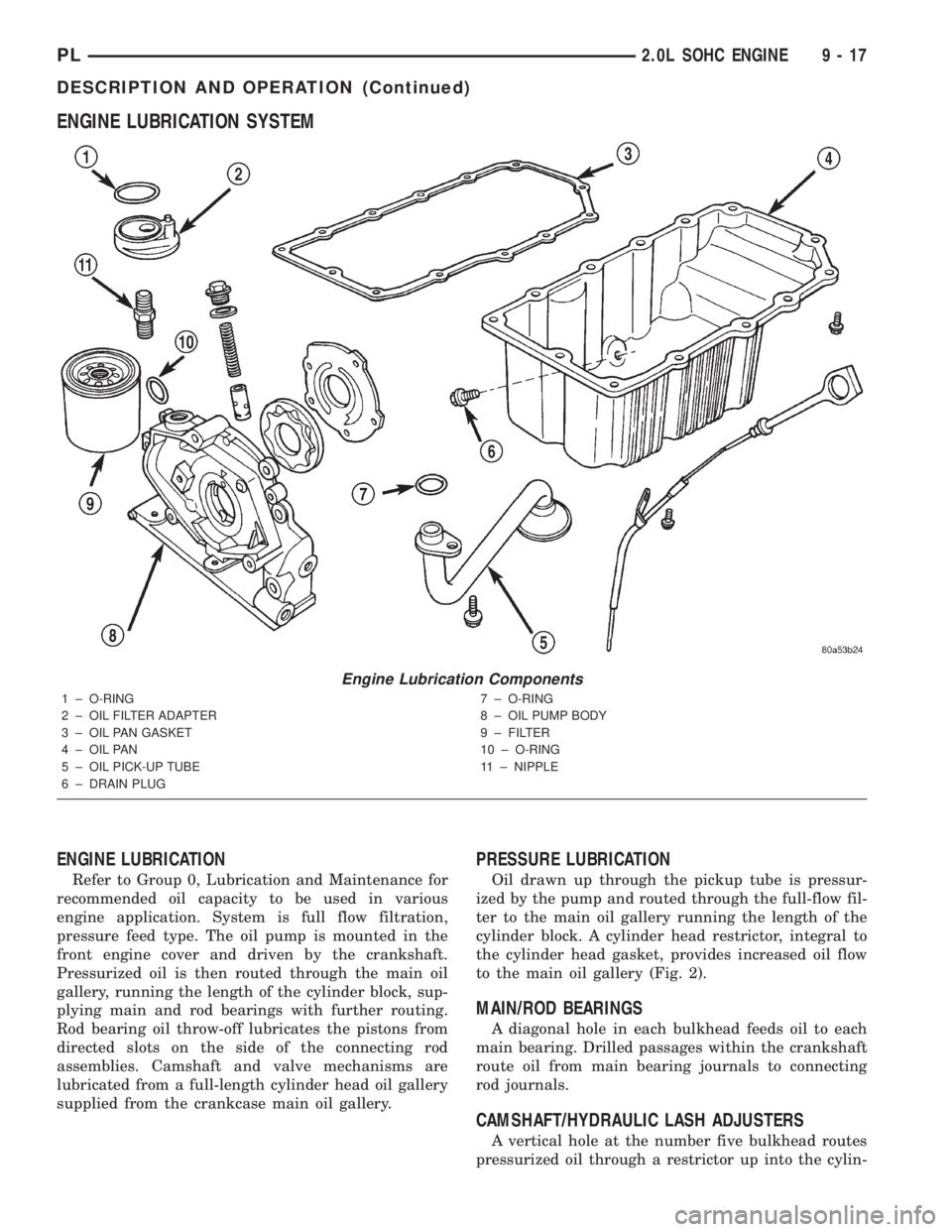

(6) Disconnect brake booster hose (Fig. 27) and

PCV hose (Fig. 28) from intake manifold.

(7) Disconnect Manifold Absolute Pressure (MAP)

sensor electrical connector (Fig. 29).

(8) Disconnect knock sensor electrical connector

(Fig. 30).

(9) Disconnect wiring at starter.

(10) Remove the intake manifold to lower support

bracket bolts (Fig. 31).

(11) Remove intake manifold screws and washers.

Discard the fasteners. Remove intake manifold.

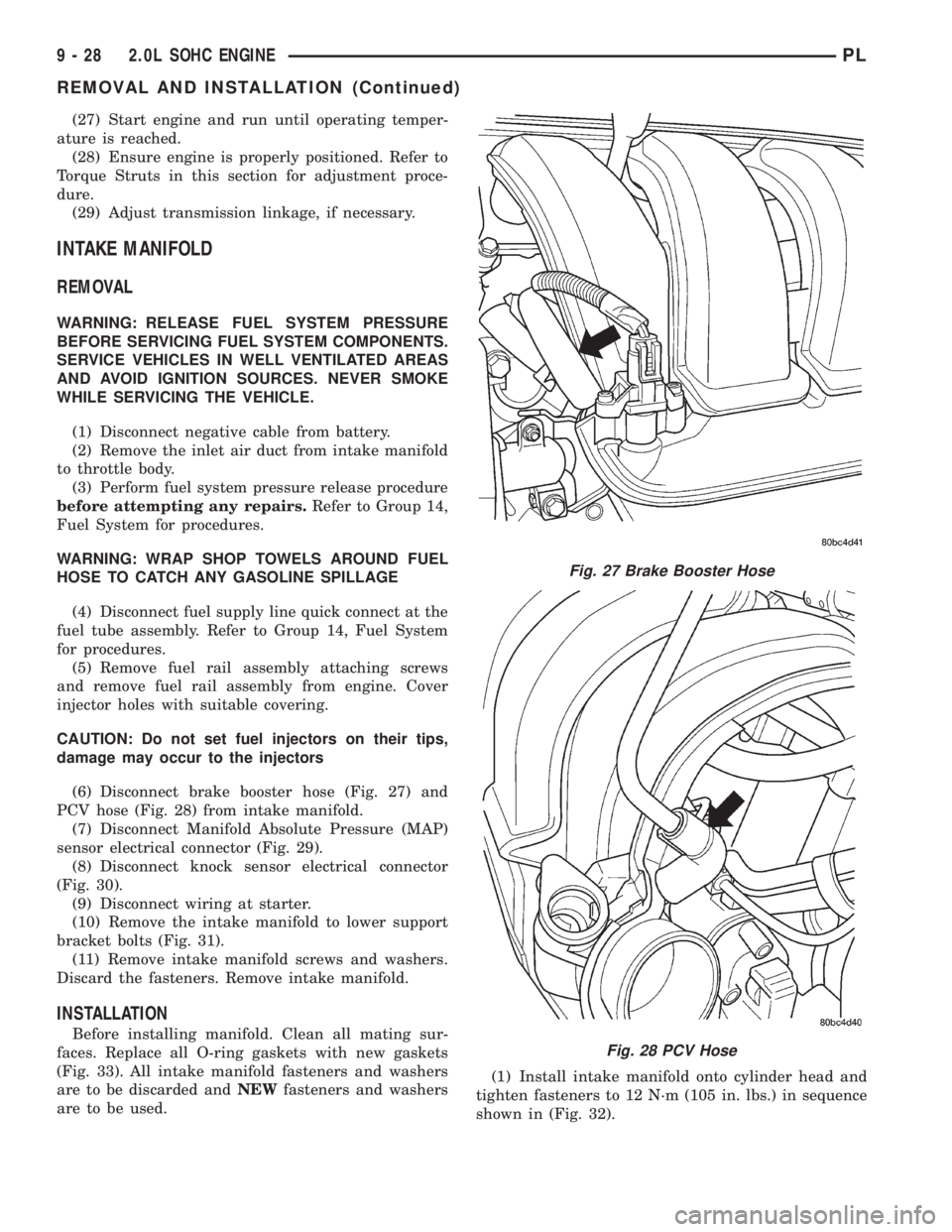

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all O-ring gaskets with new gaskets

(Fig. 33). All intake manifold fasteners and washers

are to be discarded andNEWfasteners and washers

are to be used.(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 32).

Fig. 27 Brake Booster Hose

Fig. 28 PCV Hose

9 - 28 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 753 of 1285

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

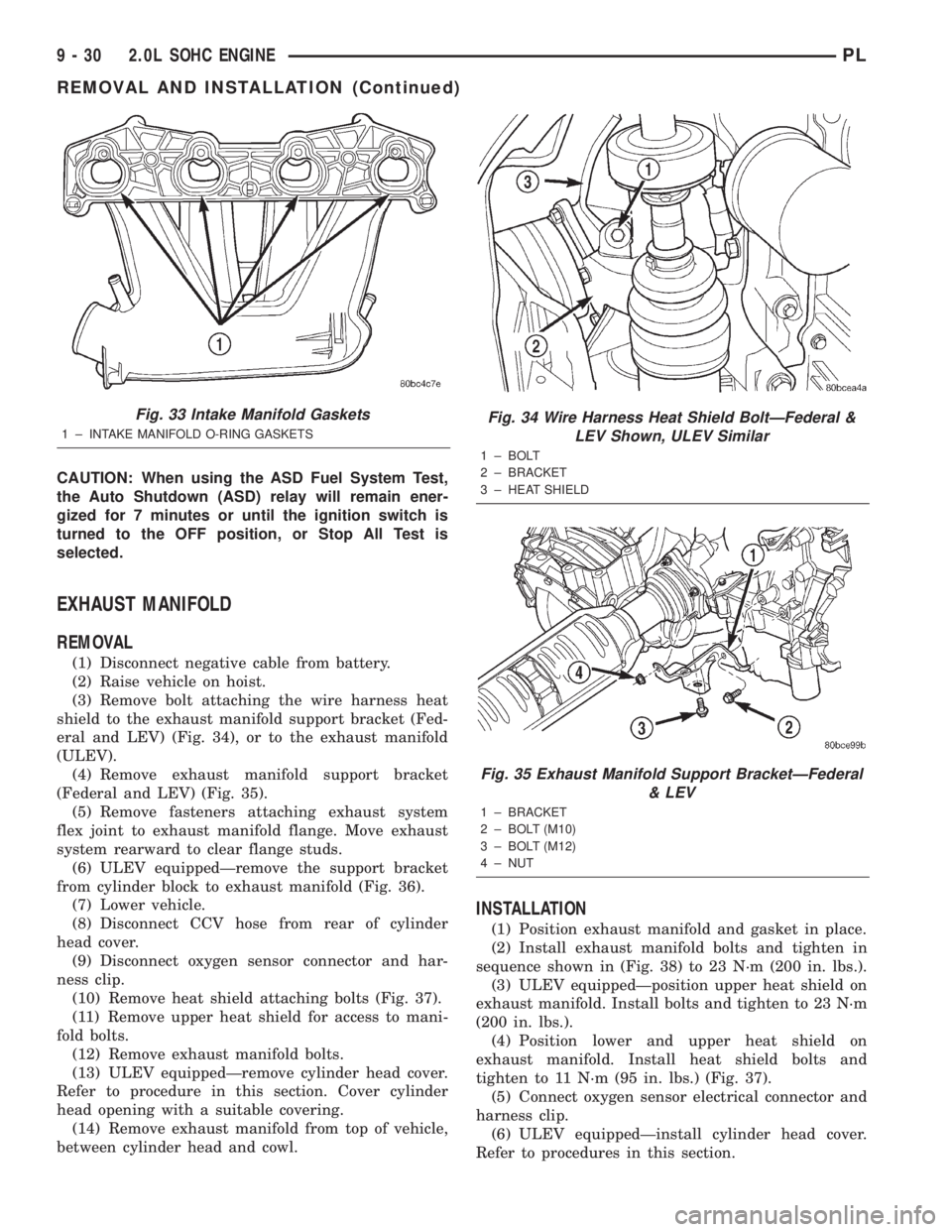

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove bolt attaching the wire harness heat

shield to the exhaust manifold support bracket (Fed-

eral and LEV) (Fig. 34), or to the exhaust manifold

(ULEV).

(4) Remove exhaust manifold support bracket

(Federal and LEV) (Fig. 35).

(5) Remove fasteners attaching exhaust system

flex joint to exhaust manifold flange. Move exhaust

system rearward to clear flange studs.

(6) ULEV equippedÐremove the support bracket

from cylinder block to exhaust manifold (Fig. 36).

(7) Lower vehicle.

(8) Disconnect CCV hose from rear of cylinder

head cover.

(9) Disconnect oxygen sensor connector and har-

ness clip.

(10) Remove heat shield attaching bolts (Fig. 37).

(11) Remove upper heat shield for access to mani-

fold bolts.

(12) Remove exhaust manifold bolts.

(13) ULEV equippedÐremove cylinder head cover.

Refer to procedure in this section. Cover cylinder

head opening with a suitable covering.

(14) Remove exhaust manifold from top of vehicle,

between cylinder head and cowl.

INSTALLATION

(1) Position exhaust manifold and gasket in place.

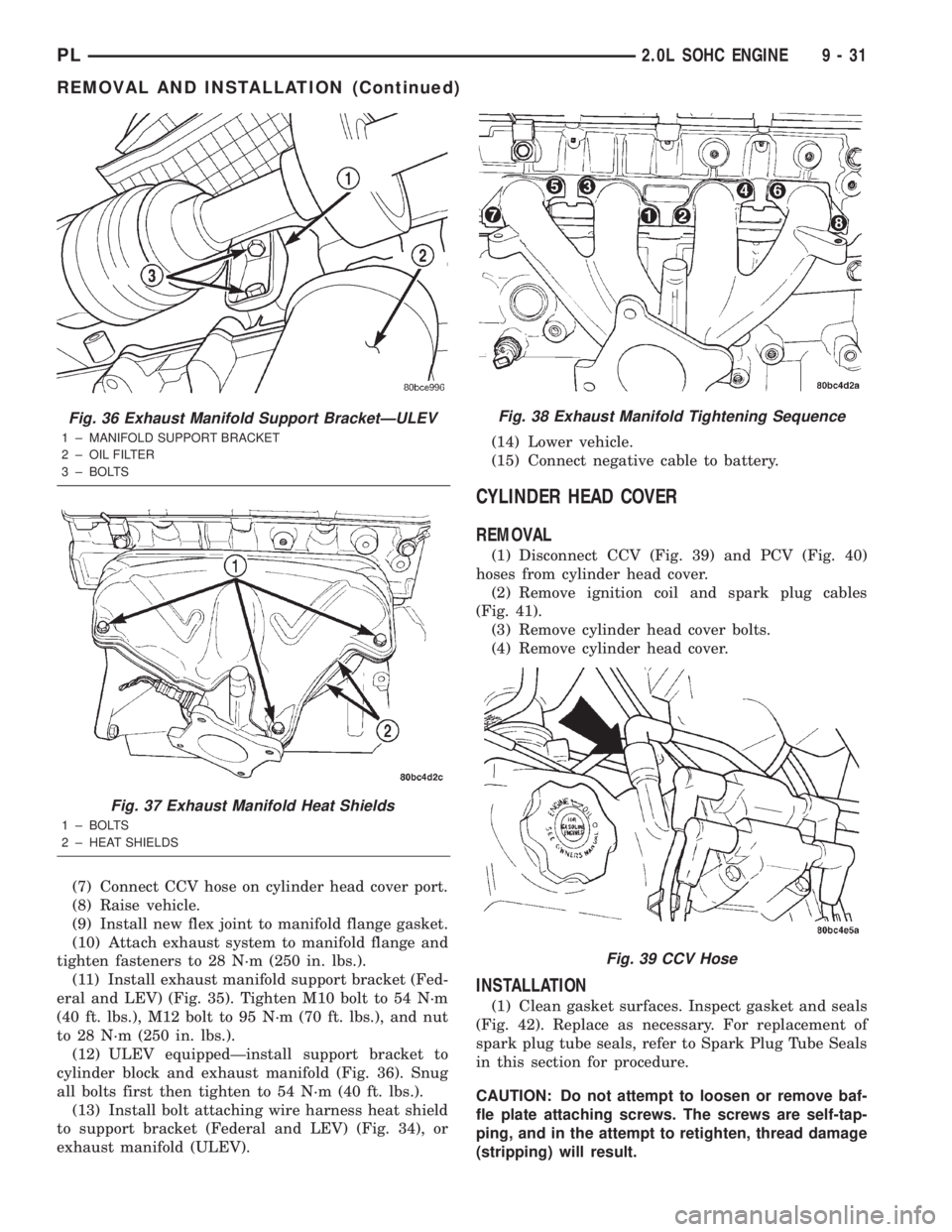

(2) Install exhaust manifold bolts and tighten in

sequence shown in (Fig. 38) to 23 N´m (200 in. lbs.).

(3) ULEV equippedÐposition upper heat shield on

exhaust manifold. Install bolts and tighten to 23 N´m

(200 in. lbs.).

(4) Position lower and upper heat shield on

exhaust manifold. Install heat shield bolts and

tighten to 11 N´m (95 in. lbs.) (Fig. 37).

(5) Connect oxygen sensor electrical connector and

harness clip.

(6) ULEV equippedÐinstall cylinder head cover.

Refer to procedures in this section.

Fig. 33 Intake Manifold Gaskets

1 ± INTAKE MANIFOLD O-RING GASKETS

Fig. 34 Wire Harness Heat Shield BoltÐFederal &

LEV Shown, ULEV Similar

1 ± BOLT

2 ± BRACKET

3 ± HEAT SHIELD

Fig. 35 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

9 - 30 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 754 of 1285

(7) Connect CCV hose on cylinder head cover port.

(8) Raise vehicle.

(9) Install new flex joint to manifold flange gasket.

(10) Attach exhaust system to manifold flange and

tighten fasteners to 28 N´m (250 in. lbs.).

(11) Install exhaust manifold support bracket (Fed-

eral and LEV) (Fig. 35). Tighten M10 bolt to 54 N´m

(40 ft. lbs.), M12 bolt to 95 N´m (70 ft. lbs.), and nut

to 28 N´m (250 in. lbs.).

(12) ULEV equippedÐinstall support bracket to

cylinder block and exhaust manifold (Fig. 36). Snug

all bolts first then tighten to 54 N´m (40 ft. lbs.).

(13) Install bolt attaching wire harness heat shield

to support bracket (Federal and LEV) (Fig. 34), or

exhaust manifold (ULEV).(14) Lower vehicle.

(15) Connect negative cable to battery.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect CCV (Fig. 39) and PCV (Fig. 40)

hoses from cylinder head cover.

(2) Remove ignition coil and spark plug cables

(Fig. 41).

(3) Remove cylinder head cover bolts.

(4) Remove cylinder head cover.

INSTALLATION

(1) Clean gasket surfaces. Inspect gasket and seals

(Fig. 42). Replace as necessary. For replacement of

spark plug tube seals, refer to Spark Plug Tube Seals

in this section for procedure.

CAUTION: Do not attempt to loosen or remove baf-

fle plate attaching screws. The screws are self-tap-

ping, and in the attempt to retighten, thread damage

(stripping) will result.

Fig. 36 Exhaust Manifold Support BracketÐULEV

1 ± MANIFOLD SUPPORT BRACKET

2 ± OIL FILTER

3 ± BOLTS

Fig. 37 Exhaust Manifold Heat Shields

1 ± BOLTS

2 ± HEAT SHIELDS

Fig. 38 Exhaust Manifold Tightening Sequence

Fig. 39 CCV Hose

PL2.0L SOHC ENGINE 9 - 31

REMOVAL AND INSTALLATION (Continued)