heating DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(33) Remove the upper engine torque strut.

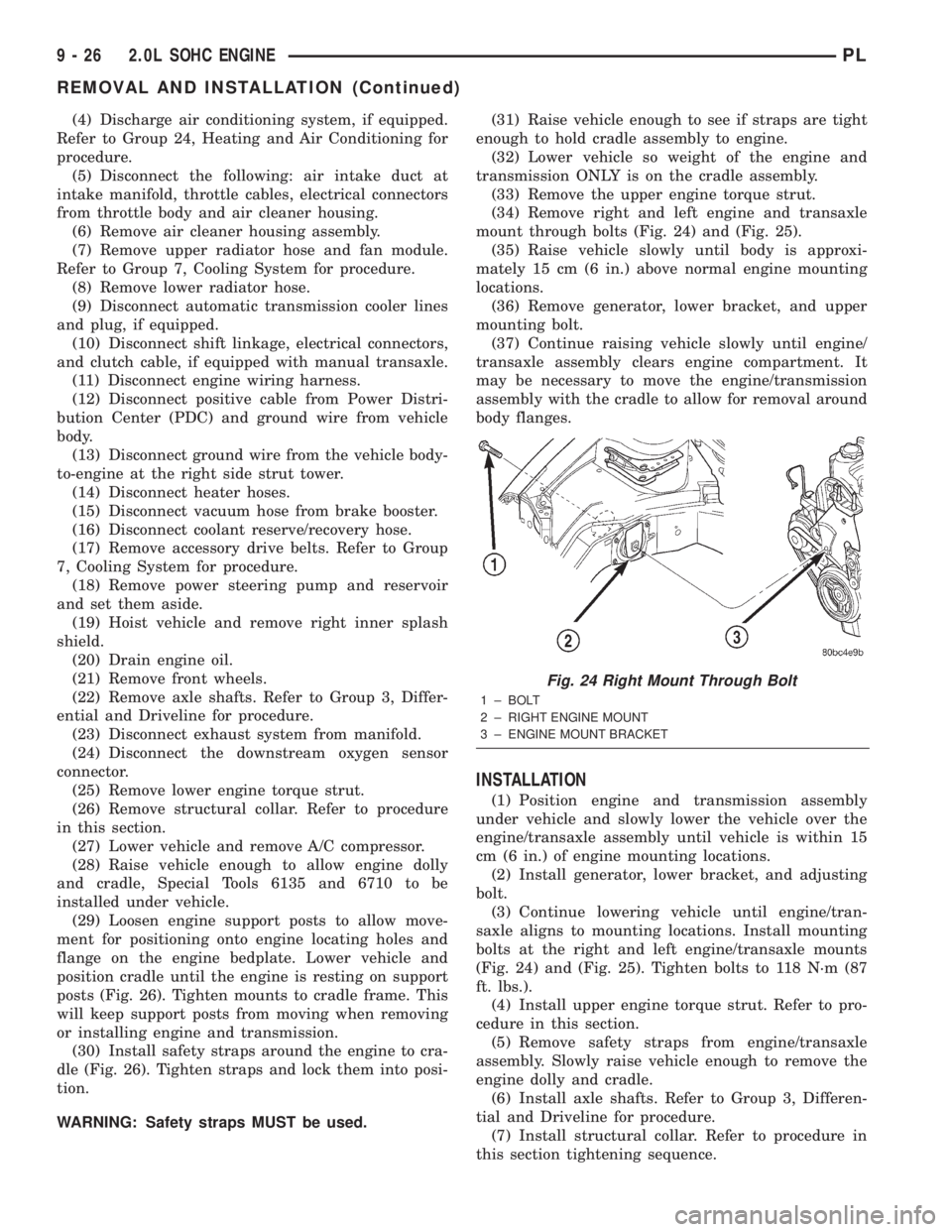

(34) Remove right and left engine and transaxle

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 845 of 1285

²All inputs monitored for proper voltage range.

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in response to MAP

sensor feedback.

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

SYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information see On-Board Diagnostics.

POWER DISTRIBUTION CENTER

The Power Distribution Center (PDC) is located

next to the battery (Fig. 1). The PDC contains the

starter relay, radiator fan relay, A/C compressor

clutch relay, auto shutdown relay, fuel pump relay

and several fuses.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various

engine and vehicle operations through devices that

are referred to as PCM Outputs.

PCM Inputs:

14 - 24 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 847 of 1285

²Coolant temperature

²Engine speed (crankshaft position sensor)

²Engine run time

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²Transmission gear selection (park/neutral

switch)

²Vehicle distance (speed)

The Auto Shutdown (ASD) and fuel pump relays

are mounted externally, but turned on and off by the

PCM.

The crankshaft position sensor signal is sent to the

PCM. If the PCM does not receive the signal within

approximately one second of engine cranking, it deac-

tivates the ASD relay and fuel pump relay. When

these relays deactivate, power is shut off from the

fuel injectors, ignition coils, heating element in the

oxygen sensors and the fuel pump.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8 volts direct

current to power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5 volt direct current supply for

the manifold absolute pressure sensor and throttle

position sensor.

PCM GROUND

OPERATION

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as three different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side of any relay, solenoid, ignition coil or injector.

The signal ground is used for any input that uses

sensor return for ground, and the ground side of any

internal processing component.

The SBEC III case is shielded to prevent RFI and

EMI. The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the case is also

grounded separately from the ground pins.

5 VOLT SUPPLYÐPCM OUTPUT

OPERATION

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Engine coolant temperature sensor

²Manifold absolute pressure sensor

²Throttle position sensor

²Linear EGR solenoid

8-VOLT SUPPLYÐPCM OUTPUT

OPERATION

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

FUEL CORRECTION or ADAPTIVE MEMORIES

DESCRIPTION

In Open Loop, the PCM changes pulse width with-

out feedback from the O2 Sensors. Once the engine

warms up to approximately 30 to 35É F, the PCM

goes into closed loopShort Term Correctionand

utilitzes feedback from the O2 Sensors. Closed loop

Long Term Adaptive Memoryis maintained above

170É to 190É F unless the PCM senses wide open

throttle. At that time the PCM returns to Open Loop

operation.

OPERATION

Short Term

The first fuel correction program that begins func-

tioning is the short term fuel correction. This system

corrects fuel delivery in direct proportion to the read-

ings from the Upstream O2 Sensor.

The PCM monitors the air/fuel ratio by using the

input voltage from the O2 Sensor. When the voltage

reaches its preset high or low limit, the PCM begins

to add or remove fuel until the sensor reaches its

switch point. The short term corrections then begin.

The PCM makes a series of quick changes in the

injector pulse-width until the O2 Sensor reaches its

opposite preset limit or switch point. The process

then repeats itself in the opposite direction.

Short term fuel correction will keep increasing or

decreasing injector pulse-width based upon the

upstream O2 Sensor input. The maximum range of

authority for short term memory is 25% (+/-) of base

pulse-width.

Long Term

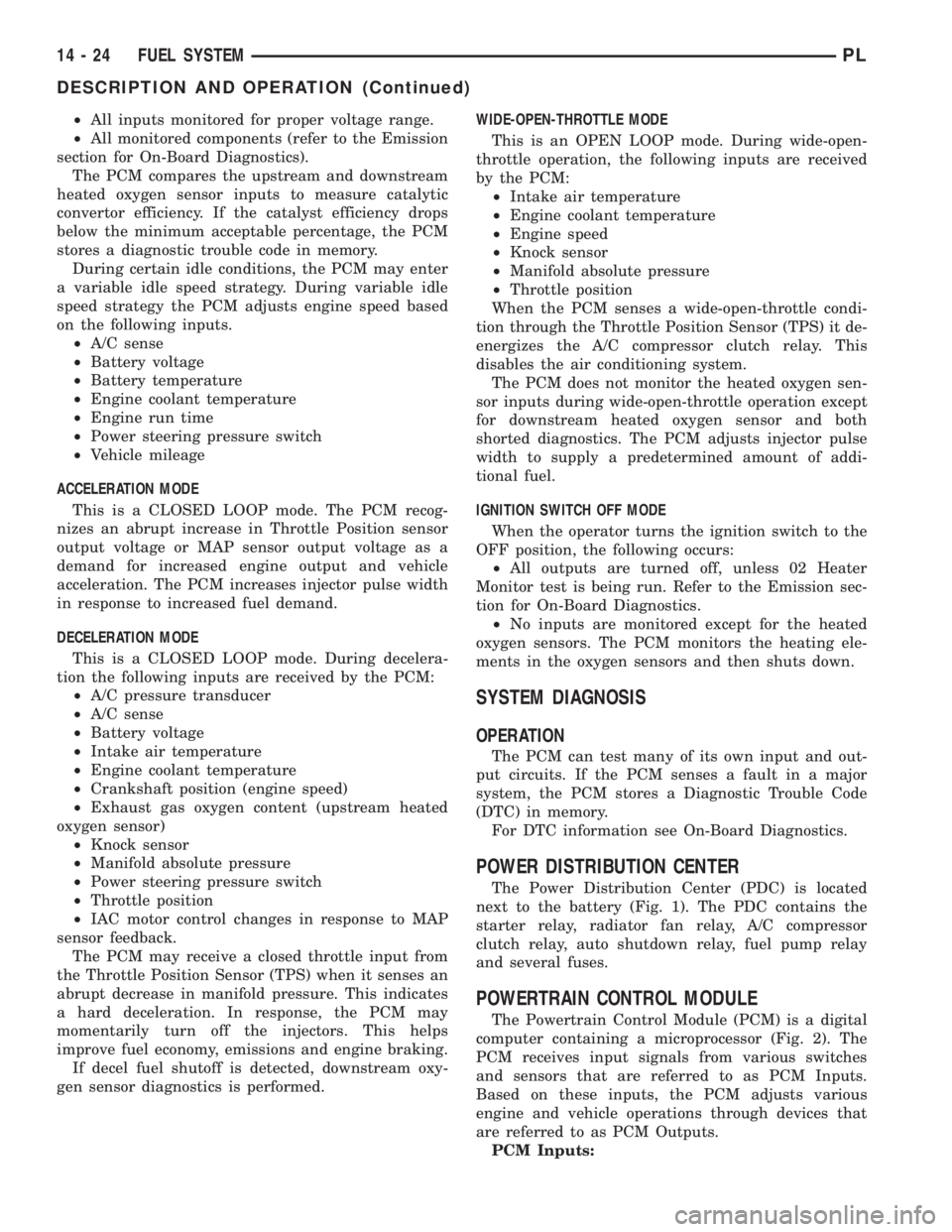

The second fuel correction program is the long

term adaptive memory. In order to maintain correct

emission throughout all operating ranges of the

engine, a cell structure based on engine rpm and load

(MAP) is used.

There are up to 16 cells. Two cells are used only

during idle, based upon TPS and Park/Neutral

switch inputs. There may be two other cells used for

deceleration, based on TPS, engine rpm, and vehicle

speed. The other twelve cells represent a manifold

pressure and an rpm range. Six of the cells are high

rpm and the other six are low rpm. Each of these

cells is a specific MAP voltage range.

14 - 26 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 848 of 1285

As the engine enters one of these cells the PCM

looks at the amount of short term correction being

used. Because the goal is to keep short term at 0 (O2

Sensor switching at 0.5 volt), long term will update

in the same direction as short term correction was

moving to bring the short term back to 0. Once short

term is back at 0, this long term correction factor is

stored in memory.

The values stored in long term adaptive memory

are used for all operating conditions, including open

loop. However, the updating of the long term memoryoccurs after the engine has exceeded approximately

17É F, with fuel control in closed loop and two min-

utes of engine run time. This is done to prevent any

transitional temperature or start-up compensations

from corrupting long term fuel correction.

Long term adaptive memory can change the pulse-

width by as much as 25%, which means it can correct

for all of short term. It is possible to have a problem

that would drive long term to 25% and short term to

another 25% for a total change of 50% away from

base pulse-width calculation.

TYPICAL ADAPTIVE MEMORY FUEL CELLS

Open

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

Throttle Idle Decel

Vacuum 20 17 13 9 5 0

Above 1,984

rpm1 3 5 7 9 11 13 Drive 15

Below 1,984

rpm02 4 6 8 1012

Neutral14

MAP volt =0 1.4 2.0 2.6 3.3 3.9

Fuel Correction Diagnostics

There are two fuel correction diagnostic routines:

²Fuel System Rich

²Fuel System Lean

A DTC is set and the MIL is illuminated if the

PCM detects either of these conditions.

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS

OPERATION

Various modules exchange information through a

communications port called the PCI Bus. The Power-

train Control Module (PCM) transmits the Malfunc-

tion Indicator Lamp (Check Engine) On/Off signal

and engine RPM on the PCI Bus. The PCM receives

the Air Conditioning select input, transaxle gear

position inputs over the PCI Bus. The PCM also

receives the air conditioning evaporator temperature

signal from the PCI Bus.

The following components access or send informa-

tion on the PCI Bus.

²Instrument Panel

²Body Control Module

²Air Bag System Diagnostic Module

²Full ATC Display Head

²ABS Module

²Transmission Control Module

²Powertrain Control Module

²Overhead Travel Module

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT

OPERATION

The Powertrain Control Module (PCM) monitors

the A/C compressor discharge (high side) pressure

through the air conditioning pressure transducer.

The transducer supplies an input to the PCM. The

PCM engages the A/C compressor clutch if pressure

is sufficient for A/C system operation.

AUTOMATIC SHUTDOWN (ASD) SENSEÐPCM

INPUT

OPERATION

The ASD sense circuit informs the PCM when the

ASD relay energizes. A 12 volt signal at this input

indicates to the PCM that the ASD has been acti-

vated. This input is used only to sense that the ASD

relay is energized.

When energized, the ASD relay supplies battery

voltage to the fuel injectors, ignition coils and the

heating element in each oxygen sensor. If the PCM

does not receive 12 volts from this input after

grounding the ASD relay, it sets a Diagnostic Trouble

Code (DTC).

PLFUEL SYSTEM 14 - 27

DESCRIPTION AND OPERATION (Continued)

Page 853 of 1285

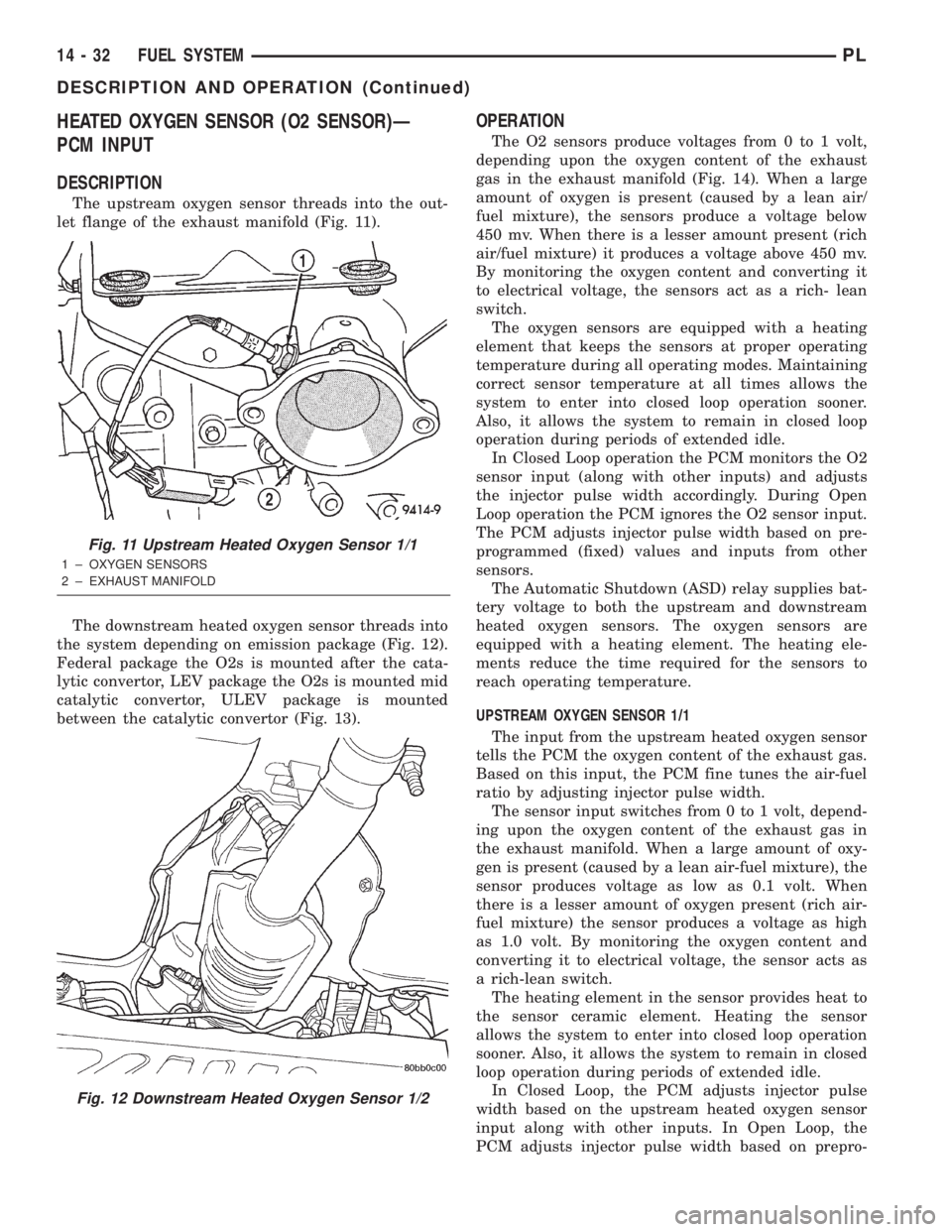

HEATED OXYGEN SENSOR (O2 SENSOR)Ð

PCM INPUT

DESCRIPTION

The upstream oxygen sensor threads into the out-

let flange of the exhaust manifold (Fig. 11).

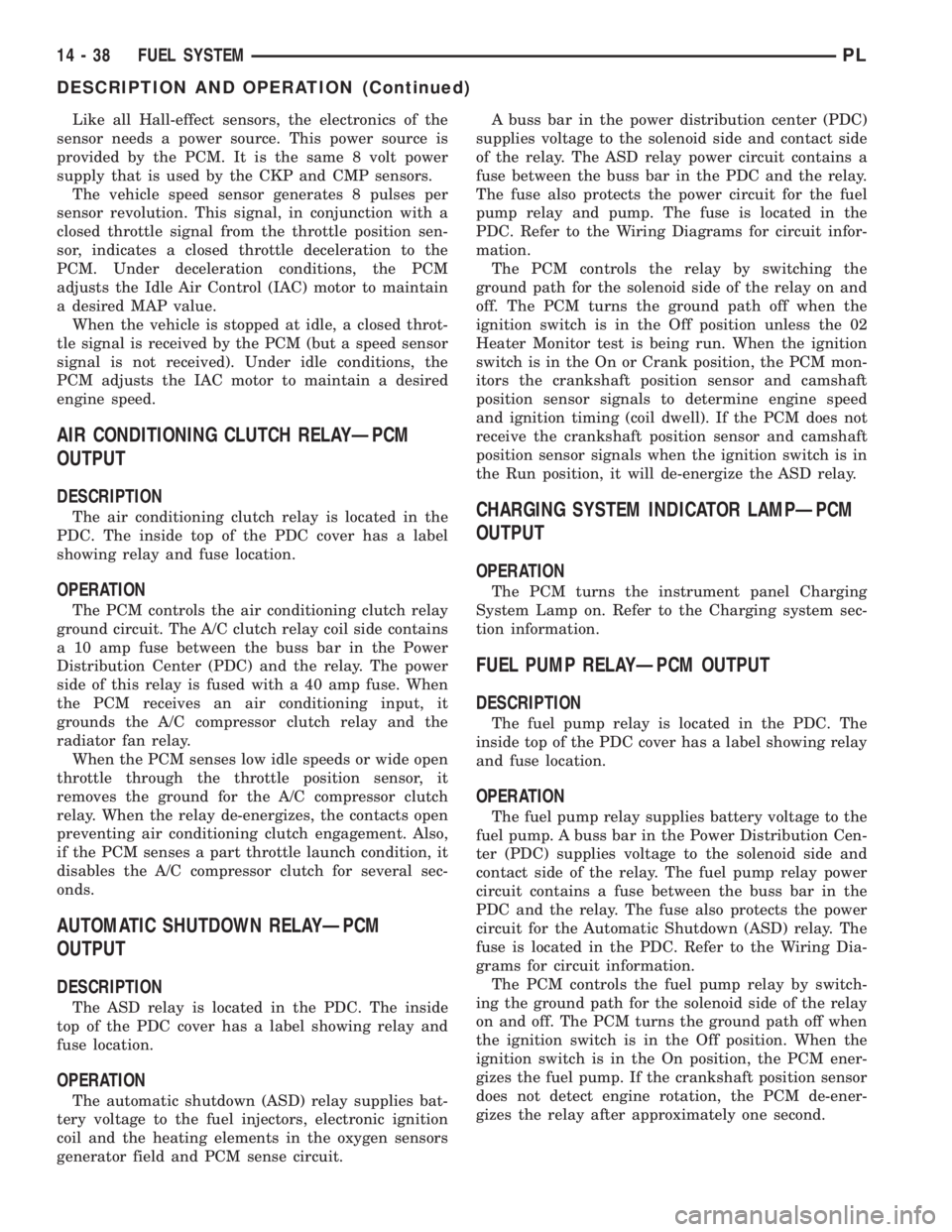

The downstream heated oxygen sensor threads into

the system depending on emission package (Fig. 12).

Federal package the O2s is mounted after the cata-

lytic convertor, LEV package the O2s is mounted mid

catalytic convertor, ULEV package is mounted

between the catalytic convertor (Fig. 13).

OPERATION

The O2 sensors produce voltages from 0 to 1 volt,

depending upon the oxygen content of the exhaust

gas in the exhaust manifold (Fig. 14). When a large

amount of oxygen is present (caused by a lean air/

fuel mixture), the sensors produce a voltage below

450 mv. When there is a lesser amount present (rich

air/fuel mixture) it produces a voltage above 450 mv.

By monitoring the oxygen content and converting it

to electrical voltage, the sensors act as a rich- lean

switch.

The oxygen sensors are equipped with a heating

element that keeps the sensors at proper operating

temperature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into closed loop operation sooner.

Also, it allows the system to remain in closed loop

operation during periods of extended idle.

In Closed Loop operation the PCM monitors the O2

sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During Open

Loop operation the PCM ignores the O2 sensor input.

The PCM adjusts injector pulse width based on pre-

programmed (fixed) values and inputs from other

sensors.

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to both the upstream and downstream

heated oxygen sensors. The oxygen sensors are

equipped with a heating element. The heating ele-

ments reduce the time required for the sensors to

reach operating temperature.

UPSTREAM OXYGEN SENSOR 1/1

The input from the upstream heated oxygen sensor

tells the PCM the oxygen content of the exhaust gas.

Based on this input, the PCM fine tunes the air-fuel

ratio by adjusting injector pulse width.

The sensor input switches from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold. When a large amount of oxy-

gen is present (caused by a lean air-fuel mixture), the

sensor produces voltage as low as 0.1 volt. When

there is a lesser amount of oxygen present (rich air-

fuel mixture) the sensor produces a voltage as high

as 1.0 volt. By monitoring the oxygen content and

converting it to electrical voltage, the sensor acts as

a rich-lean switch.

The heating element in the sensor provides heat to

the sensor ceramic element. Heating the sensor

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop, the PCM adjusts injector pulse

width based on the upstream heated oxygen sensor

input along with other inputs. In Open Loop, the

PCM adjusts injector pulse width based on prepro-

Fig. 11 Upstream Heated Oxygen Sensor 1/1

1 ± OXYGEN SENSORS

2 ± EXHAUST MANIFOLD

Fig. 12 Downstream Heated Oxygen Sensor 1/2

14 - 32 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 859 of 1285

Like all Hall-effect sensors, the electronics of the

sensor needs a power source. This power source is

provided by the PCM. It is the same 8 volt power

supply that is used by the CKP and CMP sensors.

The vehicle speed sensor generates 8 pulses per

sensor revolution. This signal, in conjunction with a

closed throttle signal from the throttle position sen-

sor, indicates a closed throttle deceleration to the

PCM. Under deceleration conditions, the PCM

adjusts the Idle Air Control (IAC) motor to maintain

a desired MAP value.

When the vehicle is stopped at idle, a closed throt-

tle signal is received by the PCM (but a speed sensor

signal is not received). Under idle conditions, the

PCM adjusts the IAC motor to maintain a desired

engine speed.

AIR CONDITIONING CLUTCH RELAYÐPCM

OUTPUT

DESCRIPTION

The air conditioning clutch relay is located in the

PDC. The inside top of the PDC cover has a label

showing relay and fuse location.

OPERATION

The PCM controls the air conditioning clutch relay

ground circuit. The A/C clutch relay coil side contains

a 10 amp fuse between the buss bar in the Power

Distribution Center (PDC) and the relay. The power

side of this relay is fused with a 40 amp fuse. When

the PCM receives an air conditioning input, it

grounds the A/C compressor clutch relay and the

radiator fan relay.

When the PCM senses low idle speeds or wide open

throttle through the throttle position sensor, it

removes the ground for the A/C compressor clutch

relay. When the relay de-energizes, the contacts open

preventing air conditioning clutch engagement. Also,

if the PCM senses a part throttle launch condition, it

disables the A/C compressor clutch for several sec-

onds.

AUTOMATIC SHUTDOWN RELAYÐPCM

OUTPUT

DESCRIPTION

The ASD relay is located in the PDC. The inside

top of the PDC cover has a label showing relay and

fuse location.

OPERATION

The automatic shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors

generator field and PCM sense circuit.A buss bar in the power distribution center (PDC)

supplies voltage to the solenoid side and contact side

of the relay. The ASD relay power circuit contains a

fuse between the buss bar in the PDC and the relay.

The fuse also protects the power circuit for the fuel

pump relay and pump. The fuse is located in the

PDC. Refer to the Wiring Diagrams for circuit infor-

mation.

The PCM controls the relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position unless the 02

Heater Monitor test is being run. When the ignition

switch is in the On or Crank position, the PCM mon-

itors the crankshaft position sensor and camshaft

position sensor signals to determine engine speed

and ignition timing (coil dwell). If the PCM does not

receive the crankshaft position sensor and camshaft

position sensor signals when the ignition switch is in

the Run position, it will de-energize the ASD relay.

CHARGING SYSTEM INDICATOR LAMPÐPCM

OUTPUT

OPERATION

The PCM turns the instrument panel Charging

System Lamp on. Refer to the Charging system sec-

tion information.

FUEL PUMP RELAYÐPCM OUTPUT

DESCRIPTION

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

OPERATION

The fuel pump relay supplies battery voltage to the

fuel pump. A buss bar in the Power Distribution Cen-

ter (PDC) supplies voltage to the solenoid side and

contact side of the relay. The fuel pump relay power

circuit contains a fuse between the buss bar in the

PDC and the relay. The fuse also protects the power

circuit for the Automatic Shutdown (ASD) relay. The

fuse is located in the PDC. Refer to the Wiring Dia-

grams for circuit information.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

14 - 38 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 968 of 1285

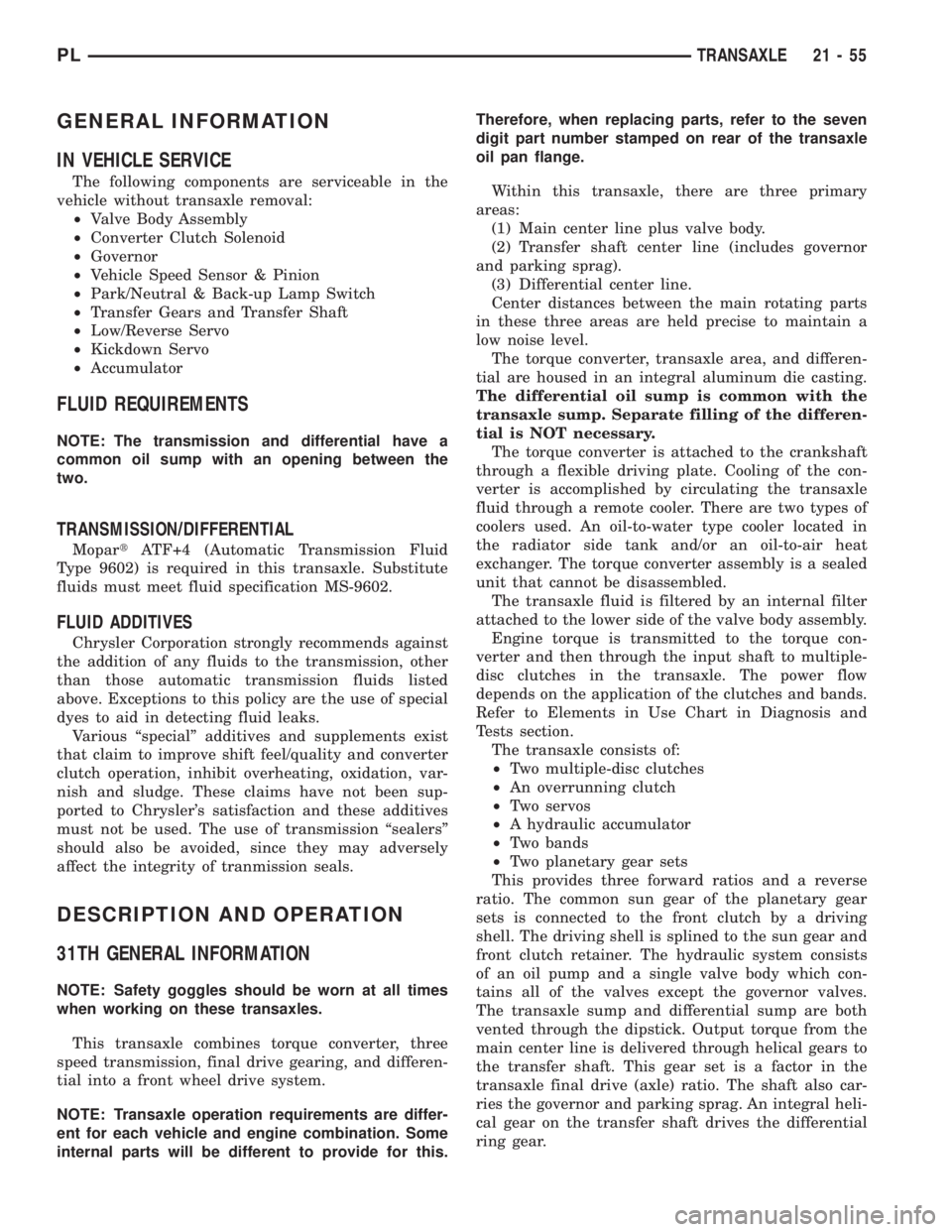

GENERAL INFORMATION

IN VEHICLE SERVICE

The following components are serviceable in the

vehicle without transaxle removal:

²Valve Body Assembly

²Converter Clutch Solenoid

²Governor

²Vehicle Speed Sensor & Pinion

²Park/Neutral & Back-up Lamp Switch

²Transfer Gears and Transfer Shaft

²Low/Reverse Servo

²Kickdown Servo

²Accumulator

FLUID REQUIREMENTS

NOTE: The transmission and differential have a

common oil sump with an opening between the

two.

TRANSMISSION/DIFFERENTIAL

MopartATF+4 (Automatic Transmission Fluid

Type 9602) is required in this transaxle. Substitute

fluids must meet fluid specification MS-9602.

FLUID ADDITIVES

Chrysler Corporation strongly recommends against

the addition of any fluids to the transmission, other

than those automatic transmission fluids listed

above. Exceptions to this policy are the use of special

dyes to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel/quality and converter

clutch operation, inhibit overheating, oxidation, var-

nish and sludge. These claims have not been sup-

ported to Chrysler's satisfaction and these additives

must not be used. The use of transmission ªsealersº

should also be avoided, since they may adversely

affect the integrity of tranmission seals.

DESCRIPTION AND OPERATION

31TH GENERAL INFORMATION

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system.

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heat

exchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

ries the governor and parking sprag. An integral heli-

cal gear on the transfer shaft drives the differential

ring gear.

PLTRANSAXLE 21 - 55

Page 1080 of 1285

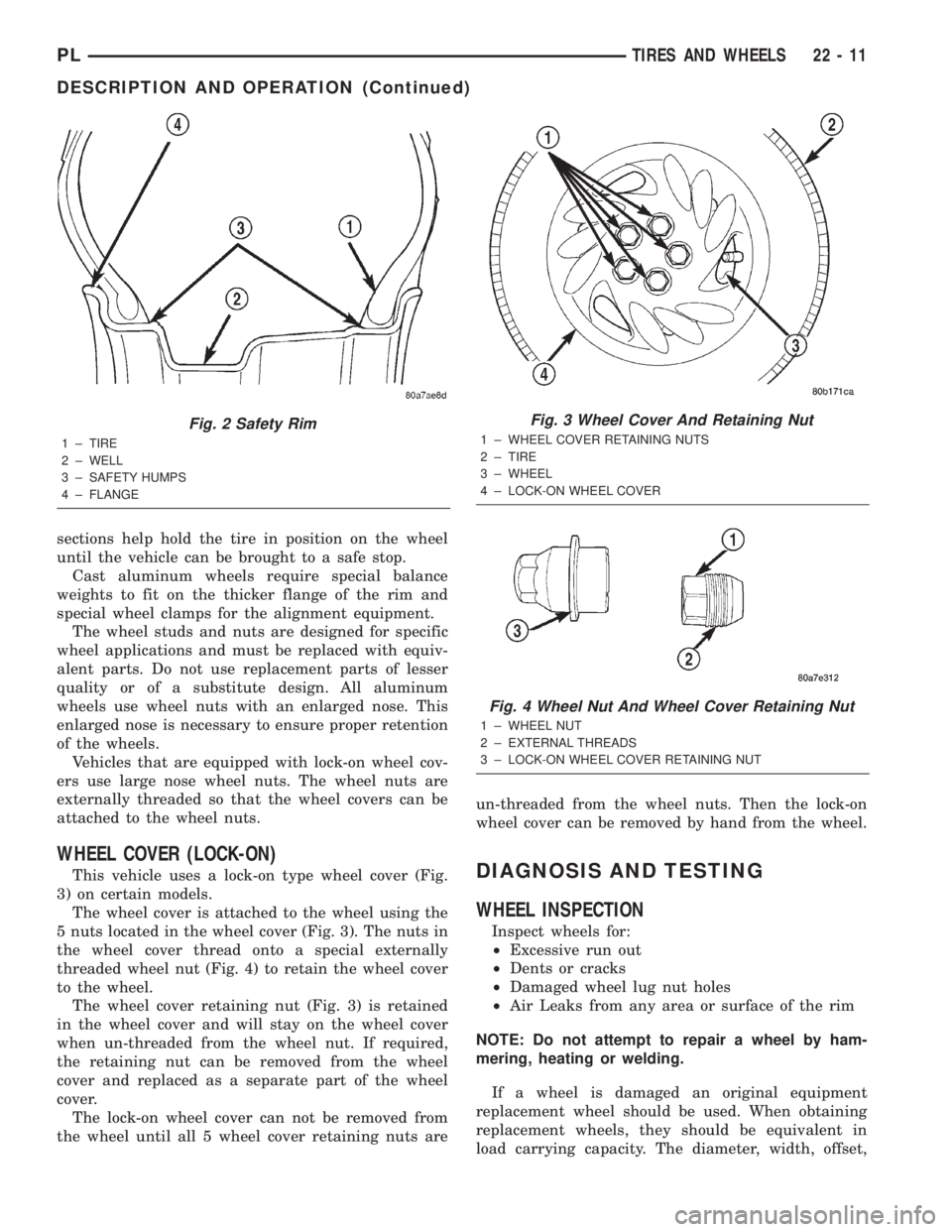

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts. Do not use replacement parts of lesser

quality or of a substitute design. All aluminum

wheels use wheel nuts with an enlarged nose. This

enlarged nose is necessary to ensure proper retention

of the wheels.

Vehicles that are equipped with lock-on wheel cov-

ers use large nose wheel nuts. The wheel nuts are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

WHEEL COVER (LOCK-ON)

This vehicle uses a lock-on type wheel cover (Fig.

3) on certain models.

The wheel cover is attached to the wheel using the

5 nuts located in the wheel cover (Fig. 3). The nuts in

the wheel cover thread onto a special externally

threaded wheel nut (Fig. 4) to retain the wheel cover

to the wheel.

The wheel cover retaining nut (Fig. 3) is retained

in the wheel cover and will stay on the wheel cover

when un-threaded from the wheel nut. If required,

the retaining nut can be removed from the wheel

cover and replaced as a separate part of the wheel

cover.

The lock-on wheel cover can not be removed from

the wheel until all 5 wheel cover retaining nuts areun-threaded from the wheel nuts. Then the lock-on

wheel cover can be removed by hand from the wheel.DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by ham-

mering, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

Fig. 2 Safety Rim

1 ± TIRE

2 ± WELL

3 ± SAFETY HUMPS

4 ± FLANGE

Fig. 3 Wheel Cover And Retaining Nut

1 ± WHEEL COVER RETAINING NUTS

2 ± TIRE

3 ± WHEEL

4 ± LOCK-ON WHEEL COVER

Fig. 4 Wheel Nut And Wheel Cover Retaining Nut

1 ± WHEEL NUT

2 ± EXTERNAL THREADS

3 ± LOCK-ON WHEEL COVER RETAINING NUT

PLTIRES AND WHEELS 22 - 11

DESCRIPTION AND OPERATION (Continued)

Page 1108 of 1285

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure

²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Monitor if over-

lapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault isrepaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

an The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

PLEMISSION CONTROL SYSTEMS 25 - 21

DESCRIPTION AND OPERATION (Continued)

Page 1137 of 1285

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.

USE AN OSHA APPROVED BREATHING DEVICE

WHEN MIXING EPOXY, GRINDING RTM AND SMC,

AND SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

EPOXY RESIN, PETROLEUM, OR ALCOHOL BASED

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

PANEL SECTIONING

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Smooth the filler with a spatula, wooden tongue

depressor, or squeegee. For fine texturing, a small

amount of water can be applied to the filler surface

while smoothing. The cured filler can be sanded as

necessary and, as a final step, cleanup can be done

withy soapy water. Wipe the surface clean with a dry

cloth allowing time for the panel to dry before mov-

ing on with the repair.

PANEL REINFORCEMENT

Structural repair procedures for rigid panels such

as Sheet Molded compound (SMC) or Resin Transfer

Molded (RTM) with large cracks and holes will

require a reinforcement backing. Reinforcements can

be made with several applications of glass cloth sat-

urated with epoxy structural adhesive, semirigid or

flexible repair materials should be used for semirigid

or flexible part repairs (Fig. 3) and (Fig. 4). Open

meshed fiberglass dry wall tape can be used to form

a reinforcement. The dry wall tape allows the resin

to penetrate through and make a good bond between

the panel and the epoxy adhesive. Structurally, the

more dry wall tape used, the stronger the repair.

Another kind of repair that can be done to repair

large cracks and holes is to use a scrap piece of sim-

ilar plastic and bond with structural adhesive. The

reinforcement should cover the entire break and

should have a generous amount of overlap on either

side of the cracked or broken area.

When repairing plastic, the damaged area is first

ªV'dº out, or beveled. Large bonding areas are desir-

able when repairing plastic because small repairs are

less likely to hold permanently. Beveling the area

around a crack at a 20 degree angle will increase the

bonding surface for a repair (Fig. 5). It is recom-

mended that sharp edges be avoided because the

joint may show through after the panel is refinished.

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 6).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

Fig. 2 Panel Sectioning

1 ± EXISTING PANEL

2 ± NEW PANEL

3 ± PANEL ADHESIVE

4 ± BONDING STRIP

23 - 20 BODYPL

SERVICE PROCEDURES (Continued)