wipers DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1 of 1285

GROUP TAB LOCATORINIntroductionINaIntroduction0Lubrication and Maintenance2Suspension3Differential and Driveline5Brakes6Clutch7Cooling8ABattery8BStarting8CCharging System8DIgnition System8EInstrument Panel and Systems8EaInstrument Panel and Systems8FAudio System8GHorns8HVehicle Speed Control System8JTurn Signal and Flashers8KWindshield Wipers and Washers8LLamps8LaLamps8MRestraint System8NElectrically Heated Systems8OPower Distribution Systems8PPower Door Locks8QImmobilizer System8SPower Windows8TPower Mirrors8TaPower Mirrors8UChime Warning/Reminder System8WWiring Diagrams - LHD and RHD9Engine11Exhaust System13Frame and Bumpers14Fuel System19Steering21Transaxle22Tires and Wheels23Body24Heating and Air Conditioning24aHeating and Air Conditioning25Emission Control Systems

Page 283 of 1285

REMOVAL AND INSTALLATION

HORN

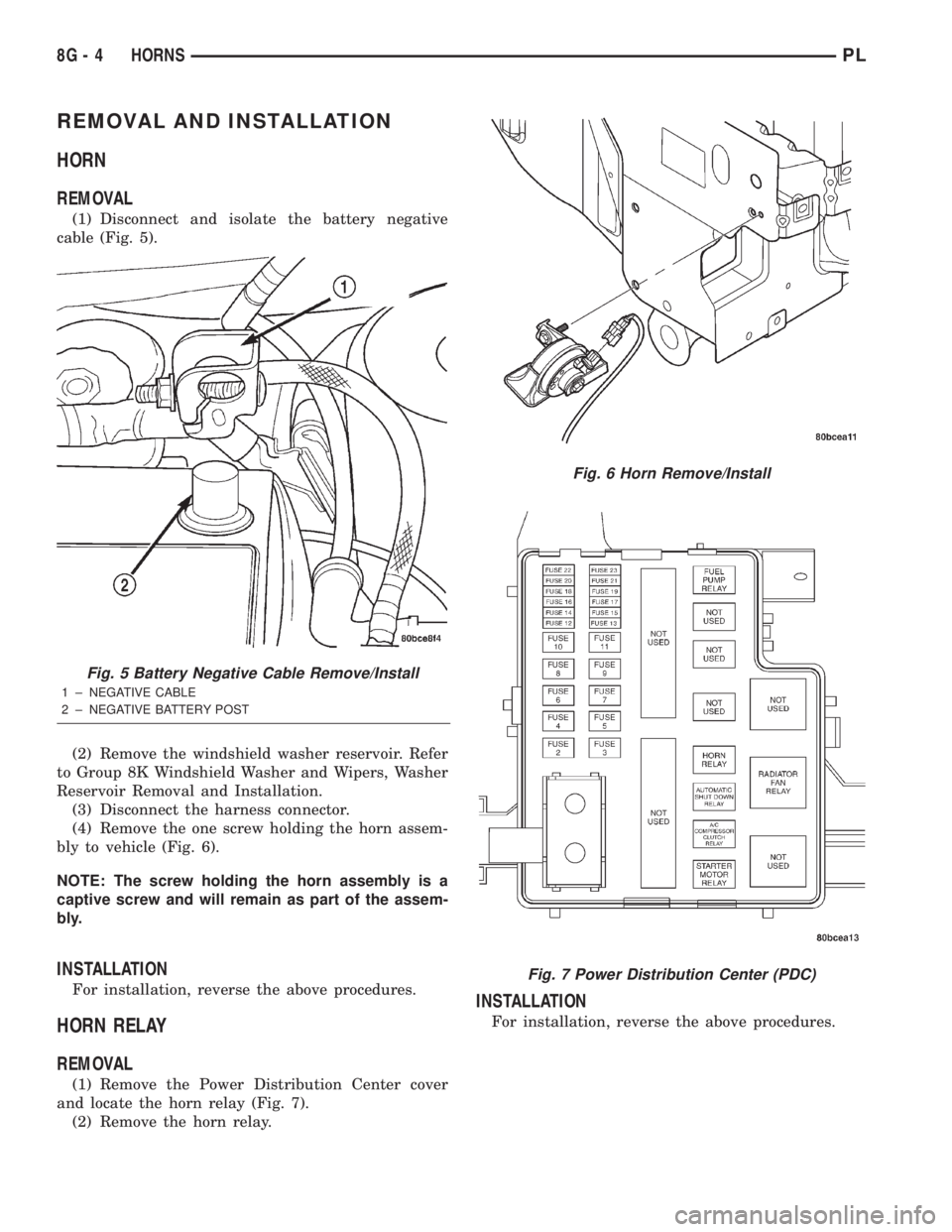

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 5).

(2) Remove the windshield washer reservoir. Refer

to Group 8K Windshield Washer and Wipers, Washer

Reservoir Removal and Installation.

(3) Disconnect the harness connector.

(4) Remove the one screw holding the horn assem-

bly to vehicle (Fig. 6).

NOTE: The screw holding the horn assembly is a

captive screw and will remain as part of the assem-

bly.

INSTALLATION

For installation, reverse the above procedures.

HORN RELAY

REMOVAL

(1) Remove the Power Distribution Center cover

and locate the horn relay (Fig. 7).

(2) Remove the horn relay.

INSTALLATION

For installation, reverse the above procedures.

Fig. 5 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 6 Horn Remove/Install

Fig. 7 Power Distribution Center (PDC)

8G - 4 HORNSPL

Page 298 of 1285

WINDSHIELD WIPER and WASHER SYSTEMS

TABLE OF CONTENTS

page page

WINDSHIELD WIPER SYSTEM................ 1WINDSHIELD WASHER SYSTEM.............. 8

WINDSHIELD WIPER SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

WIPER BLADES...........................1

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS............2

WINDSHIELD WIPER MOTOR................3

WINDSHIELD WIPER/WASHER SWITCH........5

REMOVAL AND INSTALLATION

WINDSHIELD WIPER ARM(S)................5WINDSHIELD WIPER BLADE(S)..............5

WINDSHIELD WIPER BLADE ELEMENT........5

WINDSHIELD WIPER LINKAGE...............5

WINDSHIELD WIPER MODULE...............6

WINDSHIELD WIPER MOTOR................6

WINDSHIELD WIPER/WASHER SWITCH........6

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)..............6

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)................6

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The windshield wipers will only operate with the

ignition switch in the ACCESSORY or IGNITION

RUN position. The wiper circuit is protected against

over loads by a fuse in the fuse block and a circuit

breaker within the wiper motor. This protects the cir-

cuitry of the wiper system and the vehicle. The wiper

motor has permanent magnet fields.

The intermittent wiper system, in addition to low

and high speed, has a delay mode and a pulse wipe

mode. The delay mode has a range of 1 to 15 seconds.

Pulse wipe is accomplished by momentarily moving

the stalk lever into the WASH position while the

wiper switch is in either OFF or DELAY position.

The wiper blades then sweep once or twice and

return to the previous wiper switch mode, OFF or

DELAY.The intermittent wiper function is integral to the

wiper switch. All electronics and relay are inside the

switch assembly.

The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

The wiper switch also includes the MIST feature

which provides a single wipe when actuated.

DESCRIPTION AND OPERATION

WIPER BLADES

Wiper blades, exposed to the weather for a long

period of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the blades continue to

streak or smear, they should be replaced. The right

and left wipers are different blade lengths. The

driver side length is 550 mm and the passenger side

length is 475 mm. The blades should not be inter-

changed.

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 1

Page 300 of 1285

(a) If no voltage, repair wiring as necessary. If

OK, go to Step b.

(b) Check wiper switch low speed. Connect volt-

meter positive lead to terminal 6 of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal 5 of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 1

in fuse block.

(a) If fuse does not blow, replace motor.

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector. Turn wiper motor on and check

ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.

(2) Using an ohmmeter, check the high and low

circuits for a short to ground. Refer to Group 8W,

Wiring Diagrams.

(3) Check to see if wiper linkage or pivots are

binding or caught.

WIPERS RUN AT HIGH SPEED WITH SWITCH IN

LOW SPEED POSITION OR WIPERS RUN AT LOW

SPEED WITH SWITCH IN HIGH SPEED POSITION.

(1) Check for crossed wires in the motor pigtail

wire connector. Refer to Group 8W, Wiring Diagrams.

(2) Check for crossed wires in harness connector

from wiper switch to motor.

(3) If OK, replace wiper switch.

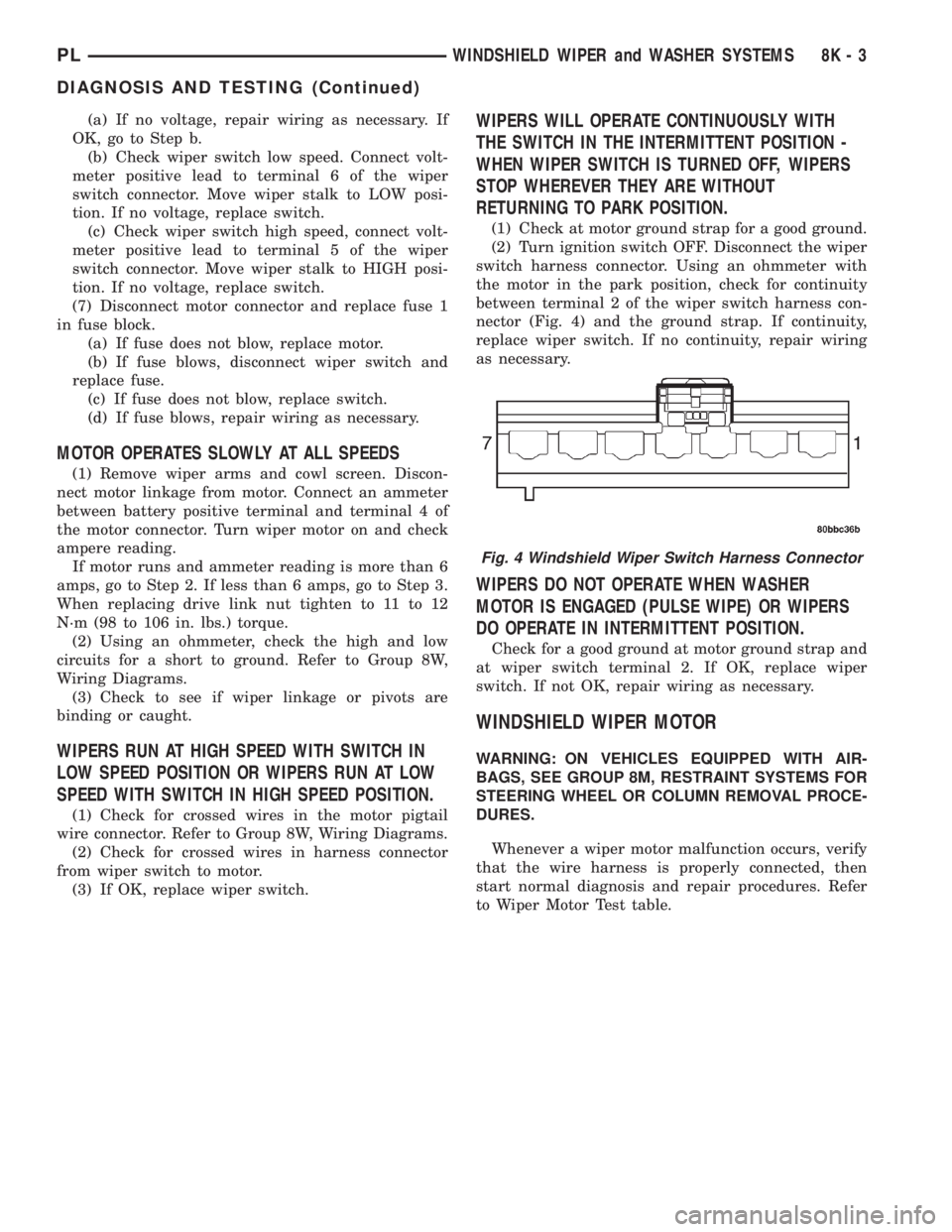

WIPERS WILL OPERATE CONTINUOUSLY WITH

THE SWITCH IN THE INTERMITTENT POSITION -

WHEN WIPER SWITCH IS TURNED OFF, WIPERS

STOP WHEREVER THEY ARE WITHOUT

RETURNING TO PARK POSITION.

(1) Check at motor ground strap for a good ground.

(2) Turn ignition switch OFF. Disconnect the wiper

switch harness connector. Using an ohmmeter with

the motor in the park position, check for continuity

between terminal 2 of the wiper switch harness con-

nector (Fig. 4) and the ground strap. If continuity,

replace wiper switch. If no continuity, repair wiring

as necessary.

WIPERS DO NOT OPERATE WHEN WASHER

MOTOR IS ENGAGED (PULSE WIPE) OR WIPERS

DO OPERATE IN INTERMITTENT POSITION.

Check for a good ground at motor ground strap and

at wiper switch terminal 2. If OK, replace wiper

switch. If not OK, repair wiring as necessary.

WINDSHIELD WIPER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, verify

that the wire harness is properly connected, then

start normal diagnosis and repair procedures. Refer

to Wiper Motor Test table.

Fig. 4 Windshield Wiper Switch Harness Connector

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 3

DIAGNOSIS AND TESTING (Continued)

Page 303 of 1285

WINDSHIELD WIPER MODULE

REMOVAL

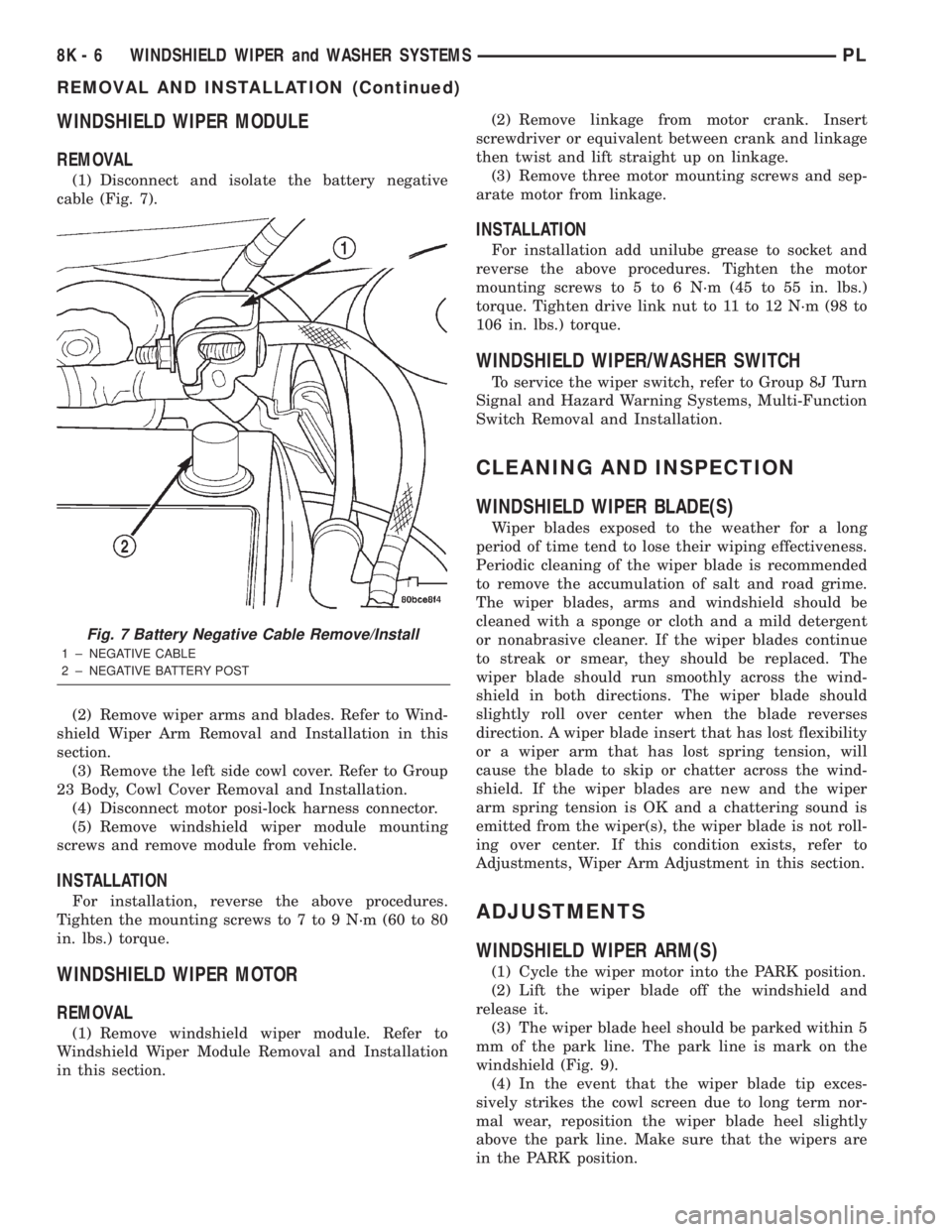

(1) Disconnect and isolate the battery negative

cable (Fig. 7).

(2) Remove wiper arms and blades. Refer to Wind-

shield Wiper Arm Removal and Installation in this

section.

(3) Remove the left side cowl cover. Refer to Group

23 Body, Cowl Cover Removal and Installation.

(4) Disconnect motor posi-lock harness connector.

(5) Remove windshield wiper module mounting

screws and remove module from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Tighten the mounting screws to 7 to 9 N´m (60 to 80

in. lbs.) torque.

WINDSHIELD WIPER MOTOR

REMOVAL

(1) Remove windshield wiper module. Refer to

Windshield Wiper Module Removal and Installation

in this section.(2) Remove linkage from motor crank. Insert

screwdriver or equivalent between crank and linkage

then twist and lift straight up on linkage.

(3) Remove three motor mounting screws and sep-

arate motor from linkage.

INSTALLATION

For installation add unilube grease to socket and

reverse the above procedures. Tighten the motor

mounting screws to 5 to 6 N´m (45 to 55 in. lbs.)

torque. Tighten drive link nut to 11 to 12 N´m (98 to

106 in. lbs.) torque.

WINDSHIELD WIPER/WASHER SWITCH

To service the wiper switch, refer to Group 8J Turn

Signal and Hazard Warning Systems, Multi-Function

Switch Removal and Installation.

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, refer to

Adjustments, Wiper Arm Adjustment in this section.

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)

(1) Cycle the wiper motor into the PARK position.

(2) Lift the wiper blade off the windshield and

release it.

(3) The wiper blade heel should be parked within 5

mm of the park line. The park line is mark on the

windshield (Fig. 9).

(4) In the event that the wiper blade tip exces-

sively strikes the cowl screen due to long term nor-

mal wear, reposition the wiper blade heel slightly

above the park line. Make sure that the wipers are

in the PARK position.

Fig. 7 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

8K - 6 WINDSHIELD WIPER and WASHER SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 305 of 1285

WINDSHIELD WASHER SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WINDSHIELD WASHER NOZZLE(S)............8

WINDSHIELD WASHER SYSTEM.............8

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM.............9REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE................9

WINDSHIELD WASHER NOZZLES.............9

WINDSHIELD WASHER RESERVOIR..........10

WINDSHIELD WASHER PUMP...............10

DESCRIPTION AND OPERATION

WINDSHIELD WASHER NOZZLE(S)

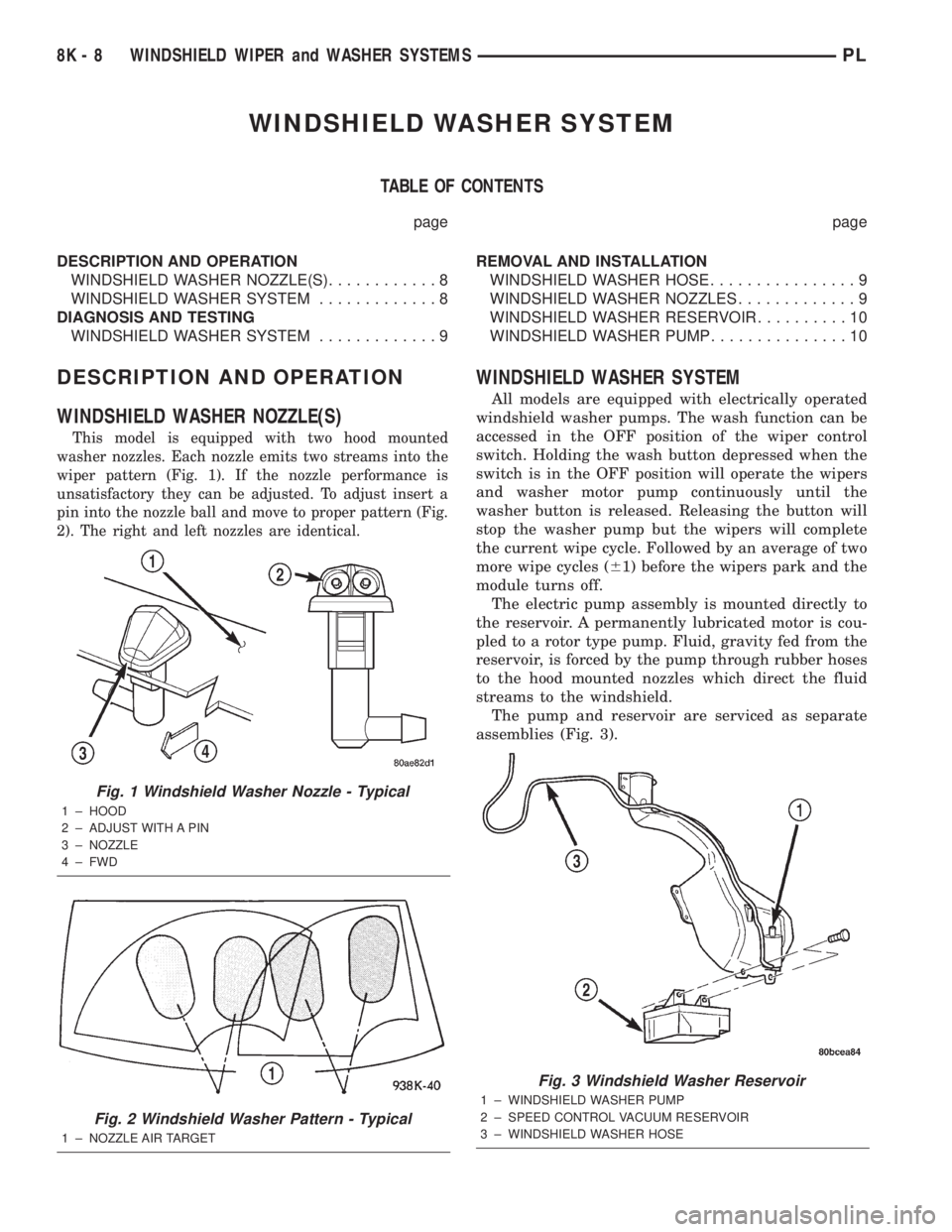

This model is equipped with two hood mounted

washer nozzles. Each nozzle emits two streams into the

wiper pattern (Fig. 1). If the nozzle performance is

unsatisfactory they can be adjusted. To adjust insert a

pin into the nozzle ball and move to proper pattern (Fig.

2). The right and left nozzles are identical.

WINDSHIELD WASHER SYSTEM

All models are equipped with electrically operated

windshield washer pumps. The wash function can be

accessed in the OFF position of the wiper control

switch. Holding the wash button depressed when the

switch is in the OFF position will operate the wipers

and washer motor pump continuously until the

washer button is released. Releasing the button will

stop the washer pump but the wipers will complete

the current wipe cycle. Followed by an average of two

more wipe cycles (61) before the wipers park and the

module turns off.

The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated motor is cou-

pled to a rotor type pump. Fluid, gravity fed from the

reservoir, is forced by the pump through rubber hoses

to the hood mounted nozzles which direct the fluid

streams to the windshield.

The pump and reservoir are serviced as separate

assemblies (Fig. 3).

Fig. 1 Windshield Washer Nozzle - Typical

1 ± HOOD

2 ± ADJUST WITH A PIN

3 ± NOZZLE

4 ± FWD

Fig. 2 Windshield Washer Pattern - Typical

1 ± NOZZLE AIR TARGET

Fig. 3 Windshield Washer Reservoir

1 ± WINDSHIELD WASHER PUMP

2 ± SPEED CONTROL VACUUM RESERVOIR

3 ± WINDSHIELD WASHER HOSE

8K - 8 WINDSHIELD WIPER and WASHER SYSTEMSPL

Page 392 of 1285

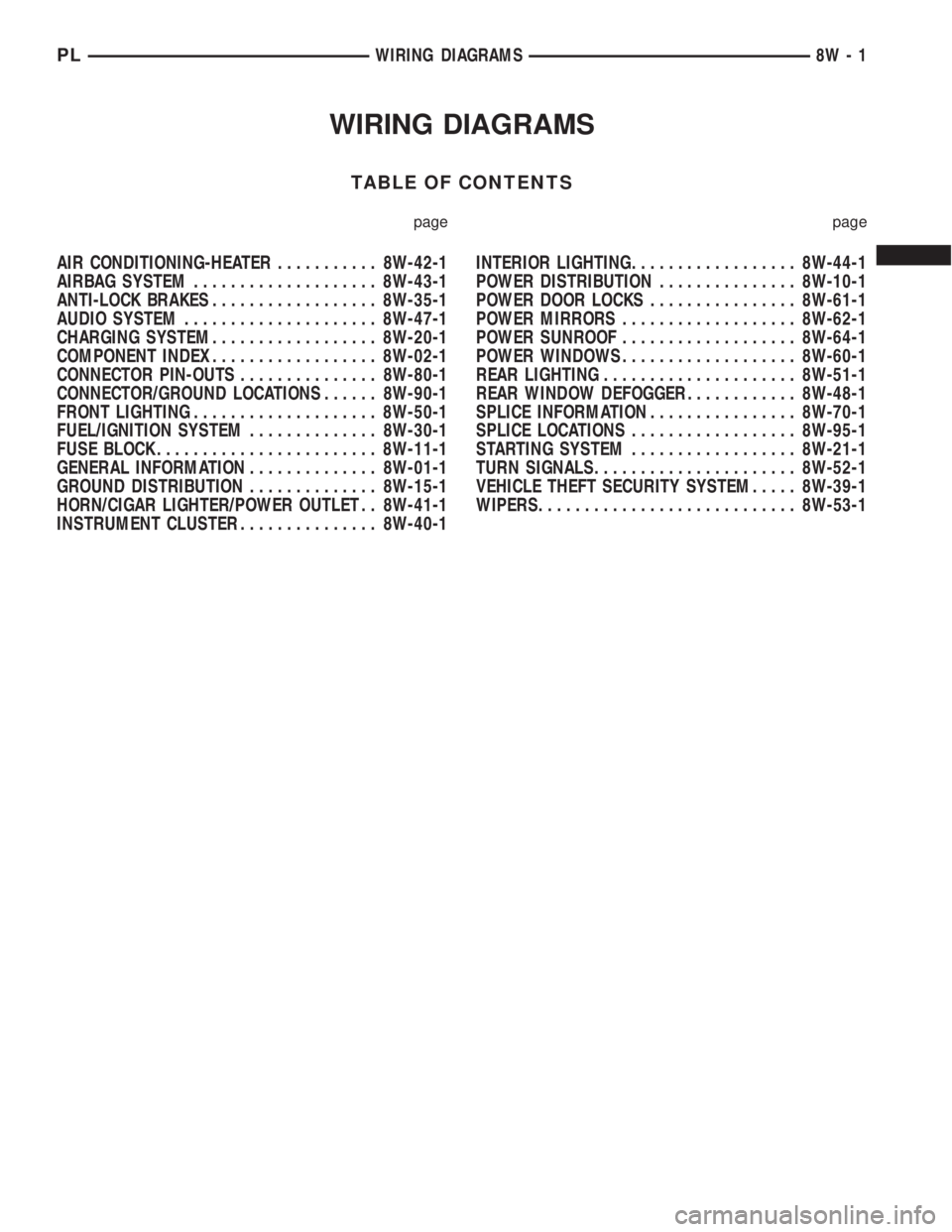

WIRING DIAGRAMS

TABLE OF CONTENTS

page page

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

ANTI-LOCK BRAKES.................. 8W-35-1

AUDIO SYSTEM..................... 8W-47-1

CHARGING SYSTEM.................. 8W-20-1

COMPONENT INDEX.................. 8W-02-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND LOCATIONS...... 8W-90-1

FRONT LIGHTING.................... 8W-50-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

FUSE BLOCK........................ 8W-11-1

GENERAL INFORMATION.............. 8W-01-1

GROUND DISTRIBUTION.............. 8W-15-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

INSTRUMENT CLUSTER............... 8W-40-1INTERIOR LIGHTING.................. 8W-44-1

POWER DISTRIBUTION............... 8W-10-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SUNROOF................... 8W-64-1

POWER WINDOWS................... 8W-60-1

REAR LIGHTING..................... 8W-51-1

REAR WINDOW DEFOGGER............ 8W-48-1

SPLICE INFORMATION................ 8W-70-1

SPLICE LOCATIONS.................. 8W-95-1

STARTING SYSTEM.................. 8W-21-1

TURN SIGNALS...................... 8W-52-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

WIPERS............................ 8W-53-1

PLWIRING DIAGRAMS 8W - 1

Page 398 of 1285

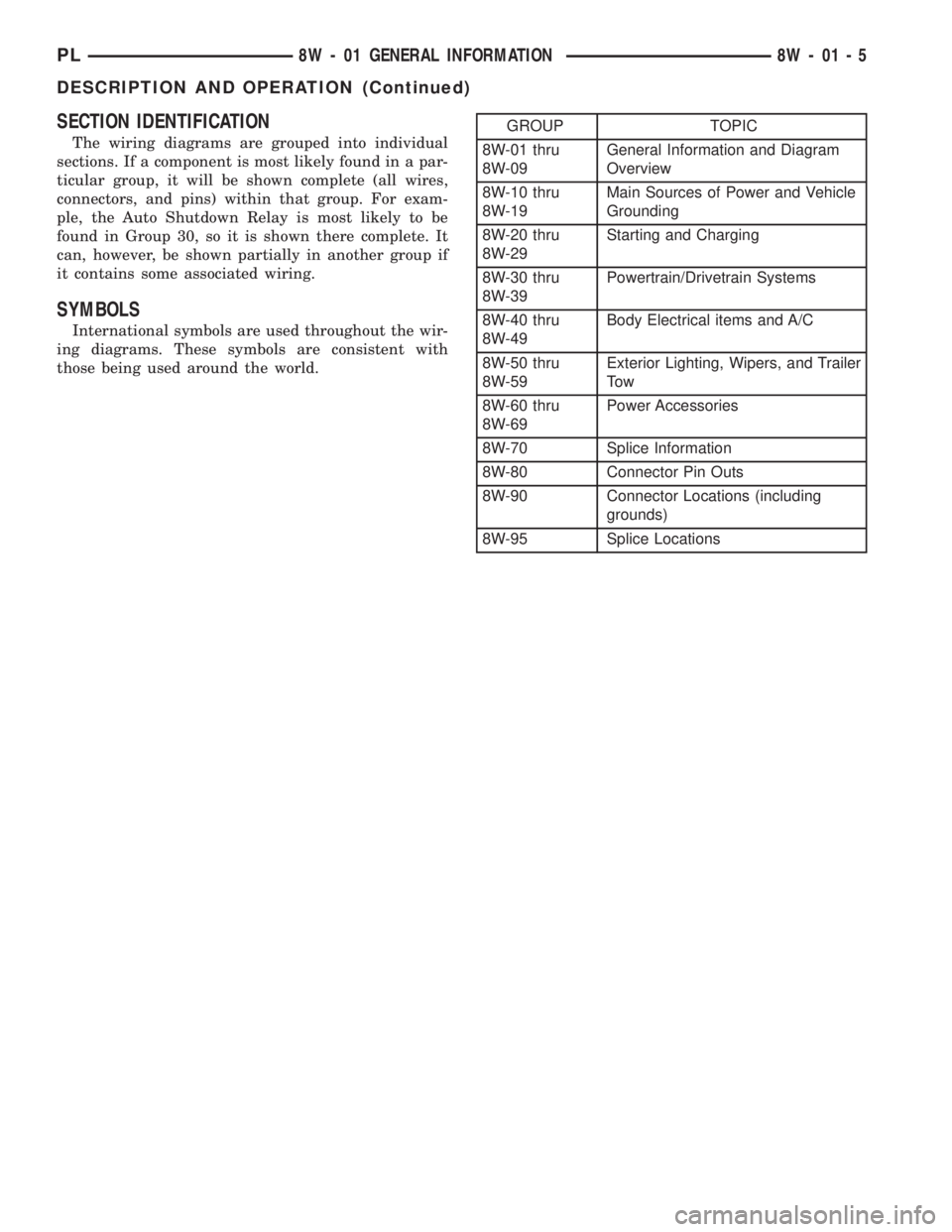

SECTION IDENTIFICATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world.

GROUP TOPIC

8W-01 thru

8W-09General Information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and Vehicle

Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers, and Trailer

To w

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-90 Connector Locations (including

grounds)

8W-95 Splice Locations

PL8W - 01 GENERAL INFORMATION 8W - 01 - 5

DESCRIPTION AND OPERATION (Continued)

Page 580 of 1285

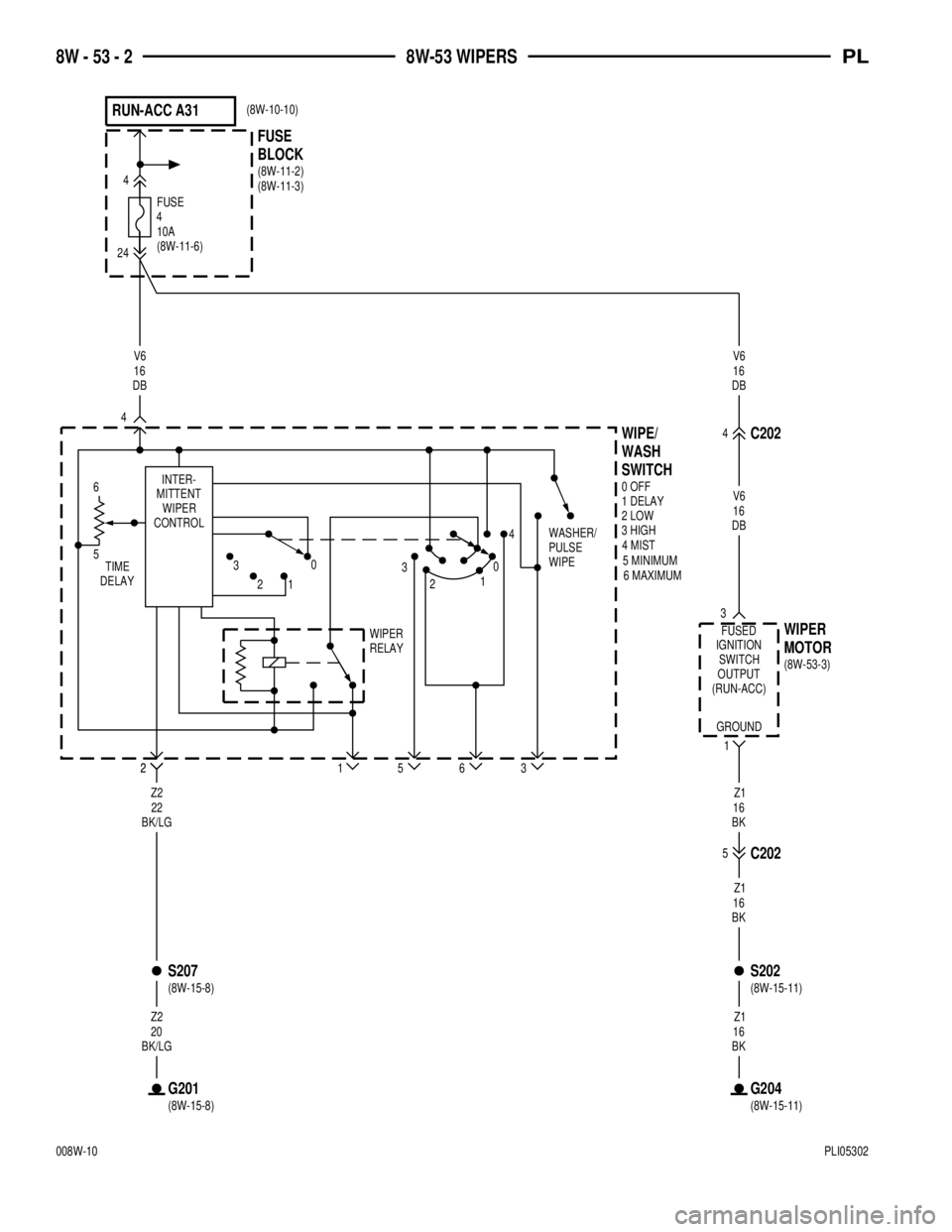

8W-53 WIPERS

Component Page

Fuse 4 (FB).......................8W-53-2, 3

Fuse Block.......................8W-53-2, 3

G103..............................8W-53-3

G201..............................8W-53-2Component Page

G204............................8W-53-2, 3

Windshield Washer Pump..............8W-53-3

Wipe/Wash Switch..................8W-53-2, 3

Wiper Motor......................8W-53-2, 3

PL8W - 53 WIPERS 8W - 53 - 1

Page 581 of 1285

FUSE

BLOCK

4FUSE10A

RUN-ACC A31

S202

C20251 3

2 4

4C202

G201G204

S207

Z2

22

BK/LG

Z2

20

BK/LGZ1

16

BK

Z1

16

BK

V6

16

DB

V6

16

DBV6

16

DB

FUSED

IGNITION

SWITCH

OUTPUT

(RUN-ACC)

GROUND 244

MOTOR WIPER

2

0

1 2 33

210

MITTENT

WIPER

CONTROL

1

INTER-

563

4

6

5

TIME

DELAYWASHER/

PULSE

WIPE

WIPER

RELAY6 MAXIMUM 5 MINIMUM

WIPE/

3 HIGH 2 LOW

1 DELAY

0 OFF

WASH

SWITCH

4 MIST

Z1

16

BK

(8W-11-2)

(8W-11-3)

(8W-11-6)(8W-10-10)

(8W-15-11)

(8W-15-8)(8W-15-11) (8W-15-8)(8W-53-3)

8W - 53 - 2 8W-53 WIPERSPL

008W-10PLI05302