seat adjustment DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 784 of 1285

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The following specifications apply

to both intake and exhaust valve springs:

²Valve Closed Nominal TensionÐ70 lbs. @ 39.8

mm (1.57 in.)

²Valve Closed Nominal TensionÐ160 lbs. @ 32.6

mm (1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 in.) out

of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 121). Intake valves with less than

0.95 mm (1/32 in.) margin and exhaust valves with

less than 1.05 mm (3/64 in.) margin should be dis-

carded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For specifications, refer to Engine Specifi-

cations in this section.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed 0.051 mm (0.002 in.)

(total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

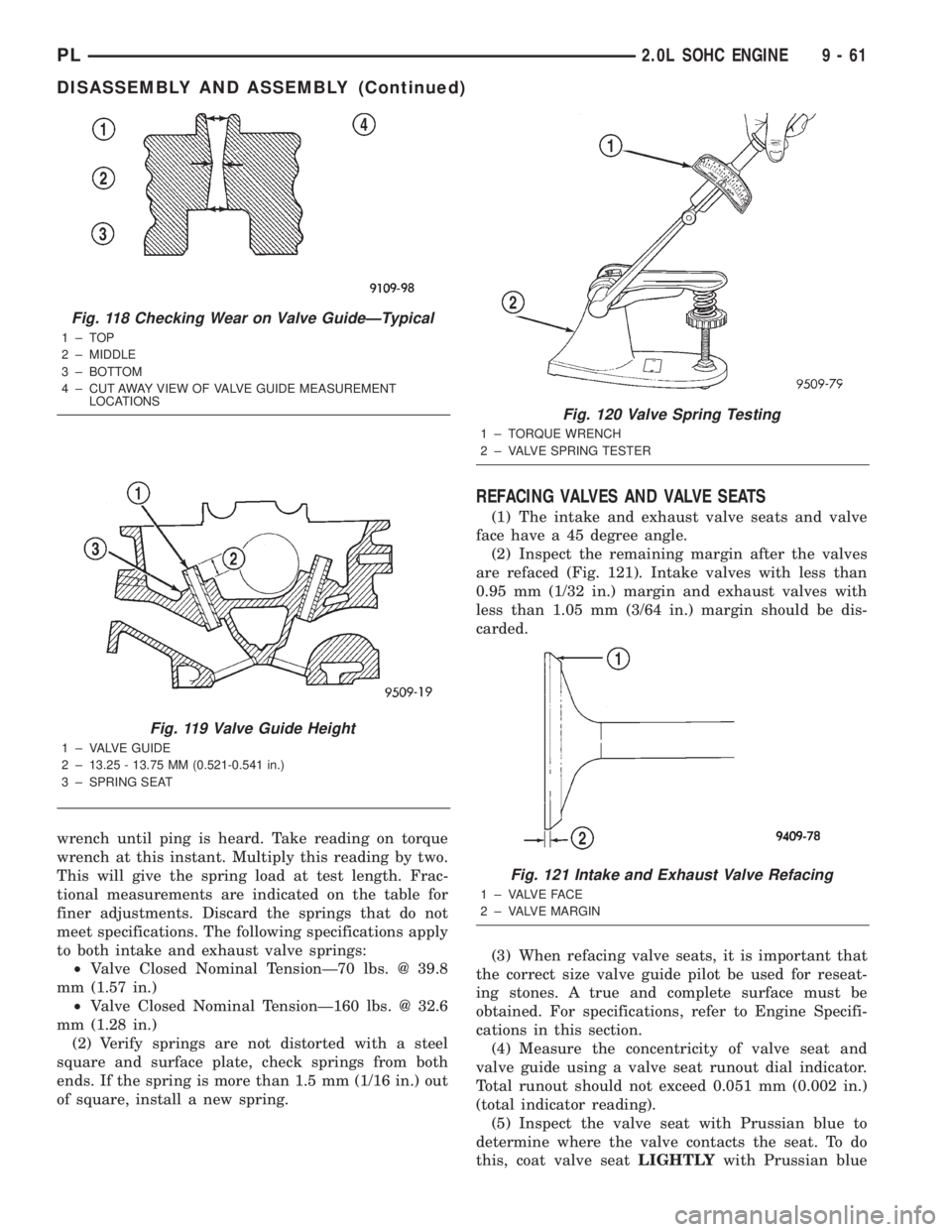

Fig. 118 Checking Wear on Valve GuideÐTypical

1±TOP

2 ± MIDDLE

3 ± BOTTOM

4 ± CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 119 Valve Guide Height

1 ± VALVE GUIDE

2 ± 13.25 - 13.75 MM (0.521-0.541 in.)

3 ± SPRING SEAT

Fig. 120 Valve Spring Testing

1 ± TORQUE WRENCH

2 ± VALVE SPRING TESTER

Fig. 121 Intake and Exhaust Valve Refacing

1 ± VALVE FACE

2 ± VALVE MARGIN

PL2.0L SOHC ENGINE 9 - 61

DISASSEMBLY AND ASSEMBLY (Continued)

Page 921 of 1285

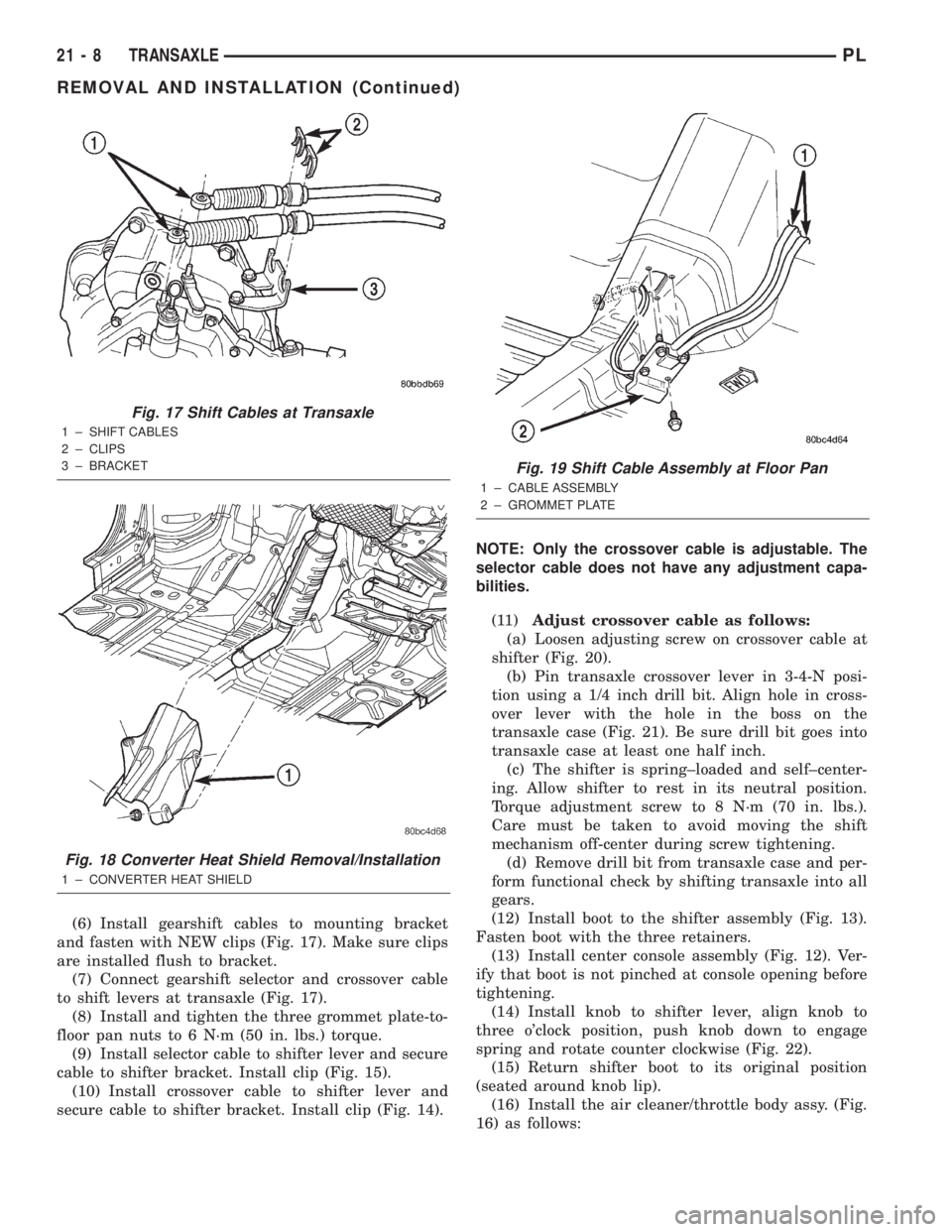

(6) Install gearshift cables to mounting bracket

and fasten with NEW clips (Fig. 17). Make sure clips

are installed flush to bracket.

(7) Connect gearshift selector and crossover cable

to shift levers at transaxle (Fig. 17).

(8) Install and tighten the three grommet plate-to-

floor pan nuts to 6 N´m (50 in. lbs.) torque.

(9) Install selector cable to shifter lever and secure

cable to shifter bracket. Install clip (Fig. 15).

(10) Install crossover cable to shifter lever and

secure cable to shifter bracket. Install clip (Fig. 14).NOTE: Only the crossover cable is adjustable. The

selector cable does not have any adjustment capa-

bilities.

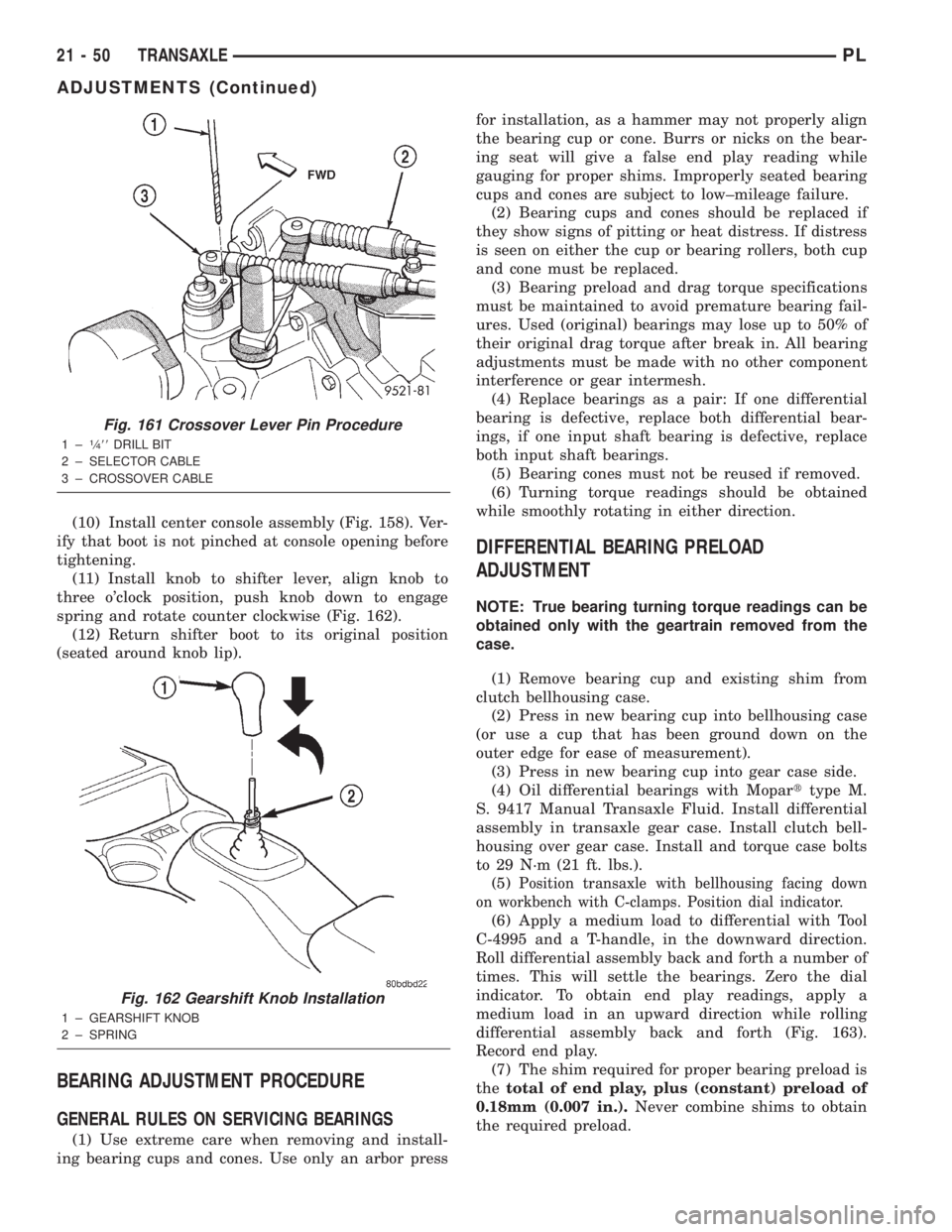

(11)Adjust crossover cable as follows:

(a) Loosen adjusting screw on crossover cable at

shifter (Fig. 20).

(b) Pin transaxle crossover lever in 3-4-N posi-

tion using a 1/4 inch drill bit. Align hole in cross-

over lever with the hole in the boss on the

transaxle case (Fig. 21). Be sure drill bit goes into

transaxle case at least one half inch.

(c) The shifter is spring±loaded and self±center-

ing. Allow shifter to rest in its neutral position.

Torque adjustment screw to 8 N´m (70 in. lbs.).

Care must be taken to avoid moving the shift

mechanism off-center during screw tightening.

(d) Remove drill bit from transaxle case and per-

form functional check by shifting transaxle into all

gears.

(12) Install boot to the shifter assembly (Fig. 13).

Fasten boot with the three retainers.

(13) Install center console assembly (Fig. 12). Ver-

ify that boot is not pinched at console opening before

tightening.

(14) Install knob to shifter lever, align knob to

three o'clock position, push knob down to engage

spring and rotate counter clockwise (Fig. 22).

(15) Return shifter boot to its original position

(seated around knob lip).

(16) Install the air cleaner/throttle body assy. (Fig.

16) as follows:

Fig. 17 Shift Cables at Transaxle

1 ± SHIFT CABLES

2 ± CLIPS

3 ± BRACKET

Fig. 18 Converter Heat Shield Removal/Installation

1 ± CONVERTER HEAT SHIELD

Fig. 19 Shift Cable Assembly at Floor Pan

1 ± CABLE ASSEMBLY

2 ± GROMMET PLATE

21 - 8 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 922 of 1285

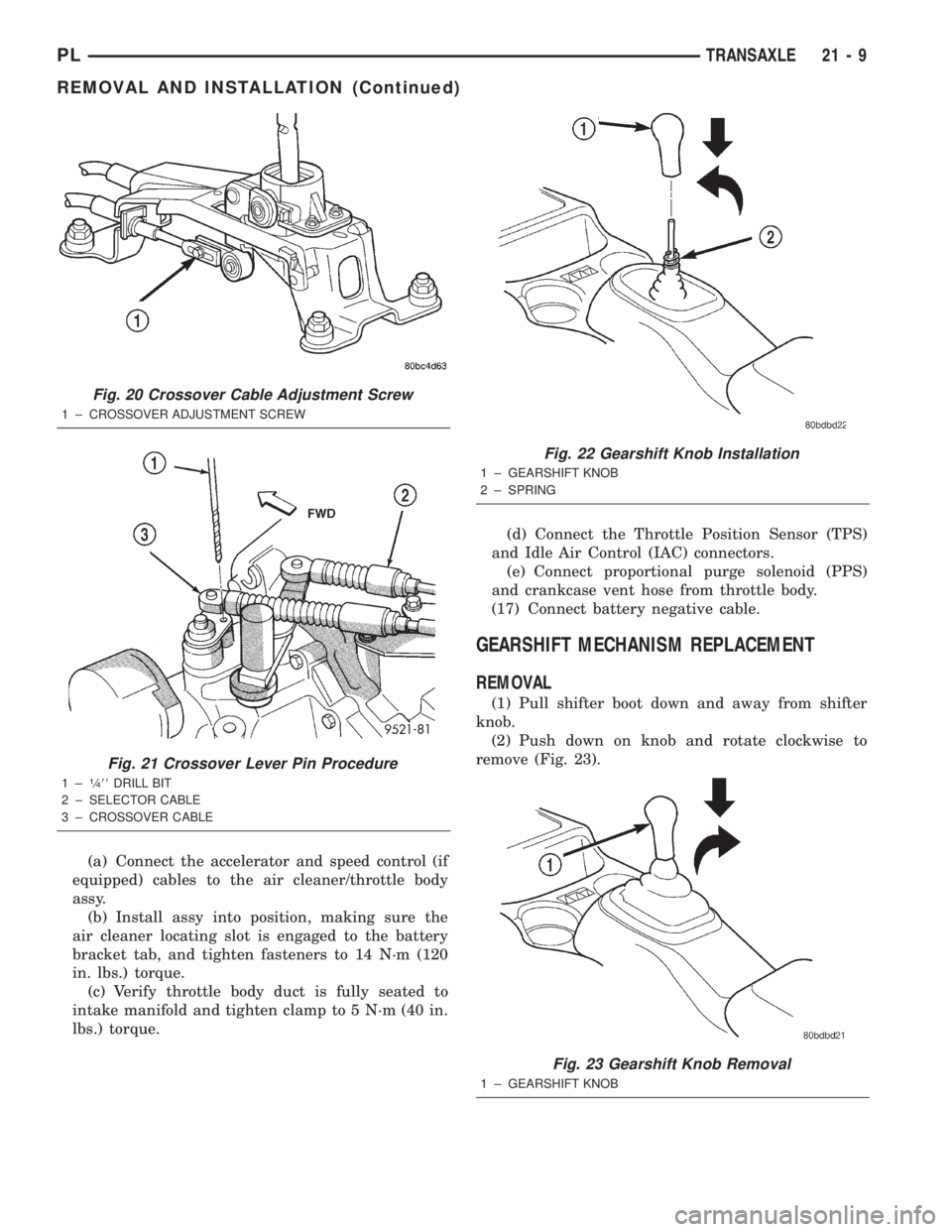

(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(17) Connect battery negative cable.

GEARSHIFT MECHANISM REPLACEMENT

REMOVAL

(1) Pull shifter boot down and away from shifter

knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 23).

Fig. 20 Crossover Cable Adjustment Screw

1 ± CROSSOVER ADJUSTMENT SCREW

Fig. 21 Crossover Lever Pin Procedure

1±1¤488DRILL BIT

2 ± SELECTOR CABLE

3 ± CROSSOVER CABLE

Fig. 22 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 23 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

PLTRANSAXLE 21 - 9

REMOVAL AND INSTALLATION (Continued)

Page 942 of 1285

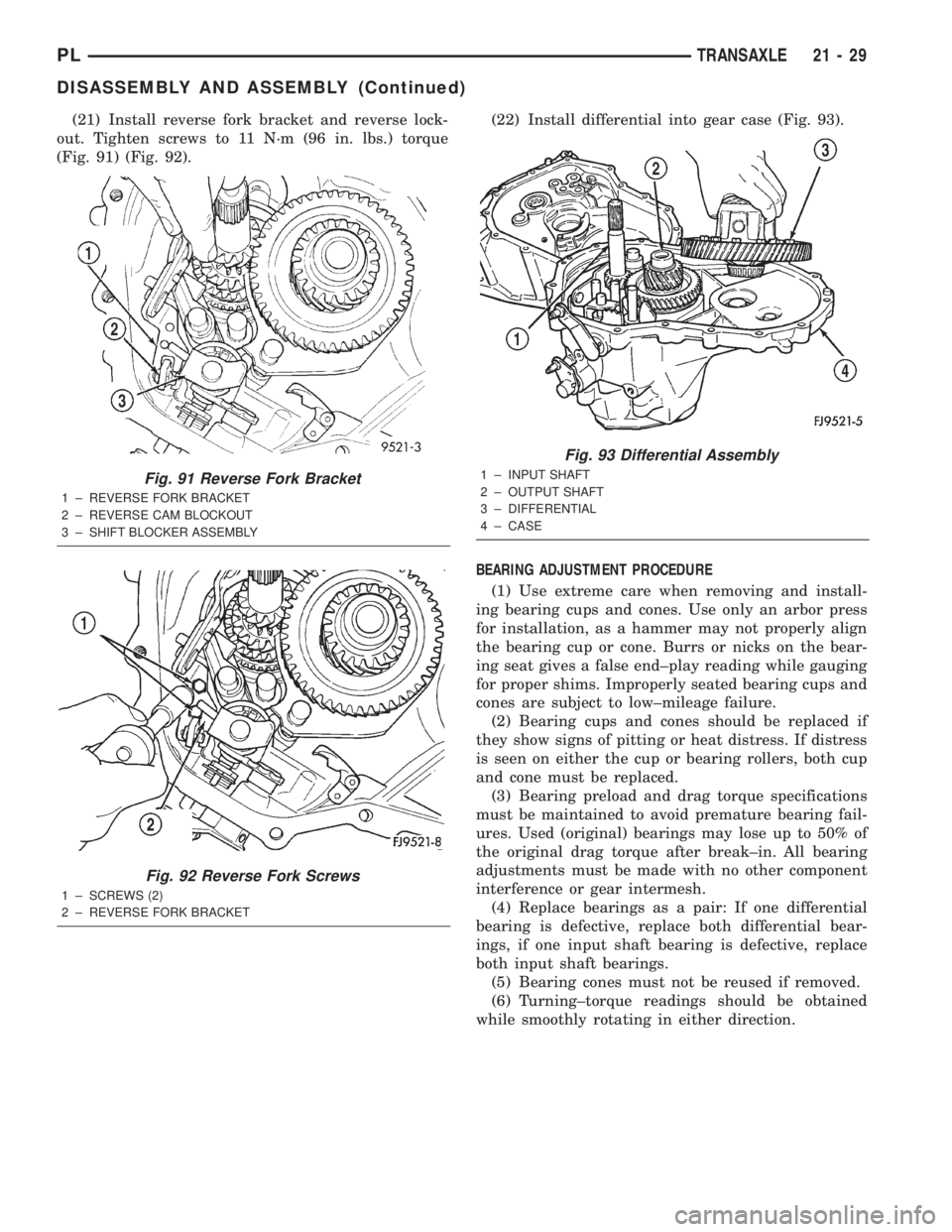

(21) Install reverse fork bracket and reverse lock-

out. Tighten screws to 11 N´m (96 in. lbs.) torque

(Fig. 91) (Fig. 92).(22) Install differential into gear case (Fig. 93).

BEARING ADJUSTMENT PROCEDURE

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor press

for installation, as a hammer may not properly align

the bearing cup or cone. Burrs or nicks on the bear-

ing seat gives a false end±play reading while gauging

for proper shims. Improperly seated bearing cups and

cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.

(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

the original drag torque after break±in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings, if one input shaft bearing is defective, replace

both input shaft bearings.

(5) Bearing cones must not be reused if removed.

(6) Turning±torque readings should be obtained

while smoothly rotating in either direction.

Fig. 91 Reverse Fork Bracket

1 ± REVERSE FORK BRACKET

2 ± REVERSE CAM BLOCKOUT

3 ± SHIFT BLOCKER ASSEMBLY

Fig. 92 Reverse Fork Screws

1 ± SCREWS (2)

2 ± REVERSE FORK BRACKET

Fig. 93 Differential Assembly

1 ± INPUT SHAFT

2 ± OUTPUT SHAFT

3 ± DIFFERENTIAL

4 ± CASE

PLTRANSAXLE 21 - 29

DISASSEMBLY AND ASSEMBLY (Continued)

Page 963 of 1285

(10) Install center console assembly (Fig. 158). Ver-

ify that boot is not pinched at console opening before

tightening.

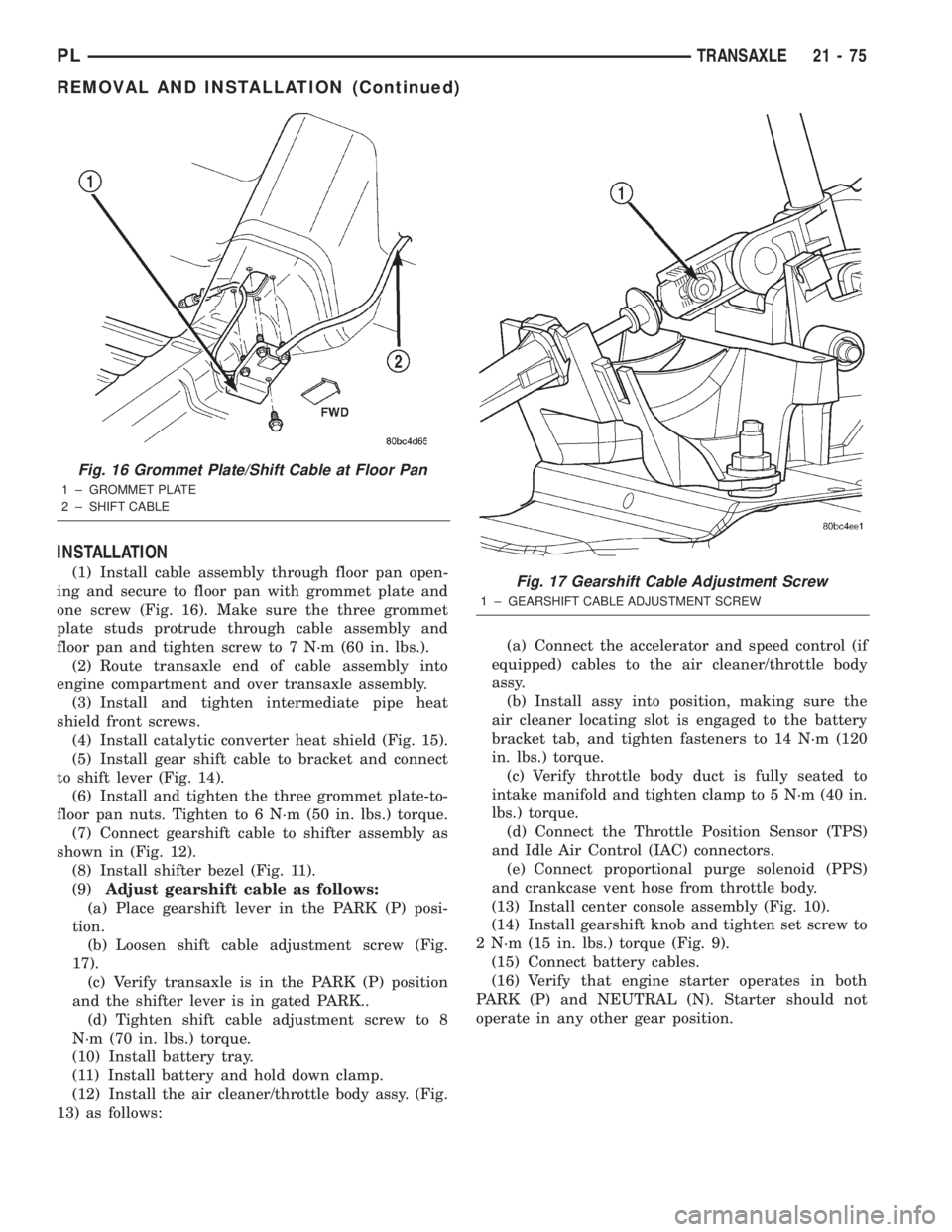

(11) Install knob to shifter lever, align knob to

three o'clock position, push knob down to engage

spring and rotate counter clockwise (Fig. 162).

(12) Return shifter boot to its original position

(seated around knob lip).

BEARING ADJUSTMENT PROCEDURE

GENERAL RULES ON SERVICING BEARINGS

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor pressfor installation, as a hammer may not properly align

the bearing cup or cone. Burrs or nicks on the bear-

ing seat will give a false end play reading while

gauging for proper shims. Improperly seated bearing

cups and cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.

(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

their original drag torque after break in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings, if one input shaft bearing is defective, replace

both input shaft bearings.

(5) Bearing cones must not be reused if removed.

(6) Turning torque readings should be obtained

while smoothly rotating in either direction.

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT

NOTE: True bearing turning torque readings can be

obtained only with the geartrain removed from the

case.

(1) Remove bearing cup and existing shim from

clutch bellhousing case.

(2) Press in new bearing cup into bellhousing case

(or use a cup that has been ground down on the

outer edge for ease of measurement).

(3) Press in new bearing cup into gear case side.

(4) Oil differential bearings with Moparttype M.

S. 9417 Manual Transaxle Fluid. Install differential

assembly in transaxle gear case. Install clutch bell-

housing over gear case. Install and torque case bolts

to 29 N´m (21 ft. lbs.).

(5)

Position transaxle with bellhousing facing down

on workbench with C-clamps. Position dial indicator.

(6) Apply a medium load to differential with Tool

C-4995 and a T-handle, in the downward direction.

Roll differential assembly back and forth a number of

times. This will settle the bearings. Zero the dial

indicator. To obtain end play readings, apply a

medium load in an upward direction while rolling

differential assembly back and forth (Fig. 163).

Record end play.

(7) The shim required for proper bearing preload is

thetotal of end play, plus (constant) preload of

0.18mm (0.007 in.).Never combine shims to obtain

the required preload.

Fig. 161 Crossover Lever Pin Procedure

1±1¤488DRILL BIT

2 ± SELECTOR CABLE

3 ± CROSSOVER CABLE

Fig. 162 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

21 - 50 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 988 of 1285

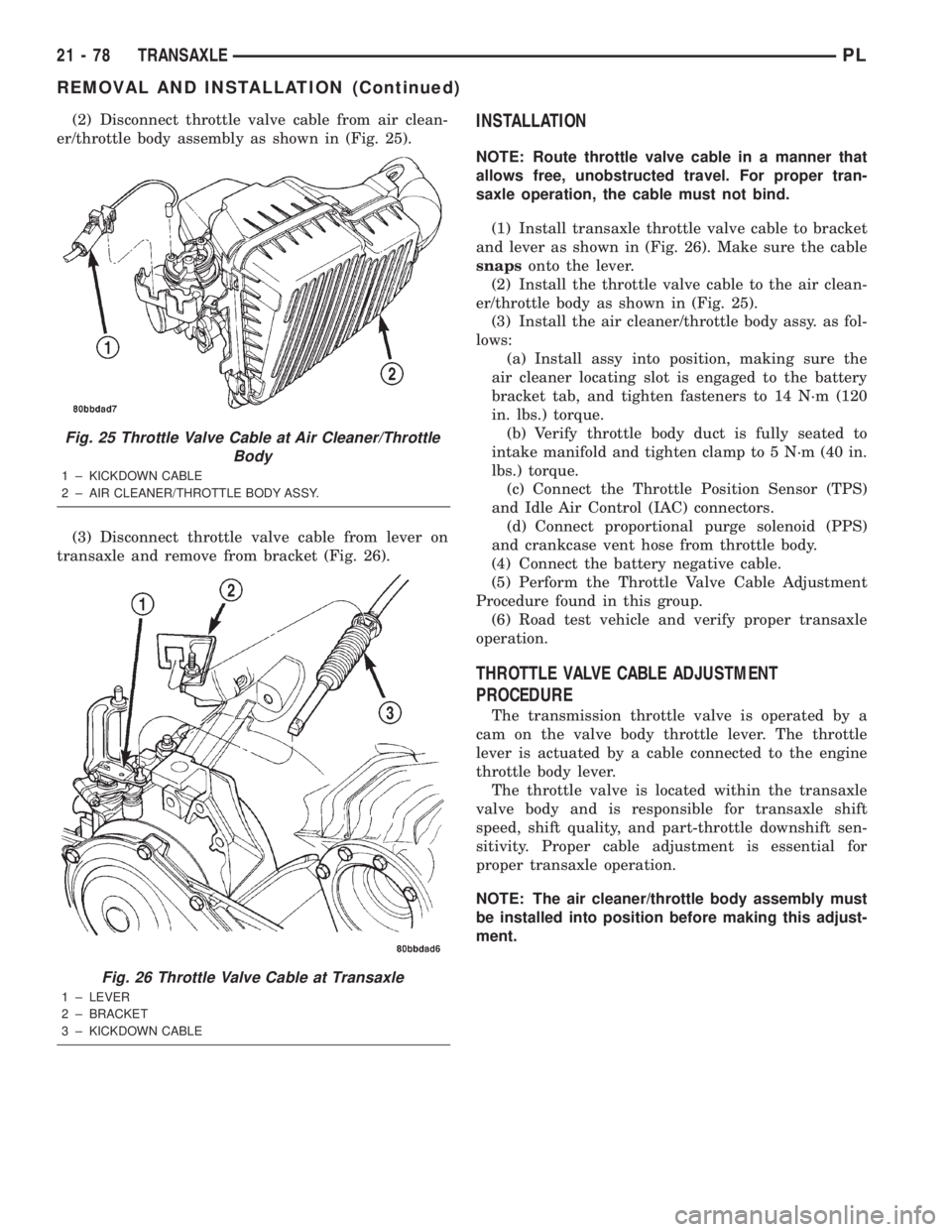

INSTALLATION

(1) Install cable assembly through floor pan open-

ing and secure to floor pan with grommet plate and

one screw (Fig. 16). Make sure the three grommet

plate studs protrude through cable assembly and

floor pan and tighten screw to 7 N´m (60 in. lbs.).

(2) Route transaxle end of cable assembly into

engine compartment and over transaxle assembly.

(3) Install and tighten intermediate pipe heat

shield front screws.

(4) Install catalytic converter heat shield (Fig. 15).

(5) Install gear shift cable to bracket and connect

to shift lever (Fig. 14).

(6) Install and tighten the three grommet plate-to-

floor pan nuts. Tighten to 6 N´m (50 in. lbs.) torque.

(7) Connect gearshift cable to shifter assembly as

shown in (Fig. 12).

(8) Install shifter bezel (Fig. 11).

(9)Adjust gearshift cable as follows:

(a) Place gearshift lever in the PARK (P) posi-

tion.

(b) Loosen shift cable adjustment screw (Fig.

17).

(c) Verify transaxle is in the PARK (P) position

and the shifter lever is in gated PARK..

(d) Tighten shift cable adjustment screw to 8

N´m (70 in. lbs.) torque.

(10) Install battery tray.

(11) Install battery and hold down clamp.

(12) Install the air cleaner/throttle body assy. (Fig.

13) as follows:(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(13) Install center console assembly (Fig. 10).

(14) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 9).

(15) Connect battery cables.

(16) Verify that engine starter operates in both

PARK (P) and NEUTRAL (N). Starter should not

operate in any other gear position.

Fig. 16 Grommet Plate/Shift Cable at Floor Pan

1 ± GROMMET PLATE

2 ± SHIFT CABLE

Fig. 17 Gearshift Cable Adjustment Screw

1 ± GEARSHIFT CABLE ADJUSTMENT SCREW

PLTRANSAXLE 21 - 75

REMOVAL AND INSTALLATION (Continued)

Page 991 of 1285

(2) Disconnect throttle valve cable from air clean-

er/throttle body assembly as shown in (Fig. 25).

(3) Disconnect throttle valve cable from lever on

transaxle and remove from bracket (Fig. 26).INSTALLATION

NOTE: Route throttle valve cable in a manner that

allows free, unobstructed travel. For proper tran-

saxle operation, the cable must not bind.

(1) Install transaxle throttle valve cable to bracket

and lever as shown in (Fig. 26). Make sure the cable

snapsonto the lever.

(2) Install the throttle valve cable to the air clean-

er/throttle body as shown in (Fig. 25).

(3) Install the air cleaner/throttle body assy. as fol-

lows:

(a) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(b) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(c) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(d) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(4) Connect the battery negative cable.

(5) Perform the Throttle Valve Cable Adjustment

Procedure found in this group.

(6) Road test vehicle and verify proper transaxle

operation.

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE

The transmission throttle valve is operated by a

cam on the valve body throttle lever. The throttle

lever is actuated by a cable connected to the engine

throttle body lever.

The throttle valve is located within the transaxle

valve body and is responsible for transaxle shift

speed, shift quality, and part-throttle downshift sen-

sitivity. Proper cable adjustment is essential for

proper transaxle operation.

NOTE: The air cleaner/throttle body assembly must

be installed into position before making this adjust-

ment.

Fig. 25 Throttle Valve Cable at Air Cleaner/Throttle

Body

1 ± KICKDOWN CABLE

2 ± AIR CLEANER/THROTTLE BODY ASSY.

Fig. 26 Throttle Valve Cable at Transaxle

1 ± LEVER

2 ± BRACKET

3 ± KICKDOWN CABLE

21 - 78 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1051 of 1285

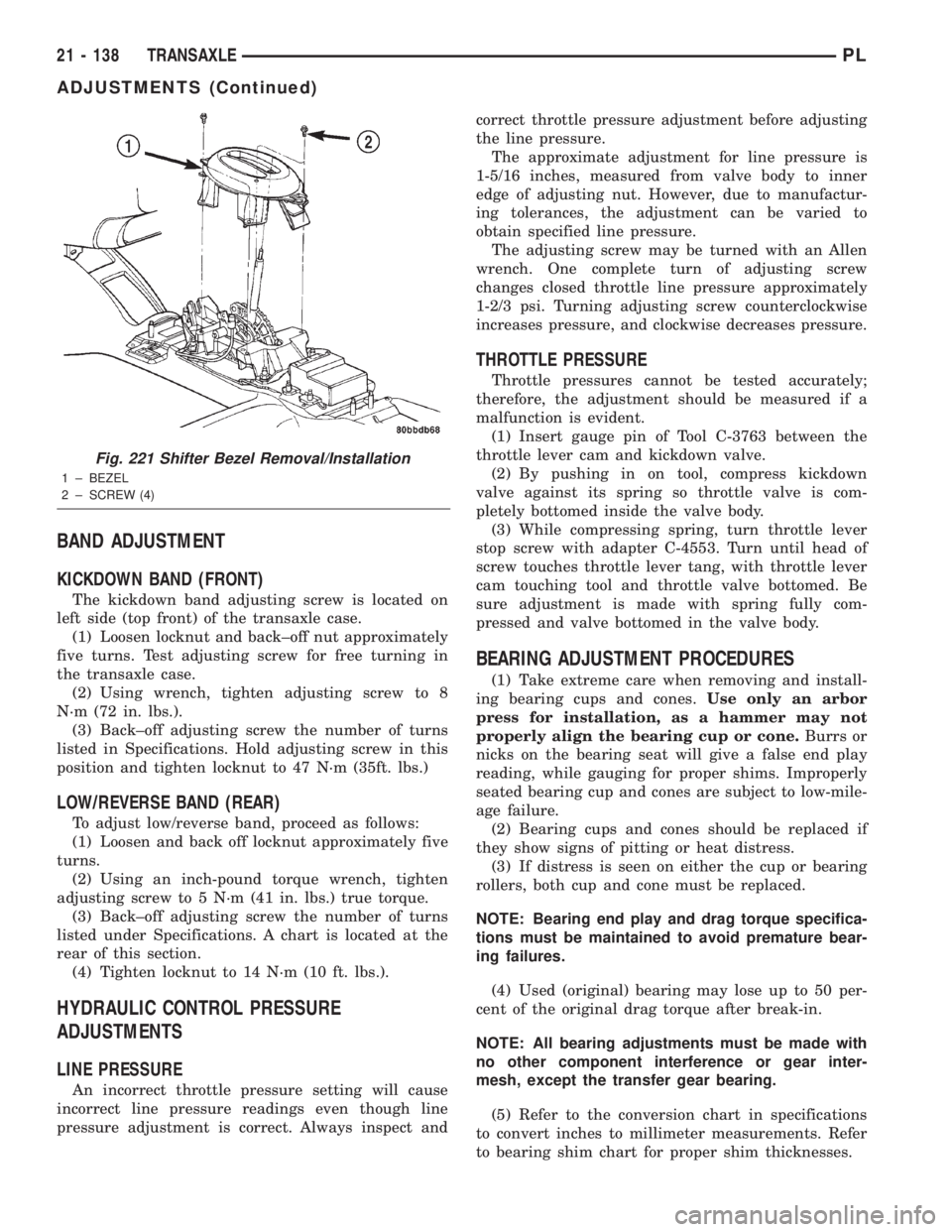

BAND ADJUSTMENT

KICKDOWN BAND (FRONT)

The kickdown band adjusting screw is located on

left side (top front) of the transaxle case.

(1) Loosen locknut and back±off nut approximately

five turns. Test adjusting screw for free turning in

the transaxle case.

(2) Using wrench, tighten adjusting screw to 8

N´m (72 in. lbs.).

(3) Back±off adjusting screw the number of turns

listed in Specifications. Hold adjusting screw in this

position and tighten locknut to 47 N´m (35ft. lbs.)

LOW/REVERSE BAND (REAR)

To adjust low/reverse band, proceed as follows:

(1) Loosen and back off locknut approximately five

turns.

(2) Using an inch-pound torque wrench, tighten

adjusting screw to 5 N´m (41 in. lbs.) true torque.

(3) Back±off adjusting screw the number of turns

listed under Specifications. A chart is located at the

rear of this section.

(4) Tighten locknut to 14 N´m (10 ft. lbs.).

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS

LINE PRESSURE

An incorrect throttle pressure setting will cause

incorrect line pressure readings even though line

pressure adjustment is correct. Always inspect andcorrect throttle pressure adjustment before adjusting

the line pressure.

The approximate adjustment for line pressure is

1-5/16 inches, measured from valve body to inner

edge of adjusting nut. However, due to manufactur-

ing tolerances, the adjustment can be varied to

obtain specified line pressure.

The adjusting screw may be turned with an Allen

wrench. One complete turn of adjusting screw

changes closed throttle line pressure approximately

1-2/3 psi. Turning adjusting screw counterclockwise

increases pressure, and clockwise decreases pressure.

THROTTLE PRESSURE

Throttle pressures cannot be tested accurately;

therefore, the adjustment should be measured if a

malfunction is evident.

(1) Insert gauge pin of Tool C-3763 between the

throttle lever cam and kickdown valve.

(2) By pushing in on tool, compress kickdown

valve against its spring so throttle valve is com-

pletely bottomed inside the valve body.

(3) While compressing spring, turn throttle lever

stop screw with adapter C-4553. Turn until head of

screw touches throttle lever tang, with throttle lever

cam touching tool and throttle valve bottomed. Be

sure adjustment is made with spring fully com-

pressed and valve bottomed in the valve body.

BEARING ADJUSTMENT PROCEDURES

(1) Take extreme care when removing and install-

ing bearing cups and cones.Use only an arbor

press for installation, as a hammer may not

properly align the bearing cup or cone.Burrs or

nicks on the bearing seat will give a false end play

reading, while gauging for proper shims. Improperly

seated bearing cup and cones are subject to low-mile-

age failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress.

(3) If distress is seen on either the cup or bearing

rollers, both cup and cone must be replaced.

NOTE: Bearing end play and drag torque specifica-

tions must be maintained to avoid premature bear-

ing failures.

(4) Used (original) bearing may lose up to 50 per-

cent of the original drag torque after break-in.

NOTE: All bearing adjustments must be made with

no other component interference or gear inter-

mesh, except the transfer gear bearing.

(5) Refer to the conversion chart in specifications

to convert inches to millimeter measurements. Refer

to bearing shim chart for proper shim thicknesses.

Fig. 221 Shifter Bezel Removal/Installation

1 ± BEZEL

2 ± SCREW (4)

21 - 138 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1052 of 1285

OUTPUT SHAFT BEARING

With output shaft gear removed, install a 13.65

mm (0.537 inch) and a 1.34 mm (0.053 inch) gauging

shim on the planetary rear annulus gear hub using

grease to hold the shim in place. The 13.65 mm shim

has a larger inside diameter and must be installed

over the output shaft first. The 1.34 mm shim pilots

on the output shaft.

Install output shaft gear and bearing assembly,

torque to 271 N´m (200 ft. lbs.).

To measure bearing end play:

(1) Attach Tool L-4432 to the output shaft gear.

(2) Mount a steel ball with grease into the end of

the output shaft.

(3) Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

(4) Using a dial indicator mounted to the transaxle

case, measure output shaft end play.

(5) Once bearing end play has been determined,

refer to the output shaft bearing shim chart.

(6) The 12.65 mm (0.498 inch), 13.15 mm (0.518

inch) or 13.65 mm (0.537 inch) shims are always

installed first.These shims have lubrication slots

that are necessary for proper bearing lubrica-

tion.

(7) Shims thinner than 12.65 mm listed in the

chart are common to both the transfer shaft and out-

put shaft bearings.

(8) Use tool L-4434 to remove the retaining nut

and washer. To remove the output shaft gear use tool

L-4407.

(9) Remove the two gauging shims and install the

proper shim combination, making sure to install the

12.65, 13.15, or 13.65 mm shim first. Use grease to

hold the shims in place. Install the output shaft gear

and bearing assembly.

(10) Install the retaining nut and washer, and

torque to 271 N´m (200 ft. lbs.).

(11) Using an inch-pound torque wrench, check the

turning torque.The torque should be between 3

and 8 inch-pounds.

(12) If the turning torque is too high, install a

0.05mm (0.002 inch) thicker shim. If the turning

torque is too low, install a 0.05 mm (0.002 inch) thin-

ner shim. Repeat until the proper turning torque is 3

to 8 inch pounds.

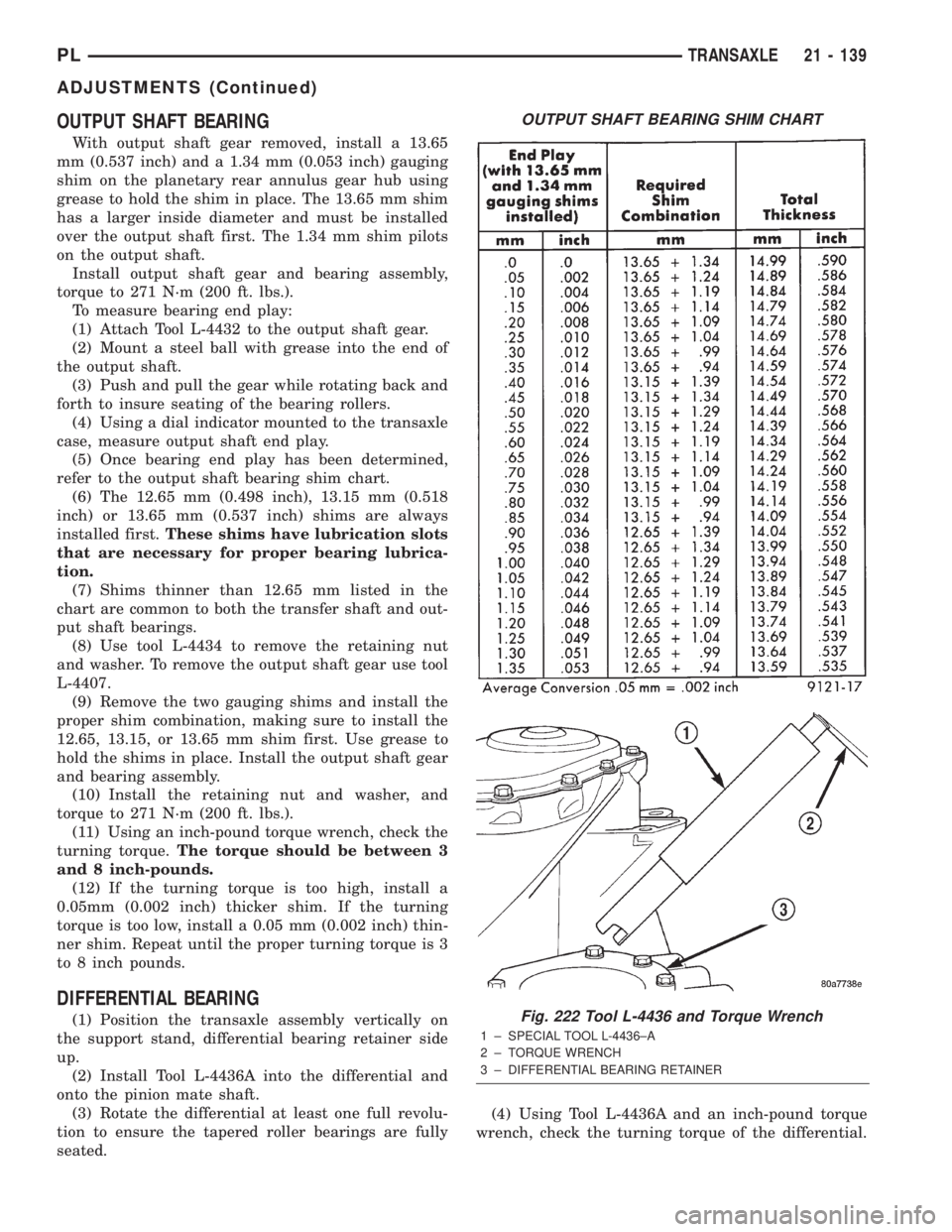

DIFFERENTIAL BEARING

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft.

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential.

OUTPUT SHAFT BEARING SHIM CHART

Fig. 222 Tool L-4436 and Torque Wrench

1 ± SPECIAL TOOL L-4436±A

2 ± TORQUE WRENCH

3 ± DIFFERENTIAL BEARING RETAINER

PLTRANSAXLE 21 - 139

ADJUSTMENTS (Continued)

Page 1053 of 1285

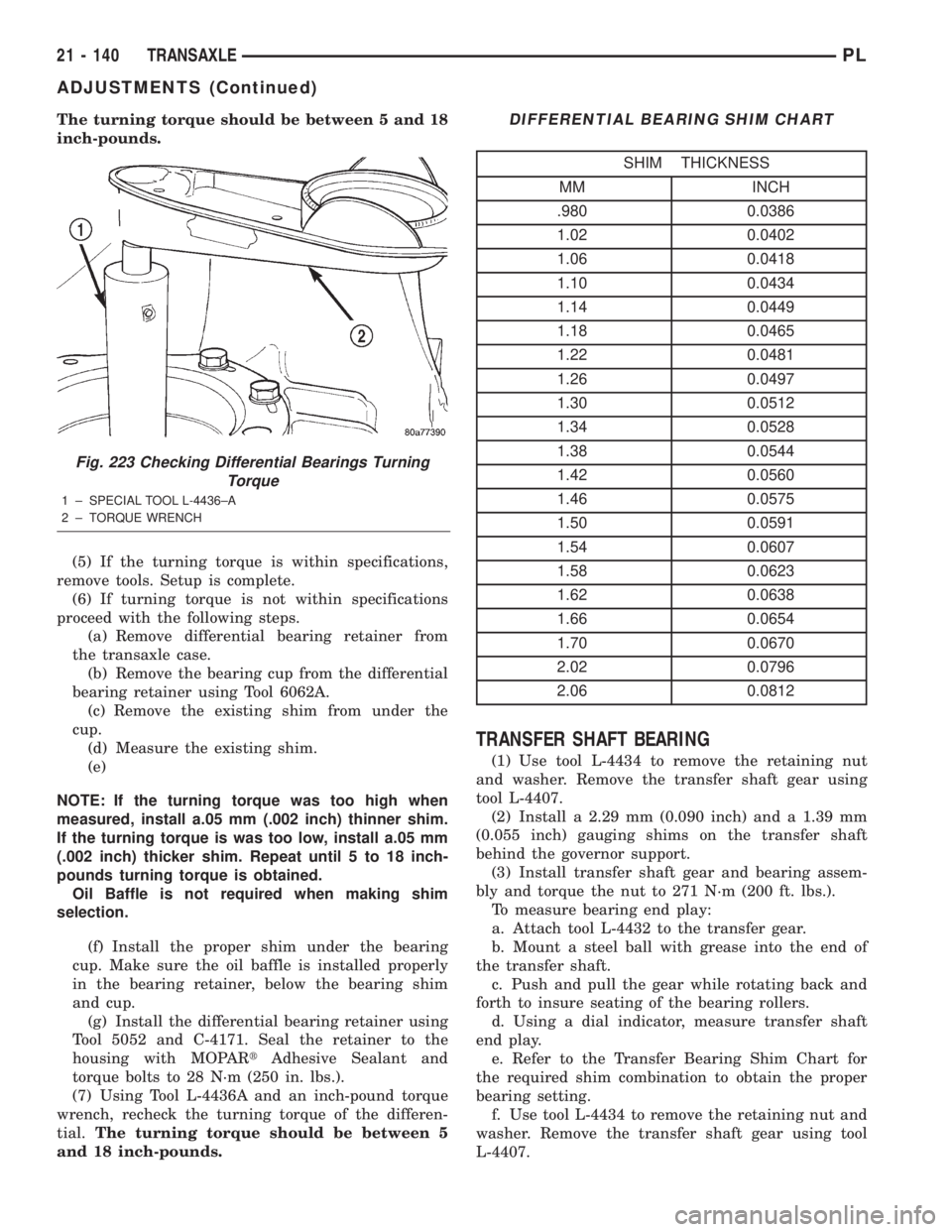

The turning torque should be between 5 and 18

inch-pounds.

(5) If the turning torque is within specifications,

remove tools. Setup is complete.

(6) If turning torque is not within specifications

proceed with the following steps.

(a) Remove differential bearing retainer from

the transaxle case.

(b) Remove the bearing cup from the differential

bearing retainer using Tool 6062A.

(c) Remove the existing shim from under the

cup.

(d) Measure the existing shim.

(e)

NOTE: If the turning torque was too high when

measured, install a.05 mm (.002 inch) thinner shim.

If the turning torque is was too low, install a.05 mm

(.002 inch) thicker shim. Repeat until 5 to 18 inch-

pounds turning torque is obtained.

Oil Baffle is not required when making shim

selection.

(f) Install the proper shim under the bearing

cup. Make sure the oil baffle is installed properly

in the bearing retainer, below the bearing shim

and cup.

(g) Install the differential bearing retainer using

Tool 5052 and C-4171. Seal the retainer to the

housing with MOPARtAdhesive Sealant and

torque bolts to 28 N´m (250 in. lbs.).

(7) Using Tool L-4436A and an inch-pound torque

wrench, recheck the turning torque of the differen-

tial.The turning torque should be between 5

and 18 inch-pounds.

TRANSFER SHAFT BEARING

(1) Use tool L-4434 to remove the retaining nut

and washer. Remove the transfer shaft gear using

tool L-4407.

(2) Install a 2.29 mm (0.090 inch) and a 1.39 mm

(0.055 inch) gauging shims on the transfer shaft

behind the governor support.

(3) Install transfer shaft gear and bearing assem-

bly and torque the nut to 271 N´m (200 ft. lbs.).

To measure bearing end play:

a. Attach tool L-4432 to the transfer gear.

b. Mount a steel ball with grease into the end of

the transfer shaft.

c. Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

d. Using a dial indicator, measure transfer shaft

end play.

e. Refer to the Transfer Bearing Shim Chart for

the required shim combination to obtain the proper

bearing setting.

f. Use tool L-4434 to remove the retaining nut and

washer. Remove the transfer shaft gear using tool

L-4407.

Fig. 223 Checking Differential Bearings Turning

Torque

1 ± SPECIAL TOOL L-4436±A

2 ± TORQUE WRENCH

DIFFERENTIAL BEARING SHIM CHART

SHIM THICKNESS

MM INCH

.980 0.0386

1.02 0.0402

1.06 0.0418

1.10 0.0434

1.14 0.0449

1.18 0.0465

1.22 0.0481

1.26 0.0497

1.30 0.0512

1.34 0.0528

1.38 0.0544

1.42 0.0560

1.46 0.0575

1.50 0.0591

1.54 0.0607

1.58 0.0623

1.62 0.0638

1.66 0.0654

1.70 0.0670

2.02 0.0796

2.06 0.0812

21 - 140 TRANSAXLEPL

ADJUSTMENTS (Continued)