wipers DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 582 of 1285

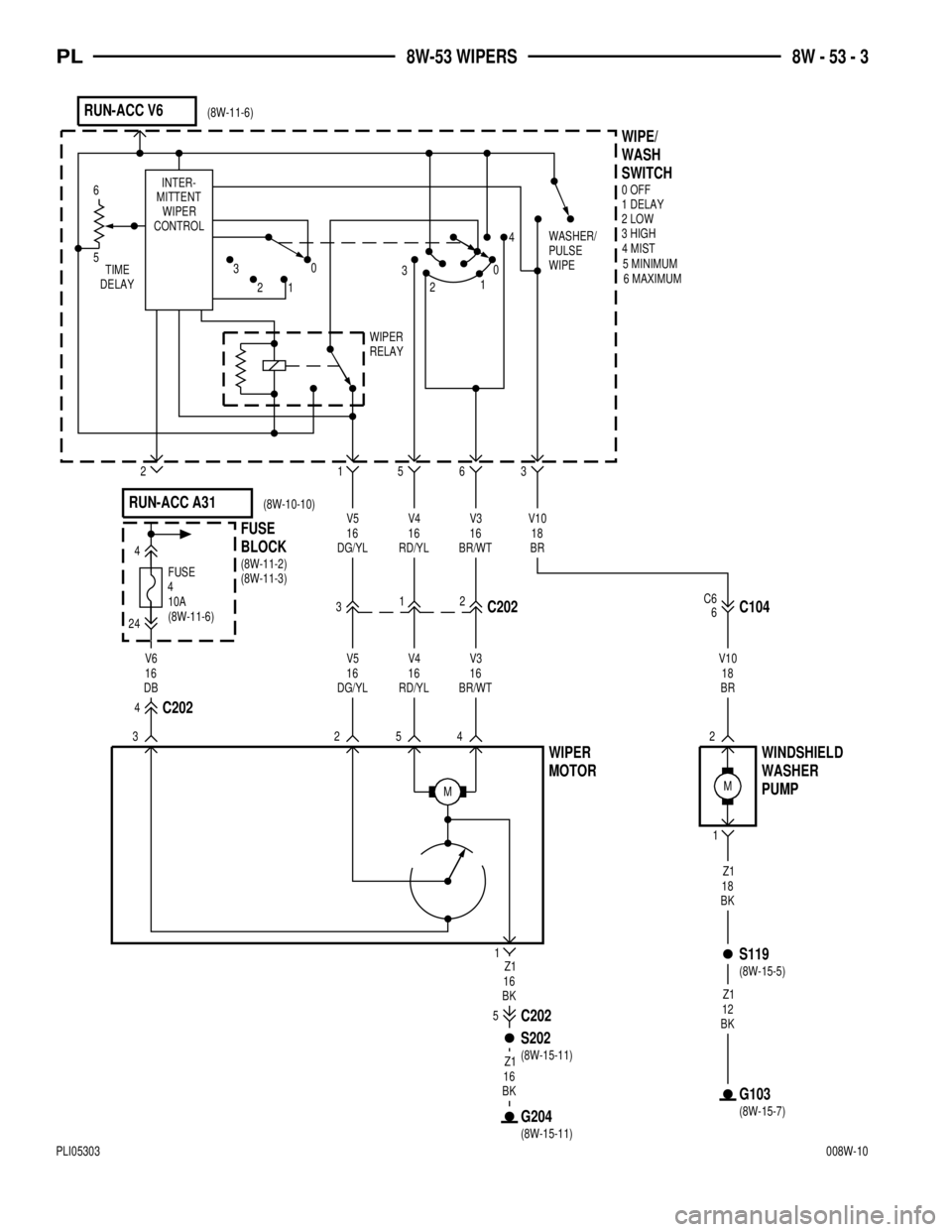

2

0

1 2 33

210

MITTENT

WIPER

CONTROL

1

INTER-

563

4

6

5

TIME

DELAYWASHER/

PULSE

WIPE

WIPER

RELAY6 MAXIMUM 5 MINIMUM

WIPE/

3 HIGH 2 LOW

1 DELAY

0 OFF

WASH

SWITCH

4 MIST

1 2

543

M

WIPER

MOTOR

312C202

M

2

1

PUMP WASHER

WINDSHIELD

C1046 C6

G103 S119

V5

16

DG/YL

V5

16

DG/YL

V4

16

RD/YL

V4

16

RD/YL

V3

16

BR/WT

V3

16

BR/WT

V10

18

BR

V10

18

BR

Z1

18

BK

Z1

12

BK

4C202

V6

16

DB

FUSE

BLOCK

10A

FUSE

4

244

RUN-ACC A31

RUN-ACC V6

G204

C2025

S202

Z1

16

BK

Z1

16

BK

(8W-15-7) (8W-15-5) (8W-11-2)

(8W-11-3)

(8W-11-6)(8W-10-10) (8W-11-6)

(8W-15-11) (8W-15-11)

PL8W-53 WIPERS 8W - 53 - 3

PLI05303008W-10

Page 909 of 1285

(25) Turn the key to OFF and remove the scan tool

from the vehicle.

(26) Test the operation of the horn, wipers and any

other functions that are steering column operated. If

applicable, reset the radio and the clock.

(27) If the steering column is a tilt column, verify

the tilt mechanism operates properly.

(28) Road test the vehicle to ensure proper opera-

tion of the steering system and the speed control sys-

tem.

STEERING COLUMN LOWER COUPLING

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section and in STEERING

GEAR.

REMOVAL

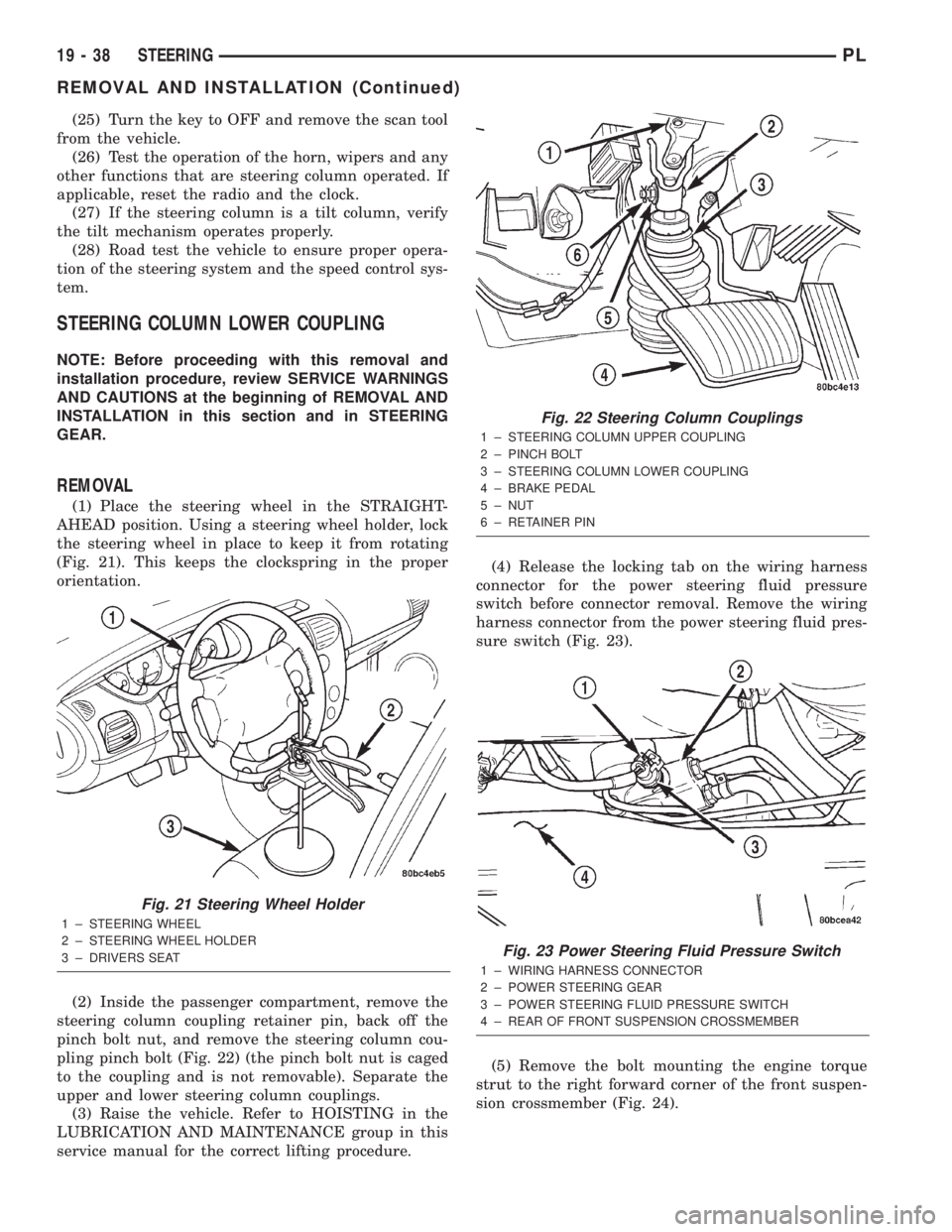

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 21). This keeps the clockspring in the proper

orientation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 22) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 23).

(5) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 24).

Fig. 21 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 22 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 23 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1123 of 1285

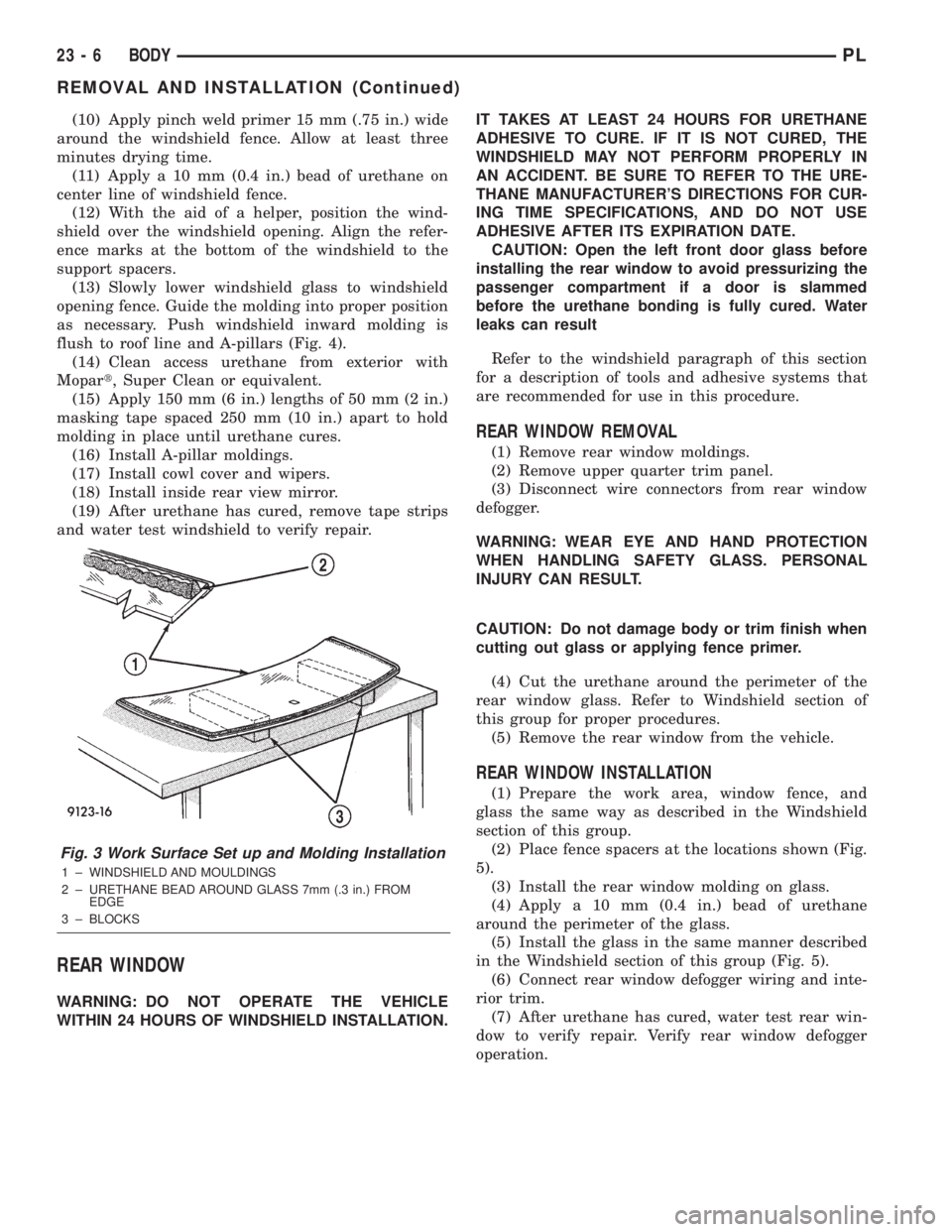

(10) Apply pinch weld primer 15 mm (.75 in.) wide

around the windshield fence. Allow at least three

minutes drying time.

(11) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(12) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

(13) Slowly lower windshield glass to windshield

opening fence. Guide the molding into proper position

as necessary. Push windshield inward molding is

flush to roof line and A-pillars (Fig. 4).

(14) Clean access urethane from exterior with

Mopart, Super Clean or equivalent.

(15) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(16) Install A-pillar moldings.

(17) Install cowl cover and wipers.

(18) Install inside rear view mirror.

(19) After urethane has cured, remove tape strips

and water test windshield to verify repair.

REAR WINDOW

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT. BE SURE TO REFER TO THE URE-

THANE MANUFACTURER'S DIRECTIONS FOR CUR-

ING TIME SPECIFICATIONS, AND DO NOT USE

ADHESIVE AFTER ITS EXPIRATION DATE.

CAUTION: Open the left front door glass before

installing the rear window to avoid pressurizing the

passenger compartment if a door is slammed

before the urethane bonding is fully cured. Water

leaks can result

Refer to the windshield paragraph of this section

for a description of tools and adhesive systems that

are recommended for use in this procedure.

REAR WINDOW REMOVAL

(1) Remove rear window moldings.

(2) Remove upper quarter trim panel.

(3) Disconnect wire connectors from rear window

defogger.

WARNING: WEAR EYE AND HAND PROTECTION

WHEN HANDLING SAFETY GLASS. PERSONAL

INJURY CAN RESULT.

CAUTION: Do not damage body or trim finish when

cutting out glass or applying fence primer.

(4) Cut the urethane around the perimeter of the

rear window glass. Refer to Windshield section of

this group for proper procedures.

(5) Remove the rear window from the vehicle.

REAR WINDOW INSTALLATION

(1) Prepare the work area, window fence, and

glass the same way as described in the Windshield

section of this group.

(2) Place fence spacers at the locations shown (Fig.

5).

(3) Install the rear window molding on glass.

(4) Apply a 10 mm (0.4 in.) bead of urethane

around the perimeter of the glass.

(5) Install the glass in the same manner described

in the Windshield section of this group (Fig. 5).

(6) Connect rear window defogger wiring and inte-

rior trim.

(7) After urethane has cured, water test rear win-

dow to verify repair. Verify rear window defogger

operation.

Fig. 3 Work Surface Set up and Molding Installation

1 ± WINDSHIELD AND MOULDINGS

2 ± URETHANE BEAD AROUND GLASS 7mm (.3 in.) FROM

EDGE

3 ± BLOCKS

23 - 6 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1253 of 1285

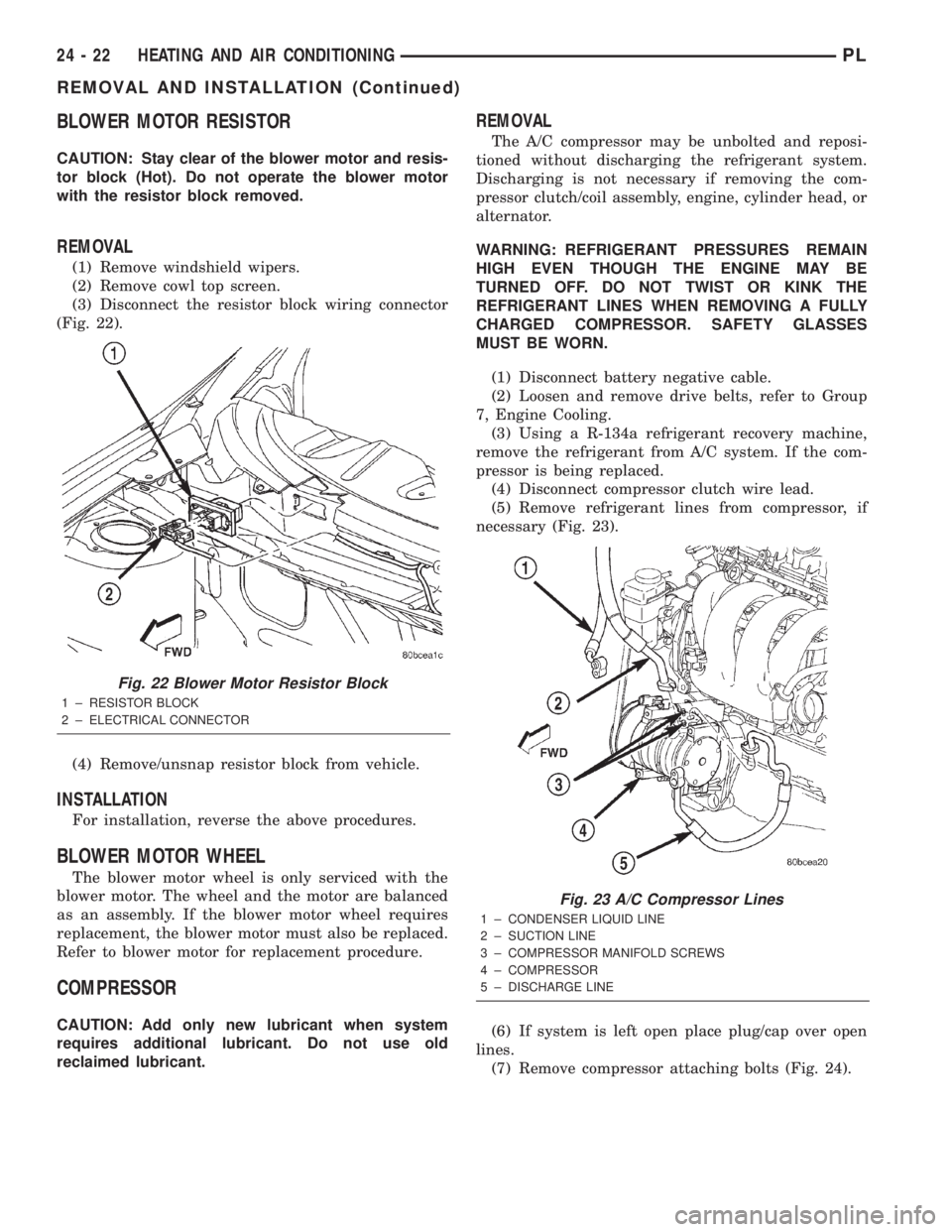

BLOWER MOTOR RESISTOR

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed.

REMOVAL

(1) Remove windshield wipers.

(2) Remove cowl top screen.

(3) Disconnect the resistor block wiring connector

(Fig. 22).

(4) Remove/unsnap resistor block from vehicle.

INSTALLATION

For installation, reverse the above procedures.

BLOWER MOTOR WHEEL

The blower motor wheel is only serviced with the

blower motor. The wheel and the motor are balanced

as an assembly. If the blower motor wheel requires

replacement, the blower motor must also be replaced.

Refer to blower motor for replacement procedure.

COMPRESSOR

CAUTION: Add only new lubricant when system

requires additional lubricant. Do not use old

reclaimed lubricant.

REMOVAL

The A/C compressor may be unbolted and reposi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the com-

pressor clutch/coil assembly, engine, cylinder head, or

alternator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. DO NOT TWIST OR KINK THE

REFRIGERANT LINES WHEN REMOVING A FULLY

CHARGED COMPRESSOR. SAFETY GLASSES

MUST BE WORN.

(1) Disconnect battery negative cable.

(2) Loosen and remove drive belts, refer to Group

7, Engine Cooling.

(3) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system. If the com-

pressor is being replaced.

(4) Disconnect compressor clutch wire lead.

(5) Remove refrigerant lines from compressor, if

necessary (Fig. 23).

(6) If system is left open place plug/cap over open

lines.

(7) Remove compressor attaching bolts (Fig. 24).

Fig. 22 Blower Motor Resistor Block

1 ± RESISTOR BLOCK

2 ± ELECTRICAL CONNECTOR

Fig. 23 A/C Compressor Lines

1 ± CONDENSER LIQUID LINE

2 ± SUCTION LINE

3 ± COMPRESSOR MANIFOLD SCREWS

4 ± COMPRESSOR

5 ± DISCHARGE LINE

24 - 22 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)