instrument panel DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1 of 1285

GROUP TAB LOCATORINIntroductionINaIntroduction0Lubrication and Maintenance2Suspension3Differential and Driveline5Brakes6Clutch7Cooling8ABattery8BStarting8CCharging System8DIgnition System8EInstrument Panel and Systems8EaInstrument Panel and Systems8FAudio System8GHorns8HVehicle Speed Control System8JTurn Signal and Flashers8KWindshield Wipers and Washers8LLamps8LaLamps8MRestraint System8NElectrically Heated Systems8OPower Distribution Systems8PPower Door Locks8QImmobilizer System8SPower Windows8TPower Mirrors8TaPower Mirrors8UChime Warning/Reminder System8WWiring Diagrams - LHD and RHD9Engine11Exhaust System13Frame and Bumpers14Fuel System19Steering21Transaxle22Tires and Wheels23Body24Heating and Air Conditioning24aHeating and Air Conditioning25Emission Control Systems

Page 81 of 1285

DESCRIPTION AND OPERATION

BASE BRAKE SYSTEM OPERATION

When a vehicle needs to be stopped, the driver

applies the brake pedal. The brake pedal pushes the

input rod of the power brake booster into the booster.

The booster uses vacuum to ease pedal effort as force

is transferred through the booster to the master cyl-

inder. The booster's output rod pushes in the master

cylinder's primary and secondary pistons applying

hydraulic pressure through the chassis brake tubes

and proportioning valves (rear only) to the brakes at

each tire and wheel assembly.

Front disc brakes control the braking of the front

wheels; rear braking is controlled by rear drum

brakes as standard equipment. Rear disc brakes and

an antilock brake system (ABS) with traction control

are optional.

The hydraulic brake system is diagonally split on

both the non-antilock and antilock braking systems.

This means the left front and right rear brakes are

on one hydraulic circuit and the right front and left

rear are on the other.

Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20e.

This system shares most base brake hardware used

on vehicles without ABS. A vehicle equipped with

ABS, however, uses a different master cylinder and

brake tubes. Also included in the ABS system is an

integrated control unit (ICU) and four wheel speed

sensors. These components are described in detail in

the ANTILOCK BRAKE SYSTEM section in this

group of the service manual. All vehicles with ABS

come standard with four-wheel-disc brakes and trac-

tion control.

The parking brakes are hand-operated. When

applied, the parking brake lever pulls on cables that

actuate brake shoes at each rear wheel. The parking

brake lever has an automatic adjusting feature that

takes up any excessive slack in the parking brake

cable system.

BASE BRAKE SYSTEM COMPONENTS

BRAKE PEDAL

A suspended-type brake pedal is used on this vehi-

cle. The pedal pivots on a shaft mounted in the pedal

support bracket under the instrument panel. The

pedal connects to the power brake booster input rod

and pushes it in when the pedal is applied.

The brake pedal and it's pad are serviceable sepa-

rately.

POWER BRAKE BOOSTER

There are two different power brake booster

designs, although externally they appear the same.

All vehicles use a 205 mm tandem diaphragm power

brake booster. The two boosters are internally tuned

differently depending on whether the vehicle is

equipped with the standard front disc/rear drum

brake combination or the optional front disc/rear disc

(four-wheel disc) brake combination. If the power

brake booster requires replacement, be sure it is

replaced with the correct part.

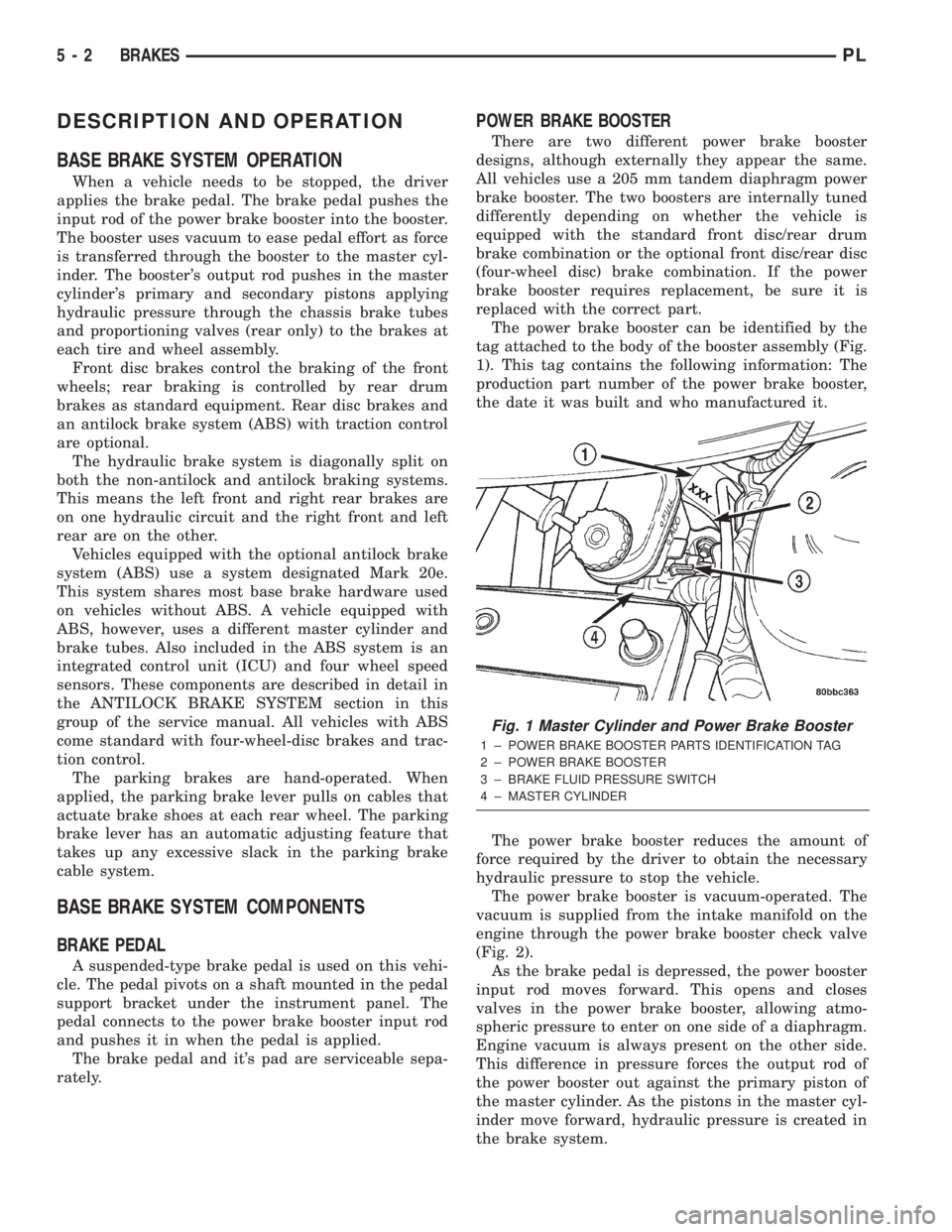

The power brake booster can be identified by the

tag attached to the body of the booster assembly (Fig.

1). This tag contains the following information: The

production part number of the power brake booster,

the date it was built and who manufactured it.

The power brake booster reduces the amount of

force required by the driver to obtain the necessary

hydraulic pressure to stop the vehicle.

The power brake booster is vacuum-operated. The

vacuum is supplied from the intake manifold on the

engine through the power brake booster check valve

(Fig. 2).

As the brake pedal is depressed, the power booster

input rod moves forward. This opens and closes

valves in the power brake booster, allowing atmo-

spheric pressure to enter on one side of a diaphragm.

Engine vacuum is always present on the other side.

This difference in pressure forces the output rod of

the power booster out against the primary piston of

the master cylinder. As the pistons in the master cyl-

inder move forward, hydraulic pressure is created in

the brake system.

Fig. 1 Master Cylinder and Power Brake Booster

1 ± POWER BRAKE BOOSTER PARTS IDENTIFICATION TAG

2 ± POWER BRAKE BOOSTER

3 ± BRAKE FLUID PRESSURE SWITCH

4 ± MASTER CYLINDER

5 - 2 BRAKESPL

Page 87 of 1285

RED BRAKE WARNING LAMP

The red BRAKE warning lamp is located in the

instrument panel cluster and illuminates when a low

brake fluid condition occurs or when the parking

brake lever is applied with the ignition key in the

ON position. In addition, the red BRAKE warning

lamp illuminates when the ignition switch is moved

from the OFF to the ON or CRANK position. This is

done to check the bulb's operation.

Problems with this system will generally be of the

type where the warning lamp fails to turn on when it

should, or remains on when it should not.

The red BRAKE warning lamp LED is supplied

with current anytime the ignition switch is ON. The

bulb is illuminated by completing the ground circuit

using any of the following components:

²the brake fluid level switch located in the mas-

ter cylinder reservoir

²the parking brake switch mounted on the park-

ing brake lever (Fig. 10)

²the ignition switch when the ignition switch is

first moved to the ON or CRANK position

²the mechanical instrument cluster (MIC) (with

ABS)

²the ABS electronic brake distribution (EBD)

The brake fluid level switch is located in the brake

fluid reservoir of the master cylinder assembly (Fig.

1). The purpose of the switch is to provide the driver

with an early warning that the brake fluid level inthe master cylinder reservoir has dropped below an

acceptable level.

As the fluid drops below the minimum level, the

fluid level switch closes and grounds the red BRAKE

warning lamp circuit. This turns on the red BRAKE

warning lamp. At this time, the master cylinder fluid

reservoir must be checked and filled to the full mark

with DOT 3 brake fluid. An abnormal loss of brake

fluid in the master cylinder fluid reservoir could be

caused by a leak in the hydraulic system. The entire

brake hydraulic system should be checked for evi-

dence of a leak.

The red BRAKE warning lamp can be turned on by

the MIC in the case where the ABS is experiencing a

problem where the amber ABS warning lamp needs

to be illuminated and cannot. The MIC will then illu-

minate the red BRAKE warning lamp.

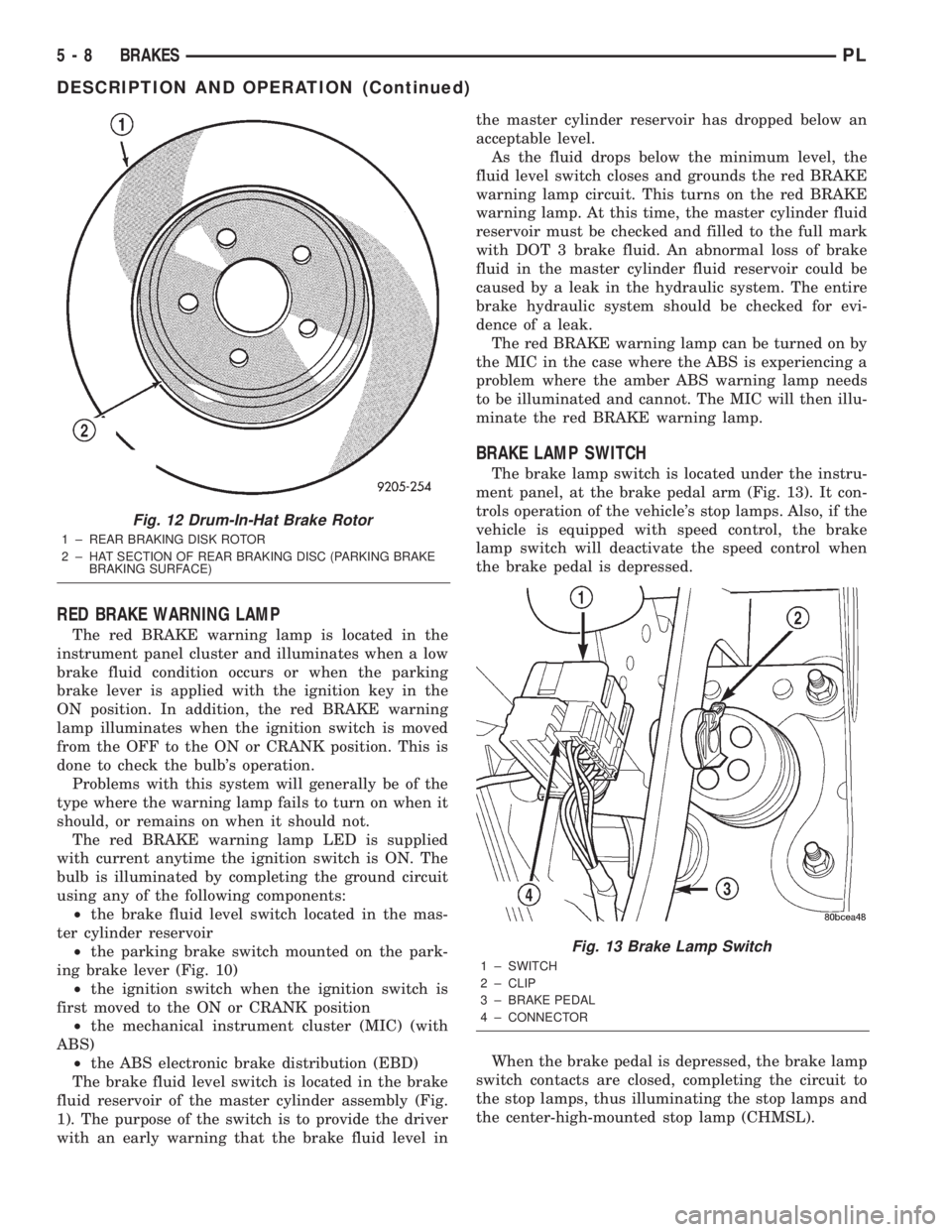

BRAKE LAMP SWITCH

The brake lamp switch is located under the instru-

ment panel, at the brake pedal arm (Fig. 13). It con-

trols operation of the vehicle's stop lamps. Also, if the

vehicle is equipped with speed control, the brake

lamp switch will deactivate the speed control when

the brake pedal is depressed.

When the brake pedal is depressed, the brake lamp

switch contacts are closed, completing the circuit to

the stop lamps, thus illuminating the stop lamps and

the center-high-mounted stop lamp (CHMSL).

Fig. 12 Drum-In-Hat Brake Rotor

1 ± REAR BRAKING DISK ROTOR

2 ± HAT SECTION OF REAR BRAKING DISC (PARKING BRAKE

BRAKING SURFACE)

Fig. 13 Brake Lamp Switch

1 ± SWITCH

2 ± CLIP

3 ± BRAKE PEDAL

4 ± CONNECTOR

5 - 8 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 104 of 1285

(10) If the vehicle is equipped with antilock

brakes, carefully push the power brake booster for-

ward until the booster contacts the ABS ICU mount-

ing bracket.

(11) If the vehicle does not have antilock brakes,

carefully push the power brake booster forward one

to two inches being careful not to stretch the brake

lines from the master cylinder to the brakes.

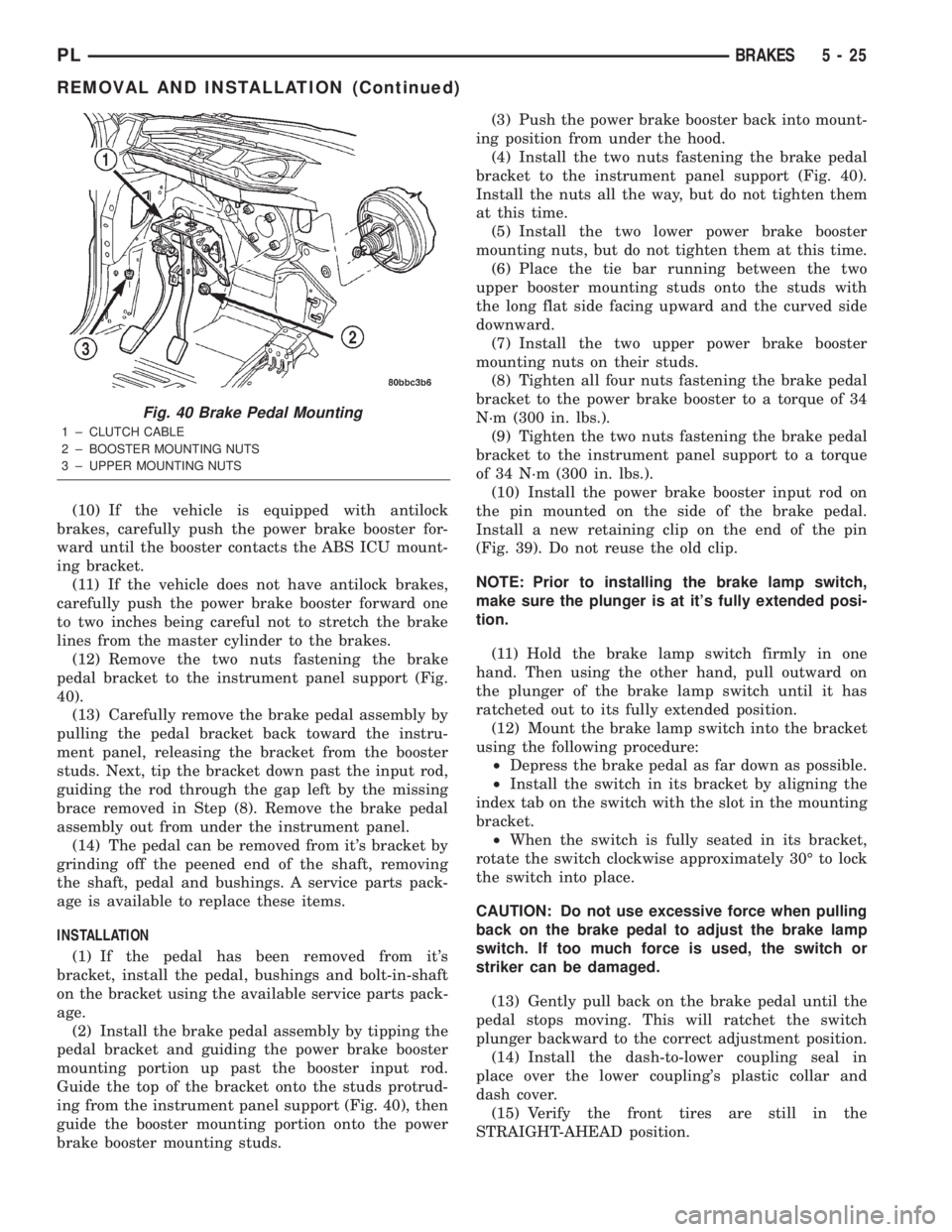

(12) Remove the two nuts fastening the brake

pedal bracket to the instrument panel support (Fig.

40).

(13) Carefully remove the brake pedal assembly by

pulling the pedal bracket back toward the instru-

ment panel, releasing the bracket from the booster

studs. Next, tip the bracket down past the input rod,

guiding the rod through the gap left by the missing

brace removed in Step (8). Remove the brake pedal

assembly out from under the instrument panel.

(14) The pedal can be removed from it's bracket by

grinding off the peened end of the shaft, removing

the shaft, pedal and bushings. A service parts pack-

age is available to replace these items.

INSTALLATION

(1) If the pedal has been removed from it's

bracket, install the pedal, bushings and bolt-in-shaft

on the bracket using the available service parts pack-

age.

(2) Install the brake pedal assembly by tipping the

pedal bracket and guiding the power brake booster

mounting portion up past the booster input rod.

Guide the top of the bracket onto the studs protrud-

ing from the instrument panel support (Fig. 40), then

guide the booster mounting portion onto the power

brake booster mounting studs.(3) Push the power brake booster back into mount-

ing position from under the hood.

(4) Install the two nuts fastening the brake pedal

bracket to the instrument panel support (Fig. 40).

Install the nuts all the way, but do not tighten them

at this time.

(5) Install the two lower power brake booster

mounting nuts, but do not tighten them at this time.

(6) Place the tie bar running between the two

upper booster mounting studs onto the studs with

the long flat side facing upward and the curved side

downward.

(7) Install the two upper power brake booster

mounting nuts on their studs.

(8) Tighten all four nuts fastening the brake pedal

bracket to the power brake booster to a torque of 34

N´m (300 in. lbs.).

(9) Tighten the two nuts fastening the brake pedal

bracket to the instrument panel support to a torque

of 34 N´m (300 in. lbs.).

(10) Install the power brake booster input rod on

the pin mounted on the side of the brake pedal.

Install a new retaining clip on the end of the pin

(Fig. 39). Do not reuse the old clip.

NOTE: Prior to installing the brake lamp switch,

make sure the plunger is at it's fully extended posi-

tion.

(11) Hold the brake lamp switch firmly in one

hand. Then using the other hand, pull outward on

the plunger of the brake lamp switch until it has

ratcheted out to its fully extended position.

(12) Mount the brake lamp switch into the bracket

using the following procedure:

²Depress the brake pedal as far down as possible.

²Install the switch in its bracket by aligning the

index tab on the switch with the slot in the mounting

bracket.

²When the switch is fully seated in its bracket,

rotate the switch clockwise approximately 30É to lock

the switch into place.

CAUTION: Do not use excessive force when pulling

back on the brake pedal to adjust the brake lamp

switch. If too much force is used, the switch or

striker can be damaged.

(13) Gently pull back on the brake pedal until the

pedal stops moving. This will ratchet the switch

plunger backward to the correct adjustment position.

(14) Install the dash-to-lower coupling seal in

place over the lower coupling's plastic collar and

dash cover.

(15) Verify the front tires are still in the

STRAIGHT-AHEAD position.

Fig. 40 Brake Pedal Mounting

1 ± CLUTCH CABLE

2 ± BOOSTER MOUNTING NUTS

3 ± UPPER MOUNTING NUTS

PLBRAKES 5 - 25

REMOVAL AND INSTALLATION (Continued)

Page 105 of 1285

(16) Reconnect the steering column lower coupling

to the steering column upper coupling (Fig. 38).

Install the coupling pinch bolt an tighten the pinch

bolt nut to a torque of 28 N´m (250 in. lbs.). Install

the pinch bolt retainer pin.

(17) Remove the steering wheel holder (Fig. 37).

(18) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

(19) Reconnect the battery negative terminal.

(20) Check the stop lamps to verify they are oper-

ating properly and not staying on when the pedal is

in the released position.

(21) Road test the vehicle to ensure proper opera-

tion of the brakes.

WITH MANUAL TRANSAXLE

REMOVAL

(1) Remove the instrument panel. Refer to the

INSTRUMENT PANELS AND SYSTEMS group in

this service manual for the required procedure.

(2) Depress and hold the brake pedal while rotat-

ing the brake lamp switch (Fig. 39) in a counterclock-

wise direction approximately 30 degrees.

(3) Pull the switch rearward and remove it from

its mounting bracket.

(4) Disconnect the clutch cable from the clutch

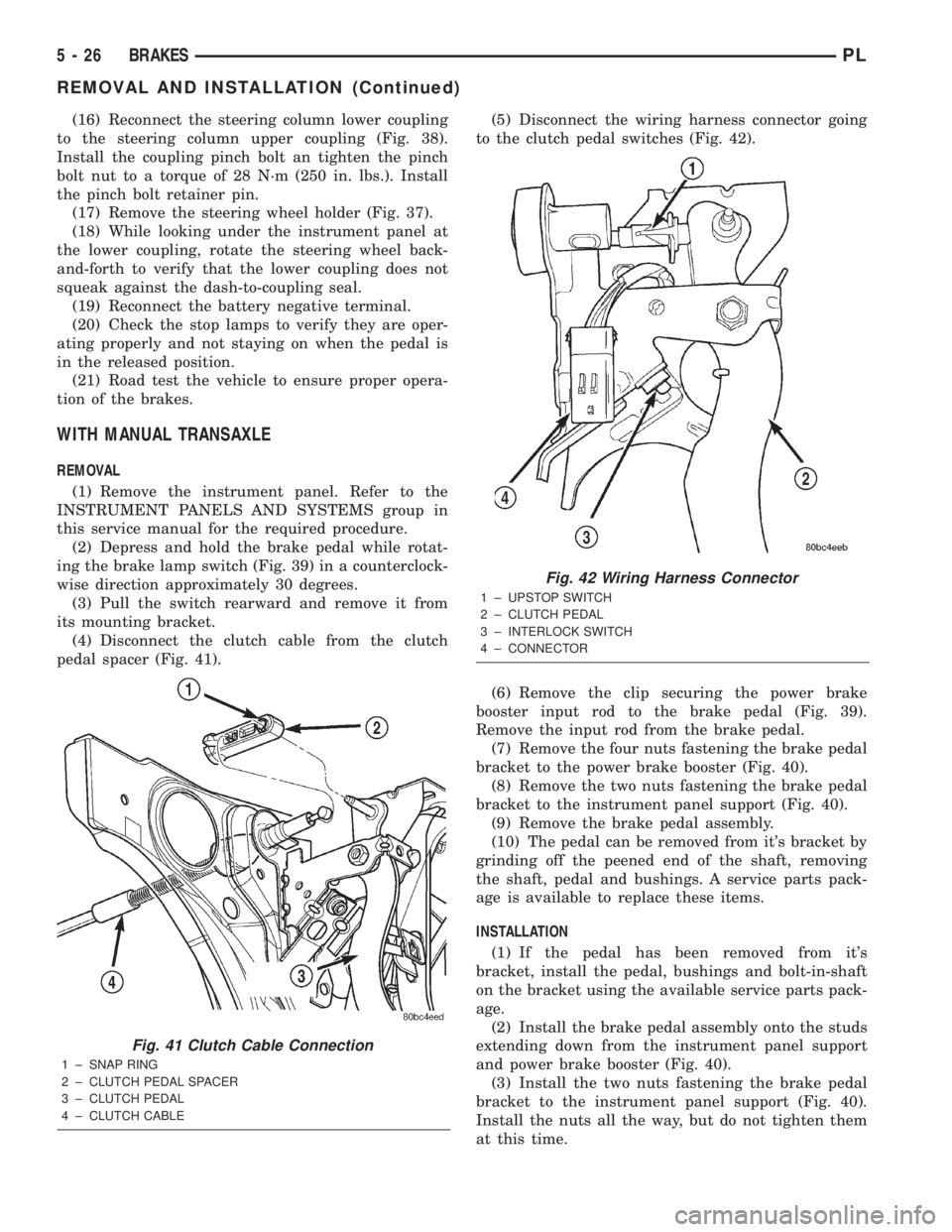

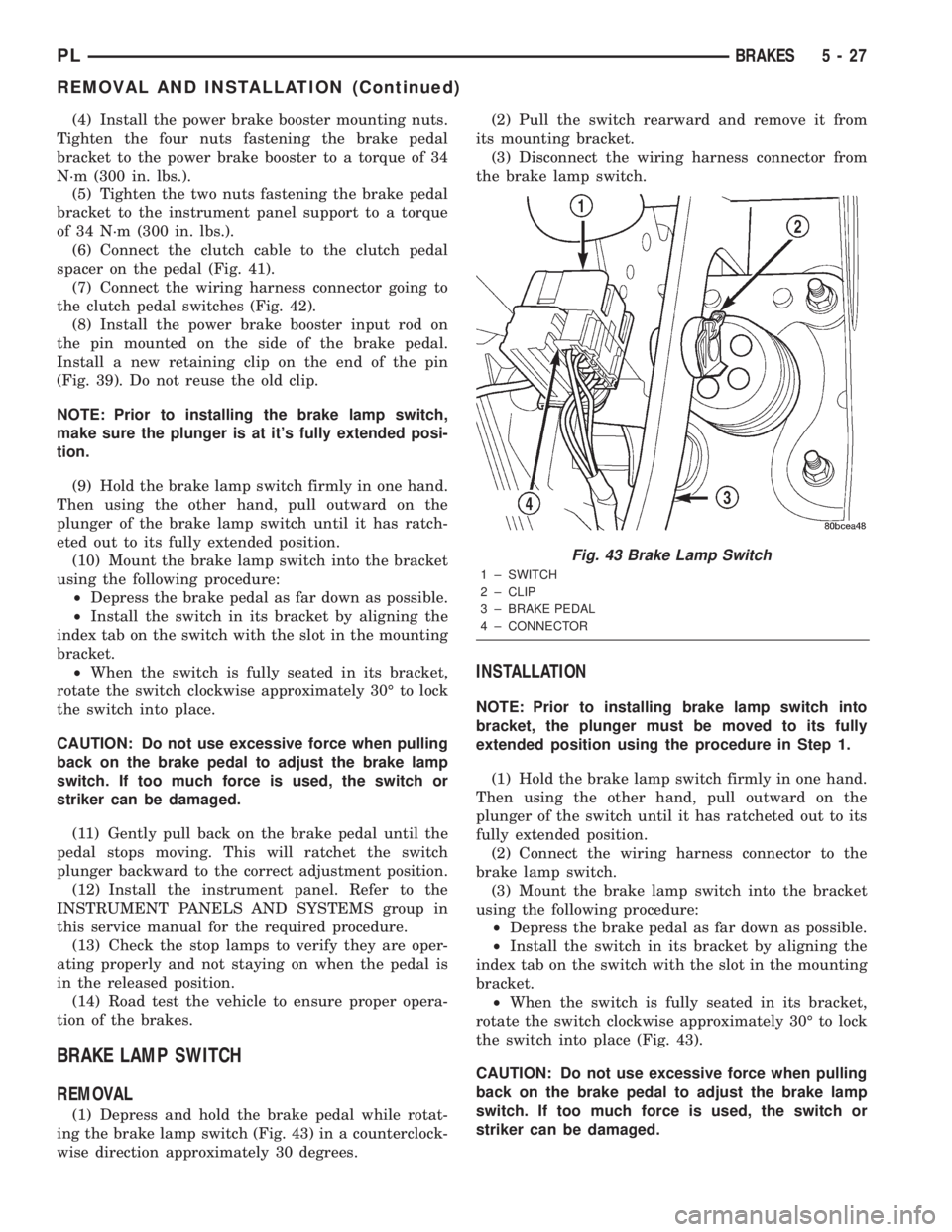

pedal spacer (Fig. 41).(5) Disconnect the wiring harness connector going

to the clutch pedal switches (Fig. 42).

(6) Remove the clip securing the power brake

booster input rod to the brake pedal (Fig. 39).

Remove the input rod from the brake pedal.

(7) Remove the four nuts fastening the brake pedal

bracket to the power brake booster (Fig. 40).

(8) Remove the two nuts fastening the brake pedal

bracket to the instrument panel support (Fig. 40).

(9) Remove the brake pedal assembly.

(10) The pedal can be removed from it's bracket by

grinding off the peened end of the shaft, removing

the shaft, pedal and bushings. A service parts pack-

age is available to replace these items.

INSTALLATION

(1) If the pedal has been removed from it's

bracket, install the pedal, bushings and bolt-in-shaft

on the bracket using the available service parts pack-

age.

(2) Install the brake pedal assembly onto the studs

extending down from the instrument panel support

and power brake booster (Fig. 40).

(3) Install the two nuts fastening the brake pedal

bracket to the instrument panel support (Fig. 40).

Install the nuts all the way, but do not tighten them

at this time.

Fig. 41 Clutch Cable Connection

1 ± SNAP RING

2 ± CLUTCH PEDAL SPACER

3 ± CLUTCH PEDAL

4 ± CLUTCH CABLE

Fig. 42 Wiring Harness Connector

1 ± UPSTOP SWITCH

2 ± CLUTCH PEDAL

3 ± INTERLOCK SWITCH

4 ± CONNECTOR

5 - 26 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 106 of 1285

(4) Install the power brake booster mounting nuts.

Tighten the four nuts fastening the brake pedal

bracket to the power brake booster to a torque of 34

N´m (300 in. lbs.).

(5) Tighten the two nuts fastening the brake pedal

bracket to the instrument panel support to a torque

of 34 N´m (300 in. lbs.).

(6) Connect the clutch cable to the clutch pedal

spacer on the pedal (Fig. 41).

(7) Connect the wiring harness connector going to

the clutch pedal switches (Fig. 42).

(8) Install the power brake booster input rod on

the pin mounted on the side of the brake pedal.

Install a new retaining clip on the end of the pin

(Fig. 39). Do not reuse the old clip.

NOTE: Prior to installing the brake lamp switch,

make sure the plunger is at it's fully extended posi-

tion.

(9) Hold the brake lamp switch firmly in one hand.

Then using the other hand, pull outward on the

plunger of the brake lamp switch until it has ratch-

eted out to its fully extended position.

(10) Mount the brake lamp switch into the bracket

using the following procedure:

²Depress the brake pedal as far down as possible.

²Install the switch in its bracket by aligning the

index tab on the switch with the slot in the mounting

bracket.

²When the switch is fully seated in its bracket,

rotate the switch clockwise approximately 30É to lock

the switch into place.

CAUTION: Do not use excessive force when pulling

back on the brake pedal to adjust the brake lamp

switch. If too much force is used, the switch or

striker can be damaged.

(11) Gently pull back on the brake pedal until the

pedal stops moving. This will ratchet the switch

plunger backward to the correct adjustment position.

(12) Install the instrument panel. Refer to the

INSTRUMENT PANELS AND SYSTEMS group in

this service manual for the required procedure.

(13) Check the stop lamps to verify they are oper-

ating properly and not staying on when the pedal is

in the released position.

(14) Road test the vehicle to ensure proper opera-

tion of the brakes.

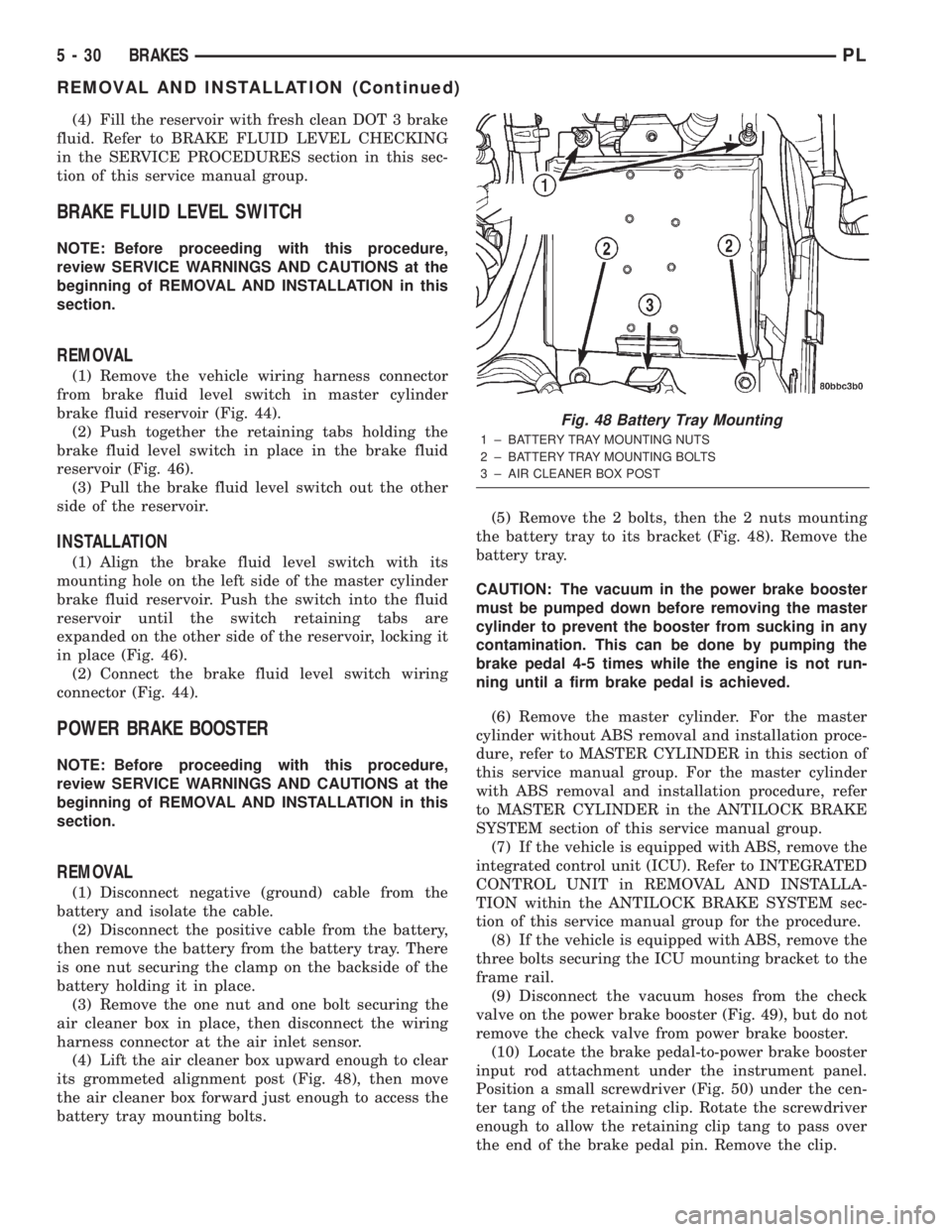

BRAKE LAMP SWITCH

REMOVAL

(1) Depress and hold the brake pedal while rotat-

ing the brake lamp switch (Fig. 43) in a counterclock-

wise direction approximately 30 degrees.(2) Pull the switch rearward and remove it from

its mounting bracket.

(3) Disconnect the wiring harness connector from

the brake lamp switch.

INSTALLATION

NOTE: Prior to installing brake lamp switch into

bracket, the plunger must be moved to its fully

extended position using the procedure in Step 1.

(1) Hold the brake lamp switch firmly in one hand.

Then using the other hand, pull outward on the

plunger of the switch until it has ratcheted out to its

fully extended position.

(2) Connect the wiring harness connector to the

brake lamp switch.

(3) Mount the brake lamp switch into the bracket

using the following procedure:

²Depress the brake pedal as far down as possible.

²Install the switch in its bracket by aligning the

index tab on the switch with the slot in the mounting

bracket.

²When the switch is fully seated in its bracket,

rotate the switch clockwise approximately 30É to lock

the switch into place (Fig. 43).

CAUTION: Do not use excessive force when pulling

back on the brake pedal to adjust the brake lamp

switch. If too much force is used, the switch or

striker can be damaged.

Fig. 43 Brake Lamp Switch

1 ± SWITCH

2 ± CLIP

3 ± BRAKE PEDAL

4 ± CONNECTOR

PLBRAKES 5 - 27

REMOVAL AND INSTALLATION (Continued)

Page 109 of 1285

(4) Fill the reservoir with fresh clean DOT 3 brake

fluid. Refer to BRAKE FLUID LEVEL CHECKING

in the SERVICE PROCEDURES section in this sec-

tion of this service manual group.

BRAKE FLUID LEVEL SWITCH

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).

(2) Push together the retaining tabs holding the

brake fluid level switch in place in the brake fluid

reservoir (Fig. 46).

(3) Pull the brake fluid level switch out the other

side of the reservoir.

INSTALLATION

(1) Align the brake fluid level switch with its

mounting hole on the left side of the master cylinder

brake fluid reservoir. Push the switch into the fluid

reservoir until the switch retaining tabs are

expanded on the other side of the reservoir, locking it

in place (Fig. 46).

(2) Connect the brake fluid level switch wiring

connector (Fig. 44).

POWER BRAKE BOOSTER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

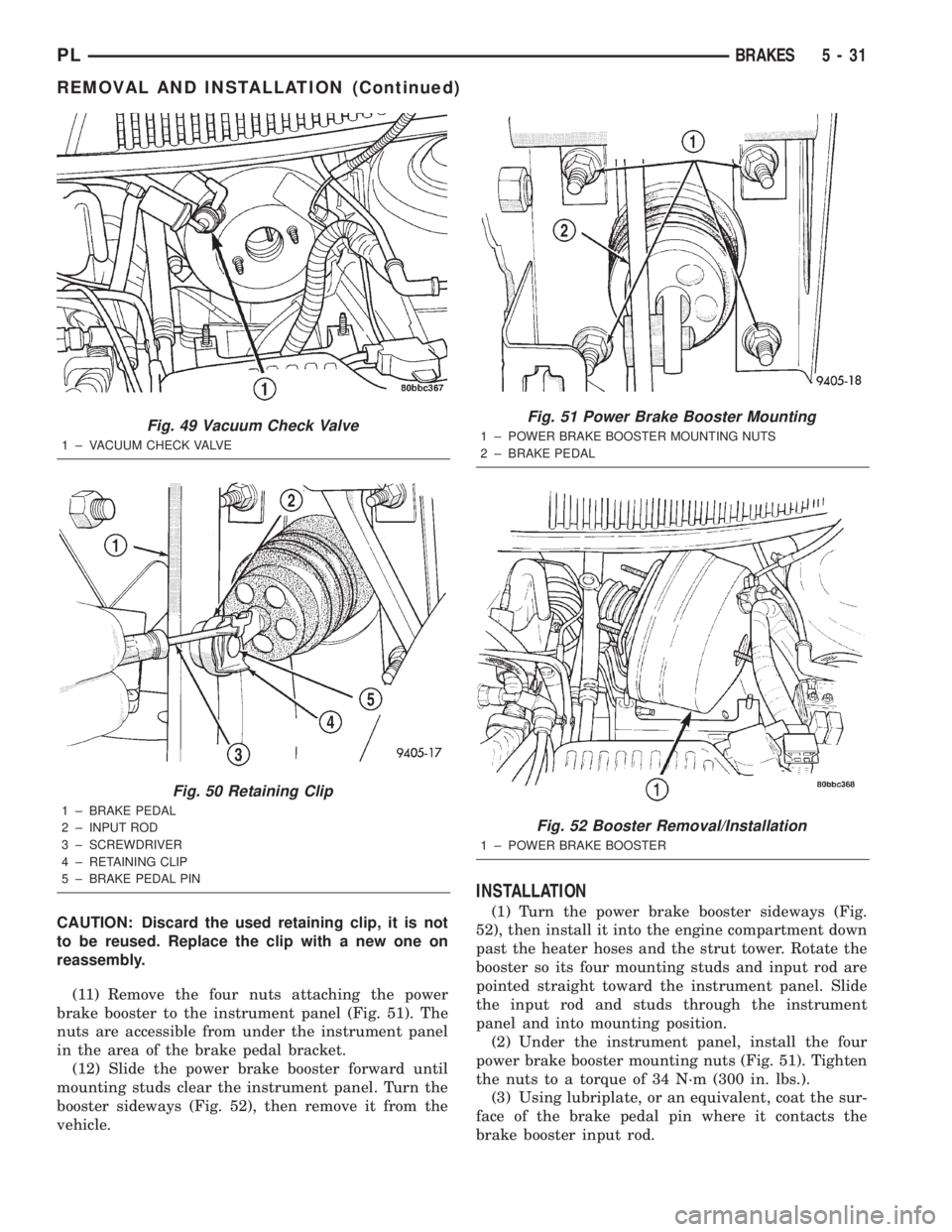

(1) Disconnect negative (ground) cable from the

battery and isolate the cable.

(2) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(3) Remove the one nut and one bolt securing the

air cleaner box in place, then disconnect the wiring

harness connector at the air inlet sensor.

(4) Lift the air cleaner box upward enough to clear

its grommeted alignment post (Fig. 48), then move

the air cleaner box forward just enough to access the

battery tray mounting bolts.(5) Remove the 2 bolts, then the 2 nuts mounting

the battery tray to its bracket (Fig. 48). Remove the

battery tray.

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal 4-5 times while the engine is not run-

ning until a firm brake pedal is achieved.

(6) Remove the master cylinder. For the master

cylinder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(7) If the vehicle is equipped with ABS, remove the

integrated control unit (ICU). Refer to INTEGRATED

CONTROL UNIT in REMOVAL AND INSTALLA-

TION within the ANTILOCK BRAKE SYSTEM sec-

tion of this service manual group for the procedure.

(8) If the vehicle is equipped with ABS, remove the

three bolts securing the ICU mounting bracket to the

frame rail.

(9) Disconnect the vacuum hoses from the check

valve on the power brake booster (Fig. 49), but do not

remove the check valve from power brake booster.

(10) Locate the brake pedal-to-power brake booster

input rod attachment under the instrument panel.

Position a small screwdriver (Fig. 50) under the cen-

ter tang of the retaining clip. Rotate the screwdriver

enough to allow the retaining clip tang to pass over

the end of the brake pedal pin. Remove the clip.

Fig. 48 Battery Tray Mounting

1 ± BATTERY TRAY MOUNTING NUTS

2 ± BATTERY TRAY MOUNTING BOLTS

3 ± AIR CLEANER BOX POST

5 - 30 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 110 of 1285

CAUTION: Discard the used retaining clip, it is not

to be reused. Replace the clip with a new one on

reassembly.

(11) Remove the four nuts attaching the power

brake booster to the instrument panel (Fig. 51). The

nuts are accessible from under the instrument panel

in the area of the brake pedal bracket.

(12) Slide the power brake booster forward until

mounting studs clear the instrument panel. Turn the

booster sideways (Fig. 52), then remove it from the

vehicle.

INSTALLATION

(1) Turn the power brake booster sideways (Fig.

52), then install it into the engine compartment down

past the heater hoses and the strut tower. Rotate the

booster so its four mounting studs and input rod are

pointed straight toward the instrument panel. Slide

the input rod and studs through the instrument

panel and into mounting position.

(2) Under the instrument panel, install the four

power brake booster mounting nuts (Fig. 51). Tighten

the nuts to a torque of 34 N´m (300 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake booster input rod.

Fig. 49 Vacuum Check Valve

1 ± VACUUM CHECK VALVE

Fig. 50 Retaining Clip

1 ± BRAKE PEDAL

2 ± INPUT ROD

3 ± SCREWDRIVER

4 ± RETAINING CLIP

5 ± BRAKE PEDAL PIN

Fig. 51 Power Brake Booster Mounting

1 ± POWER BRAKE BOOSTER MOUNTING NUTS

2 ± BRAKE PEDAL

Fig. 52 Booster Removal/Installation

1 ± POWER BRAKE BOOSTER

PLBRAKES 5 - 31

REMOVAL AND INSTALLATION (Continued)

Page 147 of 1285

CONTROLLER ANTILOCK BRAKE INPUTS

²wheel speed sensors (four)

²stop lamp switch

²ignition switch

²system relay voltage

²ground

²traction control lamp

²diagnostic communication (PCI)

CONTROLLER ANTILOCK BRAKE OUTPUTS

²amber ABS warning lamp actuation (through

MIC)

²red BRAKE warning lamp actuation (through

MIC)

²traction control lamp actuation (through MIC)

²diagnostic communication. (PCI)

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 2). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet solenoid valves. The inlet valves are spring-

loaded in the open position and the outlet valves are

spring-loaded in the closed position during normal

braking. The fluid is allowed to flow from the master

cylinder to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

There are four other valves in the HCU. These four

remaining valves are used for traction control. Two

traction control (TC) valves, mounted in the HCU

valve block, are normally in the open position and

close only when the traction control is applied. There

are also two shuttle valves which control pressure

return to the master cylinder under ABS and traction

control conditions.

These TC valves are used to isolate the rear (non-

driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is beingapplied so the rear wheels do not drag. For more

information on the TC and shuttle valves, see TRAC-

TION CONTROL SYSTEM in this section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU: one

for the primary hydraulic circuit, and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 3 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

There are two noise dampening chambers in the

HCU on this vehicle equipped with traction control.

PUMP/MOTOR

There are two pump assemblies in the HCU: one

for the primary hydraulic circuit, and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor (Fig. 2). This DC-type motor

is integral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, these pistons

are used to purge fluid from the accumulators back

into the master cylinder circuits. When the antilock

stop is complete, the pump/motor drains the accumu-

lators.

The pump motor is also used to build pressure

when the system goes into traction control mode. For

more information, refer to TRACTION CONTROL

SYSTEM in this section.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

ABS FUSES

The ABS fuse and the ABS pump/motor fuse are

located in the power distribution center (PDC). Refer

to the sticker on the inside of the PDC cover for the

location of these fuses. The PDC is located on the

driver's side of the engine compartment between the

back of the battery and the brake master cylinder.

The CAB fuse can be found in the fuse junction

block under the instrument panel.

5 - 68 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 149 of 1285

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes. This back-and-forth pro-

cess will continue until the required slip difference is

obtained. At the end of EBD braking (brakes

released) the fluid in the LPA drains back to themaster cylinder by switching on the outlet valve and

draining through the inlet valve check valve. At the

same time the inlet valve is switched on in case of

another brake application.

The EBD will remain functional during many ABS

fault modes. If both the red BRAKE, and amber ABS

warning lamps are illuminated, the EBD may not be

functioning.

TRACTION CONTROL SYSTEM

Traction control reduces wheel slip and maintains

traction at the driving wheels at speeds below 56 kph

(35 mph) when road surfaces are slippery. The trac-

tion control system reduces wheel slip by braking the

wheel that is losing traction.

The CAB monitors wheel speed. During accelera-

tion, if the CAB detects front (drive) wheel slip and

the brakes are not applied, the CAB enters traction

control mode. Traction control operation proceeds in

the following order:

(1) Close the normally open traction control (TC)

valves.

(2) Start the pump/motor and supply volume and

pressure to the front (drive) hydraulic circuit. (The

pump/motor runs continuously during traction con-

trol operation.)

(3) Open and close the build and decay solenoid

valves to maintain minimum wheel slip and maxi-

mum traction.

The cycling of the build and decay valves during

traction control is similar to that during antilock

braking, except the valves work to control wheel spin

by applying the brakes, whereas the ABS function is

to control wheel skid by releasing the brakes.

HYDRAULIC SHUTTLE VALVES

Two pressure relief shuttle valves allow pressure

and volume to return to the master cylinder reservoir

when not consumed by the build and decay valves.

These valves are necessary because the pump/motor

supplies more volume than the system requires.

If the brakes are applied at anytime during a trac-

tion control cycle, the brake lamp switch triggers the

control module to switch off traction control.

TRACTION CONTROL FUNCTION LAMP

The traction control function lamp illuminates dur-

ing a traction control cycle, displaying TRAC on the

instrument panel.

The traction control system is enabled at each igni-

tion cycle. It may be turned off by depressing the

traction control switch button. The traction control

function lamp (TRAC OFF) illuminates immediately

upon depressing the button. Pressing this button

again, or turning off and restarting the vehicle will

enable the traction control system.

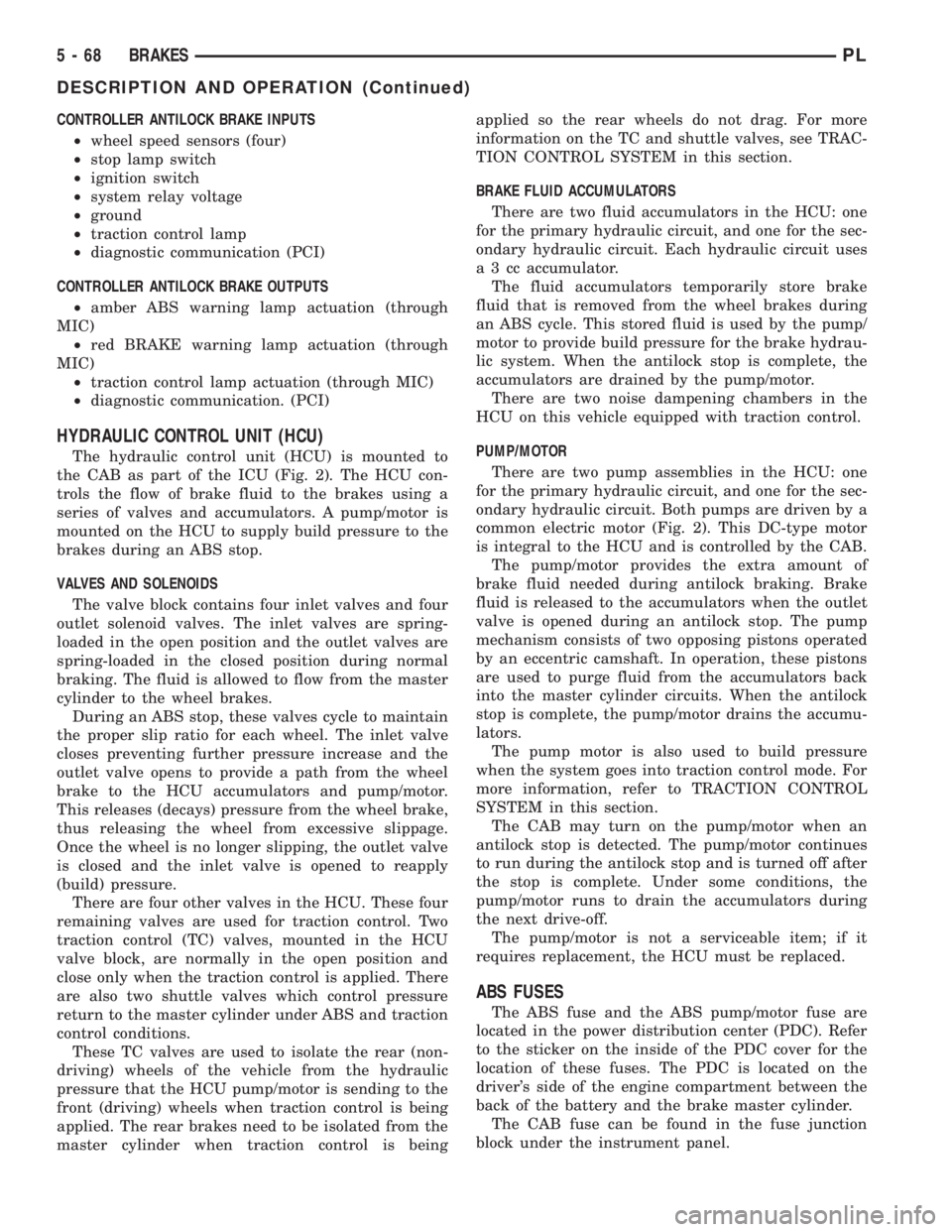

Fig. 5 Left Rear Wheel Speed Sensor

1 ± LEFT REAR WHEEL SPEED SENSOR

2 ± TENSION STRUT

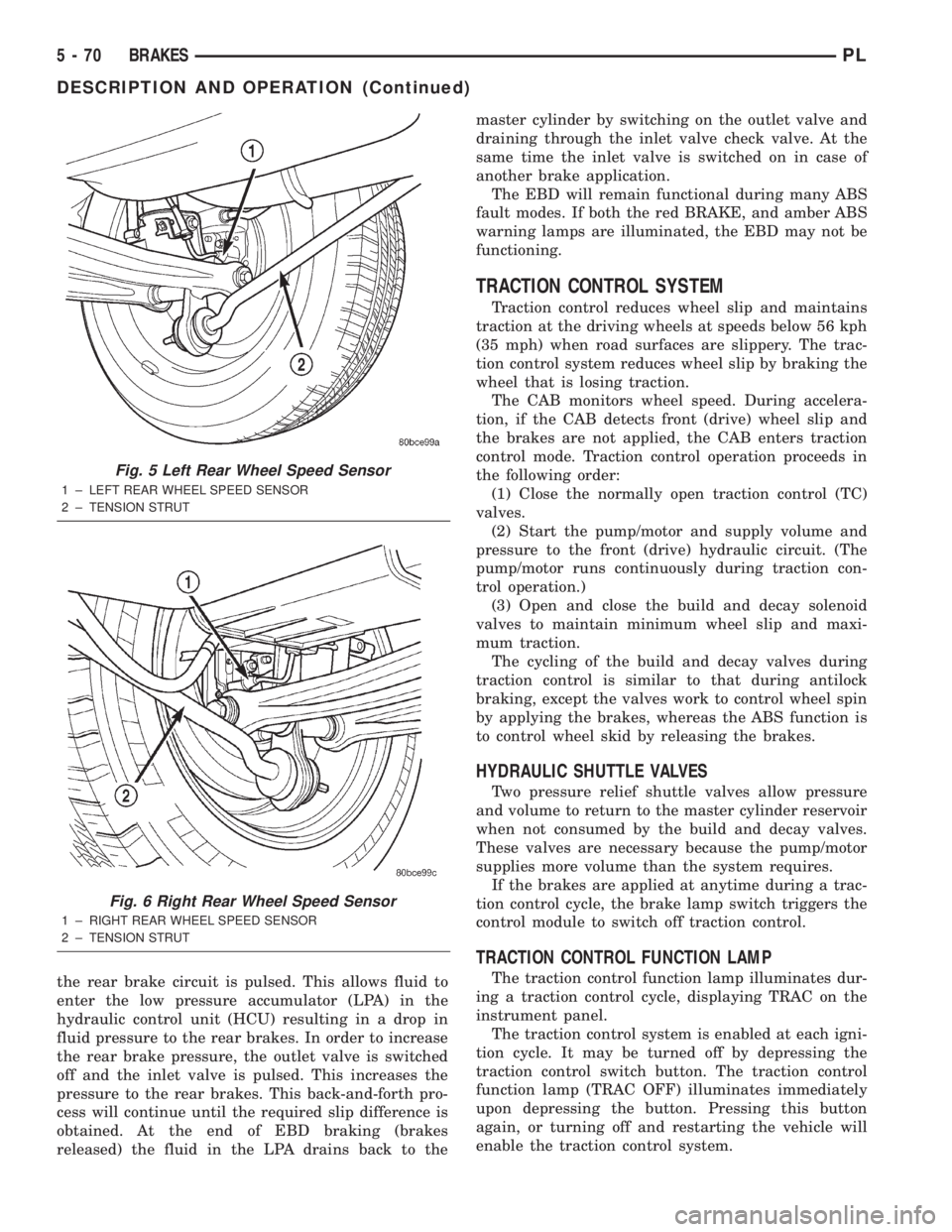

Fig. 6 Right Rear Wheel Speed Sensor

1 ± RIGHT REAR WHEEL SPEED SENSOR

2 ± TENSION STRUT

5 - 70 BRAKESPL

DESCRIPTION AND OPERATION (Continued)