boot DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 78 of 1285

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Driveshaft-to-Hub/Bearing

Nut................... 244N´m(180 ft. lbs.)

Knuckle-to-Ball Joint

Bolt/Nut................. 95N´m(70ft.lbs.)

Wheel/Tire-to-Hub/Bearing

Lug Nuts............... 128N´m(95ft.lbs.)

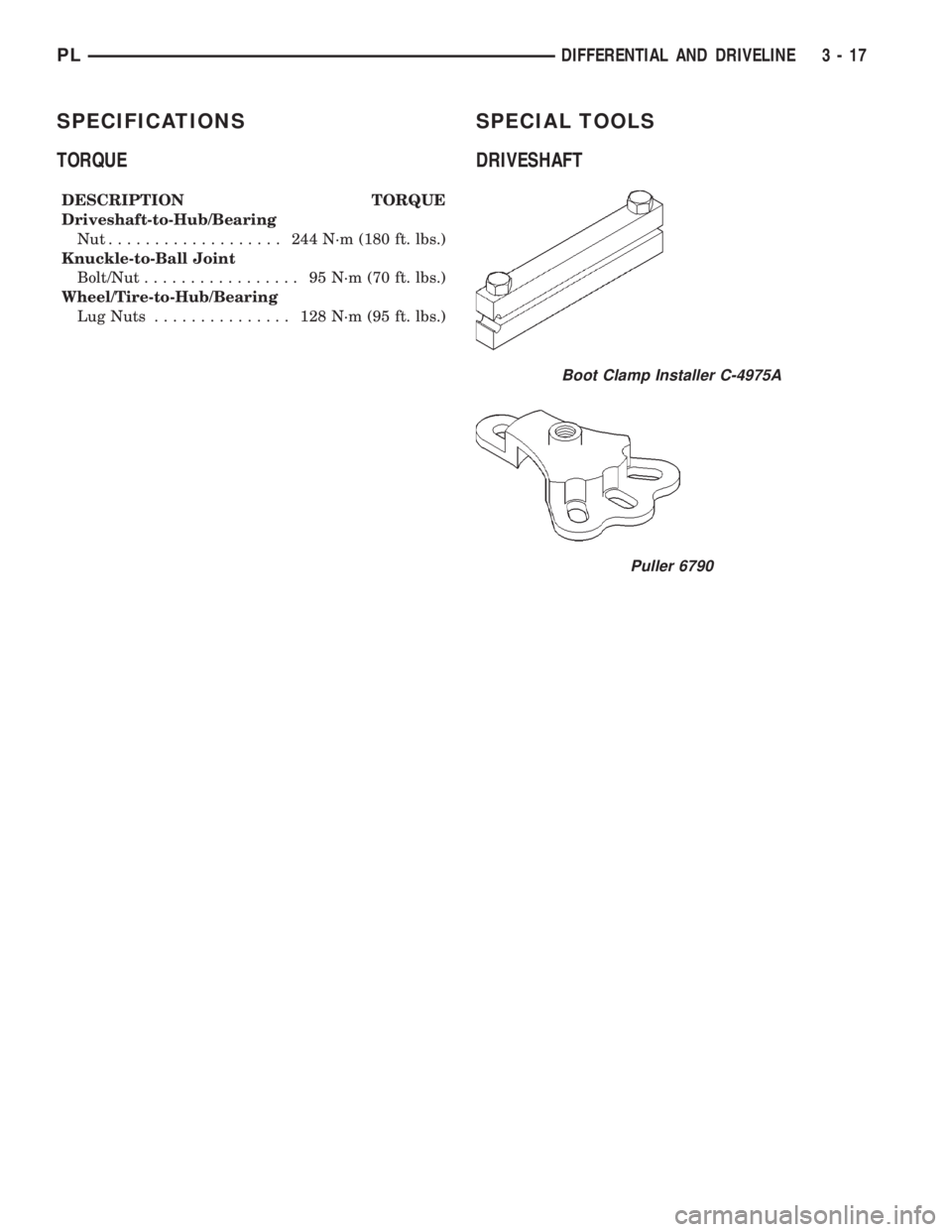

SPECIAL TOOLS

DRIVESHAFT

Boot Clamp Installer C-4975A

Puller 6790

PLDIFFERENTIAL AND DRIVELINE 3 - 17

Page 83 of 1285

Proportioning valves balance front to rear braking

by controlling the brake fluid hydraulic pressure to

the rear brakes. Under light pedal application, the

proportioning valve allows normal fluid flow to the

rear brakes. Under higher pedal effort, the valve

reduces fluid pressure to the rear brakes.

The non-antilock master cylinder is a four-outlet

design with two screw-in proportioning valves

attached directly to the master cylinder housing (Fig.

3). One proportioning valve controls each rear brake.

BRAKE TUBES AND HOSES

The purpose of the brake tubes and flex hoses is to

transfer the pressurized brake fluid developed by the

master cylinder to the brakes at each wheel of the

vehicle. The flex hoses connect the chassis brake

tubes, which are mounted to the vehicle's underbody,

to the brake at each wheel, allowing for movement of

the vehicle's suspension. The brake tubes are steel

with a corrosion-resistant nylon coating applied to

the external surfaces. The flex hoses are made of

reinforced rubber.

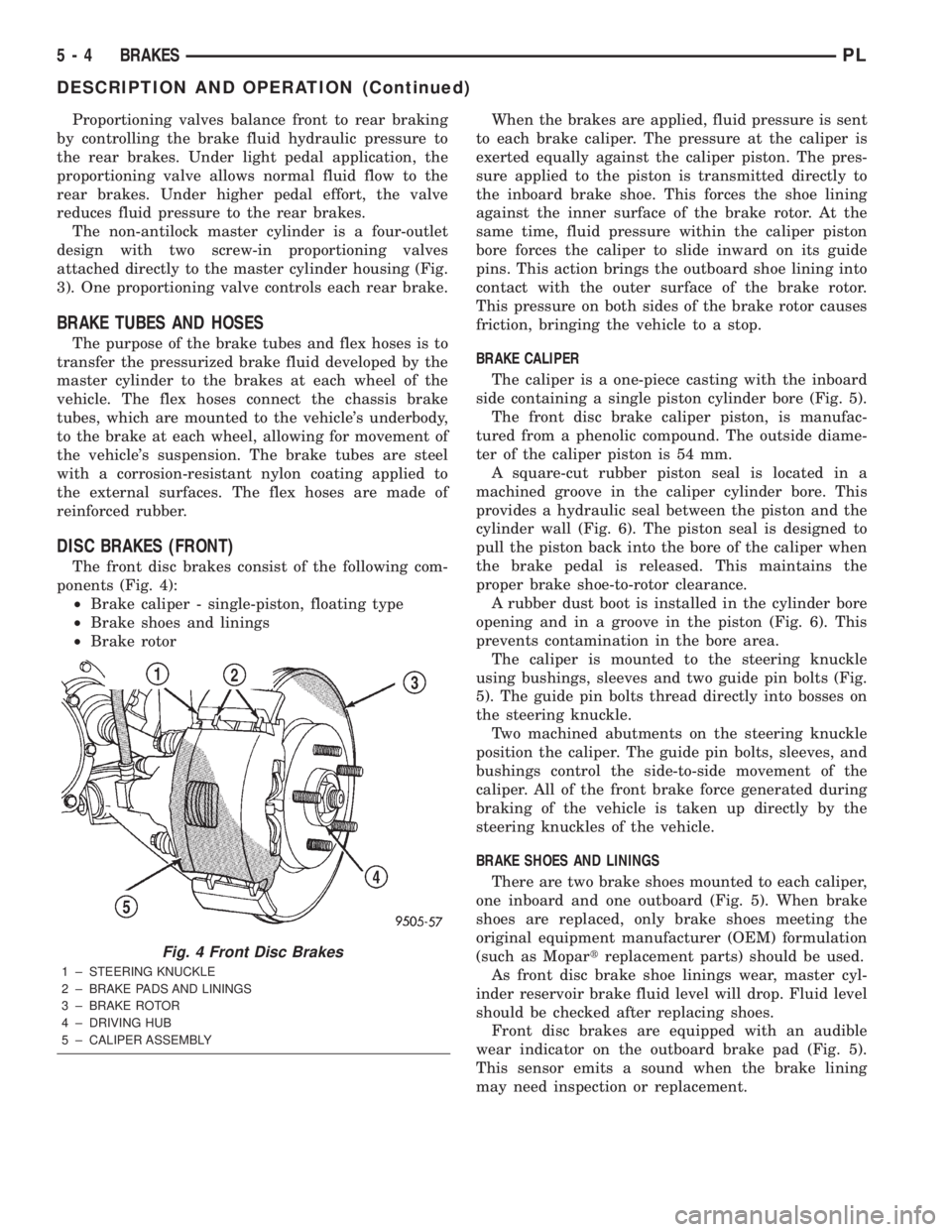

DISC BRAKES (FRONT)

The front disc brakes consist of the following com-

ponents (Fig. 4):

²Brake caliper - single-piston, floating type

²Brake shoes and linings

²Brake rotorWhen the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

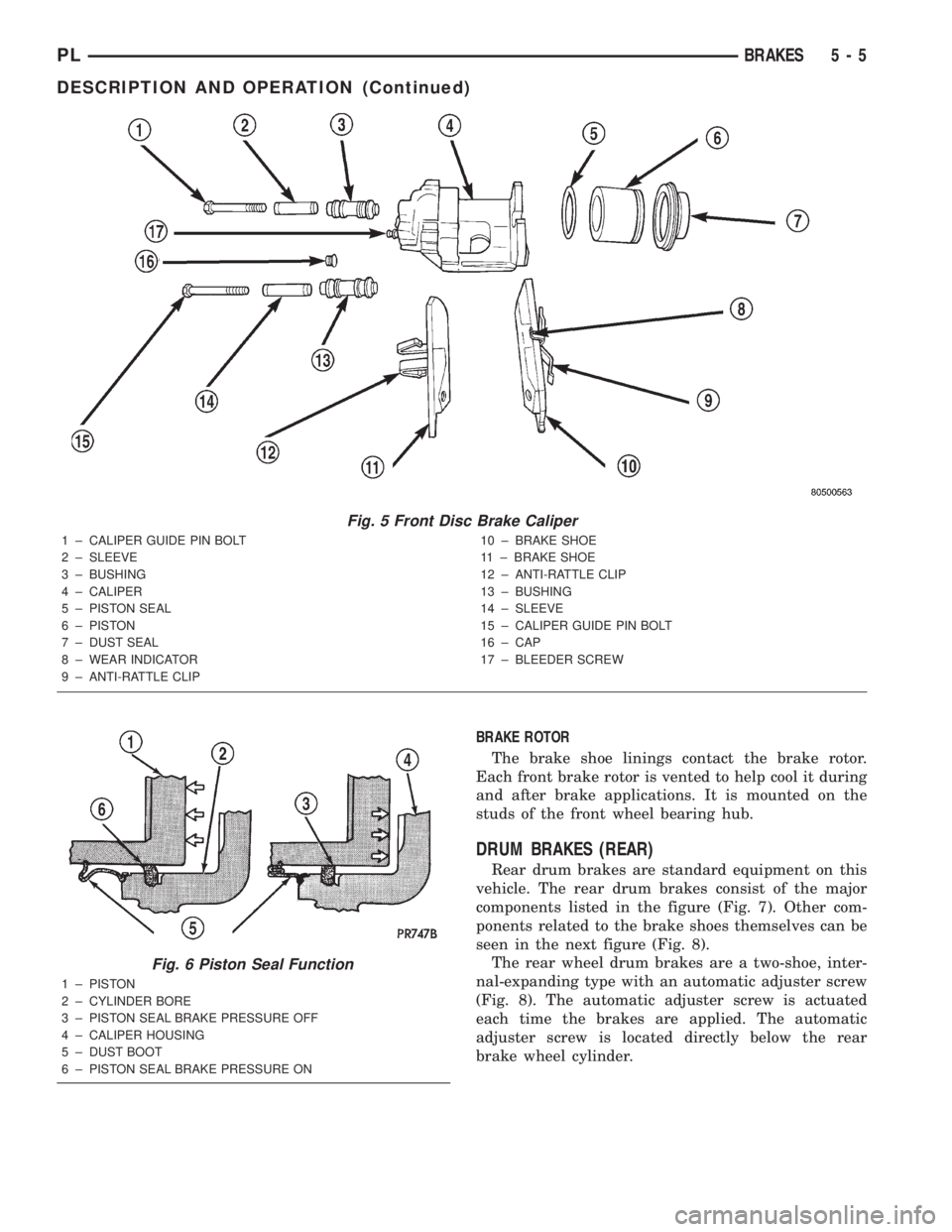

BRAKE CALIPER

The caliper is a one-piece casting with the inboard

side containing a single piston cylinder bore (Fig. 5).

The front disc brake caliper piston, is manufac-

tured from a phenolic compound. The outside diame-

ter of the caliper piston is 54 mm.

A square-cut rubber piston seal is located in a

machined groove in the caliper cylinder bore. This

provides a hydraulic seal between the piston and the

cylinder wall (Fig. 6). The piston seal is designed to

pull the piston back into the bore of the caliper when

the brake pedal is released. This maintains the

proper brake shoe-to-rotor clearance.

A rubber dust boot is installed in the cylinder bore

opening and in a groove in the piston (Fig. 6). This

prevents contamination in the bore area.

The caliper is mounted to the steering knuckle

using bushings, sleeves and two guide pin bolts (Fig.

5). The guide pin bolts thread directly into bosses on

the steering knuckle.

Two machined abutments on the steering knuckle

position the caliper. The guide pin bolts, sleeves, and

bushings control the side-to-side movement of the

caliper. All of the front brake force generated during

braking of the vehicle is taken up directly by the

steering knuckles of the vehicle.

BRAKE SHOES AND LININGS

There are two brake shoes mounted to each caliper,

one inboard and one outboard (Fig. 5). When brake

shoes are replaced, only brake shoes meeting the

original equipment manufacturer (OEM) formulation

(such as Mopartreplacement parts) should be used.

As front disc brake shoe linings wear, master cyl-

inder reservoir brake fluid level will drop. Fluid level

should be checked after replacing shoes.

Front disc brakes are equipped with an audible

wear indicator on the outboard brake pad (Fig. 5).

This sensor emits a sound when the brake lining

may need inspection or replacement.

Fig. 4 Front Disc Brakes

1 ± STEERING KNUCKLE

2 ± BRAKE PADS AND LININGS

3 ± BRAKE ROTOR

4 ± DRIVING HUB

5 ± CALIPER ASSEMBLY

5 - 4 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 84 of 1285

BRAKE ROTOR

The brake shoe linings contact the brake rotor.

Each front brake rotor is vented to help cool it during

and after brake applications. It is mounted on the

studs of the front wheel bearing hub.

DRUM BRAKES (REAR)

Rear drum brakes are standard equipment on this

vehicle. The rear drum brakes consist of the major

components listed in the figure (Fig. 7). Other com-

ponents related to the brake shoes themselves can be

seen in the next figure (Fig. 8).

The rear wheel drum brakes are a two-shoe, inter-

nal-expanding type with an automatic adjuster screw

(Fig. 8). The automatic adjuster screw is actuated

each time the brakes are applied. The automatic

adjuster screw is located directly below the rear

brake wheel cylinder.

Fig. 5 Front Disc Brake Caliper

1 ± CALIPER GUIDE PIN BOLT

2 ± SLEEVE

3 ± BUSHING

4 ± CALIPER

5 ± PISTON SEAL

6 ± PISTON

7 ± DUST SEAL

8 ± WEAR INDICATOR

9 ± ANTI-RATTLE CLIP10 ± BRAKE SHOE

11 ± BRAKE SHOE

12 ± ANTI-RATTLE CLIP

13 ± BUSHING

14 ± SLEEVE

15 ± CALIPER GUIDE PIN BOLT

16 ± CAP

17 ± BLEEDER SCREW

Fig. 6 Piston Seal Function

1 ± PISTON

2 ± CYLINDER BORE

3 ± PISTON SEAL BRAKE PRESSURE OFF

4 ± CALIPER HOUSING

5 ± DUST BOOT

6 ± PISTON SEAL BRAKE PRESSURE ON

PLBRAKES 5 - 5

DESCRIPTION AND OPERATION (Continued)

Page 135 of 1285

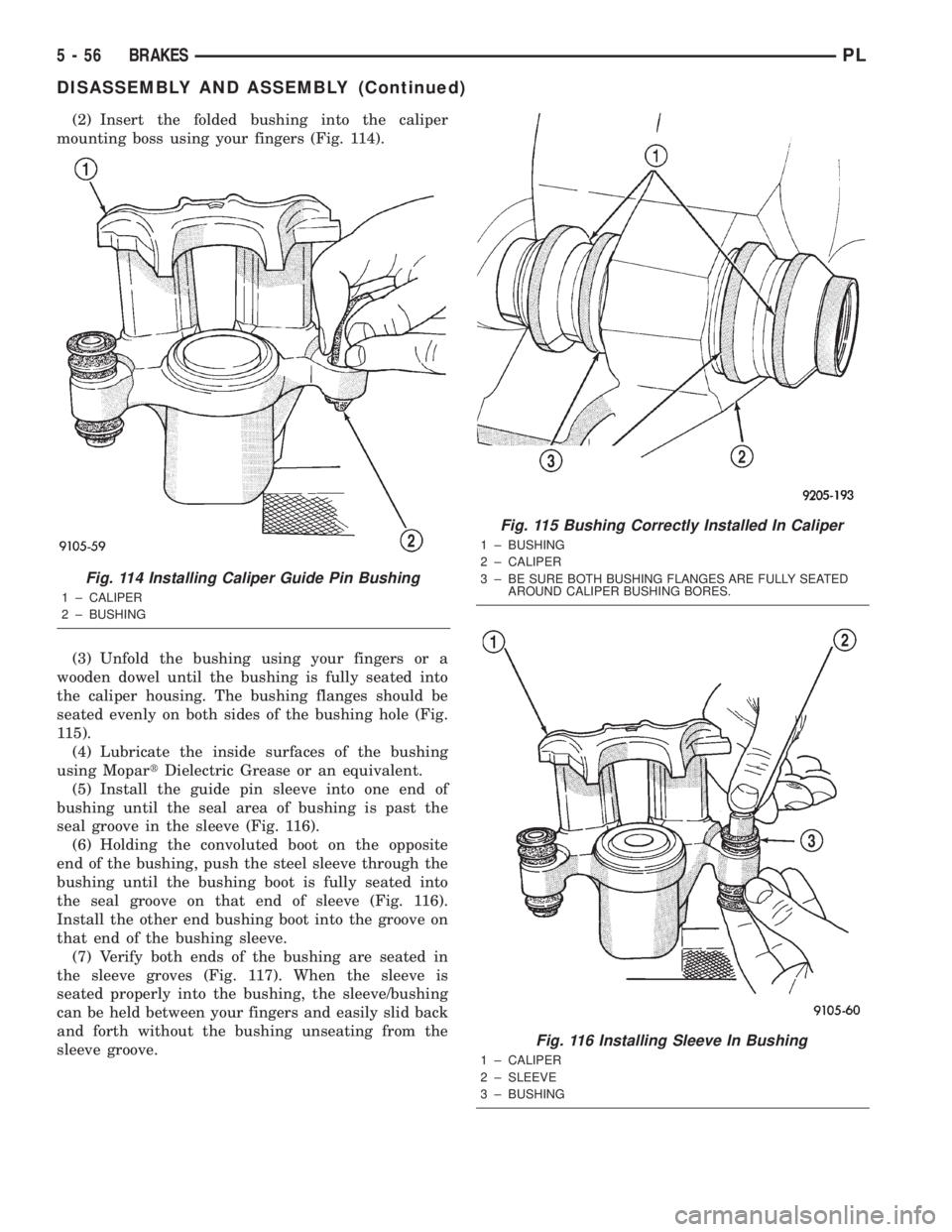

(2) Insert the folded bushing into the caliper

mounting boss using your fingers (Fig. 114).

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into

the caliper housing. The bushing flanges should be

seated evenly on both sides of the bushing hole (Fig.

115).

(4) Lubricate the inside surfaces of the bushing

using MopartDielectric Grease or an equivalent.

(5) Install the guide pin sleeve into one end of

bushing until the seal area of bushing is past the

seal groove in the sleeve (Fig. 116).

(6) Holding the convoluted boot on the opposite

end of the bushing, push the steel sleeve through the

bushing until the bushing boot is fully seated into

the seal groove on that end of sleeve (Fig. 116).

Install the other end bushing boot into the groove on

that end of the bushing sleeve.

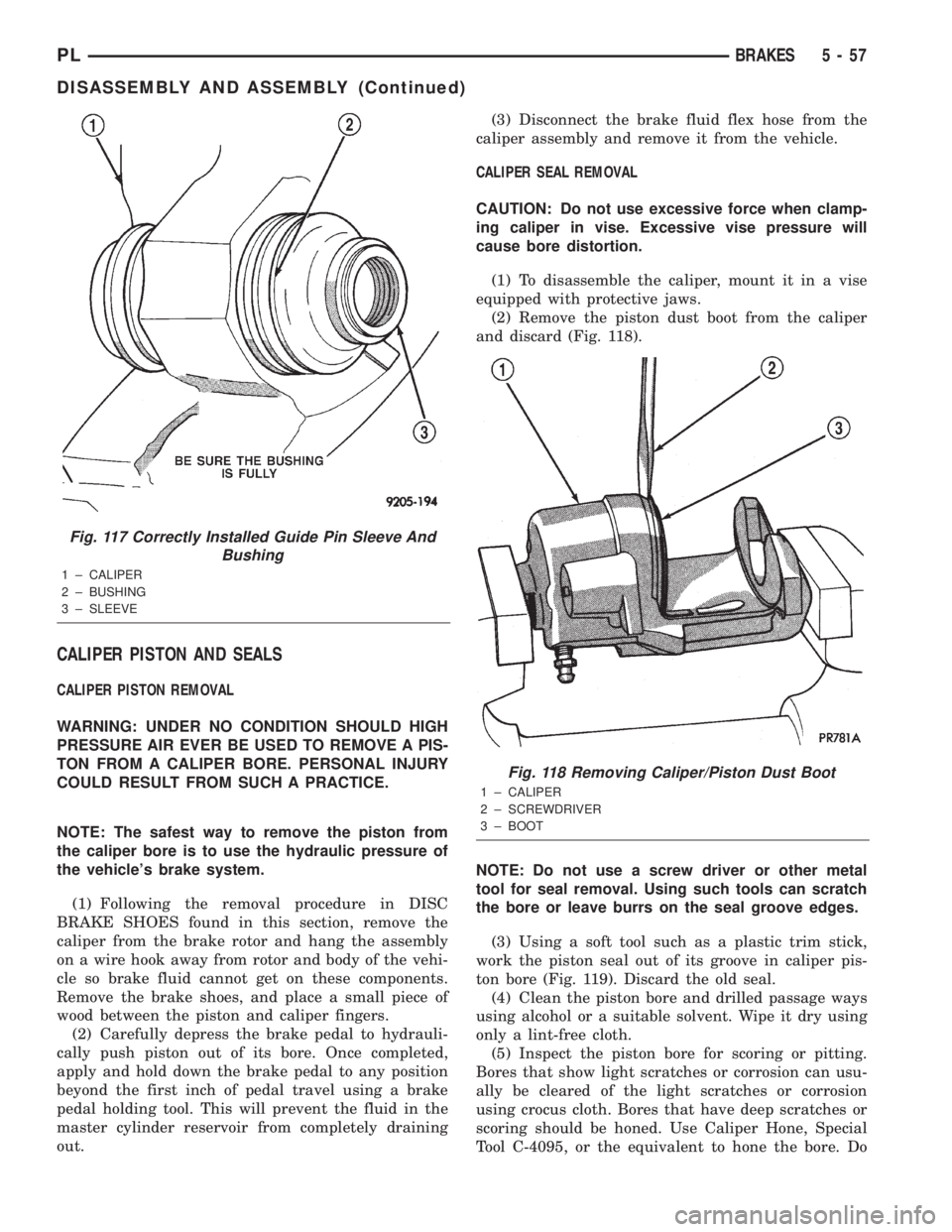

(7) Verify both ends of the bushing are seated in

the sleeve groves (Fig. 117). When the sleeve is

seated properly into the bushing, the sleeve/bushing

can be held between your fingers and easily slid back

and forth without the bushing unseating from the

sleeve groove.

Fig. 114 Installing Caliper Guide Pin Bushing

1 ± CALIPER

2 ± BUSHING

Fig. 115 Bushing Correctly Installed In Caliper

1 ± BUSHING

2 ± CALIPER

3 ± BE SURE BOTH BUSHING FLANGES ARE FULLY SEATED

AROUND CALIPER BUSHING BORES.

Fig. 116 Installing Sleeve In Bushing

1 ± CALIPER

2 ± SLEEVE

3 ± BUSHING

5 - 56 BRAKESPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 136 of 1285

CALIPER PISTON AND SEALS

CALIPER PISTON REMOVAL

WARNING: UNDER NO CONDITION SHOULD HIGH

PRESSURE AIR EVER BE USED TO REMOVE A PIS-

TON FROM A CALIPER BORE. PERSONAL INJURY

COULD RESULT FROM SUCH A PRACTICE.

NOTE: The safest way to remove the piston from

the caliper bore is to use the hydraulic pressure of

the vehicle's brake system.

(1) Following the removal procedure in DISC

BRAKE SHOES found in this section, remove the

caliper from the brake rotor and hang the assembly

on a wire hook away from rotor and body of the vehi-

cle so brake fluid cannot get on these components.

Remove the brake shoes, and place a small piece of

wood between the piston and caliper fingers.

(2) Carefully depress the brake pedal to hydrauli-

cally push piston out of its bore. Once completed,

apply and hold down the brake pedal to any position

beyond the first inch of pedal travel using a brake

pedal holding tool. This will prevent the fluid in the

master cylinder reservoir from completely draining

out.(3) Disconnect the brake fluid flex hose from the

caliper assembly and remove it from the vehicle.

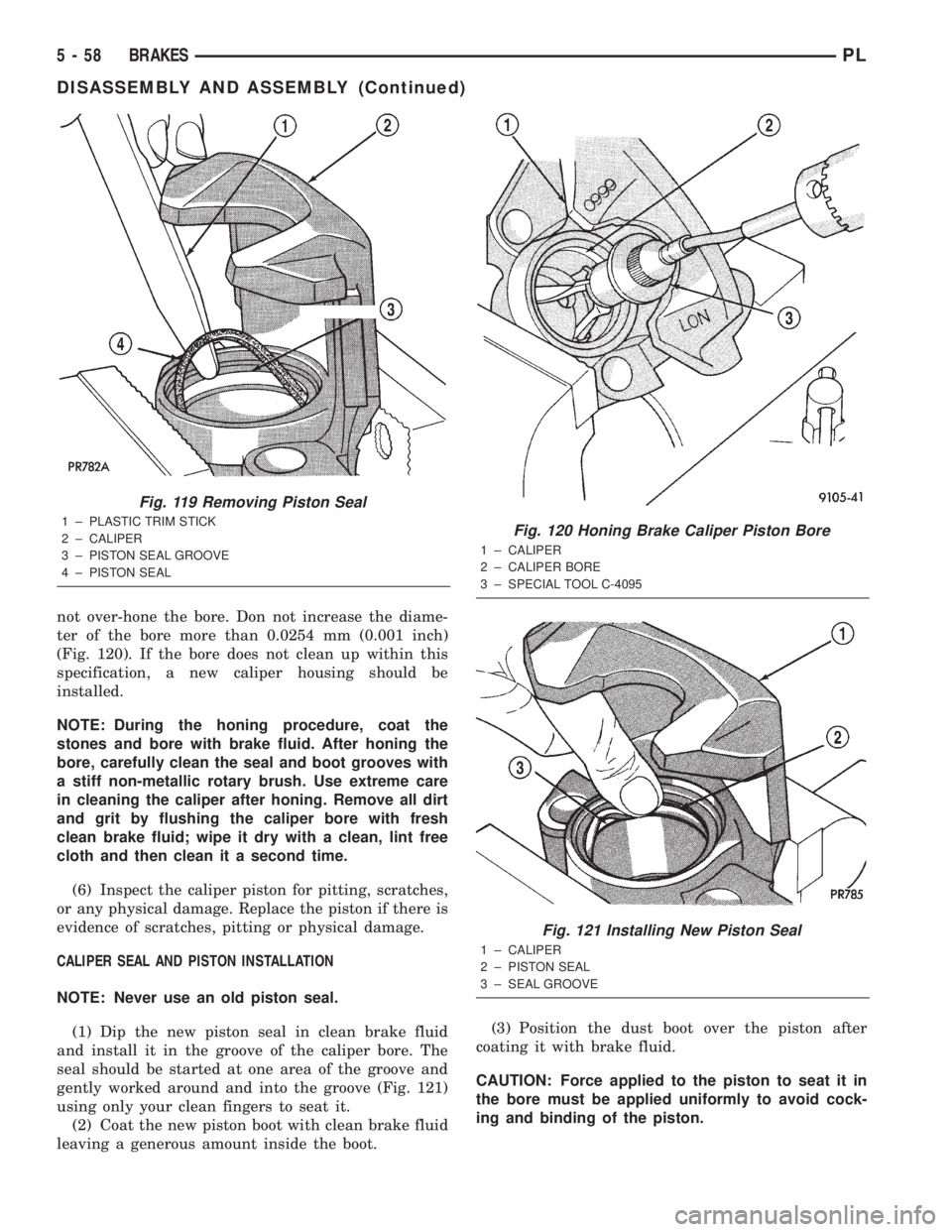

CALIPER SEAL REMOVAL

CAUTION: Do not use excessive force when clamp-

ing caliper in vise. Excessive vise pressure will

cause bore distortion.

(1) To disassemble the caliper, mount it in a vise

equipped with protective jaws.

(2) Remove the piston dust boot from the caliper

and discard (Fig. 118).

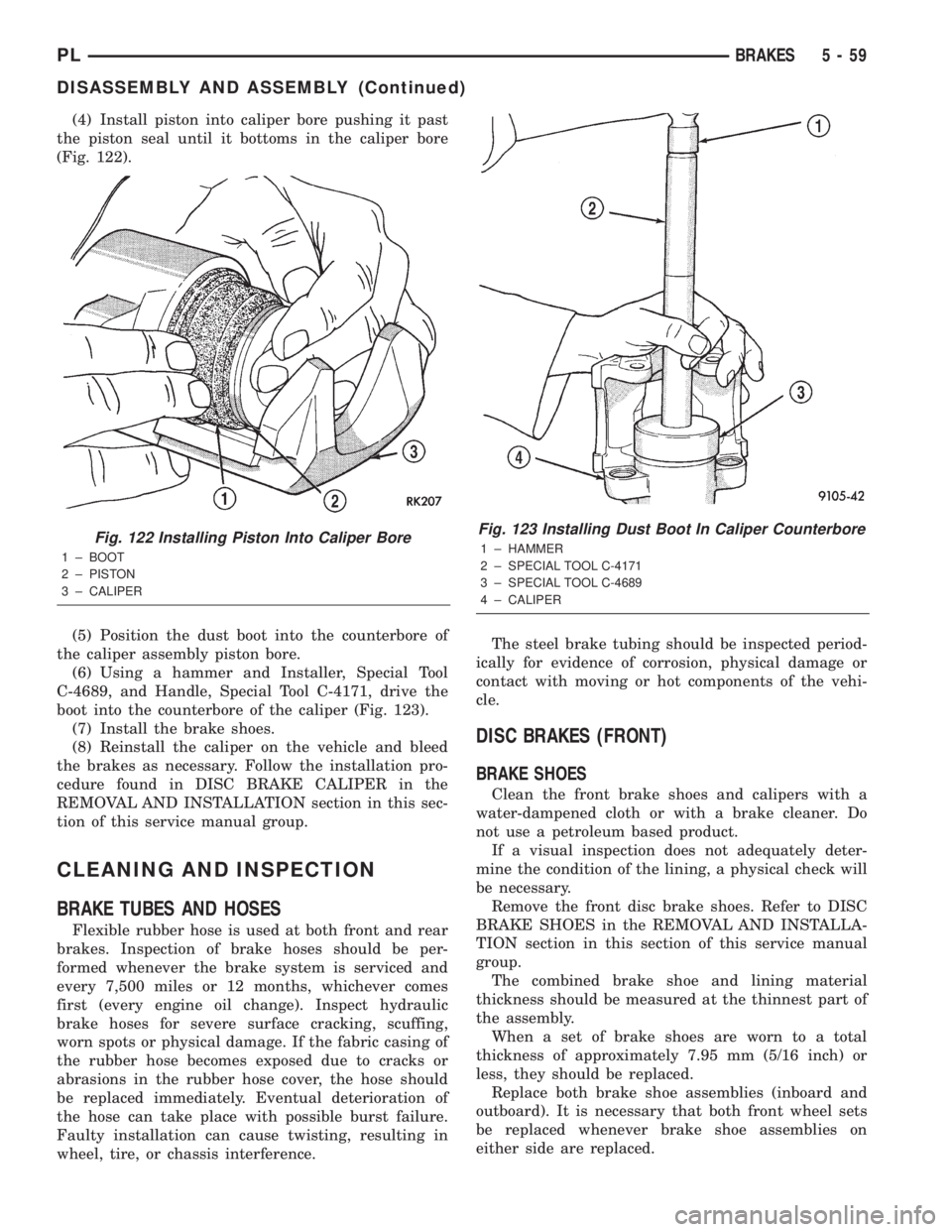

NOTE: Do not use a screw driver or other metal

tool for seal removal. Using such tools can scratch

the bore or leave burrs on the seal groove edges.

(3) Using a soft tool such as a plastic trim stick,

work the piston seal out of its groove in caliper pis-

ton bore (Fig. 119). Discard the old seal.

(4) Clean the piston bore and drilled passage ways

using alcohol or a suitable solvent. Wipe it dry using

only a lint-free cloth.

(5) Inspect the piston bore for scoring or pitting.

Bores that show light scratches or corrosion can usu-

ally be cleared of the light scratches or corrosion

using crocus cloth. Bores that have deep scratches or

scoring should be honed. Use Caliper Hone, Special

Tool C-4095, or the equivalent to hone the bore. Do

Fig. 117 Correctly Installed Guide Pin Sleeve And

Bushing

1 ± CALIPER

2 ± BUSHING

3 ± SLEEVE

Fig. 118 Removing Caliper/Piston Dust Boot

1 ± CALIPER

2 ± SCREWDRIVER

3 ± BOOT

PLBRAKES 5 - 57

DISASSEMBLY AND ASSEMBLY (Continued)

Page 137 of 1285

not over-hone the bore. Don not increase the diame-

ter of the bore more than 0.0254 mm (0.001 inch)

(Fig. 120). If the bore does not clean up within this

specification, a new caliper housing should be

installed.

NOTE: During the honing procedure, coat the

stones and bore with brake fluid. After honing the

bore, carefully clean the seal and boot grooves with

a stiff non-metallic rotary brush. Use extreme care

in cleaning the caliper after honing. Remove all dirt

and grit by flushing the caliper bore with fresh

clean brake fluid; wipe it dry with a clean, lint free

cloth and then clean it a second time.

(6) Inspect the caliper piston for pitting, scratches,

or any physical damage. Replace the piston if there is

evidence of scratches, pitting or physical damage.

CALIPER SEAL AND PISTON INSTALLATION

NOTE: Never use an old piston seal.

(1) Dip the new piston seal in clean brake fluid

and install it in the groove of the caliper bore. The

seal should be started at one area of the groove and

gently worked around and into the groove (Fig. 121)

using only your clean fingers to seat it.

(2) Coat the new piston boot with clean brake fluid

leaving a generous amount inside the boot.(3) Position the dust boot over the piston after

coating it with brake fluid.

CAUTION: Force applied to the piston to seat it in

the bore must be applied uniformly to avoid cock-

ing and binding of the piston.

Fig. 119 Removing Piston Seal

1 ± PLASTIC TRIM STICK

2 ± CALIPER

3 ± PISTON SEAL GROOVE

4 ± PISTON SEALFig. 120 Honing Brake Caliper Piston Bore

1 ± CALIPER

2 ± CALIPER BORE

3 ± SPECIAL TOOL C-4095

Fig. 121 Installing New Piston Seal

1 ± CALIPER

2 ± PISTON SEAL

3 ± SEAL GROOVE

5 - 58 BRAKESPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 138 of 1285

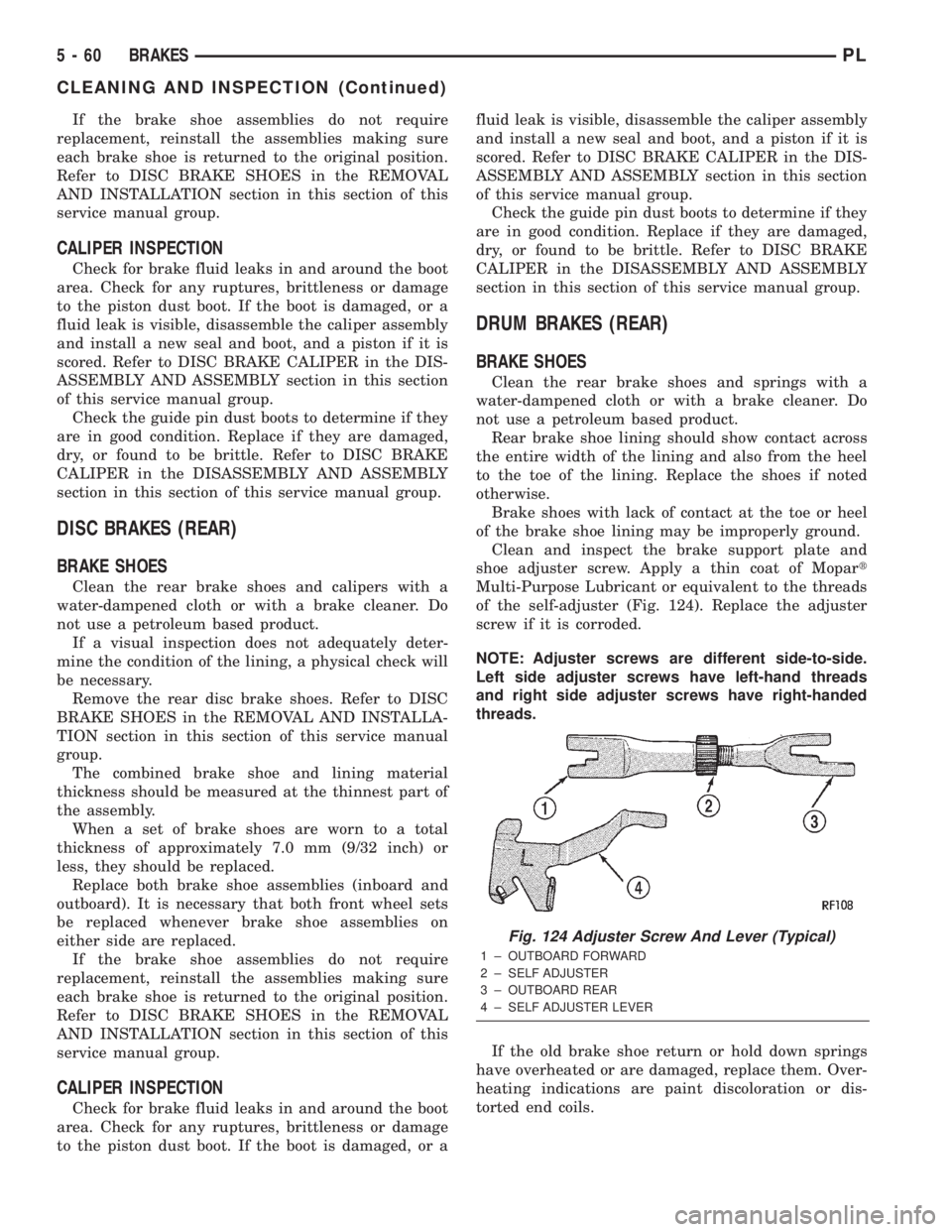

(4) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 122).

(5) Position the dust boot into the counterbore of

the caliper assembly piston bore.

(6) Using a hammer and Installer, Special Tool

C-4689, and Handle, Special Tool C-4171, drive the

boot into the counterbore of the caliper (Fig. 123).

(7) Install the brake shoes.

(8) Reinstall the caliper on the vehicle and bleed

the brakes as necessary. Follow the installation pro-

cedure found in DISC BRAKE CALIPER in the

REMOVAL AND INSTALLATION section in this sec-

tion of this service manual group.

CLEANING AND INSPECTION

BRAKE TUBES AND HOSES

Flexible rubber hose is used at both front and rear

brakes. Inspection of brake hoses should be per-

formed whenever the brake system is serviced and

every 7,500 miles or 12 months, whichever comes

first (every engine oil change). Inspect hydraulic

brake hoses for severe surface cracking, scuffing,

worn spots or physical damage. If the fabric casing of

the rubber hose becomes exposed due to cracks or

abrasions in the rubber hose cover, the hose should

be replaced immediately. Eventual deterioration of

the hose can take place with possible burst failure.

Faulty installation can cause twisting, resulting in

wheel, tire, or chassis interference.The steel brake tubing should be inspected period-

ically for evidence of corrosion, physical damage or

contact with moving or hot components of the vehi-

cle.

DISC BRAKES (FRONT)

BRAKE SHOES

Clean the front brake shoes and calipers with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary.

Remove the front disc brake shoes. Refer to DISC

BRAKE SHOES in the REMOVAL AND INSTALLA-

TION section in this section of this service manual

group.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.95 mm (5/16 inch) or

less, they should be replaced.

Replace both brake shoe assemblies (inboard and

outboard). It is necessary that both front wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

Fig. 122 Installing Piston Into Caliper Bore

1 ± BOOT

2 ± PISTON

3 ± CALIPER

Fig. 123 Installing Dust Boot In Caliper Counterbore

1 ± HAMMER

2 ± SPECIAL TOOL C-4171

3 ± SPECIAL TOOL C-4689

4 ± CALIPER

PLBRAKES 5 - 59

DISASSEMBLY AND ASSEMBLY (Continued)

Page 139 of 1285

If the brake shoe assemblies do not require

replacement, reinstall the assemblies making sure

each brake shoe is returned to the original position.

Refer to DISC BRAKE SHOES in the REMOVAL

AND INSTALLATION section in this section of this

service manual group.

CALIPER INSPECTION

Check for brake fluid leaks in and around the boot

area. Check for any ruptures, brittleness or damage

to the piston dust boot. If the boot is damaged, or a

fluid leak is visible, disassemble the caliper assembly

and install a new seal and boot, and a piston if it is

scored. Refer to DISC BRAKE CALIPER in the DIS-

ASSEMBLY AND ASSEMBLY section in this section

of this service manual group.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to DISC BRAKE

CALIPER in the DISASSEMBLY AND ASSEMBLY

section in this section of this service manual group.

DISC BRAKES (REAR)

BRAKE SHOES

Clean the rear brake shoes and calipers with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary.

Remove the rear disc brake shoes. Refer to DISC

BRAKE SHOES in the REMOVAL AND INSTALLA-

TION section in this section of this service manual

group.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.0 mm (9/32 inch) or

less, they should be replaced.

Replace both brake shoe assemblies (inboard and

outboard). It is necessary that both front wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

If the brake shoe assemblies do not require

replacement, reinstall the assemblies making sure

each brake shoe is returned to the original position.

Refer to DISC BRAKE SHOES in the REMOVAL

AND INSTALLATION section in this section of this

service manual group.

CALIPER INSPECTION

Check for brake fluid leaks in and around the boot

area. Check for any ruptures, brittleness or damage

to the piston dust boot. If the boot is damaged, or afluid leak is visible, disassemble the caliper assembly

and install a new seal and boot, and a piston if it is

scored. Refer to DISC BRAKE CALIPER in the DIS-

ASSEMBLY AND ASSEMBLY section in this section

of this service manual group.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to DISC BRAKE

CALIPER in the DISASSEMBLY AND ASSEMBLY

section in this section of this service manual group.

DRUM BRAKES (REAR)

BRAKE SHOES

Clean the rear brake shoes and springs with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

Rear brake shoe lining should show contact across

the entire width of the lining and also from the heel

to the toe of the lining. Replace the shoes if noted

otherwise.

Brake shoes with lack of contact at the toe or heel

of the brake shoe lining may be improperly ground.

Clean and inspect the brake support plate and

shoe adjuster screw. Apply a thin coat of Mopart

Multi-Purpose Lubricant or equivalent to the threads

of the self-adjuster (Fig. 124). Replace the adjuster

screw if it is corroded.

NOTE: Adjuster screws are different side-to-side.

Left side adjuster screws have left-hand threads

and right side adjuster screws have right-handed

threads.

If the old brake shoe return or hold down springs

have overheated or are damaged, replace them. Over-

heating indications are paint discoloration or dis-

torted end coils.

Fig. 124 Adjuster Screw And Lever (Typical)

1 ± OUTBOARD FORWARD

2 ± SELF ADJUSTER

3 ± OUTBOARD REAR

4 ± SELF ADJUSTER LEVER

5 - 60 BRAKESPL

CLEANING AND INSPECTION (Continued)

Page 140 of 1285

WHEEL CYLINDER

With the brake drums removed, inspect the wheel

cylinder boots for evidence of a brake fluid leak.

Visually check the boots for cuts, tears, or heat

cracks. If any of these conditions exist, the wheel cyl-

inders should be completely cleaned, inspected and

new parts installed.

If a wheel cylinder is leaking and the brake lining

material is saturated with brake fluid, the brake

shoes must be replaced.

ADJUSTMENTS

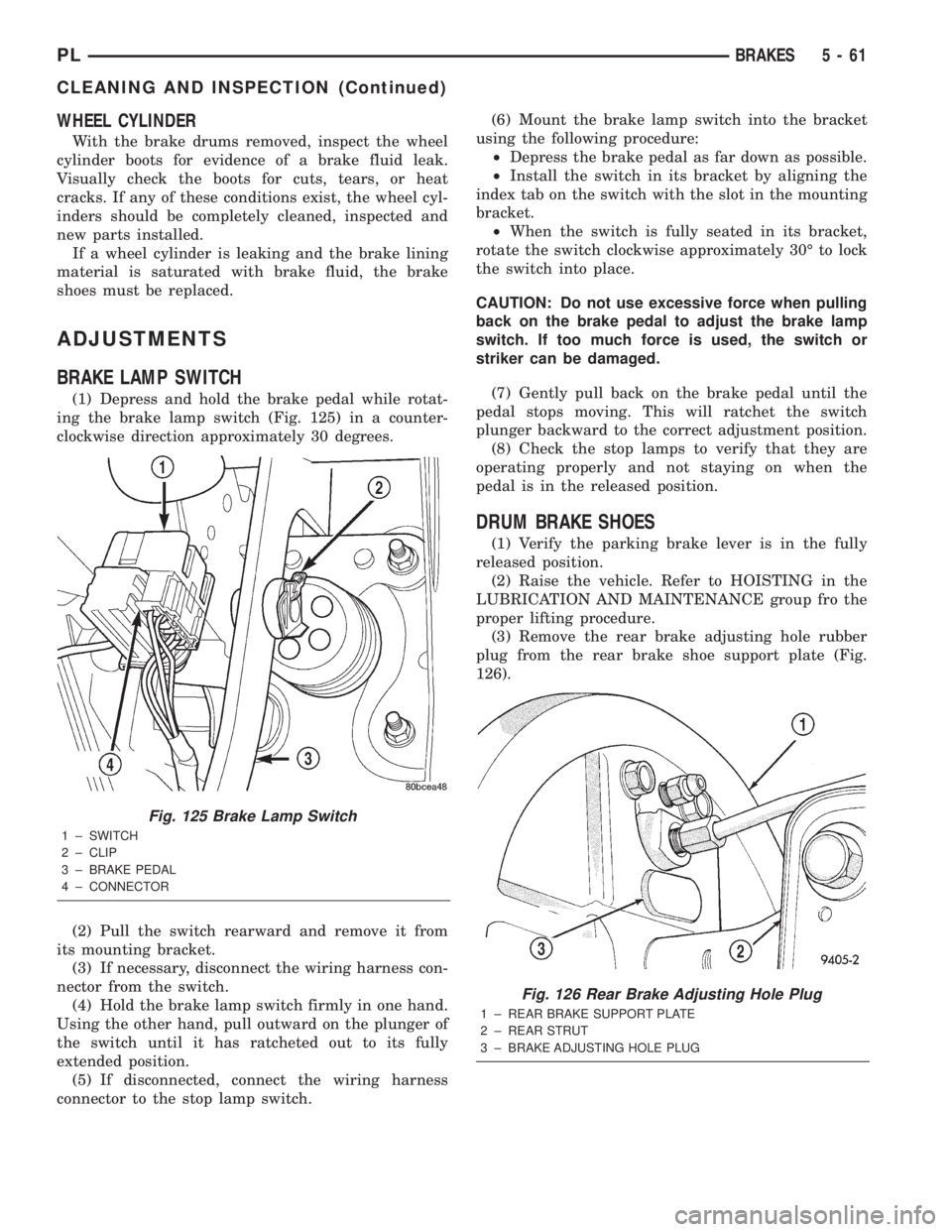

BRAKE LAMP SWITCH

(1) Depress and hold the brake pedal while rotat-

ing the brake lamp switch (Fig. 125) in a counter-

clockwise direction approximately 30 degrees.

(2) Pull the switch rearward and remove it from

its mounting bracket.

(3) If necessary, disconnect the wiring harness con-

nector from the switch.

(4) Hold the brake lamp switch firmly in one hand.

Using the other hand, pull outward on the plunger of

the switch until it has ratcheted out to its fully

extended position.

(5) If disconnected, connect the wiring harness

connector to the stop lamp switch.(6) Mount the brake lamp switch into the bracket

using the following procedure:

²Depress the brake pedal as far down as possible.

²Install the switch in its bracket by aligning the

index tab on the switch with the slot in the mounting

bracket.

²When the switch is fully seated in its bracket,

rotate the switch clockwise approximately 30É to lock

the switch into place.

CAUTION: Do not use excessive force when pulling

back on the brake pedal to adjust the brake lamp

switch. If too much force is used, the switch or

striker can be damaged.

(7) Gently pull back on the brake pedal until the

pedal stops moving. This will ratchet the switch

plunger backward to the correct adjustment position.

(8) Check the stop lamps to verify that they are

operating properly and not staying on when the

pedal is in the released position.

DRUM BRAKE SHOES

(1) Verify the parking brake lever is in the fully

released position.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group fro the

proper lifting procedure.

(3) Remove the rear brake adjusting hole rubber

plug from the rear brake shoe support plate (Fig.

126).

Fig. 125 Brake Lamp Switch

1 ± SWITCH

2 ± CLIP

3 ± BRAKE PEDAL

4 ± CONNECTOR

Fig. 126 Rear Brake Adjusting Hole Plug

1 ± REAR BRAKE SUPPORT PLATE

2 ± REAR STRUT

3 ± BRAKE ADJUSTING HOLE PLUG

PLBRAKES 5 - 61

CLEANING AND INSPECTION (Continued)

Page 143 of 1285

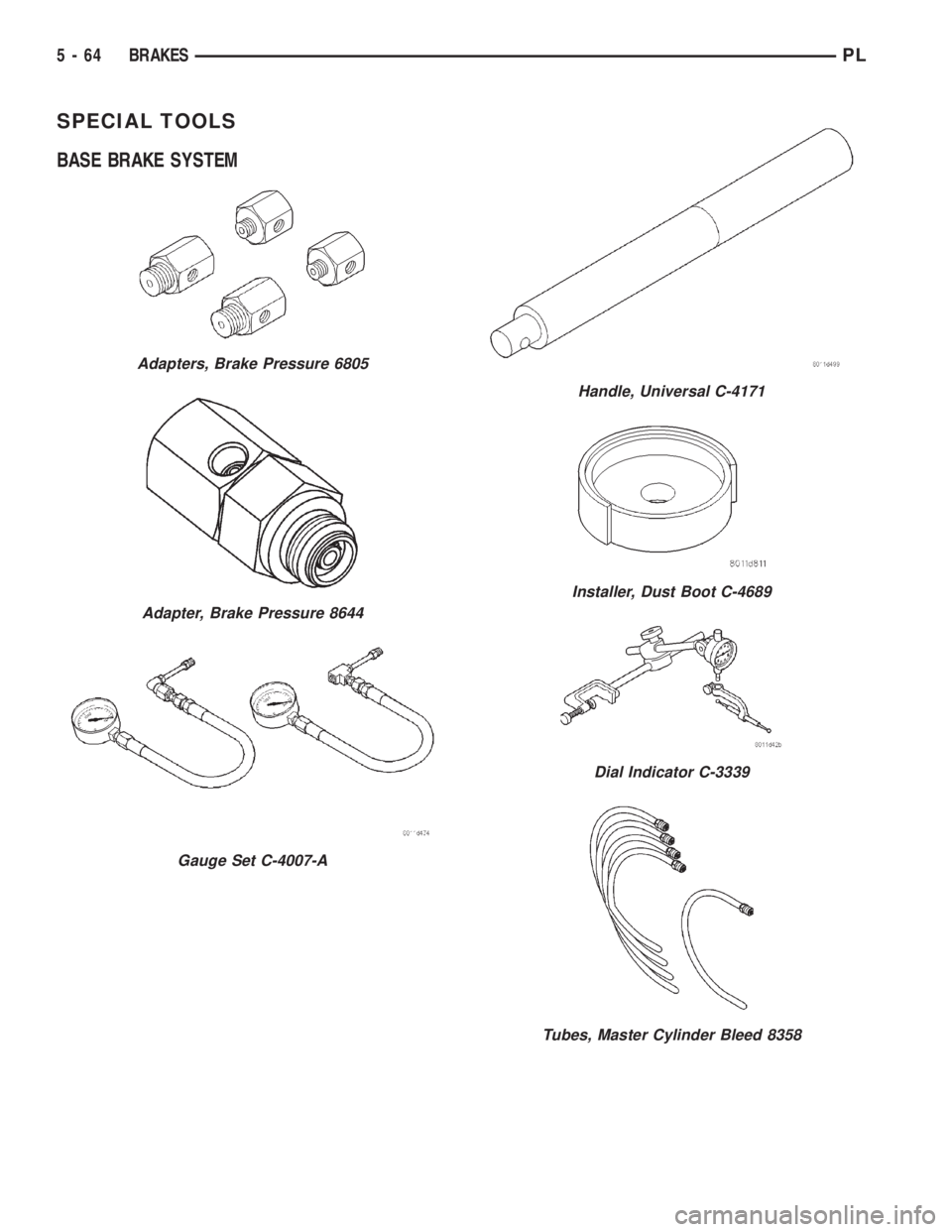

SPECIAL TOOLS

BASE BRAKE SYSTEM

Adapters, Brake Pressure 6805

Adapter, Brake Pressure 8644

Gauge Set C-4007-A

Handle, Universal C-4171

Installer, Dust Boot C-4689

Dial Indicator C-3339

Tubes, Master Cylinder Bleed 8358

5 - 64 BRAKESPL