boot DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 217 of 1285

²It passes the 15 second load test. Refer to Bat-

tery Load Test.

²The built in test indicator dot is GREEN (Fig.

2).

NOTE: The battery cannot be refilled with water, it

must be replaced.

WARNING: DO NOT CHARGE A BATTERY THAT

HAS EXCESSIVELY LOW ELECTROLYTE LEVEL.

BATTERY MAY SPARK INTERNALLY AND

EXPLODE. EXPLOSIVE GASES FORM OVER THE

BATTERY. DO NOT SMOKE, USE FLAME, OR CRE-

ATE SPARKS NEAR BATTERY. DO NOT ASSIST

BOOST OR CHARGE A FROZEN BATTERY. BAT-

TERY CASING MAY FRACTURE. BATTERY ACID IS

POISON, AND MAY CAUSE SEVERE BURNS. BAT-

TERIES CONTAIN SULFURIC ACID. AVOID CON-

TACT WITH SKIN, EYES, OR CLOTHING. IN THE

EVENT OF CONTACT, FLUSH WITH WATER AND

CALL PHYSICIAN IMMEDIATELY. KEEP OUT OF

REACH OF CHILDREN.

CAUTION: Disconnect the battery NEGATIVE cable

first, before charging battery to avoid damage to

electrical systems. Lift the red battery boot cover

from the positive cable clamp. Do not exceed 16.0

volts while charging battery. Refer to the instruc-

tions supplied with charging equipment

Battery electrolyte may bubble inside of battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive.

Some battery chargers are equipped with polarity

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat-

tery state of charge is too low for the polarity sensor

to detect, the sensor must be bypassed for charger to

operate. Refer to operating instructions provided

with battery charger being used.

CAUTION: Charge battery until test indicator

appears green. Do not overcharge.

It may be necessary to jiggle the battery or vehicle

to bring the green dot in the test indicator into view.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. Refer to Battery Load Test in this Group. If

the battery passes the load test, the battery is OK to

use. If battery will not pass the load test, it must be

replaced. Properly clean and inspect battery holddowns, tray, terminals, cables, posts, and top before

completing service.

CHARGING COMPLETELY DISCHARGED

BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless procedure is

properly followed, a good battery may be needlessly

replaced. Refer to Battery Charging Rate Table for

proper charging time.

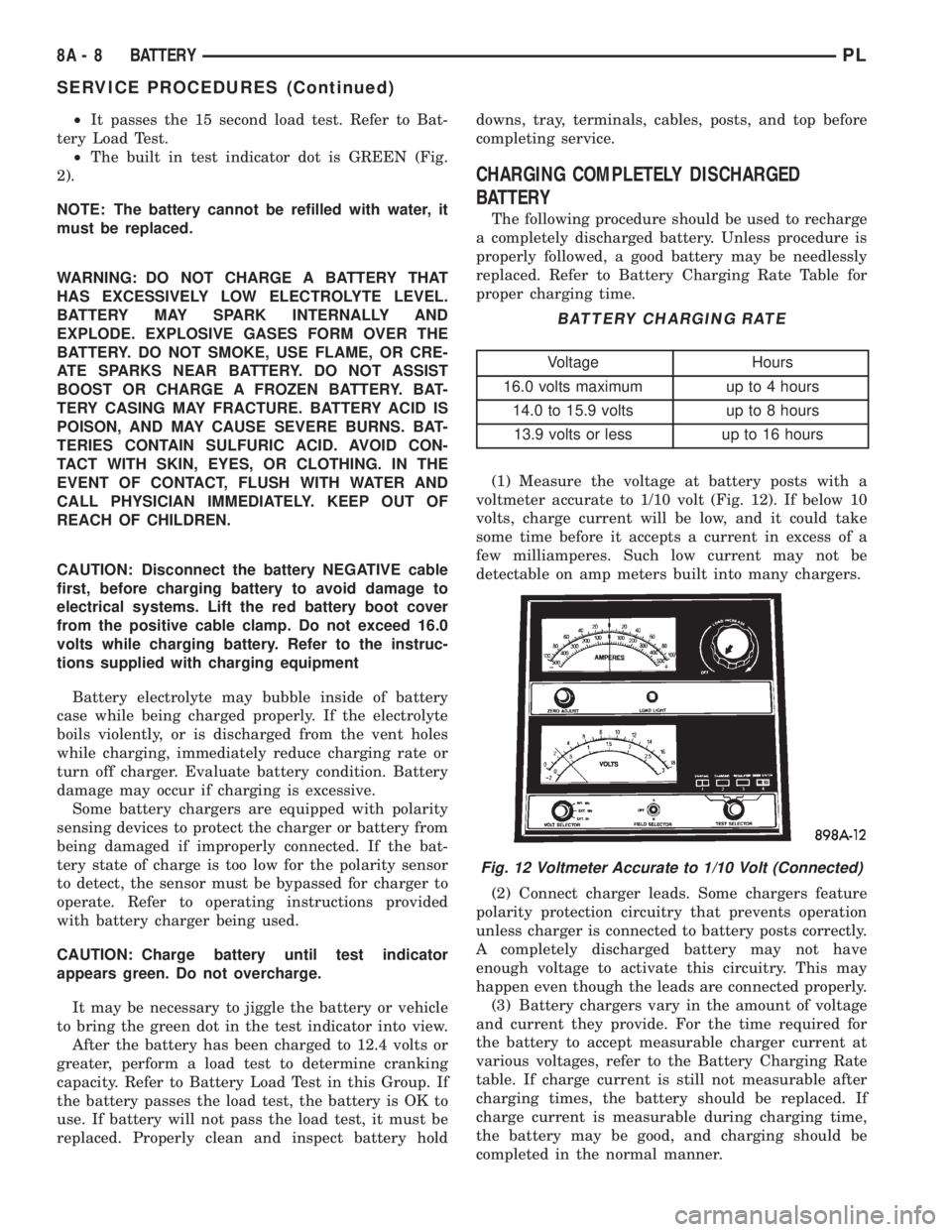

(1) Measure the voltage at battery posts with a

voltmeter accurate to 1/10 volt (Fig. 12). If below 10

volts, charge current will be low, and it could take

some time before it accepts a current in excess of a

few milliamperes. Such low current may not be

detectable on amp meters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry that prevents operation

unless charger is connected to battery posts correctly.

A completely discharged battery may not have

enough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

(3) Battery chargers vary in the amount of voltage

and current they provide. For the time required for

the battery to accept measurable charger current at

various voltages, refer to the Battery Charging Rate

table. If charge current is still not measurable after

charging times, the battery should be replaced. If

charge current is measurable during charging time,

the battery may be good, and charging should be

completed in the normal manner.

BATTERY CHARGING RATE

Voltage Hours

16.0 volts maximum up to 4 hours

14.0 to 15.9 volts up to 8 hours

13.9 volts or less up to 16 hours

Fig. 12 Voltmeter Accurate to 1/10 Volt (Connected)

8A - 8 BATTERYPL

SERVICE PROCEDURES (Continued)

Page 236 of 1285

IGNITION SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

IGNITION SYSTEM........................1

SPARK PLUGS...........................1

SPARK PLUG CABLES.....................1

ELECTRONIC IGNITION COILS...............2

AUTOMATIC SHUTDOWN RELAY.............2

CRANKSHAFT POSITION SENSORÐPCM

INPUT................................3

CAMSHAFT POSITION SENSORÐPCM

INPUT................................4

KNOCK SENSOR..........................5

IGNITION SWITCH........................5

LOCK KEY CYLINDER......................5

IGNITION INTERLOCK.....................6

REMOVAL AND INSTALLATION

SPARK PLUG SERVICE....................6SPARK PLUG CABLE SERVICE..............6

IGNITION COIL...........................6

AUTOMATIC SHUTDOWN RELAY.............6

CAMSHAFT POSITION SENSOR..............6

CRANKSHAFT POSITION SENSOR............8

KNOCK SENSOR..........................8

IGNITION SWITCH........................8

LOCK KEY CYLINDER......................9

IGNITION INTERLOCK....................10

SPECIFICATIONS

VECI LABEL............................10

FIRING ORDERÐ2.0L....................10

TORQUE SPECIFICATION..................11

SPARK PLUG CABLE RESISTANCEÐSOHC....11

SPARK PLUG...........................11

IGNITION COIL..........................11

DESCRIPTION AND OPERATION

IGNITION SYSTEM

DESCRIPTION

The system's three main components are the coil

pack, crankshaft position sensor, and camshaft posi-

tion sensor.

OPERATION

Basic ignition timing is not adjustable.The

Powertrain Control Module (PCM) determines spark

advance. The 2.0L engines use a fixed ignition timing

system. The distributorless electronic ignition system

is referred to as the Direct Ignition System (DIS).

SPARK PLUGS

The 2.0L engines uses resistor spark plugs. For

spark plug identification and specifications, Refer to

the Specifications section at the end of this group.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. Aftercleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 1) to the dimensions specified in the

chart at the end of this section by bending the

ground electrode (just above the attachment weld)

with the appropriate tool.

Never apply any force between the electrode or

damage to the center electrode assembly will result.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and damage.

Tighten spark plugs to 28 N´m (20 ft. lbs.) torque.

SPARK PLUG CABLES

Spark plug cables are sometimes referred to as sec-

ondary ignition wires. The wires transfer electrical

current from the coil pack to individual spark plugs

at each cylinder. The resistor type, nonmetallic spark

plug cables provide suppression of radio frequency

emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil and spark plugs. Terminals should

be fully seated. The nipples and spark plug covers

should be in good condition. Nipples should fit tightly

on the coil. Spark plug boot should completely cover

the spark plug hole in the cylinder head cover. Install

the boot until the terminal snaps over the spark

plug. A snap must be felt to ensure the spark plug

cable terminal engaged the spark plug.

PLIGNITION SYSTEM 8D - 1

Page 241 of 1285

IGNITION INTERLOCK

OPERATION

All vehicles equipped with automatic transaxles

have an interlock system. The system prevents shift-

ing the vehicle out of Park unless the ignition lock

cylinder is in the Off, Run or Start position. In addi-

tion, the operator cannot rotate the key to the lock

position unless the shifter is in the park position. On

vehicles equipped with floor shift refer to the - Tran-

saxle for Automatic Transmission Shifter/Ignition

Interlock.

REMOVAL AND INSTALLATION

SPARK PLUG SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

REMOVE CABLES FROM COIL FIRST.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

(1) Remove the spark plug using a quality socket

with a rubber or foam insert.

(2) Inspect the spark plug condition.

INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(2) Tighten spark plugs to 28 N´m (20 ft. lbs.)

torque.

(3) Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube.

Reconnect to coil.

SPARK PLUG CABLE SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

Remove spark plug cable from coil first.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

INSTALLATION

Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube. The connect theother end to coil pack. Be sure that dual plastic clip

holds the cables off of the valve cover.

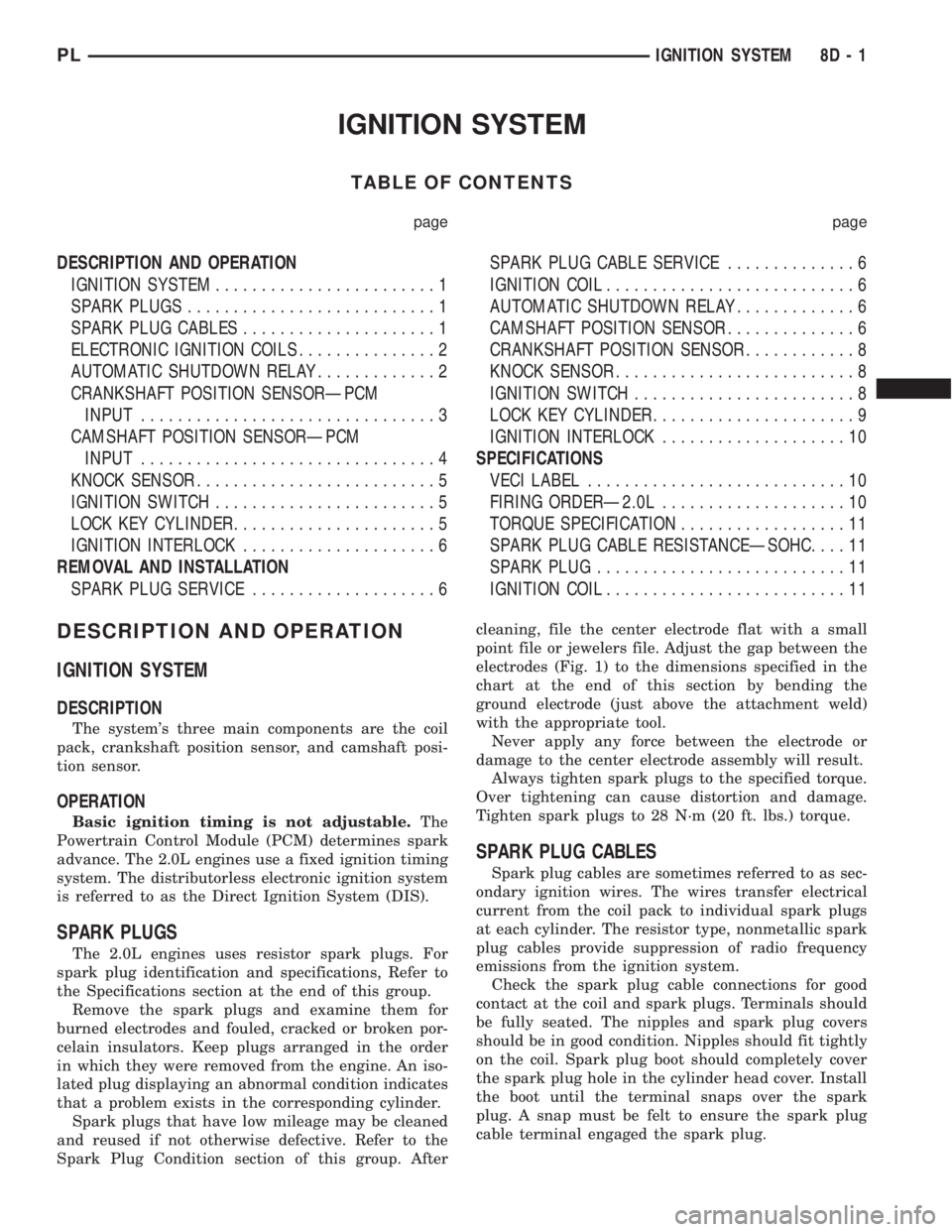

IGNITION COIL

The electronic ignition coil pack attaches directly

to the valve cover (Fig. 11).

REMOVAL

(1) Disconnect electrical connector from coil pack

(Fig. 10).

(2) Remove coil pack mounting bolts.

(3) Remove coil pack.

INSTALLATION

(1) Install coil pack on valve cover.

(2) Transfer spark plug cables to new coil pack.

The coil pack towers are numbered with the cylinder

identification. Be sure the ignition cables snap onto

the towers.

AUTOMATIC SHUTDOWN RELAY

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 12). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

CAMSHAFT POSITION SENSOR

The camshaft position sensor is mounted to the

rear of the cylinder head (Fig. 13).

Fig. 10 Electronic Ignition Coil Connector

1 ± COIL

2 ± LOCKING TAB

8D - 6 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 264 of 1285

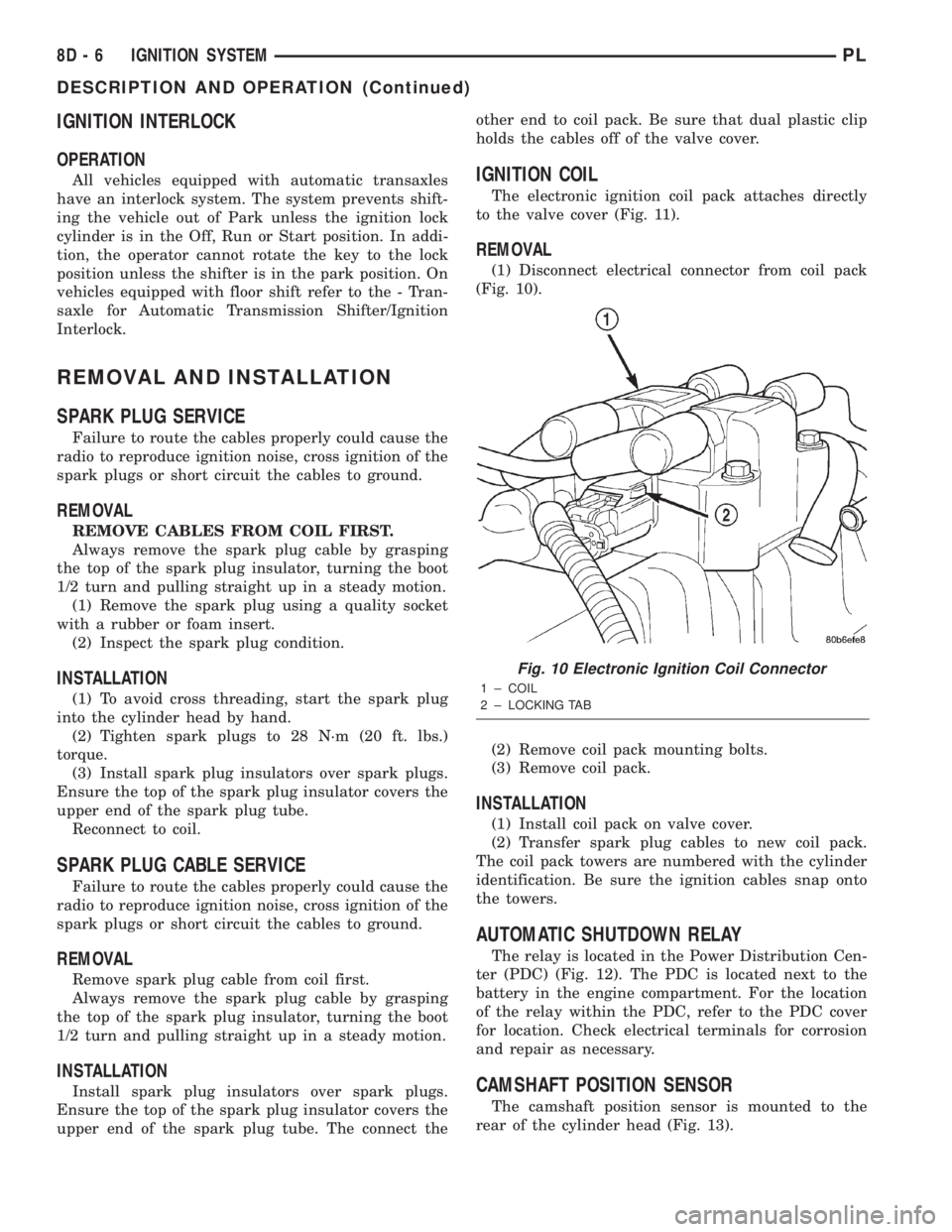

(15) Rotate the A/C outlet registers to the full

down position. Grip each outlet at its outboard end

and gently over-rotate to release from its pivot point.

Swing outlet straight out and remove by hand

(16) Remove the (4) HVAC control knobs by pull-

ing them straight off the switch shaft by hand.

(17) Remove the (2) screws from the center instru-

ment bezel (Fig. 12).

(18) Remove the center instrument bezel. Gently

pull it straight out to unsnap the (4) retaining clips.(19) Remove the (2) HVAC control head retaining

screws. Pull the control away from the I. P. and

rotate the control horizontally to position the assem-

bly through the hole in the instrument panel. This

will eliminate the need to disconnect the control

cables.

(20) Unclip the Data Link Connector from the

right side of the I. P. frame.

(21) Disconnect the instrument panel wire harness

from behind the right kick panel. To disconnect the

harness remove the (2) screws retaining the I. P. con-

nector to the steering column casting. Remove the

plastic clips from the connector retainer. Unclip the

bottom retainer and slide the mated I. P. and head-

lamp connectors out of the holder. Disconnect the I.

P. wire harness connector.

(22) Disconnect the (3) wire harnesses from the

top of the I. P.

(23) Unclip the wire harness along the center con-

sole and disconnect the airbag control module, park-

ing brake and PRNDL lamp if equipped.

(24) Gently pry the right front door wire harness

boot away from the A-pillar to access and disconnect

the right door wire harness connector.

(25) Gently pry the left front door wire harness

boot away from the A-pillar to access and disconnect

the left door wire harness connector.

(26) Disconnect the radio antenna. Located below

the glove compartment.

(27) Remove the (4) I. P. retaining fasteners from

the top of the I. P.

Fig. 11 Steering Shaft Coupler Pinch Bolt

1 ± STEERING SHAFT COUPLER

2 ± STEERING SHAFT COUPLER PINCH BOLT

Fig. 12 Center Instrument Bezel Retaining Screws

1 ± CENTER BEZEL

2±

CENTER BEZEL RETAINING SCREWS (BEHIND REGISTERS)

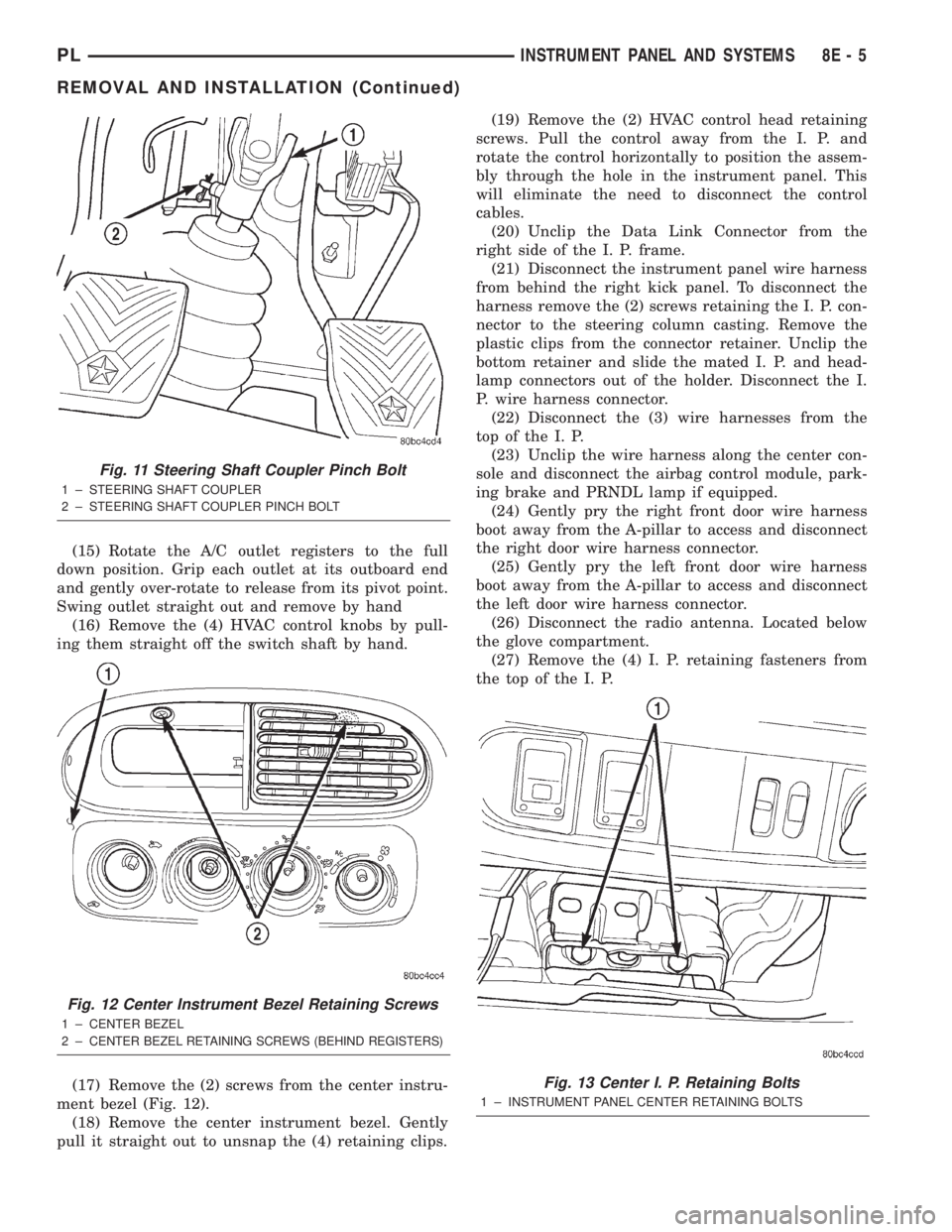

Fig. 13 Center I. P. Retaining Bolts

1 ± INSTRUMENT PANEL CENTER RETAINING BOLTS

PLINSTRUMENT PANEL AND SYSTEMS 8E - 5

REMOVAL AND INSTALLATION (Continued)

Page 265 of 1285

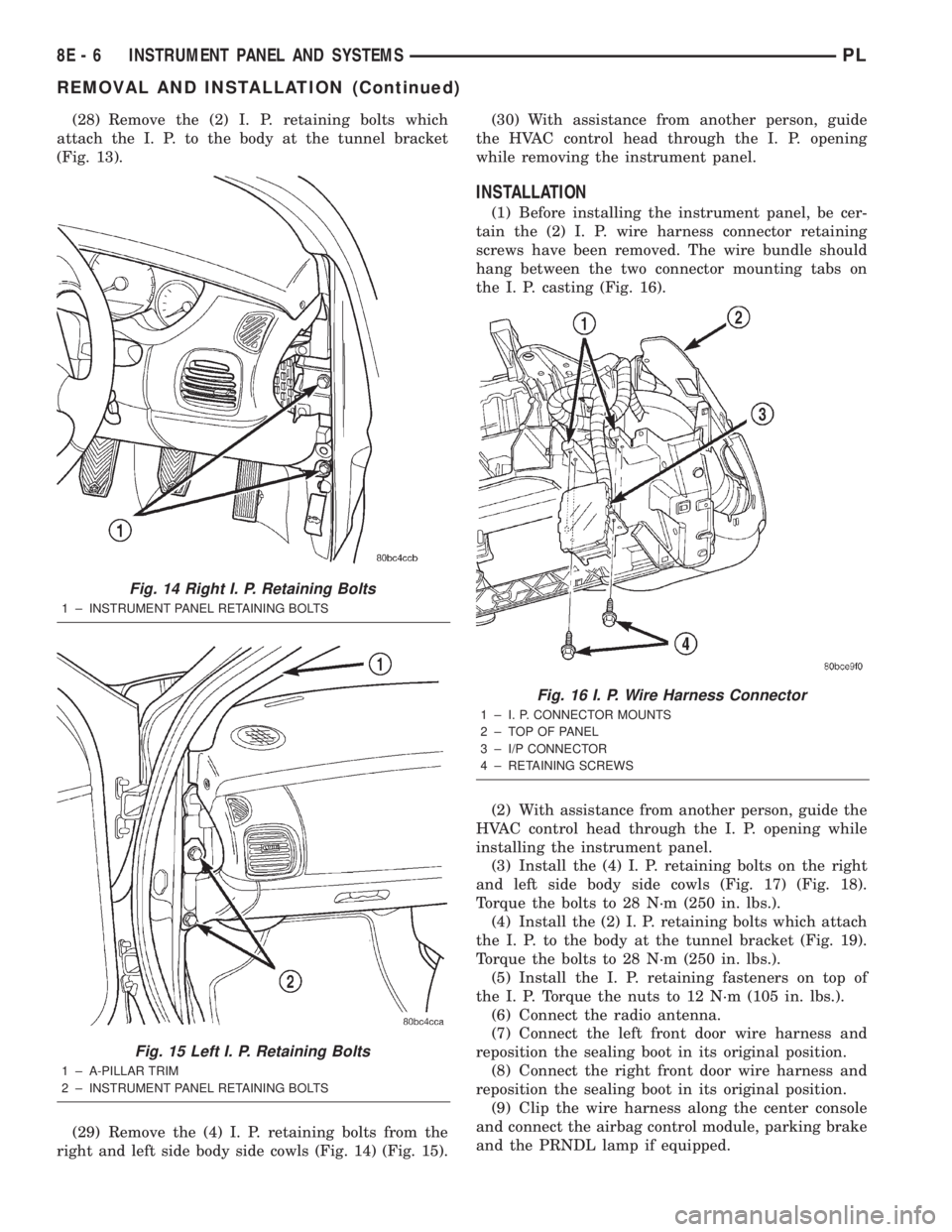

(28) Remove the (2) I. P. retaining bolts which

attach the I. P. to the body at the tunnel bracket

(Fig. 13).

(29) Remove the (4) I. P. retaining bolts from the

right and left side body side cowls (Fig. 14) (Fig. 15).(30) With assistance from another person, guide

the HVAC control head through the I. P. opening

while removing the instrument panel.

INSTALLATION

(1) Before installing the instrument panel, be cer-

tain the (2) I. P. wire harness connector retaining

screws have been removed. The wire bundle should

hang between the two connector mounting tabs on

the I. P. casting (Fig. 16).

(2) With assistance from another person, guide the

HVAC control head through the I. P. opening while

installing the instrument panel.

(3) Install the (4) I. P. retaining bolts on the right

and left side body side cowls (Fig. 17) (Fig. 18).

Torque the bolts to 28 N´m (250 in. lbs.).

(4) Install the (2) I. P. retaining bolts which attach

the I. P. to the body at the tunnel bracket (Fig. 19).

Torque the bolts to 28 N´m (250 in. lbs.).

(5) Install the I. P. retaining fasteners on top of

the I. P. Torque the nuts to 12 N´m (105 in. lbs.).

(6) Connect the radio antenna.

(7) Connect the left front door wire harness and

reposition the sealing boot in its original position.

(8) Connect the right front door wire harness and

reposition the sealing boot in its original position.

(9) Clip the wire harness along the center console

and connect the airbag control module, parking brake

and the PRNDL lamp if equipped.

Fig. 14 Right I. P. Retaining Bolts

1 ± INSTRUMENT PANEL RETAINING BOLTS

Fig. 15 Left I. P. Retaining Bolts

1 ± A-PILLAR TRIM

2 ± INSTRUMENT PANEL RETAINING BOLTS

Fig. 16 I. P. Wire Harness Connector

1 ± I. P. CONNECTOR MOUNTS

2 ± TOP OF PANEL

3 ± I/P CONNECTOR

4 ± RETAINING SCREWS

8E - 6 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 330 of 1285

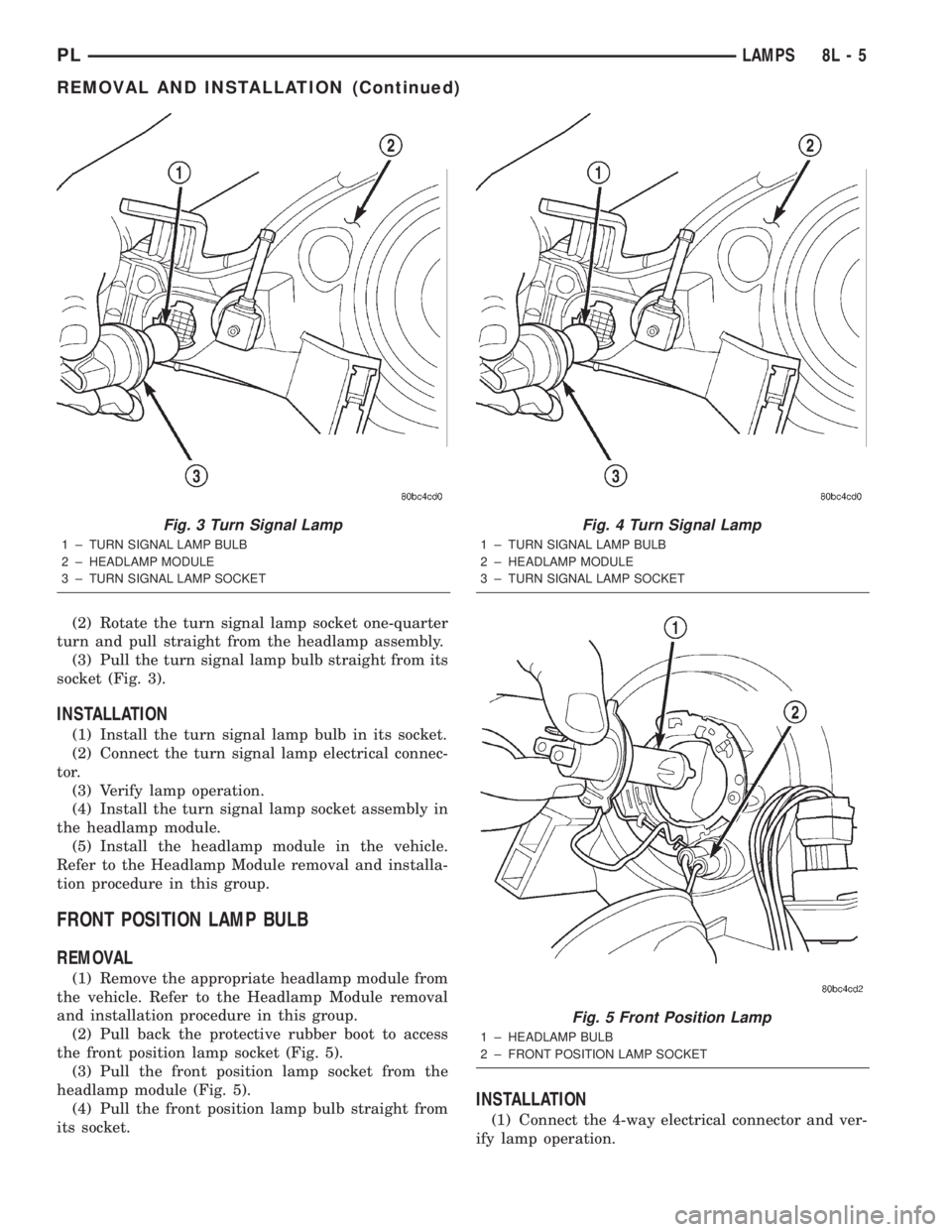

(2) Rotate the turn signal lamp socket one-quarter

turn and pull straight from the headlamp assembly.

(3) Pull the turn signal lamp bulb straight from its

socket (Fig. 3).

INSTALLATION

(1) Install the turn signal lamp bulb in its socket.

(2) Connect the turn signal lamp electrical connec-

tor.

(3) Verify lamp operation.

(4) Install the turn signal lamp socket assembly in

the headlamp module.

(5) Install the headlamp module in the vehicle.

Refer to the Headlamp Module removal and installa-

tion procedure in this group.

FRONT POSITION LAMP BULB

REMOVAL

(1) Remove the appropriate headlamp module from

the vehicle. Refer to the Headlamp Module removal

and installation procedure in this group.

(2) Pull back the protective rubber boot to access

the front position lamp socket (Fig. 5).

(3) Pull the front position lamp socket from the

headlamp module (Fig. 5).

(4) Pull the front position lamp bulb straight from

its socket.

INSTALLATION

(1) Connect the 4-way electrical connector and ver-

ify lamp operation.

Fig. 3 Turn Signal Lamp

1 ± TURN SIGNAL LAMP BULB

2 ± HEADLAMP MODULE

3 ± TURN SIGNAL LAMP SOCKET

Fig. 4 Turn Signal Lamp

1 ± TURN SIGNAL LAMP BULB

2 ± HEADLAMP MODULE

3 ± TURN SIGNAL LAMP SOCKET

Fig. 5 Front Position Lamp

1 ± HEADLAMP BULB

2 ± FRONT POSITION LAMP SOCKET

PLLAMPS 8L - 5

REMOVAL AND INSTALLATION (Continued)

Page 331 of 1285

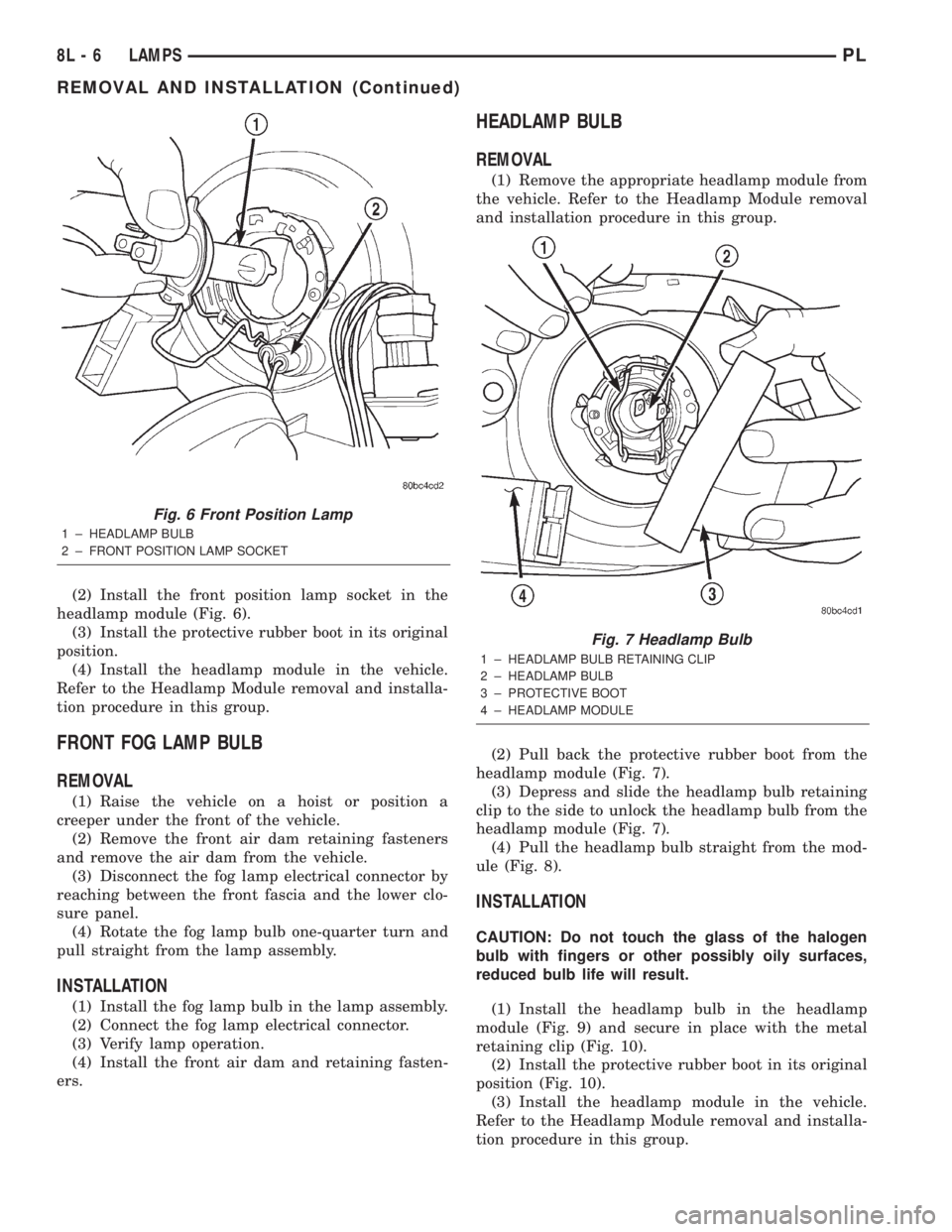

(2) Install the front position lamp socket in the

headlamp module (Fig. 6).

(3) Install the protective rubber boot in its original

position.

(4) Install the headlamp module in the vehicle.

Refer to the Headlamp Module removal and installa-

tion procedure in this group.

FRONT FOG LAMP BULB

REMOVAL

(1) Raise the vehicle on a hoist or position a

creeper under the front of the vehicle.

(2) Remove the front air dam retaining fasteners

and remove the air dam from the vehicle.

(3) Disconnect the fog lamp electrical connector by

reaching between the front fascia and the lower clo-

sure panel.

(4) Rotate the fog lamp bulb one-quarter turn and

pull straight from the lamp assembly.

INSTALLATION

(1) Install the fog lamp bulb in the lamp assembly.

(2) Connect the fog lamp electrical connector.

(3) Verify lamp operation.

(4) Install the front air dam and retaining fasten-

ers.

HEADLAMP BULB

REMOVAL

(1) Remove the appropriate headlamp module from

the vehicle. Refer to the Headlamp Module removal

and installation procedure in this group.

(2) Pull back the protective rubber boot from the

headlamp module (Fig. 7).

(3) Depress and slide the headlamp bulb retaining

clip to the side to unlock the headlamp bulb from the

headlamp module (Fig. 7).

(4) Pull the headlamp bulb straight from the mod-

ule (Fig. 8).

INSTALLATION

CAUTION: Do not touch the glass of the halogen

bulb with fingers or other possibly oily surfaces,

reduced bulb life will result.

(1) Install the headlamp bulb in the headlamp

module (Fig. 9) and secure in place with the metal

retaining clip (Fig. 10).

(2) Install the protective rubber boot in its original

position (Fig. 10).

(3) Install the headlamp module in the vehicle.

Refer to the Headlamp Module removal and installa-

tion procedure in this group.

Fig. 6 Front Position Lamp

1 ± HEADLAMP BULB

2 ± FRONT POSITION LAMP SOCKET

Fig. 7 Headlamp Bulb

1 ± HEADLAMP BULB RETAINING CLIP

2 ± HEADLAMP BULB

3 ± PROTECTIVE BOOT

4 ± HEADLAMP MODULE

8L - 6 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 332 of 1285

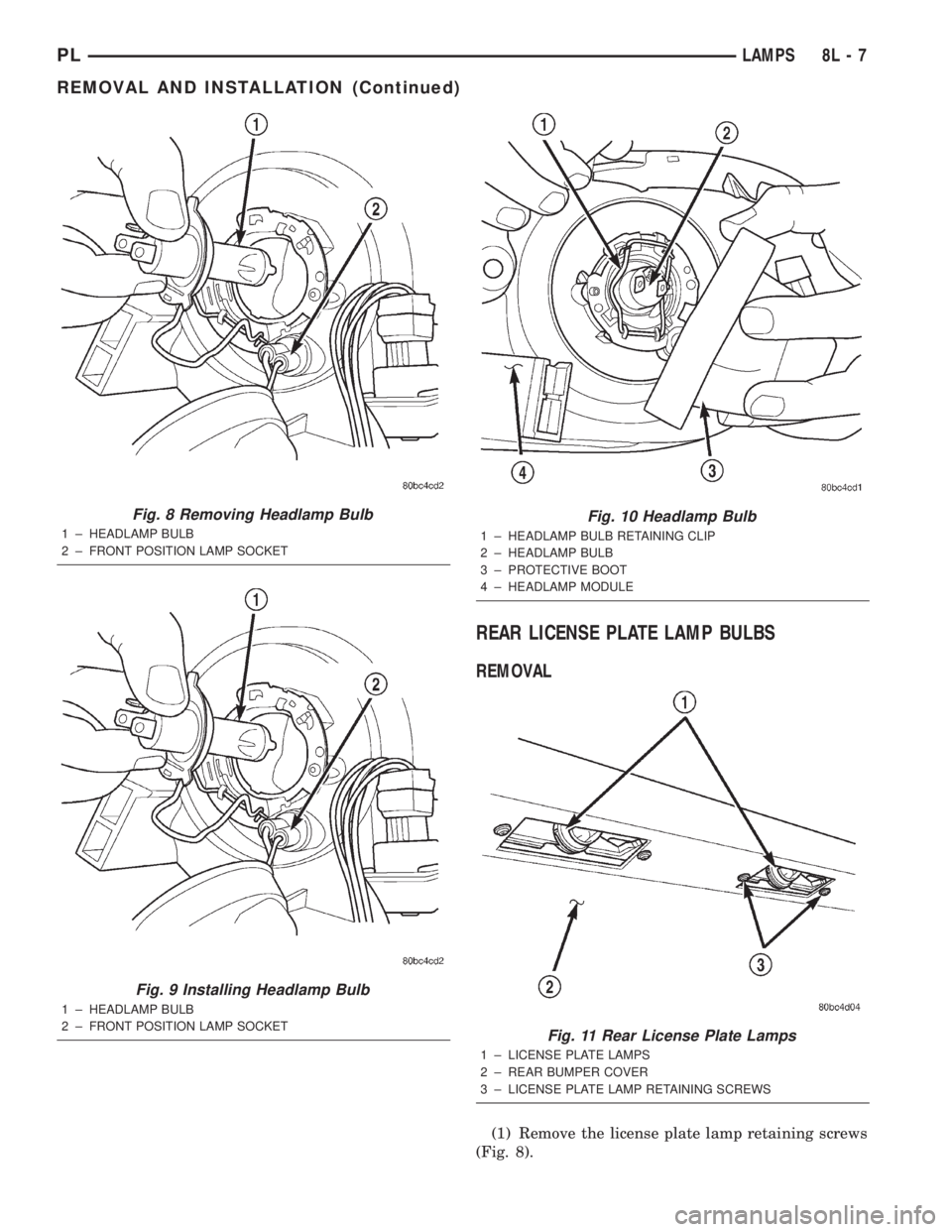

REAR LICENSE PLATE LAMP BULBS

REMOVAL

(1) Remove the license plate lamp retaining screws

(Fig. 8).

Fig. 8 Removing Headlamp Bulb

1 ± HEADLAMP BULB

2 ± FRONT POSITION LAMP SOCKET

Fig. 9 Installing Headlamp Bulb

1 ± HEADLAMP BULB

2 ± FRONT POSITION LAMP SOCKET

Fig. 10 Headlamp Bulb

1 ± HEADLAMP BULB RETAINING CLIP

2 ± HEADLAMP BULB

3 ± PROTECTIVE BOOT

4 ± HEADLAMP MODULE

Fig. 11 Rear License Plate Lamps

1 ± LICENSE PLATE LAMPS

2 ± REAR BUMPER COVER

3 ± LICENSE PLATE LAMP RETAINING SCREWS

PLLAMPS 8L - 7

REMOVAL AND INSTALLATION (Continued)

Page 914 of 1285

TRANSAXLE

TABLE OF CONTENTS

page page

NV T350 (A-578) MANUAL TRANSAXLE........ 131TH AUTOMATIC TRANSAXLE.............. 54

NV T350 (A-578) MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE.........1

TRANSAXLE IDENTIFICATION................2

FLUID REQUIREMENTS....................2

SPECIAL ADDITIVES.......................2

SEALANTS..............................2

GEAR RATIOS............................2

GEARSHIFT PATTERN......................3

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES...............3

HARD SHIFTING..........................3

NOISY OPERATION........................3

SLIPS OUT OF GEAR......................3

LOW LUBRICANT LEVEL....................4

FLUID LEAKS............................4

CLUTCH PROBLEMS.......................4

SERVICE PROCEDURES

FLUID DRAIN AND FILL.....................4

REMOVAL AND INSTALLATION

GEARSHIFT KNOB........................4

GEARSHIFT BOOT........................5

GEARSHIFT CABLE ASSEMBLY..............6

GEARSHIFT MECHANISM REPLACEMENT......9

VEHICLE SPEED SENSOR AND DRIVE

PINION...............................11

BACK-UP LAMP SWITCH...................12CROSSOVER LEVER......................12

SELECTOR LEVER.......................12

AXLE SHAFT SEALS......................13

SHIFT SHAFT SEALS......................13

TRANSAXLE............................14

DISASSEMBLY AND ASSEMBLY

TRANSAXLE............................18

INPUT SHAFT...........................31

OUTPUT SHAFT.........................36

DIFFERENTIAL..........................36

SYNCHRONIZER.........................41

SHIFT RAILS OVERHAUL..................42

TRANSAXLE CASE OVERHAUL..............42

CLEANING AND INSPECTION

TRANSAXLE............................48

SYNCHRONIZER.........................48

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE...........49

BEARING ADJUSTMENT PROCEDURE........50

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT..........................50

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS...........51

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE........52

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE

The NV T350 (A-578) transaxle is a fully synchro-

nized (except reverse), constant-mesh transaxle. The

transaxle case is constructed of die-cast aluminum,

and is a two-piece design (bell housing case half and

rear housing case half) with a steel end plate bearing

cover. All forward gears are in constant-mesh witheach other, which eliminates the need to move gears

together for engagement. This feature improves

response and eliminates gear ªclashº noises. The

reverse idler gear is supported and rotates on a spin-

dle idler shaft. Depending on application, a reverse

gear brake/blocking ring is available on some units

for shifting ease.

The NV T350 (A-578) transaxle also incorporates an

open differential, which converts power from the output

shaft pinion gear to the differential ring gear. The dif-

PLTRANSAXLE 21 - 1

Page 917 of 1285

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

FLUID LEAKS

Fluid leaks can occur around the input shaft seal,

axleshaft seals, case split lines, and the end cover. Be

careful not to misdiagnose an input shaft seal leak

for an engine rear main seal leak. Also, the transaxle

case sealer (split line) will accumulate dirt and look

like an oil leak.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

SERVICE PROCEDURES

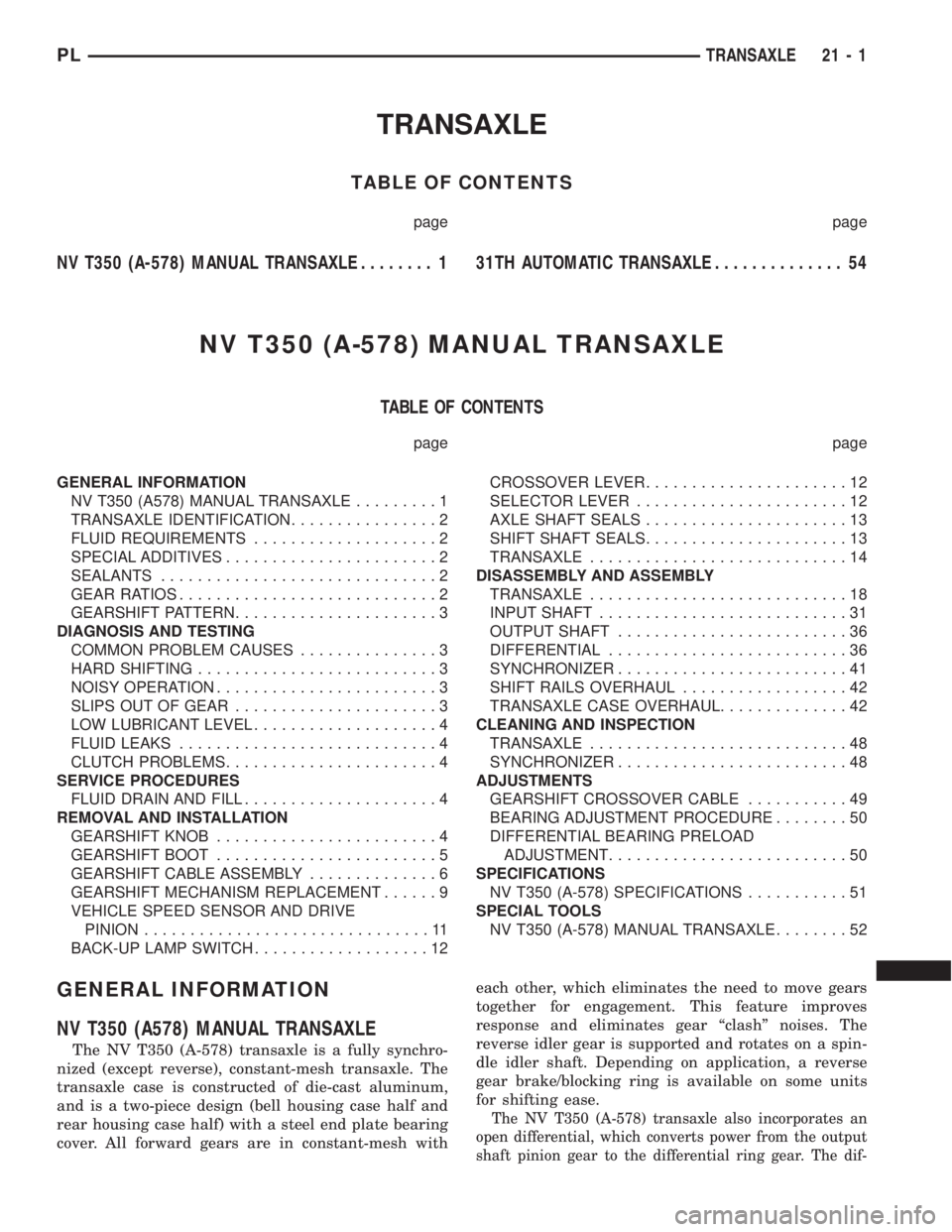

FLUID DRAIN AND FILL

All NV T350 (A-578) transaxles are equipped with

a fill plug. The fill plug is located on the left side of

the transaxle differential area (Fig. 3). The fluid level

should be within 3/16 inch from the bottom of the

transaxle fill hole (vehicle must be level when check-

ing).All NV T350 (A-578) transaxles are equipped with

a drain plug. The drain plug is located on the lower

right side of the transaxle differential housing (Fig.

4). Tighten drain plug to 28 N´m (250 in. lbs.)

Dry fill lubricant capacity is approximately 1.9-2.2

liters (4.0-4.6 pints). Wipe the outside of the tran-

saxle if any lubricant spills.

REMOVAL AND INSTALLATION

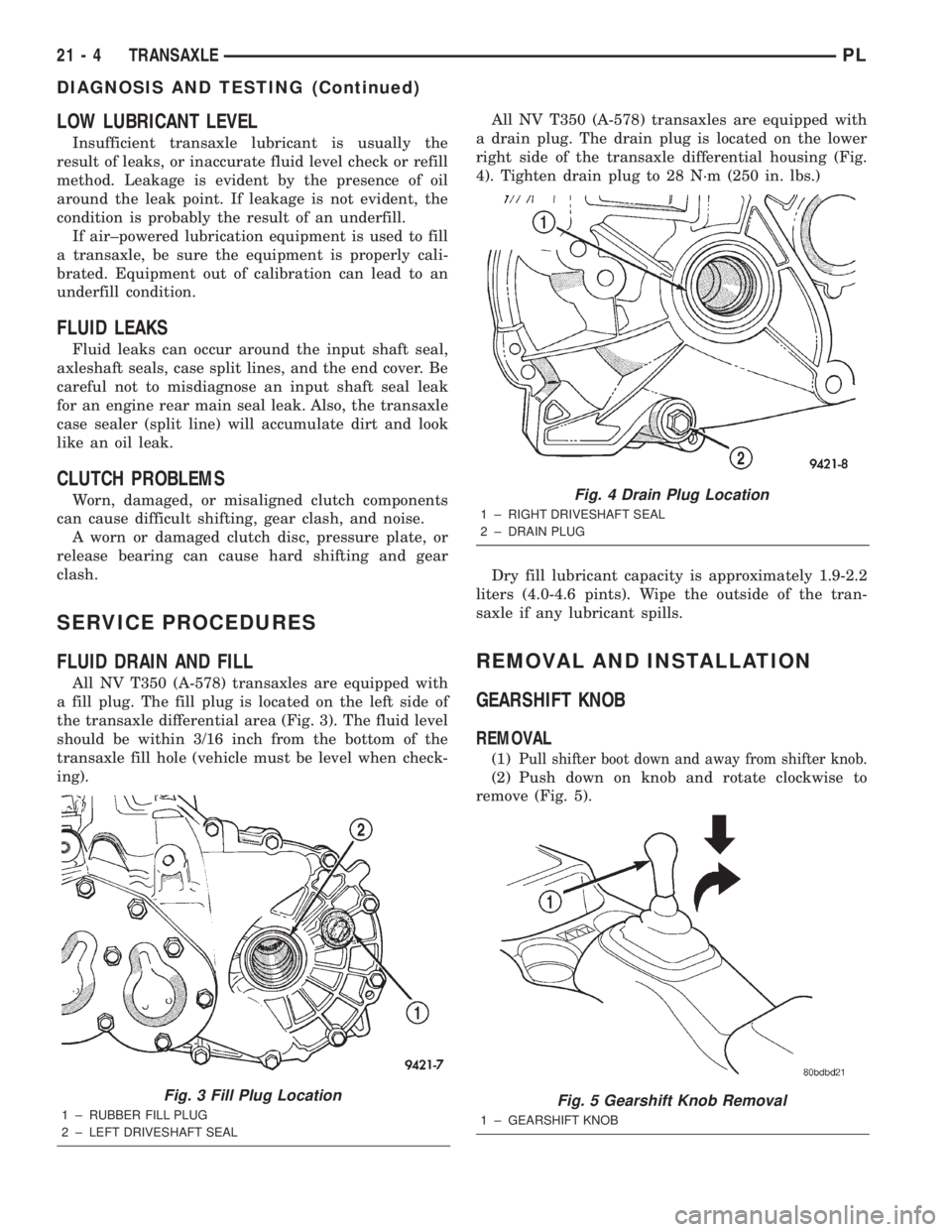

GEARSHIFT KNOB

REMOVAL

(1)Pull shifter boot down and away from shifter knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 5).

Fig. 3 Fill Plug Location

1 ± RUBBER FILL PLUG

2 ± LEFT DRIVESHAFT SEAL

Fig. 4 Drain Plug Location

1 ± RIGHT DRIVESHAFT SEAL

2 ± DRAIN PLUG

Fig. 5 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

21 - 4 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)