diagram DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 280 of 1285

HORNS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

HORN..................................2

HORN RELAY............................2

HORN SWITCH...........................2HORN SYSTEM TEST......................2

REMOVAL AND INSTALLATION

HORN..................................4

HORN RELAY............................4

HORN SWITCH...........................5

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, PASSIVE RESTRAINT SYS-

TEMS FOR STEERING WHEEL REMOVAL.

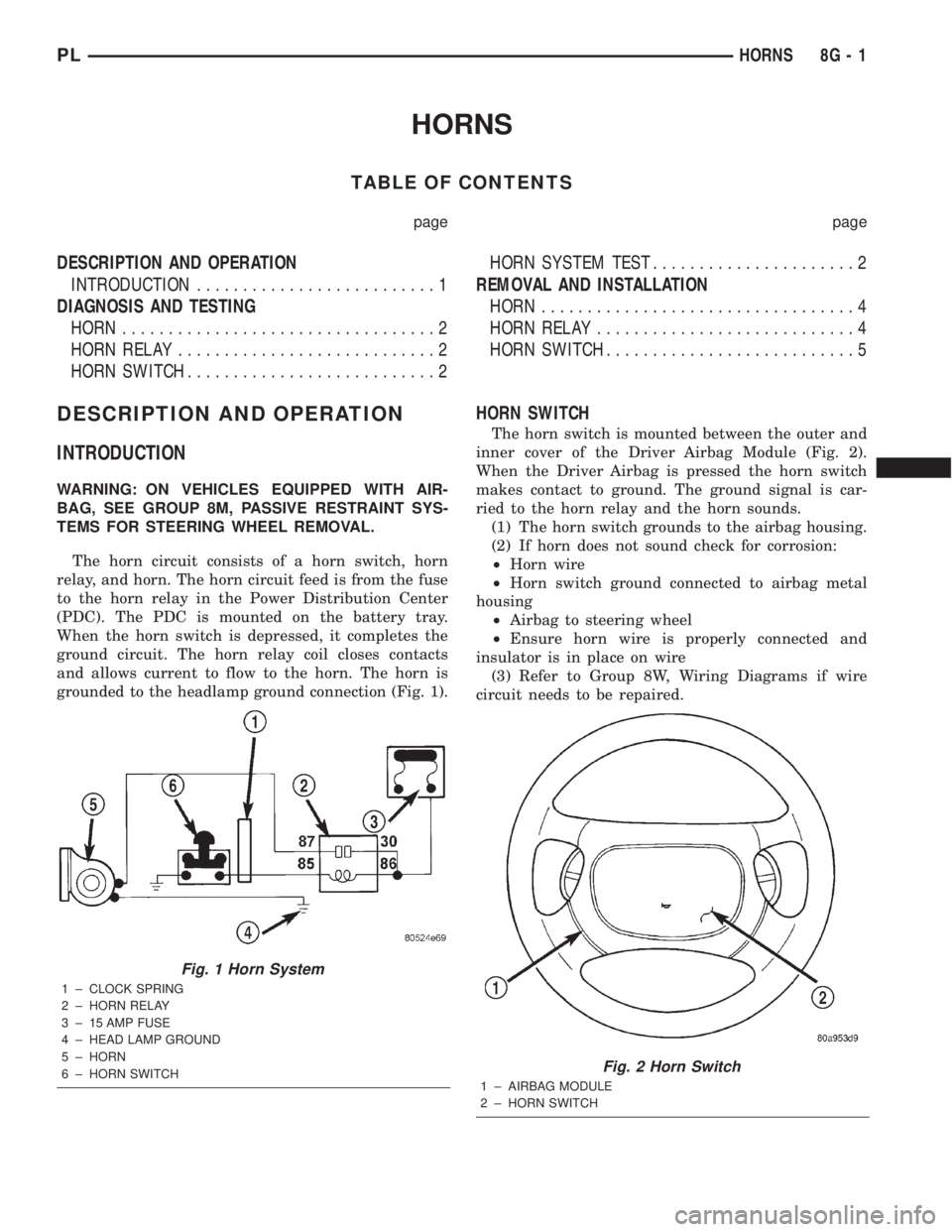

The horn circuit consists of a horn switch, horn

relay, and horn. The horn circuit feed is from the fuse

to the horn relay in the Power Distribution Center

(PDC). The PDC is mounted on the battery tray.

When the horn switch is depressed, it completes the

ground circuit. The horn relay coil closes contacts

and allows current to flow to the horn. The horn is

grounded to the headlamp ground connection (Fig. 1).

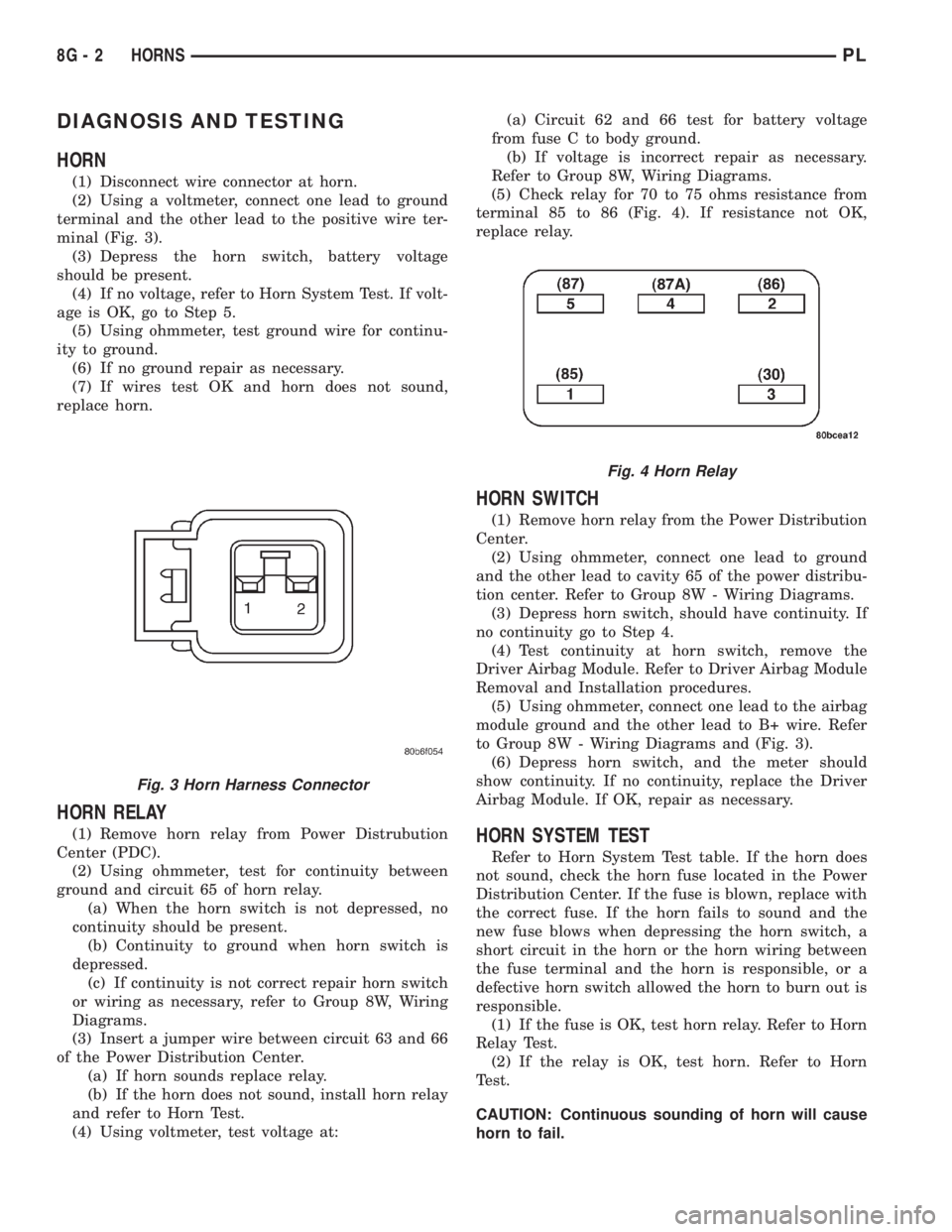

HORN SWITCH

The horn switch is mounted between the outer and

inner cover of the Driver Airbag Module (Fig. 2).

When the Driver Airbag is pressed the horn switch

makes contact to ground. The ground signal is car-

ried to the horn relay and the horn sounds.

(1) The horn switch grounds to the airbag housing.

(2) If horn does not sound check for corrosion:

²Horn wire

²Horn switch ground connected to airbag metal

housing

²Airbag to steering wheel

²Ensure horn wire is properly connected and

insulator is in place on wire

(3) Refer to Group 8W, Wiring Diagrams if wire

circuit needs to be repaired.

Fig. 1 Horn System

1 ± CLOCK SPRING

2 ± HORN RELAY

3 ± 15 AMP FUSE

4 ± HEAD LAMP GROUND

5 ± HORN

6 ± HORN SWITCH

Fig. 2 Horn Switch

1 ± AIRBAG MODULE

2 ± HORN SWITCH

PLHORNS 8G - 1

Page 281 of 1285

DIAGNOSIS AND TESTING

HORN

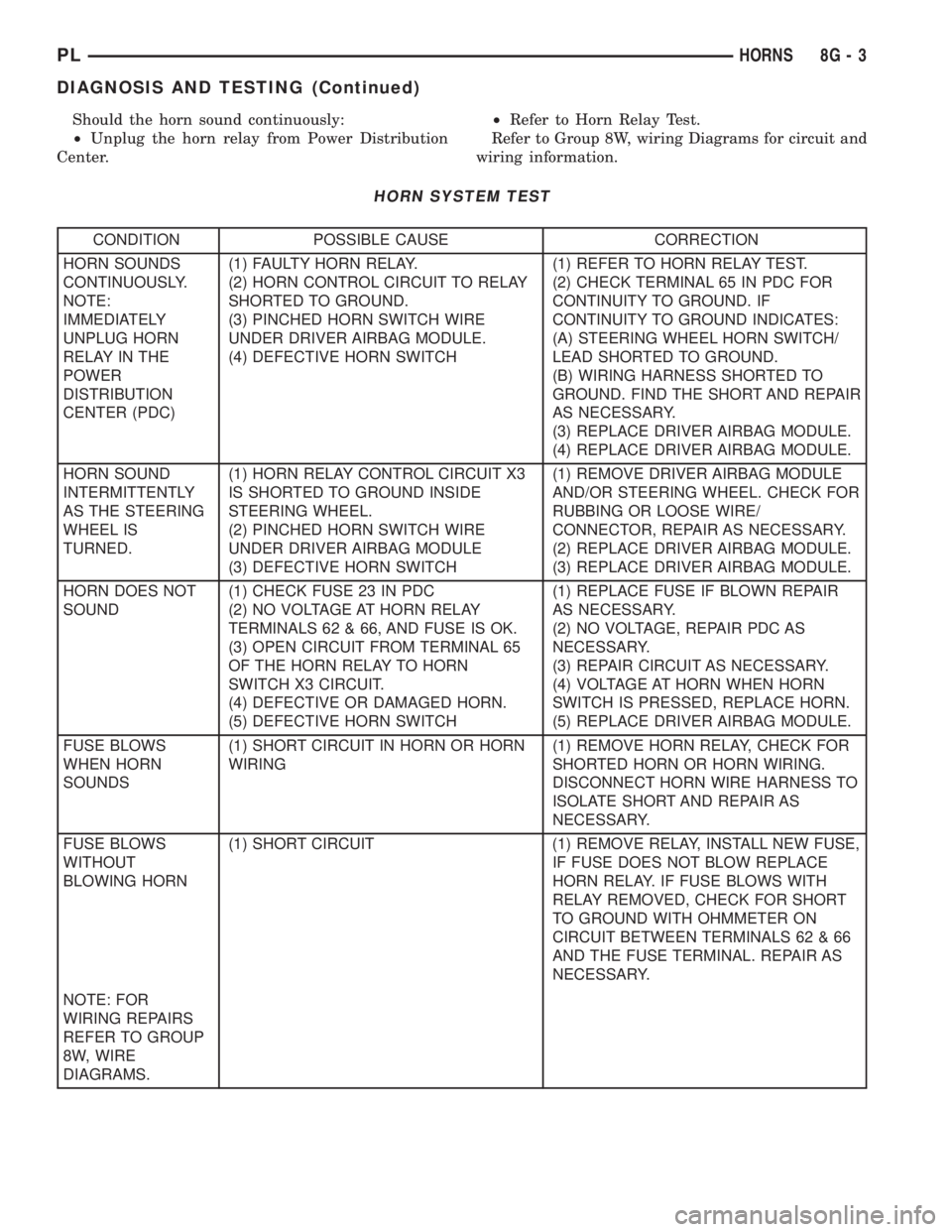

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 3).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer to Horn System Test. If volt-

age is OK, go to Step 5.

(5) Using ohmmeter, test ground wire for continu-

ity to ground.

(6) If no ground repair as necessary.

(7) If wires test OK and horn does not sound,

replace horn.

HORN RELAY

(1) Remove horn relay from Power Distrubution

Center (PDC).

(2) Using ohmmeter, test for continuity between

ground and circuit 65 of horn relay.

(a) When the horn switch is not depressed, no

continuity should be present.

(b) Continuity to ground when horn switch is

depressed.

(c) If continuity is not correct repair horn switch

or wiring as necessary, refer to Group 8W, Wiring

Diagrams.

(3) Insert a jumper wire between circuit 63 and 66

of the Power Distribution Center.

(a) If horn sounds replace relay.

(b) If the horn does not sound, install horn relay

and refer to Horn Test.

(4) Using voltmeter, test voltage at:(a) Circuit 62 and 66 test for battery voltage

from fuse C to body ground.

(b) If voltage is incorrect repair as necessary.

Refer to Group 8W, Wiring Diagrams.

(5) Check relay for 70 to 75 ohms resistance from

terminal 85 to 86 (Fig. 4). If resistance not OK,

replace relay.

HORN SWITCH

(1) Remove horn relay from the Power Distribution

Center.

(2) Using ohmmeter, connect one lead to ground

and the other lead to cavity 65 of the power distribu-

tion center. Refer to Group 8W - Wiring Diagrams.

(3) Depress horn switch, should have continuity. If

no continuity go to Step 4.

(4) Test continuity at horn switch, remove the

Driver Airbag Module. Refer to Driver Airbag Module

Removal and Installation procedures.

(5) Using ohmmeter, connect one lead to the airbag

module ground and the other lead to B+ wire. Refer

to Group 8W - Wiring Diagrams and (Fig. 3).

(6) Depress horn switch, and the meter should

show continuity. If no continuity, replace the Driver

Airbag Module. If OK, repair as necessary.

HORN SYSTEM TEST

Refer to Horn System Test table. If the horn does

not sound, check the horn fuse located in the Power

Distribution Center. If the fuse is blown, replace with

the correct fuse. If the horn fails to sound and the

new fuse blows when depressing the horn switch, a

short circuit in the horn or the horn wiring between

the fuse terminal and the horn is responsible, or a

defective horn switch allowed the horn to burn out is

responsible.

(1) If the fuse is OK, test horn relay. Refer to Horn

Relay Test.

(2) If the relay is OK, test horn. Refer to Horn

Test.

CAUTION: Continuous sounding of horn will cause

horn to fail.

Fig. 3 Horn Harness Connector

Fig. 4 Horn Relay

8G - 2 HORNSPL

Page 282 of 1285

Should the horn sound continuously:

²Unplug the horn relay from Power Distribution

Center.²Refer to Horn Relay Test.

Refer to Group 8W, wiring Diagrams for circuit and

wiring information.

HORN SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

HORN SOUNDS

CONTINUOUSLY.

NOTE:

IMMEDIATELY

UNPLUG HORN

RELAY IN THE

POWER

DISTRIBUTION

CENTER (PDC)(1) FAULTY HORN RELAY.

(2) HORN CONTROL CIRCUIT TO RELAY

SHORTED TO GROUND.

(3) PINCHED HORN SWITCH WIRE

UNDER DRIVER AIRBAG MODULE.

(4) DEFECTIVE HORN SWITCH(1) REFER TO HORN RELAY TEST.

(2) CHECK TERMINAL 65 IN PDC FOR

CONTINUITY TO GROUND. IF

CONTINUITY TO GROUND INDICATES:

(A) STEERING WHEEL HORN SWITCH/

LEAD SHORTED TO GROUND.

(B) WIRING HARNESS SHORTED TO

GROUND. FIND THE SHORT AND REPAIR

AS NECESSARY.

(3) REPLACE DRIVER AIRBAG MODULE.

(4) REPLACE DRIVER AIRBAG MODULE.

HORN SOUND

INTERMITTENTLY

AS THE STEERING

WHEEL IS

TURNED.(1) HORN RELAY CONTROL CIRCUIT X3

IS SHORTED TO GROUND INSIDE

STEERING WHEEL.

(2) PINCHED HORN SWITCH WIRE

UNDER DRIVER AIRBAG MODULE

(3) DEFECTIVE HORN SWITCH(1) REMOVE DRIVER AIRBAG MODULE

AND/OR STEERING WHEEL. CHECK FOR

RUBBING OR LOOSE WIRE/

CONNECTOR, REPAIR AS NECESSARY.

(2) REPLACE DRIVER AIRBAG MODULE.

(3) REPLACE DRIVER AIRBAG MODULE.

HORN DOES NOT

SOUND(1) CHECK FUSE 23 IN PDC

(2) NO VOLTAGE AT HORN RELAY

TERMINALS 62 & 66, AND FUSE IS OK.

(3) OPEN CIRCUIT FROM TERMINAL 65

OF THE HORN RELAY TO HORN

SWITCH X3 CIRCUIT.

(4) DEFECTIVE OR DAMAGED HORN.

(5) DEFECTIVE HORN SWITCH(1) REPLACE FUSE IF BLOWN REPAIR

AS NECESSARY.

(2) NO VOLTAGE, REPAIR PDC AS

NECESSARY.

(3) REPAIR CIRCUIT AS NECESSARY.

(4) VOLTAGE AT HORN WHEN HORN

SWITCH IS PRESSED, REPLACE HORN.

(5) REPLACE DRIVER AIRBAG MODULE.

FUSE BLOWS

WHEN HORN

SOUNDS(1) SHORT CIRCUIT IN HORN OR HORN

WIRING(1) REMOVE HORN RELAY, CHECK FOR

SHORTED HORN OR HORN WIRING.

DISCONNECT HORN WIRE HARNESS TO

ISOLATE SHORT AND REPAIR AS

NECESSARY.

FUSE BLOWS

WITHOUT

BLOWING HORN(1) SHORT CIRCUIT (1) REMOVE RELAY, INSTALL NEW FUSE,

IF FUSE DOES NOT BLOW REPLACE

HORN RELAY. IF FUSE BLOWS WITH

RELAY REMOVED, CHECK FOR SHORT

TO GROUND WITH OHMMETER ON

CIRCUIT BETWEEN TERMINALS 62 & 66

AND THE FUSE TERMINAL. REPAIR AS

NECESSARY.

NOTE: FOR

WIRING REPAIRS

REFER TO GROUP

8W, WIRE

DIAGRAMS.

PLHORNS 8G - 3

DIAGNOSIS AND TESTING (Continued)

Page 299 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken.

Whatever the problem, disconnect motor wire har-

ness and clean the terminals, then connect motor

wire harness and test.

Refer to Group 8W Wiring Diagrams for circuit

information and connector call-outs.

MOTOR WILL NOT OPERATE IN SOME OR ALL

SWITCH POSITIONS

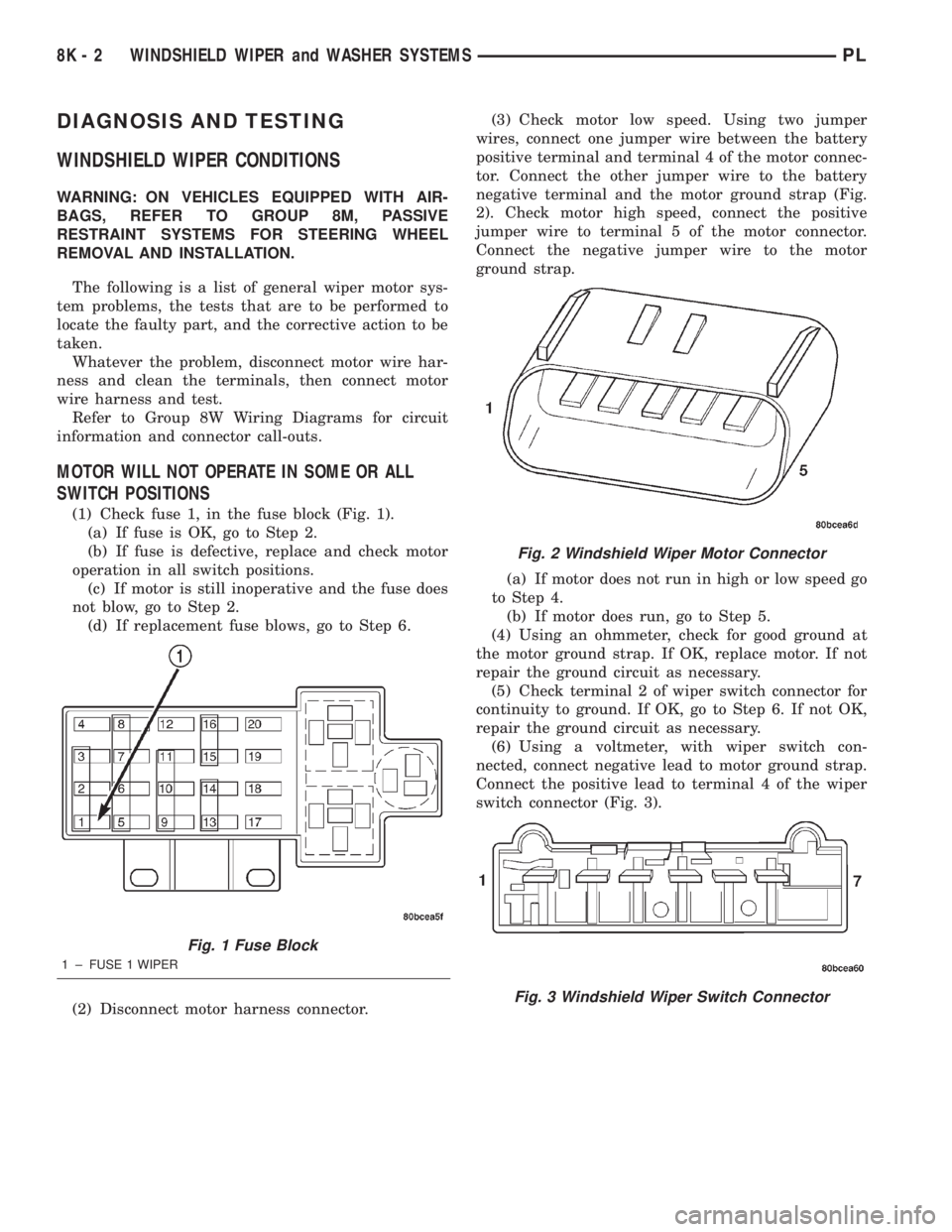

(1) Check fuse 1, in the fuse block (Fig. 1).

(a) If fuse is OK, go to Step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions.

(c) If motor is still inoperative and the fuse does

not blow, go to Step 2.

(d) If replacement fuse blows, go to Step 6.

(2) Disconnect motor harness connector.(3) Check motor low speed. Using two jumper

wires, connect one jumper wire between the battery

positive terminal and terminal 4 of the motor connec-

tor. Connect the other jumper wire to the battery

negative terminal and the motor ground strap (Fig.

2). Check motor high speed, connect the positive

jumper wire to terminal 5 of the motor connector.

Connect the negative jumper wire to the motor

ground strap.

(a) If motor does not run in high or low speed go

to Step 4.

(b) If motor does run, go to Step 5.

(4) Using an ohmmeter, check for good ground at

the motor ground strap. If OK, replace motor. If not

repair the ground circuit as necessary.

(5) Check terminal 2 of wiper switch connector for

continuity to ground. If OK, go to Step 6. If not OK,

repair the ground circuit as necessary.

(6) Using a voltmeter, with wiper switch con-

nected, connect negative lead to motor ground strap.

Connect the positive lead to terminal 4 of the wiper

switch connector (Fig. 3).

Fig. 1 Fuse Block

1 ± FUSE 1 WIPER

Fig. 2 Windshield Wiper Motor Connector

Fig. 3 Windshield Wiper Switch Connector

8K - 2 WINDSHIELD WIPER and WASHER SYSTEMSPL

Page 300 of 1285

(a) If no voltage, repair wiring as necessary. If

OK, go to Step b.

(b) Check wiper switch low speed. Connect volt-

meter positive lead to terminal 6 of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal 5 of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 1

in fuse block.

(a) If fuse does not blow, replace motor.

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector. Turn wiper motor on and check

ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.

(2) Using an ohmmeter, check the high and low

circuits for a short to ground. Refer to Group 8W,

Wiring Diagrams.

(3) Check to see if wiper linkage or pivots are

binding or caught.

WIPERS RUN AT HIGH SPEED WITH SWITCH IN

LOW SPEED POSITION OR WIPERS RUN AT LOW

SPEED WITH SWITCH IN HIGH SPEED POSITION.

(1) Check for crossed wires in the motor pigtail

wire connector. Refer to Group 8W, Wiring Diagrams.

(2) Check for crossed wires in harness connector

from wiper switch to motor.

(3) If OK, replace wiper switch.

WIPERS WILL OPERATE CONTINUOUSLY WITH

THE SWITCH IN THE INTERMITTENT POSITION -

WHEN WIPER SWITCH IS TURNED OFF, WIPERS

STOP WHEREVER THEY ARE WITHOUT

RETURNING TO PARK POSITION.

(1) Check at motor ground strap for a good ground.

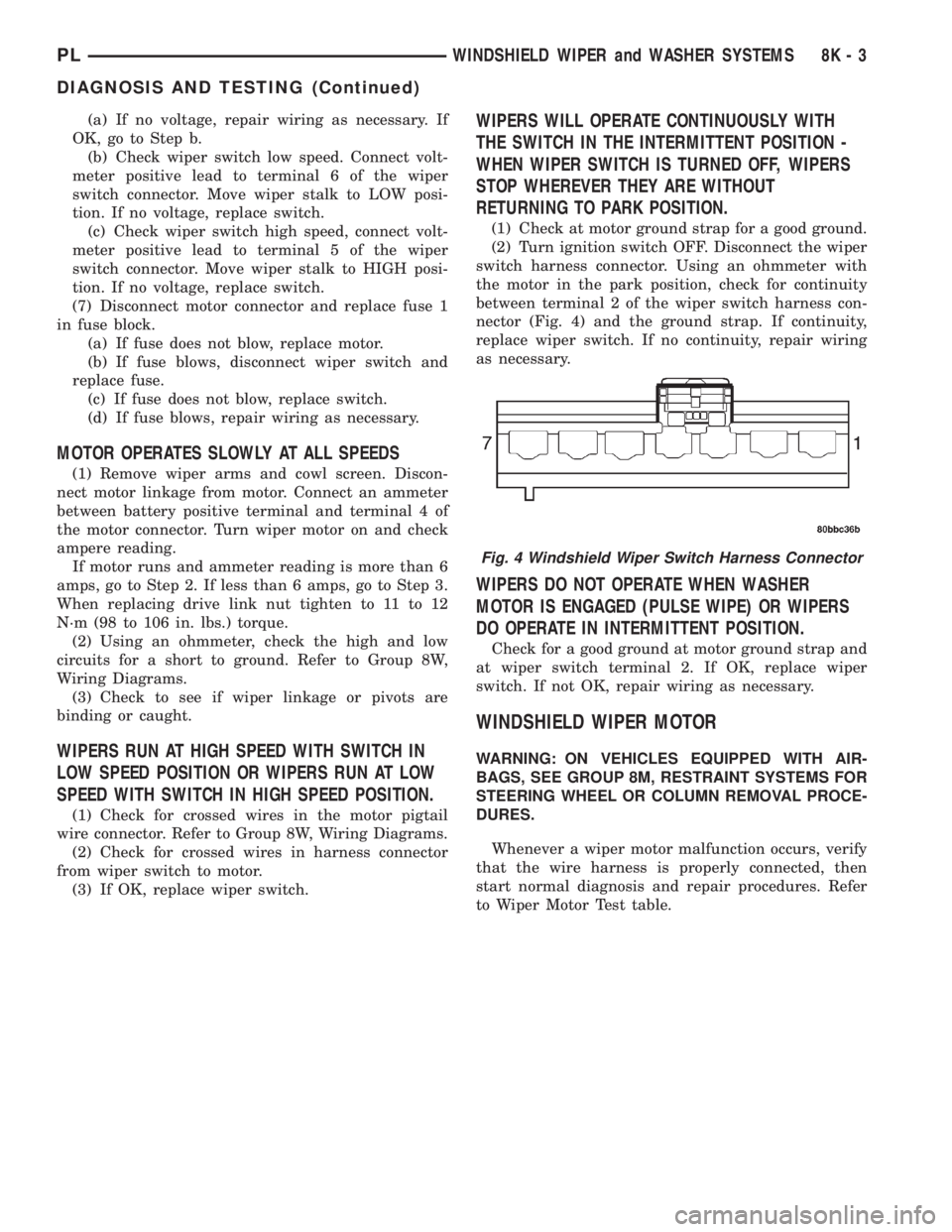

(2) Turn ignition switch OFF. Disconnect the wiper

switch harness connector. Using an ohmmeter with

the motor in the park position, check for continuity

between terminal 2 of the wiper switch harness con-

nector (Fig. 4) and the ground strap. If continuity,

replace wiper switch. If no continuity, repair wiring

as necessary.

WIPERS DO NOT OPERATE WHEN WASHER

MOTOR IS ENGAGED (PULSE WIPE) OR WIPERS

DO OPERATE IN INTERMITTENT POSITION.

Check for a good ground at motor ground strap and

at wiper switch terminal 2. If OK, replace wiper

switch. If not OK, repair wiring as necessary.

WINDSHIELD WIPER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, verify

that the wire harness is properly connected, then

start normal diagnosis and repair procedures. Refer

to Wiper Motor Test table.

Fig. 4 Windshield Wiper Switch Harness Connector

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 3

DIAGNOSIS AND TESTING (Continued)

Page 301 of 1285

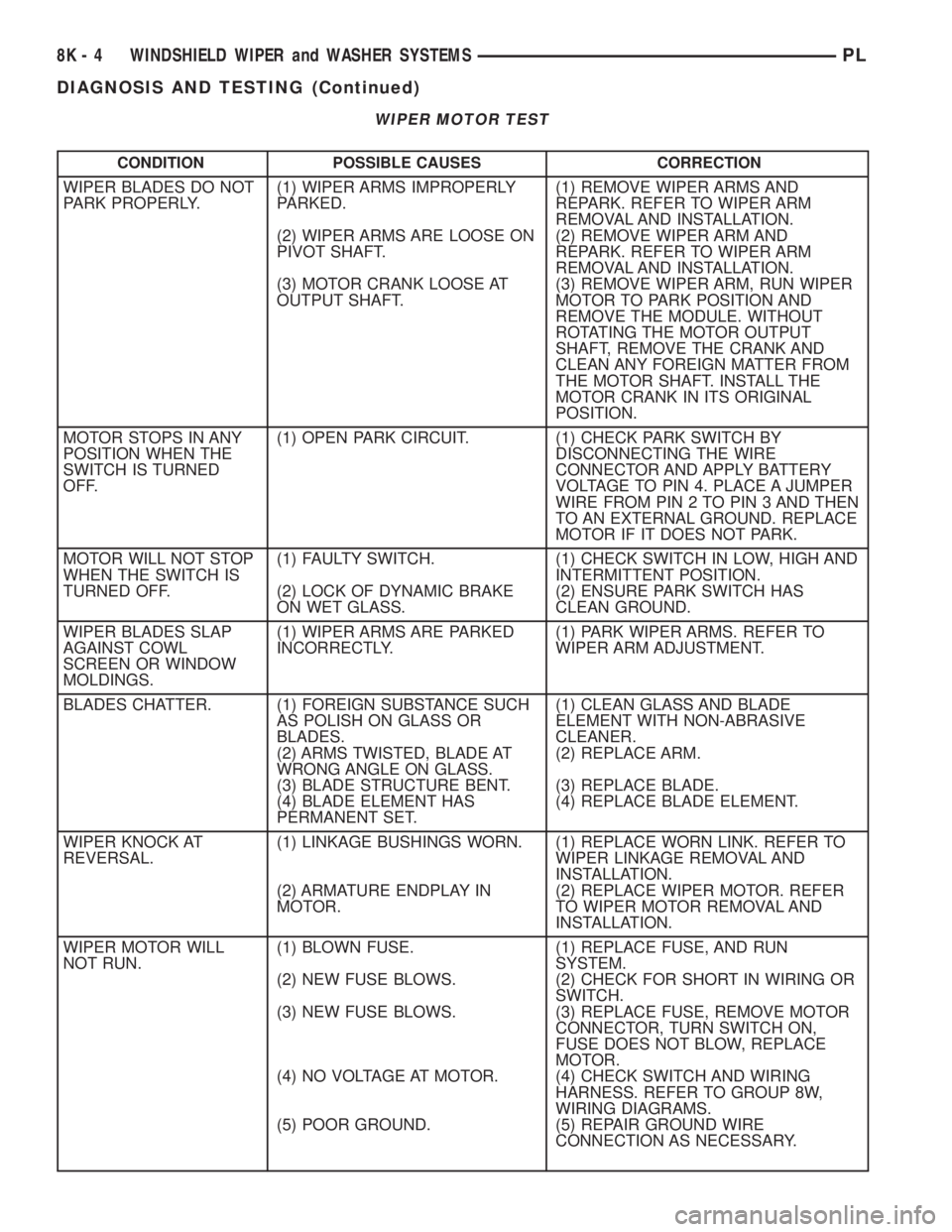

WIPER MOTOR TEST

CONDITION POSSIBLE CAUSES CORRECTION

WIPER BLADES DO NOT

PARK PROPERLY.(1) WIPER ARMS IMPROPERLY

PARKED.

(2) WIPER ARMS ARE LOOSE ON

PIVOT SHAFT.

(3) MOTOR CRANK LOOSE AT

OUTPUT SHAFT.(1) REMOVE WIPER ARMS AND

REPARK. REFER TO WIPER ARM

REMOVAL AND INSTALLATION.

(2) REMOVE WIPER ARM AND

REPARK. REFER TO WIPER ARM

REMOVAL AND INSTALLATION.

(3) REMOVE WIPER ARM, RUN WIPER

MOTOR TO PARK POSITION AND

REMOVE THE MODULE. WITHOUT

ROTATING THE MOTOR OUTPUT

SHAFT, REMOVE THE CRANK AND

CLEAN ANY FOREIGN MATTER FROM

THE MOTOR SHAFT. INSTALL THE

MOTOR CRANK IN ITS ORIGINAL

POSITION.

MOTOR STOPS IN ANY

POSITION WHEN THE

SWITCH IS TURNED

OFF.(1) OPEN PARK CIRCUIT. (1) CHECK PARK SWITCH BY

DISCONNECTING THE WIRE

CONNECTOR AND APPLY BATTERY

VOLTAGE TO PIN 4. PLACE A JUMPER

WIRE FROM PIN 2 TO PIN 3 AND THEN

TO AN EXTERNAL GROUND. REPLACE

MOTOR IF IT DOES NOT PARK.

MOTOR WILL NOT STOP

WHEN THE SWITCH IS

TURNED OFF.(1) FAULTY SWITCH.

(2) LOCK OF DYNAMIC BRAKE

ON WET GLASS.(1) CHECK SWITCH IN LOW, HIGH AND

INTERMITTENT POSITION.

(2) ENSURE PARK SWITCH HAS

CLEAN GROUND.

WIPER BLADES SLAP

AGAINST COWL

SCREEN OR WINDOW

MOLDINGS.(1) WIPER ARMS ARE PARKED

INCORRECTLY.(1) PARK WIPER ARMS. REFER TO

WIPER ARM ADJUSTMENT.

BLADES CHATTER. (1) FOREIGN SUBSTANCE SUCH

AS POLISH ON GLASS OR

BLADES.

(2) ARMS TWISTED, BLADE AT

WRONG ANGLE ON GLASS.

(3) BLADE STRUCTURE BENT.

(4) BLADE ELEMENT HAS

PERMANENT SET.(1) CLEAN GLASS AND BLADE

ELEMENT WITH NON-ABRASIVE

CLEANER.

(2) REPLACE ARM.

(3) REPLACE BLADE.

(4) REPLACE BLADE ELEMENT.

WIPER KNOCK AT

REVERSAL.(1) LINKAGE BUSHINGS WORN.

(2) ARMATURE ENDPLAY IN

MOTOR.(1) REPLACE WORN LINK. REFER TO

WIPER LINKAGE REMOVAL AND

INSTALLATION.

(2) REPLACE WIPER MOTOR. REFER

TO WIPER MOTOR REMOVAL AND

INSTALLATION.

WIPER MOTOR WILL

NOT RUN.(1) BLOWN FUSE.

(2) NEW FUSE BLOWS.

(3) NEW FUSE BLOWS.

(4) NO VOLTAGE AT MOTOR.

(5) POOR GROUND.(1) REPLACE FUSE, AND RUN

SYSTEM.

(2) CHECK FOR SHORT IN WIRING OR

SWITCH.

(3) REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON,

FUSE DOES NOT BLOW, REPLACE

MOTOR.

(4) CHECK SWITCH AND WIRING

HARNESS. REFER TO GROUP 8W,

WIRING DIAGRAMS.

(5) REPAIR GROUND WIRE

CONNECTION AS NECESSARY.

8K - 4 WINDSHIELD WIPER and WASHER SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 308 of 1285

LAMPS

TABLE OF CONTENTS

page page

LAMP DIAGNOSIS......................... 1

HEADLAMP ALIGNMENT.................... 4

LAMP BULB SERVICE...................... 7LAMP SERVICE........................... 12

LAMP SYSTEMS.......................... 16

BULB APPLICATION....................... 17

LAMP DIAGNOSIS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

DIAGNOSTIC PROCEDURES................1

SAFETY PRECAUTIONS....................1

DAYTIME RUNNING LAMP MODULE...........1DIAGNOSIS AND TESTING

HEADLAMP DIAGNOSIS....................1

FOG LAMP..............................3

DESCRIPTION AND OPERATION

DIAGNOSTIC PROCEDURES

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, fuses, charging system, headlamp bulbs,

wire connectors, relay, high beam switch, dimmer

switch, and headlamp switch. Refer to Group 8W,

Wiring Diagrams for component locations and circuit

information.

SAFETY PRECAUTIONS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

Do not use bulbs with higher candle power than

indicated in the Bulb Application table at the end of

this group. Damage to lamp and/or Daytime Run-

ning Lamp Module can result.

Do not use fuses, circuit breakers or relays hav-

ing greater amperage value than indicated on the

fuse panel or in the Owners Manual.When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

DAYTIME RUNNING LAMP MODULE

PL vehicles built for use in Canada are equipped

with a Daytime Running Lamp (DRL) system. Turn

signal lamp circuitry always comes from the multi-

function switch, and goes to the cluster connector,

into the cluster, then back out to the front turn sig-

nal switch lamps. The Canadian cluster provides

steady illumination of the front turn signal when the

ignition switch is in the ON position. The DRL func-

tion may be inhibited by activating the turn signals,

the hazard flashers, the headlamp switch, or park

brake.

DIAGNOSIS AND TESTING

HEADLAMP DIAGNOSIS

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to

Group 8W, Wiring Diagrams.

Conventional and halogen headlamps are inter-

changeable. It is recommended that they not be

intermixed on a given vehicle.

PLLAMPS 8L - 1

Page 337 of 1285

LAMP SERVICE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

HEADLAMP SWITCH......................12

HEADLAMP LEVELING SWITCH.............12

HEADLAMP DIMMER SWITCH...............12

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)..............................12HEADLAMP MODULE.....................12

HEADLAMP LEVELING MOTOR..............14

FRONT FOG LAMP.......................15

REAR LICENSE PLATE LAMPS..............15

REAR FOG LAMP........................15

SIDE REPEATER LAMP....................17

TAIL, STOP AND TURN SIGNAL LAMP........18

GENERAL INFORMATION

HEADLAMP SWITCH

Service procedures for the headlamp switch can be

found in Group 8E, Instrument Panel and Gauges.

More information can be found in Group 8W, Wiring

Diagrams.

HEADLAMP LEVELING SWITCH

Service procedures for the headlamp leveling

switch can be found in Group 8E, Instrument Panel

Systems. More information can be found in Group

8W, Wiring Diagrams.

HEADLAMP DIMMER SWITCH

The headlamp dimmer switch is incorporated into

the multi-function (turn signal) switch. Proper proce-

dures can be found in Group 8J, Turn Signal and

Flashers. More information can be found in Group

8W, Wiring Diagrams.

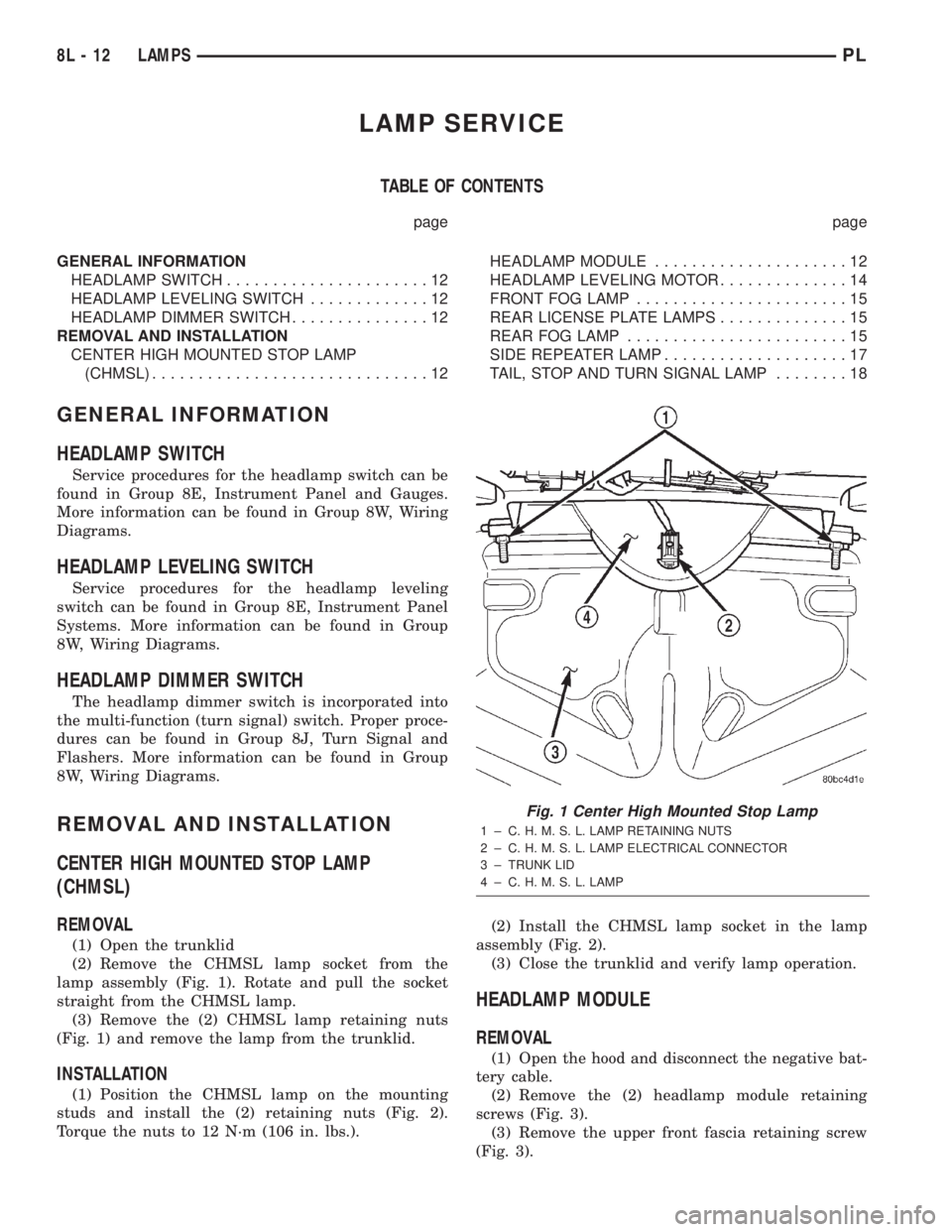

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)

REMOVAL

(1) Open the trunklid

(2) Remove the CHMSL lamp socket from the

lamp assembly (Fig. 1). Rotate and pull the socket

straight from the CHMSL lamp.

(3) Remove the (2) CHMSL lamp retaining nuts

(Fig. 1) and remove the lamp from the trunklid.

INSTALLATION

(1) Position the CHMSL lamp on the mounting

studs and install the (2) retaining nuts (Fig. 2).

Torque the nuts to 12 N´m (106 in. lbs.).(2) Install the CHMSL lamp socket in the lamp

assembly (Fig. 2).

(3) Close the trunklid and verify lamp operation.

HEADLAMP MODULE

REMOVAL

(1) Open the hood and disconnect the negative bat-

tery cable.

(2) Remove the (2) headlamp module retaining

screws (Fig. 3).

(3) Remove the upper front fascia retaining screw

(Fig. 3).

Fig. 1 Center High Mounted Stop Lamp

1 ± C. H. M. S. L. LAMP RETAINING NUTS

2 ± C. H. M. S. L. LAMP ELECTRICAL CONNECTOR

3 ± TRUNK LID

4 ± C. H. M. S. L. LAMP

8L - 12 LAMPSPL

Page 357 of 1285

DIAGNOSIS AND TESTING

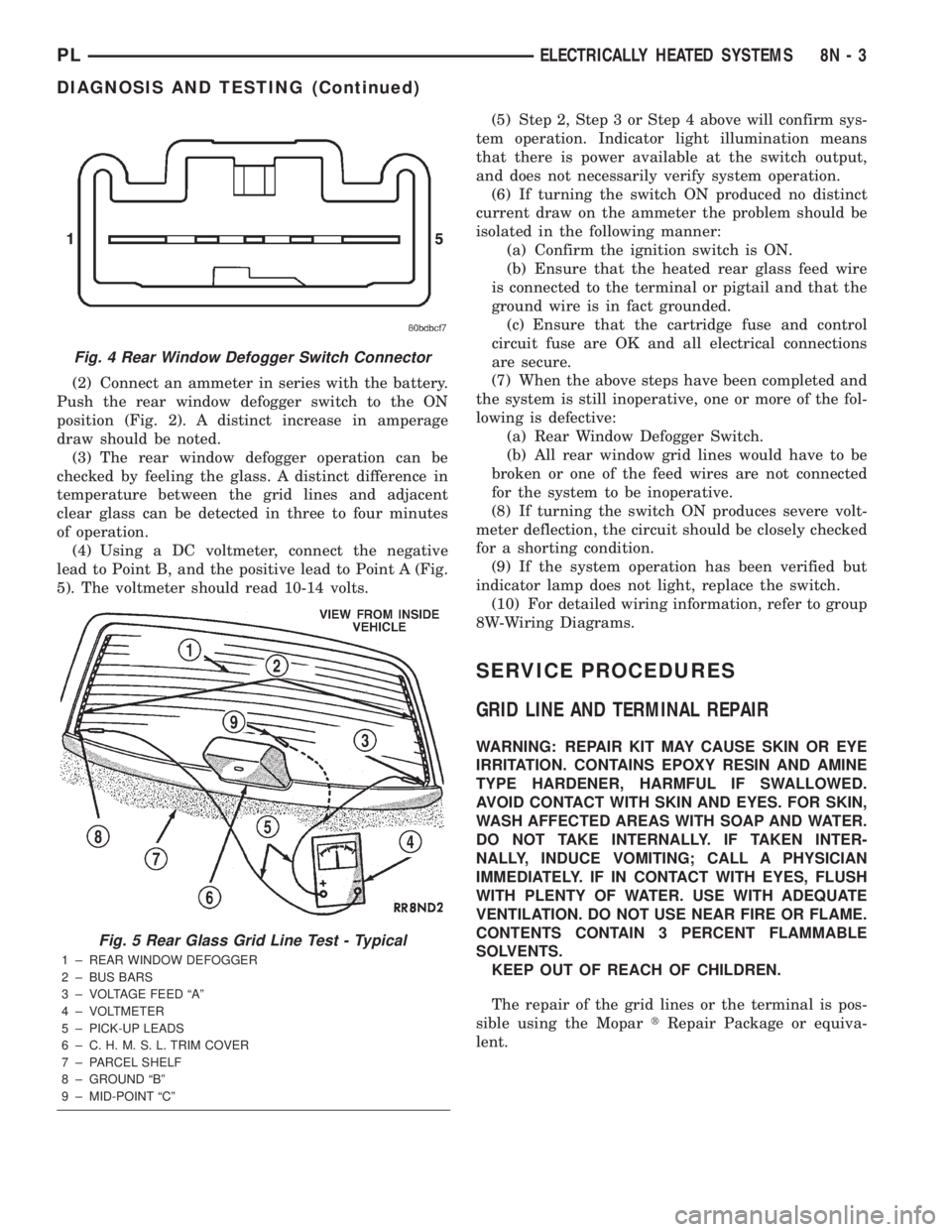

GRID LINES

The horizontal grid lines and vertical bus bar lines

printed and fired on the inside surface of rear win-

dow glass (Fig. 5) comprise an electrical parallel cir-

cuit. The electrically conductive lines are composed of

a silver-ceramic material which when fired on glass

becomes bonded to the glass and is highly resistant

to abrasion. It is possible however, that a break may

occur in an individual grid line resulting in no cur-

rent flow through the line. To detect breaks in grid

lines the following procedure is required:

(1) Turn ignition ON and turn control switch to

ON. The LED should come on.

(2) Using a DC voltmeter with 0-15 volt range,

contact terminal (B) with the negative lead of the

voltmeter. With the positive lead of the voltmeter,

contact terminal (A) (Fig. 5). The voltmeter should

read 10-14 volts. A lower voltage reading indicates a

poor connection in the feed or the ground circuit.

(3) With the negative lead of the voltmeter, contact

a good body ground point. The voltage reading should

not change.

(4) Connect the negative lead of the voltmeter to

terminal (B) and touch each grid line at Mid-Point

with the positive lead. A reading of:

²Approximately 6 volts indicates the line is OK.

²0 volts indicates a break in line between Mid-

Point (C) and terminal (A).

²10-14 volts indicates a break between Mid-Point

(C) and terminal (B).

Move the lead toward the break and voltage will

change as soon as the break is crossed. Refer to (Fig.

5).

REAR WINDOW DEFOGGER SWITCH

The rear window defogger switch may be tested in

the vehicle or out of the vehicle, on the bench.

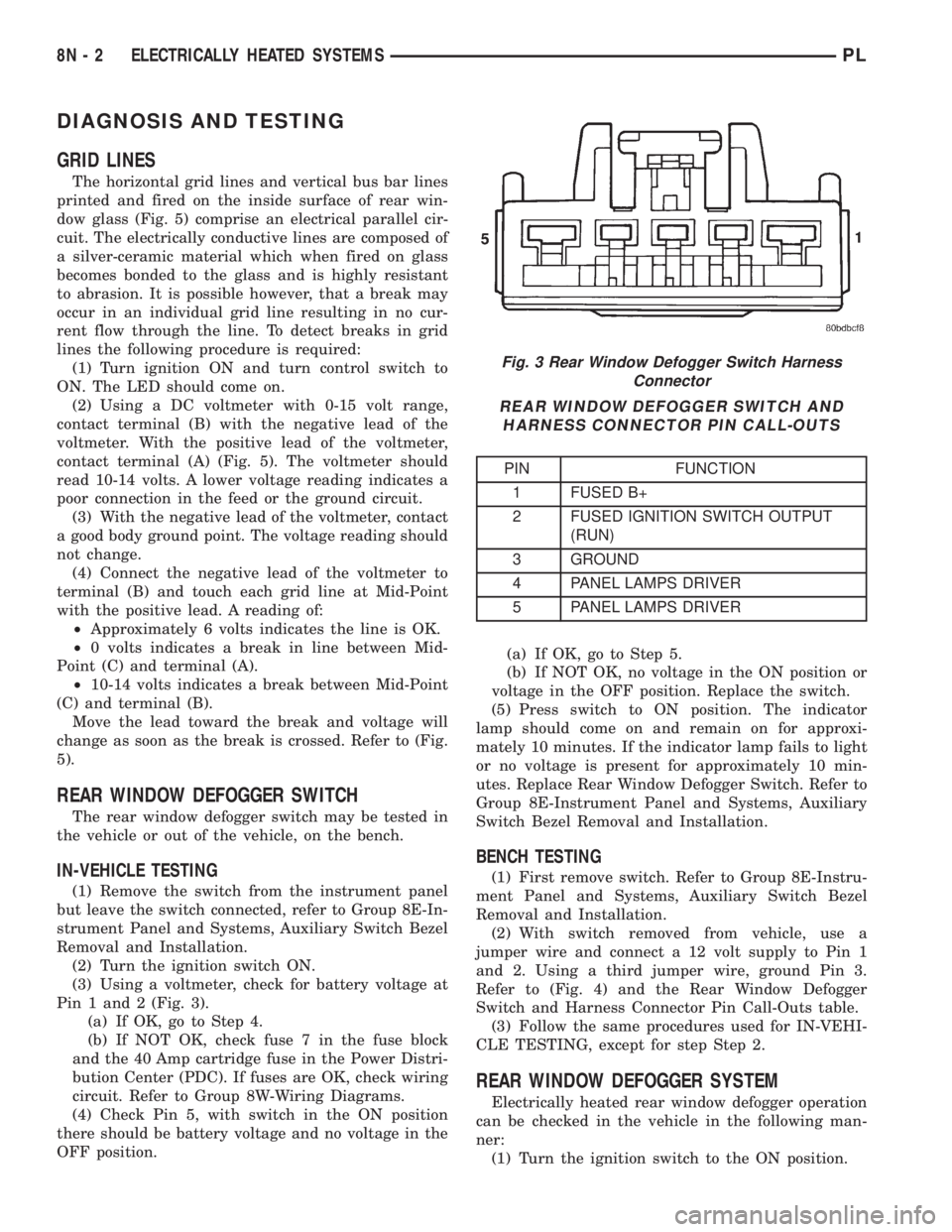

IN-VEHICLE TESTING

(1) Remove the switch from the instrument panel

but leave the switch connected, refer to Group 8E-In-

strument Panel and Systems, Auxiliary Switch Bezel

Removal and Installation.

(2) Turn the ignition switch ON.

(3) Using a voltmeter, check for battery voltage at

Pin 1 and 2 (Fig. 3).

(a) If OK, go to Step 4.

(b) If NOT OK, check fuse 7 in the fuse block

and the 40 Amp cartridge fuse in the Power Distri-

bution Center (PDC). If fuses are OK, check wiring

circuit. Refer to Group 8W-Wiring Diagrams.

(4) Check Pin 5, with switch in the ON position

there should be battery voltage and no voltage in the

OFF position.(a) If OK, go to Step 5.

(b) If NOT OK, no voltage in the ON position or

voltage in the OFF position. Replace the switch.

(5) Press switch to ON position. The indicator

lamp should come on and remain on for approxi-

mately 10 minutes. If the indicator lamp fails to light

or no voltage is present for approximately 10 min-

utes. Replace Rear Window Defogger Switch. Refer to

Group 8E-Instrument Panel and Systems, Auxiliary

Switch Bezel Removal and Installation.

BENCH TESTING

(1) First remove switch. Refer to Group 8E-Instru-

ment Panel and Systems, Auxiliary Switch Bezel

Removal and Installation.

(2) With switch removed from vehicle, use a

jumper wire and connect a 12 volt supply to Pin 1

and 2. Using a third jumper wire, ground Pin 3.

Refer to (Fig. 4) and the Rear Window Defogger

Switch and Harness Connector Pin Call-Outs table.

(3) Follow the same procedures used for IN-VEHI-

CLE TESTING, except for step Step 2.

REAR WINDOW DEFOGGER SYSTEM

Electrically heated rear window defogger operation

can be checked in the vehicle in the following man-

ner:

(1) Turn the ignition switch to the ON position.

Fig. 3 Rear Window Defogger Switch Harness

Connector

REAR WINDOW DEFOGGER SWITCH AND

HARNESS CONNECTOR PIN CALL-OUTS

PIN FUNCTION

1 FUSED B+

2 FUSED IGNITION SWITCH OUTPUT

(RUN)

3 GROUND

4 PANEL LAMPS DRIVER

5 PANEL LAMPS DRIVER

8N - 2 ELECTRICALLY HEATED SYSTEMSPL

Page 358 of 1285

(2) Connect an ammeter in series with the battery.

Push the rear window defogger switch to the ON

position (Fig. 2). A distinct increase in amperage

draw should be noted.

(3) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected in three to four minutes

of operation.

(4) Using a DC voltmeter, connect the negative

lead to Point B, and the positive lead to Point A (Fig.

5). The voltmeter should read 10-14 volts.(5) Step 2, Step 3 or Step 4 above will confirm sys-

tem operation. Indicator light illumination means

that there is power available at the switch output,

and does not necessarily verify system operation.

(6) If turning the switch ON produced no distinct

current draw on the ammeter the problem should be

isolated in the following manner:

(a) Confirm the ignition switch is ON.

(b) Ensure that the heated rear glass feed wire

is connected to the terminal or pigtail and that the

ground wire is in fact grounded.

(c) Ensure that the cartridge fuse and control

circuit fuse are OK and all electrical connections

are secure.

(7) When the above steps have been completed and

the system is still inoperative, one or more of the fol-

lowing is defective:

(a) Rear Window Defogger Switch.

(b) All rear window grid lines would have to be

broken or one of the feed wires are not connected

for the system to be inoperative.

(8) If turning the switch ON produces severe volt-

meter deflection, the circuit should be closely checked

for a shorting condition.

(9) If the system operation has been verified but

indicator lamp does not light, replace the switch.

(10) For detailed wiring information, refer to group

8W-Wiring Diagrams.

SERVICE PROCEDURES

GRID LINE AND TERMINAL REPAIR

WARNING: REPAIR KIT MAY CAUSE SKIN OR EYE

IRRITATION. CONTAINS EPOXY RESIN AND AMINE

TYPE HARDENER, HARMFUL IF SWALLOWED.

AVOID CONTACT WITH SKIN AND EYES. FOR SKIN,

WASH AFFECTED AREAS WITH SOAP AND WATER.

DO NOT TAKE INTERNALLY. IF TAKEN INTER-

NALLY, INDUCE VOMITING; CALL A PHYSICIAN

IMMEDIATELY. IF IN CONTACT WITH EYES, FLUSH

WITH PLENTY OF WATER. USE WITH ADEQUATE

VENTILATION. DO NOT USE NEAR FIRE OR FLAME.

CONTENTS CONTAIN 3 PERCENT FLAMMABLE

SOLVENTS.

KEEP OUT OF REACH OF CHILDREN.

The repair of the grid lines or the terminal is pos-

sible using the MopartRepair Package or equiva-

lent.

Fig. 4 Rear Window Defogger Switch Connector

Fig. 5 Rear Glass Grid Line Test - Typical

1 ± REAR WINDOW DEFOGGER

2 ± BUS BARS

3 ± VOLTAGE FEED ªAº

4 ± VOLTMETER

5 ± PICK-UP LEADS

6 ± C. H. M. S. L. TRIM COVER

7 ± PARCEL SHELF

8 ± GROUND ªBº

9 ± MID-POINT ªCº

PLELECTRICALLY HEATED SYSTEMS 8N - 3

DIAGNOSIS AND TESTING (Continued)