stop start DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 410 of 1285

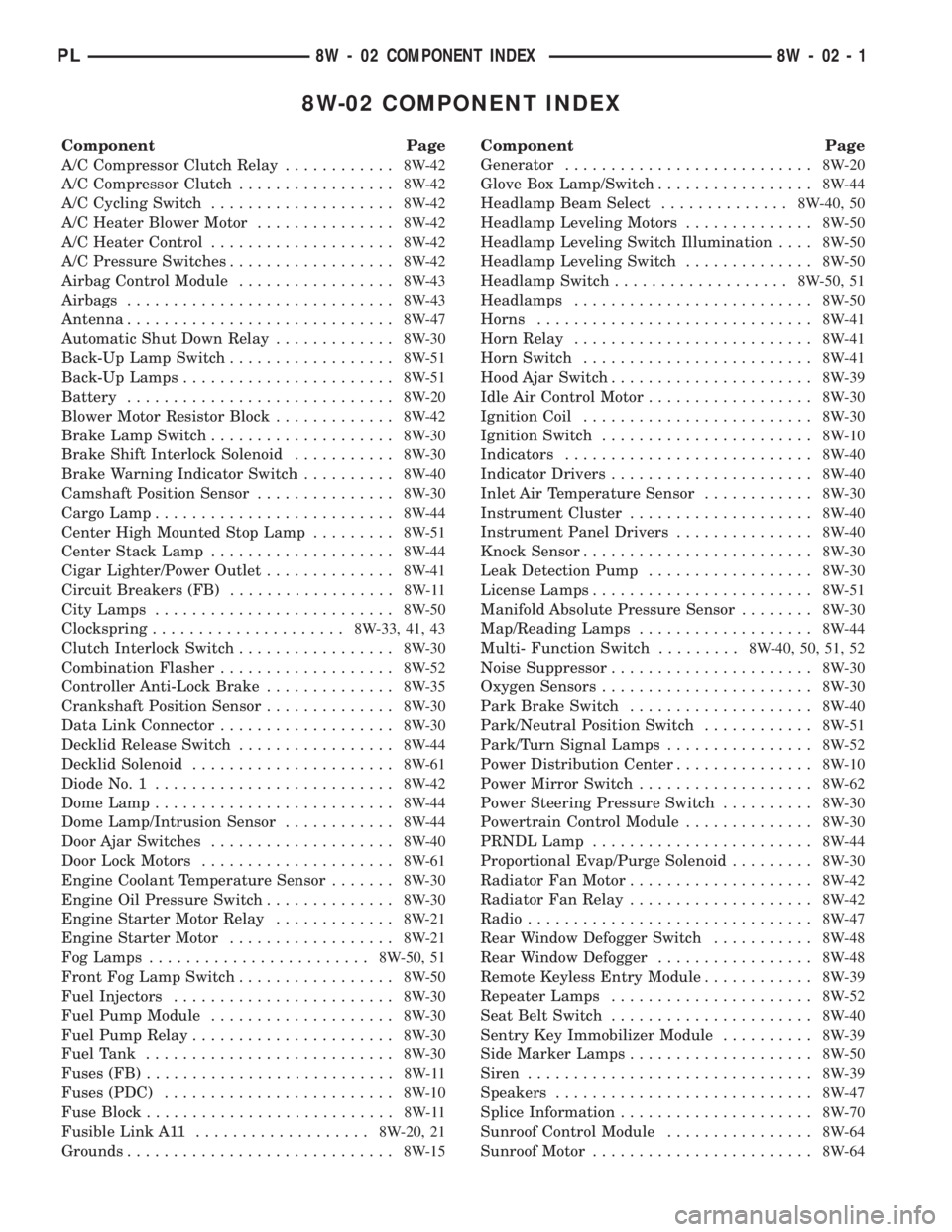

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay............8W-42

A/C Compressor Clutch.................8W-42

A/C Cycling Switch....................8W-42

A/C Heater Blower Motor...............8W-42

A/C Heater Control....................8W-42

A/C Pressure Switches..................8W-42

Airbag Control Module.................8W-43

Airbags.............................8W-43

Antenna.............................8W-47

Automatic Shut Down Relay.............8W-30

Back-Up Lamp Switch..................8W-51

Back-Up Lamps.......................8W-51

Battery.............................8W-20

Blower Motor Resistor Block.............8W-42

Brake Lamp Switch....................8W-30

Brake Shift Interlock Solenoid...........8W-30

Brake Warning Indicator Switch..........8W-40

Camshaft Position Sensor...............8W-30

Cargo Lamp..........................8W-44

Center High Mounted Stop Lamp.........8W-51

Center Stack Lamp....................8W-44

Cigar Lighter/Power Outlet..............8W-41

Circuit Breakers (FB)..................8W-11

City Lamps..........................8W-50

Clockspring.....................8W-33, 41, 43

Clutch Interlock Switch.................8W-30

Combination Flasher...................8W-52

Controller Anti-Lock Brake..............8W-35

Crankshaft Position Sensor..............8W-30

Data Link Connector...................8W-30

Decklid Release Switch.................8W-44

Decklid Solenoid......................8W-61

Diode No. 1..........................8W-42

Dome Lamp..........................8W-44

Dome Lamp/Intrusion Sensor............8W-44

Door Ajar Switches....................8W-40

Door Lock Motors.....................8W-61

Engine Coolant Temperature Sensor.......8W-30

Engine Oil Pressure Switch..............8W-30

Engine Starter Motor Relay.............8W-21

Engine Starter Motor..................8W-21

Fog Lamps........................8W-50, 51

Front Fog Lamp Switch.................8W-50

Fuel Injectors........................8W-30

Fuel Pump Module....................8W-30

Fuel Pump Relay......................8W-30

Fuel Tank...........................8W-30

Fuses (FB)...........................8W-11

Fuses (PDC).........................8W-10

Fuse Block...........................8W-11

Fusible Link A11...................8W-20, 21

Grounds.............................8W-15Component Page

Generator...........................8W-20

Glove Box Lamp/Switch.................8W-44

Headlamp Beam Select..............8W-40, 50

Headlamp Leveling Motors..............8W-50

Headlamp Leveling Switch Illumination....8W-50

Headlamp Leveling Switch..............8W-50

Headlamp Switch...................8W-50, 51

Headlamps..........................8W-50

Horns..............................8W-41

Horn Relay..........................8W-41

Horn Switch.........................8W-41

Hood Ajar Switch......................8W-39

Idle Air Control Motor..................8W-30

Ignition Coil.........................8W-30

Ignition Switch.......................8W-10

Indicators...........................8W-40

Indicator Drivers......................8W-40

Inlet Air Temperature Sensor............8W-30

Instrument Cluster....................8W-40

Instrument Panel Drivers...............8W-40

Knock Sensor.........................8W-30

Leak Detection Pump..................8W-30

License Lamps........................8W-51

Manifold Absolute Pressure Sensor........8W-30

Map/Reading Lamps...................8W-44

Multi- Function Switch.........8W-40, 50, 51, 52

Noise Suppressor......................8W-30

Oxygen Sensors.......................8W-30

Park Brake Switch....................8W-40

Park/Neutral Position Switch............8W-51

Park/Turn Signal Lamps................8W-52

Power Distribution Center...............8W-10

Power Mirror Switch...................8W-62

Power Steering Pressure Switch..........8W-30

Powertrain Control Module..............8W-30

PRNDL Lamp........................8W-44

Proportional Evap/Purge Solenoid.........8W-30

Radiator Fan Motor....................8W-42

Radiator Fan Relay....................8W-42

Radio...............................8W-47

Rear Window Defogger Switch...........8W-48

Rear Window Defogger.................8W-48

Remote Keyless Entry Module............8W-39

Repeater Lamps......................8W-52

Seat Belt Switch......................8W-40

Sentry Key Immobilizer Module..........8W-39

Side Marker Lamps....................8W-50

Siren...............................8W-39

Speakers............................8W-47

Splice Information.....................8W-70

Sunroof Control Module................8W-64

Sunroof Motor........................8W-64

PL8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 412 of 1285

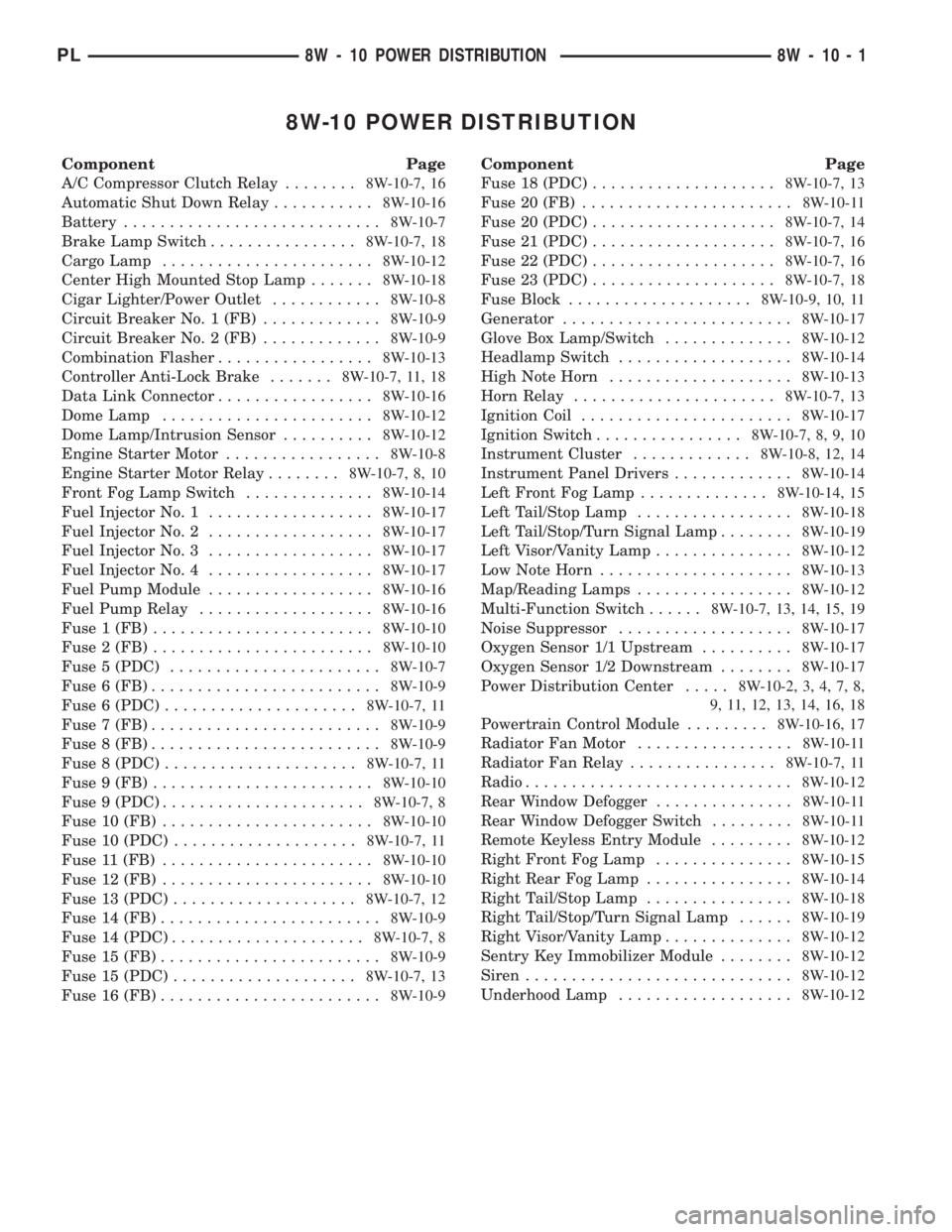

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch Relay........8W-10-7, 16

Automatic Shut Down Relay...........8W-10-16

Battery............................8W-10-7

Brake Lamp Switch................8W-10-7, 18

Cargo Lamp.......................8W-10-12

Center High Mounted Stop Lamp.......8W-10-18

Cigar Lighter/Power Outlet............8W-10-8

Circuit Breaker No. 1 (FB).............8W-10-9

Circuit Breaker No. 2 (FB).............8W-10-9

Combination Flasher.................8W-10-13

Controller Anti-Lock Brake.......8W-10-7, 11, 18

Data Link Connector.................8W-10-16

Dome Lamp.......................8W-10-12

Dome Lamp/Intrusion Sensor..........8W-10-12

Engine Starter Motor.................8W-10-8

Engine Starter Motor Relay........8W-10-7, 8, 10

Front Fog Lamp Switch..............8W-10-14

Fuel Injector No. 1..................8W-10-17

Fuel Injector No. 2..................8W-10-17

Fuel Injector No. 3..................8W-10-17

Fuel Injector No. 4..................8W-10-17

Fuel Pump Module..................8W-10-16

Fuel Pump Relay...................8W-10-16

Fuse 1 (FB)........................8W-10-10

Fuse 2 (FB)........................8W-10-10

Fuse 5 (PDC).......................8W-10-7

Fuse 6 (FB).........................8W-10-9

Fuse 6 (PDC).....................8W-10-7, 11

Fuse 7 (FB).........................8W-10-9

Fuse 8 (FB).........................8W-10-9

Fuse 8 (PDC).....................8W-10-7, 11

Fuse 9 (FB)........................8W-10-10

Fuse 9 (PDC)......................8W-10-7, 8

Fuse 10 (FB).......................8W-10-10

Fuse 10 (PDC)....................8W-10-7, 11

Fuse 11 (FB).......................8W-10-10

Fuse 12 (FB).......................8W-10-10

Fuse 13 (PDC)....................8W-10-7, 12

Fuse 14 (FB)........................8W-10-9

Fuse 14 (PDC).....................8W-10-7, 8

Fuse 15 (FB)........................8W-10-9

Fuse 15 (PDC)....................8W-10-7, 13

Fuse 16 (FB)........................8W-10-9Component Page

Fuse 18 (PDC)....................8W-10-7, 13

Fuse 20 (FB).......................8W-10-11

Fuse 20 (PDC)....................8W-10-7, 14

Fuse 21 (PDC)....................8W-10-7, 16

Fuse 22 (PDC)....................8W-10-7, 16

Fuse 23 (PDC)....................8W-10-7, 18

Fuse Block....................8W-10-9, 10, 11

Generator.........................8W-10-17

Glove Box Lamp/Switch..............8W-10-12

Headlamp Switch...................8W-10-14

High Note Horn....................8W-10-13

Horn Relay......................8W-10-7, 13

Ignition Coil.......................8W-10-17

Ignition Switch................8W-10-7, 8, 9, 10

Instrument Cluster.............8W-10-8, 12, 14

Instrument Panel Drivers.............8W-10-14

Left Front Fog Lamp..............8W-10-14, 15

Left Tail/Stop Lamp.................8W-10-18

Left Tail/Stop/Turn Signal Lamp........8W-10-19

Left Visor/Vanity Lamp...............8W-10-12

Low Note Horn.....................8W-10-13

Map/Reading Lamps.................8W-10-12

Multi-Function Switch......8W-10-7, 13, 14, 15, 19

Noise Suppressor...................8W-10-17

Oxygen Sensor 1/1 Upstream..........8W-10-17

Oxygen Sensor 1/2 Downstream........8W-10-17

Power Distribution Center.....8W-10-2, 3, 4, 7, 8,

9, 11, 12, 13, 14, 16, 18

Powertrain Control Module.........8W-10-16, 17

Radiator Fan Motor.................8W-10-11

Radiator Fan Relay................8W-10-7, 11

Radio.............................8W-10-12

Rear Window Defogger...............8W-10-11

Rear Window Defogger Switch.........8W-10-11

Remote Keyless Entry Module.........8W-10-12

Right Front Fog Lamp...............8W-10-15

Right Rear Fog Lamp................8W-10-14

Right Tail/Stop Lamp................8W-10-18

Right Tail/Stop/Turn Signal Lamp......8W-10-19

Right Visor/Vanity Lamp..............8W-10-12

Sentry Key Immobilizer Module........8W-10-12

Siren.............................8W-10-12

Underhood Lamp...................8W-10-12

PL8W - 10 POWER DISTRIBUTION 8W - 10 - 1

Page 474 of 1285

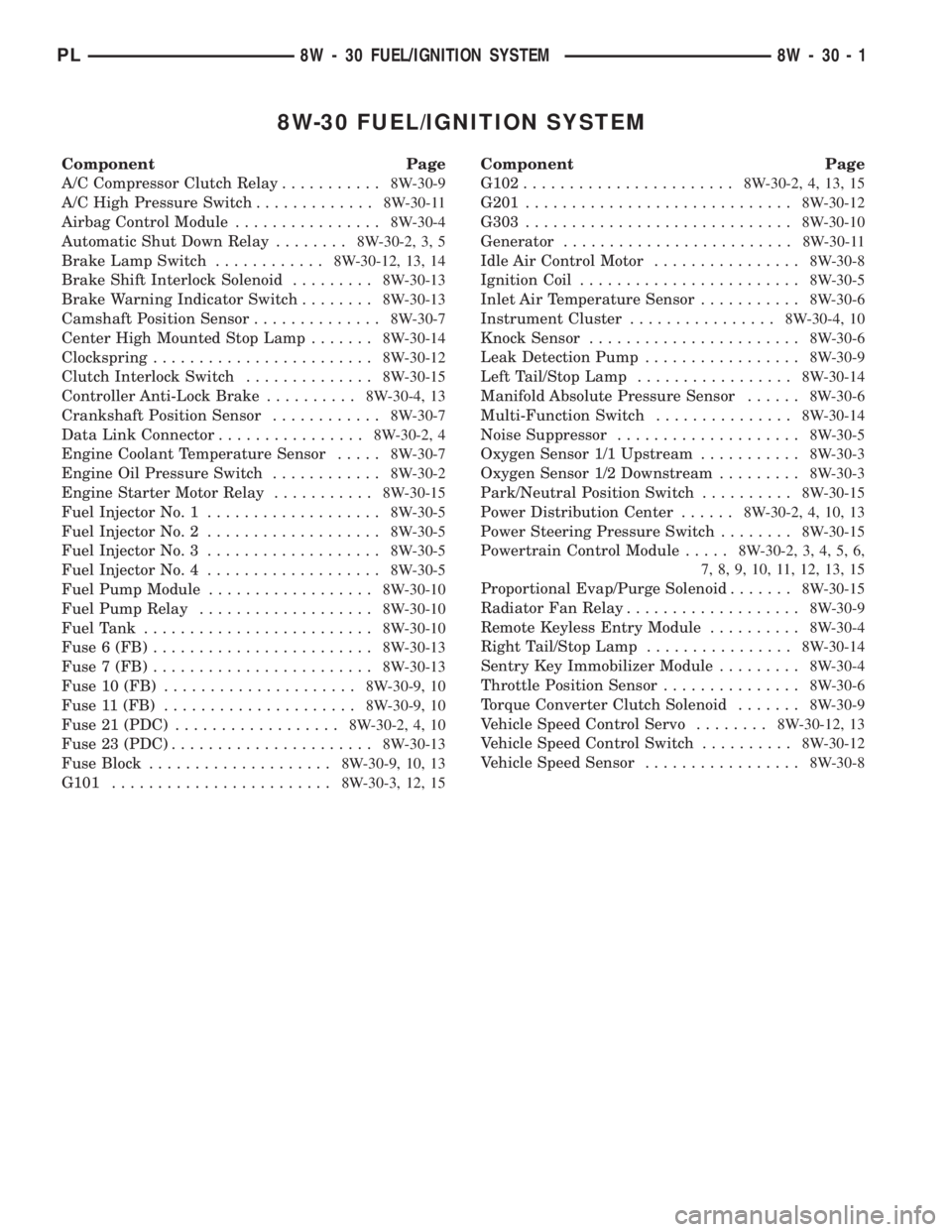

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch Relay...........8W-30-9

A/C High Pressure Switch.............8W-30-11

Airbag Control Module................8W-30-4

Automatic Shut Down Relay........8W-30-2, 3, 5

Brake Lamp Switch............8W-30-12, 13, 14

Brake Shift Interlock Solenoid.........8W-30-13

Brake Warning Indicator Switch........8W-30-13

Camshaft Position Sensor..............8W-30-7

Center High Mounted Stop Lamp.......8W-30-14

Clockspring........................8W-30-12

Clutch Interlock Switch..............8W-30-15

Controller Anti-Lock Brake..........8W-30-4, 13

Crankshaft Position Sensor............8W-30-7

Data Link Connector................8W-30-2, 4

Engine Coolant Temperature Sensor.....8W-30-7

Engine Oil Pressure Switch............8W-30-2

Engine Starter Motor Relay...........8W-30-15

Fuel Injector No. 1...................8W-30-5

Fuel Injector No. 2...................8W-30-5

Fuel Injector No. 3...................8W-30-5

Fuel Injector No. 4...................8W-30-5

Fuel Pump Module..................8W-30-10

Fuel Pump Relay...................8W-30-10

Fuel Tank.........................8W-30-10

Fuse 6 (FB)........................8W-30-13

Fuse 7 (FB)........................8W-30-13

Fuse 10 (FB).....................8W-30-9, 10

Fuse 11 (FB).....................8W-30-9, 10

Fuse 21 (PDC)..................8W-30-2, 4, 10

Fuse 23 (PDC)......................8W-30-13

Fuse Block....................8W-30-9, 10, 13

G101........................8W-30-3, 12, 15Component Page

G102.......................8W-30-2, 4, 13, 15

G201.............................8W-30-12

G303.............................8W-30-10

Generator.........................8W-30-11

Idle Air Control Motor................8W-30-8

Ignition Coil........................8W-30-5

Inlet Air Temperature Sensor...........8W-30-6

Instrument Cluster................8W-30-4, 10

Knock Sensor.......................8W-30-6

Leak Detection Pump.................8W-30-9

Left Tail/Stop Lamp.................8W-30-14

Manifold Absolute Pressure Sensor......8W-30-6

Multi-Function Switch...............8W-30-14

Noise Suppressor....................8W-30-5

Oxygen Sensor 1/1 Upstream...........8W-30-3

Oxygen Sensor 1/2 Downstream.........8W-30-3

Park/Neutral Position Switch..........8W-30-15

Power Distribution Center......8W-30-2, 4, 10, 13

Power Steering Pressure Switch........8W-30-15

Powertrain Control Module.....8W-30-2, 3, 4, 5, 6,

7, 8, 9, 10, 11, 12, 13, 15

Proportional Evap/Purge Solenoid.......8W-30-15

Radiator Fan Relay...................8W-30-9

Remote Keyless Entry Module..........8W-30-4

Right Tail/Stop Lamp................8W-30-14

Sentry Key Immobilizer Module.........8W-30-4

Throttle Position Sensor...............8W-30-6

Torque Converter Clutch Solenoid.......8W-30-9

Vehicle Speed Control Servo........8W-30-12, 13

Vehicle Speed Control Switch..........8W-30-12

Vehicle Speed Sensor.................8W-30-8

PL8W - 30 FUEL/IGNITION SYSTEM 8W - 30 - 1

Page 679 of 1285

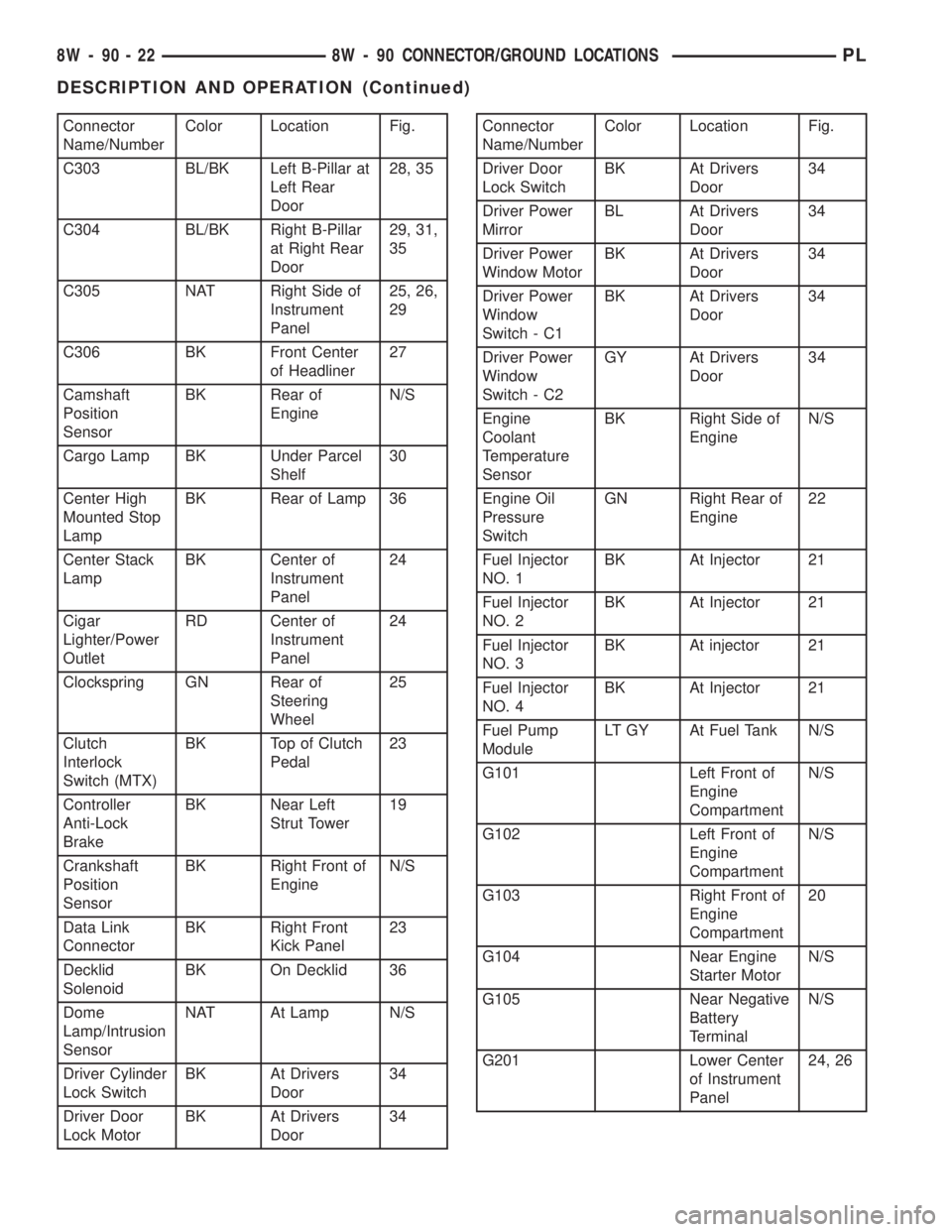

Connector

Name/NumberColor Location Fig.

C303 BL/BK Left B-Pillar at

Left Rear

Door28, 35

C304 BL/BK Right B-Pillar

at Right Rear

Door29, 31,

35

C305 NAT Right Side of

Instrument

Panel25, 26,

29

C306 BK Front Center

of Headliner27

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf30

Center High

Mounted Stop

LampBK Rear of Lamp 36

Center Stack

LampBK Center of

Instrument

Panel24

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel24

Clockspring GN Rear of

Steering

Wheel25

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal23

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower19

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK Right Front

Kick Panel23

Decklid

SolenoidBK On Decklid 36

Dome

Lamp/Intrusion

SensorNAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door34

Driver Door

Lock MotorBK At Drivers

Door34Connector

Name/NumberColor Location Fig.

Driver Door

Lock SwitchBK At Drivers

Door34

Driver Power

MirrorBL At Drivers

Door34

Driver Power

Window MotorBK At Drivers

Door34

Driver Power

Window

Switch - C1BK At Drivers

Door34

Driver Power

Window

Switch - C2GY At Drivers

Door34

Engine

Coolant

Temperature

SensorBK Right Side of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine22

Fuel Injector

NO. 1BK At Injector 21

Fuel Injector

NO. 2BK At Injector 21

Fuel Injector

NO. 3BK At injector 21

Fuel Injector

NO. 4BK At Injector 21

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

G102 Left Front of

Engine

CompartmentN/S

G103 Right Front of

Engine

Compartment20

G104 Near Engine

Starter MotorN/S

G105 Near Negative

Battery

TerminalN/S

G201 Lower Center

of Instrument

Panel24, 26

8W - 90 - 22 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 730 of 1285

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

SAE 5W-30 engine oil is preferred. Select an engine

oil that is best suited to your particular temperature

range and variation (Fig. 9).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of the engine oil

container.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 10).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Group 0, Lubrication and Mainte-

nance.TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Group 0, Lubrication and Maintenance for

Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

Fig. 9 Temperature/Engine Oil Viscosity

Fig. 10 Engine Oil Container Standard Notations

PLENGINE 9 - 7

GENERAL INFORMATION (Continued)

Page 732 of 1285

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 827 of 1285

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

ONBOARD REFUELING VAPOR RECOVERY

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I. D.) creates an aspiration effect which

draws air into the fill tube. During refueling, the fuel

tank is vented to the vapor canister to capture escap-

ing vapors. With air flowing into the filler tube, there

are no fuel vapors escaping to the atmosphere. Once

the refueling vapors are captured by the canister, the

vehicle's computer controlled purge system draws

vapor out of the canister for the engine to burn. The

vapors flow is metered by the purge solenoid so that

there is no or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve contains a float that rises to

seal the large diameter vent path to the canister. At

this point in the fueling of the vehicle, the tank pres-

sure increase, the check valve closes (preventing tank

fuel from spiting back at the operator), and fuel then

rises up the filler tube to shut-off the dispensing noz-

zle.If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

CONTROL VALVE/PRESSURE RELIEF

OPERATION

If the fuel tank should over-pressurize, the control

valve incorporates a pressure relief port that allows

pressure relief capability under extreme conditions.

Example, if the canister vent line was to get pinched

or obstructed, the relief valve would vent the pres-

sure.

QUICK-CONNECT FITTINGS

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 6).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 6). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

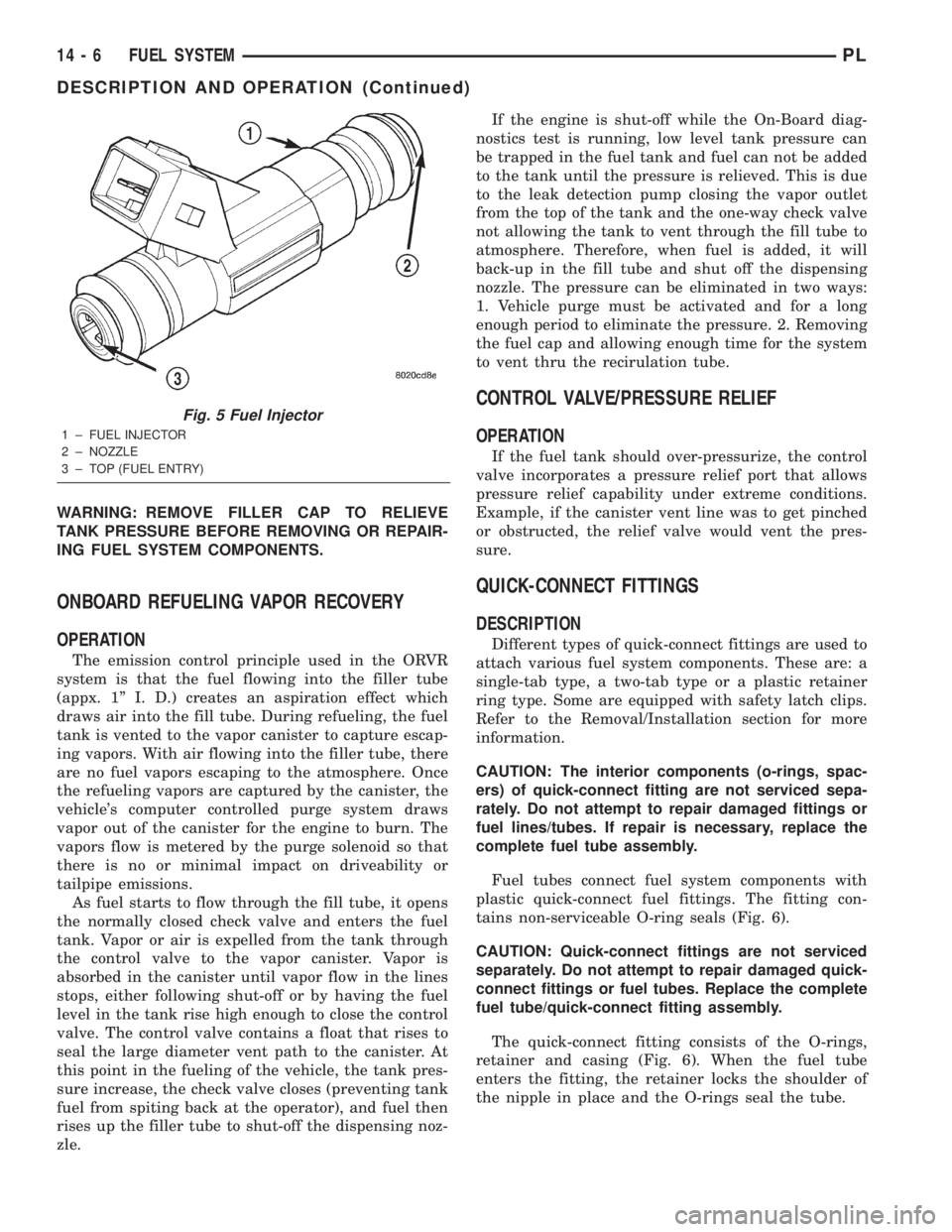

Fig. 5 Fuel Injector

1 ± FUEL INJECTOR

2 ± NOZZLE

3 ± TOP (FUEL ENTRY)

14 - 6 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 850 of 1285

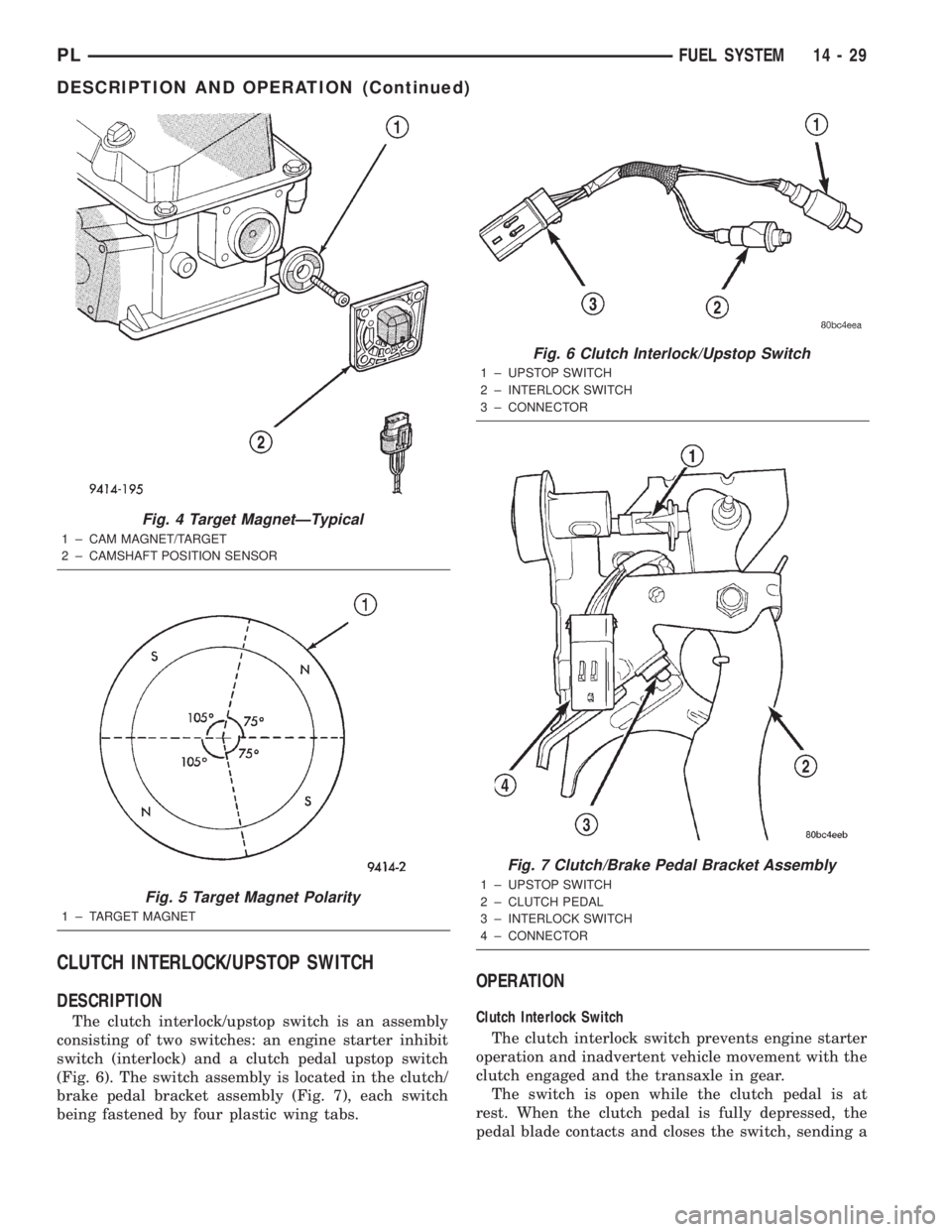

CLUTCH INTERLOCK/UPSTOP SWITCH

DESCRIPTION

The clutch interlock/upstop switch is an assembly

consisting of two switches: an engine starter inhibit

switch (interlock) and a clutch pedal upstop switch

(Fig. 6). The switch assembly is located in the clutch/

brake pedal bracket assembly (Fig. 7), each switch

being fastened by four plastic wing tabs.

OPERATION

Clutch Interlock Switch

The clutch interlock switch prevents engine starter

operation and inadvertent vehicle movement with the

clutch engaged and the transaxle in gear.

The switch is open while the clutch pedal is at

rest. When the clutch pedal is fully depressed, the

pedal blade contacts and closes the switch, sending a

Fig. 4 Target MagnetÐTypical

1 ± CAM MAGNET/TARGET

2 ± CAMSHAFT POSITION SENSOR

Fig. 5 Target Magnet Polarity

1 ± TARGET MAGNET

Fig. 6 Clutch Interlock/Upstop Switch

1 ± UPSTOP SWITCH

2 ± INTERLOCK SWITCH

3 ± CONNECTOR

Fig. 7 Clutch/Brake Pedal Bracket Assembly

1 ± UPSTOP SWITCH

2 ± CLUTCH PEDAL

3 ± INTERLOCK SWITCH

4 ± CONNECTOR

PLFUEL SYSTEM 14 - 29

DESCRIPTION AND OPERATION (Continued)

Page 851 of 1285

signal to the PCM, allowing engine starter operation.

The interlock switch is not adjustable.

Clutch Pedal Upstop Switch

With the clutch pedal at rest, the clutch pedal

upstop switch is closed, allowing speed control oper-

ation. When the clutch pedal is depressed, the upstop

switch opens and signals the PCM to cancel speed

control operation, and enter a modified engine cali-

bration schedule to improve driveability during gear-

to-gear shifts. The upstop switch is not adjustable.

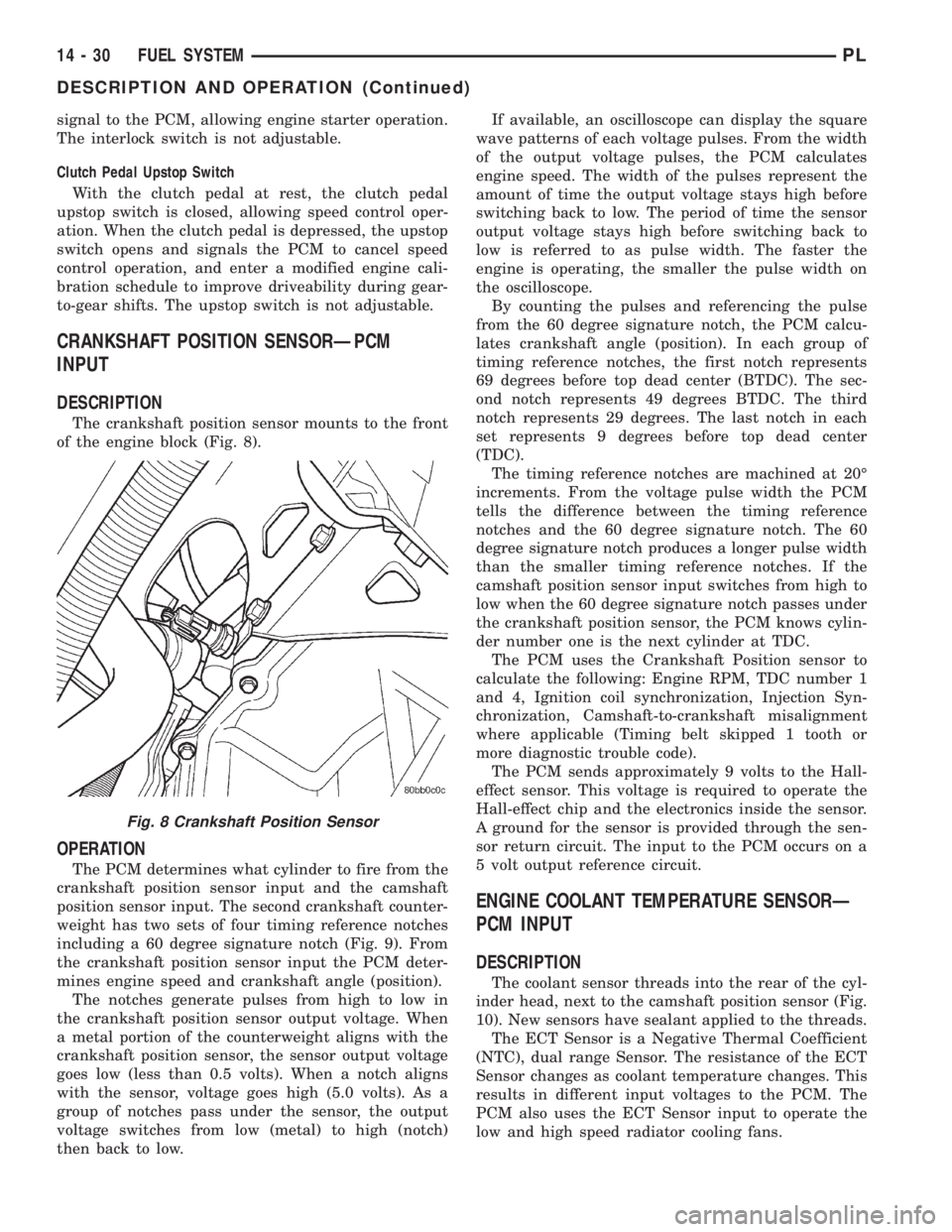

CRANKSHAFT POSITION SENSORÐPCM

INPUT

DESCRIPTION

The crankshaft position sensor mounts to the front

of the engine block (Fig. 8).

OPERATION

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 9). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The PCM uses the Crankshaft Position sensor to

calculate the following: Engine RPM, TDC number 1

and 4, Ignition coil synchronization, Injection Syn-

chronization, Camshaft-to-crankshaft misalignment

where applicable (Timing belt skipped 1 tooth or

more diagnostic trouble code).

The PCM sends approximately 9 volts to the Hall-

effect sensor. This voltage is required to operate the

Hall-effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT

DESCRIPTION

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

10). New sensors have sealant applied to the threads.

The ECT Sensor is a Negative Thermal Coefficient

(NTC), dual range Sensor. The resistance of the ECT

Sensor changes as coolant temperature changes. This

results in different input voltages to the PCM. The

PCM also uses the ECT Sensor input to operate the

low and high speed radiator cooling fans.

Fig. 8 Crankshaft Position Sensor

14 - 30 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 882 of 1285

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

as pump damage may result.

(6) Completely open the valve on the Power Steer-

ing Analyzer flow meter. Turn the steering wheel to

the extreme left until the stop in the steering gear is

met, then turn the steering wheel to the right until

the right stop is met. Record the highest indicated

pressure at each position. Compare the recorded

readings to the specifications. If the highest output

pressure reading against one stop is within 50 psi of

the highest reading at the other stop, the steering

gear is leaking internally and must be replaced.

If the power steering gear requires replacement,

refer to the section POWER STEERING GEAR

within this group for the removal and installation

procedure.

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL

CHECK

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

Before opening power steering system, wipe the

reservoir filler cap free of dirt and debris. Remove

the cap and check the fluid level on its dipstick.

When the fluid is at normal ambient temperature,

approximately 21ÉC to 27ÉC (70ÉF to 80ÉF), the dip-

stick level should indicateCOLD. Do not overfill the

power steering system. In all power steering systems,

use only Mopar Power Steering Fluid, or its equiva-

lent.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

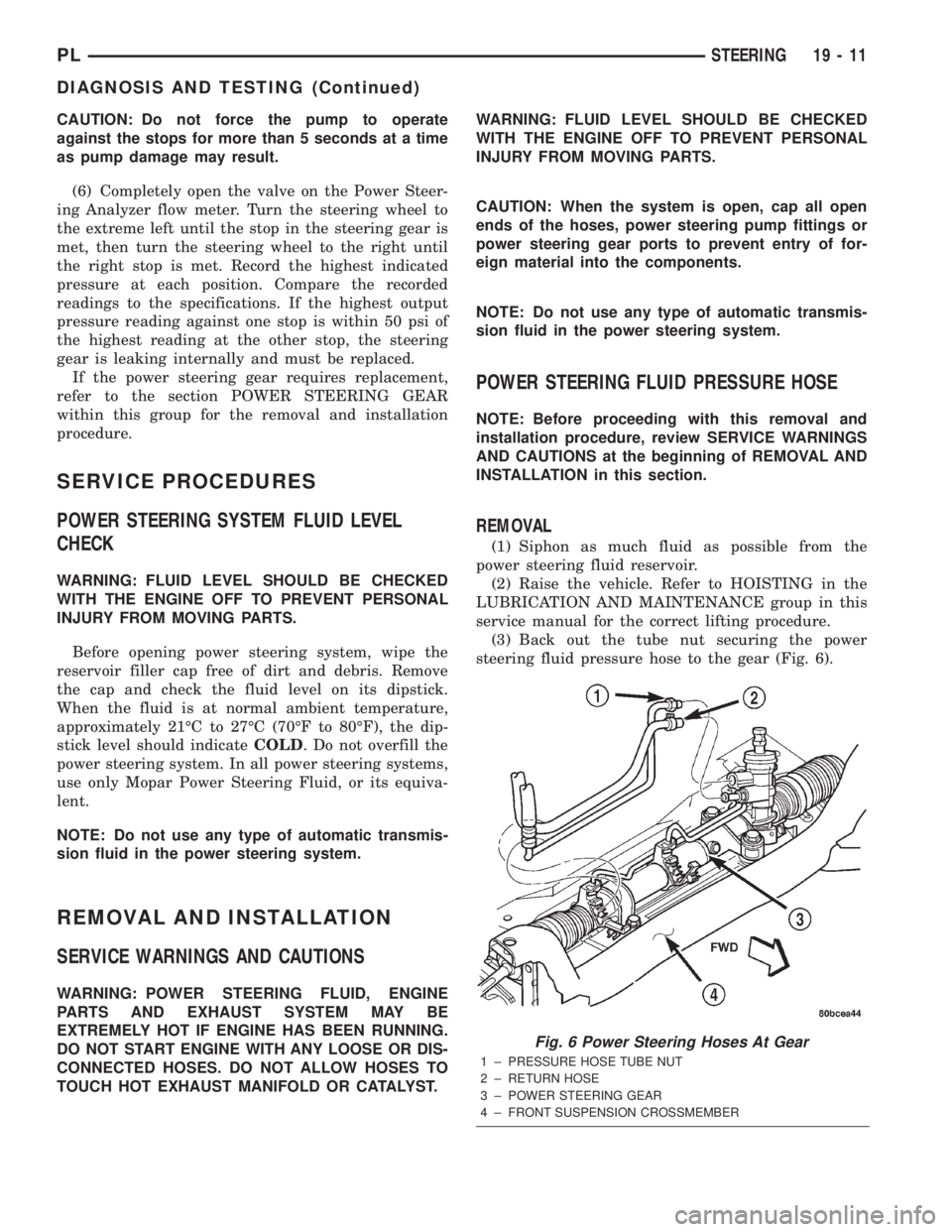

POWER STEERING FLUID PRESSURE HOSE

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Back out the tube nut securing the power

steering fluid pressure hose to the gear (Fig. 6).

Fig. 6 Power Steering Hoses At Gear

1 ± PRESSURE HOSE TUBE NUT

2 ± RETURN HOSE

3 ± POWER STEERING GEAR

4 ± FRONT SUSPENSION CROSSMEMBER

PLSTEERING 19 - 11

DIAGNOSIS AND TESTING (Continued)