oxygen DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 848 of 1285

As the engine enters one of these cells the PCM

looks at the amount of short term correction being

used. Because the goal is to keep short term at 0 (O2

Sensor switching at 0.5 volt), long term will update

in the same direction as short term correction was

moving to bring the short term back to 0. Once short

term is back at 0, this long term correction factor is

stored in memory.

The values stored in long term adaptive memory

are used for all operating conditions, including open

loop. However, the updating of the long term memoryoccurs after the engine has exceeded approximately

17É F, with fuel control in closed loop and two min-

utes of engine run time. This is done to prevent any

transitional temperature or start-up compensations

from corrupting long term fuel correction.

Long term adaptive memory can change the pulse-

width by as much as 25%, which means it can correct

for all of short term. It is possible to have a problem

that would drive long term to 25% and short term to

another 25% for a total change of 50% away from

base pulse-width calculation.

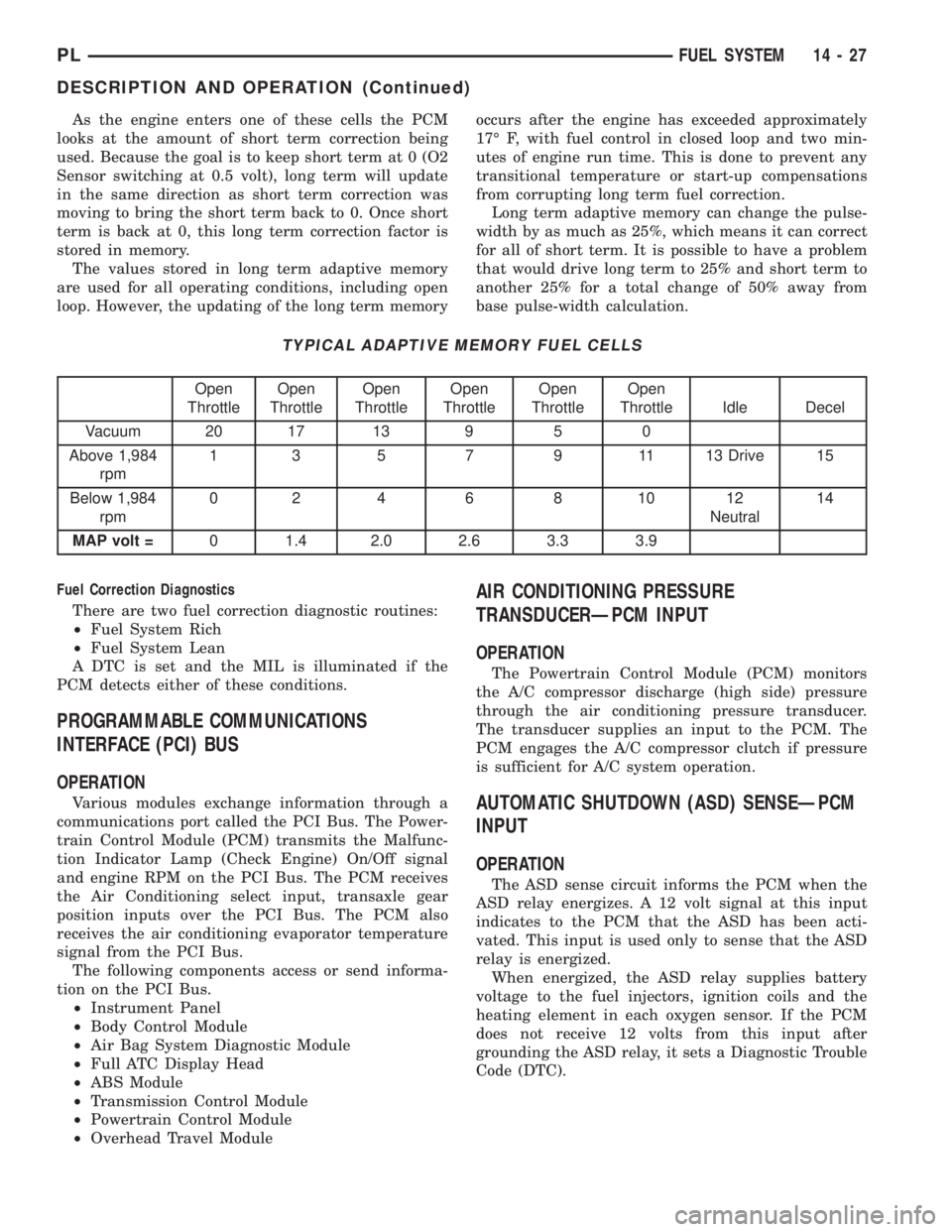

TYPICAL ADAPTIVE MEMORY FUEL CELLS

Open

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

ThrottleOpen

Throttle Idle Decel

Vacuum 20 17 13 9 5 0

Above 1,984

rpm1 3 5 7 9 11 13 Drive 15

Below 1,984

rpm02 4 6 8 1012

Neutral14

MAP volt =0 1.4 2.0 2.6 3.3 3.9

Fuel Correction Diagnostics

There are two fuel correction diagnostic routines:

²Fuel System Rich

²Fuel System Lean

A DTC is set and the MIL is illuminated if the

PCM detects either of these conditions.

PROGRAMMABLE COMMUNICATIONS

INTERFACE (PCI) BUS

OPERATION

Various modules exchange information through a

communications port called the PCI Bus. The Power-

train Control Module (PCM) transmits the Malfunc-

tion Indicator Lamp (Check Engine) On/Off signal

and engine RPM on the PCI Bus. The PCM receives

the Air Conditioning select input, transaxle gear

position inputs over the PCI Bus. The PCM also

receives the air conditioning evaporator temperature

signal from the PCI Bus.

The following components access or send informa-

tion on the PCI Bus.

²Instrument Panel

²Body Control Module

²Air Bag System Diagnostic Module

²Full ATC Display Head

²ABS Module

²Transmission Control Module

²Powertrain Control Module

²Overhead Travel Module

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT

OPERATION

The Powertrain Control Module (PCM) monitors

the A/C compressor discharge (high side) pressure

through the air conditioning pressure transducer.

The transducer supplies an input to the PCM. The

PCM engages the A/C compressor clutch if pressure

is sufficient for A/C system operation.

AUTOMATIC SHUTDOWN (ASD) SENSEÐPCM

INPUT

OPERATION

The ASD sense circuit informs the PCM when the

ASD relay energizes. A 12 volt signal at this input

indicates to the PCM that the ASD has been acti-

vated. This input is used only to sense that the ASD

relay is energized.

When energized, the ASD relay supplies battery

voltage to the fuel injectors, ignition coils and the

heating element in each oxygen sensor. If the PCM

does not receive 12 volts from this input after

grounding the ASD relay, it sets a Diagnostic Trouble

Code (DTC).

PLFUEL SYSTEM 14 - 27

DESCRIPTION AND OPERATION (Continued)

Page 853 of 1285

HEATED OXYGEN SENSOR (O2 SENSOR)Ð

PCM INPUT

DESCRIPTION

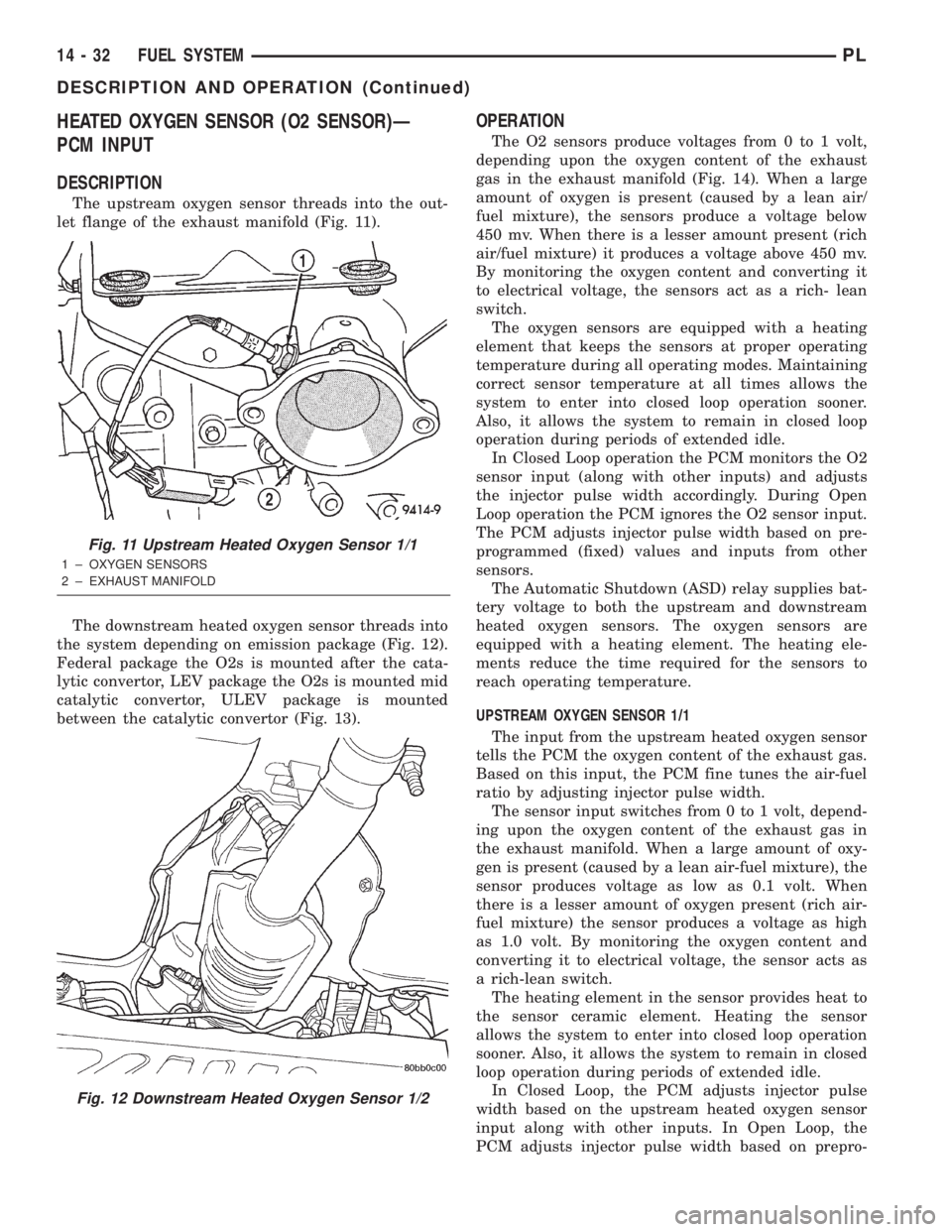

The upstream oxygen sensor threads into the out-

let flange of the exhaust manifold (Fig. 11).

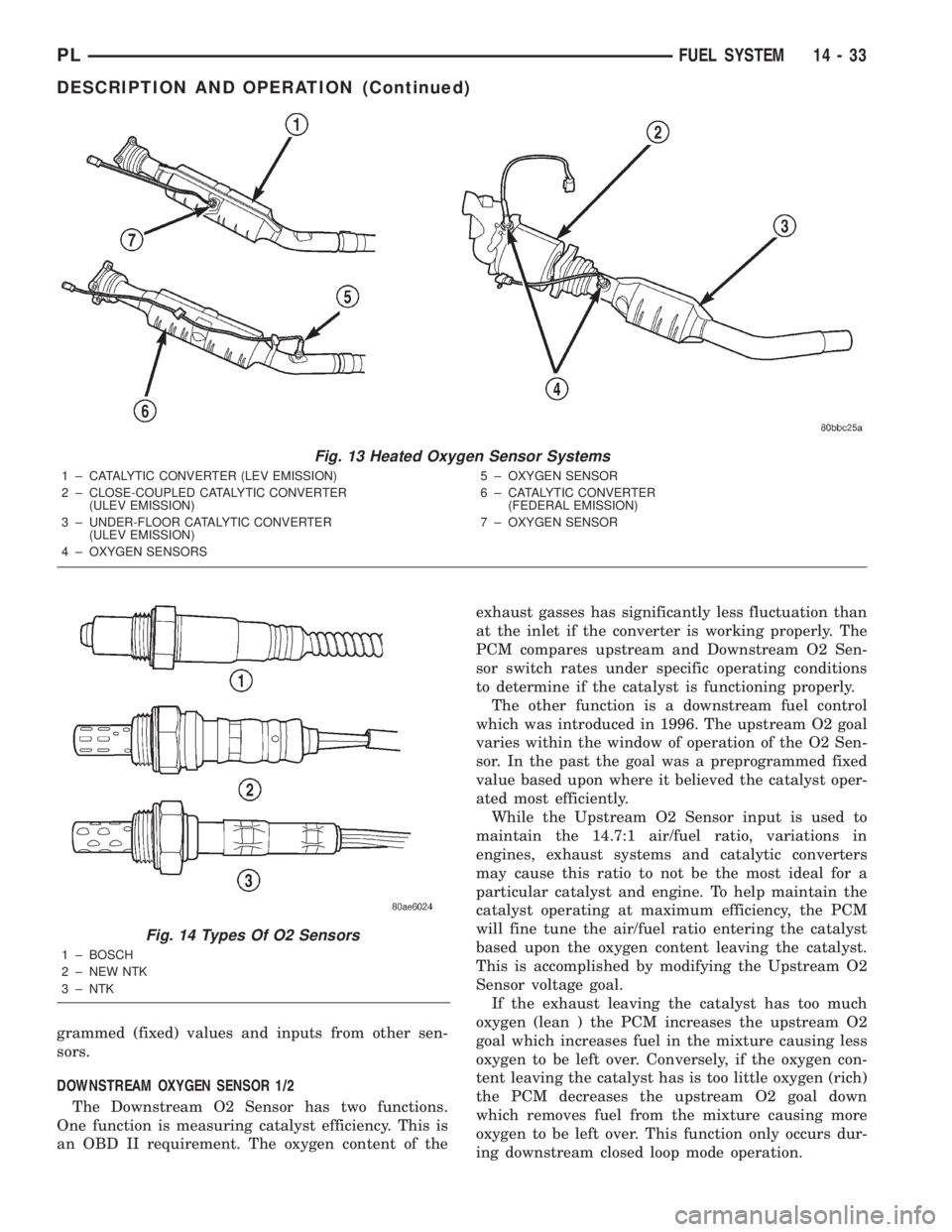

The downstream heated oxygen sensor threads into

the system depending on emission package (Fig. 12).

Federal package the O2s is mounted after the cata-

lytic convertor, LEV package the O2s is mounted mid

catalytic convertor, ULEV package is mounted

between the catalytic convertor (Fig. 13).

OPERATION

The O2 sensors produce voltages from 0 to 1 volt,

depending upon the oxygen content of the exhaust

gas in the exhaust manifold (Fig. 14). When a large

amount of oxygen is present (caused by a lean air/

fuel mixture), the sensors produce a voltage below

450 mv. When there is a lesser amount present (rich

air/fuel mixture) it produces a voltage above 450 mv.

By monitoring the oxygen content and converting it

to electrical voltage, the sensors act as a rich- lean

switch.

The oxygen sensors are equipped with a heating

element that keeps the sensors at proper operating

temperature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into closed loop operation sooner.

Also, it allows the system to remain in closed loop

operation during periods of extended idle.

In Closed Loop operation the PCM monitors the O2

sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During Open

Loop operation the PCM ignores the O2 sensor input.

The PCM adjusts injector pulse width based on pre-

programmed (fixed) values and inputs from other

sensors.

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to both the upstream and downstream

heated oxygen sensors. The oxygen sensors are

equipped with a heating element. The heating ele-

ments reduce the time required for the sensors to

reach operating temperature.

UPSTREAM OXYGEN SENSOR 1/1

The input from the upstream heated oxygen sensor

tells the PCM the oxygen content of the exhaust gas.

Based on this input, the PCM fine tunes the air-fuel

ratio by adjusting injector pulse width.

The sensor input switches from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold. When a large amount of oxy-

gen is present (caused by a lean air-fuel mixture), the

sensor produces voltage as low as 0.1 volt. When

there is a lesser amount of oxygen present (rich air-

fuel mixture) the sensor produces a voltage as high

as 1.0 volt. By monitoring the oxygen content and

converting it to electrical voltage, the sensor acts as

a rich-lean switch.

The heating element in the sensor provides heat to

the sensor ceramic element. Heating the sensor

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop, the PCM adjusts injector pulse

width based on the upstream heated oxygen sensor

input along with other inputs. In Open Loop, the

PCM adjusts injector pulse width based on prepro-

Fig. 11 Upstream Heated Oxygen Sensor 1/1

1 ± OXYGEN SENSORS

2 ± EXHAUST MANIFOLD

Fig. 12 Downstream Heated Oxygen Sensor 1/2

14 - 32 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 854 of 1285

grammed (fixed) values and inputs from other sen-

sors.

DOWNSTREAM OXYGEN SENSOR 1/2

The Downstream O2 Sensor has two functions.

One function is measuring catalyst efficiency. This is

an OBD II requirement. The oxygen content of theexhaust gasses has significantly less fluctuation than

at the inlet if the converter is working properly. The

PCM compares upstream and Downstream O2 Sen-

sor switch rates under specific operating conditions

to determine if the catalyst is functioning properly.

The other function is a downstream fuel control

which was introduced in 1996. The upstream O2 goal

varies within the window of operation of the O2 Sen-

sor. In the past the goal was a preprogrammed fixed

value based upon where it believed the catalyst oper-

ated most efficiently.

While the Upstream O2 Sensor input is used to

maintain the 14.7:1 air/fuel ratio, variations in

engines, exhaust systems and catalytic converters

may cause this ratio to not be the most ideal for a

particular catalyst and engine. To help maintain the

catalyst operating at maximum efficiency, the PCM

will fine tune the air/fuel ratio entering the catalyst

based upon the oxygen content leaving the catalyst.

This is accomplished by modifying the Upstream O2

Sensor voltage goal.

If the exhaust leaving the catalyst has too much

oxygen (lean ) the PCM increases the upstream O2

goal which increases fuel in the mixture causing less

oxygen to be left over. Conversely, if the oxygen con-

tent leaving the catalyst has is too little oxygen (rich)

the PCM decreases the upstream O2 goal down

which removes fuel from the mixture causing more

oxygen to be left over. This function only occurs dur-

ing downstream closed loop mode operation.

Fig. 13 Heated Oxygen Sensor Systems

1 ± CATALYTIC CONVERTER (LEV EMISSION)

2 ± CLOSE-COUPLED CATALYTIC CONVERTER

(ULEV EMISSION)

3 ± UNDER-FLOOR CATALYTIC CONVERTER

(ULEV EMISSION)

4 ± OXYGEN SENSORS5 ± OXYGEN SENSOR

6 ± CATALYTIC CONVERTER

(FEDERAL EMISSION)

7 ± OXYGEN SENSOR

Fig. 14 Types Of O2 Sensors

1 ± BOSCH

2 ± NEW NTK

3 ± NTK

PLFUEL SYSTEM 14 - 33

DESCRIPTION AND OPERATION (Continued)

Page 859 of 1285

Like all Hall-effect sensors, the electronics of the

sensor needs a power source. This power source is

provided by the PCM. It is the same 8 volt power

supply that is used by the CKP and CMP sensors.

The vehicle speed sensor generates 8 pulses per

sensor revolution. This signal, in conjunction with a

closed throttle signal from the throttle position sen-

sor, indicates a closed throttle deceleration to the

PCM. Under deceleration conditions, the PCM

adjusts the Idle Air Control (IAC) motor to maintain

a desired MAP value.

When the vehicle is stopped at idle, a closed throt-

tle signal is received by the PCM (but a speed sensor

signal is not received). Under idle conditions, the

PCM adjusts the IAC motor to maintain a desired

engine speed.

AIR CONDITIONING CLUTCH RELAYÐPCM

OUTPUT

DESCRIPTION

The air conditioning clutch relay is located in the

PDC. The inside top of the PDC cover has a label

showing relay and fuse location.

OPERATION

The PCM controls the air conditioning clutch relay

ground circuit. The A/C clutch relay coil side contains

a 10 amp fuse between the buss bar in the Power

Distribution Center (PDC) and the relay. The power

side of this relay is fused with a 40 amp fuse. When

the PCM receives an air conditioning input, it

grounds the A/C compressor clutch relay and the

radiator fan relay.

When the PCM senses low idle speeds or wide open

throttle through the throttle position sensor, it

removes the ground for the A/C compressor clutch

relay. When the relay de-energizes, the contacts open

preventing air conditioning clutch engagement. Also,

if the PCM senses a part throttle launch condition, it

disables the A/C compressor clutch for several sec-

onds.

AUTOMATIC SHUTDOWN RELAYÐPCM

OUTPUT

DESCRIPTION

The ASD relay is located in the PDC. The inside

top of the PDC cover has a label showing relay and

fuse location.

OPERATION

The automatic shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors

generator field and PCM sense circuit.A buss bar in the power distribution center (PDC)

supplies voltage to the solenoid side and contact side

of the relay. The ASD relay power circuit contains a

fuse between the buss bar in the PDC and the relay.

The fuse also protects the power circuit for the fuel

pump relay and pump. The fuse is located in the

PDC. Refer to the Wiring Diagrams for circuit infor-

mation.

The PCM controls the relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position unless the 02

Heater Monitor test is being run. When the ignition

switch is in the On or Crank position, the PCM mon-

itors the crankshaft position sensor and camshaft

position sensor signals to determine engine speed

and ignition timing (coil dwell). If the PCM does not

receive the crankshaft position sensor and camshaft

position sensor signals when the ignition switch is in

the Run position, it will de-energize the ASD relay.

CHARGING SYSTEM INDICATOR LAMPÐPCM

OUTPUT

OPERATION

The PCM turns the instrument panel Charging

System Lamp on. Refer to the Charging system sec-

tion information.

FUEL PUMP RELAYÐPCM OUTPUT

DESCRIPTION

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

OPERATION

The fuel pump relay supplies battery voltage to the

fuel pump. A buss bar in the Power Distribution Cen-

ter (PDC) supplies voltage to the solenoid side and

contact side of the relay. The fuel pump relay power

circuit contains a fuse between the buss bar in the

PDC and the relay. The fuse also protects the power

circuit for the Automatic Shutdown (ASD) relay. The

fuse is located in the PDC. Refer to the Wiring Dia-

grams for circuit information.

The PCM controls the fuel pump relay by switch-

ing the ground path for the solenoid side of the relay

on and off. The PCM turns the ground path off when

the ignition switch is in the Off position. When the

ignition switch is in the On position, the PCM ener-

gizes the fuel pump. If the crankshaft position sensor

does not detect engine rotation, the PCM de-ener-

gizes the relay after approximately one second.

14 - 38 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 866 of 1285

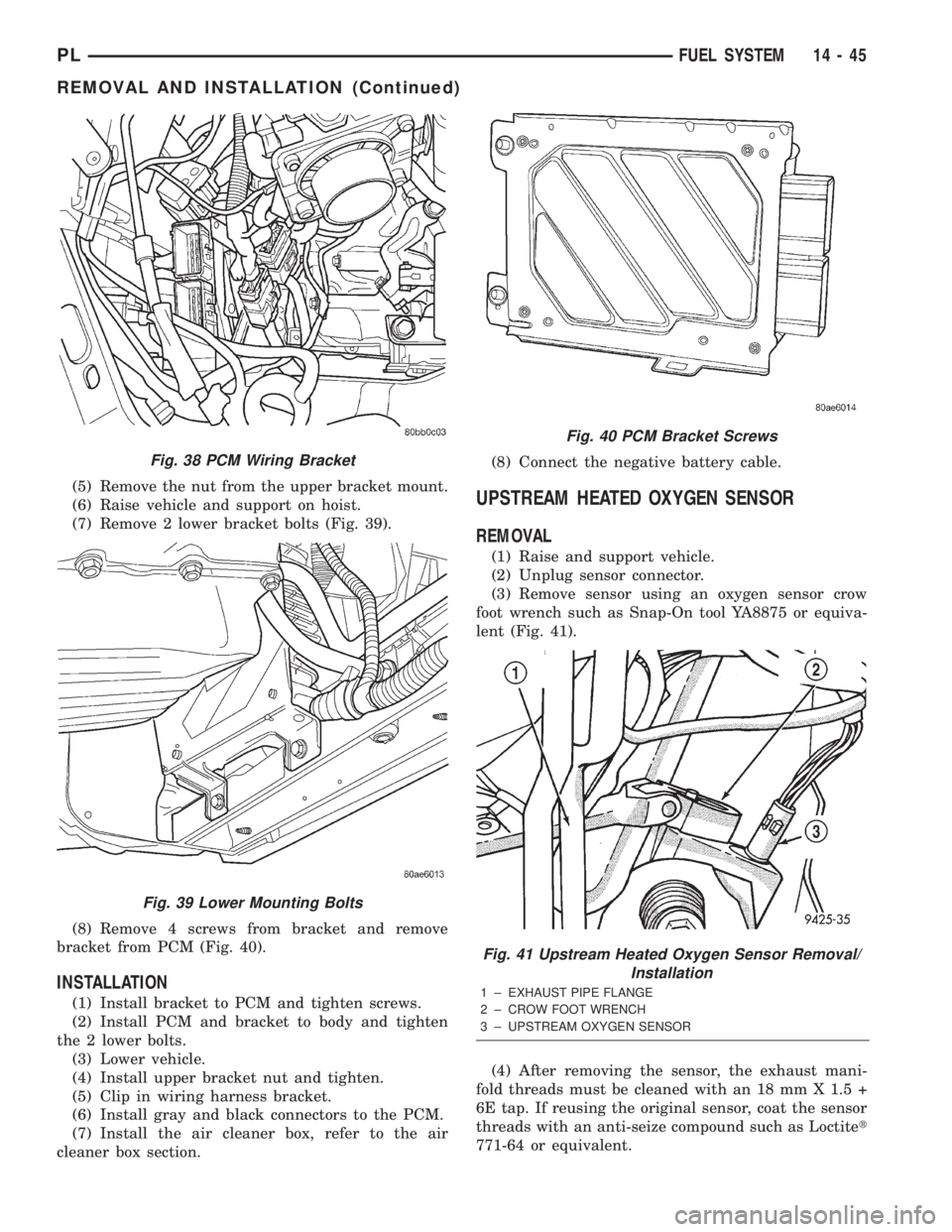

(5) Remove the nut from the upper bracket mount.

(6) Raise vehicle and support on hoist.

(7) Remove 2 lower bracket bolts (Fig. 39).

(8) Remove 4 screws from bracket and remove

bracket from PCM (Fig. 40).

INSTALLATION

(1) Install bracket to PCM and tighten screws.

(2) Install PCM and bracket to body and tighten

the 2 lower bolts.

(3) Lower vehicle.

(4) Install upper bracket nut and tighten.

(5) Clip in wiring harness bracket.

(6) Install gray and black connectors to the PCM.

(7) Install the air cleaner box, refer to the air

cleaner box section.(8) Connect the negative battery cable.

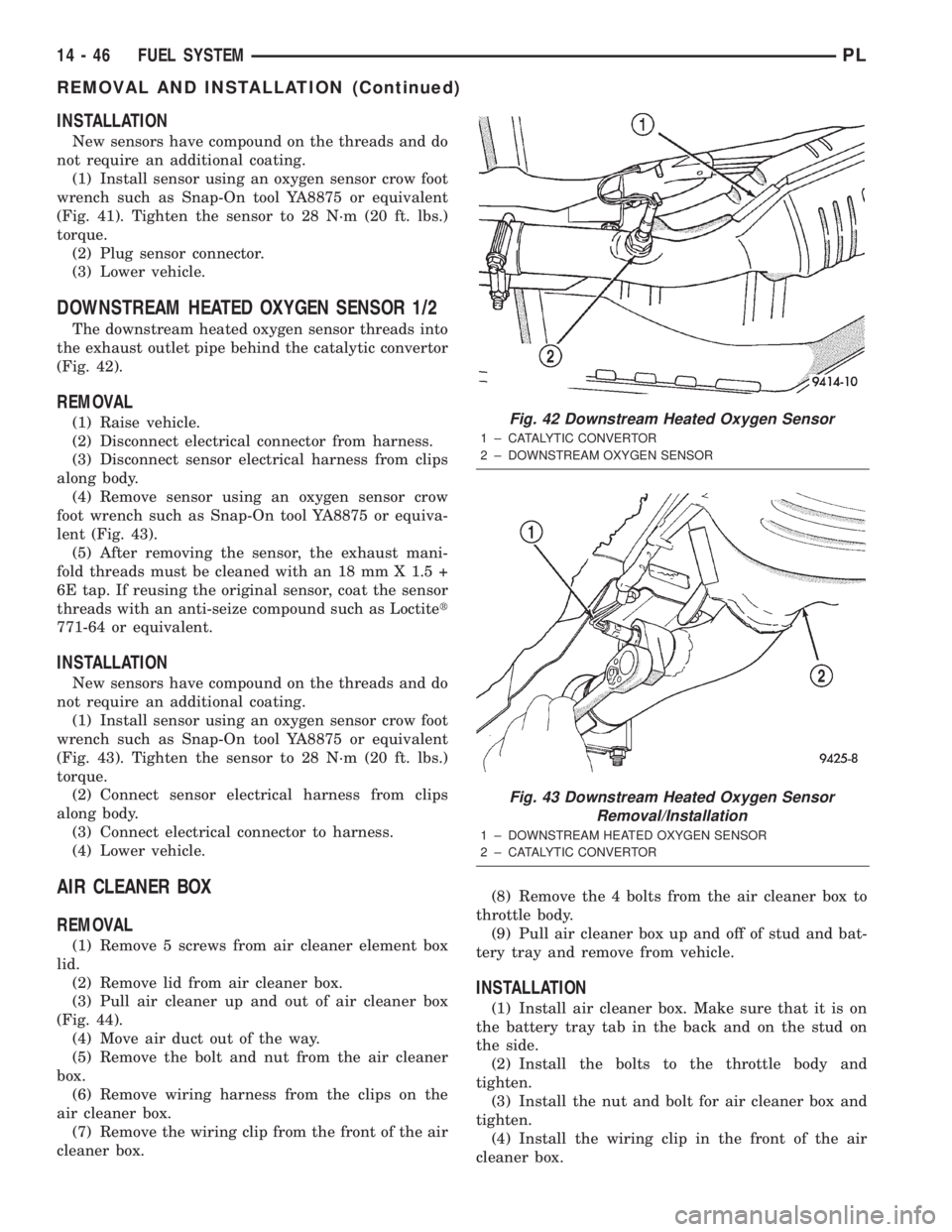

UPSTREAM HEATED OXYGEN SENSOR

REMOVAL

(1) Raise and support vehicle.

(2) Unplug sensor connector.

(3) Remove sensor using an oxygen sensor crow

foot wrench such as Snap-On tool YA8875 or equiva-

lent (Fig. 41).

(4) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctitet

771-64 or equivalent.

Fig. 38 PCM Wiring Bracket

Fig. 39 Lower Mounting Bolts

Fig. 40 PCM Bracket Screws

Fig. 41 Upstream Heated Oxygen Sensor Removal/

Installation

1 ± EXHAUST PIPE FLANGE

2 ± CROW FOOT WRENCH

3 ± UPSTREAM OXYGEN SENSOR

PLFUEL SYSTEM 14 - 45

REMOVAL AND INSTALLATION (Continued)

Page 867 of 1285

INSTALLATION

New sensors have compound on the threads and do

not require an additional coating.

(1) Install sensor using an oxygen sensor crow foot

wrench such as Snap-On tool YA8875 or equivalent

(Fig. 41). Tighten the sensor to 28 N´m (20 ft. lbs.)

torque.

(2) Plug sensor connector.

(3) Lower vehicle.

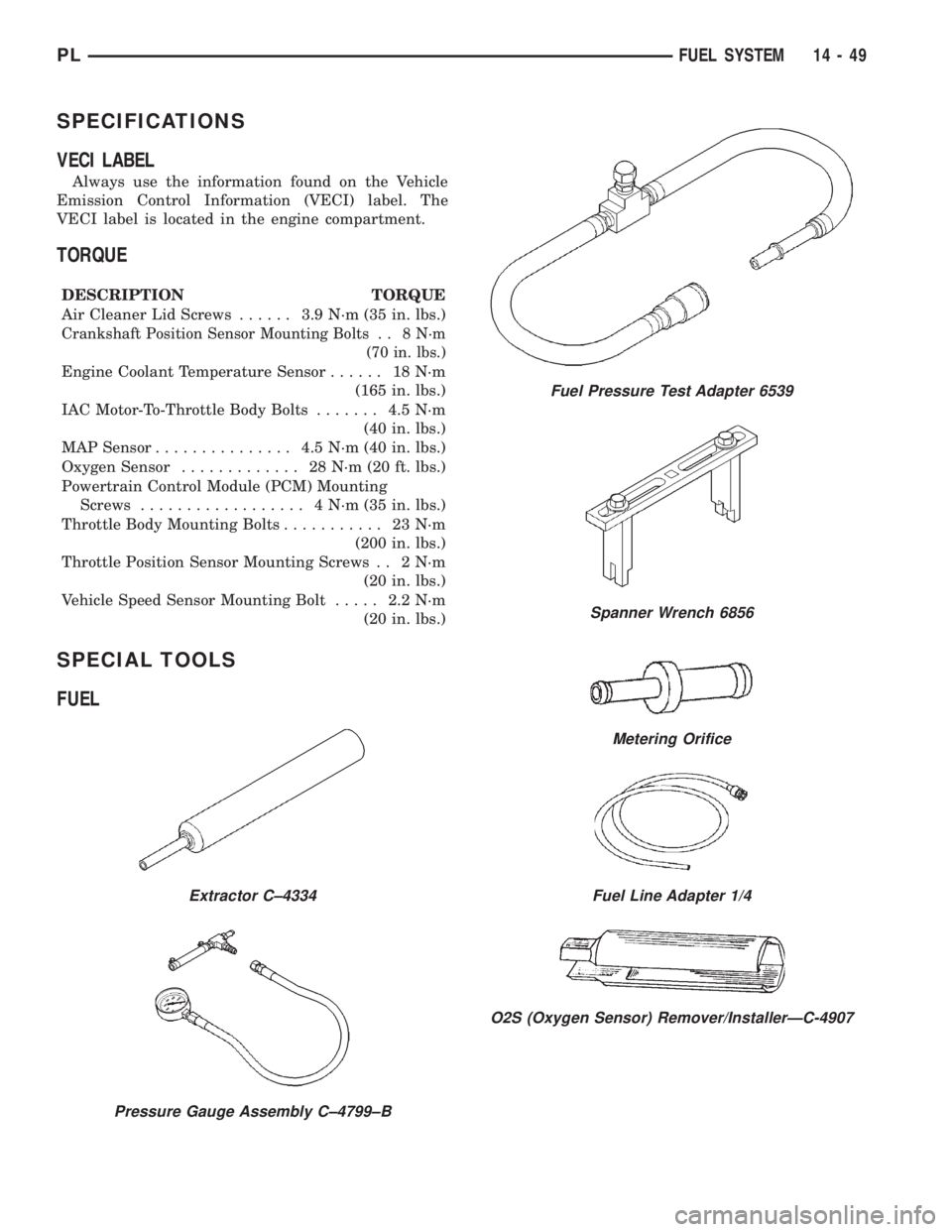

DOWNSTREAM HEATED OXYGEN SENSOR 1/2

The downstream heated oxygen sensor threads into

the exhaust outlet pipe behind the catalytic convertor

(Fig. 42).

REMOVAL

(1) Raise vehicle.

(2) Disconnect electrical connector from harness.

(3) Disconnect sensor electrical harness from clips

along body.

(4) Remove sensor using an oxygen sensor crow

foot wrench such as Snap-On tool YA8875 or equiva-

lent (Fig. 43).

(5) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctitet

771-64 or equivalent.

INSTALLATION

New sensors have compound on the threads and do

not require an additional coating.

(1) Install sensor using an oxygen sensor crow foot

wrench such as Snap-On tool YA8875 or equivalent

(Fig. 43). Tighten the sensor to 28 N´m (20 ft. lbs.)

torque.

(2) Connect sensor electrical harness from clips

along body.

(3) Connect electrical connector to harness.

(4) Lower vehicle.

AIR CLEANER BOX

REMOVAL

(1) Remove 5 screws from air cleaner element box

lid.

(2) Remove lid from air cleaner box.

(3) Pull air cleaner up and out of air cleaner box

(Fig. 44).

(4) Move air duct out of the way.

(5) Remove the bolt and nut from the air cleaner

box.

(6) Remove wiring harness from the clips on the

air cleaner box.

(7) Remove the wiring clip from the front of the air

cleaner box.(8) Remove the 4 bolts from the air cleaner box to

throttle body.

(9) Pull air cleaner box up and off of stud and bat-

tery tray and remove from vehicle.

INSTALLATION

(1) Install air cleaner box. Make sure that it is on

the battery tray tab in the back and on the stud on

the side.

(2) Install the bolts to the throttle body and

tighten.

(3) Install the nut and bolt for air cleaner box and

tighten.

(4) Install the wiring clip in the front of the air

cleaner box.

Fig. 42 Downstream Heated Oxygen Sensor

1 ± CATALYTIC CONVERTOR

2 ± DOWNSTREAM OXYGEN SENSOR

Fig. 43 Downstream Heated Oxygen Sensor

Removal/Installation

1 ± DOWNSTREAM HEATED OXYGEN SENSOR

2 ± CATALYTIC CONVERTOR

14 - 46 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 870 of 1285

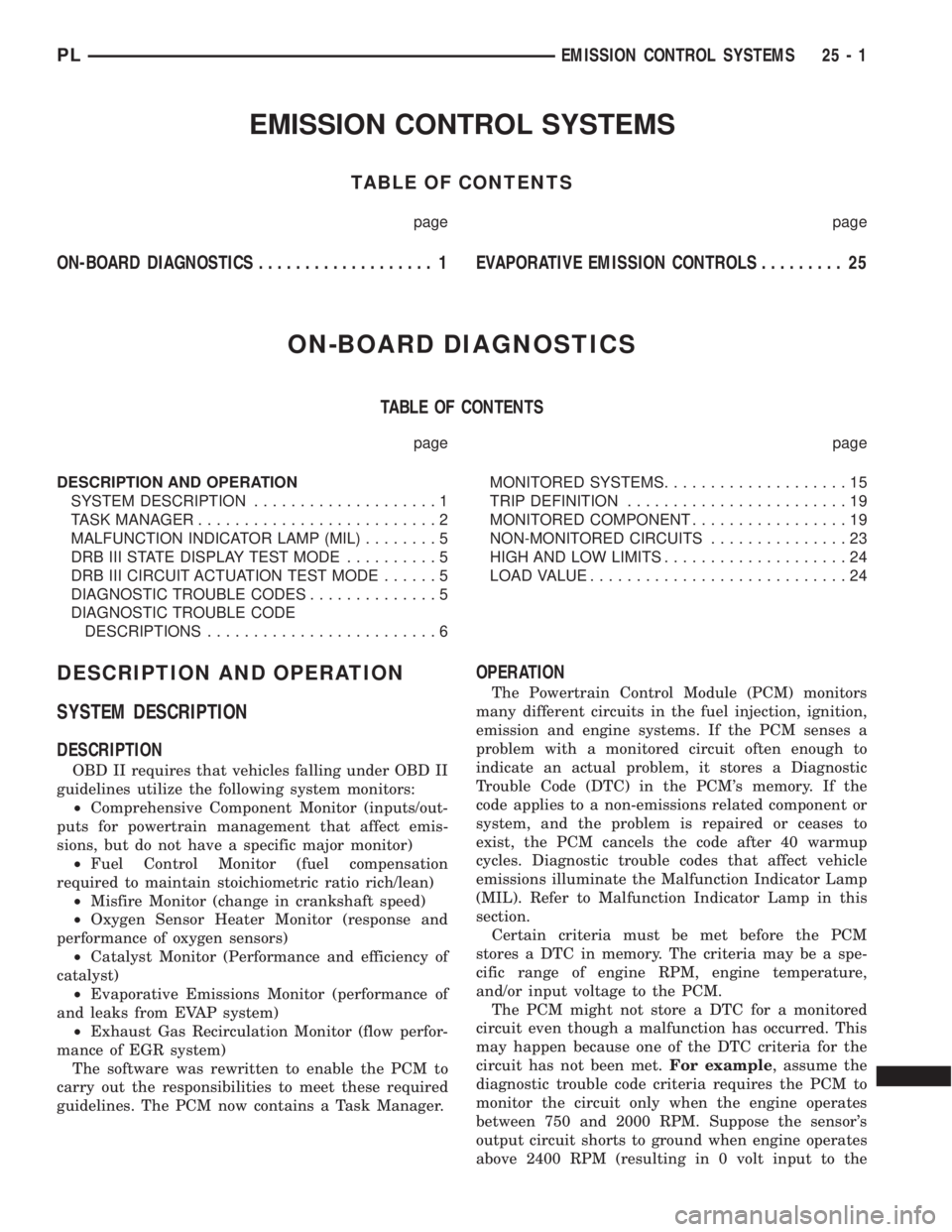

SPECIFICATIONS

VECI LABEL

Always use the information found on the Vehicle

Emission Control Information (VECI) label. The

VECI label is located in the engine compartment.

TORQUE

DESCRIPTION TORQUE

Air Cleaner Lid Screws...... 3.9N´m(35in.lbs.)

Crankshaft Position Sensor Mounting Bolts . . 8 N´m

(70 in. lbs.)

Engine Coolant Temperature Sensor...... 18N´m

(165 in. lbs.)

IAC Motor-To-Throttle Body Bolts....... 4.5N´m

(40 in. lbs.)

MAP Sensor............... 4.5N´m(40in.lbs.)

Oxygen Sensor............. 28N´m(20ft.lbs.)

Powertrain Control Module (PCM) Mounting

Screws.................. 4N´m(35in.lbs.)

Throttle Body Mounting Bolts........... 23N´m

(200 in. lbs.)

Throttle Position Sensor Mounting Screws . . 2 N´m

(20 in. lbs.)

Vehicle Speed Sensor Mounting Bolt..... 2.2N´m

(20 in. lbs.)

SPECIAL TOOLS

FUEL

Extractor C±4334

Pressure Gauge Assembly C±4799±B

Fuel Pressure Test Adapter 6539

Spanner Wrench 6856

Metering Orifice

Fuel Line Adapter 1/4

O2S (Oxygen Sensor) Remover/InstallerÐC-4907

PLFUEL SYSTEM 14 - 49

Page 1088 of 1285

EMISSION CONTROL SYSTEMS

TABLE OF CONTENTS

page page

ON-BOARD DIAGNOSTICS................... 1 EVAPORATIVE EMISSION CONTROLS......... 25

ON-BOARD DIAGNOSTICS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

SYSTEM DESCRIPTION....................1

TASK MANAGER..........................2

MALFUNCTION INDICATOR LAMP (MIL)........5

DRB III STATE DISPLAY TEST MODE..........5

DRB III CIRCUIT ACTUATION TEST MODE......5

DIAGNOSTIC TROUBLE CODES..............5

DIAGNOSTIC TROUBLE CODE

DESCRIPTIONS.........................6MONITORED SYSTEMS....................15

TRIP DEFINITION........................19

MONITORED COMPONENT.................19

NON-MONITORED CIRCUITS...............23

HIGH AND LOW LIMITS....................24

LOAD VALUE............................24

DESCRIPTION AND OPERATION

SYSTEM DESCRIPTION

DESCRIPTION

OBD II requires that vehicles falling under OBD II

guidelines utilize the following system monitors:

²Comprehensive Component Monitor (inputs/out-

puts for powertrain management that affect emis-

sions, but do not have a specific major monitor)

²Fuel Control Monitor (fuel compensation

required to maintain stoichiometric ratio rich/lean)

²Misfire Monitor (change in crankshaft speed)

²Oxygen Sensor Heater Monitor (response and

performance of oxygen sensors)

²Catalyst Monitor (Performance and efficiency of

catalyst)

²Evaporative Emissions Monitor (performance of

and leaks from EVAP system)

²Exhaust Gas Recirculation Monitor (flow perfor-

mance of EGR system)

The software was rewritten to enable the PCM to

carry out the responsibilities to meet these required

guidelines. The PCM now contains a Task Manager.

OPERATION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PLEMISSION CONTROL SYSTEMS 25 - 1

Page 1089 of 1285

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRB III scan tool

to erase all DTC's and extinguish the MIL.

Technicians can display stored DTC's by using the

DRB III scan tool. Refer to Diagnostic Trouble Codes

in this section. For DTC information, refer to charts

in this section.

TASK MANAGER

DESCRIPTION

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is call the 'Task Manager'.

OPERATION

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The Task

Manager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

determine if conditions are appropriate for tests to berun, monitor the parameters for a trip for each test,

and record the results of the test. Following are the

responsibilities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator

²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are know as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will not

run a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

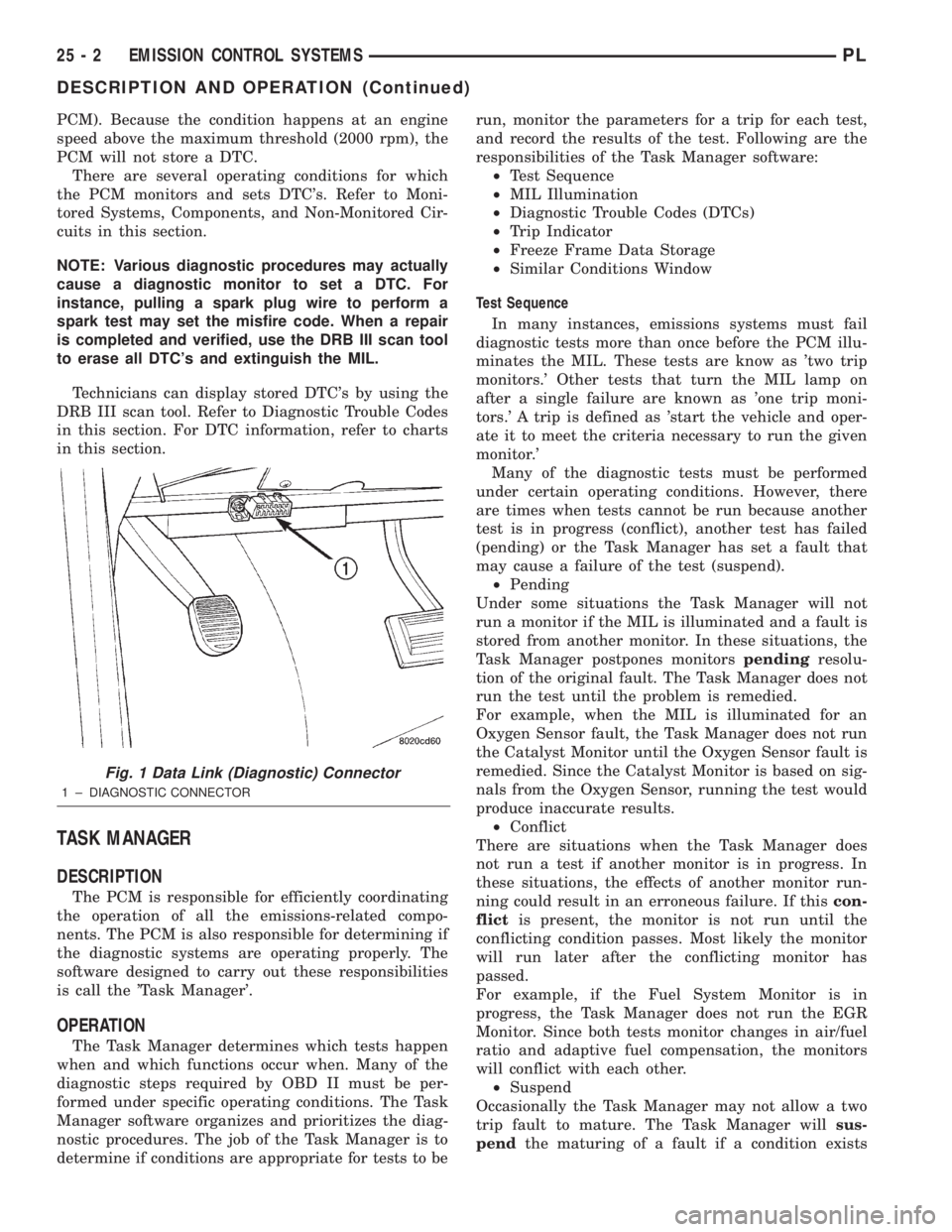

Fig. 1 Data Link (Diagnostic) Connector

1 ± DIAGNOSTIC CONNECTOR

25 - 2 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1090 of 1285

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within6375

RPM and load is within610% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Global Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Global Good Trip

To increment a Global Good Trip, the Oxygen sen-

sor and Catalyst efficiency monitors must have run

and passed.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

PLEMISSION CONTROL SYSTEMS 25 - 3

DESCRIPTION AND OPERATION (Continued)