timing belt DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 794 of 1285

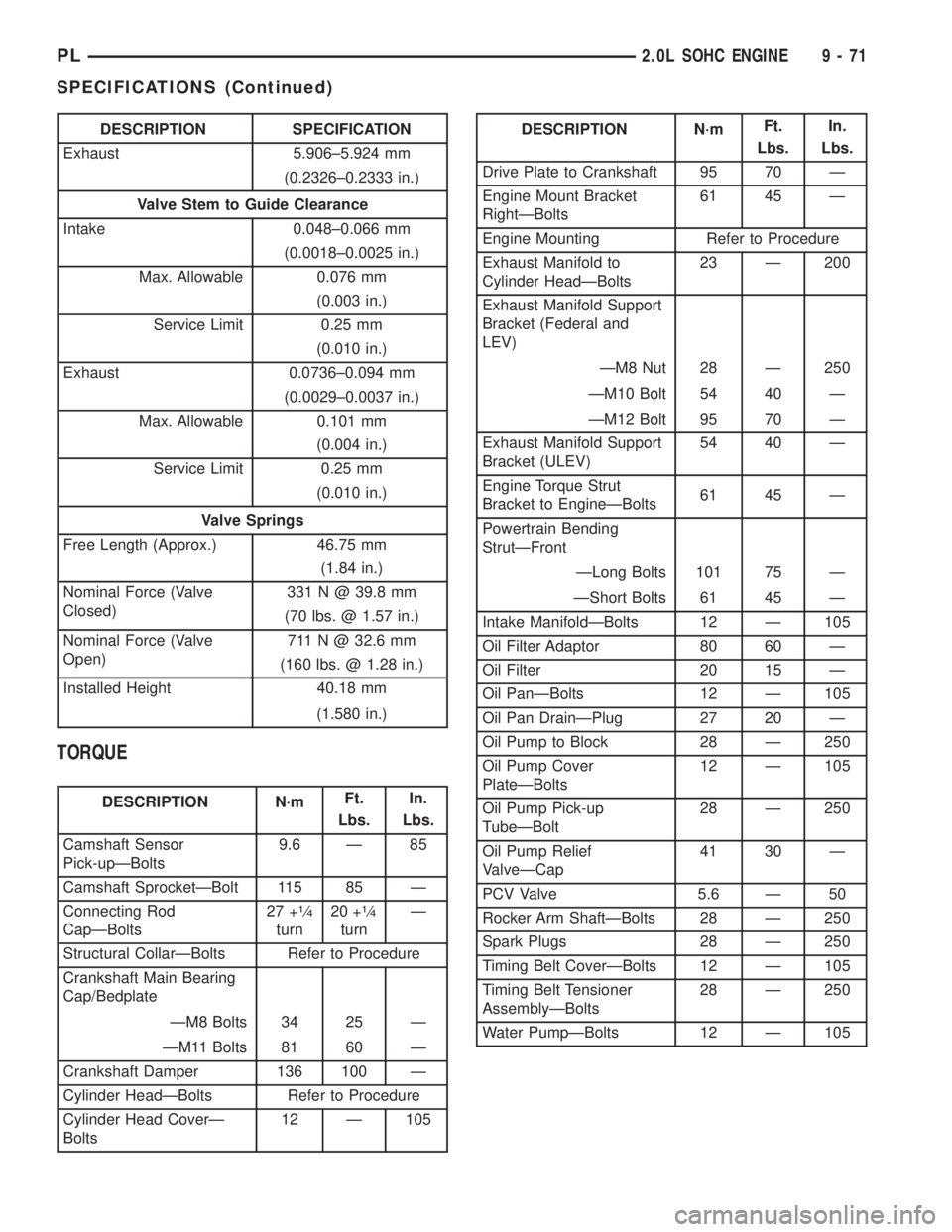

DESCRIPTION SPECIFICATION

Exhaust 5.906±5.924 mm

(0.2326±0.2333 in.)

Valve Stem to Guide Clearance

Intake 0.048±0.066 mm

(0.0018±0.0025 in.)

Max. Allowable 0.076 mm

(0.003 in.)

Service Limit 0.25 mm

(0.010 in.)

Exhaust 0.0736±0.094 mm

(0.0029±0.0037 in.)

Max. Allowable 0.101 mm

(0.004 in.)

Service Limit 0.25 mm

(0.010 in.)

Valve Springs

Free Length (Approx.) 46.75 mm

(1.84 in.)

Nominal Force (Valve

Closed)331 N @ 39.8 mm

(70 lbs. @ 1.57 in.)

Nominal Force (Valve

Open)711 N @ 32.6 mm

(160 lbs. @ 1.28 in.)

Installed Height 40.18 mm

(1.580 in.)

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Camshaft Sensor

Pick-upÐBolts9.6 Ð 85

Camshaft SprocketÐBolt 115 85 Ð

Connecting Rod

CapÐBolts27 +

1¤4

turn20 +

1¤4

turnÐ

Structural CollarÐBolts Refer to Procedure

Crankshaft Main Bearing

Cap/Bedplate

ÐM8 Bolts 34 25 Ð

ÐM11 Bolts 81 60 Ð

Crankshaft Damper 136 100 Ð

Cylinder HeadÐBolts Refer to Procedure

Cylinder Head CoverÐ

Bolts12 Ð 105

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Drive Plate to Crankshaft 95 70 Ð

Engine Mount Bracket

RightÐBolts61 45 Ð

Engine Mounting Refer to Procedure

Exhaust Manifold to

Cylinder HeadÐBolts23 Ð 200

Exhaust Manifold Support

Bracket (Federal and

LEV)

ÐM8 Nut 28 Ð 250

ÐM10 Bolt 54 40 Ð

ÐM12 Bolt 95 70 Ð

Exhaust Manifold Support

Bracket (ULEV)54 40 Ð

Engine Torque Strut

Bracket to EngineÐBolts61 45 Ð

Powertrain Bending

StrutÐFront

ÐLong Bolts 101 75 Ð

ÐShort Bolts 61 45 Ð

Intake ManifoldÐBolts 12 Ð 105

Oil Filter Adaptor 80 60 Ð

Oil Filter 20 15 Ð

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pump to Block 28 Ð 250

Oil Pump Cover

PlateÐBolts12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 Ð 250

Oil Pump Relief

ValveÐCap41 30 Ð

PCV Valve 5.6 Ð 50

Rocker Arm ShaftÐBolts 28 Ð 250

Spark Plugs 28 Ð 250

Timing Belt CoverÐBolts 12 Ð 105

Timing Belt Tensioner

AssemblyÐBolts28 Ð 250

Water PumpÐBolts 12 Ð 105

PL2.0L SOHC ENGINE 9 - 71

SPECIFICATIONS (Continued)

Page 851 of 1285

signal to the PCM, allowing engine starter operation.

The interlock switch is not adjustable.

Clutch Pedal Upstop Switch

With the clutch pedal at rest, the clutch pedal

upstop switch is closed, allowing speed control oper-

ation. When the clutch pedal is depressed, the upstop

switch opens and signals the PCM to cancel speed

control operation, and enter a modified engine cali-

bration schedule to improve driveability during gear-

to-gear shifts. The upstop switch is not adjustable.

CRANKSHAFT POSITION SENSORÐPCM

INPUT

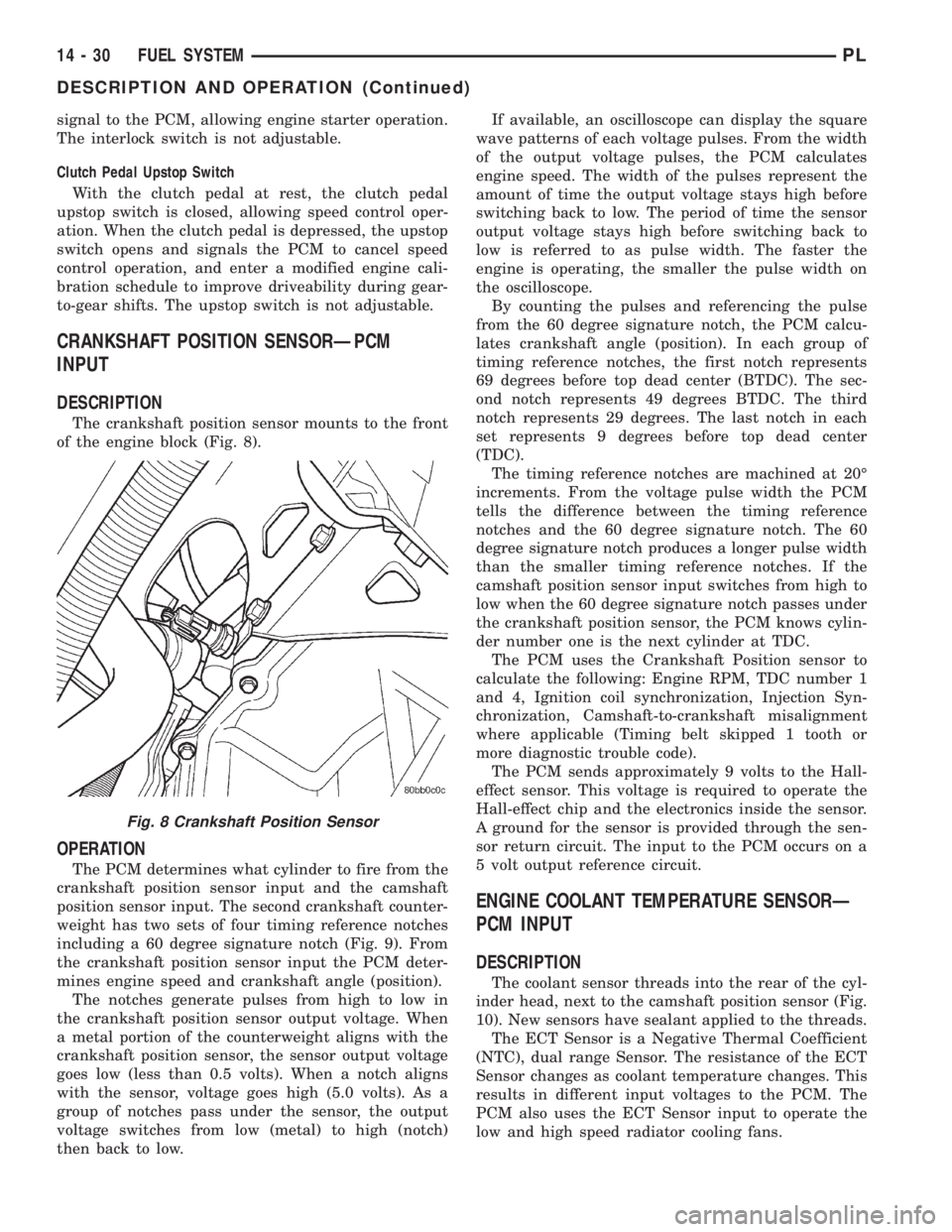

DESCRIPTION

The crankshaft position sensor mounts to the front

of the engine block (Fig. 8).

OPERATION

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 9). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The PCM uses the Crankshaft Position sensor to

calculate the following: Engine RPM, TDC number 1

and 4, Ignition coil synchronization, Injection Syn-

chronization, Camshaft-to-crankshaft misalignment

where applicable (Timing belt skipped 1 tooth or

more diagnostic trouble code).

The PCM sends approximately 9 volts to the Hall-

effect sensor. This voltage is required to operate the

Hall-effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT

DESCRIPTION

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

10). New sensors have sealant applied to the threads.

The ECT Sensor is a Negative Thermal Coefficient

(NTC), dual range Sensor. The resistance of the ECT

Sensor changes as coolant temperature changes. This

results in different input voltages to the PCM. The

PCM also uses the ECT Sensor input to operate the

low and high speed radiator cooling fans.

Fig. 8 Crankshaft Position Sensor

14 - 30 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 1099 of 1285

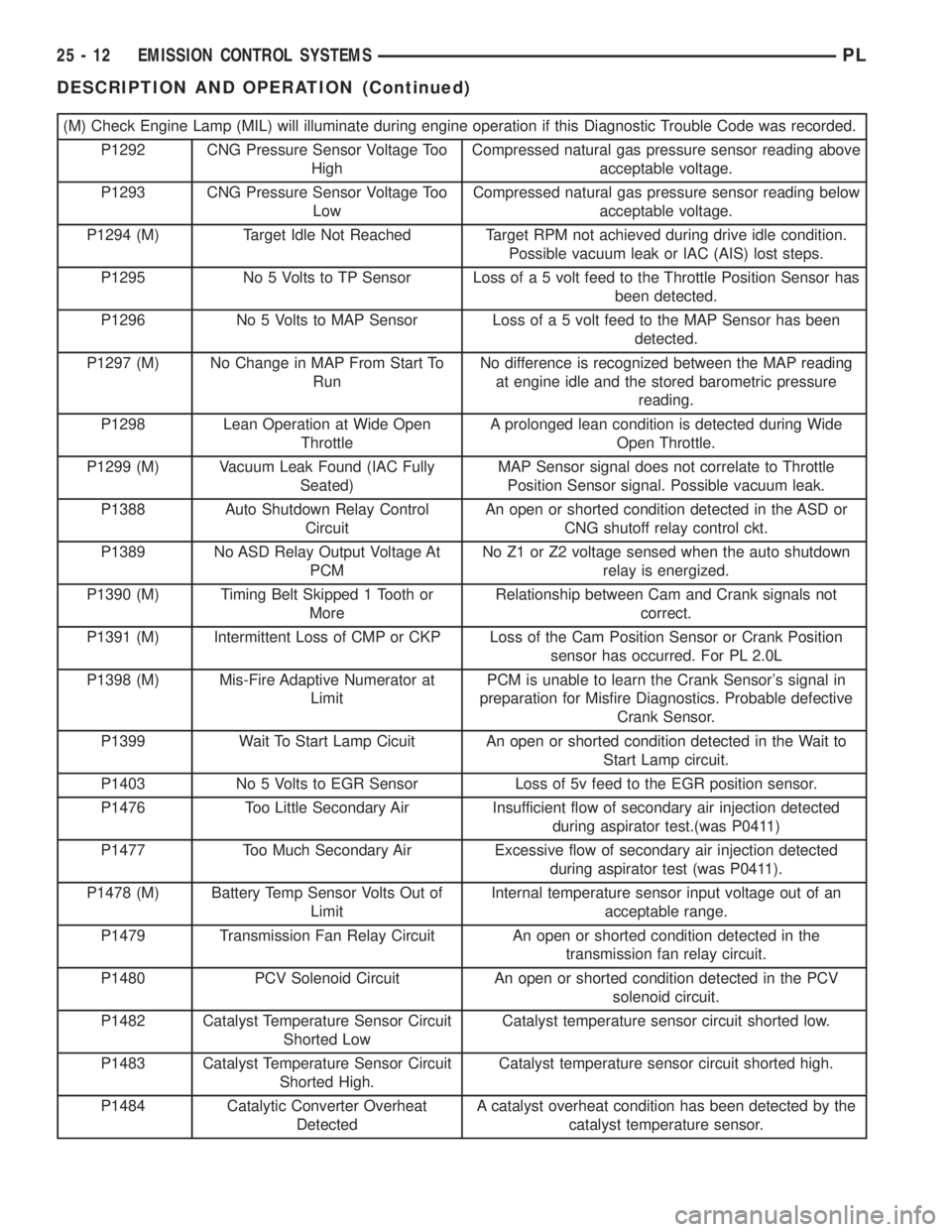

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P1292 CNG Pressure Sensor Voltage Too

HighCompressed natural gas pressure sensor reading above

acceptable voltage.

P1293 CNG Pressure Sensor Voltage Too

LowCompressed natural gas pressure sensor reading below

acceptable voltage.

P1294 (M) Target Idle Not Reached Target RPM not achieved during drive idle condition.

Possible vacuum leak or IAC (AIS) lost steps.

P1295 No 5 Volts to TP Sensor Loss of a 5 volt feed to the Throttle Position Sensor has

been detected.

P1296 No 5 Volts to MAP Sensor Loss of a 5 volt feed to the MAP Sensor has been

detected.

P1297 (M) No Change in MAP From Start To

RunNo difference is recognized between the MAP reading

at engine idle and the stored barometric pressure

reading.

P1298 Lean Operation at Wide Open

ThrottleA prolonged lean condition is detected during Wide

Open Throttle.

P1299 (M) Vacuum Leak Found (IAC Fully

Seated)MAP Sensor signal does not correlate to Throttle

Position Sensor signal. Possible vacuum leak.

P1388 Auto Shutdown Relay Control

CircuitAn open or shorted condition detected in the ASD or

CNG shutoff relay control ckt.

P1389 No ASD Relay Output Voltage At

PCMNo Z1 or Z2 voltage sensed when the auto shutdown

relay is energized.

P1390 (M) Timing Belt Skipped 1 Tooth or

MoreRelationship between Cam and Crank signals not

correct.

P1391 (M) Intermittent Loss of CMP or CKP Loss of the Cam Position Sensor or Crank Position

sensor has occurred. For PL 2.0L

P1398 (M) Mis-Fire Adaptive Numerator at

LimitPCM is unable to learn the Crank Sensor's signal in

preparation for Misfire Diagnostics. Probable defective

Crank Sensor.

P1399 Wait To Start Lamp Cicuit An open or shorted condition detected in the Wait to

Start Lamp circuit.

P1403 No 5 Volts to EGR Sensor Loss of 5v feed to the EGR position sensor.

P1476 Too Little Secondary Air Insufficient flow of secondary air injection detected

during aspirator test.(was P0411)

P1477 Too Much Secondary Air Excessive flow of secondary air injection detected

during aspirator test (was P0411).

P1478 (M) Battery Temp Sensor Volts Out of

LimitInternal temperature sensor input voltage out of an

acceptable range.

P1479 Transmission Fan Relay Circuit An open or shorted condition detected in the

transmission fan relay circuit.

P1480 PCV Solenoid Circuit An open or shorted condition detected in the PCV

solenoid circuit.

P1482 Catalyst Temperature Sensor Circuit

Shorted LowCatalyst temperature sensor circuit shorted low.

P1483 Catalyst Temperature Sensor Circuit

Shorted High.Catalyst temperature sensor circuit shorted high.

P1484 Catalytic Converter Overheat

DetectedA catalyst overheat condition has been detected by the

catalyst temperature sensor.

25 - 12 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)