weight DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 974 of 1285

CONDITION POSSIBLE CAUSES CORRECTION

SHIFTS DELAYED OR

ERRATIC (ALSO SHIFTS

HARSH AT TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

clutch material or metal particles, an

overhaul may be necessary. Perform lube

flow test.

3. Throttle Linkage Misadjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

to closed throttle at transmission.

5. Gearshift Linkage/Cable

Misadjusted.5. Adjust linkage/cable as described in

service section.

6. Governor Valve Sticking. 6. Inspect, clean or repair.

7. Governor Seal Rings Worn/

Damaged.7. Inspect/replace.

8. Clutch or Servo Failure. 8. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

9. Front Band Misadjusted. 9. Adjust band.

10. Pump Suction Passage Leak. 10. Check for excessive foam on dipstick

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

NO REVERSE (D RANGES

OK)1. Gearshift Linkage/Cable

Misadjusted/Damaged.1. Repair or replace linkage parts as

needed.

2. Rear Band Misadjusted/Worn. 2. Adjust band; replace.

3. Valve Body Malfunction. 3. Remove and service valve body. Replace

valve body if any valves or valve bores are

worn or damaged.

4. Rear Servo Malfunction. 4. Remove and disassemble transmission.

Replace worn/damaged servo parts as

necessary.

5. Direct Clutch in Overdrive Worn 5. Disassemble overdrive. Replace worn or

damaged parts.

6. Front Clutch Burnt. 6. Remove and disassemble transmission.

Replace worn, damaged clutch parts as

required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Valve, Shaft, Weights or

Body Damaged/Stuck.1. Remove governor assembly and clean or

repair as necessary.

2. Valve Body Malfunction. 2. Stuck 1-2 shift valve or governor plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

stuck 1-2 valve or governor plug.

2. Governor Valve Sticking. 2. Remove, clean and inspect. Replace

faulty parts.

PLTRANSAXLE 21 - 61

DIAGNOSIS AND TESTING (Continued)

Page 1063 of 1285

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type .........Automatic three speed with torque

converter and integral differential

Torque Converter Diameter...... 241millimeters

(9.48 in.)

OilType .....................MopartATF+4

(Automatic Transmission Fluid) Type 9602

Cooling Method.... Water Heat Exchanger and/or

air to oil heat exchanger

Lubrication . . . Pump (internal-external gear-type)

Transmission Gear Ratios

First Gear............................2.69

Second Gear...........................1.55

Third Gear............................1.00

Reverse Gear..........................2.10

Band Adjustment

KickdownÐBacked Off From 8 N²m

(72 in. lbs.).................... 21/4Turns

Low-ReverseÐBacked Off From 5 N²m

(41 in. lbs.).................... 31/2Turns

Clutch Pack Clearances

Front Clutch (Not Adjustable)......1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.......0.71-1.10mm (0.028-0.043 in.)

End Play

Input Shaft........0.19±1.50 mm (.008±.060 in.)

Front Clutch Retainer...........0.76±2.69 mm

(.030±.106 in.)

Front Carrier.......0.89±1.45 mm (.007±.057 in.)

Front Annulus Gear . . 0.09±0.50 mm (.0035±.020 in.)

Planet Pinion.......0.15±0.59 mm (.006±.023 in.)

Reverse Drum......0.76±3.36 mm (.030±.132 in.)

Oil Pump Clearances

Outer Gear To Pocket...........0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.......0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.......0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . 6 to 12 in. lbs. Drag Torque

Output Hub.......... 0to3in.lbs. Drag Torque

Transfer Shaft.......0.002 to 0.010 in. End Play

Overall Drag At Output

Hub ............. 3to16in.lbs. Drag TorqueThrust Washers

Reaction Shaft Support (No. 1).....1.55±1.60 mm

(.061±.063 in.)

Rear Clutch Retainer (No. 2)......1.55±1.60 mm

(.061±.063 in.)

Output Shaft (No. 3) (Select)......1.98±2.03 mm

(.077±.080 in.)

Output Shaft (No. 3) (Select)......2.15±2.22 mm

(.085±.087 in.)

Output Shaft (No. 3) (Select)......2.34±2.41 mm

(.092±.095 in.)

Front Annulus (No. 4)............2.95±3.05 mm

(.116±.120 in.)

Front Carrier (Nos. 5&6).........1.22±1.28 mm

(.0948±.050 in.)

Sun Gear-Front (No. 7)...........0.85±0.91 mm

(.033±.036 in.)

Sun Gear-Rear (No. 8)...........0.85±0.91 mm

(.033±.036 in.)

Rear Carrier (Nos. 9&10).........1.22±1.28 mm

(.0948±.050 in.)

Rev. Drum (No. 11) . . 1.55±1.60 mm (.061±.063 in.)

31TH TRANSAXLE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Bell Housing Cover Bolts.... 12N´m(105 in. lbs.)

Cooler Line Clamps.......... 2N´m(18in.lbs.)

Diff. Bear. Ret. To Case Bolt . . 34 N´m (300 in. lbs.)

Diff. Cover To Case Bolt..... 19N´m(165 in. lbs.)

Exten. Hous. To Case Bolt . . . 28 N´m (250 in. lbs.)

Drive Plate To Crankshaft

Bolts................... 95N´m(70ft.lbs.)

Drive Plate To Torque Conv.

Bolts................... 88N´m(65ft.lbs.)

Fluid Filter Screw........... 5N´m(45in.lbs.)

Governor Counterweight

Screw................. 28N´m(250 in. lbs.)

Governor To Support Bolt...... 7N´m(60in.lbs.)

Kickdown Band Adj. Lock Nut . . 47 N´m (35 ft. lbs.)

Left Motor Mount Bolts....... 54N´m(40ft.lbs.)

Manual Cable To Trans.

Case Bolt.............. 28N´m(250 in. lbs.)

Manual Control Lever Screw . . 12 N´m (105 in. lbs.)

Oil Pan To Trans. Case

Screw................. 19N´m(165 in. lbs.)

Output Gear Strap Bolts...... 23N´m(17ft.lbs.)

Output Shaft Nut......... 271N´m(200 ft. lbs.)

Park/Neutral Switch......... 34N´m(25ft.lbs.)

Pressure Check Plug......... 5N´m(45in.lbs.)

Pump To Case Bolts........ 31N´m(275 in. lbs.)

Reaction Shaft Assembly

Bolt................... 28N´m(250 in. lbs.)

Rear Cover To Case Screw . . . 19 N´m (165 in. lbs.)

Reverse Band Adj. Lock Nut . . 14 N´m (125 in. lbs.)

21 - 150 TRANSAXLEPL

Page 1071 of 1285

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 2).

Performance tires will have a speed rating letter

after the aspect ratio number. For example, the letter

ªSº indicates that the tire is speed rated up to 112

mph (180 km/h). The speed rating is not always

printed on the tire sidewall.

²Q -up to 100 mph (160 km/h)

²T -up to 118 mph (190 km/h)

²U -up to 124 mph (200 km/h)

²H -up to 130 mph (210 km/h)

²V -up to 149 mph (240 km/h)

²Z -more than 149 mph (240 km/h) (consult the

tire manufacturer for the specific speed rating)

An All Season type tire will have eitherM+S,M

& S or M-S (indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

Refer to the owners manual supplied with the vehi-

cle to determine whether the use of tire chains is per-

mitted on this vehicle.

RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.

Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

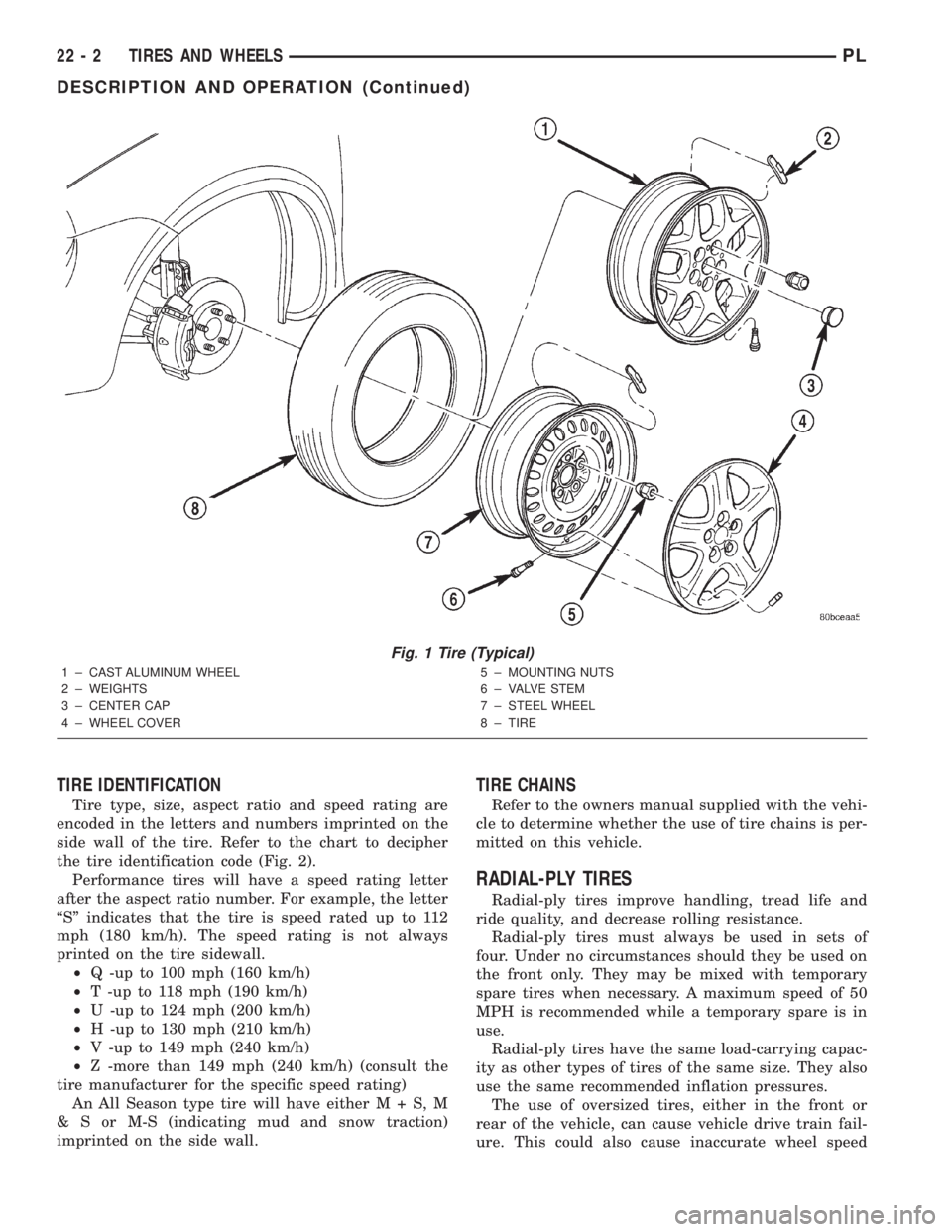

Fig. 1 Tire (Typical)

1 ± CAST ALUMINUM WHEEL

2 ± WEIGHTS

3 ± CENTER CAP

4 ± WHEEL COVER5 ± MOUNTING NUTS

6 ± VALVE STEM

7 ± STEEL WHEEL

8 ± TIRE

22 - 2 TIRES AND WHEELSPL

DESCRIPTION AND OPERATION (Continued)

Page 1079 of 1285

WHEELS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WHEEL................................10

WHEEL COVER (LOCK-ON).................11

DIAGNOSIS AND TESTING

WHEEL INSPECTION......................11

TIRE AND WHEEL RUNOUT................12

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE................13REMOVAL AND INSTALLATION

WHEEL COVER (LOCK-ON).................15

WHEEL COVER RETAINING NUT............15

TIRE AND WHEEL ASSEMBLY...............16

SPECIFICATIONS

WHEEL SPECIFICATIONS..................17

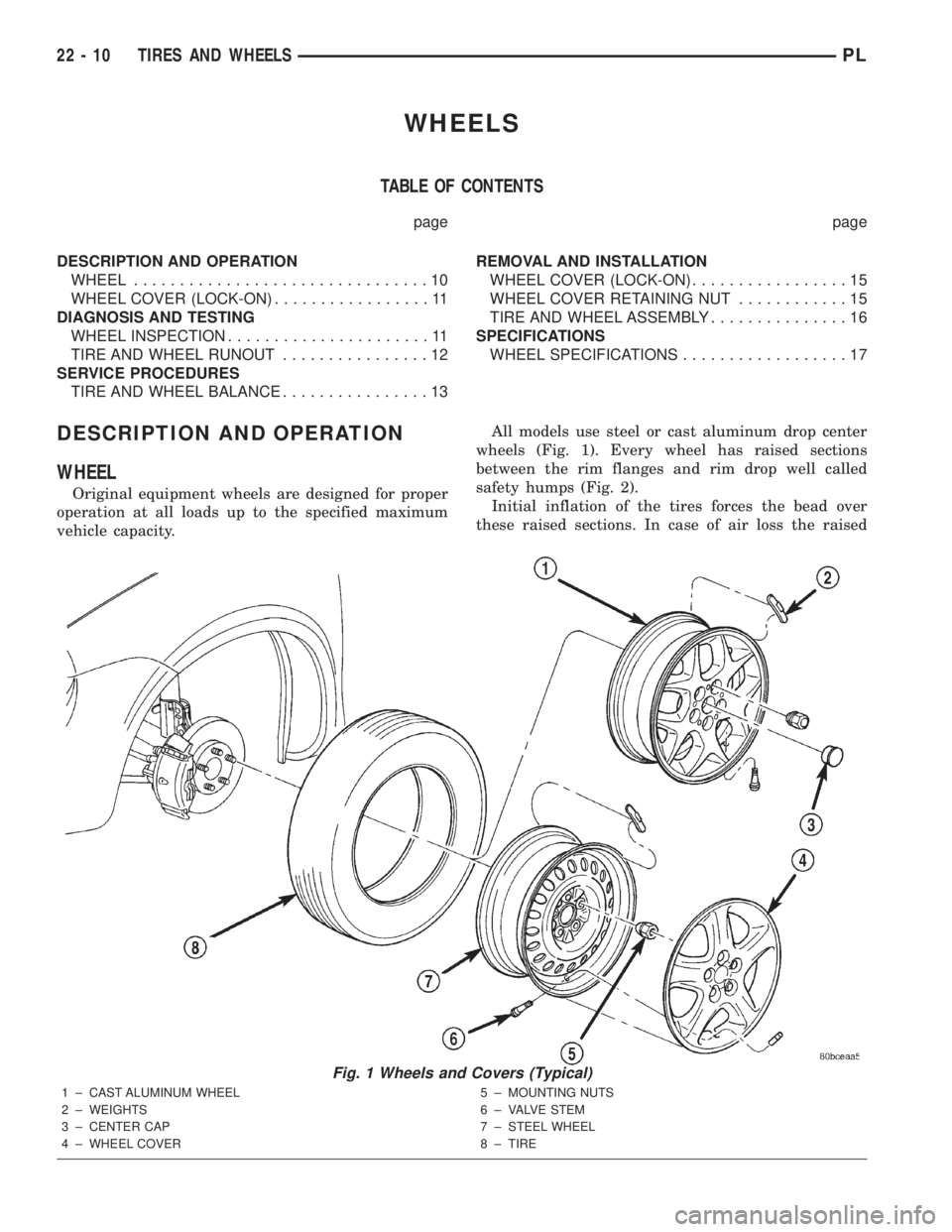

DESCRIPTION AND OPERATION

WHEEL

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

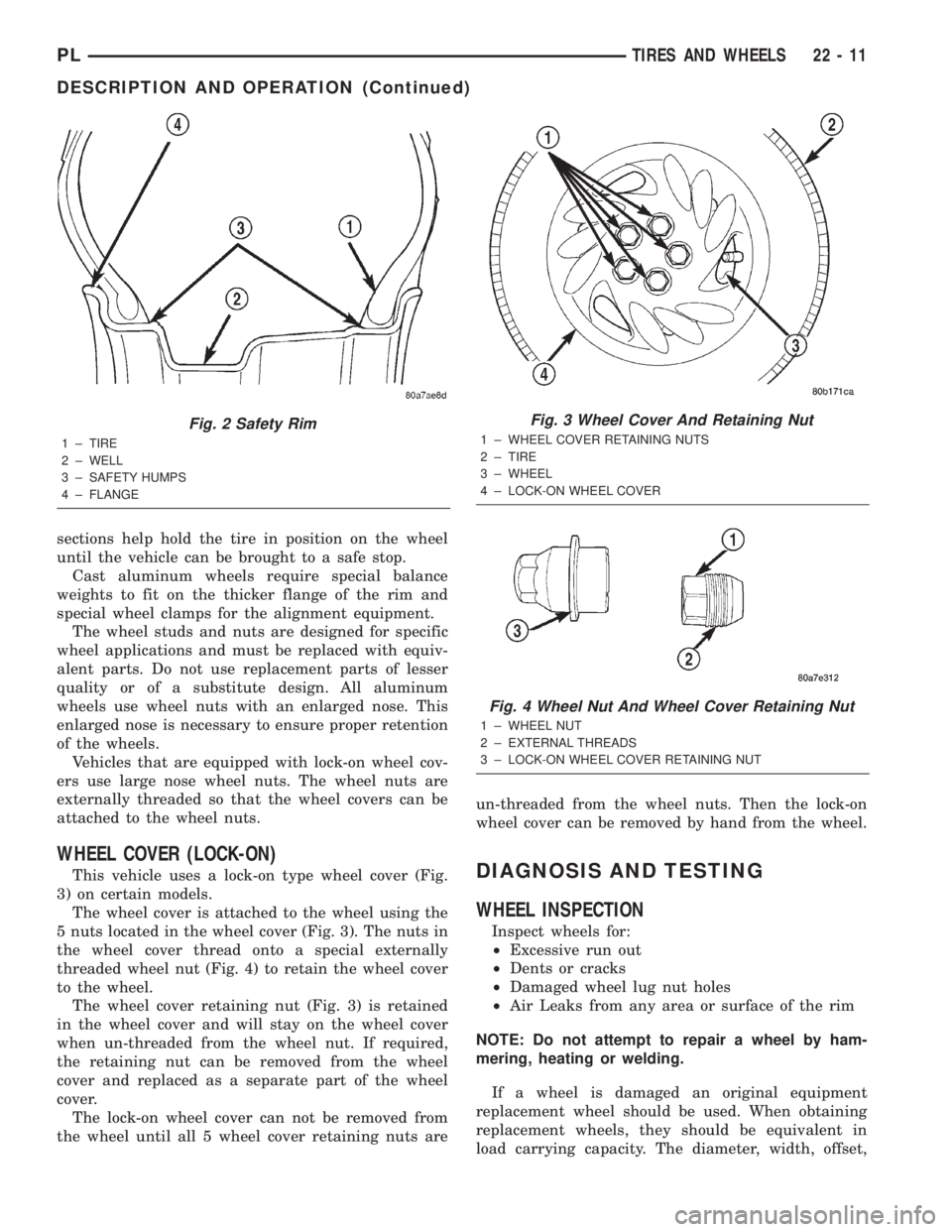

vehicle capacity.All models use steel or cast aluminum drop center

wheels (Fig. 1). Every wheel has raised sections

between the rim flanges and rim drop well called

safety humps (Fig. 2).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

Fig. 1 Wheels and Covers (Typical)

1 ± CAST ALUMINUM WHEEL

2 ± WEIGHTS

3 ± CENTER CAP

4 ± WHEEL COVER5 ± MOUNTING NUTS

6 ± VALVE STEM

7 ± STEEL WHEEL

8 ± TIRE

22 - 10 TIRES AND WHEELSPL

Page 1080 of 1285

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts. Do not use replacement parts of lesser

quality or of a substitute design. All aluminum

wheels use wheel nuts with an enlarged nose. This

enlarged nose is necessary to ensure proper retention

of the wheels.

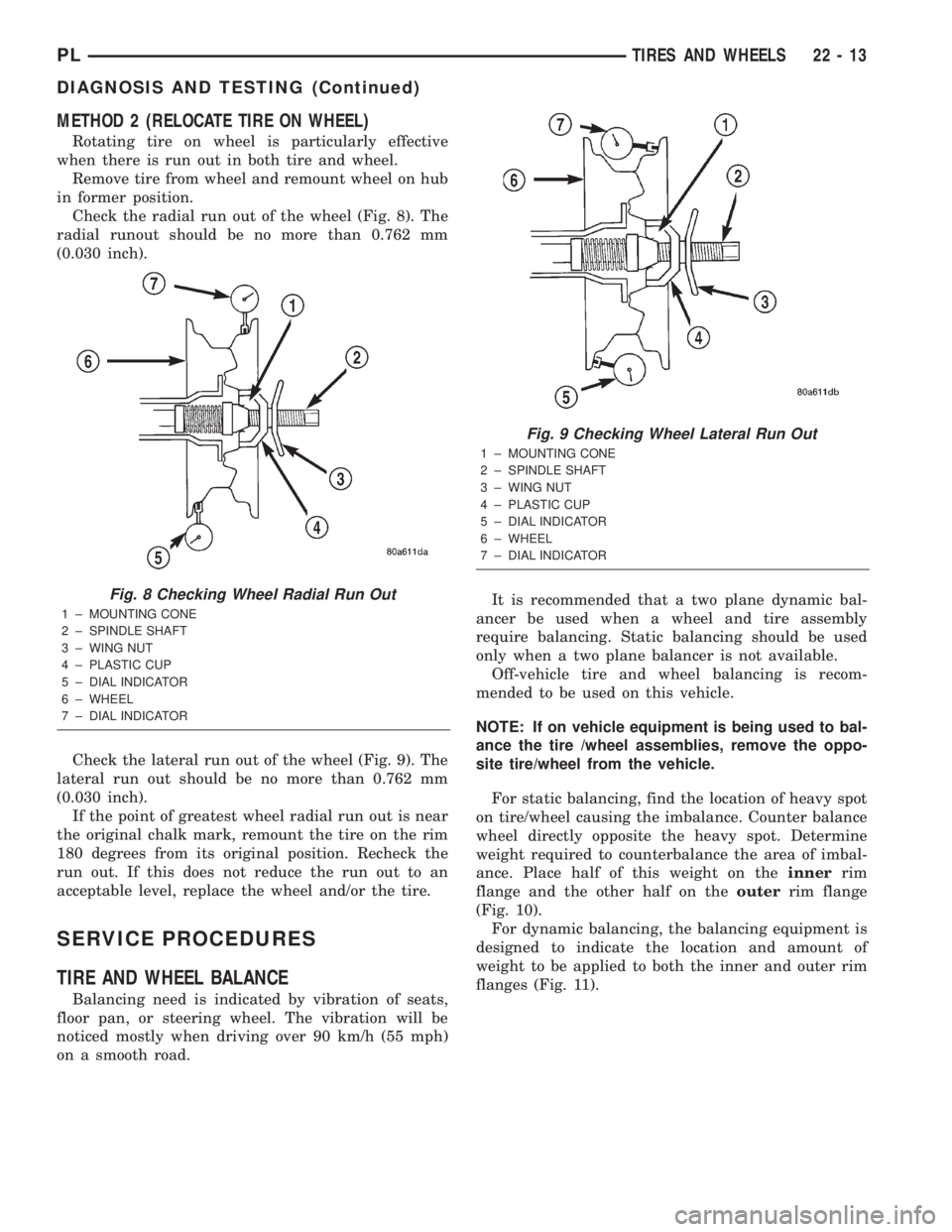

Vehicles that are equipped with lock-on wheel cov-

ers use large nose wheel nuts. The wheel nuts are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

WHEEL COVER (LOCK-ON)

This vehicle uses a lock-on type wheel cover (Fig.

3) on certain models.

The wheel cover is attached to the wheel using the

5 nuts located in the wheel cover (Fig. 3). The nuts in

the wheel cover thread onto a special externally

threaded wheel nut (Fig. 4) to retain the wheel cover

to the wheel.

The wheel cover retaining nut (Fig. 3) is retained

in the wheel cover and will stay on the wheel cover

when un-threaded from the wheel nut. If required,

the retaining nut can be removed from the wheel

cover and replaced as a separate part of the wheel

cover.

The lock-on wheel cover can not be removed from

the wheel until all 5 wheel cover retaining nuts areun-threaded from the wheel nuts. Then the lock-on

wheel cover can be removed by hand from the wheel.DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by ham-

mering, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

Fig. 2 Safety Rim

1 ± TIRE

2 ± WELL

3 ± SAFETY HUMPS

4 ± FLANGE

Fig. 3 Wheel Cover And Retaining Nut

1 ± WHEEL COVER RETAINING NUTS

2 ± TIRE

3 ± WHEEL

4 ± LOCK-ON WHEEL COVER

Fig. 4 Wheel Nut And Wheel Cover Retaining Nut

1 ± WHEEL NUT

2 ± EXTERNAL THREADS

3 ± LOCK-ON WHEEL COVER RETAINING NUT

PLTIRES AND WHEELS 22 - 11

DESCRIPTION AND OPERATION (Continued)

Page 1082 of 1285

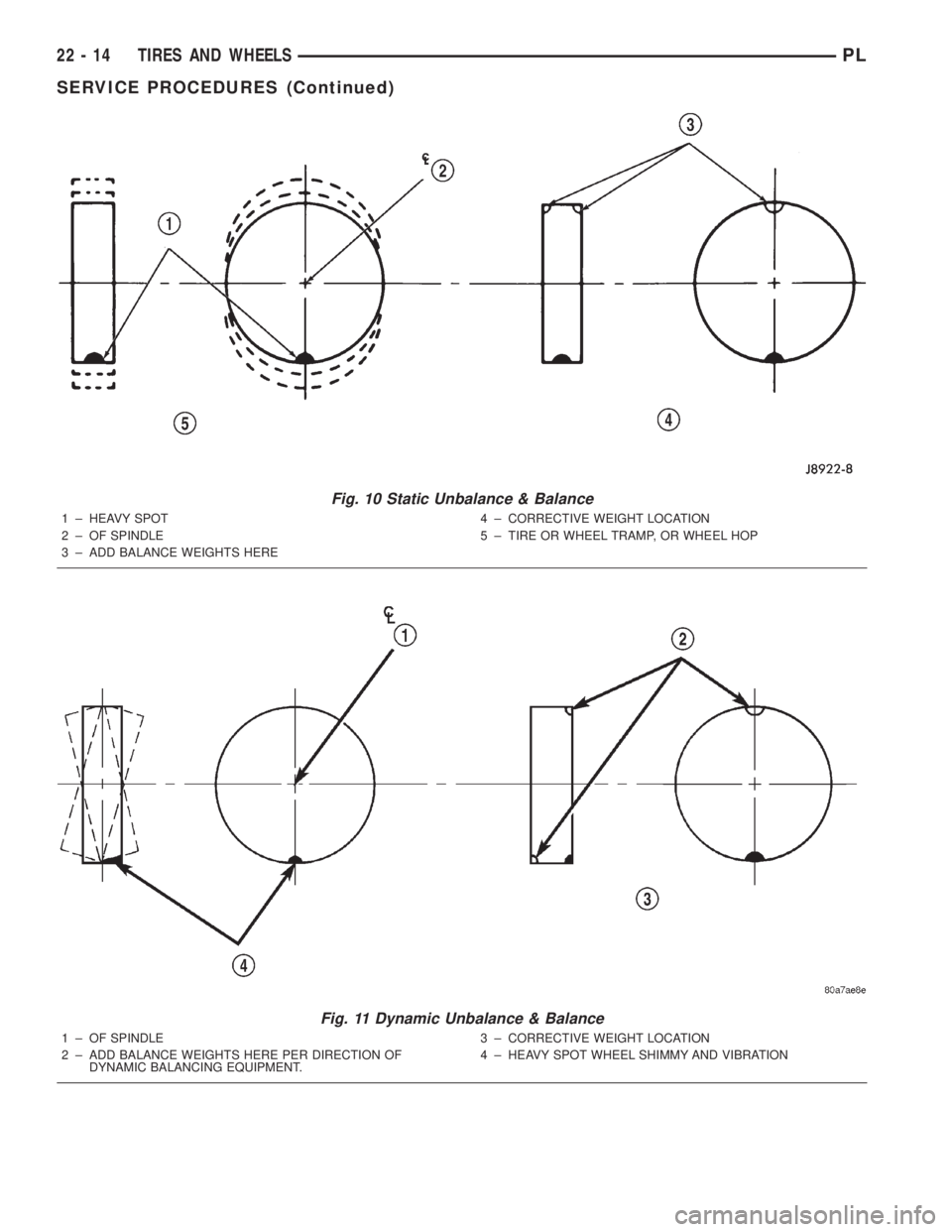

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is run out in both tire and wheel.

Remove tire from wheel and remount wheel on hub

in former position.

Check the radial run out of the wheel (Fig. 8). The

radial runout should be no more than 0.762 mm

(0.030 inch).

Check the lateral run out of the wheel (Fig. 9). The

lateral run out should be no more than 0.762 mm

(0.030 inch).

If the point of greatest wheel radial run out is near

the original chalk mark, remount the tire on the rim

180 degrees from its original position. Recheck the

run out. If this does not reduce the run out to an

acceptable level, replace the wheel and/or the tire.

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel. The vibration will be

noticed mostly when driving over 90 km/h (55 mph)

on a smooth road.It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly

require balancing. Static balancing should be used

only when a two plane balancer is not available.

Off-vehicle tire and wheel balancing is recom-

mended to be used on this vehicle.

NOTE: If on vehicle equipment is being used to bal-

ance the tire /wheel assemblies, remove the oppo-

site tire/wheel from the vehicle.

For static balancing, find the location of heavy spot

on tire/wheel causing the imbalance. Counter balance

wheel directly opposite the heavy spot. Determine

weight required to counterbalance the area of imbal-

ance. Place half of this weight on theinnerrim

flange and the other half on theouterrim flange

(Fig. 10).

For dynamic balancing, the balancing equipment is

designed to indicate the location and amount of

weight to be applied to both the inner and outer rim

flanges (Fig. 11).

Fig. 8 Checking Wheel Radial Run Out

1 ± MOUNTING CONE

2 ± SPINDLE SHAFT

3 ± WING NUT

4 ± PLASTIC CUP

5 ± DIAL INDICATOR

6 ± WHEEL

7 ± DIAL INDICATOR

Fig. 9 Checking Wheel Lateral Run Out

1 ± MOUNTING CONE

2 ± SPINDLE SHAFT

3 ± WING NUT

4 ± PLASTIC CUP

5 ± DIAL INDICATOR

6 ± WHEEL

7 ± DIAL INDICATOR

PLTIRES AND WHEELS 22 - 13

DIAGNOSIS AND TESTING (Continued)

Page 1083 of 1285

Fig. 10 Static Unbalance & Balance

1 ± HEAVY SPOT

2 ± OF SPINDLE

3 ± ADD BALANCE WEIGHTS HERE4 ± CORRECTIVE WEIGHT LOCATION

5 ± TIRE OR WHEEL TRAMP, OR WHEEL HOP

Fig. 11 Dynamic Unbalance & Balance

1 ± OF SPINDLE

2 ± ADD BALANCE WEIGHTS HERE PER DIRECTION OF

DYNAMIC BALANCING EQUIPMENT.3 ± CORRECTIVE WEIGHT LOCATION

4 ± HEAVY SPOT WHEEL SHIMMY AND VIBRATION

22 - 14 TIRES AND WHEELSPL

SERVICE PROCEDURES (Continued)

Page 1275 of 1285

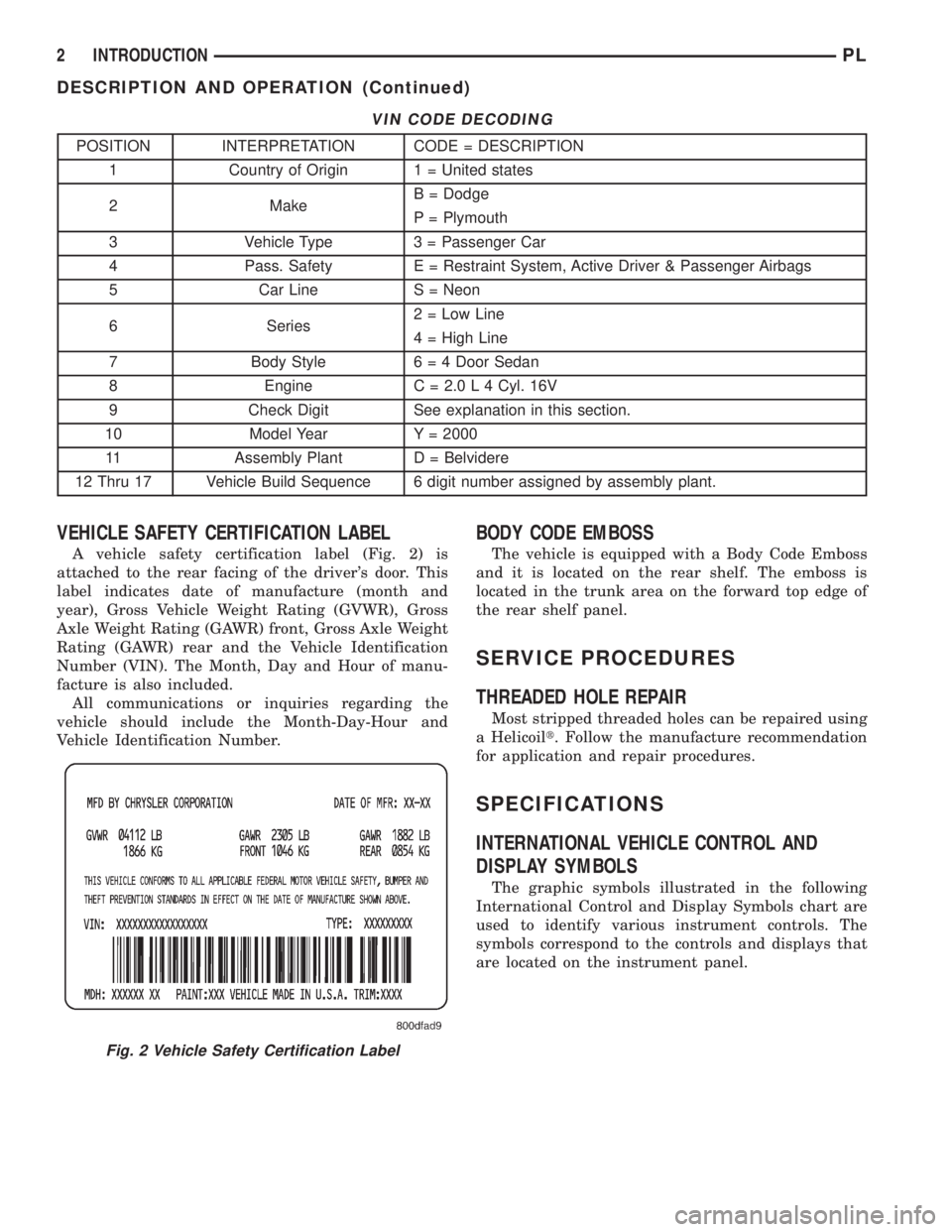

VIN CODE DECODING

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1 = United states

2 MakeB = Dodge

P = Plymouth

3 Vehicle Type 3 = Passenger Car

4 Pass. Safety E = Restraint System, Active Driver & Passenger Airbags

5 Car Line S = Neon

6 Series2 = Low Line

4 = High Line

7 Body Style6 = 4 Door Sedan

8 Engine C = 2.0 L 4 Cyl. 16V

9 Check Digit See explanation in this section.

10 Model Year Y = 2000

11 Assembly Plant D = Belvidere

12 Thru 17 Vehicle Build Sequence 6 digit number assigned by assembly plant.

VEHICLE SAFETY CERTIFICATION LABEL

A vehicle safety certification label (Fig. 2) is

attached to the rear facing of the driver's door. This

label indicates date of manufacture (month and

year), Gross Vehicle Weight Rating (GVWR), Gross

Axle Weight Rating (GAWR) front, Gross Axle Weight

Rating (GAWR) rear and the Vehicle Identification

Number (VIN). The Month, Day and Hour of manu-

facture is also included.

All communications or inquiries regarding the

vehicle should include the Month-Day-Hour and

Vehicle Identification Number.

BODY CODE EMBOSS

The vehicle is equipped with a Body Code Emboss

and it is located on the rear shelf. The emboss is

located in the trunk area on the forward top edge of

the rear shelf panel.

SERVICE PROCEDURES

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the manufacture recommendation

for application and repair procedures.

SPECIFICATIONS

INTERNATIONAL VEHICLE CONTROL AND

DISPLAY SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

Fig. 2 Vehicle Safety Certification Label

2 INTRODUCTIONPL

DESCRIPTION AND OPERATION (Continued)