weight DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 780 of 1285

(8) Install oil pick-up tube and oil pan.

(9) Install rear timing belt cover and camshaft

sprocket.

(10) Install timing belt tensioner, timing belt, and

front timing belt cover.

(11) Install crankshaft damper.

(12) Fill engine crankcase with proper oil to cor-

rect level.

(13) Connect negative cable to battery.

PISTON AND CONNECTING ROD

REMOVAL

(1) Remove cylinder head and oil pan. Refer to pro-

cedures in this section.

(2) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 108).

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(3) Using a permanent ink marker or scribe tool

mark the cylinder number on the side of the rod and

cap (Fig. 109) for identification.

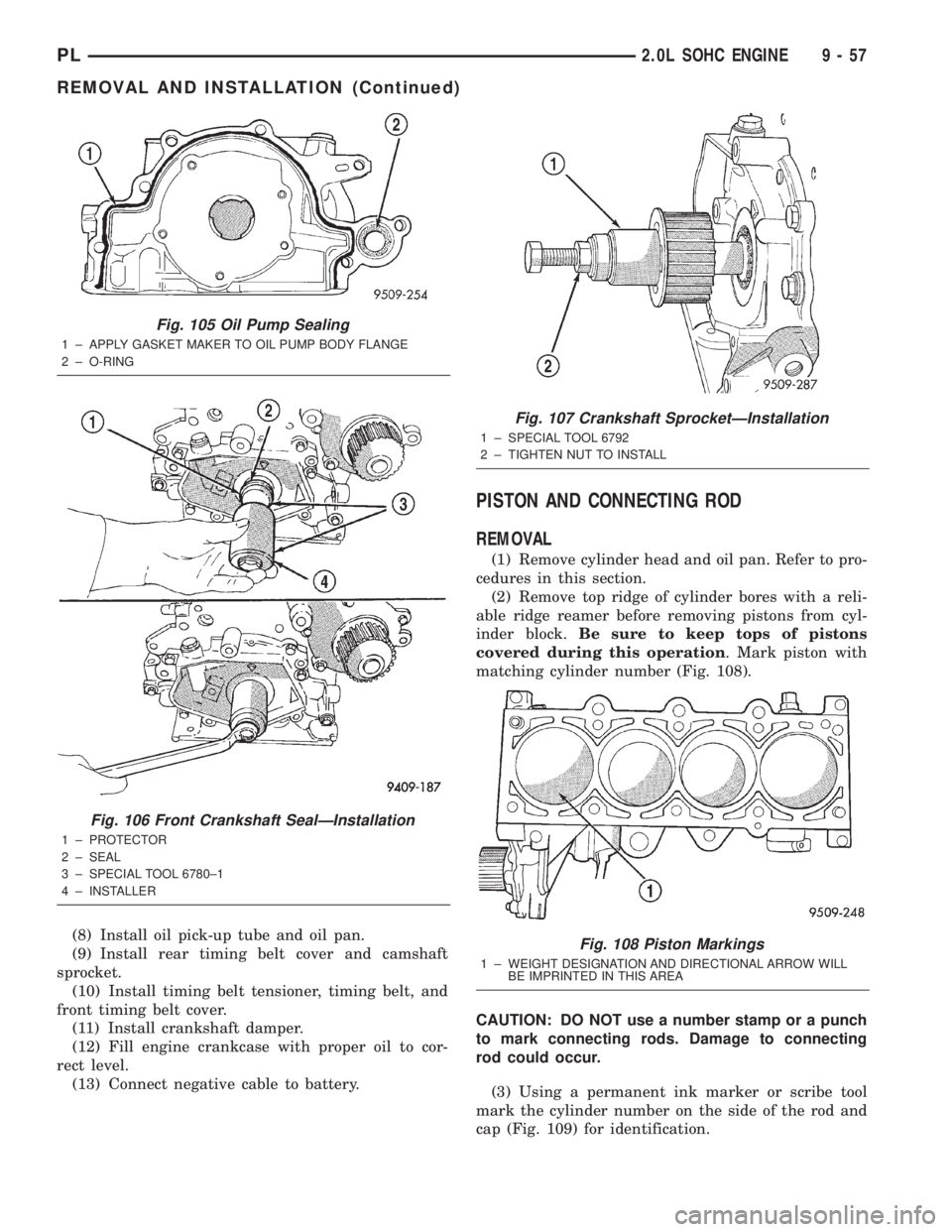

Fig. 105 Oil Pump Sealing

1 ± APPLY GASKET MAKER TO OIL PUMP BODY FLANGE

2 ± O-RING

Fig. 106 Front Crankshaft SealÐInstallation

1 ± PROTECTOR

2 ± SEAL

3 ± SPECIAL TOOL 6780±1

4 ± INSTALLER

Fig. 107 Crankshaft SprocketÐInstallation

1 ± SPECIAL TOOL 6792

2 ± TIGHTEN NUT TO INSTALL

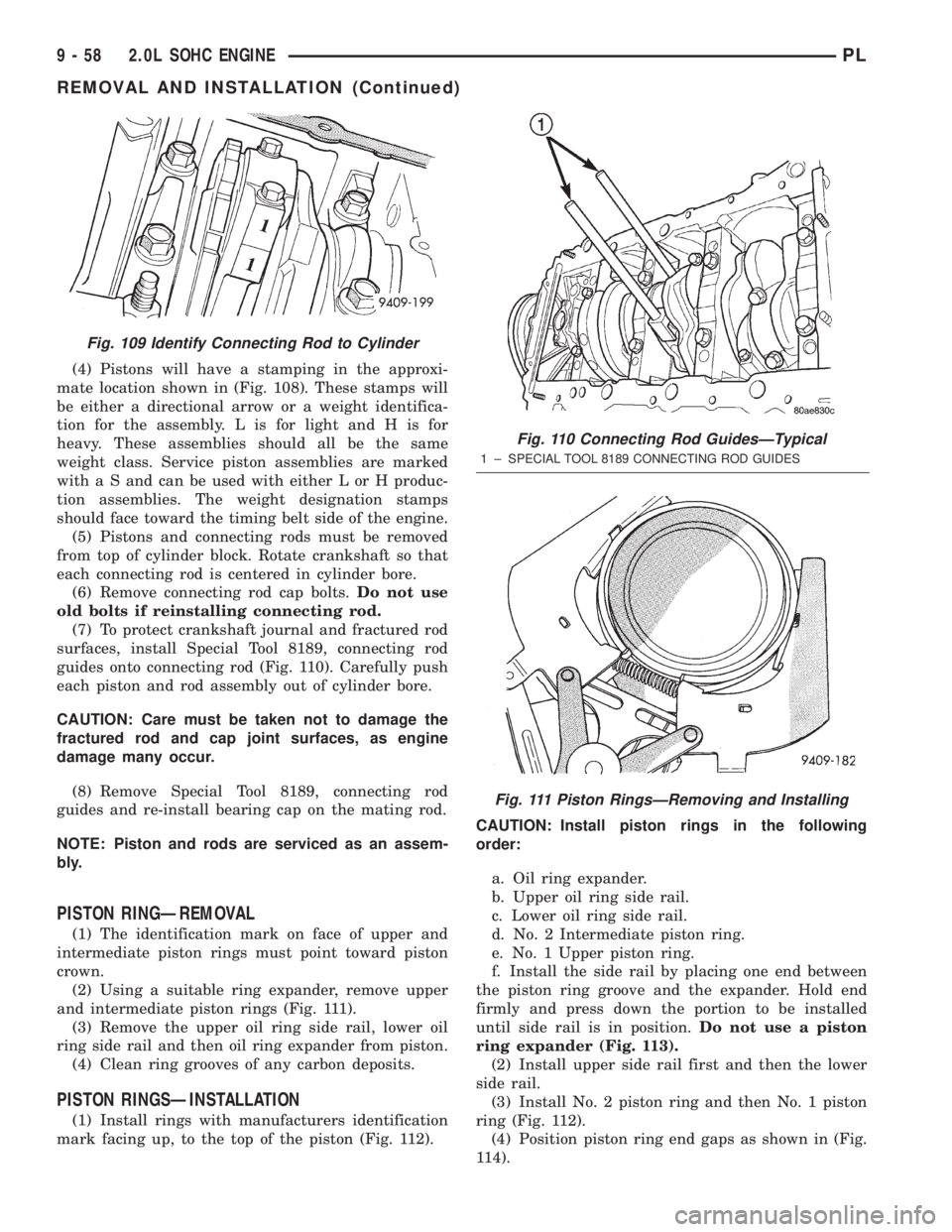

Fig. 108 Piston Markings

1 ± WEIGHT DESIGNATION AND DIRECTIONAL ARROW WILL

BE IMPRINTED IN THIS AREA

PL2.0L SOHC ENGINE 9 - 57

REMOVAL AND INSTALLATION (Continued)

Page 781 of 1285

(4) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 108). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(5) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(6) Remove connecting rod cap bolts.Do not use

old bolts if reinstalling connecting rod.

(7) To protect crankshaft journal and fractured rod

surfaces, install Special Tool 8189, connecting rod

guides onto connecting rod (Fig. 110). Carefully push

each piston and rod assembly out of cylinder bore.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint surfaces, as engine

damage many occur.

(8) Remove Special Tool 8189, connecting rod

guides and re-install bearing cap on the mating rod.

NOTE: Piston and rods are serviced as an assem-

bly.

PISTON RINGÐREMOVAL

(1) The identification mark on face of upper and

intermediate piston rings must point toward piston

crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 111).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

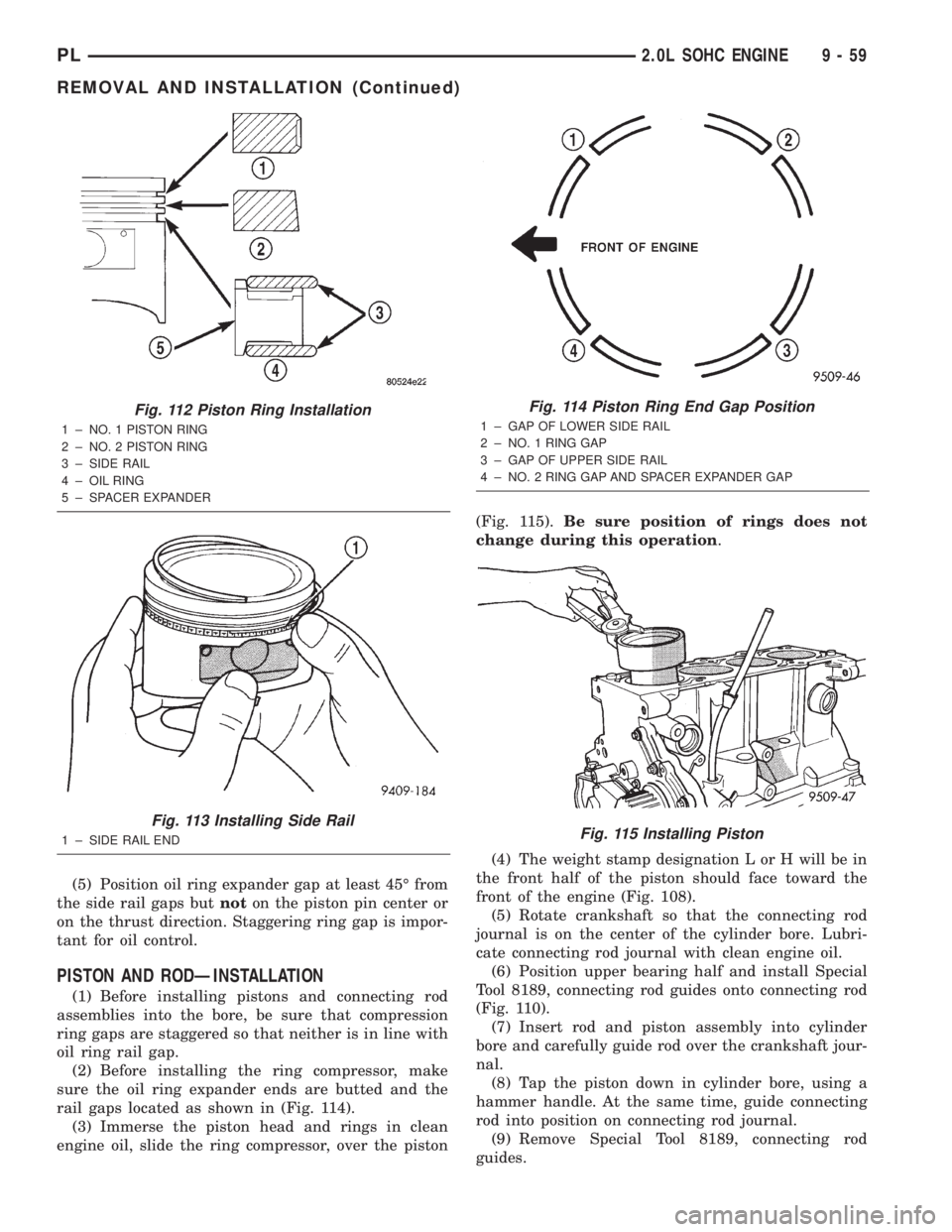

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers identification

mark facing up, to the top of the piston (Fig. 112).CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

c. Lower oil ring side rail.

d. No. 2 Intermediate piston ring.

e. No. 1 Upper piston ring.

f. Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position.Do not use a piston

ring expander (Fig. 113).

(2) Install upper side rail first and then the lower

side rail.

(3) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 112).

(4) Position piston ring end gaps as shown in (Fig.

114).

Fig. 109 Identify Connecting Rod to Cylinder

Fig. 110 Connecting Rod GuidesÐTypical

1 ± SPECIAL TOOL 8189 CONNECTING ROD GUIDES

Fig. 111 Piston RingsÐRemoving and Installing

9 - 58 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 782 of 1285

(5) Position oil ring expander gap at least 45É from

the side rail gaps butnoton the piston pin center or

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND RODÐINSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 114).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston(Fig. 115).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine (Fig. 108).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Lubri-

cate connecting rod journal with clean engine oil.

(6) Position upper bearing half and install Special

Tool 8189, connecting rod guides onto connecting rod

(Fig. 110).

(7) Insert rod and piston assembly into cylinder

bore and carefully guide rod over the crankshaft jour-

nal.

(8) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(9) Remove Special Tool 8189, connecting rod

guides.

Fig. 112 Piston Ring Installation

1 ± NO. 1 PISTON RING

2 ± NO. 2 PISTON RING

3 ± SIDE RAIL

4 ± OIL RING

5 ± SPACER EXPANDER

Fig. 113 Installing Side Rail

1 ± SIDE RAIL END

Fig. 114 Piston Ring End Gap Position

1 ± GAP OF LOWER SIDE RAIL

2 ± NO. 1 RING GAP

3 ± GAP OF UPPER SIDE RAIL

4 ± NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 115 Installing Piston

PL2.0L SOHC ENGINE 9 - 59

REMOVAL AND INSTALLATION (Continued)

Page 791 of 1285

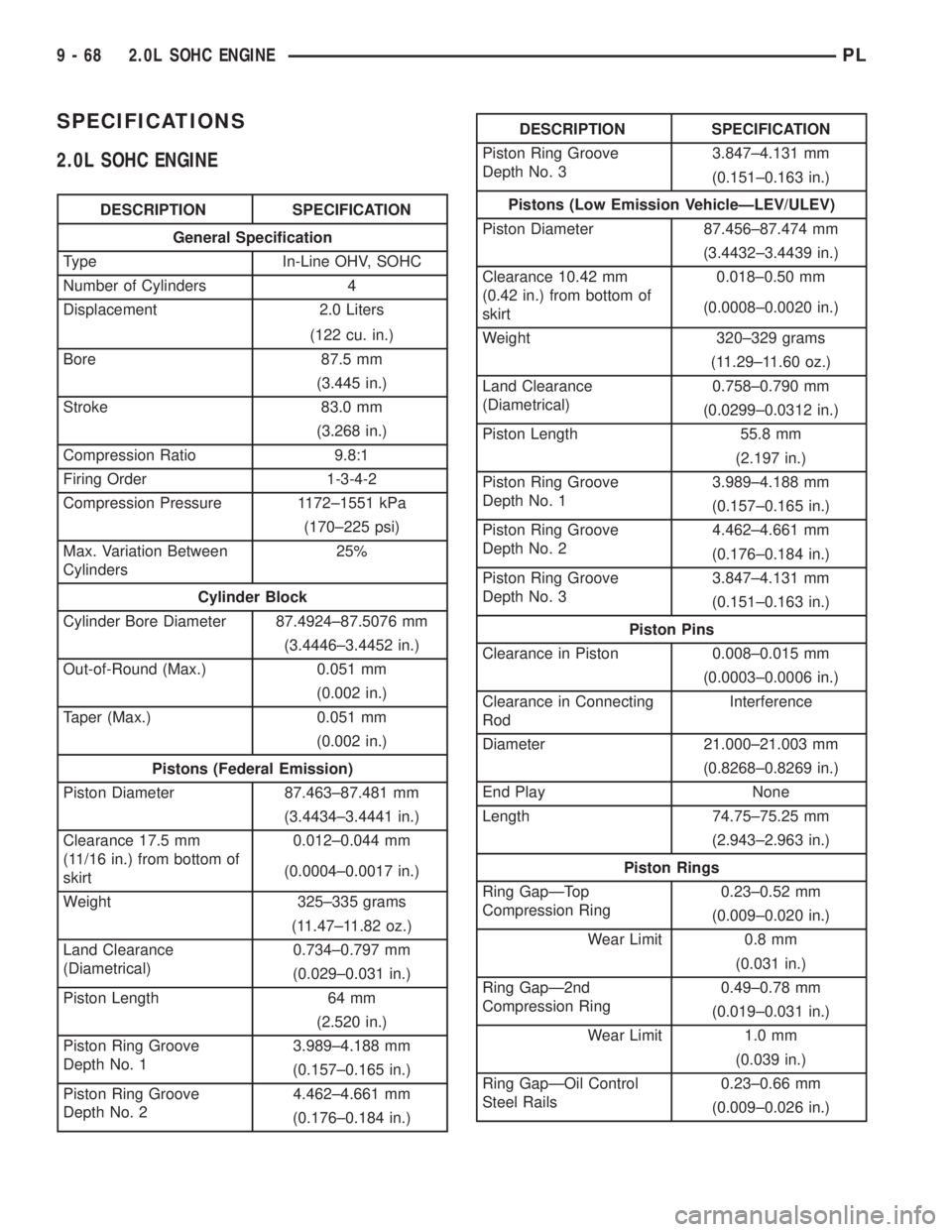

SPECIFICATIONS

2.0L SOHC ENGINE

DESCRIPTION SPECIFICATION

General Specification

Type In-Line OHV, SOHC

Number of Cylinders 4

Displacement 2.0 Liters

(122 cu. in.)

Bore 87.5 mm

(3.445 in.)

Stroke 83.0 mm

(3.268 in.)

Compression Ratio 9.8:1

Firing Order 1-3-4-2

Compression Pressure 1172±1551 kPa

(170±225 psi)

Max. Variation Between

Cylinders25%

Cylinder Block

Cylinder Bore Diameter 87.4924±87.5076 mm

(3.4446±3.4452 in.)

Out-of-Round (Max.) 0.051 mm

(0.002 in.)

Taper (Max.) 0.051 mm

(0.002 in.)

Pistons (Federal Emission)

Piston Diameter 87.463±87.481 mm

(3.4434±3.4441 in.)

Clearance 17.5 mm

(11/16 in.) from bottom of

skirt0.012±0.044 mm

(0.0004±0.0017 in.)

Weight 325±335 grams

(11.47±11.82 oz.)

Land Clearance

(Diametrical)0.734±0.797 mm

(0.029±0.031 in.)

Piston Length 64 mm

(2.520 in.)

Piston Ring Groove

Depth No. 13.989±4.188 mm

(0.157±0.165 in.)

Piston Ring Groove

Depth No. 24.462±4.661 mm

(0.176±0.184 in.)

DESCRIPTION SPECIFICATION

Piston Ring Groove

Depth No. 33.847±4.131 mm

(0.151±0.163 in.)

Pistons (Low Emission VehicleÐLEV/ULEV)

Piston Diameter 87.456±87.474 mm

(3.4432±3.4439 in.)

Clearance 10.42 mm

(0.42 in.) from bottom of

skirt0.018±0.50 mm

(0.0008±0.0020 in.)

Weight 320±329 grams

(11.29±11.60 oz.)

Land Clearance

(Diametrical)0.758±0.790 mm

(0.0299±0.0312 in.)

Piston Length 55.8 mm

(2.197 in.)

Piston Ring Groove

Depth No. 13.989±4.188 mm

(0.157±0.165 in.)

Piston Ring Groove

Depth No. 24.462±4.661 mm

(0.176±0.184 in.)

Piston Ring Groove

Depth No. 33.847±4.131 mm

(0.151±0.163 in.)

Piston Pins

Clearance in Piston 0.008±0.015 mm

(0.0003±0.0006 in.)

Clearance in Connecting

RodInterference

Diameter 21.000±21.003 mm

(0.8268±0.8269 in.)

End Play None

Length 74.75±75.25 mm

(2.943±2.963 in.)

Piston Rings

Ring GapÐTop

Compression Ring0.23±0.52 mm

(0.009±0.020 in.)

Wear Limit 0.8 mm

(0.031 in.)

Ring GapÐ2nd

Compression Ring0.49±0.78 mm

(0.019±0.031 in.)

Wear Limit 1.0 mm

(0.039 in.)

Ring GapÐOil Control

Steel Rails0.23±0.66 mm

(0.009±0.026 in.)

9 - 68 2.0L SOHC ENGINEPL

Page 792 of 1285

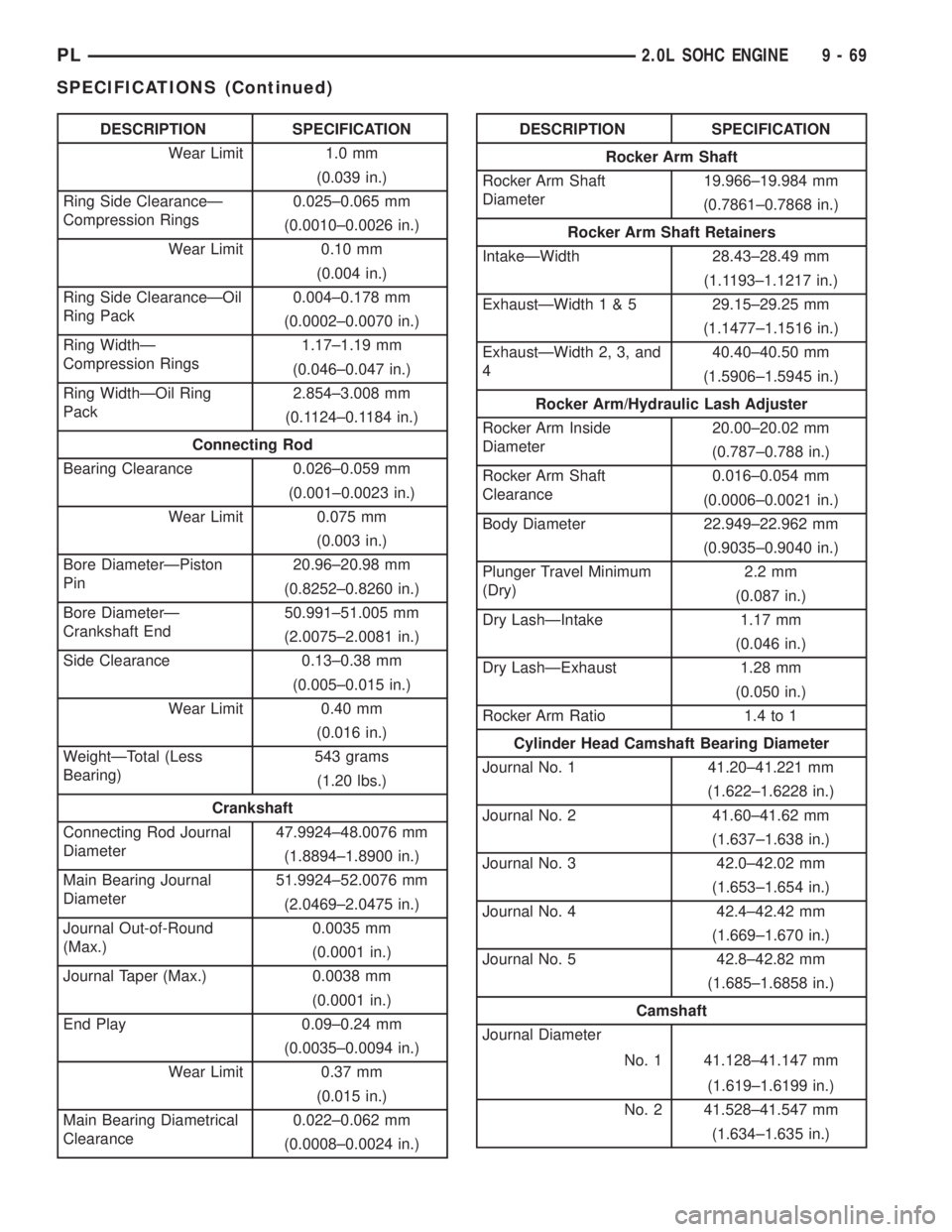

DESCRIPTION SPECIFICATION

Wear Limit 1.0 mm

(0.039 in.)

Ring Side ClearanceÐ

Compression Rings0.025±0.065 mm

(0.0010±0.0026 in.)

Wear Limit 0.10 mm

(0.004 in.)

Ring Side ClearanceÐOil

Ring Pack0.004±0.178 mm

(0.0002±0.0070 in.)

Ring WidthÐ

Compression Rings1.17±1.19 mm

(0.046±0.047 in.)

Ring WidthÐOil Ring

Pack2.854±3.008 mm

(0.1124±0.1184 in.)

Connecting Rod

Bearing Clearance 0.026±0.059 mm

(0.001±0.0023 in.)

Wear Limit 0.075 mm

(0.003 in.)

Bore DiameterÐPiston

Pin20.96±20.98 mm

(0.8252±0.8260 in.)

Bore DiameterÐ

Crankshaft End50.991±51.005 mm

(2.0075±2.0081 in.)

Side Clearance 0.13±0.38 mm

(0.005±0.015 in.)

Wear Limit 0.40 mm

(0.016 in.)

WeightÐTotal (Less

Bearing)543 grams

(1.20 lbs.)

Crankshaft

Connecting Rod Journal

Diameter47.9924±48.0076 mm

(1.8894±1.8900 in.)

Main Bearing Journal

Diameter51.9924±52.0076 mm

(2.0469±2.0475 in.)

Journal Out-of-Round

(Max.)0.0035 mm

(0.0001 in.)

Journal Taper (Max.) 0.0038 mm

(0.0001 in.)

End Play 0.09±0.24 mm

(0.0035±0.0094 in.)

Wear Limit 0.37 mm

(0.015 in.)

Main Bearing Diametrical

Clearance0.022±0.062 mm

(0.0008±0.0024 in.)DESCRIPTION SPECIFICATION

Rocker Arm Shaft

Rocker Arm Shaft

Diameter19.966±19.984 mm

(0.7861±0.7868 in.)

Rocker Arm Shaft Retainers

IntakeÐWidth 28.43±28.49 mm

(1.1193±1.1217 in.)

ExhaustÐWidth1&529.15±29.25 mm

(1.1477±1.1516 in.)

ExhaustÐWidth 2, 3, and

440.40±40.50 mm

(1.5906±1.5945 in.)

Rocker Arm/Hydraulic Lash Adjuster

Rocker Arm Inside

Diameter20.00±20.02 mm

(0.787±0.788 in.)

Rocker Arm Shaft

Clearance0.016±0.054 mm

(0.0006±0.0021 in.)

Body Diameter 22.949±22.962 mm

(0.9035±0.9040 in.)

Plunger Travel Minimum

(Dry)2.2 mm

(0.087 in.)

Dry LashÐIntake 1.17 mm

(0.046 in.)

Dry LashÐExhaust 1.28 mm

(0.050 in.)

Rocker Arm Ratio 1.4 to 1

Cylinder Head Camshaft Bearing Diameter

Journal No. 1 41.20±41.221 mm

(1.622±1.6228 in.)

Journal No. 2 41.60±41.62 mm

(1.637±1.638 in.)

Journal No. 3 42.0±42.02 mm

(1.653±1.654 in.)

Journal No. 4 42.4±42.42 mm

(1.669±1.670 in.)

Journal No. 5 42.8±42.82 mm

(1.685±1.6858 in.)

Camshaft

Journal Diameter

No. 1 41.128±41.147 mm

(1.619±1.6199 in.)

No. 2 41.528±41.547 mm

(1.634±1.635 in.)

PL2.0L SOHC ENGINE 9 - 69

SPECIFICATIONS (Continued)

Page 831 of 1285

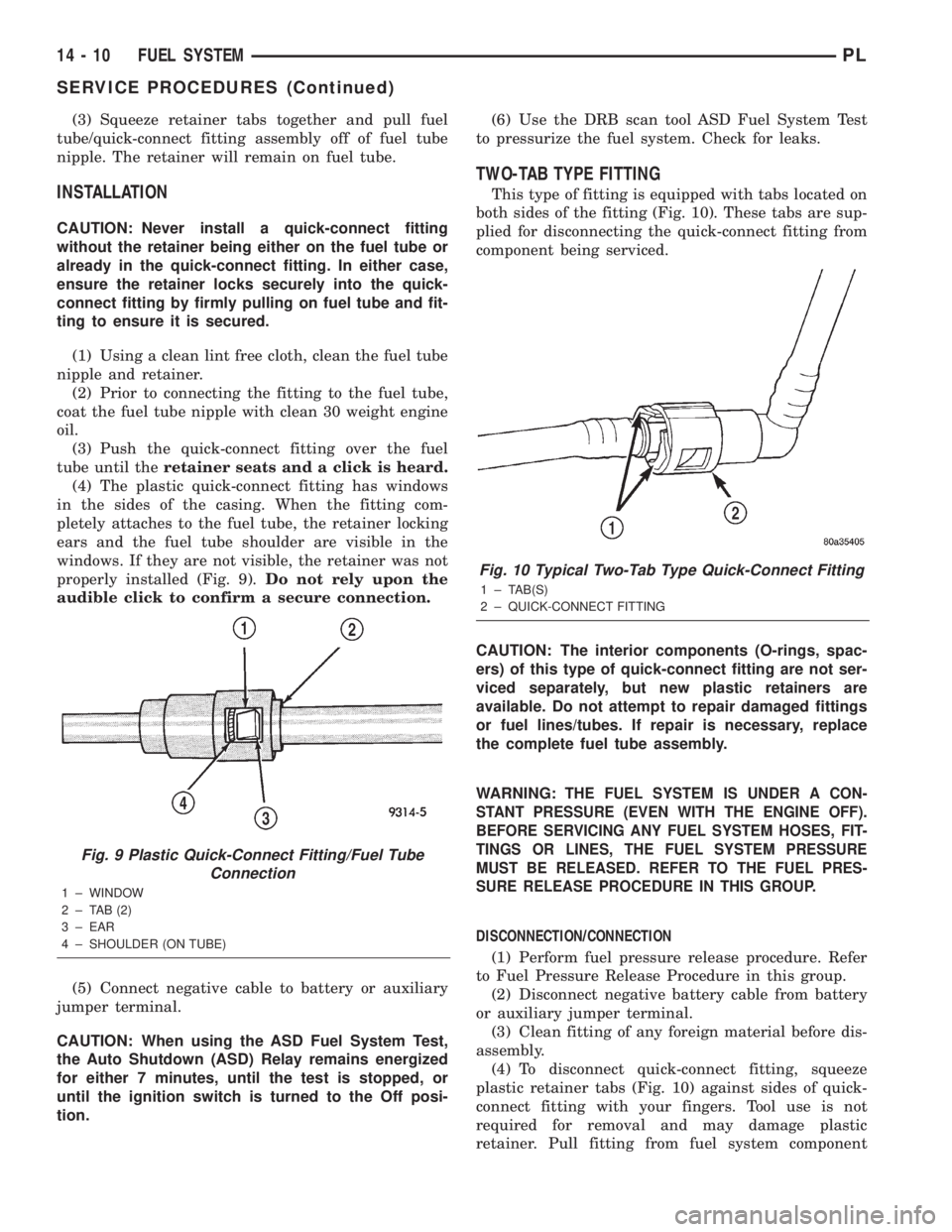

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 9).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 10). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

WARNING:

THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES, FIT-

TINGS OR LINES, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 10) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

Fig. 9 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 ± WINDOW

2 ± TAB (2)

3 ± EAR

4 ± SHOULDER (ON TUBE)

Fig. 10 Typical Two-Tab Type Quick-Connect Fitting

1 ± TAB(S)

2 ± QUICK-CONNECT FITTING

14 - 10 FUEL SYSTEMPL

SERVICE PROCEDURES (Continued)

Page 851 of 1285

signal to the PCM, allowing engine starter operation.

The interlock switch is not adjustable.

Clutch Pedal Upstop Switch

With the clutch pedal at rest, the clutch pedal

upstop switch is closed, allowing speed control oper-

ation. When the clutch pedal is depressed, the upstop

switch opens and signals the PCM to cancel speed

control operation, and enter a modified engine cali-

bration schedule to improve driveability during gear-

to-gear shifts. The upstop switch is not adjustable.

CRANKSHAFT POSITION SENSORÐPCM

INPUT

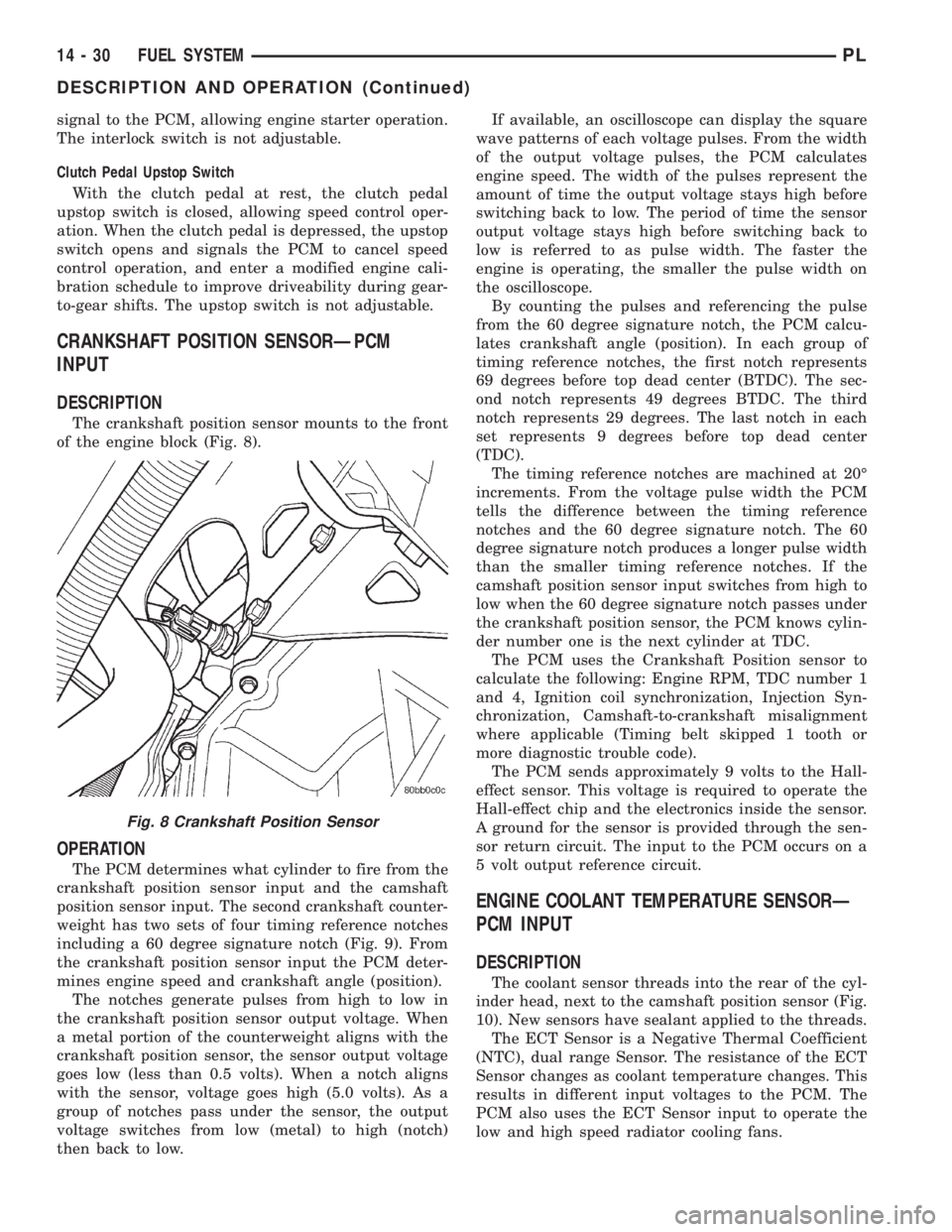

DESCRIPTION

The crankshaft position sensor mounts to the front

of the engine block (Fig. 8).

OPERATION

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 9). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The PCM uses the Crankshaft Position sensor to

calculate the following: Engine RPM, TDC number 1

and 4, Ignition coil synchronization, Injection Syn-

chronization, Camshaft-to-crankshaft misalignment

where applicable (Timing belt skipped 1 tooth or

more diagnostic trouble code).

The PCM sends approximately 9 volts to the Hall-

effect sensor. This voltage is required to operate the

Hall-effect chip and the electronics inside the sensor.

A ground for the sensor is provided through the sen-

sor return circuit. The input to the PCM occurs on a

5 volt output reference circuit.

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT

DESCRIPTION

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

10). New sensors have sealant applied to the threads.

The ECT Sensor is a Negative Thermal Coefficient

(NTC), dual range Sensor. The resistance of the ECT

Sensor changes as coolant temperature changes. This

results in different input voltages to the PCM. The

PCM also uses the ECT Sensor input to operate the

low and high speed radiator cooling fans.

Fig. 8 Crankshaft Position Sensor

14 - 30 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 895 of 1285

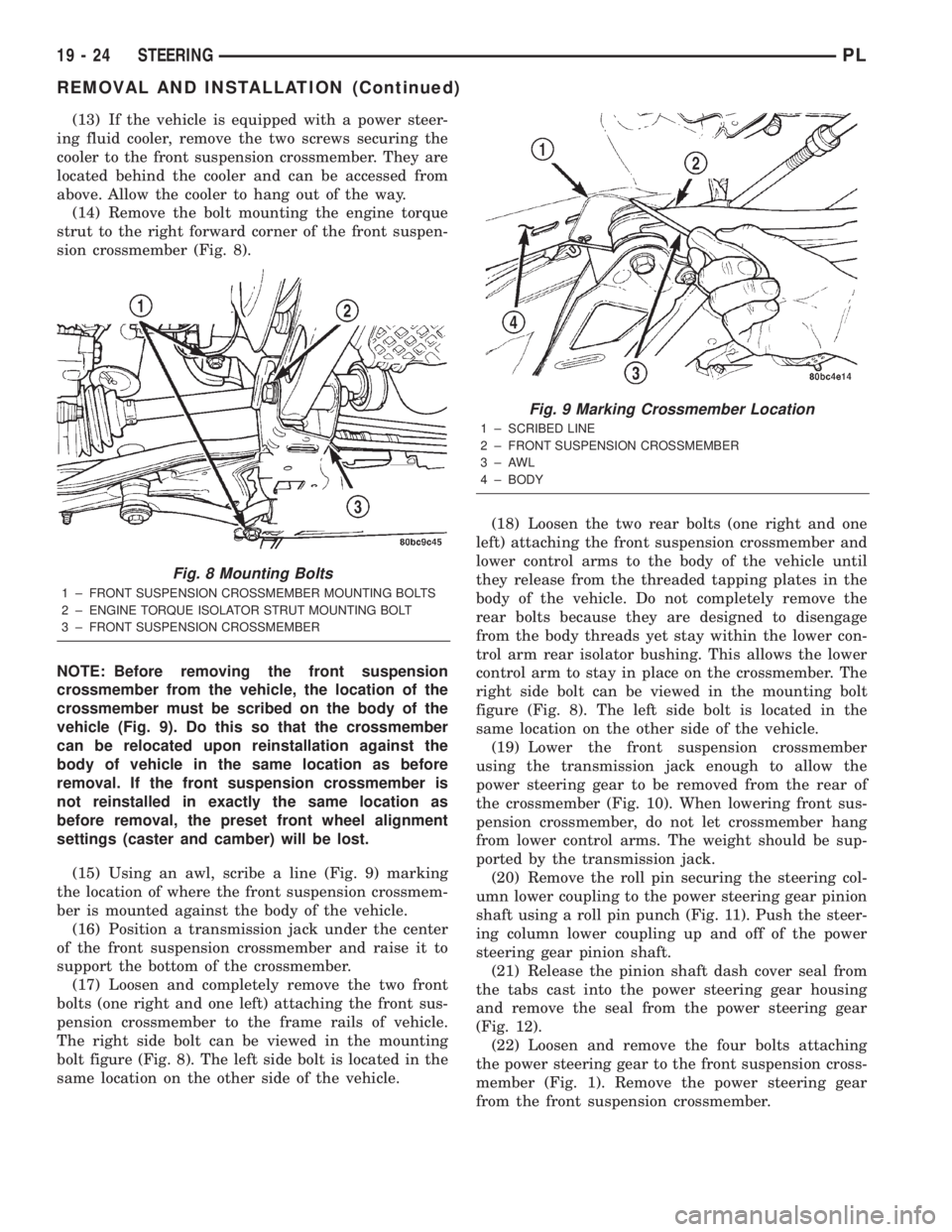

(13) If the vehicle is equipped with a power steer-

ing fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

(14) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 8).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(15) Using an awl, scribe a line (Fig. 9) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(16) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(17) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.(18) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.

(19) Lower the front suspension crossmember

using the transmission jack enough to allow the

power steering gear to be removed from the rear of

the crossmember (Fig. 10). When lowering front sus-

pension crossmember, do not let crossmember hang

from lower control arms. The weight should be sup-

ported by the transmission jack.

(20) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 11). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

(21) Release the pinion shaft dash cover seal from

the tabs cast into the power steering gear housing

and remove the seal from the power steering gear

(Fig. 12).

(22) Loosen and remove the four bolts attaching

the power steering gear to the front suspension cross-

member (Fig. 1). Remove the power steering gear

from the front suspension crossmember.

Fig. 8 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 9 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

19 - 24 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 903 of 1285

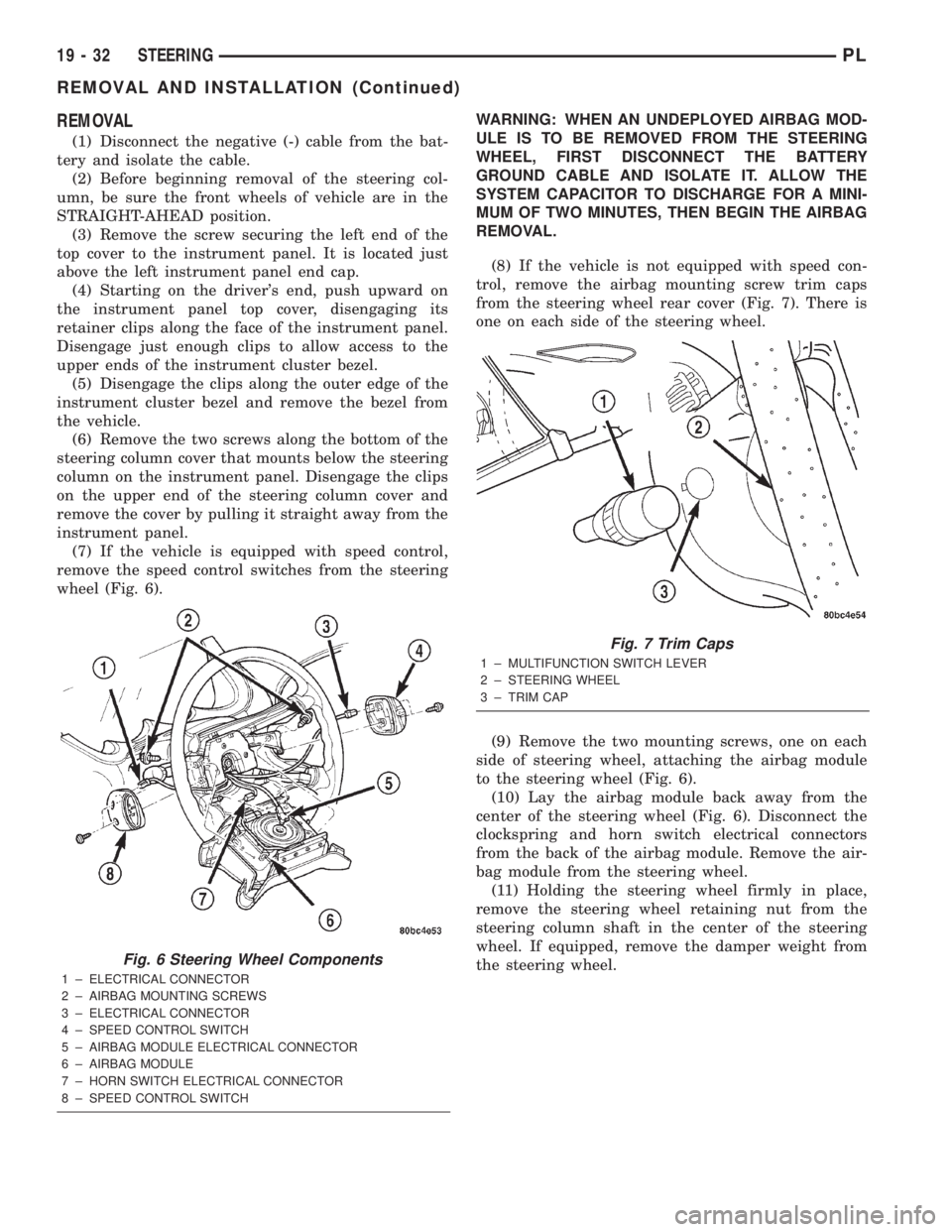

REMOVAL

(1) Disconnect the negative (-) cable from the bat-

tery and isolate the cable.

(2) Before beginning removal of the steering col-

umn, be sure the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

(3) Remove the screw securing the left end of the

top cover to the instrument panel. It is located just

above the left instrument panel end cap.

(4) Starting on the driver's end, push upward on

the instrument panel top cover, disengaging its

retainer clips along the face of the instrument panel.

Disengage just enough clips to allow access to the

upper ends of the instrument cluster bezel.

(5) Disengage the clips along the outer edge of the

instrument cluster bezel and remove the bezel from

the vehicle.

(6) Remove the two screws along the bottom of the

steering column cover that mounts below the steering

column on the instrument panel. Disengage the clips

on the upper end of the steering column cover and

remove the cover by pulling it straight away from the

instrument panel.

(7) If the vehicle is equipped with speed control,

remove the speed control switches from the steering

wheel (Fig. 6).WARNING: WHEN AN UNDEPLOYED AIRBAG MOD-

ULE IS TO BE REMOVED FROM THE STEERING

WHEEL, FIRST DISCONNECT THE BATTERY

GROUND CABLE AND ISOLATE IT. ALLOW THE

SYSTEM CAPACITOR TO DISCHARGE FOR A MINI-

MUM OF TWO MINUTES, THEN BEGIN THE AIRBAG

REMOVAL.

(8) If the vehicle is not equipped with speed con-

trol, remove the airbag mounting screw trim caps

from the steering wheel rear cover (Fig. 7). There is

one on each side of the steering wheel.

(9) Remove the two mounting screws, one on each

side of steering wheel, attaching the airbag module

to the steering wheel (Fig. 6).

(10) Lay the airbag module back away from the

center of the steering wheel (Fig. 6). Disconnect the

clockspring and horn switch electrical connectors

from the back of the airbag module. Remove the air-

bag module from the steering wheel.

(11) Holding the steering wheel firmly in place,

remove the steering wheel retaining nut from the

steering column shaft in the center of the steering

wheel. If equipped, remove the damper weight from

the steering wheel.

Fig. 6 Steering Wheel Components

1 ± ELECTRICAL CONNECTOR

2 ± AIRBAG MOUNTING SCREWS

3 ± ELECTRICAL CONNECTOR

4 ± SPEED CONTROL SWITCH

5 ± AIRBAG MODULE ELECTRICAL CONNECTOR

6 ± AIRBAG MODULE

7 ± HORN SWITCH ELECTRICAL CONNECTOR

8 ± SPEED CONTROL SWITCH

Fig. 7 Trim Caps

1 ± MULTIFUNCTION SWITCH LEVER

2 ± STEERING WHEEL

3 ± TRIM CAP

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 910 of 1285

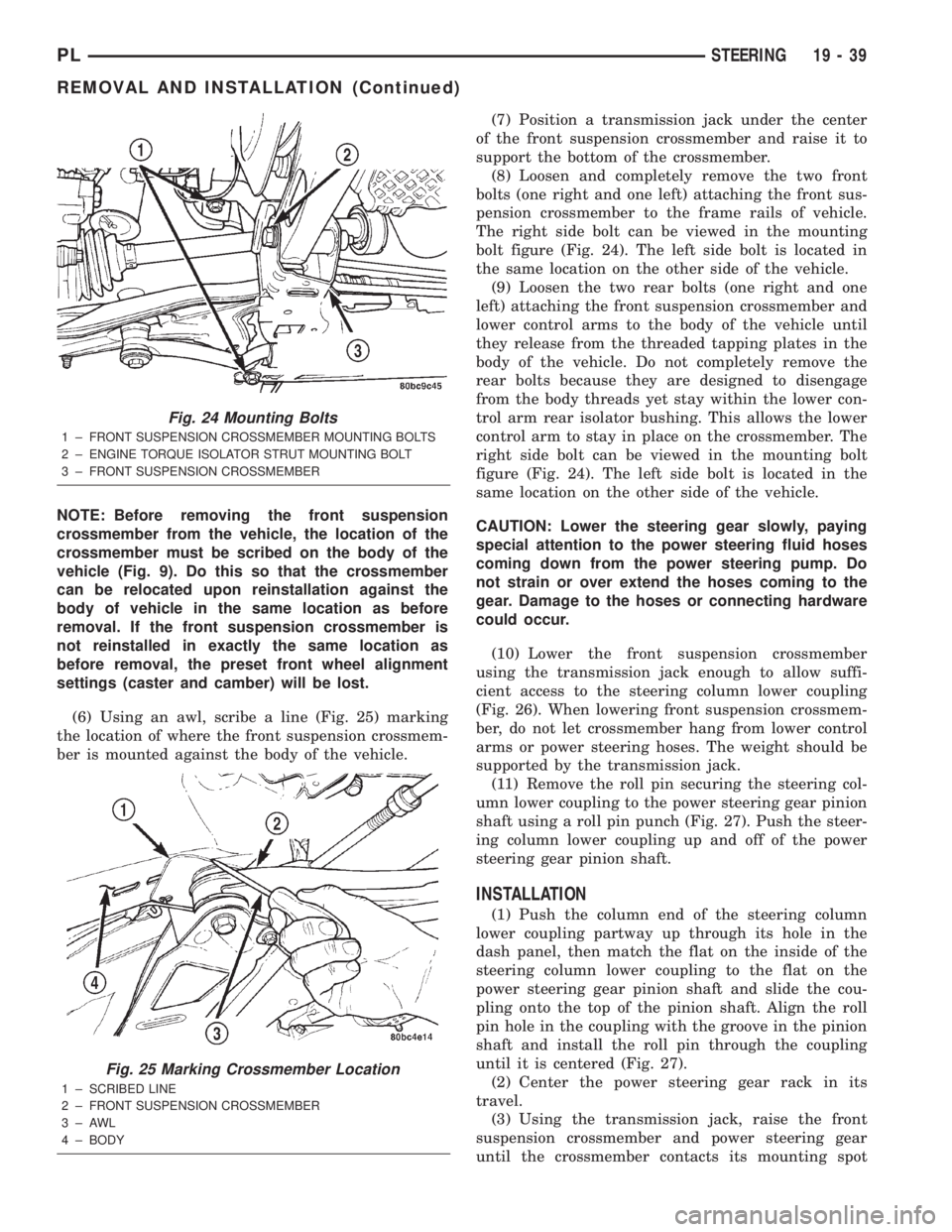

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(6) Using an awl, scribe a line (Fig. 25) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.(7) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(8) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 24). The left side bolt is located in

the same location on the other side of the vehicle.

(9) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle.

CAUTION: Lower the steering gear slowly, paying

special attention to the power steering fluid hoses

coming down from the power steering pump. Do

not strain or over extend the hoses coming to the

gear. Damage to the hoses or connecting hardware

could occur.

(10) Lower the front suspension crossmember

using the transmission jack enough to allow suffi-

cient access to the steering column lower coupling

(Fig. 26). When lowering front suspension crossmem-

ber, do not let crossmember hang from lower control

arms or power steering hoses. The weight should be

supported by the transmission jack.

(11) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 27). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

INSTALLATION

(1) Push the column end of the steering column

lower coupling partway up through its hole in the

dash panel, then match the flat on the inside of the

steering column lower coupling to the flat on the

power steering gear pinion shaft and slide the cou-

pling onto the top of the pinion shaft. Align the roll

pin hole in the coupling with the groove in the pinion

shaft and install the roll pin through the coupling

until it is centered (Fig. 27).

(2) Center the power steering gear rack in its

travel.

(3) Using the transmission jack, raise the front

suspension crossmember and power steering gear

until the crossmember contacts its mounting spot

Fig. 24 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 25 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)