motor DODGE NEON 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 366 of 1285

SERVICE PROCEDURES

DOUBLE ACTIVATION UNLOCK

The toggling of the double activation unlock fea-

ture (between enabled and disabled) can be per-

formed with the use of the DRB IIItscan tool, or by

the customer.

DRB lllTPROGRAMMING

When using the DRB IIItscan tool, select:

(1) ªTheft Alarmº

(2) ªVTSSº

(3) ªMiscellaneousº

and then the desired function.

CUSTOMER PROGRAMMING

(1) Open the driver door, sit in the driver seat, and

close the driver door.

(2) Turn the ignition switch to the RUN position

(without starting the vehicle) and then back to OFF.

Repeat this step three additional times (for a total of

four key ON/OFF cycles).

(3) Within ten seconds of switching the ignition

switch to the OFF position for the last time (at the

end of the fourth cycle in the above step), press the

driver interior door lock switch to UNLOCK.

(4) A single chime will be heard to verify that the

customer programmable toggle of the double activa-

tion unlock was successfully completed.

NOTE: When toggling the double activation unlock

feature (customer programmable), the toggle that

happens will be from the last state of the double

activation unlock. If the double activation unlock

feature was enabled, after the toggle process, it will

now be disabled and vice versa. There is no telltale

to inform you of which state the double activation

unlock feature is in.

ROLLING DOOR LOCKS

The toggling of the rolling door lock feature

(between enabled and disabled) can be performed

with the use of the DRB IIItscan tool or by the cus-

tomer.

DRB lllTPROGRAMMING

When using the DRB IIItscan tool, select:

(1) ªTheft Alarmº

(2) ªVTSSº(3) ªMiscellaneousº

and then the desired function.

CUSTOMER PROGRAMMING

(1) Open the driver door, sit in the driver seat, and

close the driver door.

(2) Turn the ignition switch to the RUN position

(without starting the vehicle) and then back to OFF.

Repeat this step three additional times (for a total of

four key ON/OFF cycles).

(3) Within ten seconds of switching the ignition

switch to the OFF position for the last time (at the

end of the fourth cycle in the above step), press the

driver interior door lock switch to LOCK.

(4) A single chime will be heard to verify that the

customer programmable toggle of the rolling door

locks was successfully completed.

NOTE: When toggling the rolling door locks (cus-

tomer programmable), the toggle that happens will

be from the last state of the rolling door locks. If

the rolling door locks were enabled, after the toggle

process, they will now be disabled and vice versa.

There is no telltale to inform you of which state the

rolling door locks are in.

REMOVAL AND INSTALLATION

DOOR LOCK MOTOR/LATCH

Refer to Group 23-Body, Front Door Latch Removal

and Installation.

DOOR LOCK SWITCH

REMOVAL

(1) Remove front door trim panel, refer to Group

23-Body, for Front Door Trim Panel Removal and

Installation.

(2) Disconnect wire connector.

(3) Remove two attaching screws.

(4) Remove the switch.

INSTALLATION

For installation, reverse the above procedures.

REMOTE KEYLESS ENTRY (RKE) MODULE

Refer to RKE Module Removal and Installation

under Remote Keyless Entry in this section.

PLPOWER LOCK SYSTEMS 8P - 3

Page 380 of 1285

POWER WINDOWS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

WIRING TEST............................1

WINDOW SWITCH........................1WINDOW MOTOR.........................1

REMOVAL AND INSTALLATION

WINDOW SWITCH........................2

WINDOW MOTOR.........................2

DESCRIPTION AND OPERATION

INTRODUCTION

The window lift motors are of the permanent mag-

net type. A battery positive and negative connection

to either of the two motor terminals will cause the

motor to rotate in one direction. Reversing current

through these same two connections will cause the

motor to rotate in the opposite direction.

Each individual motor is grounded through the

master switch.

DIAGNOSIS AND TESTING

WIRING TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the power window switches.

Remove switch for testing. Connect a voltmeter

positive lead to Pin 4 and negative lead to Pin 3 of

the switch harness connector. Turn ignition switch to

the ON position. Voltmeter should read battery volt-

age. If OK, go to Window Switch Diagnosis and Test-

ing. If not OK, check the 30 amp circuit breaker in

the fuse block or for a broken wire. Refer to Group

8W-Wiring Diagrams, for Connector Pin-Outs and

circuit descriptions.

WINDOW SWITCH

Remove the switch from its mounting, refer to Win-

dow Switch Removal and Installation in this section.

Using an ohmmeter, test the window switch for con-

tinuity in all positions Refer to Power Window

Switch Continuity table to determine if continuity is

correct. If the results are not obtained, replace the

switch.

WINDOW MOTOR

(1) Remove door trim panel. Refer to Group

23-Body, Front Door Trim Panel Removal and Instal-

lation.

(2) Connect positive (+) lead from a test battery to

either of the two motor terminals.

(3) Connect negative (-) lead from test battery to

remaining motor terminal.

(4) The motor should now rotate in one direction to

either move window up or down.

(a) If window happens to already be in full UP

position and motor is connected so as to move it in

UP direction no movement will be observed.

(b) Likewise, motor connected to move window

in DOWN direction no movement will be observed

if window is already in full DOWN position.

(c) Reverse battery leads in Step 2 and Step 3

and window should now move. If window does not

move, remove motor. Refer to Window Motor

Removal and Installation in this section.

(5) If window moved completely up or down, the

test leads should be reversed one more time to com-

plete a full window travel inspection.

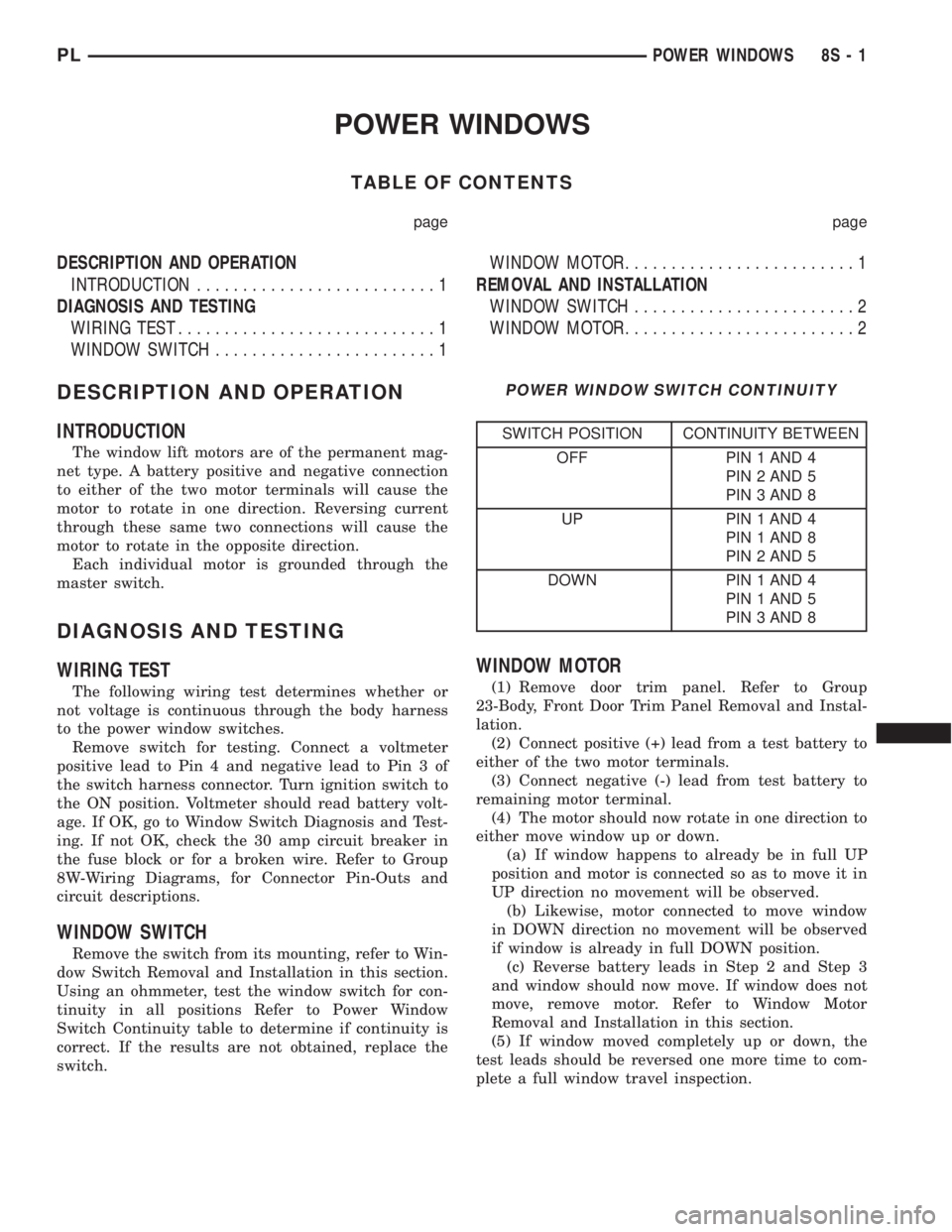

POWER WINDOW SWITCH CONTINUITY

SWITCH POSITION CONTINUITY BETWEEN

OFF PIN 1 AND 4

PIN 2 AND 5

PIN 3 AND 8

UP PIN 1 AND 4

PIN 1 AND 8

PIN 2 AND 5

DOWN PIN 1 AND 4

PIN 1 AND 5

PIN 3 AND 8

PLPOWER WINDOWS 8S - 1

Page 381 of 1285

(6) If window does not move, check to make sure

that it is free to move.

(7) It is necessary that the window be free to slide

up and down in the glass channels. If the window is

not free to move up and down, the window lift motor

will not be able to move the glass.

(8) To determine if the glass is free, disconnect the

regulator from the glass lift plate and slide the win-

dow up and down by hand.

REMOVAL AND INSTALLATION

WINDOW SWITCH

REMOVAL

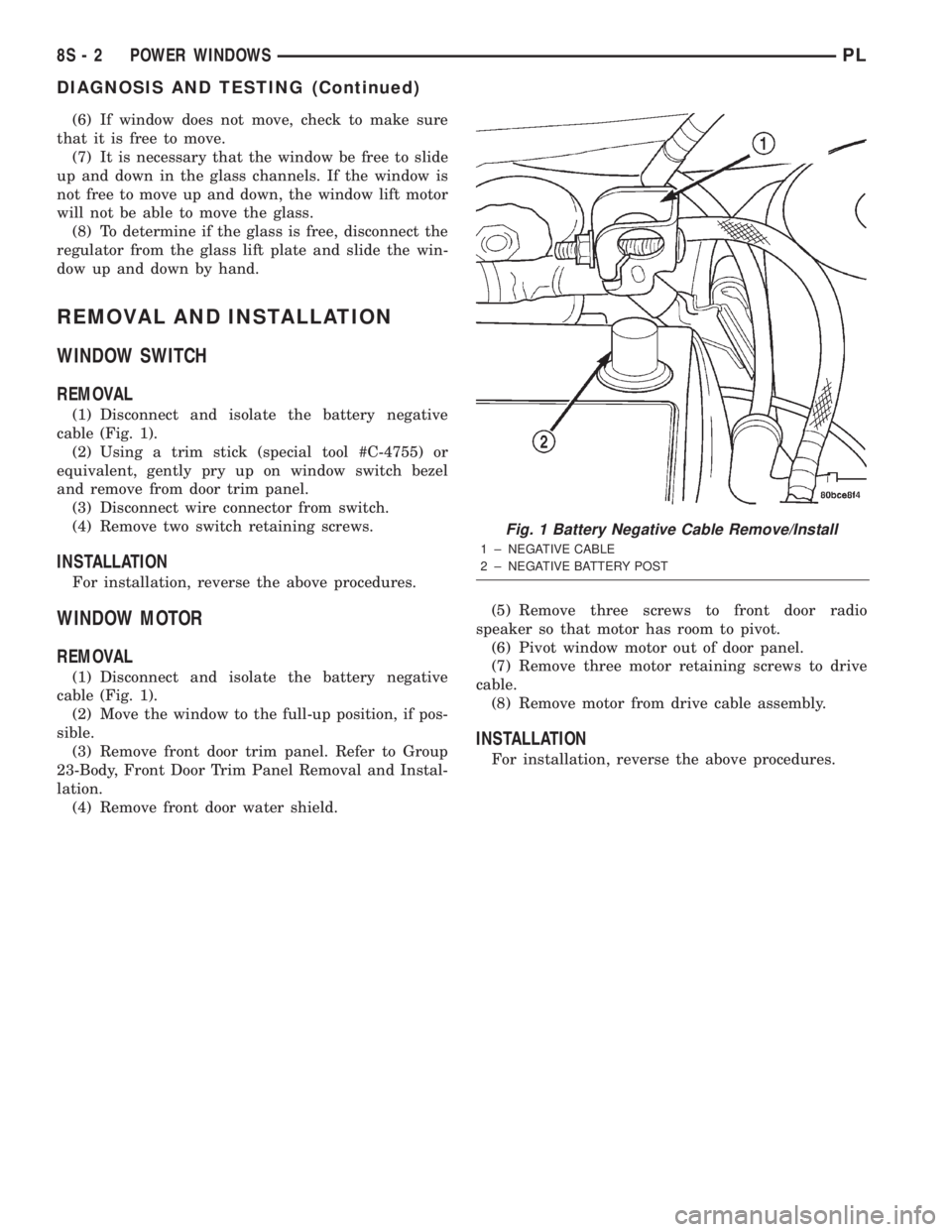

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Using a trim stick (special tool #C-4755) or

equivalent, gently pry up on window switch bezel

and remove from door trim panel.

(3) Disconnect wire connector from switch.

(4) Remove two switch retaining screws.

INSTALLATION

For installation, reverse the above procedures.

WINDOW MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Move the window to the full-up position, if pos-

sible.

(3) Remove front door trim panel. Refer to Group

23-Body, Front Door Trim Panel Removal and Instal-

lation.

(4) Remove front door water shield.(5) Remove three screws to front door radio

speaker so that motor has room to pivot.

(6) Pivot window motor out of door panel.

(7) Remove three motor retaining screws to drive

cable.

(8) Remove motor from drive cable assembly.

INSTALLATION

For installation, reverse the above procedures.

Fig. 1 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

8S - 2 POWER WINDOWSPL

DIAGNOSIS AND TESTING (Continued)

Page 382 of 1285

POWER MIRRORS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST....................1

POWER MIRROR MOTOR..................2

REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS

ASSEMBLY.............................2INSIDE MIRROR/READING LAMPS

BULB/LENS............................3

MIRROR SWITCH.........................3

POWER MIRROR ASSEMBLY................3

DESCRIPTION AND OPERATION

INTRODUCTION

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located on the driver's door trim

panel. The push button rocker switch uses L (left)

and R (right) for mirror selection and a button to

push for the desired direction of mirror movement.

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately.

The Ignition Off Draw fuse is included in the

power mirror circuity and should be checked if the

mirrors are inoperative.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position. Refer to Mirror Switch Removal and Instal-

lation in this section.

(2) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Mirror

Switch Continuity table.

(3) If test results are not obtained as shown in the

Mirror Switch Continuity table, replace the switch.

Refer to Group 8W-Wiring Diagrams for Connector

Pin-Outs and Circuit Diagrams.

PLPOWER MIRRORS 8T - 1

Page 383 of 1285

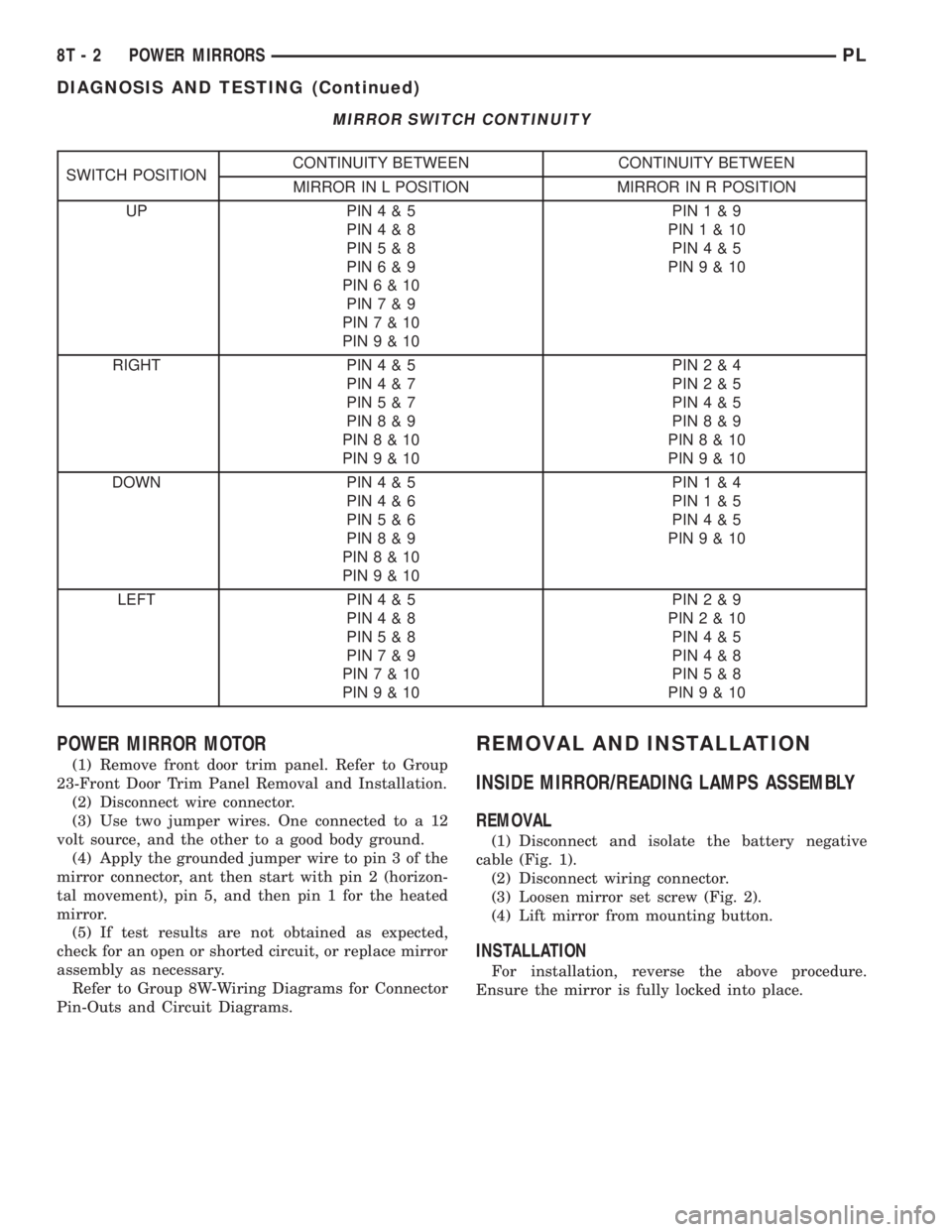

MIRROR SWITCH CONTINUITY

SWITCH POSITIONCONTINUITY BETWEEN CONTINUITY BETWEEN

MIRROR IN L POSITION MIRROR IN R POSITION

UP PIN4&5

PIN4&8

PIN5&8

PIN6&9

PIN6&10

PIN7&9

PIN7&10

PIN9&10PIN1&9

PIN1&10

PIN4&5

PIN9&10

RIGHT PIN4&5

PIN4&7

PIN5&7

PIN8&9

PIN8&10

PIN9&10PIN2&4

PIN2&5

PIN4&5

PIN8&9

PIN8&10

PIN9&10

DOWN PIN4&5

PIN4&6

PIN5&6

PIN8&9

PIN8&10

PIN9&10PIN1&4

PIN1&5

PIN4&5

PIN9&10

LEFT PIN4&5

PIN4&8

PIN5&8

PIN7&9

PIN7&10

PIN9&10PIN2&9

PIN2&10

PIN4&5

PIN4&8

PIN5&8

PIN9&10

POWER MIRROR MOTOR

(1) Remove front door trim panel. Refer to Group

23-Front Door Trim Panel Removal and Installation.

(2) Disconnect wire connector.

(3) Use two jumper wires. One connected to a 12

volt source, and the other to a good body ground.

(4) Apply the grounded jumper wire to pin 3 of the

mirror connector, ant then start with pin 2 (horizon-

tal movement), pin 5, and then pin 1 for the heated

mirror.

(5) If test results are not obtained as expected,

check for an open or shorted circuit, or replace mirror

assembly as necessary.

Refer to Group 8W-Wiring Diagrams for Connector

Pin-Outs and Circuit Diagrams.

REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS ASSEMBLY

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Disconnect wiring connector.

(3) Loosen mirror set screw (Fig. 2).

(4) Lift mirror from mounting button.

INSTALLATION

For installation, reverse the above procedure.

Ensure the mirror is fully locked into place.

8T - 2 POWER MIRRORSPL

DIAGNOSIS AND TESTING (Continued)

Page 386 of 1285

POWER MIRRORS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

POWER FOLD AWAY MIRROR SWITCH TEST...1POWER FOLD AWAY MIRROR MOTOR........1

REMOVAL AND INSTALLATION

POWER FOLD-AWAY MIRROR SWITCH.......1

POWER FOLD-AWAY MIRROR...............2

GENERAL INFORMATION

INTRODUCTION

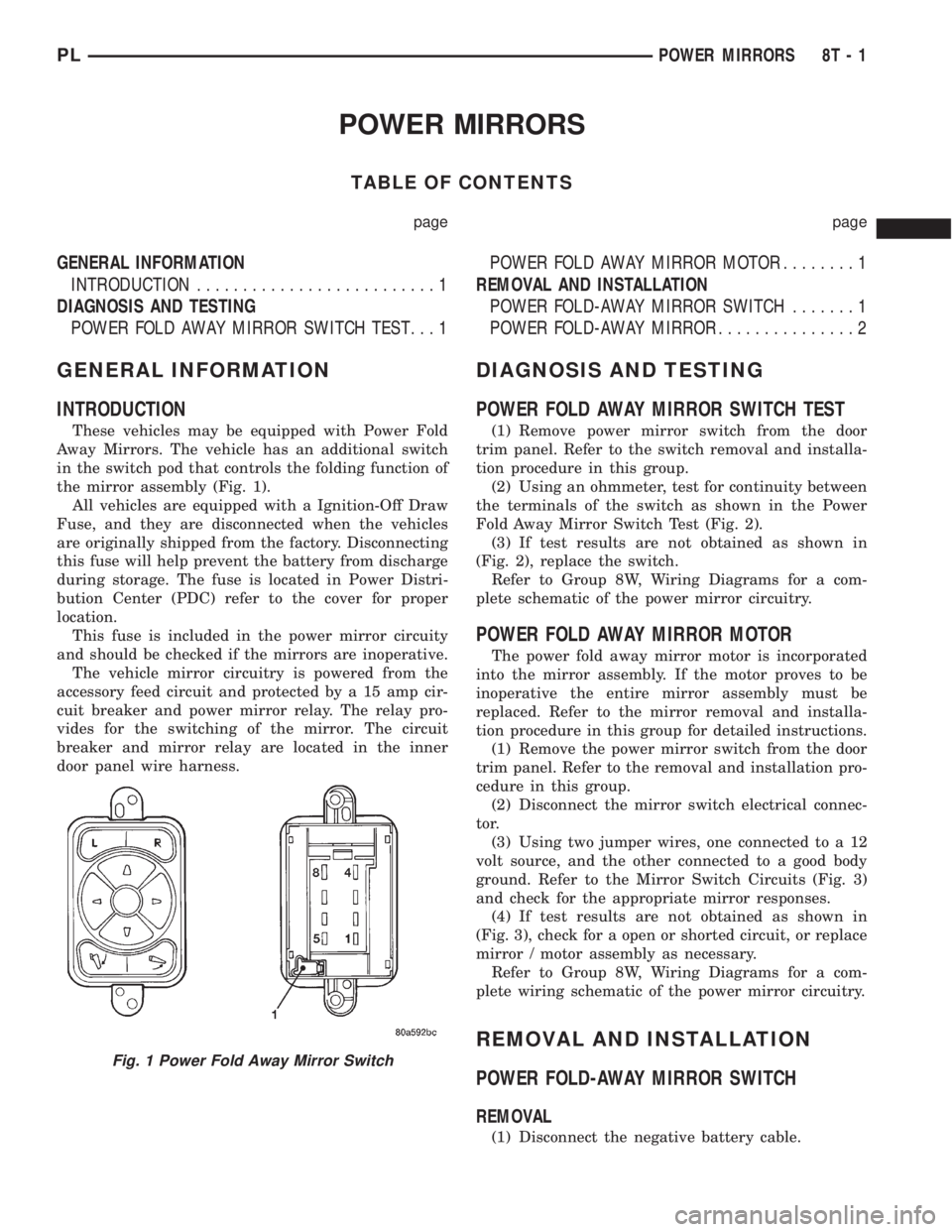

These vehicles may be equipped with Power Fold

Away Mirrors. The vehicle has an additional switch

in the switch pod that controls the folding function of

the mirror assembly (Fig. 1).

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

The vehicle mirror circuitry is powered from the

accessory feed circuit and protected by a 15 amp cir-

cuit breaker and power mirror relay. The relay pro-

vides for the switching of the mirror. The circuit

breaker and mirror relay are located in the inner

door panel wire harness.

DIAGNOSIS AND TESTING

POWER FOLD AWAY MIRROR SWITCH TEST

(1) Remove power mirror switch from the door

trim panel. Refer to the switch removal and installa-

tion procedure in this group.

(2) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Power

Fold Away Mirror Switch Test (Fig. 2).

(3) If test results are not obtained as shown in

(Fig. 2), replace the switch.

Refer to Group 8W, Wiring Diagrams for a com-

plete schematic of the power mirror circuitry.

POWER FOLD AWAY MIRROR MOTOR

The power fold away mirror motor is incorporated

into the mirror assembly. If the motor proves to be

inoperative the entire mirror assembly must be

replaced. Refer to the mirror removal and installa-

tion procedure in this group for detailed instructions.

(1) Remove the power mirror switch from the door

trim panel. Refer to the removal and installation pro-

cedure in this group.

(2) Disconnect the mirror switch electrical connec-

tor.

(3) Using two jumper wires, one connected to a 12

volt source, and the other connected to a good body

ground. Refer to the Mirror Switch Circuits (Fig. 3)

and check for the appropriate mirror responses.

(4) If test results are not obtained as shown in

(Fig. 3), check for a open or shorted circuit, or replace

mirror / motor assembly as necessary.

Refer to Group 8W, Wiring Diagrams for a com-

plete wiring schematic of the power mirror circuitry.

REMOVAL AND INSTALLATION

POWER FOLD-AWAY MIRROR SWITCH

REMOVAL

(1) Disconnect the negative battery cable.

Fig. 1 Power Fold Away Mirror Switch

PLPOWER MIRRORS 8T - 1

Page 401 of 1285

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY, AND LOOSE CLOTH-

ING.

TAKE OUTS

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component.

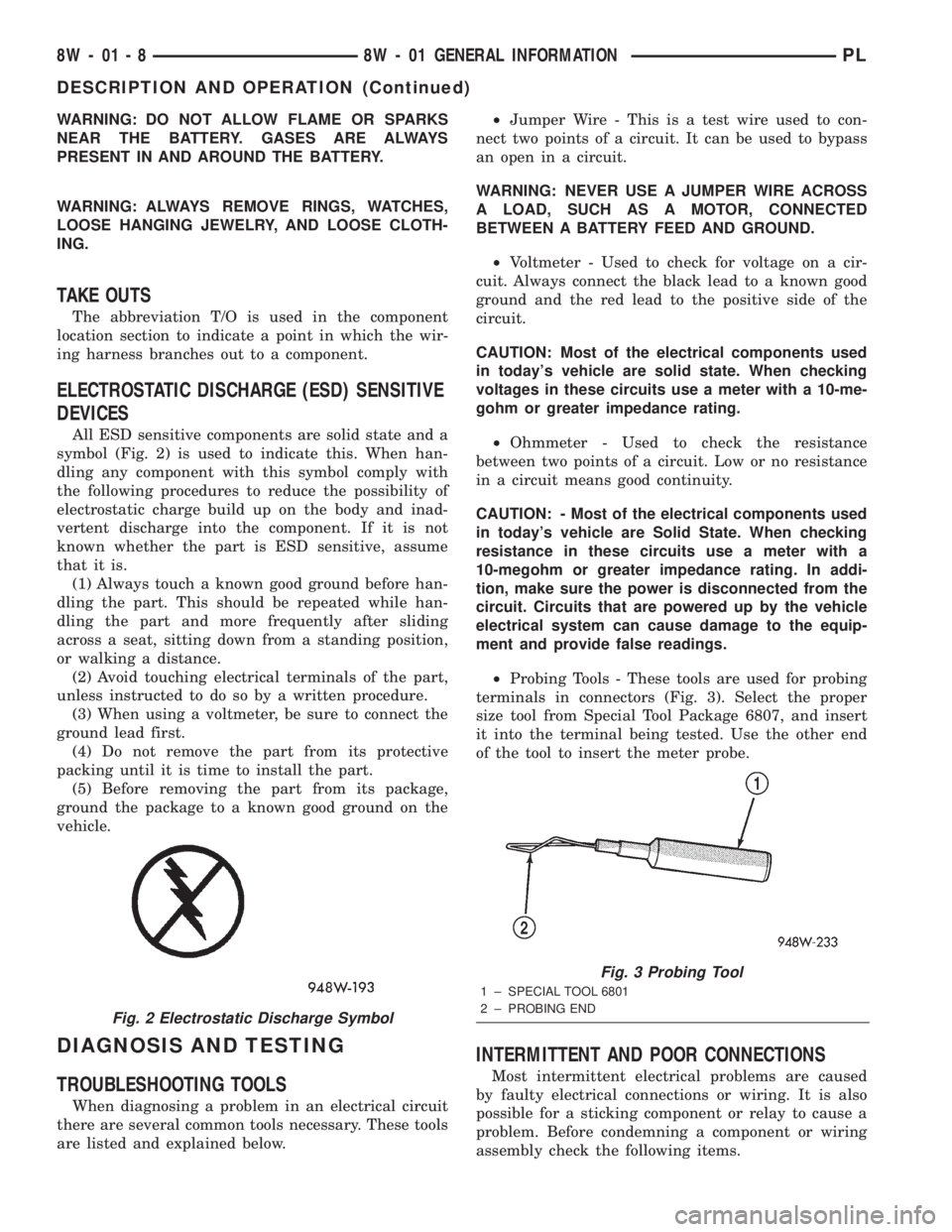

ELECTROSTATIC DISCHARGE (ESD) SENSITIVE

DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 2) is used to indicate this. When han-

dling any component with this symbol comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.

(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part from its protective

packing until it is time to install the part.

(5) Before removing the part from its package,

ground the package to a known good ground on the

vehicle.

DIAGNOSIS AND TESTING

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicle are solid state. When checking

voltages in these circuits use a meter with a 10-me-

gohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: - Most of the electrical components used

in today's vehicle are Solid State. When checking

resistance in these circuits use a meter with a

10-megohm or greater impedance rating. In addi-

tion, make sure the power is disconnected from the

circuit. Circuits that are powered up by the vehicle

electrical system can cause damage to the equip-

ment and provide false readings.

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 3). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly check the following items.

Fig. 2 Electrostatic Discharge Symbol

Fig. 3 Probing Tool

1 ± SPECIAL TOOL 6801

2 ± PROBING END

8W - 01 - 8 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 410 of 1285

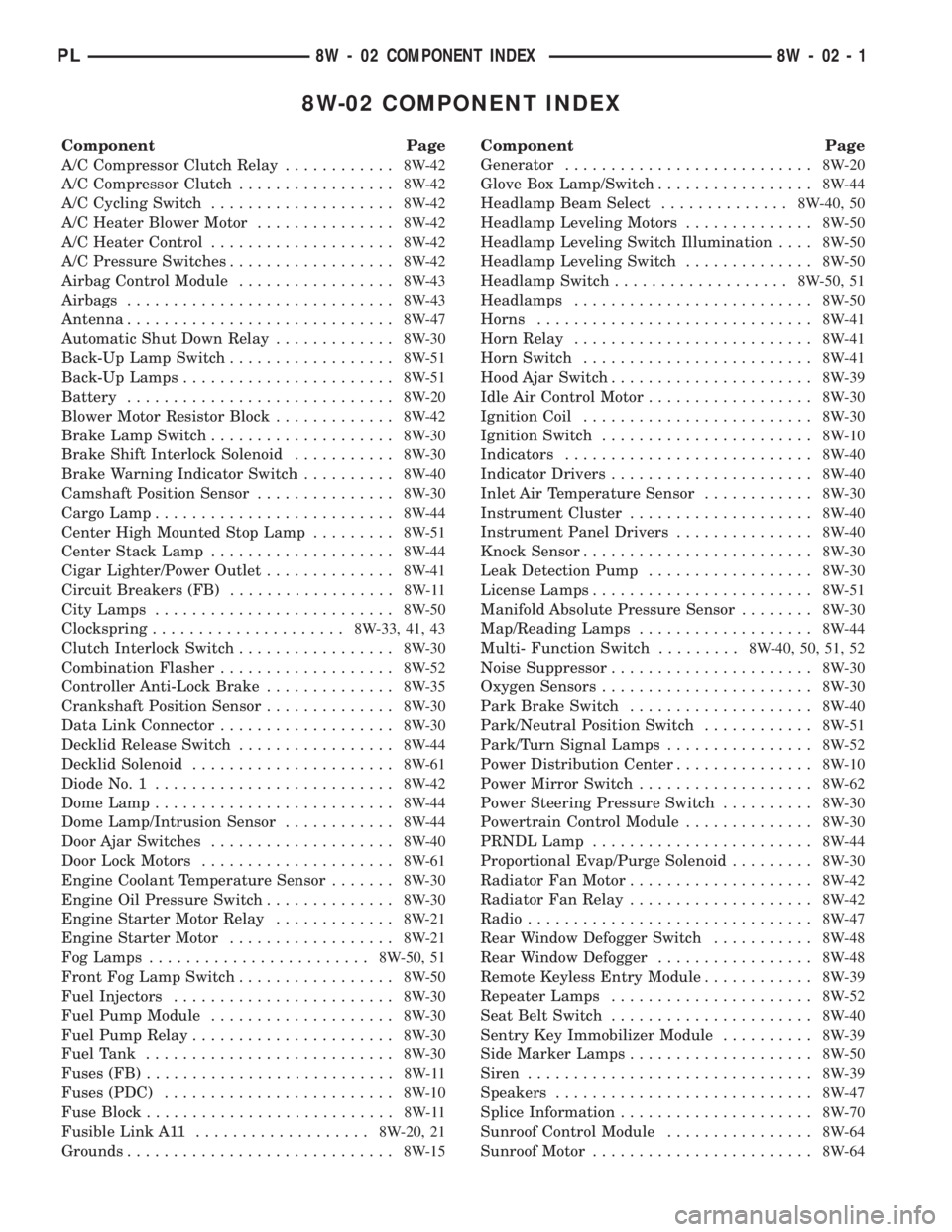

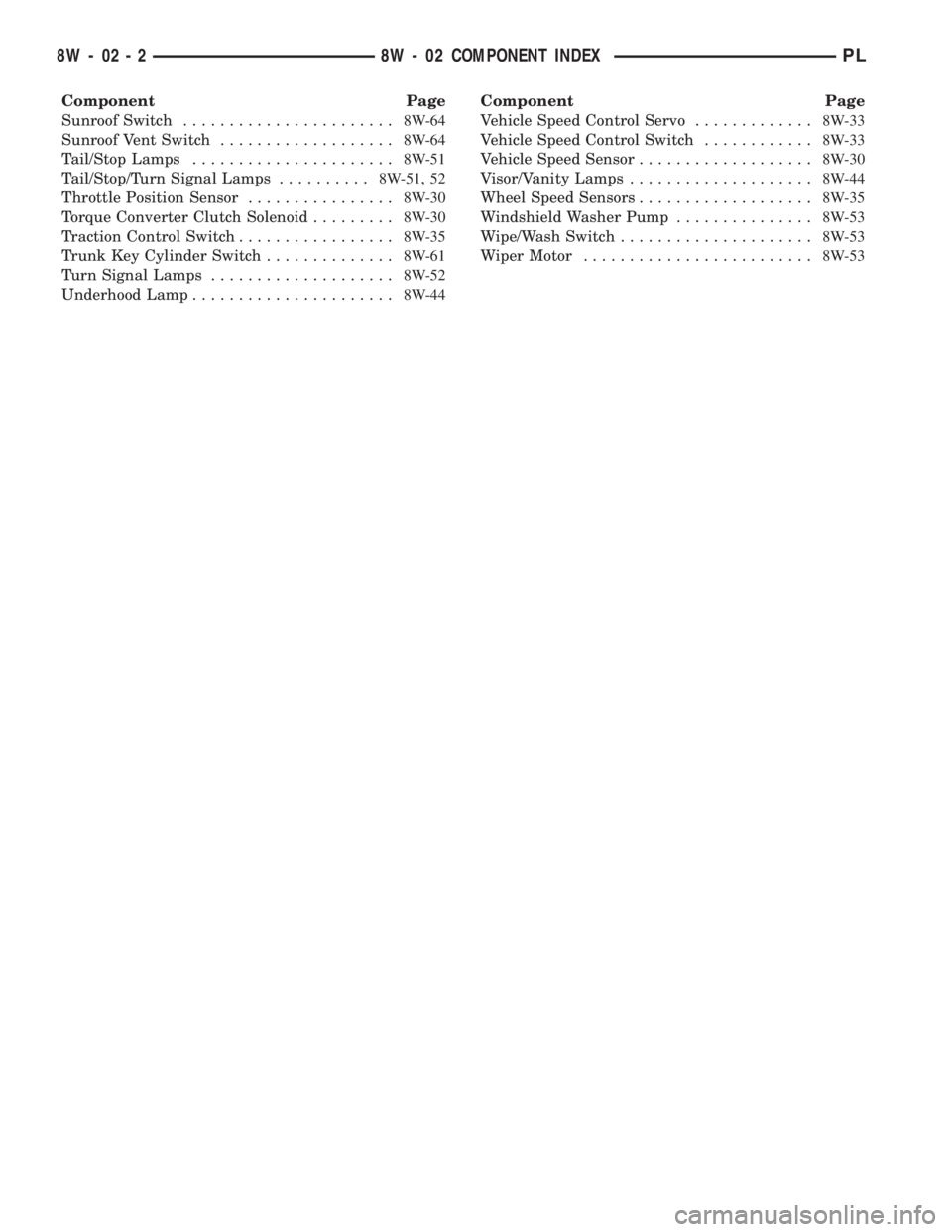

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay............8W-42

A/C Compressor Clutch.................8W-42

A/C Cycling Switch....................8W-42

A/C Heater Blower Motor...............8W-42

A/C Heater Control....................8W-42

A/C Pressure Switches..................8W-42

Airbag Control Module.................8W-43

Airbags.............................8W-43

Antenna.............................8W-47

Automatic Shut Down Relay.............8W-30

Back-Up Lamp Switch..................8W-51

Back-Up Lamps.......................8W-51

Battery.............................8W-20

Blower Motor Resistor Block.............8W-42

Brake Lamp Switch....................8W-30

Brake Shift Interlock Solenoid...........8W-30

Brake Warning Indicator Switch..........8W-40

Camshaft Position Sensor...............8W-30

Cargo Lamp..........................8W-44

Center High Mounted Stop Lamp.........8W-51

Center Stack Lamp....................8W-44

Cigar Lighter/Power Outlet..............8W-41

Circuit Breakers (FB)..................8W-11

City Lamps..........................8W-50

Clockspring.....................8W-33, 41, 43

Clutch Interlock Switch.................8W-30

Combination Flasher...................8W-52

Controller Anti-Lock Brake..............8W-35

Crankshaft Position Sensor..............8W-30

Data Link Connector...................8W-30

Decklid Release Switch.................8W-44

Decklid Solenoid......................8W-61

Diode No. 1..........................8W-42

Dome Lamp..........................8W-44

Dome Lamp/Intrusion Sensor............8W-44

Door Ajar Switches....................8W-40

Door Lock Motors.....................8W-61

Engine Coolant Temperature Sensor.......8W-30

Engine Oil Pressure Switch..............8W-30

Engine Starter Motor Relay.............8W-21

Engine Starter Motor..................8W-21

Fog Lamps........................8W-50, 51

Front Fog Lamp Switch.................8W-50

Fuel Injectors........................8W-30

Fuel Pump Module....................8W-30

Fuel Pump Relay......................8W-30

Fuel Tank...........................8W-30

Fuses (FB)...........................8W-11

Fuses (PDC).........................8W-10

Fuse Block...........................8W-11

Fusible Link A11...................8W-20, 21

Grounds.............................8W-15Component Page

Generator...........................8W-20

Glove Box Lamp/Switch.................8W-44

Headlamp Beam Select..............8W-40, 50

Headlamp Leveling Motors..............8W-50

Headlamp Leveling Switch Illumination....8W-50

Headlamp Leveling Switch..............8W-50

Headlamp Switch...................8W-50, 51

Headlamps..........................8W-50

Horns..............................8W-41

Horn Relay..........................8W-41

Horn Switch.........................8W-41

Hood Ajar Switch......................8W-39

Idle Air Control Motor..................8W-30

Ignition Coil.........................8W-30

Ignition Switch.......................8W-10

Indicators...........................8W-40

Indicator Drivers......................8W-40

Inlet Air Temperature Sensor............8W-30

Instrument Cluster....................8W-40

Instrument Panel Drivers...............8W-40

Knock Sensor.........................8W-30

Leak Detection Pump..................8W-30

License Lamps........................8W-51

Manifold Absolute Pressure Sensor........8W-30

Map/Reading Lamps...................8W-44

Multi- Function Switch.........8W-40, 50, 51, 52

Noise Suppressor......................8W-30

Oxygen Sensors.......................8W-30

Park Brake Switch....................8W-40

Park/Neutral Position Switch............8W-51

Park/Turn Signal Lamps................8W-52

Power Distribution Center...............8W-10

Power Mirror Switch...................8W-62

Power Steering Pressure Switch..........8W-30

Powertrain Control Module..............8W-30

PRNDL Lamp........................8W-44

Proportional Evap/Purge Solenoid.........8W-30

Radiator Fan Motor....................8W-42

Radiator Fan Relay....................8W-42

Radio...............................8W-47

Rear Window Defogger Switch...........8W-48

Rear Window Defogger.................8W-48

Remote Keyless Entry Module............8W-39

Repeater Lamps......................8W-52

Seat Belt Switch......................8W-40

Sentry Key Immobilizer Module..........8W-39

Side Marker Lamps....................8W-50

Siren...............................8W-39

Speakers............................8W-47

Splice Information.....................8W-70

Sunroof Control Module................8W-64

Sunroof Motor........................8W-64

PL8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 411 of 1285

Component Page

Sunroof Switch.......................8W-64

Sunroof Vent Switch...................8W-64

Tail/Stop Lamps......................8W-51

Tail/Stop/Turn Signal Lamps..........8W-51, 52

Throttle Position Sensor................8W-30

Torque Converter Clutch Solenoid.........8W-30

Traction Control Switch.................8W-35

Trunk Key Cylinder Switch..............8W-61

Turn Signal Lamps....................8W-52

Underhood Lamp......................8W-44Component Page

Vehicle Speed Control Servo.............8W-33

Vehicle Speed Control Switch............8W-33

Vehicle Speed Sensor...................8W-30

Visor/Vanity Lamps....................8W-44

Wheel Speed Sensors...................8W-35

Windshield Washer Pump...............8W-53

Wipe/Wash Switch.....................8W-53

Wiper Motor.........................8W-53

8W - 02 - 2 8W - 02 COMPONENT INDEXPL

Page 412 of 1285

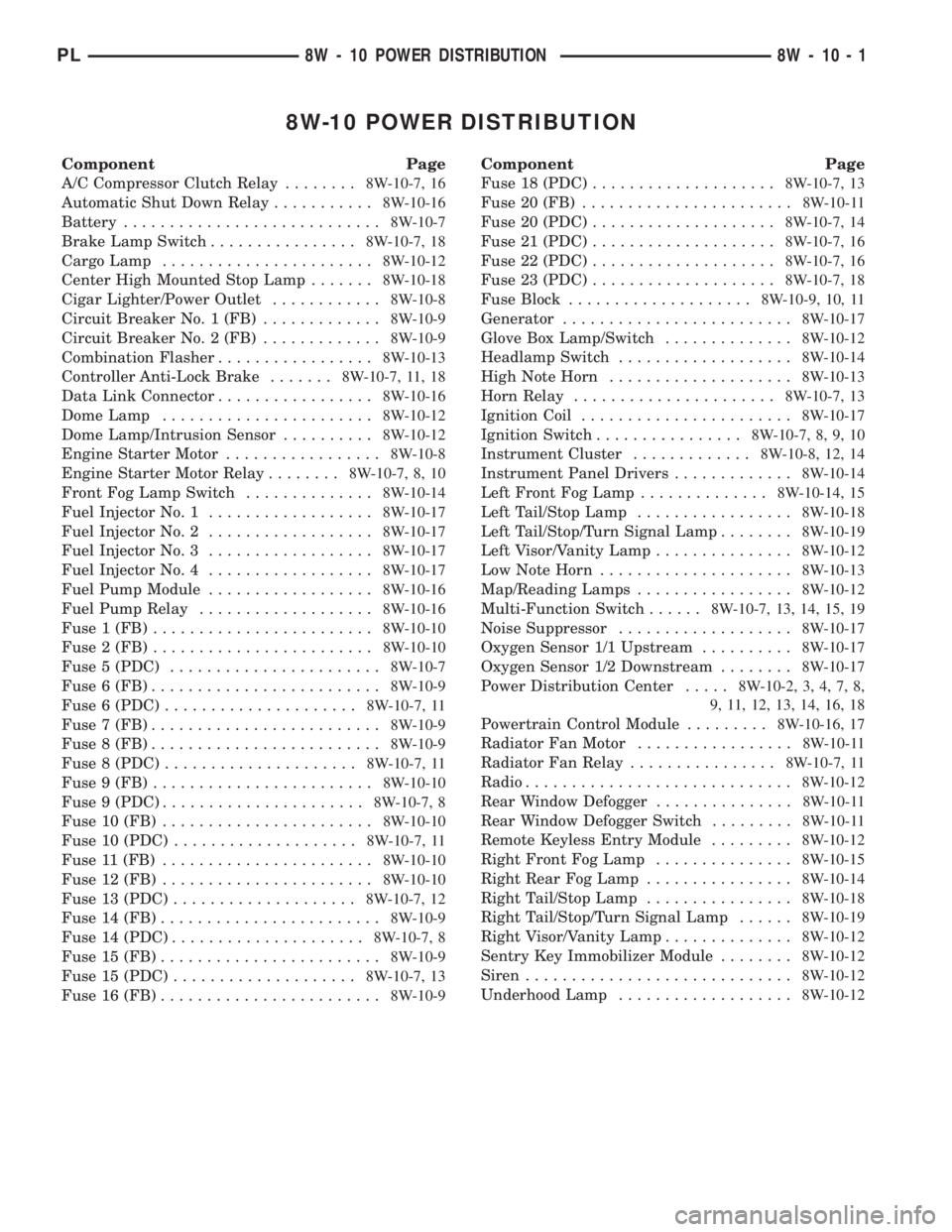

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch Relay........8W-10-7, 16

Automatic Shut Down Relay...........8W-10-16

Battery............................8W-10-7

Brake Lamp Switch................8W-10-7, 18

Cargo Lamp.......................8W-10-12

Center High Mounted Stop Lamp.......8W-10-18

Cigar Lighter/Power Outlet............8W-10-8

Circuit Breaker No. 1 (FB).............8W-10-9

Circuit Breaker No. 2 (FB).............8W-10-9

Combination Flasher.................8W-10-13

Controller Anti-Lock Brake.......8W-10-7, 11, 18

Data Link Connector.................8W-10-16

Dome Lamp.......................8W-10-12

Dome Lamp/Intrusion Sensor..........8W-10-12

Engine Starter Motor.................8W-10-8

Engine Starter Motor Relay........8W-10-7, 8, 10

Front Fog Lamp Switch..............8W-10-14

Fuel Injector No. 1..................8W-10-17

Fuel Injector No. 2..................8W-10-17

Fuel Injector No. 3..................8W-10-17

Fuel Injector No. 4..................8W-10-17

Fuel Pump Module..................8W-10-16

Fuel Pump Relay...................8W-10-16

Fuse 1 (FB)........................8W-10-10

Fuse 2 (FB)........................8W-10-10

Fuse 5 (PDC).......................8W-10-7

Fuse 6 (FB).........................8W-10-9

Fuse 6 (PDC).....................8W-10-7, 11

Fuse 7 (FB).........................8W-10-9

Fuse 8 (FB).........................8W-10-9

Fuse 8 (PDC).....................8W-10-7, 11

Fuse 9 (FB)........................8W-10-10

Fuse 9 (PDC)......................8W-10-7, 8

Fuse 10 (FB).......................8W-10-10

Fuse 10 (PDC)....................8W-10-7, 11

Fuse 11 (FB).......................8W-10-10

Fuse 12 (FB).......................8W-10-10

Fuse 13 (PDC)....................8W-10-7, 12

Fuse 14 (FB)........................8W-10-9

Fuse 14 (PDC).....................8W-10-7, 8

Fuse 15 (FB)........................8W-10-9

Fuse 15 (PDC)....................8W-10-7, 13

Fuse 16 (FB)........................8W-10-9Component Page

Fuse 18 (PDC)....................8W-10-7, 13

Fuse 20 (FB).......................8W-10-11

Fuse 20 (PDC)....................8W-10-7, 14

Fuse 21 (PDC)....................8W-10-7, 16

Fuse 22 (PDC)....................8W-10-7, 16

Fuse 23 (PDC)....................8W-10-7, 18

Fuse Block....................8W-10-9, 10, 11

Generator.........................8W-10-17

Glove Box Lamp/Switch..............8W-10-12

Headlamp Switch...................8W-10-14

High Note Horn....................8W-10-13

Horn Relay......................8W-10-7, 13

Ignition Coil.......................8W-10-17

Ignition Switch................8W-10-7, 8, 9, 10

Instrument Cluster.............8W-10-8, 12, 14

Instrument Panel Drivers.............8W-10-14

Left Front Fog Lamp..............8W-10-14, 15

Left Tail/Stop Lamp.................8W-10-18

Left Tail/Stop/Turn Signal Lamp........8W-10-19

Left Visor/Vanity Lamp...............8W-10-12

Low Note Horn.....................8W-10-13

Map/Reading Lamps.................8W-10-12

Multi-Function Switch......8W-10-7, 13, 14, 15, 19

Noise Suppressor...................8W-10-17

Oxygen Sensor 1/1 Upstream..........8W-10-17

Oxygen Sensor 1/2 Downstream........8W-10-17

Power Distribution Center.....8W-10-2, 3, 4, 7, 8,

9, 11, 12, 13, 14, 16, 18

Powertrain Control Module.........8W-10-16, 17

Radiator Fan Motor.................8W-10-11

Radiator Fan Relay................8W-10-7, 11

Radio.............................8W-10-12

Rear Window Defogger...............8W-10-11

Rear Window Defogger Switch.........8W-10-11

Remote Keyless Entry Module.........8W-10-12

Right Front Fog Lamp...............8W-10-15

Right Rear Fog Lamp................8W-10-14

Right Tail/Stop Lamp................8W-10-18

Right Tail/Stop/Turn Signal Lamp......8W-10-19

Right Visor/Vanity Lamp..............8W-10-12

Sentry Key Immobilizer Module........8W-10-12

Siren.............................8W-10-12

Underhood Lamp...................8W-10-12

PL8W - 10 POWER DISTRIBUTION 8W - 10 - 1