motor DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 226 of 1285

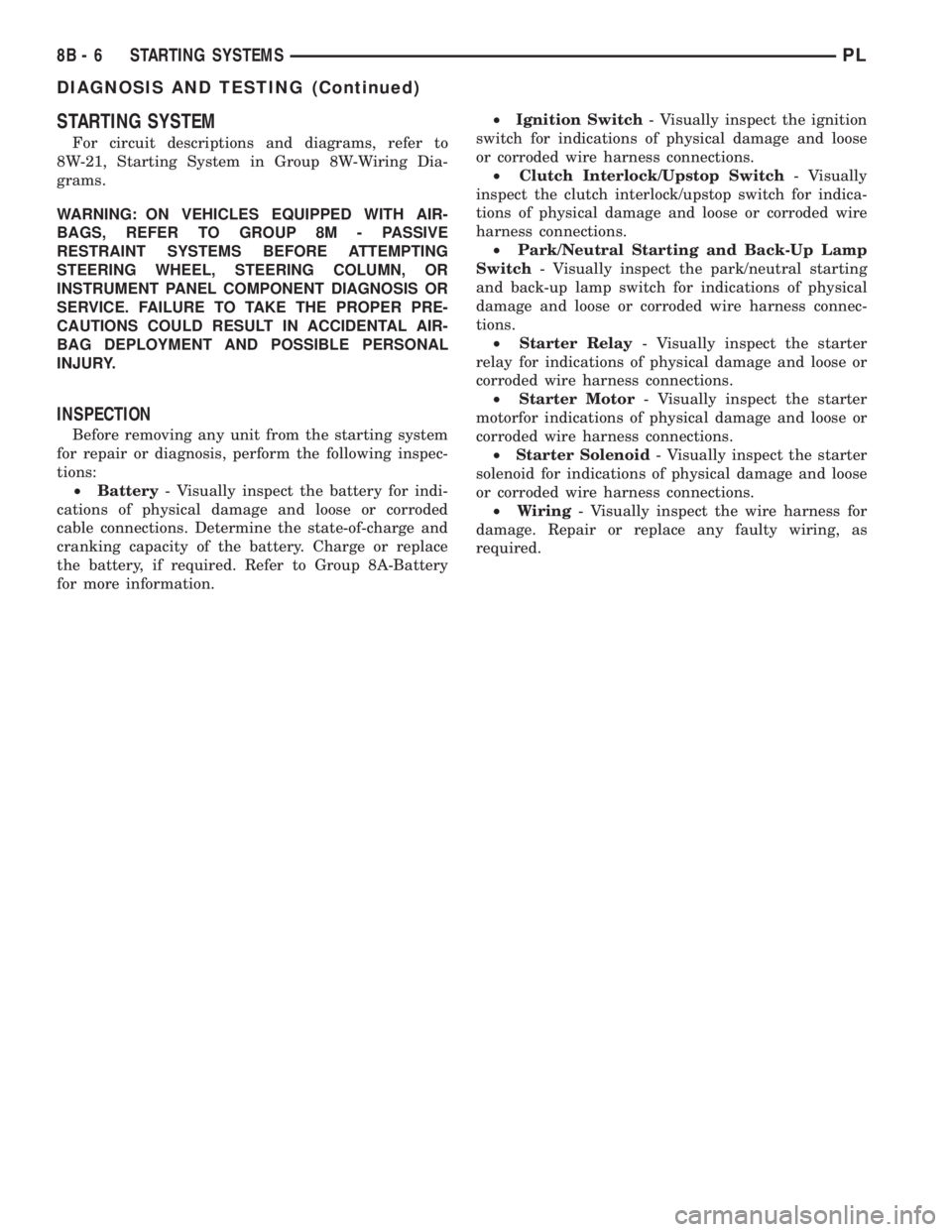

FEED CIRCUIT

The following procedure will require a suitable

volt-ampere tester (Fig. 8).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

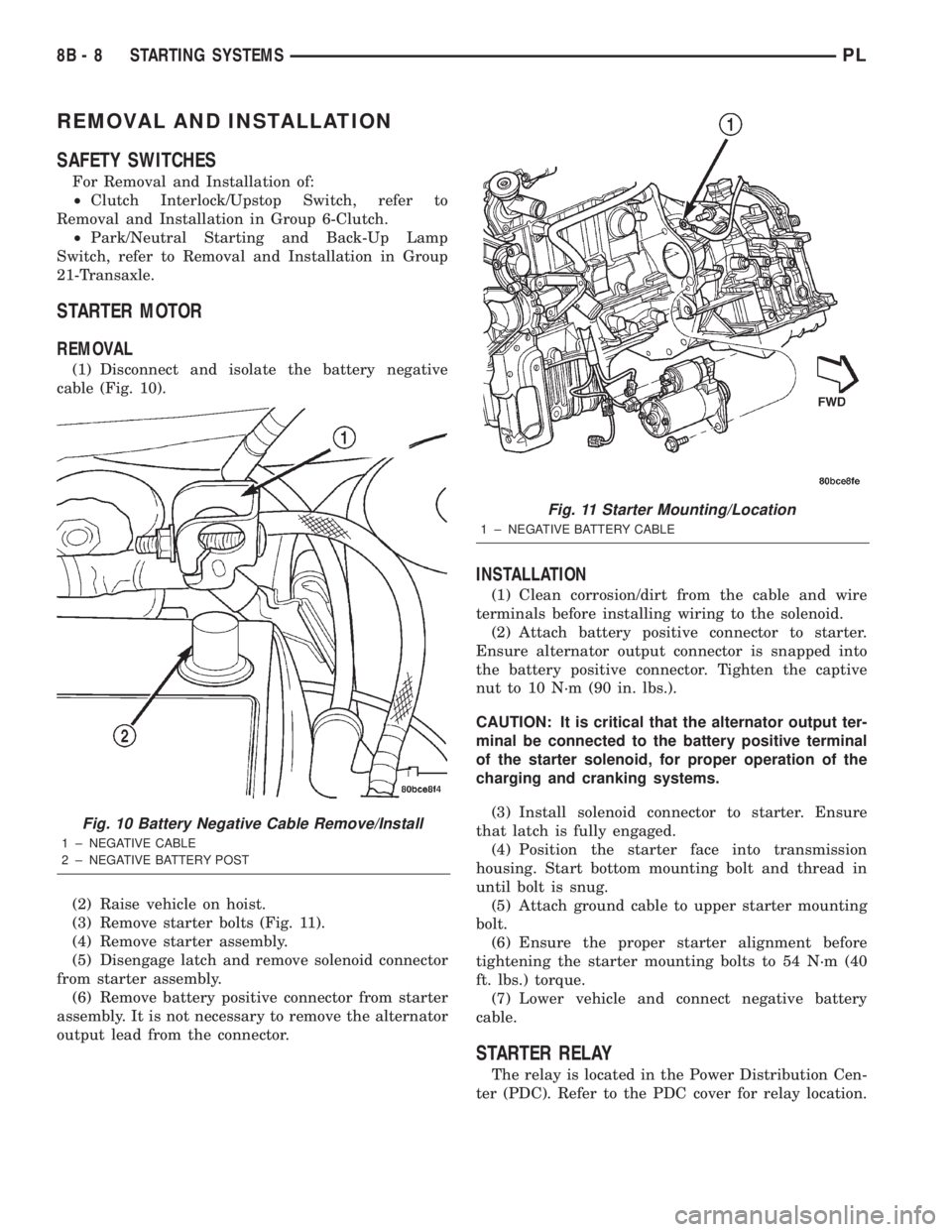

(1) Connect a volt-ampere tester to the battery ter-

minals (Fig. 9). Refer to the operating instructions

provided with the tester being used.(2) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown (ASD) Relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(3) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

position or with the clutch pedal depressed and SET

parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

8).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²If voltage is below 9.6 volts and amperage draw

is above 300 amps, the problem is the starter.

Replace the starter. Refer to Starter Removal and

Installation in this section.

(5) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect the ASD relay. Start the vehi-

cle several times to assure the problem has been cor-

rected.

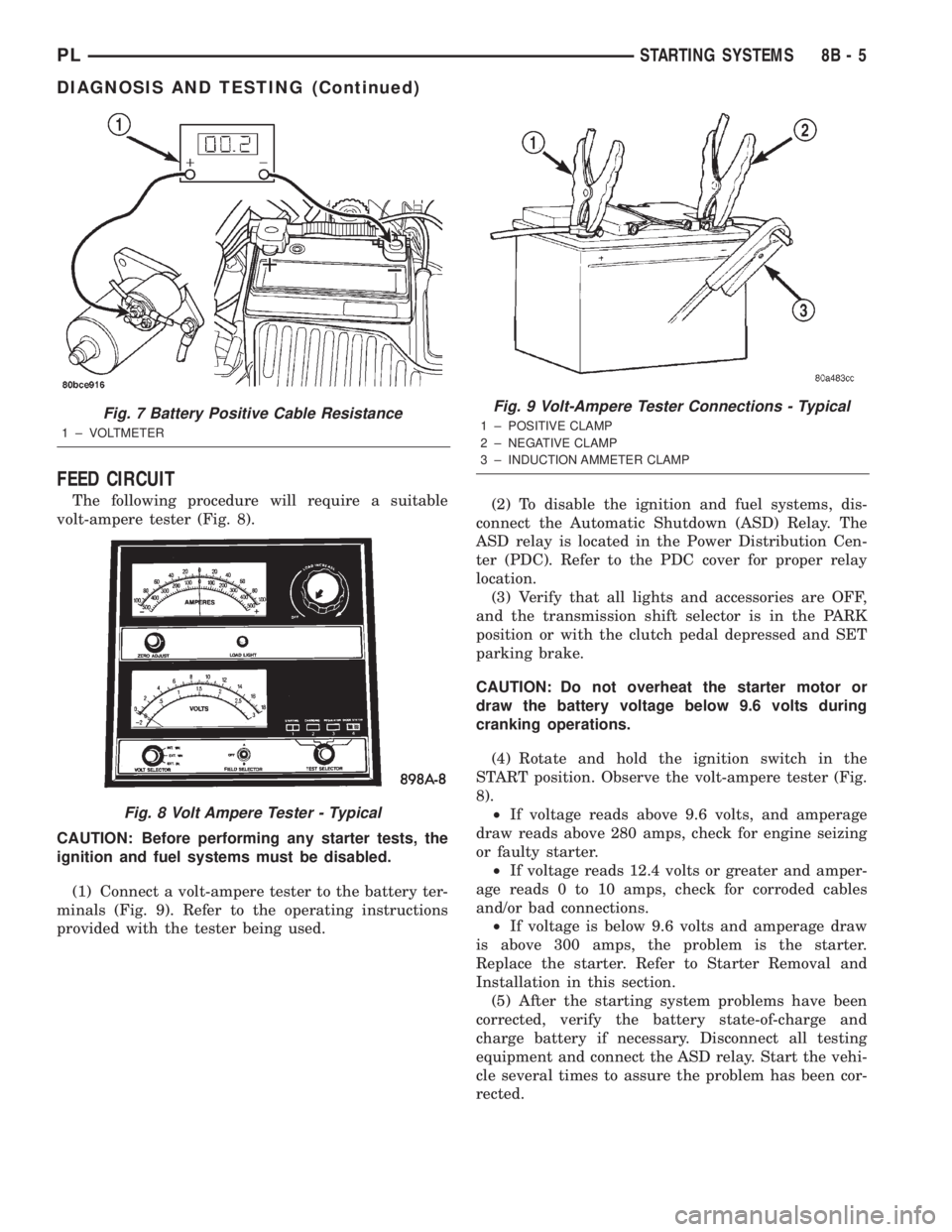

Fig. 7 Battery Positive Cable Resistance

1 ± VOLTMETER

Fig. 8 Volt Ampere Tester - Typical

Fig. 9 Volt-Ampere Tester Connections - Typical

1 ± POSITIVE CLAMP

2 ± NEGATIVE CLAMP

3 ± INDUCTION AMMETER CLAMP

PLSTARTING SYSTEMS 8B - 5

DIAGNOSIS AND TESTING (Continued)

Page 227 of 1285

STARTING SYSTEM

For circuit descriptions and diagrams, refer to

8W-21, Starting System in Group 8W-Wiring Dia-

grams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer to Group 8A-Battery

for more information.²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Clutch Interlock/Upstop Switch- Visually

inspect the clutch interlock/upstop switch for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Park/Neutral Starting and Back-Up Lamp

Switch- Visually inspect the park/neutral starting

and back-up lamp switch for indications of physical

damage and loose or corroded wire harness connec-

tions.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motorfor indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required.

8B - 6 STARTING SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 229 of 1285

REMOVAL AND INSTALLATION

SAFETY SWITCHES

For Removal and Installation of:

²Clutch Interlock/Upstop Switch, refer to

Removal and Installation in Group 6-Clutch.

²Park/Neutral Starting and Back-Up Lamp

Switch, refer to Removal and Installation in Group

21-Transaxle.

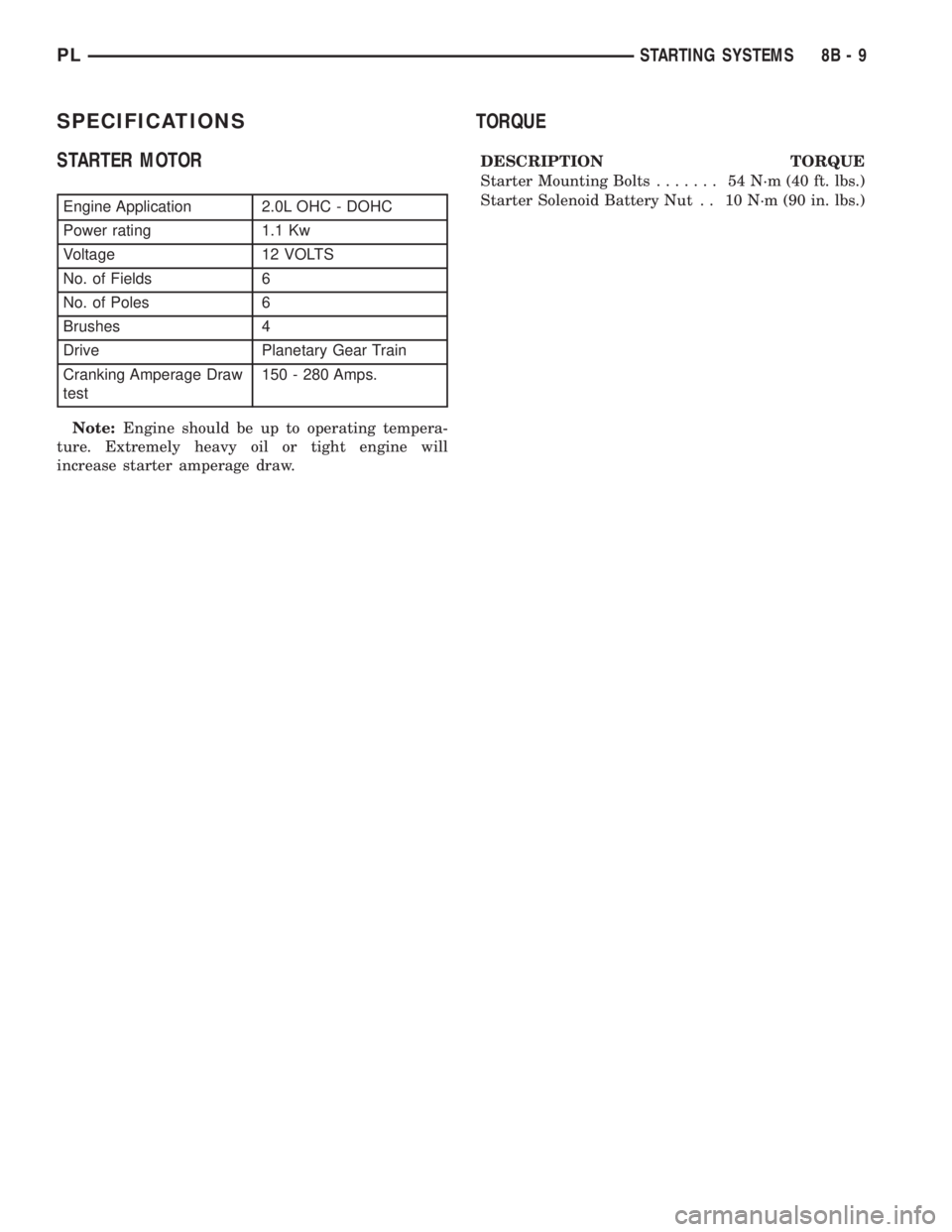

STARTER MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 10).

(2) Raise vehicle on hoist.

(3) Remove starter bolts (Fig. 11).

(4) Remove starter assembly.

(5) Disengage latch and remove solenoid connector

from starter assembly.

(6) Remove battery positive connector from starter

assembly. It is not necessary to remove the alternator

output lead from the connector.

INSTALLATION

(1) Clean corrosion/dirt from the cable and wire

terminals before installing wiring to the solenoid.

(2) Attach battery positive connector to starter.

Ensure alternator output connector is snapped into

the battery positive connector. Tighten the captive

nut to 10 N´m (90 in. lbs.).

CAUTION: It is critical that the alternator output ter-

minal be connected to the battery positive terminal

of the starter solenoid, for proper operation of the

charging and cranking systems.

(3) Install solenoid connector to starter. Ensure

that latch is fully engaged.

(4) Position the starter face into transmission

housing. Start bottom mounting bolt and thread in

until bolt is snug.

(5) Attach ground cable to upper starter mounting

bolt.

(6) Ensure the proper starter alignment before

tightening the starter mounting bolts to 54 N´m (40

ft. lbs.) torque.

(7) Lower vehicle and connect negative battery

cable.

STARTER RELAY

The relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for relay location.

Fig. 10 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 11 Starter Mounting/Location

1 ± NEGATIVE BATTERY CABLE

8B - 8 STARTING SYSTEMSPL

Page 230 of 1285

SPECIFICATIONS

STARTER MOTOR

Engine Application 2.0L OHC - DOHC

Power rating 1.1 Kw

Voltage 12 VOLTS

No. of Fields 6

No. of Poles 6

Brushes 4

Drive Planetary Gear Train

Cranking Amperage Draw

test150 - 280 Amps.

Note:Engine should be up to operating tempera-

ture. Extremely heavy oil or tight engine will

increase starter amperage draw.

TORQUE

DESCRIPTION TORQUE

Starter Mounting Bolts....... 54N´m(40ft.lbs.)

Starter Solenoid Battery Nut . . 10 N´m (90 in. lbs.)

PLSTARTING SYSTEMS 8B - 9

Page 260 of 1285

INSTRUMENT PANEL AND SYSTEMS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

HEADLAMP LEVELING SWITCH..............1

INSTRUMENT PANEL AND COMPONENTS.....1

REMOVAL AND INSTALLATION

HEADLAMP LEVELING SWITCH..............2INSTRUMENT PANEL ± R. H. D..............3

SPECIFICATIONS

TORQUE SPECIFICATIONS..................9

DIAGNOSIS AND TESTING

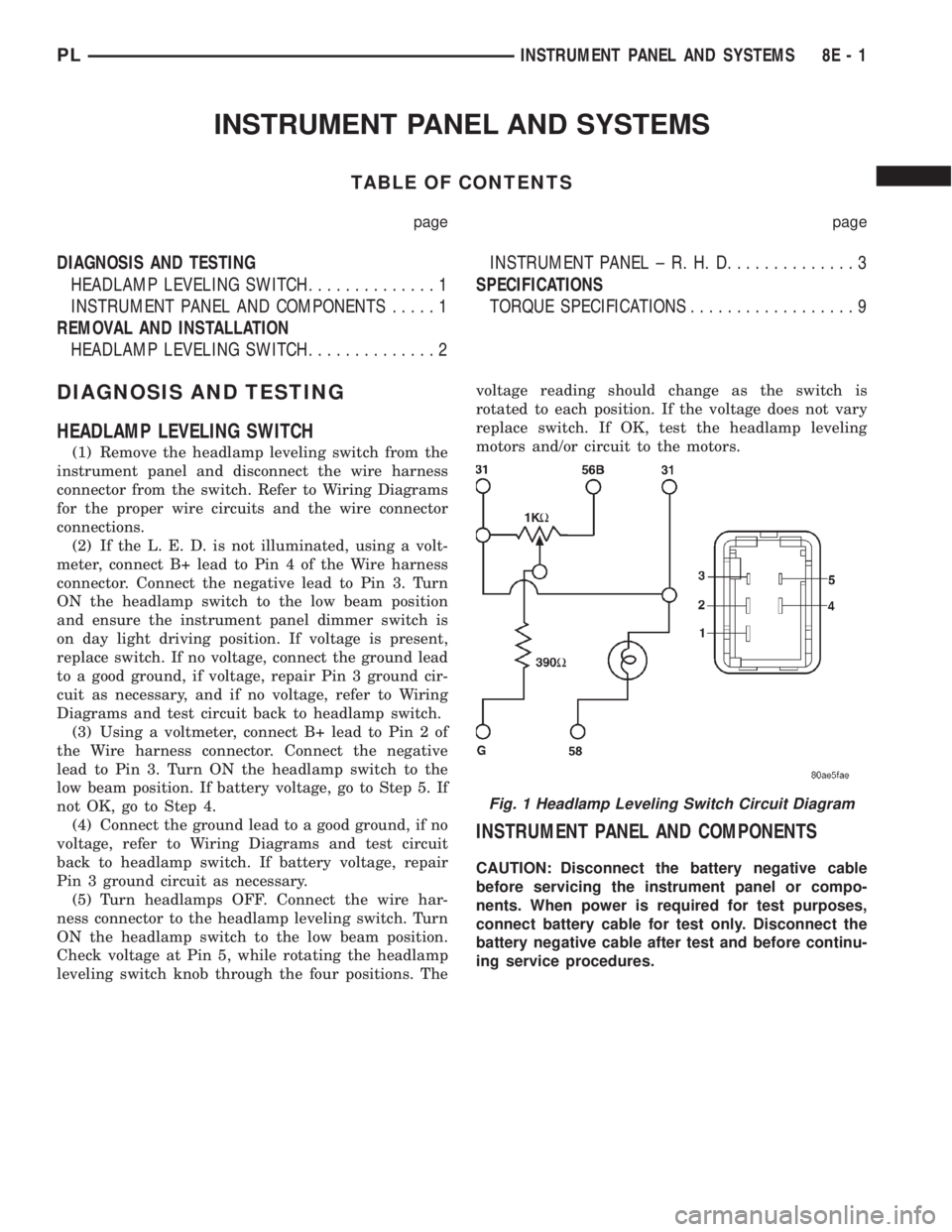

HEADLAMP LEVELING SWITCH

(1) Remove the headlamp leveling switch from the

instrument panel and disconnect the wire harness

connector from the switch. Refer to Wiring Diagrams

for the proper wire circuits and the wire connector

connections.

(2) If the L. E. D. is not illuminated, using a volt-

meter, connect B+ lead to Pin 4 of the Wire harness

connector. Connect the negative lead to Pin 3. Turn

ON the headlamp switch to the low beam position

and ensure the instrument panel dimmer switch is

on day light driving position. If voltage is present,

replace switch. If no voltage, connect the ground lead

to a good ground, if voltage, repair Pin 3 ground cir-

cuit as necessary, and if no voltage, refer to Wiring

Diagrams and test circuit back to headlamp switch.

(3) Using a voltmeter, connect B+ lead to Pin 2 of

the Wire harness connector. Connect the negative

lead to Pin 3. Turn ON the headlamp switch to the

low beam position. If battery voltage, go to Step 5. If

not OK, go to Step 4.

(4) Connect the ground lead to a good ground, if no

voltage, refer to Wiring Diagrams and test circuit

back to headlamp switch. If battery voltage, repair

Pin 3 ground circuit as necessary.

(5) Turn headlamps OFF. Connect the wire har-

ness connector to the headlamp leveling switch. Turn

ON the headlamp switch to the low beam position.

Check voltage at Pin 5, while rotating the headlamp

leveling switch knob through the four positions. Thevoltage reading should change as the switch is

rotated to each position. If the voltage does not vary

replace switch. If OK, test the headlamp leveling

motors and/or circuit to the motors.

INSTRUMENT PANEL AND COMPONENTS

CAUTION: Disconnect the battery negative cable

before servicing the instrument panel or compo-

nents. When power is required for test purposes,

connect battery cable for test only. Disconnect the

battery negative cable after test and before continu-

ing service procedures.

Fig. 1 Headlamp Leveling Switch Circuit Diagram

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 298 of 1285

WINDSHIELD WIPER and WASHER SYSTEMS

TABLE OF CONTENTS

page page

WINDSHIELD WIPER SYSTEM................ 1WINDSHIELD WASHER SYSTEM.............. 8

WINDSHIELD WIPER SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

WIPER BLADES...........................1

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS............2

WINDSHIELD WIPER MOTOR................3

WINDSHIELD WIPER/WASHER SWITCH........5

REMOVAL AND INSTALLATION

WINDSHIELD WIPER ARM(S)................5WINDSHIELD WIPER BLADE(S)..............5

WINDSHIELD WIPER BLADE ELEMENT........5

WINDSHIELD WIPER LINKAGE...............5

WINDSHIELD WIPER MODULE...............6

WINDSHIELD WIPER MOTOR................6

WINDSHIELD WIPER/WASHER SWITCH........6

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)..............6

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)................6

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The windshield wipers will only operate with the

ignition switch in the ACCESSORY or IGNITION

RUN position. The wiper circuit is protected against

over loads by a fuse in the fuse block and a circuit

breaker within the wiper motor. This protects the cir-

cuitry of the wiper system and the vehicle. The wiper

motor has permanent magnet fields.

The intermittent wiper system, in addition to low

and high speed, has a delay mode and a pulse wipe

mode. The delay mode has a range of 1 to 15 seconds.

Pulse wipe is accomplished by momentarily moving

the stalk lever into the WASH position while the

wiper switch is in either OFF or DELAY position.

The wiper blades then sweep once or twice and

return to the previous wiper switch mode, OFF or

DELAY.The intermittent wiper function is integral to the

wiper switch. All electronics and relay are inside the

switch assembly.

The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

The wiper switch also includes the MIST feature

which provides a single wipe when actuated.

DESCRIPTION AND OPERATION

WIPER BLADES

Wiper blades, exposed to the weather for a long

period of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the blades continue to

streak or smear, they should be replaced. The right

and left wipers are different blade lengths. The

driver side length is 550 mm and the passenger side

length is 475 mm. The blades should not be inter-

changed.

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 1

Page 299 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken.

Whatever the problem, disconnect motor wire har-

ness and clean the terminals, then connect motor

wire harness and test.

Refer to Group 8W Wiring Diagrams for circuit

information and connector call-outs.

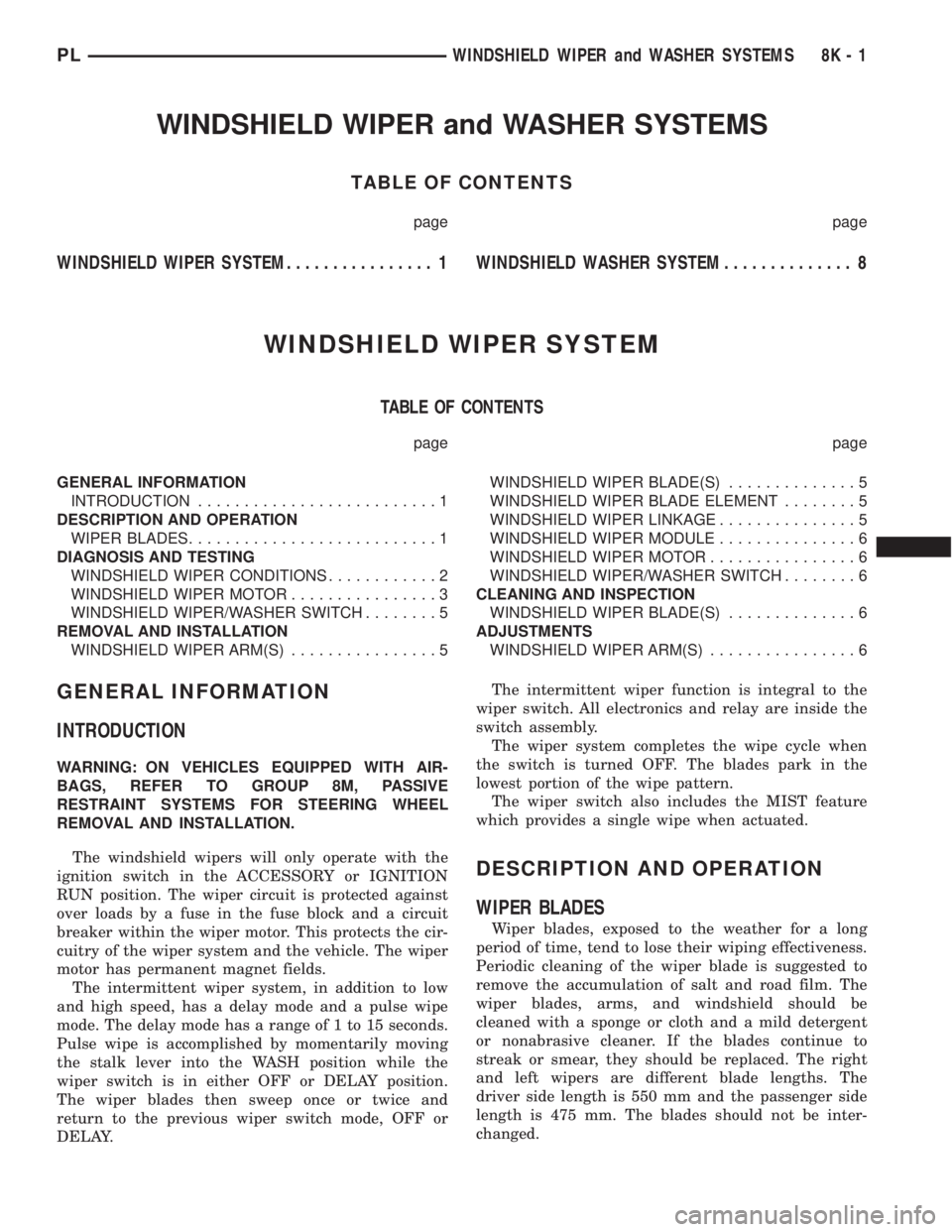

MOTOR WILL NOT OPERATE IN SOME OR ALL

SWITCH POSITIONS

(1) Check fuse 1, in the fuse block (Fig. 1).

(a) If fuse is OK, go to Step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions.

(c) If motor is still inoperative and the fuse does

not blow, go to Step 2.

(d) If replacement fuse blows, go to Step 6.

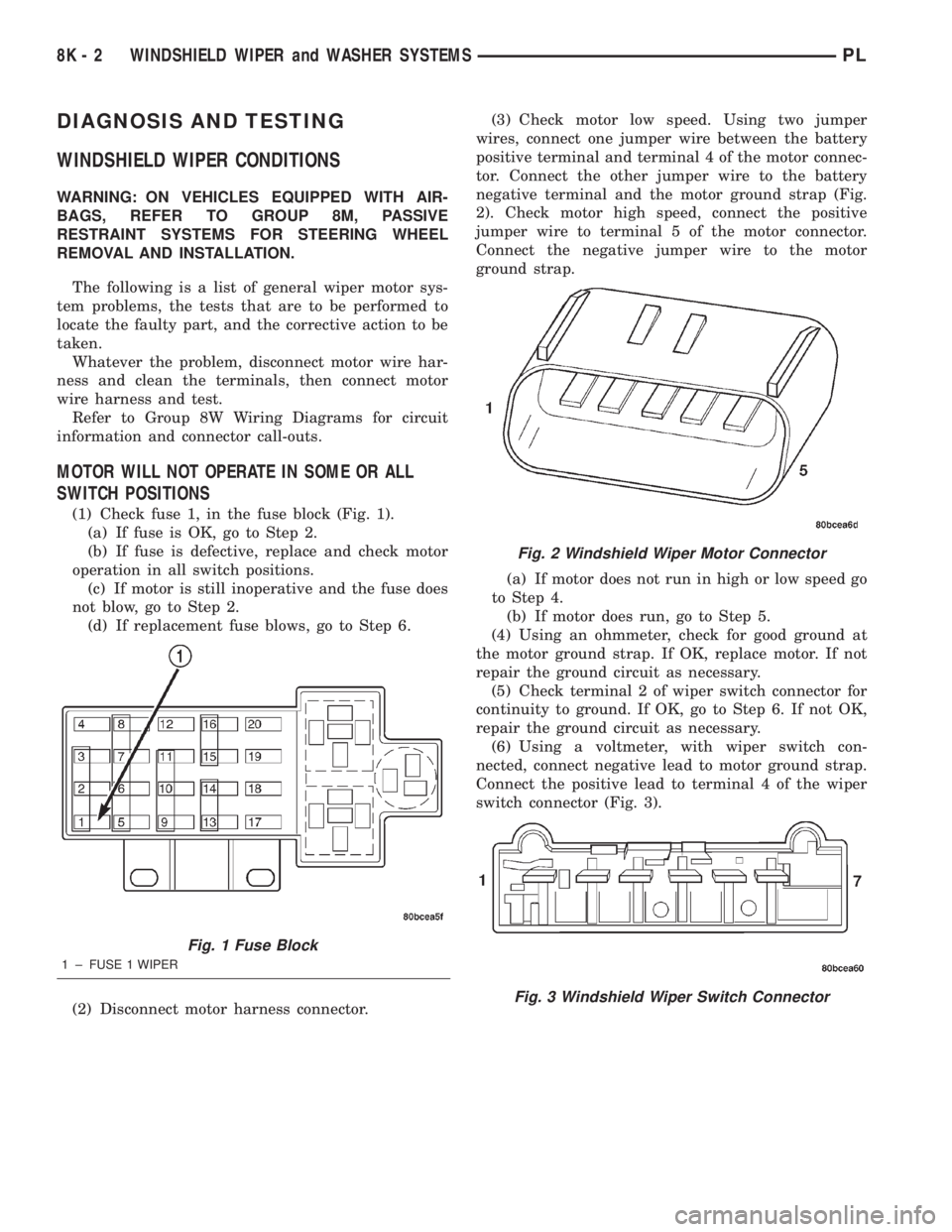

(2) Disconnect motor harness connector.(3) Check motor low speed. Using two jumper

wires, connect one jumper wire between the battery

positive terminal and terminal 4 of the motor connec-

tor. Connect the other jumper wire to the battery

negative terminal and the motor ground strap (Fig.

2). Check motor high speed, connect the positive

jumper wire to terminal 5 of the motor connector.

Connect the negative jumper wire to the motor

ground strap.

(a) If motor does not run in high or low speed go

to Step 4.

(b) If motor does run, go to Step 5.

(4) Using an ohmmeter, check for good ground at

the motor ground strap. If OK, replace motor. If not

repair the ground circuit as necessary.

(5) Check terminal 2 of wiper switch connector for

continuity to ground. If OK, go to Step 6. If not OK,

repair the ground circuit as necessary.

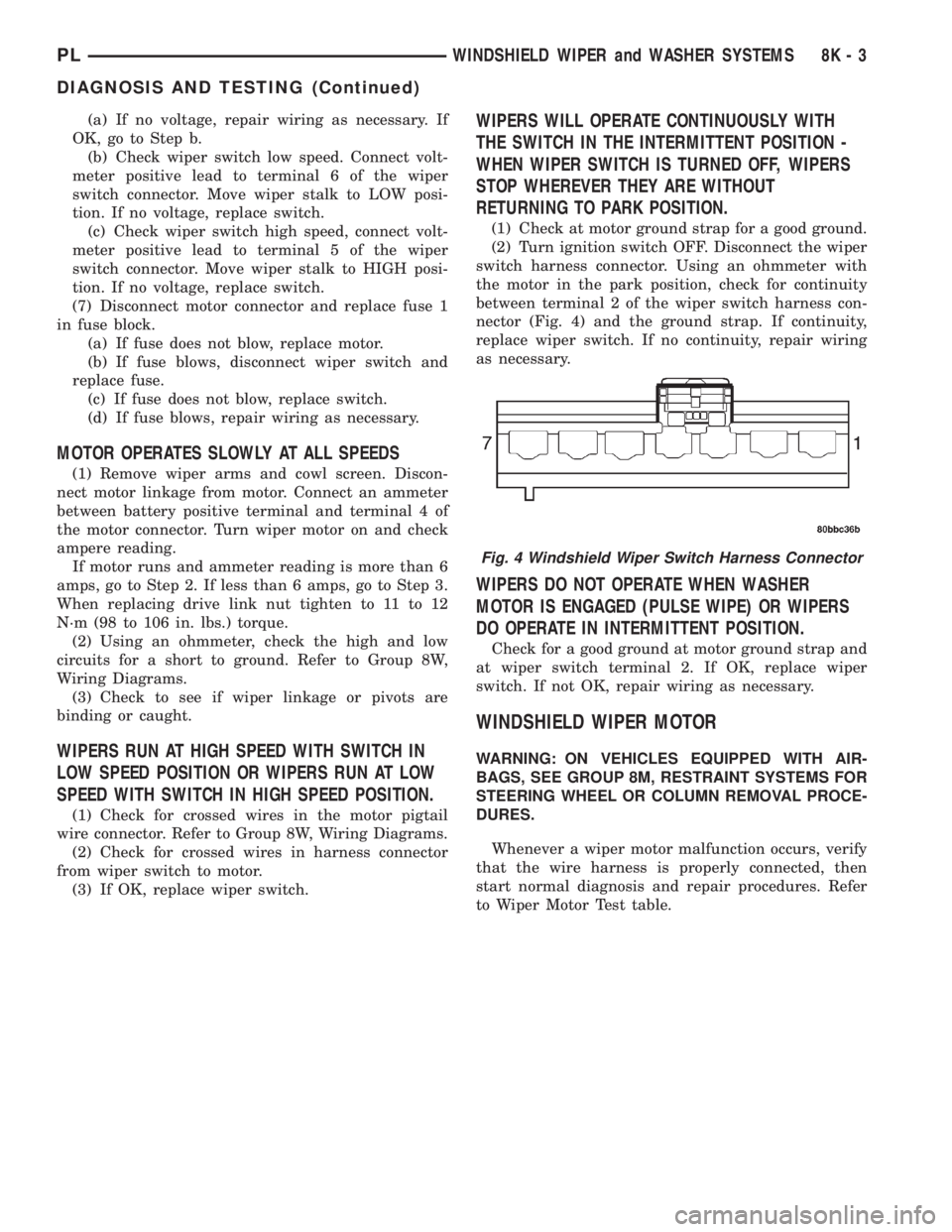

(6) Using a voltmeter, with wiper switch con-

nected, connect negative lead to motor ground strap.

Connect the positive lead to terminal 4 of the wiper

switch connector (Fig. 3).

Fig. 1 Fuse Block

1 ± FUSE 1 WIPER

Fig. 2 Windshield Wiper Motor Connector

Fig. 3 Windshield Wiper Switch Connector

8K - 2 WINDSHIELD WIPER and WASHER SYSTEMSPL

Page 300 of 1285

(a) If no voltage, repair wiring as necessary. If

OK, go to Step b.

(b) Check wiper switch low speed. Connect volt-

meter positive lead to terminal 6 of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal 5 of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 1

in fuse block.

(a) If fuse does not blow, replace motor.

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector. Turn wiper motor on and check

ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.

(2) Using an ohmmeter, check the high and low

circuits for a short to ground. Refer to Group 8W,

Wiring Diagrams.

(3) Check to see if wiper linkage or pivots are

binding or caught.

WIPERS RUN AT HIGH SPEED WITH SWITCH IN

LOW SPEED POSITION OR WIPERS RUN AT LOW

SPEED WITH SWITCH IN HIGH SPEED POSITION.

(1) Check for crossed wires in the motor pigtail

wire connector. Refer to Group 8W, Wiring Diagrams.

(2) Check for crossed wires in harness connector

from wiper switch to motor.

(3) If OK, replace wiper switch.

WIPERS WILL OPERATE CONTINUOUSLY WITH

THE SWITCH IN THE INTERMITTENT POSITION -

WHEN WIPER SWITCH IS TURNED OFF, WIPERS

STOP WHEREVER THEY ARE WITHOUT

RETURNING TO PARK POSITION.

(1) Check at motor ground strap for a good ground.

(2) Turn ignition switch OFF. Disconnect the wiper

switch harness connector. Using an ohmmeter with

the motor in the park position, check for continuity

between terminal 2 of the wiper switch harness con-

nector (Fig. 4) and the ground strap. If continuity,

replace wiper switch. If no continuity, repair wiring

as necessary.

WIPERS DO NOT OPERATE WHEN WASHER

MOTOR IS ENGAGED (PULSE WIPE) OR WIPERS

DO OPERATE IN INTERMITTENT POSITION.

Check for a good ground at motor ground strap and

at wiper switch terminal 2. If OK, replace wiper

switch. If not OK, repair wiring as necessary.

WINDSHIELD WIPER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, verify

that the wire harness is properly connected, then

start normal diagnosis and repair procedures. Refer

to Wiper Motor Test table.

Fig. 4 Windshield Wiper Switch Harness Connector

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 3

DIAGNOSIS AND TESTING (Continued)

Page 301 of 1285

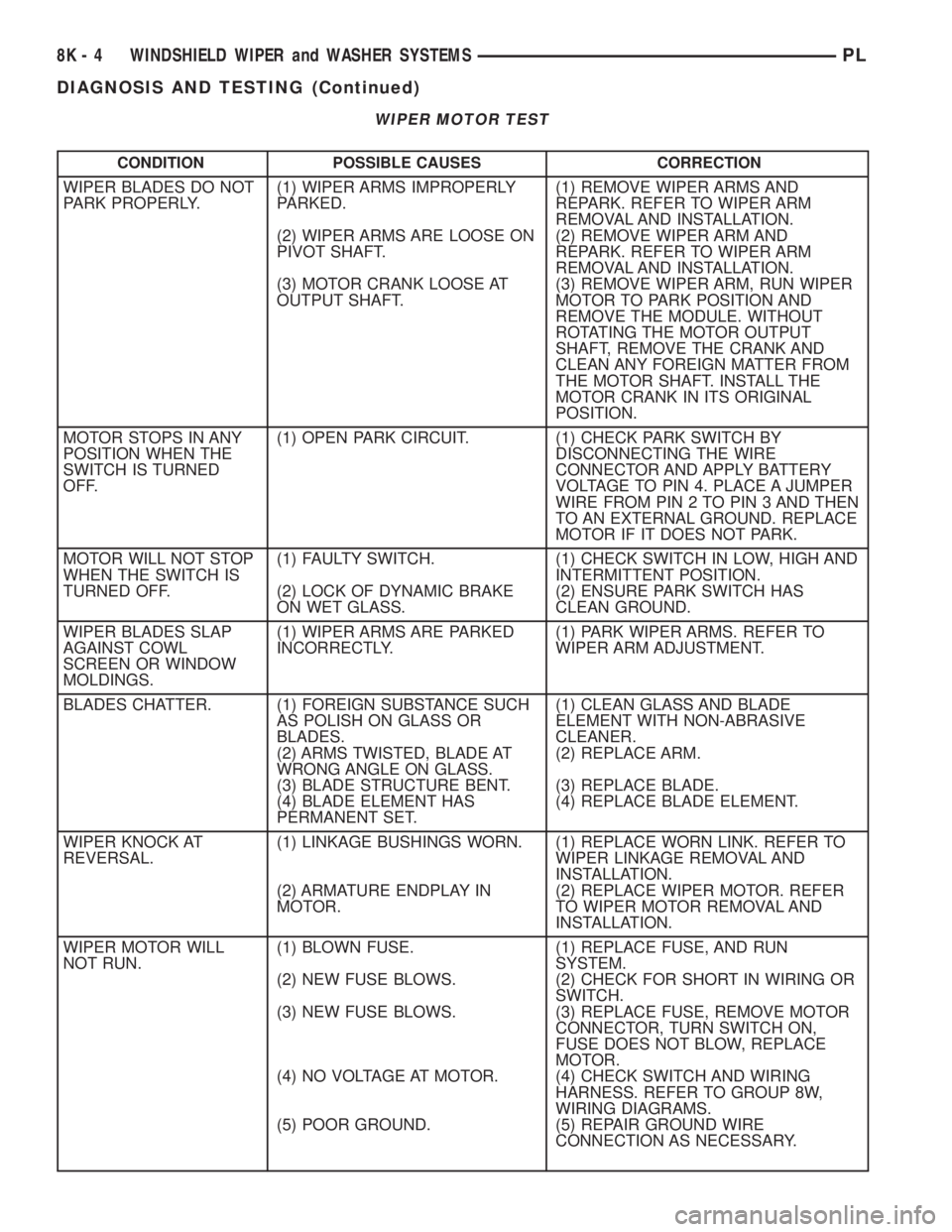

WIPER MOTOR TEST

CONDITION POSSIBLE CAUSES CORRECTION

WIPER BLADES DO NOT

PARK PROPERLY.(1) WIPER ARMS IMPROPERLY

PARKED.

(2) WIPER ARMS ARE LOOSE ON

PIVOT SHAFT.

(3) MOTOR CRANK LOOSE AT

OUTPUT SHAFT.(1) REMOVE WIPER ARMS AND

REPARK. REFER TO WIPER ARM

REMOVAL AND INSTALLATION.

(2) REMOVE WIPER ARM AND

REPARK. REFER TO WIPER ARM

REMOVAL AND INSTALLATION.

(3) REMOVE WIPER ARM, RUN WIPER

MOTOR TO PARK POSITION AND

REMOVE THE MODULE. WITHOUT

ROTATING THE MOTOR OUTPUT

SHAFT, REMOVE THE CRANK AND

CLEAN ANY FOREIGN MATTER FROM

THE MOTOR SHAFT. INSTALL THE

MOTOR CRANK IN ITS ORIGINAL

POSITION.

MOTOR STOPS IN ANY

POSITION WHEN THE

SWITCH IS TURNED

OFF.(1) OPEN PARK CIRCUIT. (1) CHECK PARK SWITCH BY

DISCONNECTING THE WIRE

CONNECTOR AND APPLY BATTERY

VOLTAGE TO PIN 4. PLACE A JUMPER

WIRE FROM PIN 2 TO PIN 3 AND THEN

TO AN EXTERNAL GROUND. REPLACE

MOTOR IF IT DOES NOT PARK.

MOTOR WILL NOT STOP

WHEN THE SWITCH IS

TURNED OFF.(1) FAULTY SWITCH.

(2) LOCK OF DYNAMIC BRAKE

ON WET GLASS.(1) CHECK SWITCH IN LOW, HIGH AND

INTERMITTENT POSITION.

(2) ENSURE PARK SWITCH HAS

CLEAN GROUND.

WIPER BLADES SLAP

AGAINST COWL

SCREEN OR WINDOW

MOLDINGS.(1) WIPER ARMS ARE PARKED

INCORRECTLY.(1) PARK WIPER ARMS. REFER TO

WIPER ARM ADJUSTMENT.

BLADES CHATTER. (1) FOREIGN SUBSTANCE SUCH

AS POLISH ON GLASS OR

BLADES.

(2) ARMS TWISTED, BLADE AT

WRONG ANGLE ON GLASS.

(3) BLADE STRUCTURE BENT.

(4) BLADE ELEMENT HAS

PERMANENT SET.(1) CLEAN GLASS AND BLADE

ELEMENT WITH NON-ABRASIVE

CLEANER.

(2) REPLACE ARM.

(3) REPLACE BLADE.

(4) REPLACE BLADE ELEMENT.

WIPER KNOCK AT

REVERSAL.(1) LINKAGE BUSHINGS WORN.

(2) ARMATURE ENDPLAY IN

MOTOR.(1) REPLACE WORN LINK. REFER TO

WIPER LINKAGE REMOVAL AND

INSTALLATION.

(2) REPLACE WIPER MOTOR. REFER

TO WIPER MOTOR REMOVAL AND

INSTALLATION.

WIPER MOTOR WILL

NOT RUN.(1) BLOWN FUSE.

(2) NEW FUSE BLOWS.

(3) NEW FUSE BLOWS.

(4) NO VOLTAGE AT MOTOR.

(5) POOR GROUND.(1) REPLACE FUSE, AND RUN

SYSTEM.

(2) CHECK FOR SHORT IN WIRING OR

SWITCH.

(3) REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON,

FUSE DOES NOT BLOW, REPLACE

MOTOR.

(4) CHECK SWITCH AND WIRING

HARNESS. REFER TO GROUP 8W,

WIRING DIAGRAMS.

(5) REPAIR GROUND WIRE

CONNECTION AS NECESSARY.

8K - 4 WINDSHIELD WIPER and WASHER SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 303 of 1285

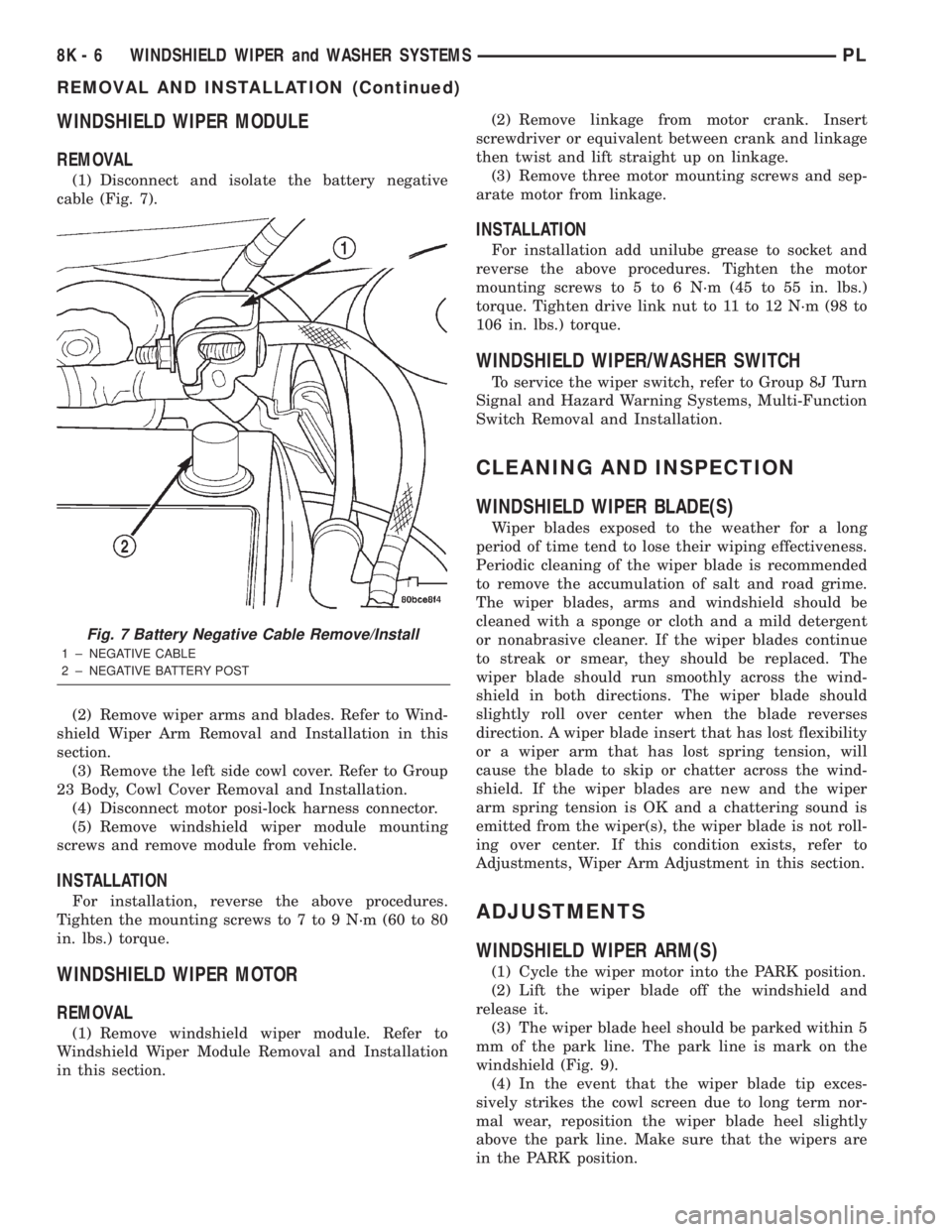

WINDSHIELD WIPER MODULE

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 7).

(2) Remove wiper arms and blades. Refer to Wind-

shield Wiper Arm Removal and Installation in this

section.

(3) Remove the left side cowl cover. Refer to Group

23 Body, Cowl Cover Removal and Installation.

(4) Disconnect motor posi-lock harness connector.

(5) Remove windshield wiper module mounting

screws and remove module from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Tighten the mounting screws to 7 to 9 N´m (60 to 80

in. lbs.) torque.

WINDSHIELD WIPER MOTOR

REMOVAL

(1) Remove windshield wiper module. Refer to

Windshield Wiper Module Removal and Installation

in this section.(2) Remove linkage from motor crank. Insert

screwdriver or equivalent between crank and linkage

then twist and lift straight up on linkage.

(3) Remove three motor mounting screws and sep-

arate motor from linkage.

INSTALLATION

For installation add unilube grease to socket and

reverse the above procedures. Tighten the motor

mounting screws to 5 to 6 N´m (45 to 55 in. lbs.)

torque. Tighten drive link nut to 11 to 12 N´m (98 to

106 in. lbs.) torque.

WINDSHIELD WIPER/WASHER SWITCH

To service the wiper switch, refer to Group 8J Turn

Signal and Hazard Warning Systems, Multi-Function

Switch Removal and Installation.

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, refer to

Adjustments, Wiper Arm Adjustment in this section.

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)

(1) Cycle the wiper motor into the PARK position.

(2) Lift the wiper blade off the windshield and

release it.

(3) The wiper blade heel should be parked within 5

mm of the park line. The park line is mark on the

windshield (Fig. 9).

(4) In the event that the wiper blade tip exces-

sively strikes the cowl screen due to long term nor-

mal wear, reposition the wiper blade heel slightly

above the park line. Make sure that the wipers are

in the PARK position.

Fig. 7 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

8K - 6 WINDSHIELD WIPER and WASHER SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)