tire DODGE NEON 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 133 of 1285

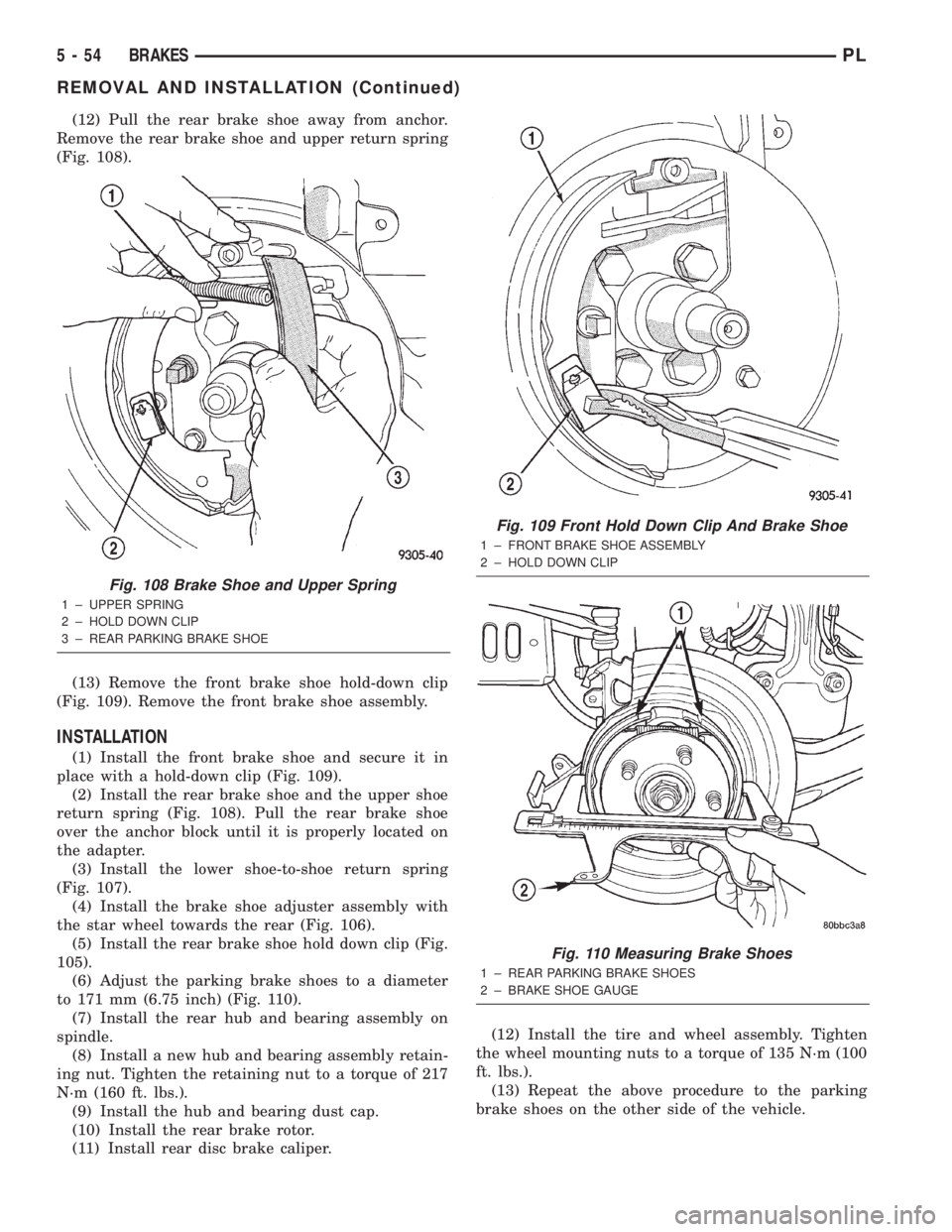

(12) Pull the rear brake shoe away from anchor.

Remove the rear brake shoe and upper return spring

(Fig. 108).

(13) Remove the front brake shoe hold-down clip

(Fig. 109). Remove the front brake shoe assembly.

INSTALLATION

(1) Install the front brake shoe and secure it in

place with a hold-down clip (Fig. 109).

(2) Install the rear brake shoe and the upper shoe

return spring (Fig. 108). Pull the rear brake shoe

over the anchor block until it is properly located on

the adapter.

(3) Install the lower shoe-to-shoe return spring

(Fig. 107).

(4) Install the brake shoe adjuster assembly with

the star wheel towards the rear (Fig. 106).

(5) Install the rear brake shoe hold down clip (Fig.

105).

(6) Adjust the parking brake shoes to a diameter

to 171 mm (6.75 inch) (Fig. 110).

(7) Install the rear hub and bearing assembly on

spindle.

(8) Install a new hub and bearing assembly retain-

ing nut. Tighten the retaining nut to a torque of 217

N´m (160 ft. lbs.).

(9) Install the hub and bearing dust cap.

(10) Install the rear brake rotor.

(11) Install rear disc brake caliper.(12) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(13) Repeat the above procedure to the parking

brake shoes on the other side of the vehicle.

Fig. 108 Brake Shoe and Upper Spring

1 ± UPPER SPRING

2 ± HOLD DOWN CLIP

3 ± REAR PARKING BRAKE SHOE

Fig. 109 Front Hold Down Clip And Brake Shoe

1 ± FRONT BRAKE SHOE ASSEMBLY

2 ± HOLD DOWN CLIP

Fig. 110 Measuring Brake Shoes

1 ± REAR PARKING BRAKE SHOES

2 ± BRAKE SHOE GAUGE

5 - 54 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 138 of 1285

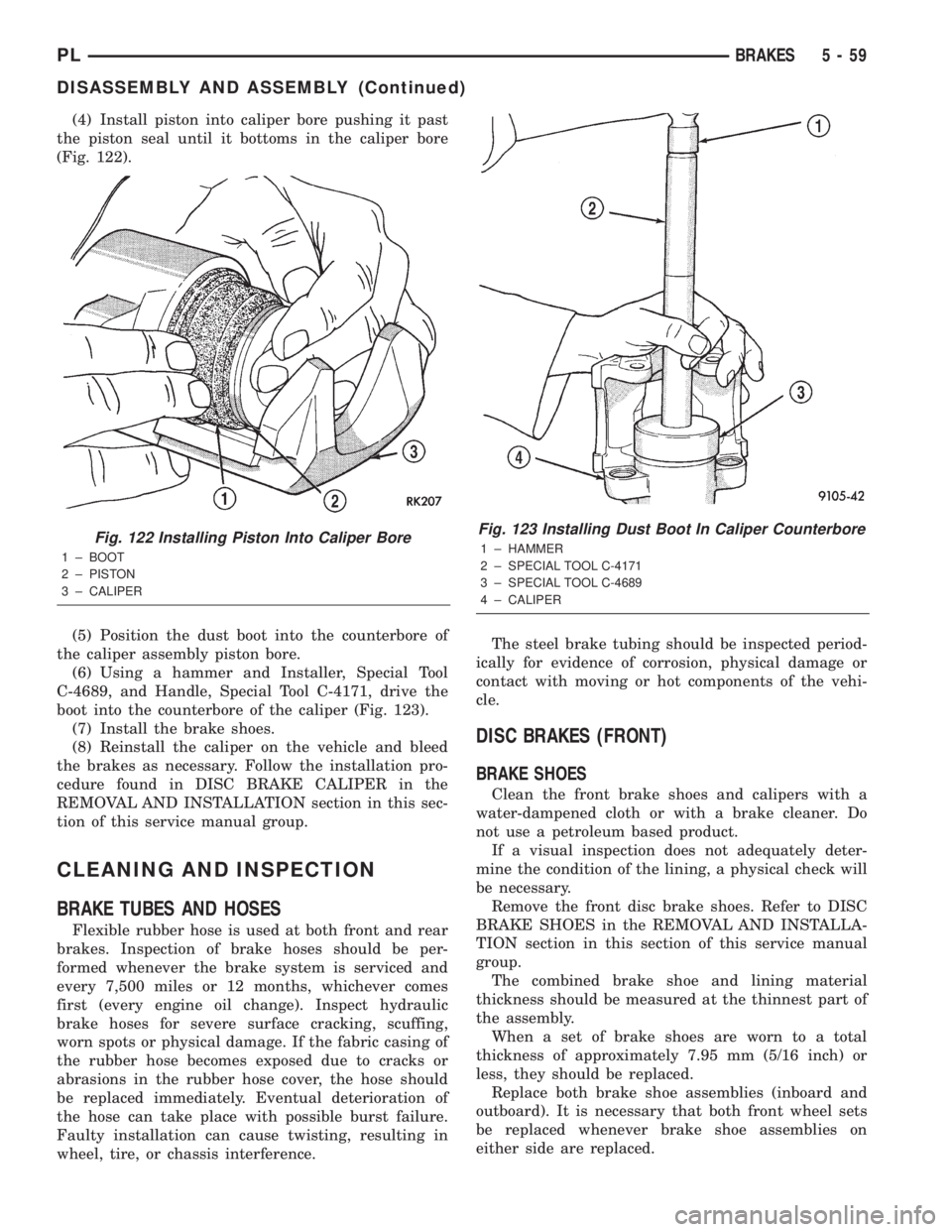

(4) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 122).

(5) Position the dust boot into the counterbore of

the caliper assembly piston bore.

(6) Using a hammer and Installer, Special Tool

C-4689, and Handle, Special Tool C-4171, drive the

boot into the counterbore of the caliper (Fig. 123).

(7) Install the brake shoes.

(8) Reinstall the caliper on the vehicle and bleed

the brakes as necessary. Follow the installation pro-

cedure found in DISC BRAKE CALIPER in the

REMOVAL AND INSTALLATION section in this sec-

tion of this service manual group.

CLEANING AND INSPECTION

BRAKE TUBES AND HOSES

Flexible rubber hose is used at both front and rear

brakes. Inspection of brake hoses should be per-

formed whenever the brake system is serviced and

every 7,500 miles or 12 months, whichever comes

first (every engine oil change). Inspect hydraulic

brake hoses for severe surface cracking, scuffing,

worn spots or physical damage. If the fabric casing of

the rubber hose becomes exposed due to cracks or

abrasions in the rubber hose cover, the hose should

be replaced immediately. Eventual deterioration of

the hose can take place with possible burst failure.

Faulty installation can cause twisting, resulting in

wheel, tire, or chassis interference.The steel brake tubing should be inspected period-

ically for evidence of corrosion, physical damage or

contact with moving or hot components of the vehi-

cle.

DISC BRAKES (FRONT)

BRAKE SHOES

Clean the front brake shoes and calipers with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary.

Remove the front disc brake shoes. Refer to DISC

BRAKE SHOES in the REMOVAL AND INSTALLA-

TION section in this section of this service manual

group.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.95 mm (5/16 inch) or

less, they should be replaced.

Replace both brake shoe assemblies (inboard and

outboard). It is necessary that both front wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

Fig. 122 Installing Piston Into Caliper Bore

1 ± BOOT

2 ± PISTON

3 ± CALIPER

Fig. 123 Installing Dust Boot In Caliper Counterbore

1 ± HAMMER

2 ± SPECIAL TOOL C-4171

3 ± SPECIAL TOOL C-4689

4 ± CALIPER

PLBRAKES 5 - 59

DISASSEMBLY AND ASSEMBLY (Continued)

Page 139 of 1285

If the brake shoe assemblies do not require

replacement, reinstall the assemblies making sure

each brake shoe is returned to the original position.

Refer to DISC BRAKE SHOES in the REMOVAL

AND INSTALLATION section in this section of this

service manual group.

CALIPER INSPECTION

Check for brake fluid leaks in and around the boot

area. Check for any ruptures, brittleness or damage

to the piston dust boot. If the boot is damaged, or a

fluid leak is visible, disassemble the caliper assembly

and install a new seal and boot, and a piston if it is

scored. Refer to DISC BRAKE CALIPER in the DIS-

ASSEMBLY AND ASSEMBLY section in this section

of this service manual group.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to DISC BRAKE

CALIPER in the DISASSEMBLY AND ASSEMBLY

section in this section of this service manual group.

DISC BRAKES (REAR)

BRAKE SHOES

Clean the rear brake shoes and calipers with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary.

Remove the rear disc brake shoes. Refer to DISC

BRAKE SHOES in the REMOVAL AND INSTALLA-

TION section in this section of this service manual

group.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.0 mm (9/32 inch) or

less, they should be replaced.

Replace both brake shoe assemblies (inboard and

outboard). It is necessary that both front wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

If the brake shoe assemblies do not require

replacement, reinstall the assemblies making sure

each brake shoe is returned to the original position.

Refer to DISC BRAKE SHOES in the REMOVAL

AND INSTALLATION section in this section of this

service manual group.

CALIPER INSPECTION

Check for brake fluid leaks in and around the boot

area. Check for any ruptures, brittleness or damage

to the piston dust boot. If the boot is damaged, or afluid leak is visible, disassemble the caliper assembly

and install a new seal and boot, and a piston if it is

scored. Refer to DISC BRAKE CALIPER in the DIS-

ASSEMBLY AND ASSEMBLY section in this section

of this service manual group.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to DISC BRAKE

CALIPER in the DISASSEMBLY AND ASSEMBLY

section in this section of this service manual group.

DRUM BRAKES (REAR)

BRAKE SHOES

Clean the rear brake shoes and springs with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

Rear brake shoe lining should show contact across

the entire width of the lining and also from the heel

to the toe of the lining. Replace the shoes if noted

otherwise.

Brake shoes with lack of contact at the toe or heel

of the brake shoe lining may be improperly ground.

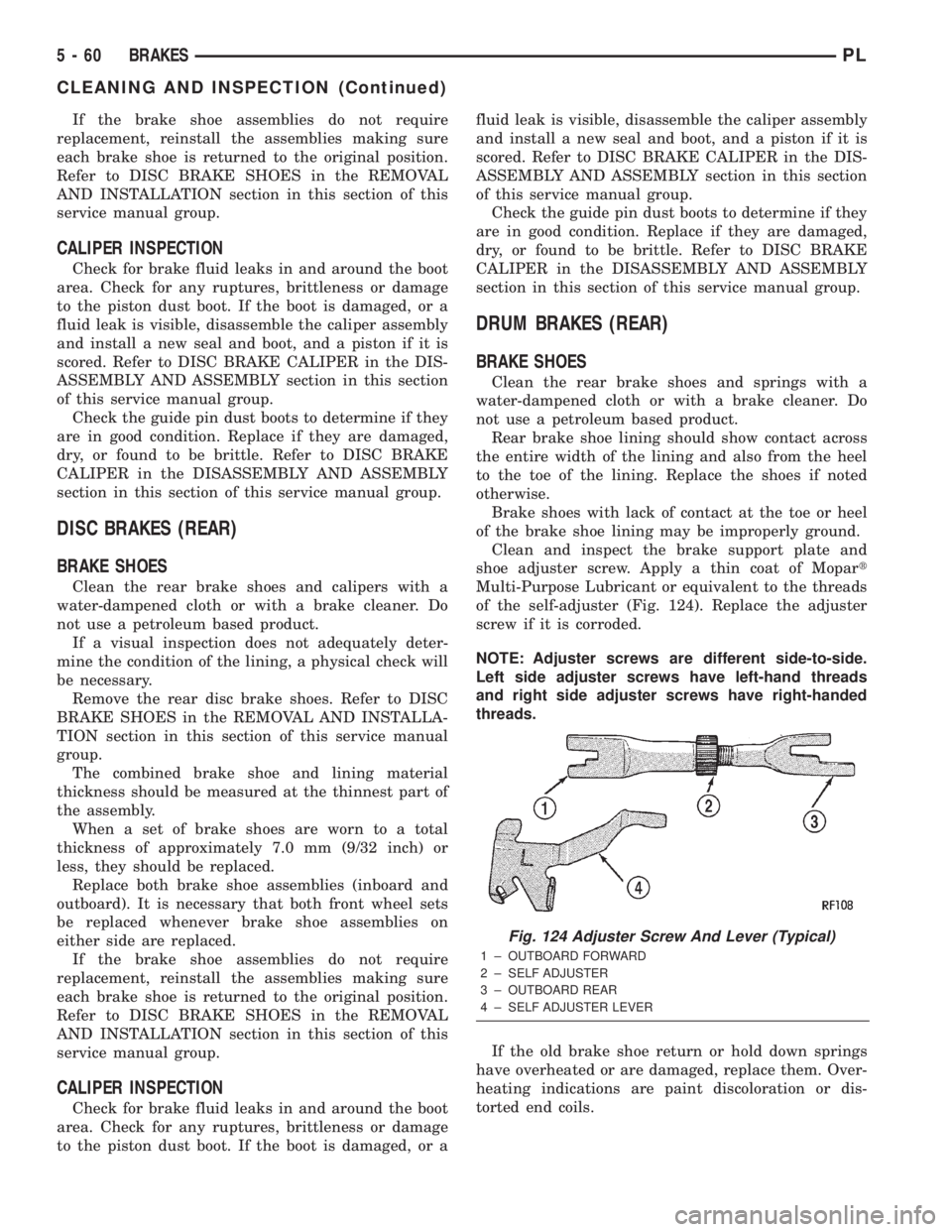

Clean and inspect the brake support plate and

shoe adjuster screw. Apply a thin coat of Mopart

Multi-Purpose Lubricant or equivalent to the threads

of the self-adjuster (Fig. 124). Replace the adjuster

screw if it is corroded.

NOTE: Adjuster screws are different side-to-side.

Left side adjuster screws have left-hand threads

and right side adjuster screws have right-handed

threads.

If the old brake shoe return or hold down springs

have overheated or are damaged, replace them. Over-

heating indications are paint discoloration or dis-

torted end coils.

Fig. 124 Adjuster Screw And Lever (Typical)

1 ± OUTBOARD FORWARD

2 ± SELF ADJUSTER

3 ± OUTBOARD REAR

4 ± SELF ADJUSTER LEVER

5 - 60 BRAKESPL

CLEANING AND INSPECTION (Continued)

Page 141 of 1285

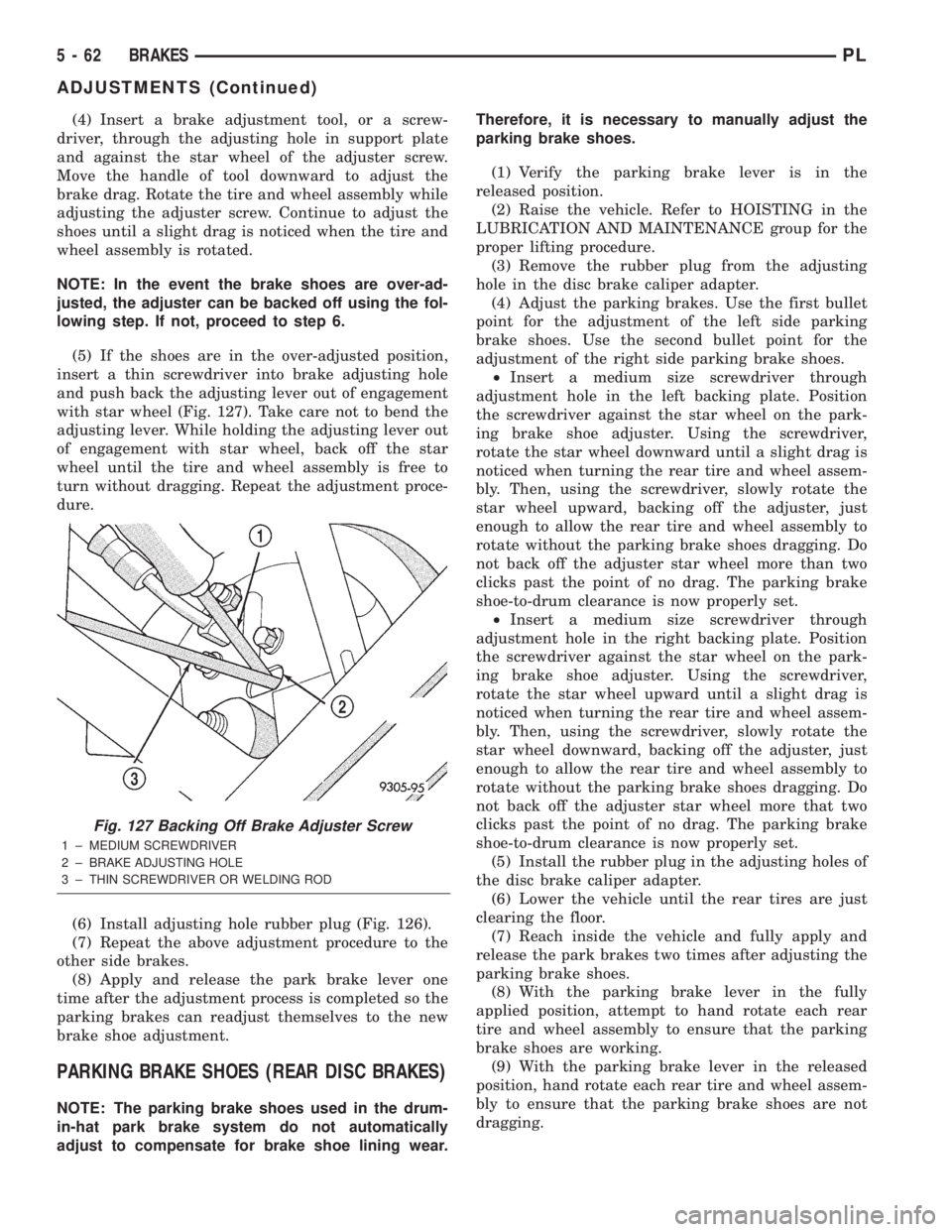

(4) Insert a brake adjustment tool, or a screw-

driver, through the adjusting hole in support plate

and against the star wheel of the adjuster screw.

Move the handle of tool downward to adjust the

brake drag. Rotate the tire and wheel assembly while

adjusting the adjuster screw. Continue to adjust the

shoes until a slight drag is noticed when the tire and

wheel assembly is rotated.

NOTE: In the event the brake shoes are over-ad-

justed, the adjuster can be backed off using the fol-

lowing step. If not, proceed to step 6.

(5) If the shoes are in the over-adjusted position,

insert a thin screwdriver into brake adjusting hole

and push back the adjusting lever out of engagement

with star wheel (Fig. 127). Take care not to bend the

adjusting lever. While holding the adjusting lever out

of engagement with star wheel, back off the star

wheel until the tire and wheel assembly is free to

turn without dragging. Repeat the adjustment proce-

dure.

(6) Install adjusting hole rubber plug (Fig. 126).

(7) Repeat the above adjustment procedure to the

other side brakes.

(8) Apply and release the park brake lever one

time after the adjustment process is completed so the

parking brakes can readjust themselves to the new

brake shoe adjustment.

PARKING BRAKE SHOES (REAR DISC BRAKES)

NOTE: The parking brake shoes used in the drum-

in-hat park brake system do not automatically

adjust to compensate for brake shoe lining wear.Therefore, it is necessary to manually adjust the

parking brake shoes.

(1) Verify the parking brake lever is in the

released position.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the rubber plug from the adjusting

hole in the disc brake caliper adapter.

(4) Adjust the parking brakes. Use the first bullet

point for the adjustment of the left side parking

brake shoes. Use the second bullet point for the

adjustment of the right side parking brake shoes.

²Insert a medium size screwdriver through

adjustment hole in the left backing plate. Position

the screwdriver against the star wheel on the park-

ing brake shoe adjuster. Using the screwdriver,

rotate the star wheel downward until a slight drag is

noticed when turning the rear tire and wheel assem-

bly. Then, using the screwdriver, slowly rotate the

star wheel upward, backing off the adjuster, just

enough to allow the rear tire and wheel assembly to

rotate without the parking brake shoes dragging. Do

not back off the adjuster star wheel more than two

clicks past the point of no drag. The parking brake

shoe-to-drum clearance is now properly set.

²Insert a medium size screwdriver through

adjustment hole in the right backing plate. Position

the screwdriver against the star wheel on the park-

ing brake shoe adjuster. Using the screwdriver,

rotate the star wheel upward until a slight drag is

noticed when turning the rear tire and wheel assem-

bly. Then, using the screwdriver, slowly rotate the

star wheel downward, backing off the adjuster, just

enough to allow the rear tire and wheel assembly to

rotate without the parking brake shoes dragging. Do

not back off the adjuster star wheel more that two

clicks past the point of no drag. The parking brake

shoe-to-drum clearance is now properly set.

(5) Install the rubber plug in the adjusting holes of

the disc brake caliper adapter.

(6) Lower the vehicle until the rear tires are just

clearing the floor.

(7) Reach inside the vehicle and fully apply and

release the park brakes two times after adjusting the

parking brake shoes.

(8) With the parking brake lever in the fully

applied position, attempt to hand rotate each rear

tire and wheel assembly to ensure that the parking

brake shoes are working.

(9) With the parking brake lever in the released

position, hand rotate each rear tire and wheel assem-

bly to ensure that the parking brake shoes are not

dragging.

Fig. 127 Backing Off Brake Adjuster Screw

1 ± MEDIUM SCREWDRIVER

2 ± BRAKE ADJUSTING HOLE

3 ± THIN SCREWDRIVER OR WELDING ROD

5 - 62 BRAKESPL

ADJUSTMENTS (Continued)

Page 142 of 1285

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid, etc.

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.....Standard

Hydraulic System.......Dual-Diagonally Split

BRAKE PEDAL:

Pedal Ratio..........................3.41

POWER BRAKE BOOSTER:

Make/Type..................Bosch/Vacuum

Mounting Studs.................. M8x1.25

Diaphragm Size/Type........ 205mmTandem

MASTER CYLINDER ASSEMBLY:

Type ........................Dual Tandem

Body Material...........Anodized Aluminum

Reservoir Material.............Polypropelene

MASTER CYLINDER BORE STROKE AND

SPLIT:

NonABS ..............22.23 mm x 34.0 mm

(0.875 in. x 1.34 in.)

ABS . . 23.82 mm x 34.0 mm (0.937 in. x 1.34 in.)

Displacement Split.................. 50/50MASTER CYLINDER FLUID OUTLET PORTS:

Tube Fitting Type...... SAE45ÉInverted Flare

W/ABS - Primary Tube Nut

Thread........................7/16 in.±24

W/ABS - Secondary Tube Nut

Thread........................ 3/8in.±24

W/O ABS - All Tube Nut Threads....7/16 in.±24

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting

Type................ SAE45ÉInverted Flare

All Tube Nut Threads............7/16 in.±24

PROPORTIONING VALVE:

Material.......................Aluminum

Function.....Hydraulic Pressure Proportioning

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts............... 17N´m(145 in. lbs.)

MASTER CYLINDER:

Mounting Nuts.......... 28N´m(250 in. lbs.)

POWER BRAKE BOOSTER:

Mounting Nuts.......... 34N´m(300 in. lbs.)

DISC BRAKE CALIPER:

Caliper Banjo Bolt......... 48N´m(35ft.lbs.)

Guide Pin Bolts.......... 22N´m(192 in. lbs.)

Bleeder Screw........... 15N´m(125 in. lbs.)

WHEEL CYLINDER (REAR):

Mounting Bolts.......... 13N´m(115in.lbs.)

Bleeder Screw............ 10N´m(80in.lbs.)

DRUM BRAKE SHOE SUPPORT PLATE

(REAR):

Mounting Bolts........... 75N´m(55ft.lbs.)

DISC BRAKE ADAPTER (REAR):

Mounting Bolts........... 75N´m(55ft.lbs.)

HUB AND BEARING (REAR):

Retaining Nut.......... 217N´m(160 ft. lbs.)

PARKING BRAKE:

Lever Mounting Nuts..... 28N´m(250 in. lbs.)

TIRE AND WHEEL:

Wheel Mounting Nut...........109±150 N´m

(80±110 ft. lbs.)

INTEGRATED CONTROL UNIT:

Mounting Bolts........... 11N´m(97in.lbs.)

CAB Mounting bolts........ 2N´m(17in.lbs.)

Bracket-to-Frame Rail Bolts.......... 23N´m

(200 in. lbs.)

WHEEL SPEED SENSOR:

Head Mounting bolt...... 12N´m(105 in. lbs.)

PLBRAKES 5 - 63

Page 145 of 1285

NOISE AND BRAKE PEDAL FEEL

During ABS braking, some brake pedal movement

may be felt. In addition, ABS braking will create

ticking, popping, or groaning noises heard by the

driver. This is normal and is due to pressurized fluid

being transferred between the master cylinder and

the brakes. If ABS operation occurs during hard

braking, some pulsation may be felt in the vehicle

body due to fore-and-aft movement of the suspension

as brake pressures are modulated.

At the end of an ABS stop, ABS is turned off when

the vehicle is slowed to a speed of 3±4 mph. There

may be a slight brake pedal drop anytime that the

ABS is deactivated, such as at the end of the stop

when the vehicle speed is less than 3 mph or during

an ABS stop where ABS is no longer required. These

conditions exist when a vehicle is being stopped on a

road surface with patches of ice, loose gravel, or sand

on it. Also, stopping a vehicle on a bumpy road sur-

face activates ABS because of the wheel hop caused

by the bumps.

TIRE NOISE AND MARKS

Although the ABS system prevents complete wheel

lockup, some wheel slip is desired in order to achieve

optimum braking performance. Wheel slip is defined

as follows: 0 percent slip means the wheel is rolling

freely and 100 percent slip means the wheel is fully

locked. During brake pressure modulation, wheel slip

is allowed to reach up to 25±30 percent. This means

that the wheel rolling velocity is 25±30 percent less

than that of a free rolling wheel at a given vehicle

speed. This slip may result in some tire chirping,

depending on the road surface. This sound should not

be interpreted as total wheel lockup.

Complete wheel lockup normally leaves black tire

marks on dry pavement. The ABS will not leave dark

black tire marks since the wheel never reaches a

fully locked condition. However, tire marks may be

noticeable as light patched marks.

START-UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

The ABS warning lamp will also be on for up to 5

seconds after the ignition is turned on. When the

vehicle is first driven off, a humming may be heard

or felt by the driver at approximately 20±40 kph

(12±25 mph). All of these conditions are a normal

function of ABS as the system is performing a diag-

nosis check.

PREMATURE ABS CYCLING

Symptoms of premature ABS cycling include: click-

ing sounds from the solenoid valves; pump/motor

running; and pulsations in the brake pedal. Prema-ture ABS cycling can occur at any braking rate of the

vehicle and on any type of road surface. Neither the

red BRAKE warning lamp, nor the amber ABS warn-

ing lamp, illuminate and no fault codes are stored in

the CAB.

Premature ABS cycling is a condition that needs to

be correctly assessed when diagnosing problems with

the antilock brake system. It may be necessary to use

a DRB scan tool to detect and verify premature ABS

cycling.

Check the following common causes when diagnos-

ing premature ABS cycling: damaged tone wheels;

incorrect tone wheels; damaged steering knuckle

wheel speed sensor mounting bosses; loose wheel

speed sensor mounting bolts; excessive tone wheel

runout; or an excessively large tone wheel-to-wheel

speed sensor air gap. Give special attention to these

components when diagnosing a vehicle exhibiting

premature ABS cycling.

After diagnosing the defective component, repair or

replace it as required. When the component repair or

replacement is completed, test drive the vehicle to

verify that premature ABS cycling has been cor-

rected.

ANTILOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the

antilock brake system components. For information

on servicing base brake system components used in

conjunction with these components, see the BASE

BRAKE SYSTEM found at the beginning of this ser-

vice manual group.

MASTER CYLINDER

A vehicle equipped with ABS uses a different mas-

ter cylinder than a vehicle that is not equipped with

ABS. Vehicles equipped with ABS use a center port

master cylinder with only two outlet ports (Fig. 1).

The brake tubes from the primary and secondary

outlet ports on the master cylinder go directly to the

integrated control unit (ICU).

The master cylinder mounts to the power brake

booster in the same manner a non-ABS master cylin-

der does.

INTEGRATED CONTROL UNIT (ICU)

The hydraulic control unit (HCU) and the control-

ler antilock brake (CAB) used with this antilock

brake system are combined (integrated) into one

unit, which is called the integrated control unit (ICU)

(Fig. 2). The ICU is located on the driver's side of the

vehicle, and is mounted to the left front frame rail

below the master cylinder (Fig. 1).

5 - 66 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 148 of 1285

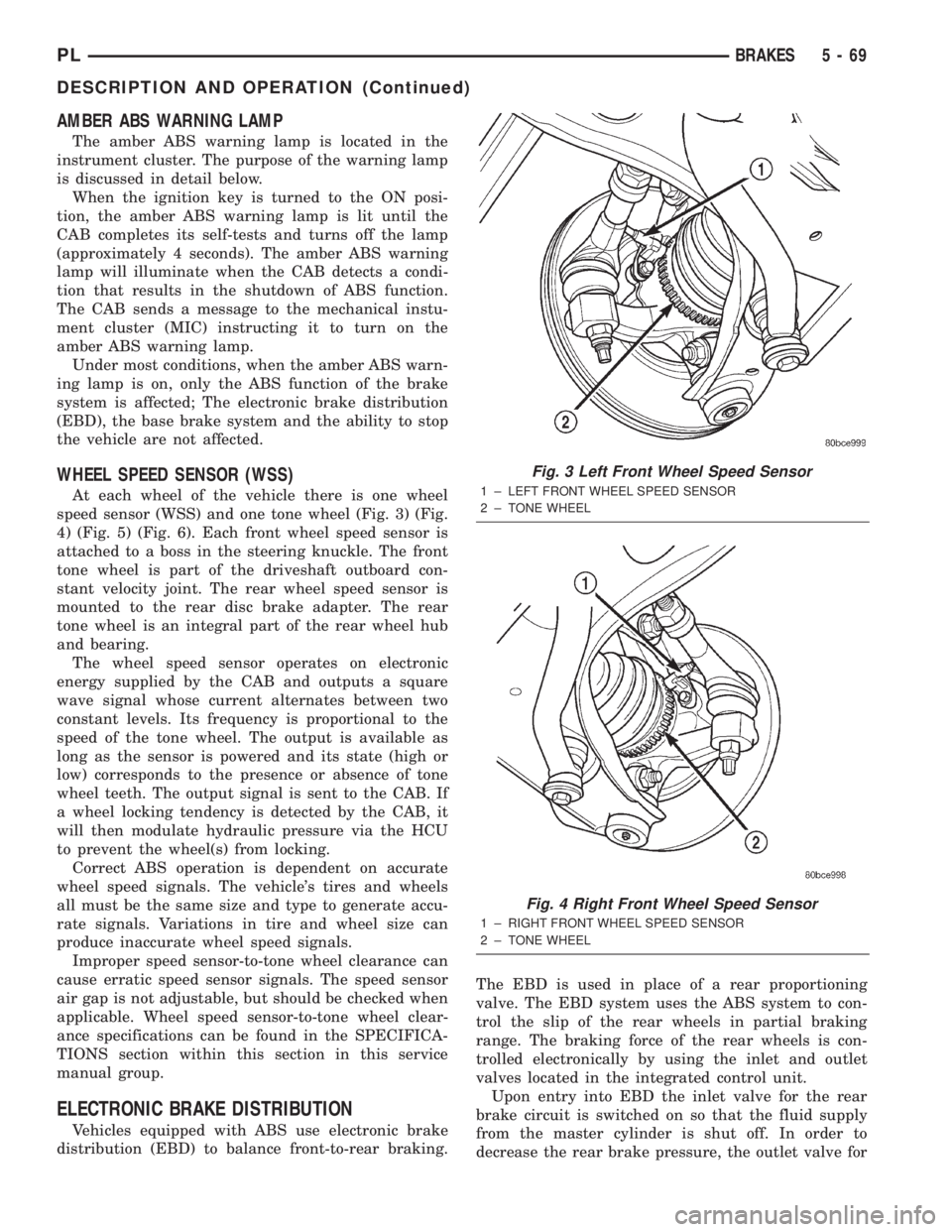

AMBER ABS WARNING LAMP

The amber ABS warning lamp is located in the

instrument cluster. The purpose of the warning lamp

is discussed in detail below.

When the ignition key is turned to the ON posi-

tion, the amber ABS warning lamp is lit until the

CAB completes its self-tests and turns off the lamp

(approximately 4 seconds). The amber ABS warning

lamp will illuminate when the CAB detects a condi-

tion that results in the shutdown of ABS function.

The CAB sends a message to the mechanical instu-

ment cluster (MIC) instructing it to turn on the

amber ABS warning lamp.

Under most conditions, when the amber ABS warn-

ing lamp is on, only the ABS function of the brake

system is affected; The electronic brake distribution

(EBD), the base brake system and the ability to stop

the vehicle are not affected.

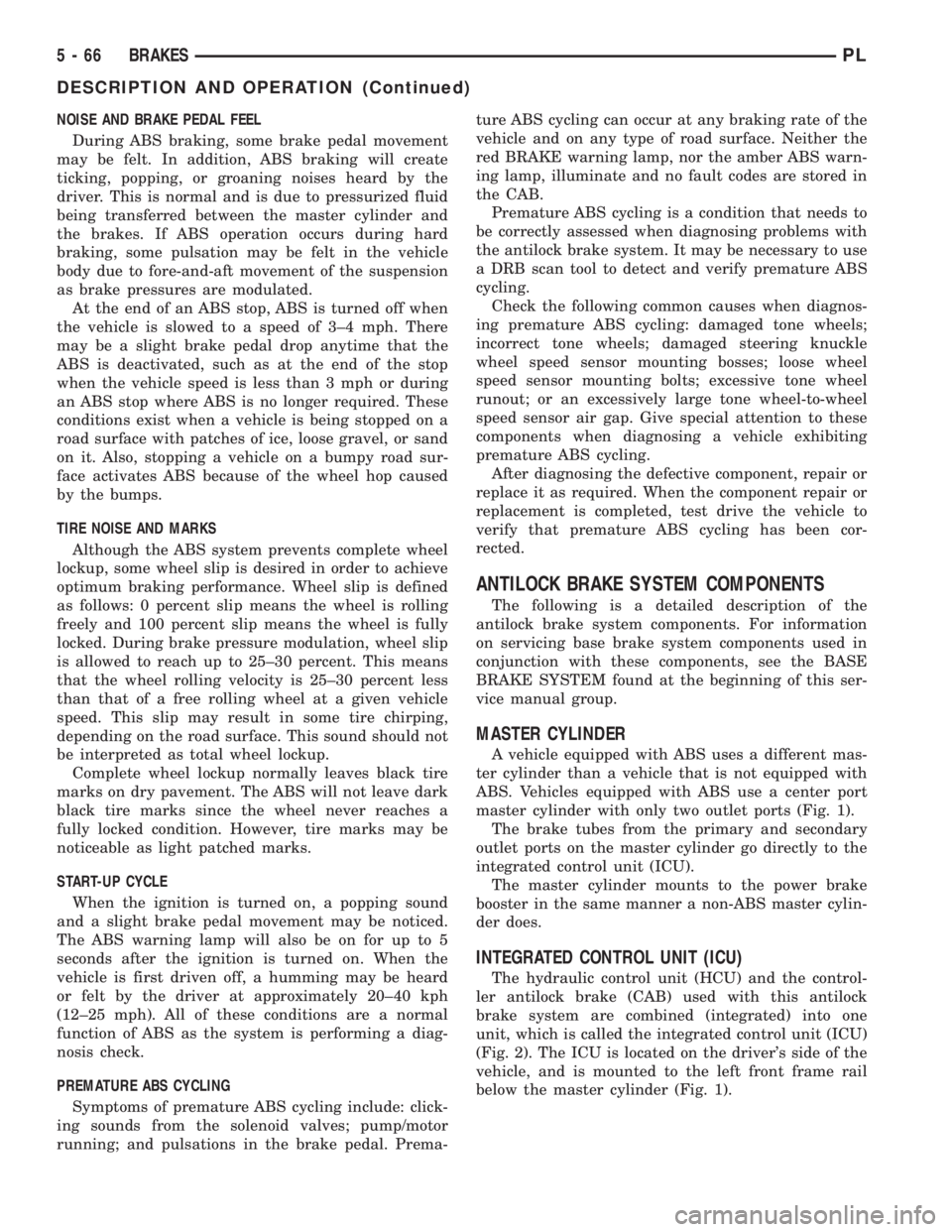

WHEEL SPEED SENSOR (WSS)

At each wheel of the vehicle there is one wheel

speed sensor (WSS) and one tone wheel (Fig. 3) (Fig.

4) (Fig. 5) (Fig. 6). Each front wheel speed sensor is

attached to a boss in the steering knuckle. The front

tone wheel is part of the driveshaft outboard con-

stant velocity joint. The rear wheel speed sensor is

mounted to the rear disc brake adapter. The rear

tone wheel is an integral part of the rear wheel hub

and bearing.

The wheel speed sensor operates on electronic

energy supplied by the CAB and outputs a square

wave signal whose current alternates between two

constant levels. Its frequency is proportional to the

speed of the tone wheel. The output is available as

long as the sensor is powered and its state (high or

low) corresponds to the presence or absence of tone

wheel teeth. The output signal is sent to the CAB. If

a wheel locking tendency is detected by the CAB, it

will then modulate hydraulic pressure via the HCU

to prevent the wheel(s) from locking.

Correct ABS operation is dependent on accurate

wheel speed signals. The vehicle's tires and wheels

all must be the same size and type to generate accu-

rate signals. Variations in tire and wheel size can

produce inaccurate wheel speed signals.

Improper speed sensor-to-tone wheel clearance can

cause erratic speed sensor signals. The speed sensor

air gap is not adjustable, but should be checked when

applicable. Wheel speed sensor-to-tone wheel clear-

ance specifications can be found in the SPECIFICA-

TIONS section within this section in this service

manual group.

ELECTRONIC BRAKE DISTRIBUTION

Vehicles equipped with ABS use electronic brake

distribution (EBD) to balance front-to-rear braking.The EBD is used in place of a rear proportioning

valve. The EBD system uses the ABS system to con-

trol the slip of the rear wheels in partial braking

range. The braking force of the rear wheels is con-

trolled electronically by using the inlet and outlet

valves located in the integrated control unit.

Upon entry into EBD the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

Fig. 3 Left Front Wheel Speed Sensor

1 ± LEFT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

Fig. 4 Right Front Wheel Speed Sensor

1 ± RIGHT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

PLBRAKES 5 - 69

DESCRIPTION AND OPERATION (Continued)

Page 151 of 1285

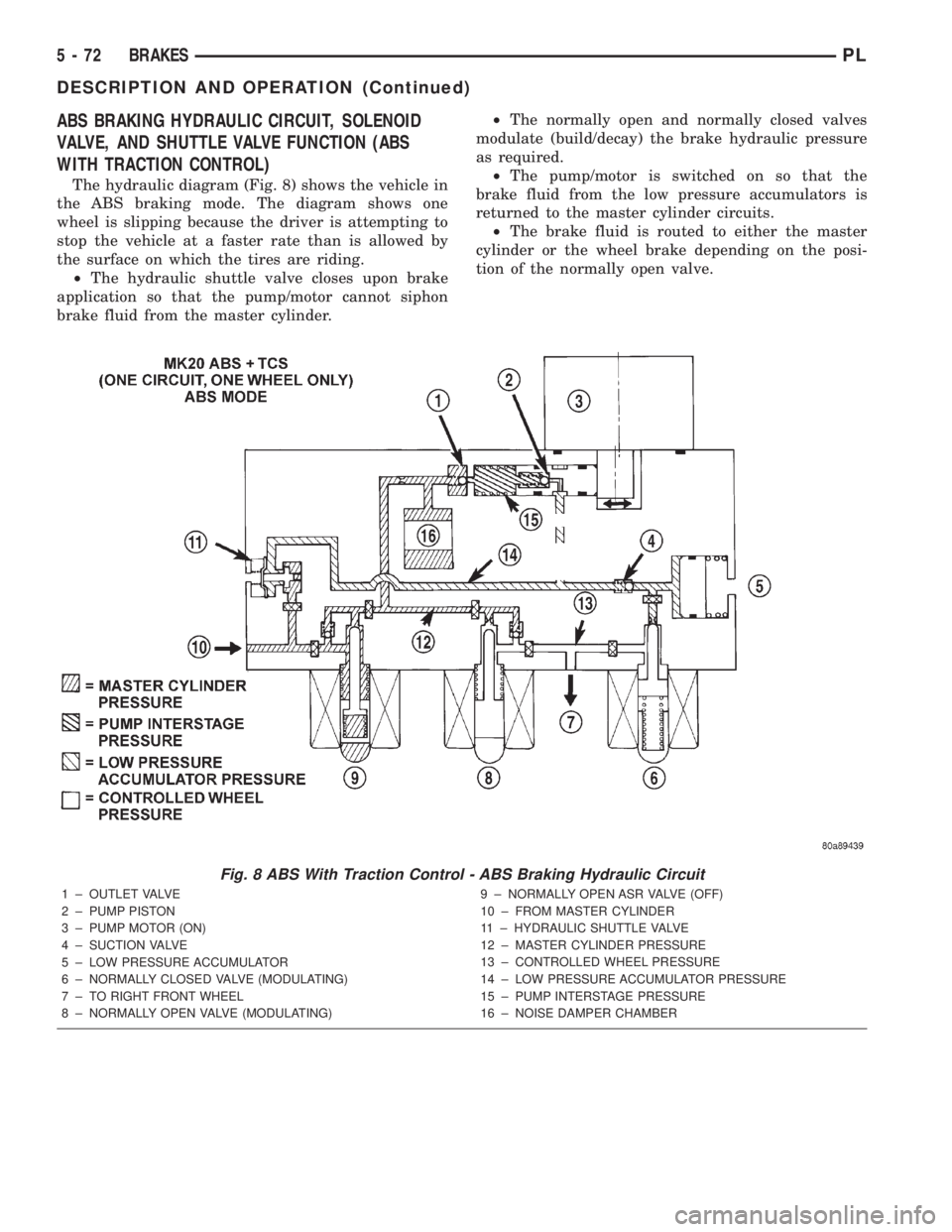

ABS BRAKING HYDRAULIC CIRCUIT, SOLENOID

VALVE, AND SHUTTLE VALVE FUNCTION (ABS

WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 8) shows the vehicle in

the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The hydraulic shuttle valve closes upon brake

application so that the pump/motor cannot siphon

brake fluid from the master cylinder.²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.

²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid is routed to either the master

cylinder or the wheel brake depending on the posi-

tion of the normally open valve.

Fig. 8 ABS With Traction Control - ABS Braking Hydraulic Circuit

1 ± OUTLET VALVE

2 ± PUMP PISTON

3 ± PUMP MOTOR (ON)

4 ± SUCTION VALVE

5 ± LOW PRESSURE ACCUMULATOR

6 ± NORMALLY CLOSED VALVE (MODULATING)

7 ± TO RIGHT FRONT WHEEL

8 ± NORMALLY OPEN VALVE (MODULATING)9 ± NORMALLY OPEN ASR VALVE (OFF)

10 ± FROM MASTER CYLINDER

11 ± HYDRAULIC SHUTTLE VALVE

12 ± MASTER CYLINDER PRESSURE

13 ± CONTROLLED WHEEL PRESSURE

14 ± LOW PRESSURE ACCUMULATOR PRESSURE

15 ± PUMP INTERSTAGE PRESSURE

16 ± NOISE DAMPER CHAMBER

5 - 72 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 155 of 1285

junction block. A label on the underside of the PDC

cover identifies the locations of the ABS fuses.

(2) Inspect the 25-way electrical connector at the

CAB for damaged, spread, or backed-out wiring ter-

minals. Verify that the 25-way connector is fully

inserted in the socket of the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Look for poor mating of connector halves or ter-

minals not fully seated in the connector body.

(5)

Check for improperly formed or damaged termi-

nals. All connector terminals in a suspect circuit should

be carefully reformed to increase contact tension.

(6) Look for poor terminal-to-wire connections.

This requires removing the terminal from the connec-

tor body to inspect it.

(7) Verify pin presence in the connector assembly

(8) Check for proper ground connections. Check all

ground connections for signs of corrosion, loose fas-

teners, or other potential defects. Refer to the wiring

diagrams for ground locations.

(9) Look for problems with the main power sources

of the vehicle. Inspect the battery, generator, ignition

circuits and other related relays and fuses.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record any trouble codes.

Most failures of the ABS disable the ABS function

for the entire ignition cycle even if the fault clears

before key-off. There are some failure conditions,

however, that allow ABS operation to resume during

the ignition cycle in which the trouble occurred even

if the trouble conditions are no longer present.

The following trouble conditions may result in

intermittent illumination of the amber ABS warning

lamp.

²Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.

²High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

Additional possible causes that may result in the

illumination of the amber ABS warning lamp are as

follows:

²Any condition that interrupts electrical current

to the CAB may cause the amber ABS warning lamp

to turn on intermittently.

²If PCI communication between the body control-

ler and the CAB is interrupted, the body controller

can turn on the amber ABS warning lamp.

TONE WHEEL

Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes:

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. Refer to the

DIFFERENTIAL AND DRIVELINE group in this

service manual for removal and installation.

If a rear tone wheel is found to need replacement,

the rear hub and bearing must be replaced. No

attempt should be made to replace just the tone

wheel. Refer to the SUSPENSION group in this ser-

vice manual for removal and installation.

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

Refer to SPECIFICATIONS in this section of the ser-

vice manual for the minimum and maximum wheel

speed sensor to tone wheel clearance.

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout. If tone

wheel runout is excessive, determine if it is caused

by a defect in the driveshaft assembly or hub and

bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft or rear hub and bearing is necessary.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swelling indicates the

presence of petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If the fluid sep-

arates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If the brake fluid is contaminated, drain and thor-

oughly flush the brake system. Replace all the rubber

parts or components containing rubber coming into

contact with the brake fluid including: the master

cylinder; proportioning valves; caliper seals; wheel

cylinder seals; ABS hydraulic control unit; and all

hydraulic fluid hoses.

5 - 76 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 157 of 1285

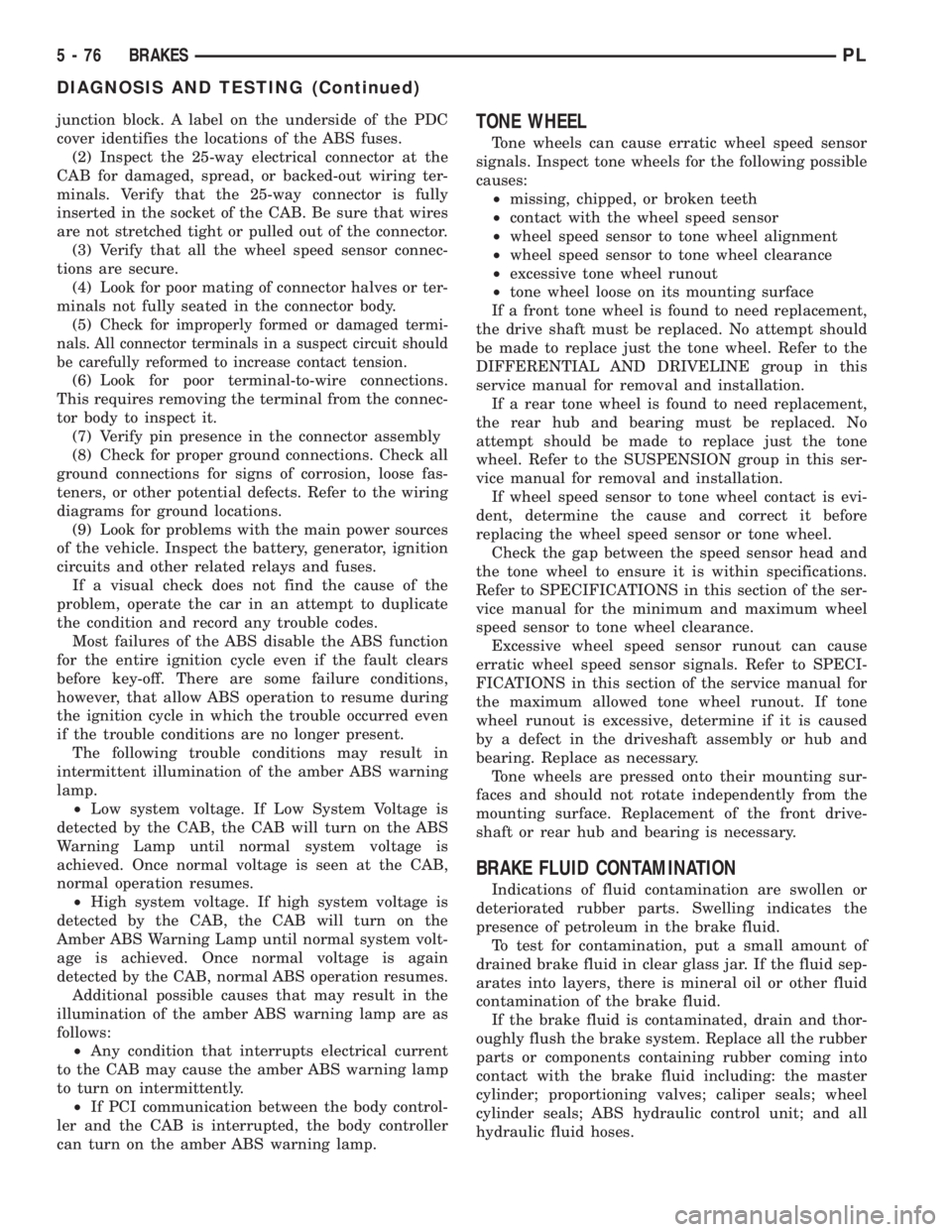

NOTE: It is not necessary to bleed the entire

hydraulic system after replacing just the master cyl-

inder unless the brake system has been open to air

for an excessive amount of time or air is present in

the lines. Only the master cylinder must be bled

and filled.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

Review this entire section prior to performing any

mechanical work on a vehicle equipped with ABS.

This section contains information on precautions per-

taining to potential component damage, vehicle dam-

age and personal injury which could result when

servicing an ABS equipped vehicle.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash off with water immediately.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.

CAUTION: If welding work is to be performed on

the vehicle, using an electric arc welder, the CAB

connector should be disconnected during the weld-

ing operation.

CAUTION: The CAB 25-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

Many components of the ABS System are not ser-

viceable and must be replaced as an assembly. Do not

disassemble any component which is not designed to

be serviced.

MASTER CYLINDER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal while the engine is not running until a

firm brake pedal is achieved.

(1) With the engine not running, pump the brake

pedal 4-5 strokes until the pedal feel is firm.

(2) Disconnect the negative (ground) cable from

the battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(4) Disconnect the wiring harness connector from

the brake fluid level switch on the master cylinder

reservoir (Fig. 12).

Fig. 11 Bleeding Master Cylinder

1 ± WOODEN DOWEL

2 ± MASTER CYLINDER

5 - 78 BRAKESPL

SERVICE PROCEDURES (Continued)