radiator DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 985 of 1285

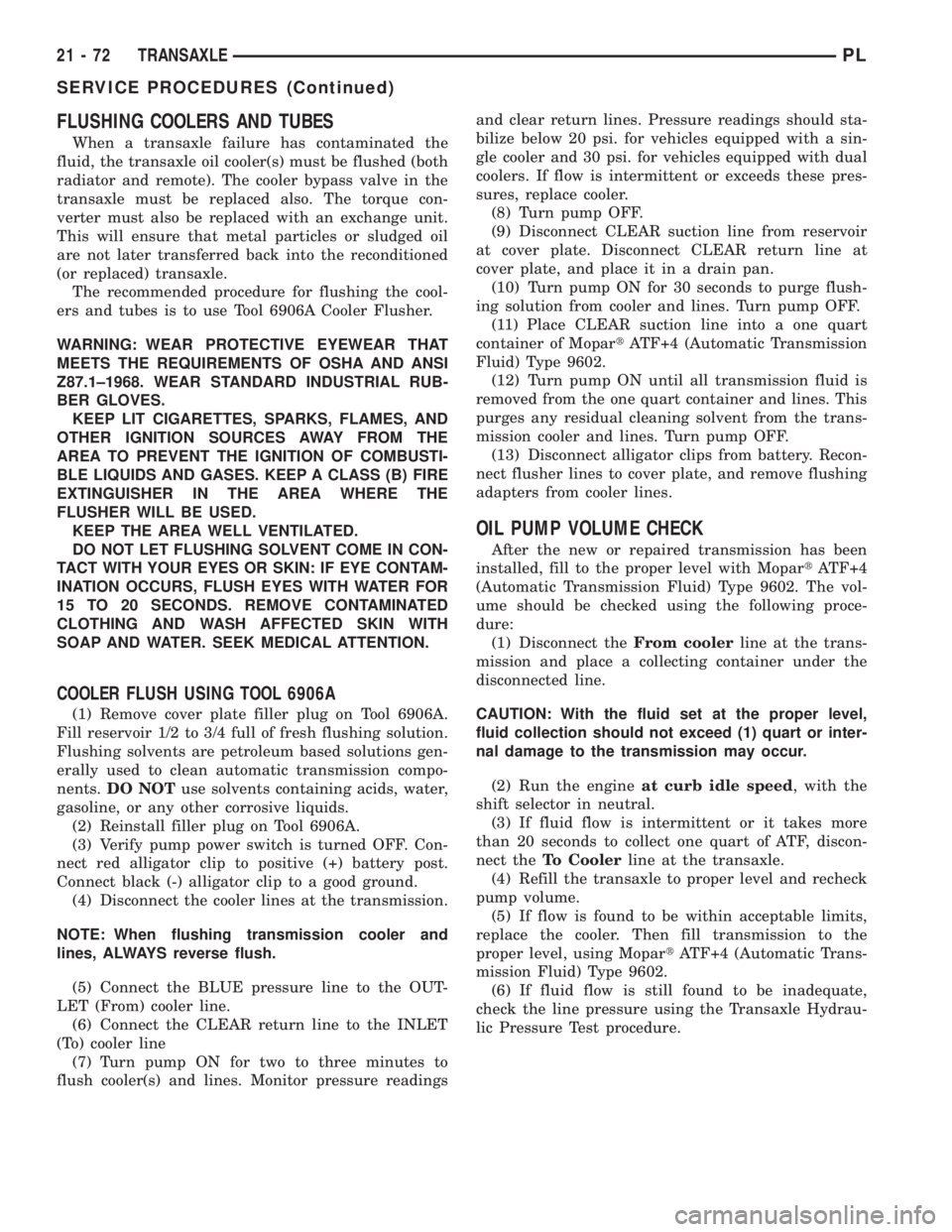

FLUSHING COOLERS AND TUBES

When a transaxle failure has contaminated the

fluid, the transaxle oil cooler(s) must be flushed (both

radiator and remote). The cooler bypass valve in the

transaxle must be replaced also. The torque con-

verter must also be replaced with an exchange unit.

This will ensure that metal particles or sludged oil

are not later transferred back into the reconditioned

(or replaced) transaxle.

The recommended procedure for flushing the cool-

ers and tubes is to use Tool 6906A Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIT CIGARETTES, SPARKS, FLAMES, AND

OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

COOLER FLUSH USING TOOL 6906A

(1) Remove cover plate filler plug on Tool 6906A.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906A.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines. Monitor pressure readingsand clear return lines. Pressure readings should sta-

bilize below 20 psi. for vehicles equipped with a sin-

gle cooler and 30 psi. for vehicles equipped with dual

coolers. If flow is intermittent or exceeds these pres-

sures, replace cooler.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of MopartATF+4 (Automatic Transmission

Fluid) Type 9602.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

OIL PUMP VOLUME CHECK

After the new or repaired transmission has been

installed, fill to the proper level with MopartATF+4

(Automatic Transmission Fluid) Type 9602. The vol-

ume should be checked using the following proce-

dure:

(1) Disconnect theFrom coolerline at the trans-

mission and place a collecting container under the

disconnected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of ATF, discon-

nect theTo Coolerline at the transaxle.

(4) Refill the transaxle to proper level and recheck

pump volume.

(5) If flow is found to be within acceptable limits,

replace the cooler. Then fill transmission to the

proper level, using MopartATF+4 (Automatic Trans-

mission Fluid) Type 9602.

(6) If fluid flow is still found to be inadequate,

check the line pressure using the Transaxle Hydrau-

lic Pressure Test procedure.

21 - 72 TRANSAXLEPL

SERVICE PROCEDURES (Continued)

Page 1098 of 1285

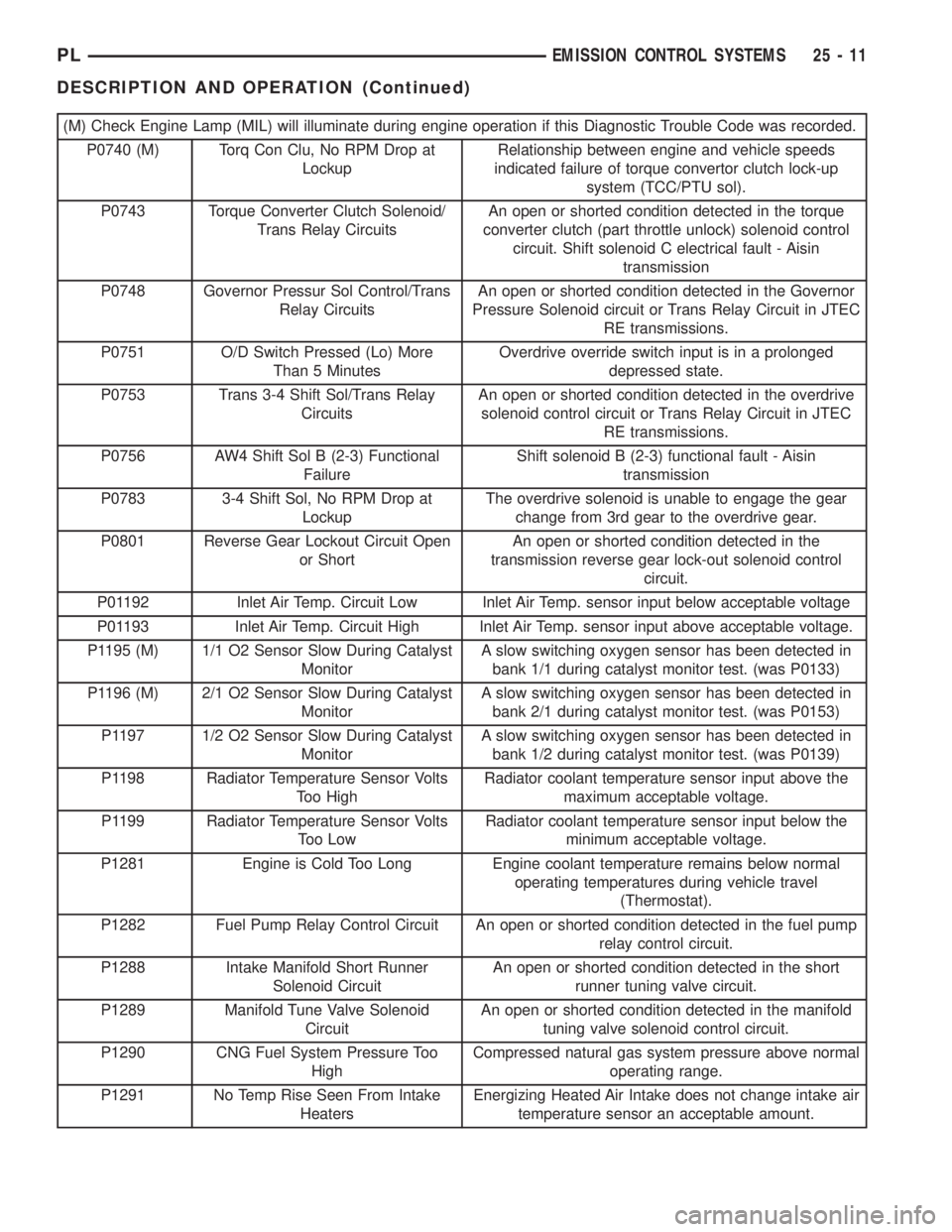

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0740 (M) Torq Con Clu, No RPM Drop at

LockupRelationship between engine and vehicle speeds

indicated failure of torque convertor clutch lock-up

system (TCC/PTU sol).

P0743 Torque Converter Clutch Solenoid/

Trans Relay CircuitsAn open or shorted condition detected in the torque

converter clutch (part throttle unlock) solenoid control

circuit. Shift solenoid C electrical fault - Aisin

transmission

P0748 Governor Pressur Sol Control/Trans

Relay CircuitsAn open or shorted condition detected in the Governor

Pressure Solenoid circuit or Trans Relay Circuit in JTEC

RE transmissions.

P0751 O/D Switch Pressed (Lo) More

Than 5 MinutesOverdrive override switch input is in a prolonged

depressed state.

P0753 Trans 3-4 Shift Sol/Trans Relay

CircuitsAn open or shorted condition detected in the overdrive

solenoid control circuit or Trans Relay Circuit in JTEC

RE transmissions.

P0756 AW4 Shift Sol B (2-3) Functional

FailureShift solenoid B (2-3) functional fault - Aisin

transmission

P0783 3-4 Shift Sol, No RPM Drop at

LockupThe overdrive solenoid is unable to engage the gear

change from 3rd gear to the overdrive gear.

P0801 Reverse Gear Lockout Circuit Open

or ShortAn open or shorted condition detected in the

transmission reverse gear lock-out solenoid control

circuit.

P01192 Inlet Air Temp. Circuit Low Inlet Air Temp. sensor input below acceptable voltage

P01193 Inlet Air Temp. Circuit High Inlet Air Temp. sensor input above acceptable voltage.

P1195 (M) 1/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/1 during catalyst monitor test. (was P0133)

P1196 (M) 2/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 2/1 during catalyst monitor test. (was P0153)

P1197 1/2 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/2 during catalyst monitor test. (was P0139)

P1198 Radiator Temperature Sensor Volts

Too HighRadiator coolant temperature sensor input above the

maximum acceptable voltage.

P1199 Radiator Temperature Sensor Volts

Too LowRadiator coolant temperature sensor input below the

minimum acceptable voltage.

P1281 Engine is Cold Too Long Engine coolant temperature remains below normal

operating temperatures during vehicle travel

(Thermostat).

P1282 Fuel Pump Relay Control Circuit An open or shorted condition detected in the fuel pump

relay control circuit.

P1288 Intake Manifold Short Runner

Solenoid CircuitAn open or shorted condition detected in the short

runner tuning valve circuit.

P1289 Manifold Tune Valve Solenoid

CircuitAn open or shorted condition detected in the manifold

tuning valve solenoid control circuit.

P1290 CNG Fuel System Pressure Too

HighCompressed natural gas system pressure above normal

operating range.

P1291 No Temp Rise Seen From Intake

HeatersEnergizing Heated Air Intake does not change intake air

temperature sensor an acceptable amount.

PLEMISSION CONTROL SYSTEMS 25 - 11

DESCRIPTION AND OPERATION (Continued)

Page 1100 of 1285

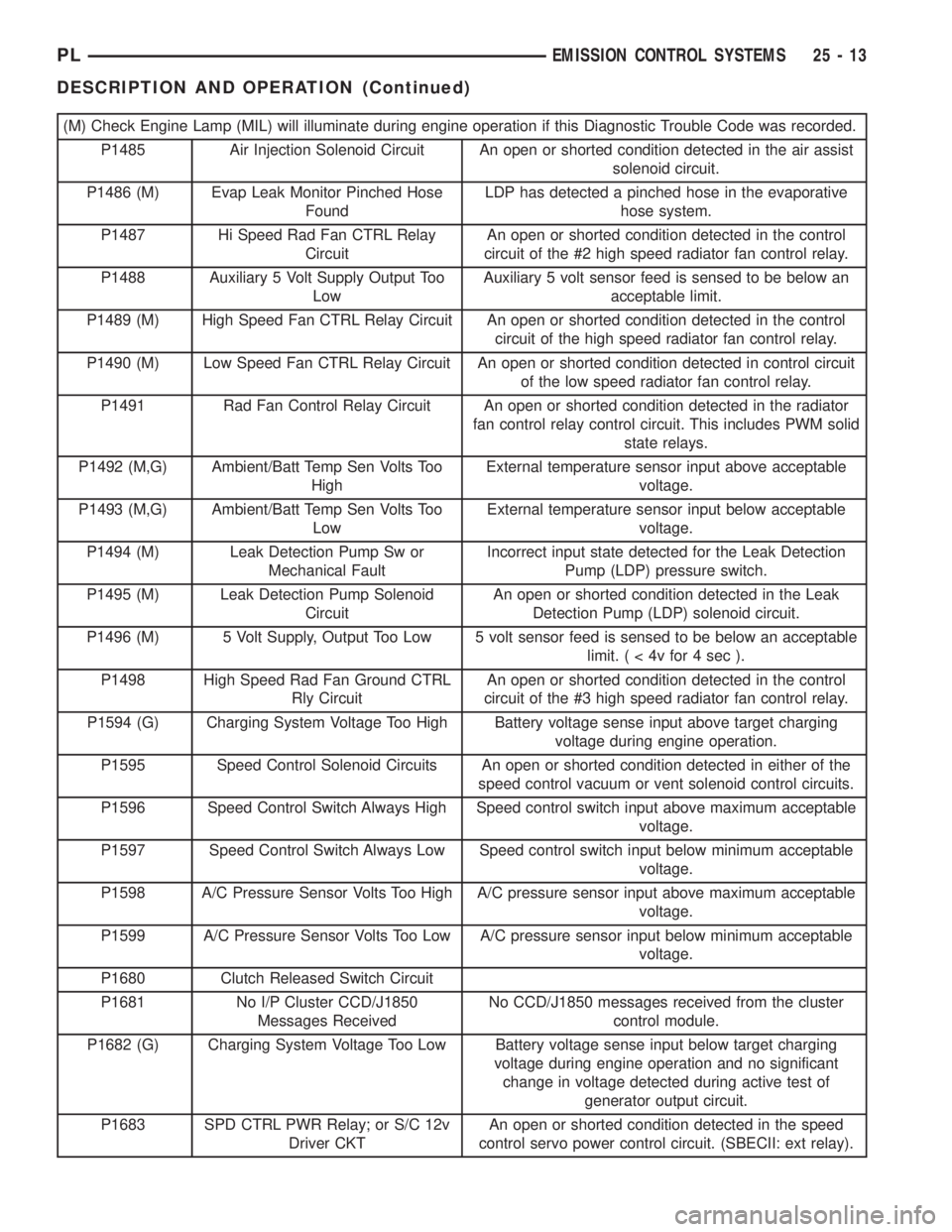

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P1485 Air Injection Solenoid Circuit An open or shorted condition detected in the air assist

solenoid circuit.

P1486 (M) Evap Leak Monitor Pinched Hose

FoundLDP has detected a pinched hose in the evaporative

hose system.

P1487 Hi Speed Rad Fan CTRL Relay

CircuitAn open or shorted condition detected in the control

circuit of the #2 high speed radiator fan control relay.

P1488 Auxiliary 5 Volt Supply Output Too

LowAuxiliary 5 volt sensor feed is sensed to be below an

acceptable limit.

P1489 (M) High Speed Fan CTRL Relay Circuit An open or shorted condition detected in the control

circuit of the high speed radiator fan control relay.

P1490 (M) Low Speed Fan CTRL Relay Circuit An open or shorted condition detected in control circuit

of the low speed radiator fan control relay.

P1491 Rad Fan Control Relay Circuit An open or shorted condition detected in the radiator

fan control relay control circuit. This includes PWM solid

state relays.

P1492 (M,G) Ambient/Batt Temp Sen Volts Too

HighExternal temperature sensor input above acceptable

voltage.

P1493 (M,G) Ambient/Batt Temp Sen Volts Too

LowExternal temperature sensor input below acceptable

voltage.

P1494 (M) Leak Detection Pump Sw or

Mechanical FaultIncorrect input state detected for the Leak Detection

Pump (LDP) pressure switch.

P1495 (M) Leak Detection Pump Solenoid

CircuitAn open or shorted condition detected in the Leak

Detection Pump (LDP) solenoid circuit.

P1496 (M) 5 Volt Supply, Output Too Low 5 volt sensor feed is sensed to be below an acceptable

limit.(<4vfor4sec).

P1498 High Speed Rad Fan Ground CTRL

Rly CircuitAn open or shorted condition detected in the control

circuit of the #3 high speed radiator fan control relay.

P1594 (G) Charging System Voltage Too High Battery voltage sense input above target charging

voltage during engine operation.

P1595 Speed Control Solenoid Circuits An open or shorted condition detected in either of the

speed control vacuum or vent solenoid control circuits.

P1596 Speed Control Switch Always High Speed control switch input above maximum acceptable

voltage.

P1597 Speed Control Switch Always Low Speed control switch input below minimum acceptable

voltage.

P1598 A/C Pressure Sensor Volts Too High A/C pressure sensor input above maximum acceptable

voltage.

P1599 A/C Pressure Sensor Volts Too Low A/C pressure sensor input below minimum acceptable

voltage.

P1680 Clutch Released Switch Circuit

P1681 No I/P Cluster CCD/J1850

Messages ReceivedNo CCD/J1850 messages received from the cluster

control module.

P1682 (G) Charging System Voltage Too Low Battery voltage sense input below target charging

voltage during engine operation and no significant

change in voltage detected during active test of

generator output circuit.

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed

control servo power control circuit. (SBECII: ext relay).

PLEMISSION CONTROL SYSTEMS 25 - 13

DESCRIPTION AND OPERATION (Continued)

Page 1105 of 1285

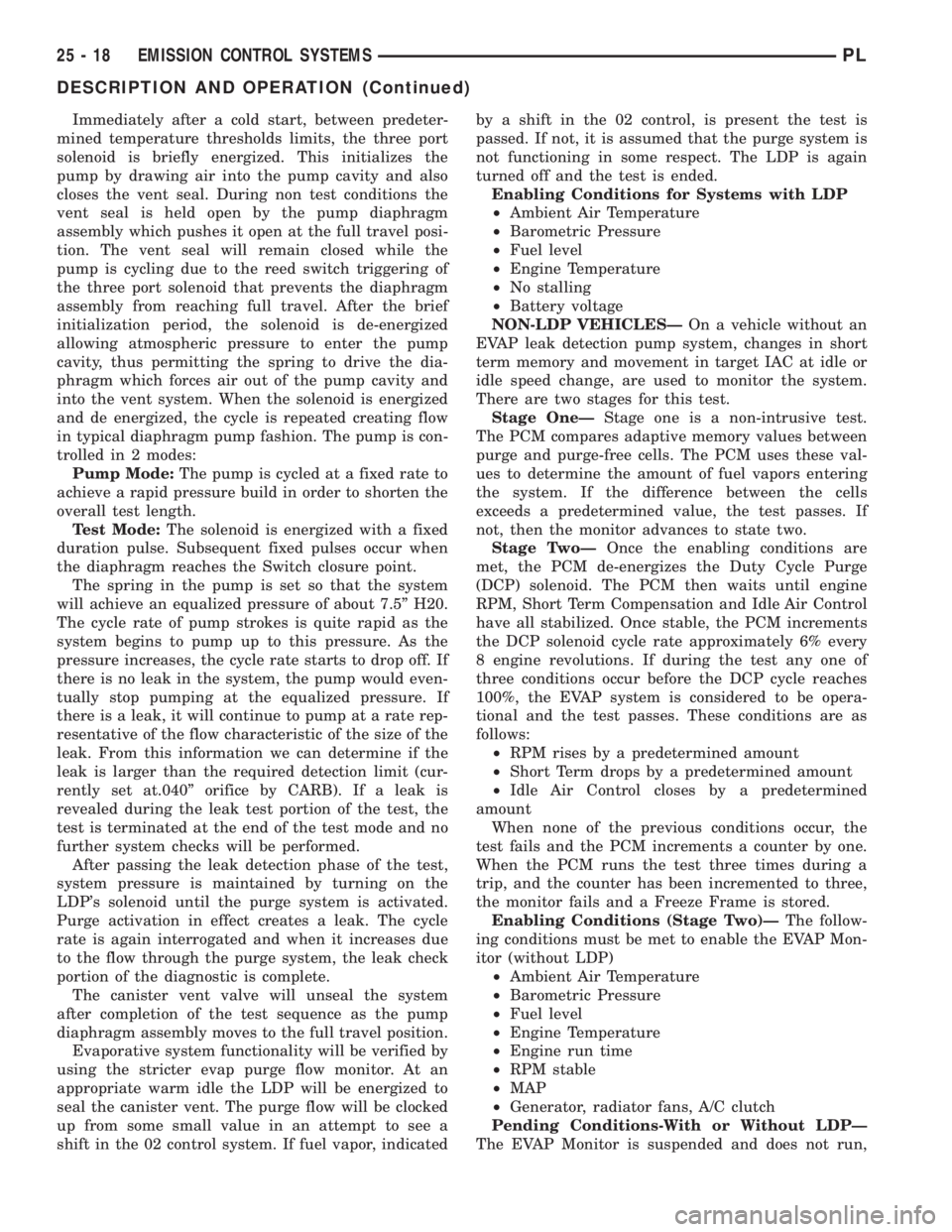

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at.040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicatedby a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

Enabling Conditions for Systems with LDP

²Ambient Air Temperature

²Barometric Pressure

²Fuel level

²Engine Temperature

²No stalling

²Battery voltage

NON-LDP VEHICLESÐOn a vehicle without an

EVAP leak detection pump system, changes in short

term memory and movement in target IAC at idle or

idle speed change, are used to monitor the system.

There are two stages for this test.

Stage OneÐStage one is a non-intrusive test.

The PCM compares adaptive memory values between

purge and purge-free cells. The PCM uses these val-

ues to determine the amount of fuel vapors entering

the system. If the difference between the cells

exceeds a predetermined value, the test passes. If

not, then the monitor advances to state two.

Stage TwoÐOnce the enabling conditions are

met, the PCM de-energizes the Duty Cycle Purge

(DCP) solenoid. The PCM then waits until engine

RPM, Short Term Compensation and Idle Air Control

have all stabilized. Once stable, the PCM increments

the DCP solenoid cycle rate approximately 6% every

8 engine revolutions. If during the test any one of

three conditions occur before the DCP cycle reaches

100%, the EVAP system is considered to be opera-

tional and the test passes. These conditions are as

follows:

²RPM rises by a predetermined amount

²Short Term drops by a predetermined amount

²Idle Air Control closes by a predetermined

amount

When none of the previous conditions occur, the

test fails and the PCM increments a counter by one.

When the PCM runs the test three times during a

trip, and the counter has been incremented to three,

the monitor fails and a Freeze Frame is stored.

Enabling Conditions (Stage Two)ÐThe follow-

ing conditions must be met to enable the EVAP Mon-

itor (without LDP)

²Ambient Air Temperature

²Barometric Pressure

²Fuel level

²Engine Temperature

²Engine run time

²RPM stable

²MAP

²Generator, radiator fans, A/C clutch

Pending Conditions-With or Without LDPÐ

The EVAP Monitor is suspended and does not run,

25 - 18 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1107 of 1285

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1140 of 1285

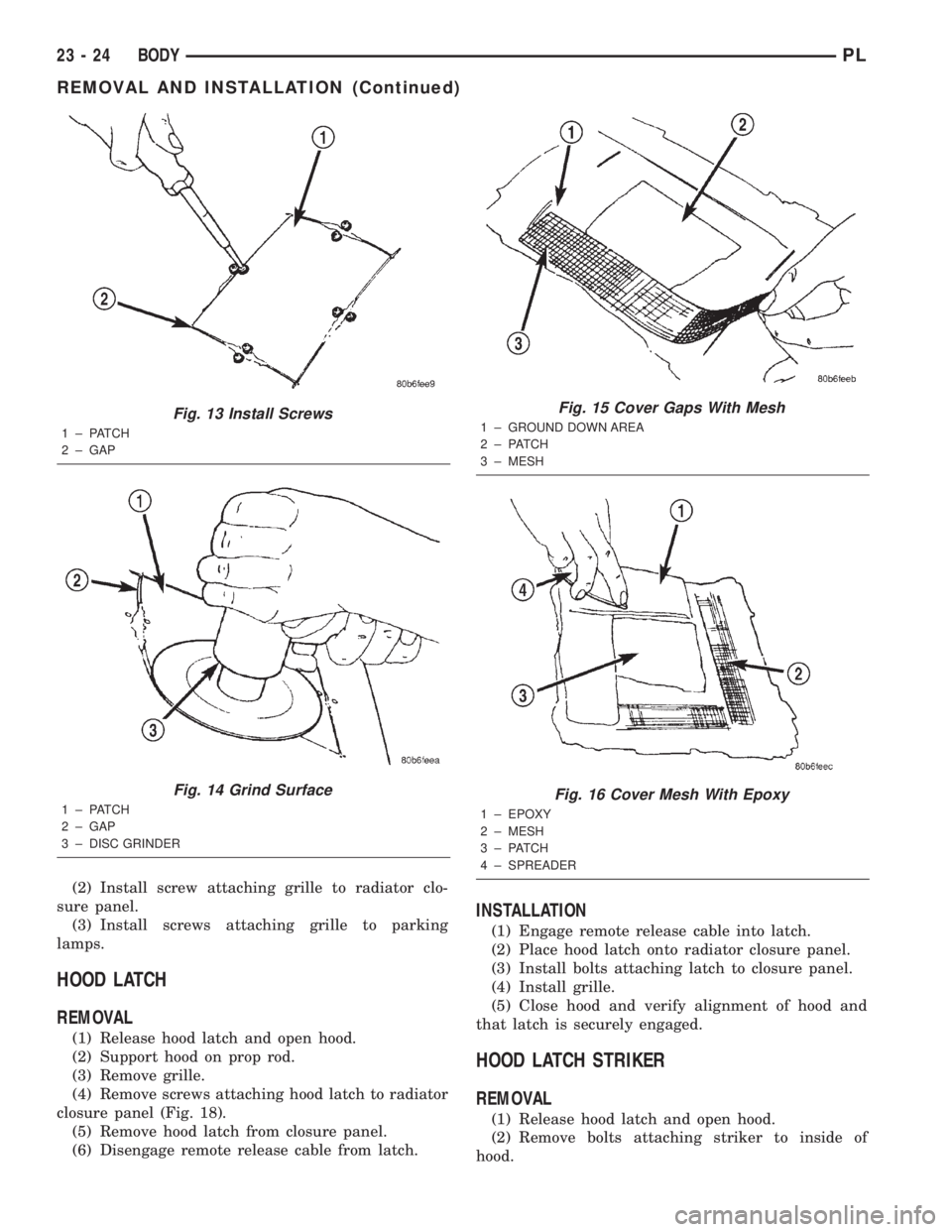

(12) Position patch in cutout against support

squares and adjust patch until the gap is equal along

all sides (Fig. 11).

(13) Drill 3 mm (0.125 in.) holes in the support

squares through the pre-drilled holes in the patch.

(14) Apply a coat of epoxy to the exposed ends of

the support squares (Fig. 12).

(15) Install screws to hold the patch to support

squares (Fig. 13). Tighten screws until patch surface

is flush with panel surface.

(16) Allow epoxy to cure, and remove all screws.

(17) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 14). With compressed air, blow dust from

around patch.

(18) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 15).

(19) Mix enough epoxy to cover the entire patch

area.

(20) Apply epoxy over the mesh around patch, and

smooth epoxy with a wide spreader to reduce finish

grinding. Use two to three layers of mesh and epoxy

to create a stronger repair (Fig. 16).

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

REMOVAL AND INSTALLATION

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

(2) Remove screws attaching grille to parking

lamps (Fig. 17).

(3) Remove screw attaching grille to radiator clo-

sure panel.

(4) Remove grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

Fig. 10 Secure Support Squares To Body Panel

1 ± SUPPORT SQUARES

2 ± SCREWS

3 ± DAMAGED BODY PANEL

Fig. 11 Position Patch In Cutout And Align

1 ± CUTOUT

2 ± SUPPORT SQUARES

Fig. 12 Apply Epoxy To Support Squares

1 ± APPLICATOR

2 ± SUPPORT SQUARES

3 ± EPOXY

PLBODY 23 - 23

SERVICE PROCEDURES (Continued)

Page 1141 of 1285

(2) Install screw attaching grille to radiator clo-

sure panel.

(3) Install screws attaching grille to parking

lamps.

HOOD LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Support hood on prop rod.

(3) Remove grille.

(4) Remove screws attaching hood latch to radiator

closure panel (Fig. 18).

(5) Remove hood latch from closure panel.

(6) Disengage remote release cable from latch.

INSTALLATION

(1) Engage remote release cable into latch.

(2) Place hood latch onto radiator closure panel.

(3) Install bolts attaching latch to closure panel.

(4) Install grille.

(5) Close hood and verify alignment of hood and

that latch is securely engaged.

HOOD LATCH STRIKER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching striker to inside of

hood.

Fig. 13 Install Screws

1 ± PATCH

2 ± GAP

Fig. 14 Grind Surface

1 ± PATCH

2 ± GAP

3 ± DISC GRINDER

Fig. 15 Cover Gaps With Mesh

1 ± GROUND DOWN AREA

2 ± PATCH

3 ± MESH

Fig. 16 Cover Mesh With Epoxy

1 ± EPOXY

2 ± MESH

3 ± PATCH

4 ± SPREADER

23 - 24 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1144 of 1285

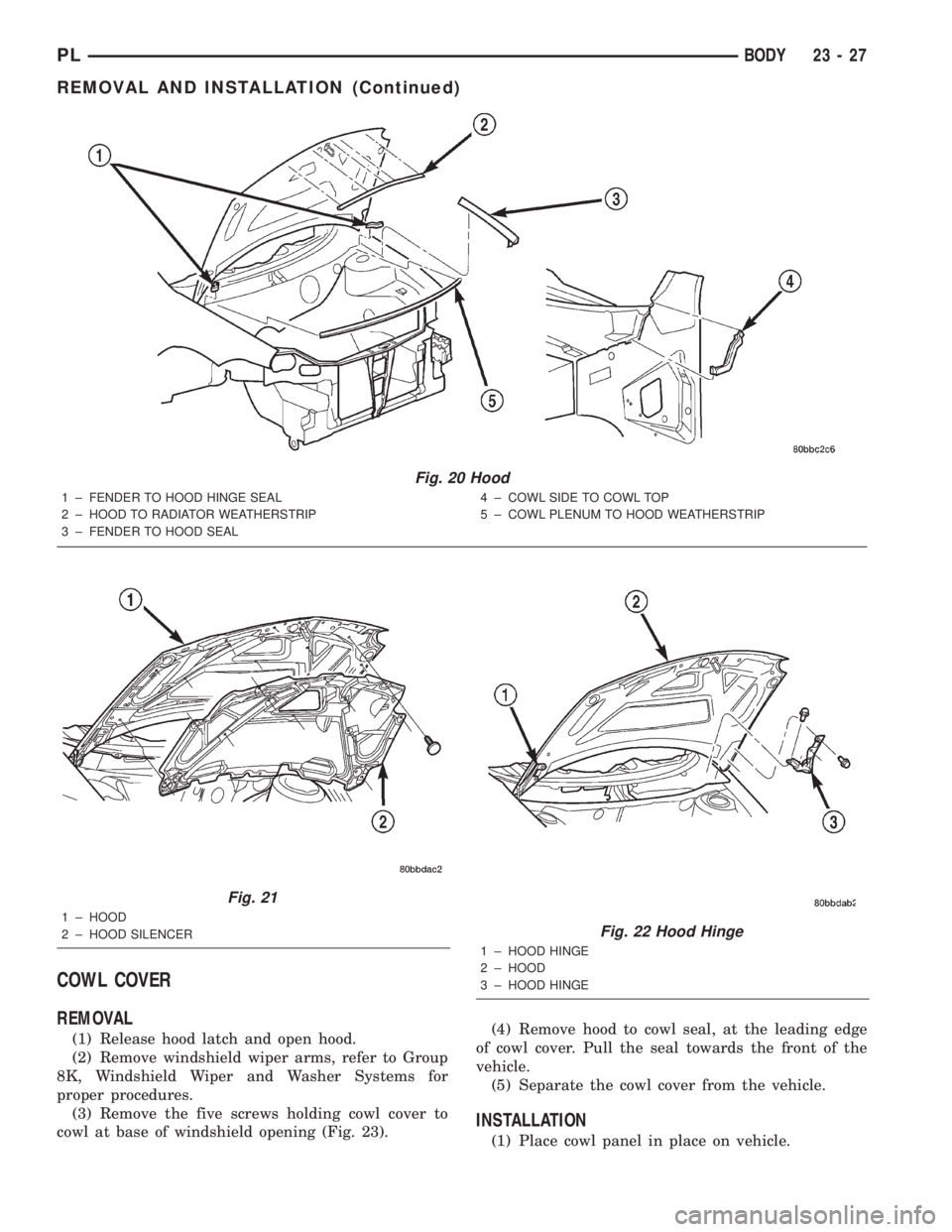

COWL COVER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems for

proper procedures.

(3) Remove the five screws holding cowl cover to

cowl at base of windshield opening (Fig. 23).(4) Remove hood to cowl seal, at the leading edge

of cowl cover. Pull the seal towards the front of the

vehicle.

(5) Separate the cowl cover from the vehicle.

INSTALLATION

(1) Place cowl panel in place on vehicle.

Fig. 20 Hood

1 ± FENDER TO HOOD HINGE SEAL

2 ± HOOD TO RADIATOR WEATHERSTRIP

3 ± FENDER TO HOOD SEAL4 ± COWL SIDE TO COWL TOP

5 ± COWL PLENUM TO HOOD WEATHERSTRIP

Fig. 21

1 ± HOOD

2 ± HOOD SILENCERFig. 22 Hood Hinge

1 ± HOOD HINGE

2 ± HOOD

3 ± HOOD HINGE

PLBODY 23 - 27

REMOVAL AND INSTALLATION (Continued)

Page 1199 of 1285

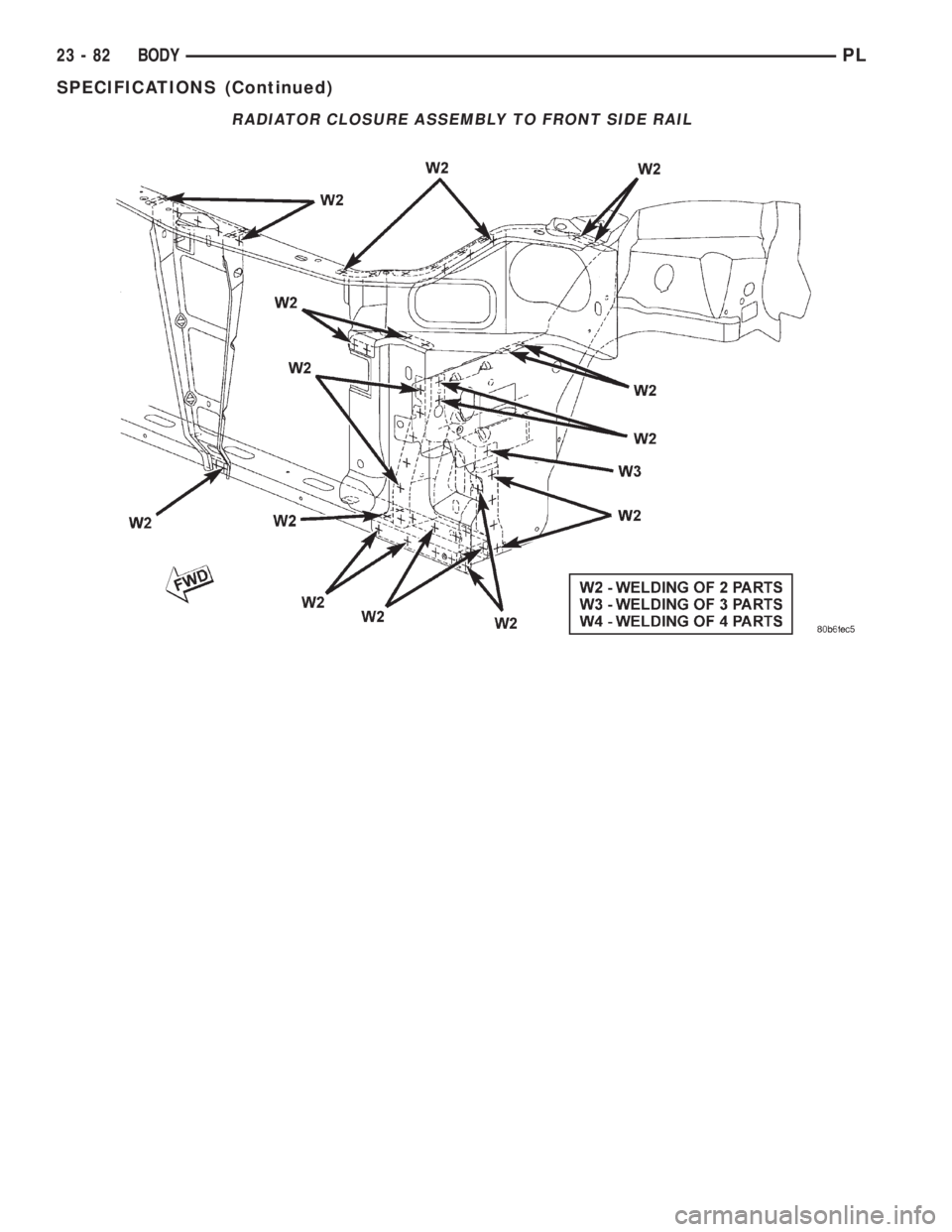

RADIATOR CLOSURE ASSEMBLY TO FRONT SIDE RAIL

23 - 82 BODYPL

SPECIFICATIONS (Continued)

Page 1244 of 1285

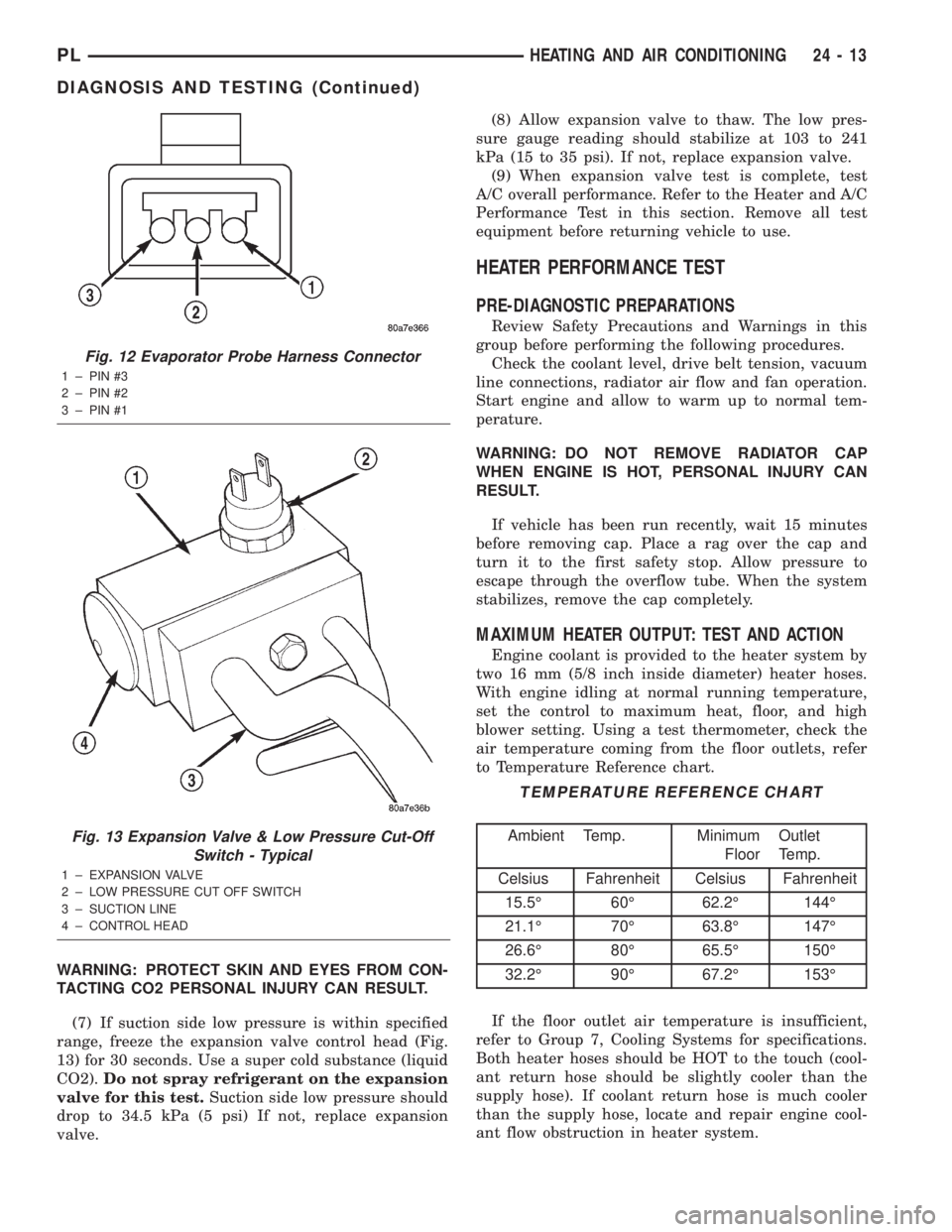

WARNING: PROTECT SKIN AND EYES FROM CON-

TACTING CO2 PERSONAL INJURY CAN RESULT.

(7) If suction side low pressure is within specified

range, freeze the expansion valve control head (Fig.

13) for 30 seconds. Use a super cold substance (liquid

CO2).Do not spray refrigerant on the expansion

valve for this test.Suction side low pressure should

drop to 34.5 kPa (5 psi) If not, replace expansion

valve.(8) Allow expansion valve to thaw. The low pres-

sure gauge reading should stabilize at 103 to 241

kPa (15 to 35 psi). If not, replace expansion valve.

(9) When expansion valve test is complete, test

A/C overall performance. Refer to the Heater and A/C

Performance Test in this section. Remove all test

equipment before returning vehicle to use.

HEATER PERFORMANCE TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings in this

group before performing the following procedures.

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference chart.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

Fig. 12 Evaporator Probe Harness Connector

1 ± PIN #3

2 ± PIN #2

3 ± PIN #1

Fig. 13 Expansion Valve & Low Pressure Cut-Off

Switch - Typical

1 ± EXPANSION VALVE

2 ± LOW PRESSURE CUT OFF SWITCH

3 ± SUCTION LINE

4 ± CONTROL HEAD

TEMPERATURE REFERENCE CHART

Ambient Temp. Minimum

FloorOutlet

Temp.

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

PLHEATING AND AIR CONDITIONING 24 - 13

DIAGNOSIS AND TESTING (Continued)