radiator DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 530 of 1285

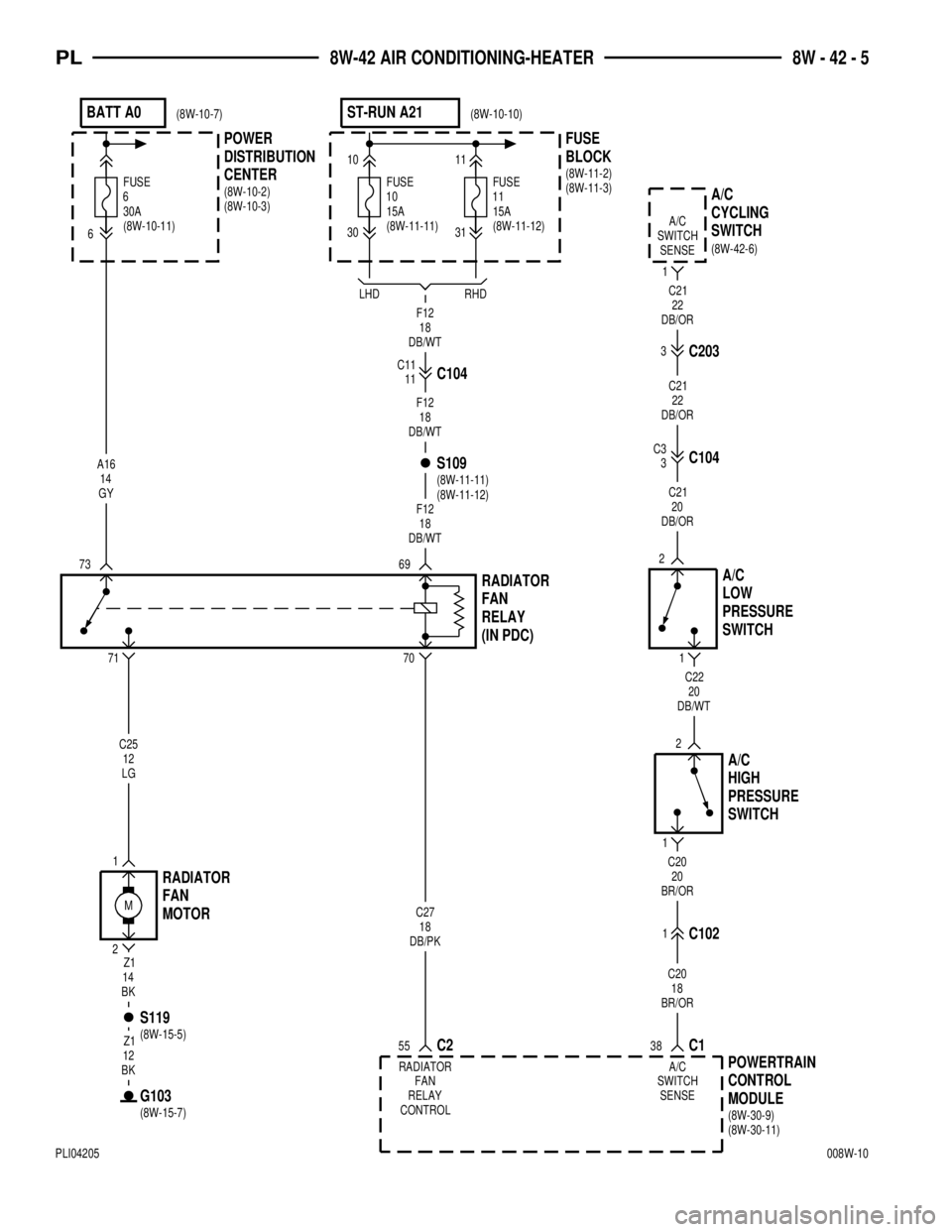

BATT A0

30A

FUSE

6

70

71

6973

6

1

2

M

G103

S119

Z1

12

BK

Z1

14

BK

POWER

DISTRIBUTION

CENTER

10

30

15A

FUSE

10

BLOCK FUSE

C10411

S109

(IN PDC) RELAY

FAN

RADIATOR

5538C2 C1

2

1

SWITCH PRESSURE

HIGH

A/C

1 2

A/C

LOW

PRESSURE

SWITCH

1

A/C

SWITCH

SENSESWITCH CYCLING

A/C

1C102

C1043

C2033

C20

18

BR/OR

C20

20

BR/OR

C22

20

DB/WT

C21

20

DB/OR

C21

22

DB/OR

C21

22

DB/OR

C27

18

DB/PK

F12

18

DB/WT

F12

18

DB/WT

F12

18

DB/WT

A16

14

GY

POWERTRAIN

CONTROL

MODULERADIATOR

FAN

RELAY

CONTROLA/C

SWITCH

SENSE

MOTOR FAN

RADIATOR

C11

C3 11FUSE

15A

31 11

RHD LHD

ST-RUN A21

LG12 C25(8W-10-7)

(8W-10-11)

(8W-15-7) (8W-15-5)(8W-10-2)

(8W-10-3)

(8W-11-11)(8W-11-2)

(8W-11-3)

(8W-11-11)

(8W-11-12)(8W-42-6)

(8W-30-9)

(8W-30-11) (8W-11-12) (8W-10-10)

PL8W-42 AIR CONDITIONING-HEATER 8W - 42 - 5

PLI04205008W-10

Page 612 of 1285

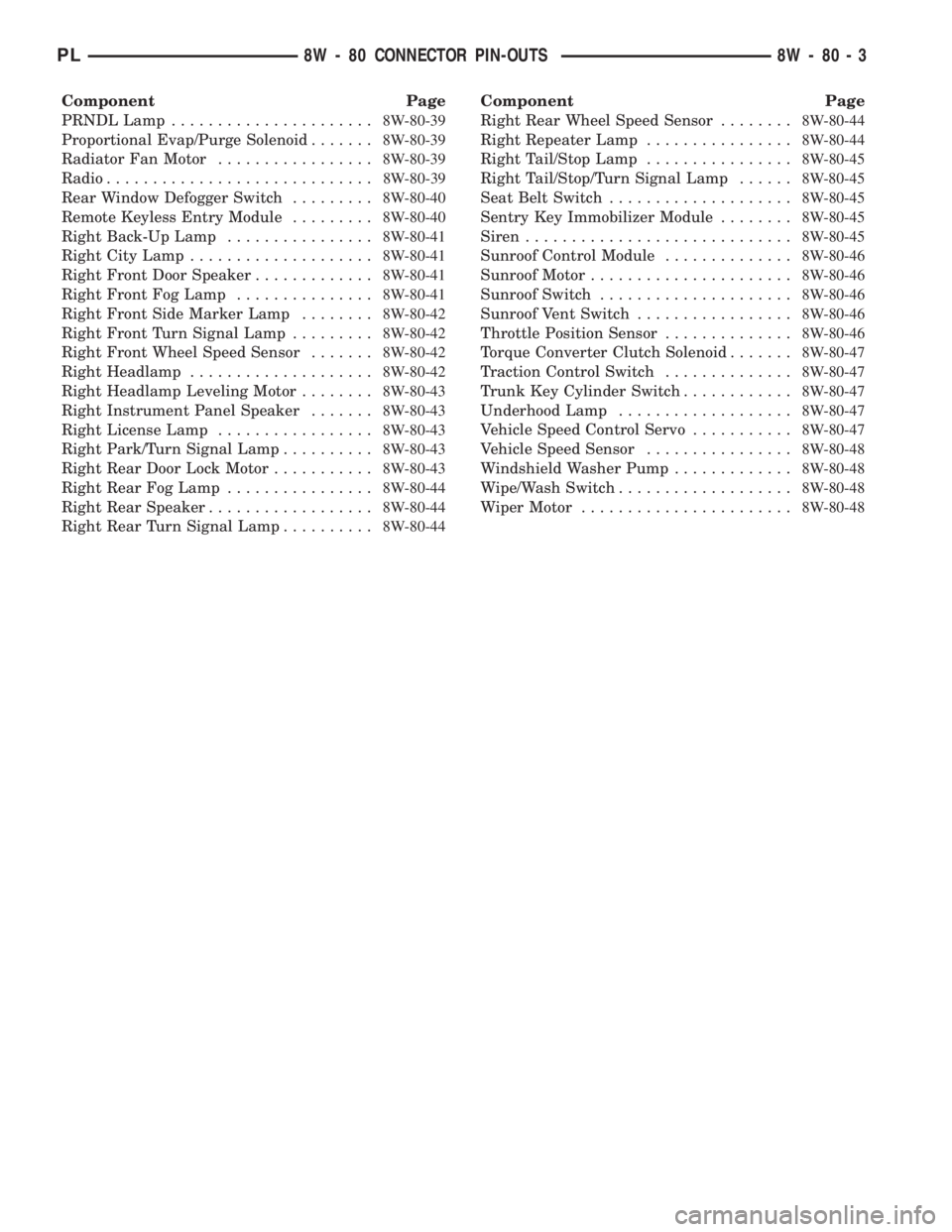

Component Page

PRNDL Lamp......................8W-80-39

Proportional Evap/Purge Solenoid.......8W-80-39

Radiator Fan Motor.................8W-80-39

Radio.............................8W-80-39

Rear Window Defogger Switch.........8W-80-40

Remote Keyless Entry Module.........8W-80-40

Right Back-Up Lamp................8W-80-41

Right City Lamp....................8W-80-41

Right Front Door Speaker.............8W-80-41

Right Front Fog Lamp...............8W-80-41

Right Front Side Marker Lamp........8W-80-42

Right Front Turn Signal Lamp.........8W-80-42

Right Front Wheel Speed Sensor.......8W-80-42

Right Headlamp....................8W-80-42

Right Headlamp Leveling Motor........8W-80-43

Right Instrument Panel Speaker.......8W-80-43

Right License Lamp.................8W-80-43

Right Park/Turn Signal Lamp..........8W-80-43

Right Rear Door Lock Motor...........8W-80-43

Right Rear Fog Lamp................8W-80-44

Right Rear Speaker..................8W-80-44

Right Rear Turn Signal Lamp..........8W-80-44Component Page

Right Rear Wheel Speed Sensor........8W-80-44

Right Repeater Lamp................8W-80-44

Right Tail/Stop Lamp................8W-80-45

Right Tail/Stop/Turn Signal Lamp......8W-80-45

Seat Belt Switch....................8W-80-45

Sentry Key Immobilizer Module........8W-80-45

Siren.............................8W-80-45

Sunroof Control Module..............8W-80-46

Sunroof Motor......................8W-80-46

Sunroof Switch.....................8W-80-46

Sunroof Vent Switch.................8W-80-46

Throttle Position Sensor..............8W-80-46

Torque Converter Clutch Solenoid.......8W-80-47

Traction Control Switch..............8W-80-47

Trunk Key Cylinder Switch............8W-80-47

Underhood Lamp...................8W-80-47

Vehicle Speed Control Servo...........8W-80-47

Vehicle Speed Sensor................8W-80-48

Windshield Washer Pump.............8W-80-48

Wipe/Wash Switch...................8W-80-48

Wiper Motor.......................8W-80-48

PL8W - 80 CONNECTOR PIN-OUTS 8W - 80 - 3

Page 647 of 1285

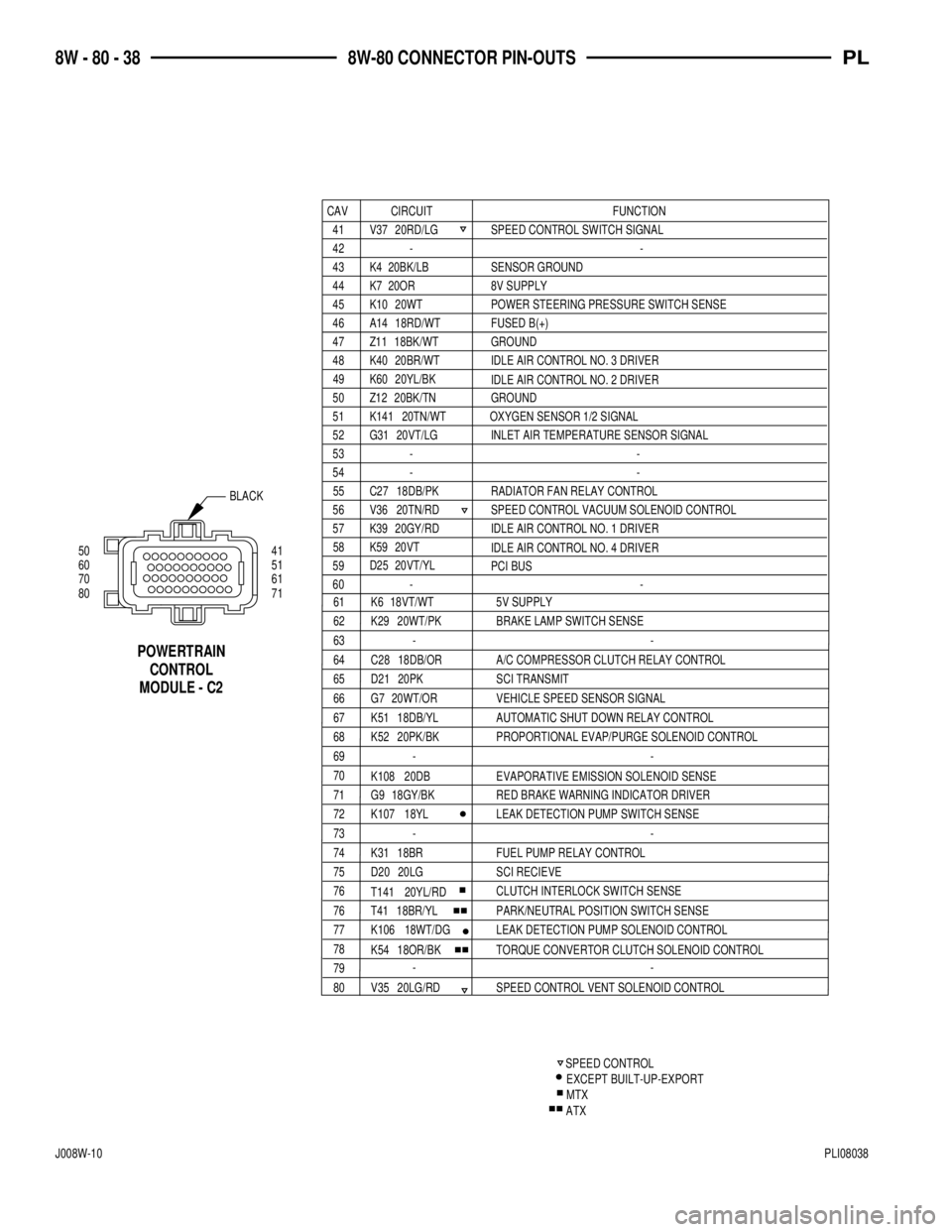

POWERTRAIN

CONTROL

MODULE - C2

61 K6 18VT/WT 5V SUPPLY

62 K29 20WT/PK BRAKE LAMP SWITCH SENSE

63 - -

64 C28 18DB/OR A/C COMPRESSOR CLUTCH RELAY CONTROL

65 D21 20PK SCI TRANSMIT

66 G7 20WT/OR VEHICLE SPEED SENSOR SIGNAL

67 K51 18DB/YL AUTOMATIC SHUT DOWN RELAY CONTROL

68 K52 20PK/BK PROPORTIONAL EVAP/PURGE SOLENOID CONTROL

69 - -

70

71

72 K107 18YL LEAK DETECTION PUMP SWITCH SENSE

73

74 K31 18BR FUEL PUMP RELAY CONTROL

75 D20 20LG SCI RECIEVE

76 CLUTCH INTERLOCK SWITCH SENSE

77 K106 18WT/DG LEAK DETECTION PUMP SOLENOID CONTROL

78

79K54 18OR/BK TORQUE CONVERTOR CLUTCH SOLENOID CONTROL

80 V35 20LG/RD SPEED CONTROL VENT SOLENOID CONTROL

BLACK

71 8061 7051 6041 50

- - 60 59

20VT K59 58

IDLE AIR CONTROL NO. 1 DRIVER 20GY/RD K39 57

SPEED CONTROL VACUUM SOLENOID CONTROL 20TN/RD V36 56

55

- - 54

- - 53

INLET AIR TEMPERATURE SENSOR SIGNAL 20VT/LG G31 52

OXYGEN SENSOR 1/2 SIGNAL 20TN/WT K141 51

GROUND 20BK/TN Z12 50

20YL/BK K60 49

IDLE AIR CONTROL NO. 3 DRIVER 20BR/WT K40 48

GROUND 18BK/WT Z11 47

FUSED B(+) 18RD/WT A14 46

POWER STEERING PRESSURE SWITCH SENSE 20WT K10 45

8V SUPPLY 20OR K7 44

SENSOR GROUND 20BK/LB K4 43

- - 42

SPEED CONTROL SWITCH SIGNAL 20RD/LG V37 41

FUNCTION CIRCUIT CAV

IDLE AIR CONTROL NO. 2 DRIVER

IDLE AIR CONTROL NO. 4 DRIVER C27 18DB/PK RADIATOR FAN RELAY CONTROL

D25 20VT/YL

PCI BUS

K108 20DB EVAPORATIVE EMISSION SOLENOID SENSE

G9 18GY/BK RED BRAKE WARNING INDICATOR DRIVER

--

-- 76 T41 18BR/YL PARK/NEUTRAL POSITION SWITCH SENSE

20YL/RD T141

SPEED CONTROLEXCEPT BUILT-UP-EXPORT

MTX

ATX

8W - 80 - 38 8W-80 CONNECTOR PIN-OUTSPL

J008W-10PLI08038

Page 648 of 1285

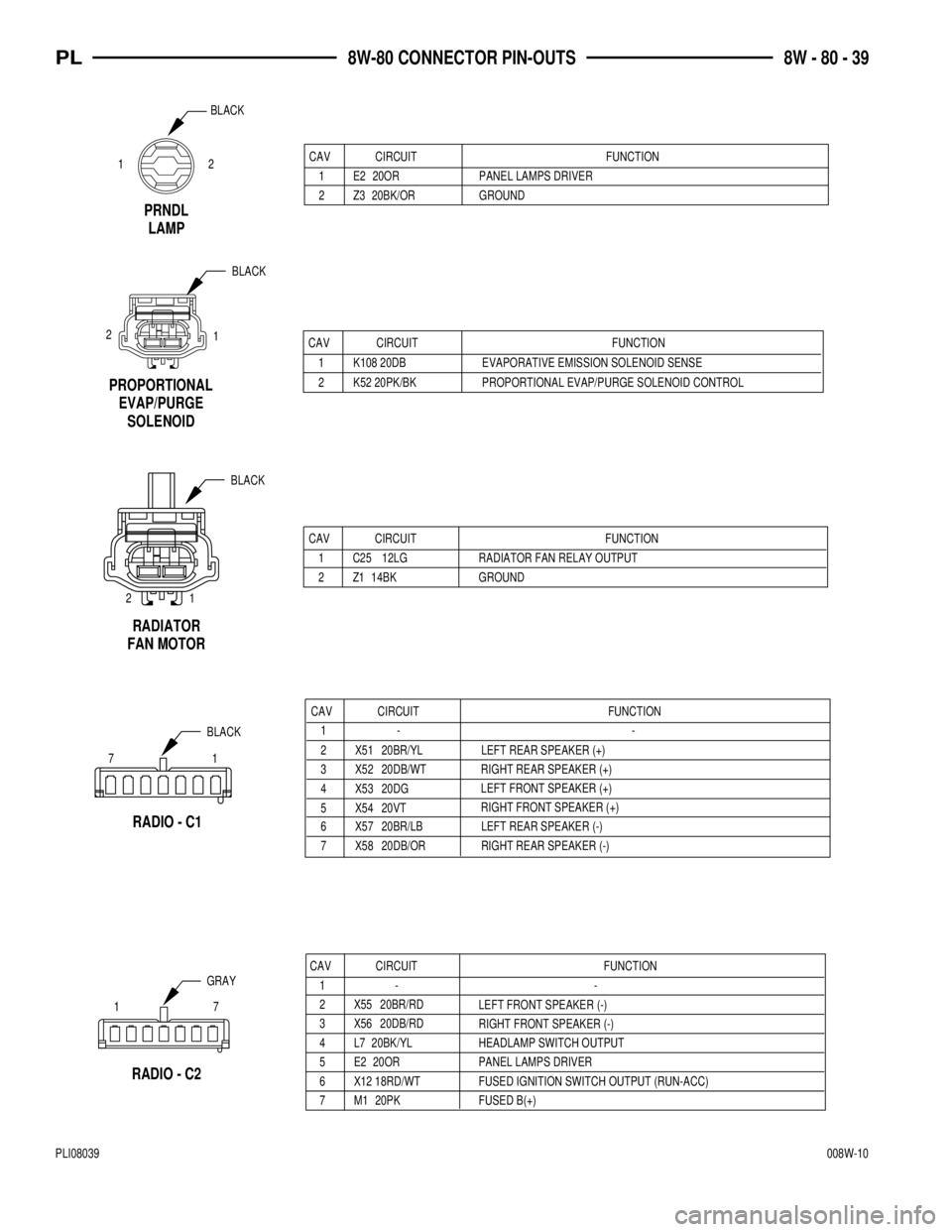

CAV CIRCUIT FUNCTION

1 E2 20OR PANEL LAMPS DRIVER

2 Z3 20BK/OR GROUND

BLACK

12

CAV CIRCUIT FUNCTION

1 C25 12LG RADIATOR FAN RELAY OUTPUT

2 Z1 14BK GROUND

CAV CIRCUIT FUNCTION

1- -

4 X53 20DG

5 X54 20VT 1

BLACK

2

BLACK

7

1

7 1

FUSED B(+) 20PK M1 7FUSED IGNITION SWITCH OUTPUT (RUN-ACC) X12 18RD/WT 6

PANEL LAMPS DRIVER 20OR E2 5

HEADLAMP SWITCH OUTPUT 20BK/YL L7 4

20DB/RD X56 3

20BR/RD X55 2

- - 1

FUNCTION CIRCUIT CAV

PRNDL

LAMP

RADIATOR

FAN MOTOR

RADIO - C1

RADIO - C2

GRAYLEFT REAR SPEAKER (+) 20BR/YL X51 2

X52 20DB/WT3

LEFT REAR SPEAKER (-)

20BR/LB X57 6

RIGHT REAR SPEAKER (-) 20DB/OR X58 7

RIGHT REAR SPEAKER (+)

RIGHT FRONT SPEAKER (+) LEFT FRONT SPEAKER (+)

RIGHT FRONT SPEAKER (-) LEFT FRONT SPEAKER (-) 1

BLACK

2

SOLENOID EVAP/PURGE PROPORTIONAL

PROPORTIONAL EVAP/PURGE SOLENOID CONTROL K52 20PK/BK 2EVAPORATIVE EMISSION SOLENOID SENSE K108 20DB 1

FUNCTION CIRCUIT CAV

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 39

PLI08039008W-10

Page 662 of 1285

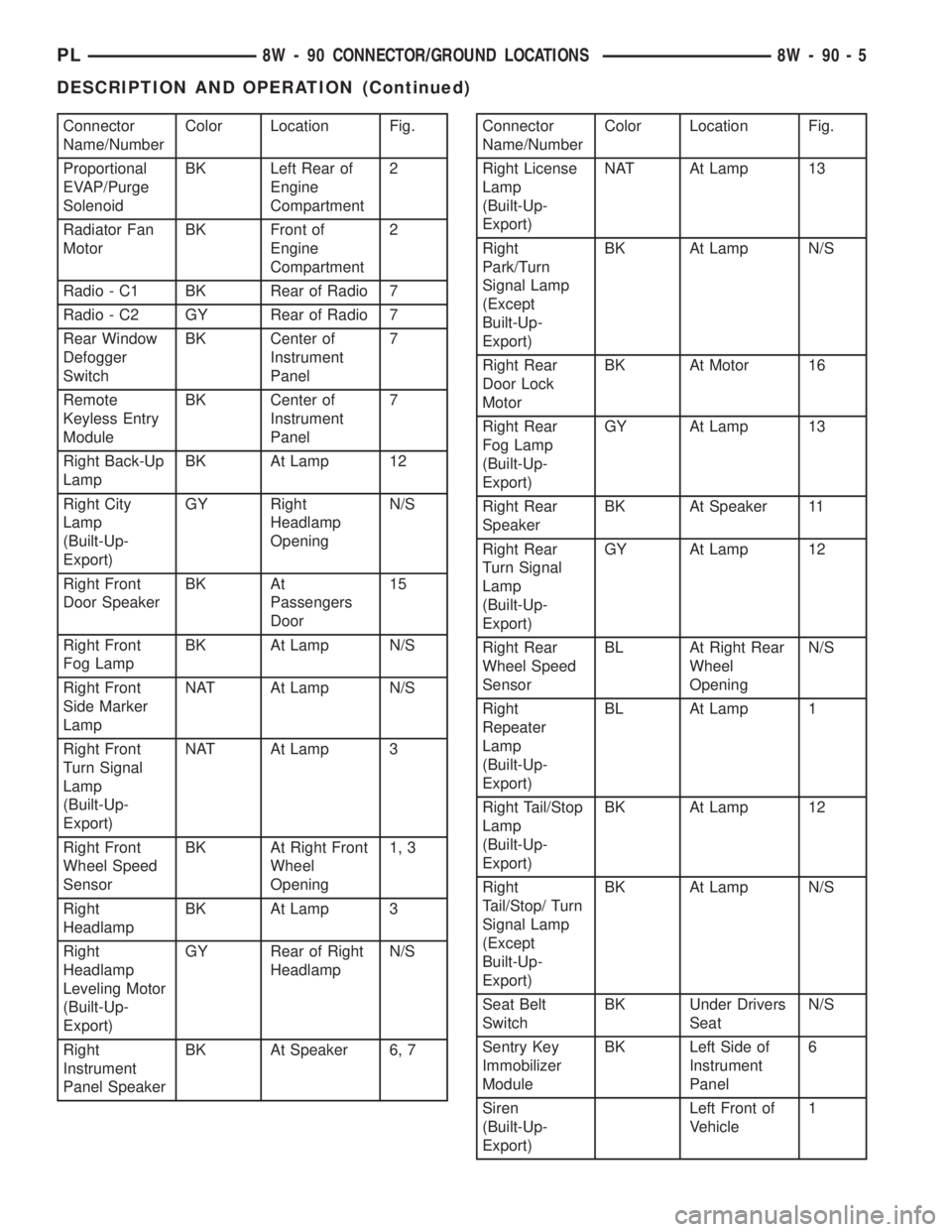

Connector

Name/NumberColor Location Fig.

Proportional

EVAP/Purge

SolenoidBK Left Rear of

Engine

Compartment2

Radiator Fan

MotorBK Front of

Engine

Compartment2

Radio - C1 BK Rear of Radio 7

Radio - C2 GY Rear of Radio 7

Rear Window

Defogger

SwitchBK Center of

Instrument

Panel7

Remote

Keyless Entry

ModuleBK Center of

Instrument

Panel7

Right Back-Up

LampBK At Lamp 12

Right City

Lamp

(Built-Up-

Export)GY Right

Headlamp

OpeningN/S

Right Front

Door SpeakerBK At

Passengers

Door15

Right Front

Fog LampBK At Lamp N/S

Right Front

Side Marker

LampNAT At Lamp N/S

Right Front

Turn Signal

Lamp

(Built-Up-

Export)NAT At Lamp 3

Right Front

Wheel Speed

SensorBK At Right Front

Wheel

Opening1, 3

Right

HeadlampBK At Lamp 3

Right

Headlamp

Leveling Motor

(Built-Up-

Export)GY Rear of Right

HeadlampN/S

Right

Instrument

Panel SpeakerBK At Speaker 6, 7Connector

Name/NumberColor Location Fig.

Right License

Lamp

(Built-Up-

Export)NAT At Lamp 13

Right

Park/Turn

Signal Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Right Rear

Door Lock

MotorBK At Motor 16

Right Rear

Fog Lamp

(Built-Up-

Export)GY At Lamp 13

Right Rear

SpeakerBK At Speaker 11

Right Rear

Turn Signal

Lamp

(Built-Up-

Export)GY At Lamp 12

Right Rear

Wheel Speed

SensorBL At Right Rear

Wheel

OpeningN/S

Right

Repeater

Lamp

(Built-Up-

Export)BL At Lamp 1

Right Tail/Stop

Lamp

(Built-Up-

Export)BK At Lamp 12

Right

Tail/Stop/ Turn

Signal Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Seat Belt

SwitchBK Under Drivers

SeatN/S

Sentry Key

Immobilizer

ModuleBK Left Side of

Instrument

Panel6

Siren

(Built-Up-

Export)Left Front of

Vehicle1

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 5

DESCRIPTION AND OPERATION (Continued)

Page 681 of 1285

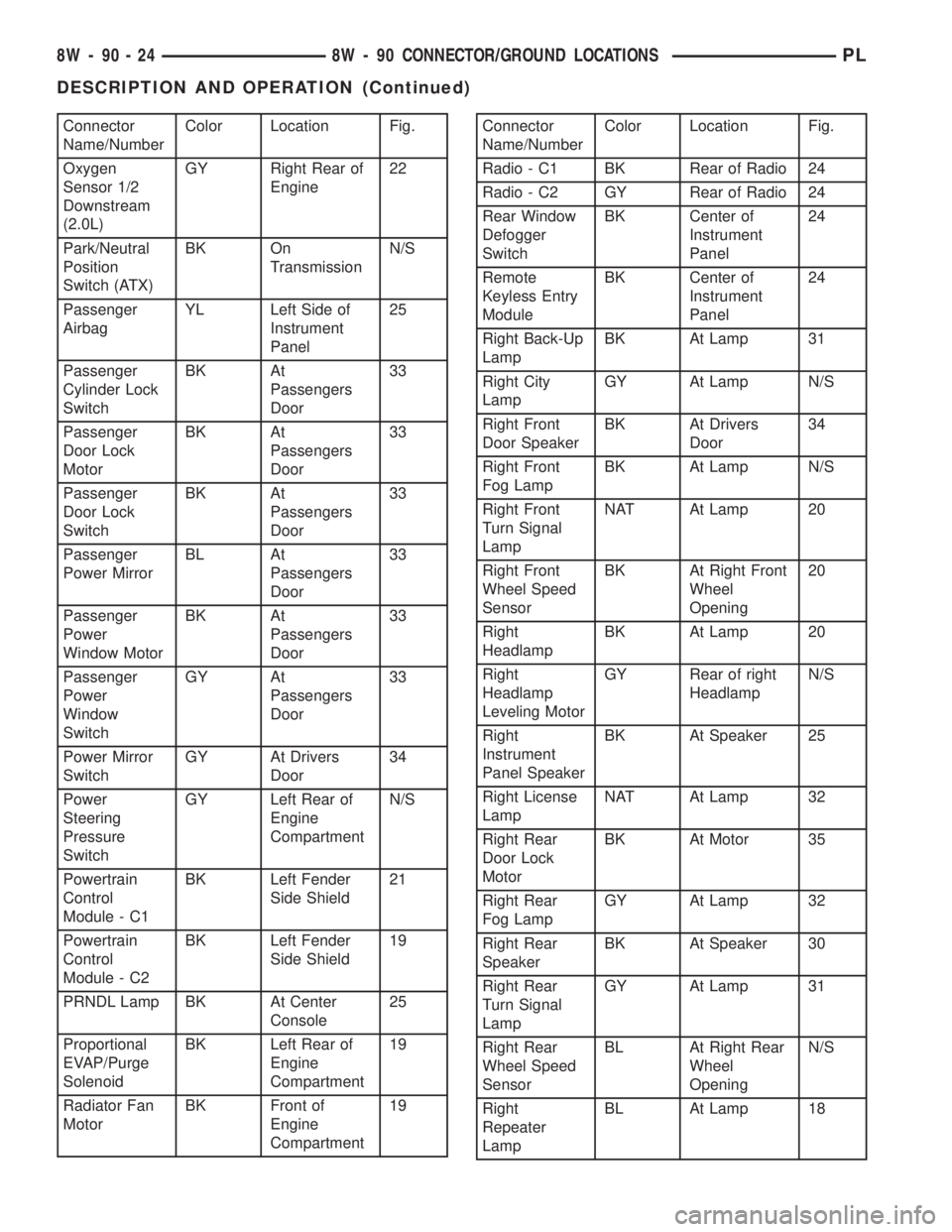

Connector

Name/NumberColor Location Fig.

Oxygen

Sensor 1/2

Downstream

(2.0L)GY Right Rear of

Engine22

Park/Neutral

Position

Switch (ATX)BK On

TransmissionN/S

Passenger

AirbagYL Left Side of

Instrument

Panel25

Passenger

Cylinder Lock

SwitchBK At

Passengers

Door33

Passenger

Door Lock

MotorBK At

Passengers

Door33

Passenger

Door Lock

SwitchBK At

Passengers

Door33

Passenger

Power MirrorBL At

Passengers

Door33

Passenger

Power

Window MotorBK At

Passengers

Door33

Passenger

Power

Window

SwitchGY At

Passengers

Door33

Power Mirror

SwitchGY At Drivers

Door34

Power

Steering

Pressure

SwitchGY Left Rear of

Engine

CompartmentN/S

Powertrain

Control

Module - C1BK Left Fender

Side Shield21

Powertrain

Control

Module - C2BK Left Fender

Side Shield19

PRNDL Lamp BK At Center

Console25

Proportional

EVAP/Purge

SolenoidBK Left Rear of

Engine

Compartment19

Radiator Fan

MotorBK Front of

Engine

Compartment19Connector

Name/NumberColor Location Fig.

Radio - C1 BK Rear of Radio 24

Radio - C2 GY Rear of Radio 24

Rear Window

Defogger

SwitchBK Center of

Instrument

Panel24

Remote

Keyless Entry

ModuleBK Center of

Instrument

Panel24

Right Back-Up

LampBK At Lamp 31

Right City

LampGY At Lamp N/S

Right Front

Door SpeakerBK At Drivers

Door34

Right Front

Fog LampBK At Lamp N/S

Right Front

Turn Signal

LampNAT At Lamp 20

Right Front

Wheel Speed

SensorBK At Right Front

Wheel

Opening20

Right

HeadlampBK At Lamp 20

Right

Headlamp

Leveling MotorGY Rear of right

HeadlampN/S

Right

Instrument

Panel SpeakerBK At Speaker 25

Right License

LampNAT At Lamp 32

Right Rear

Door Lock

MotorBK At Motor 35

Right Rear

Fog LampGY At Lamp 32

Right Rear

SpeakerBK At Speaker 30

Right Rear

Turn Signal

LampGY At Lamp 31

Right Rear

Wheel Speed

SensorBL At Right Rear

Wheel

OpeningN/S

Right

Repeater

LampBL At Lamp 18

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 698 of 1285

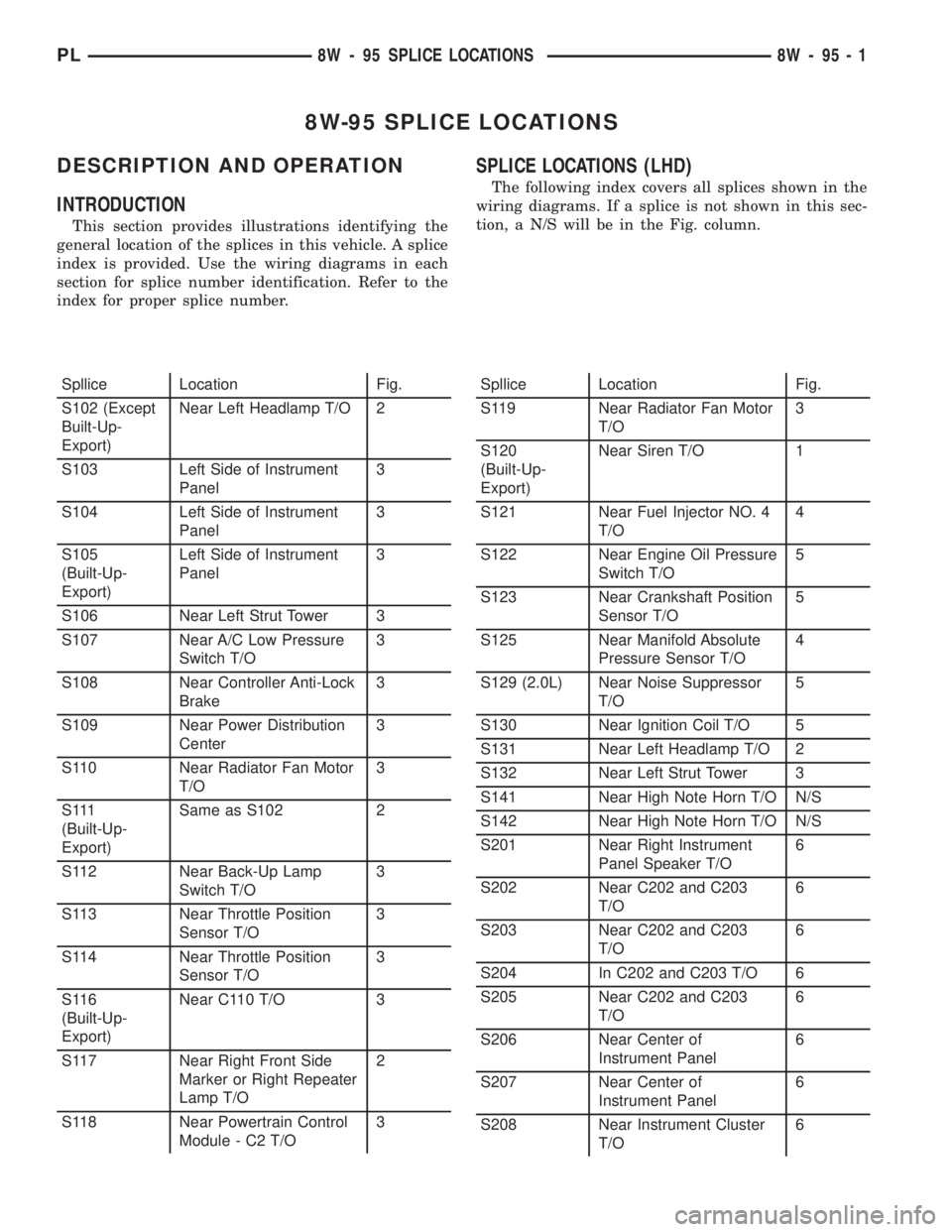

8W-95 SPLICE LOCATIONS

DESCRIPTION AND OPERATION

INTRODUCTION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for proper splice number.

SPLICE LOCATIONS (LHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S102 (Except

Built-Up-

Export)Near Left Headlamp T/O 2

S103 Left Side of Instrument

Panel3

S104 Left Side of Instrument

Panel3

S105

(Built-Up-

Export)Left Side of Instrument

Panel3

S106 Near Left Strut Tower 3

S107 Near A/C Low Pressure

Switch T/O3

S108 Near Controller Anti-Lock

Brake3

S109 Near Power Distribution

Center3

S110 Near Radiator Fan Motor

T/O3

S 111

(Built-Up-

Export)Same as S102 2

S112 Near Back-Up Lamp

Switch T/O3

S113 Near Throttle Position

Sensor T/O3

S114 Near Throttle Position

Sensor T/O3

S116

(Built-Up-

Export)Near C110 T/O 3

S117 Near Right Front Side

Marker or Right Repeater

Lamp T/O2

S118 Near Powertrain Control

Module - C2 T/O3Spllice Location Fig.

S119 Near Radiator Fan Motor

T/O3

S120

(Built-Up-

Export)Near Siren T/O 1

S121 Near Fuel Injector NO. 4

T/O4

S122 Near Engine Oil Pressure

Switch T/O5

S123 Near Crankshaft Position

Sensor T/O5

S125 Near Manifold Absolute

Pressure Sensor T/O4

S129 (2.0L) Near Noise Suppressor

T/O5

S130 Near Ignition Coil T/O 5

S131 Near Left Headlamp T/O 2

S132 Near Left Strut Tower 3

S141 Near High Note Horn T/O N/S

S142 Near High Note Horn T/O N/S

S201 Near Right Instrument

Panel Speaker T/O6

S202 Near C202 and C203

T/O6

S203 Near C202 and C203

T/O6

S204 In C202 and C203 T/O 6

S205 Near C202 and C203

T/O6

S206 Near Center of

Instrument Panel6

S207 Near Center of

Instrument Panel6

S208 Near Instrument Cluster

T/O6

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 1

Page 710 of 1285

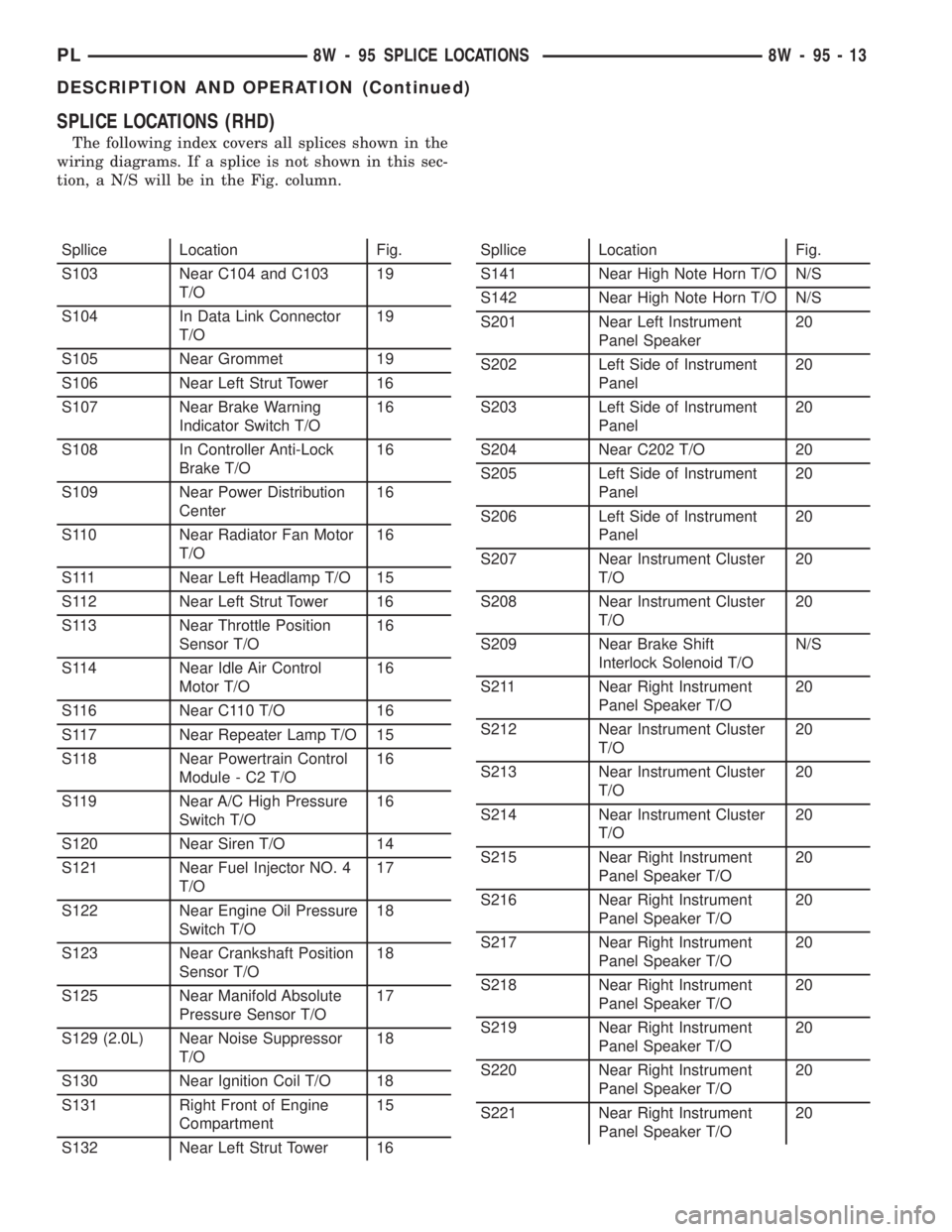

SPLICE LOCATIONS (RHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S103 Near C104 and C103

T/O19

S104 In Data Link Connector

T/O19

S105 Near Grommet 19

S106 Near Left Strut Tower 16

S107 Near Brake Warning

Indicator Switch T/O16

S108 In Controller Anti-Lock

Brake T/O16

S109 Near Power Distribution

Center16

S110 Near Radiator Fan Motor

T/O16

S111 Near Left Headlamp T/O 15

S112 Near Left Strut Tower 16

S113 Near Throttle Position

Sensor T/O16

S114 Near Idle Air Control

Motor T/O16

S116 Near C110 T/O 16

S117 Near Repeater Lamp T/O 15

S118 Near Powertrain Control

Module - C2 T/O16

S119 Near A/C High Pressure

Switch T/O16

S120 Near Siren T/O 14

S121 Near Fuel Injector NO. 4

T/O17

S122 Near Engine Oil Pressure

Switch T/O18

S123 Near Crankshaft Position

Sensor T/O18

S125 Near Manifold Absolute

Pressure Sensor T/O17

S129 (2.0L) Near Noise Suppressor

T/O18

S130 Near Ignition Coil T/O 18

S131 Right Front of Engine

Compartment15

S132 Near Left Strut Tower 16Spllice Location Fig.

S141 Near High Note Horn T/O N/S

S142 Near High Note Horn T/O N/S

S201 Near Left Instrument

Panel Speaker20

S202 Left Side of Instrument

Panel20

S203 Left Side of Instrument

Panel20

S204 Near C202 T/O 20

S205 Left Side of Instrument

Panel20

S206 Left Side of Instrument

Panel20

S207 Near Instrument Cluster

T/O20

S208 Near Instrument Cluster

T/O20

S209 Near Brake Shift

Interlock Solenoid T/ON/S

S211 Near Right Instrument

Panel Speaker T/O20

S212 Near Instrument Cluster

T/O20

S213 Near Instrument Cluster

T/O20

S214 Near Instrument Cluster

T/O20

S215 Near Right Instrument

Panel Speaker T/O20

S216 Near Right Instrument

Panel Speaker T/O20

S217 Near Right Instrument

Panel Speaker T/O20

S218 Near Right Instrument

Panel Speaker T/O20

S219 Near Right Instrument

Panel Speaker T/O20

S220 Near Right Instrument

Panel Speaker T/O20

S221 Near Right Instrument

Panel Speaker T/O20

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 13

DESCRIPTION AND OPERATION (Continued)

Page 732 of 1285

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 739 of 1285

CRANKSHAFT

A nodular cast iron crankshaft is used. The engine

has five main bearings. The number three main is

flanged to control thrust. The mains and connecting

rod journals have undercut fillet radiuses that are

deep rolled for added strength. To optimize bearing

loading, eight counterweights are used. Hydrody-

namic seals provide end sealing, where the crank-

shaft exits the block. Anaerobic gasket material is

used for parting line sealing. A sintered iron timing

belt sprocket is mounted on the crankshaft nose. This

sprocket transmits crankshaft movement, via timing

belt to the camshaft sprocket providing timed valve

actuation.

PISTONS

The engineDOES NOThave provision for a free

wheeling valve train. Non free wheeling valve train

means, in the event of a broken timing belt pistons

will contact the valves. The engine uses pressed-in

piston pins to attach forged powdered metal connect-

ing rods. The connecting rods are a cracked cap

design and are not repairable. Hex head cap screw

are used to provide alignment and durability in the

assembly. Pistons and connecting rods are serviced as

an assembly.

PISTON RINGS

The piston rings include a molybdenum faced top

ring for reliable compression sealing and a taper

faced intermediate ring for additional cylinder pres-

sure control. Oil Control Ring Package consist of two

steel rails and an expander spacer.

CYLINDER HEAD

The aluminum cylinder head features a Single

Over Head Camshaft (SOHC), four-valves per cylin-

der, cross flow design. The valves are arranged in

two inline banks, with the two intake per cylinder

facing toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFT

The nodular iron camshaft has five bearing jour-

nals and three cam lobes per cylinder. Provision for a

cam position sensor is provided on the camshaft at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVES

Four valves per cylinder are actuated by roller

rocker arms/hydraulic lash adjusters assemblies

which pivot on rocker arm shafts. All valves have

chrome plated valve stems. Viton rubber valve stem

seals are integral with spring seats. Valve springs,

spring retainers, and locks are conventional design.

INTAKE MANIFOLD

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with five fasten-

ers. This long branch design enhances low and mid-

range torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit the manifold into an articulated joint connection

and exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure in this section.

9 - 16 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)