steering wheel DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 351 of 1285

(9) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

DRIVER AIRBAG MODULE

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 1 MINUTE BEFORE REMOVING ANY AIRBAG

COMPONENTS.

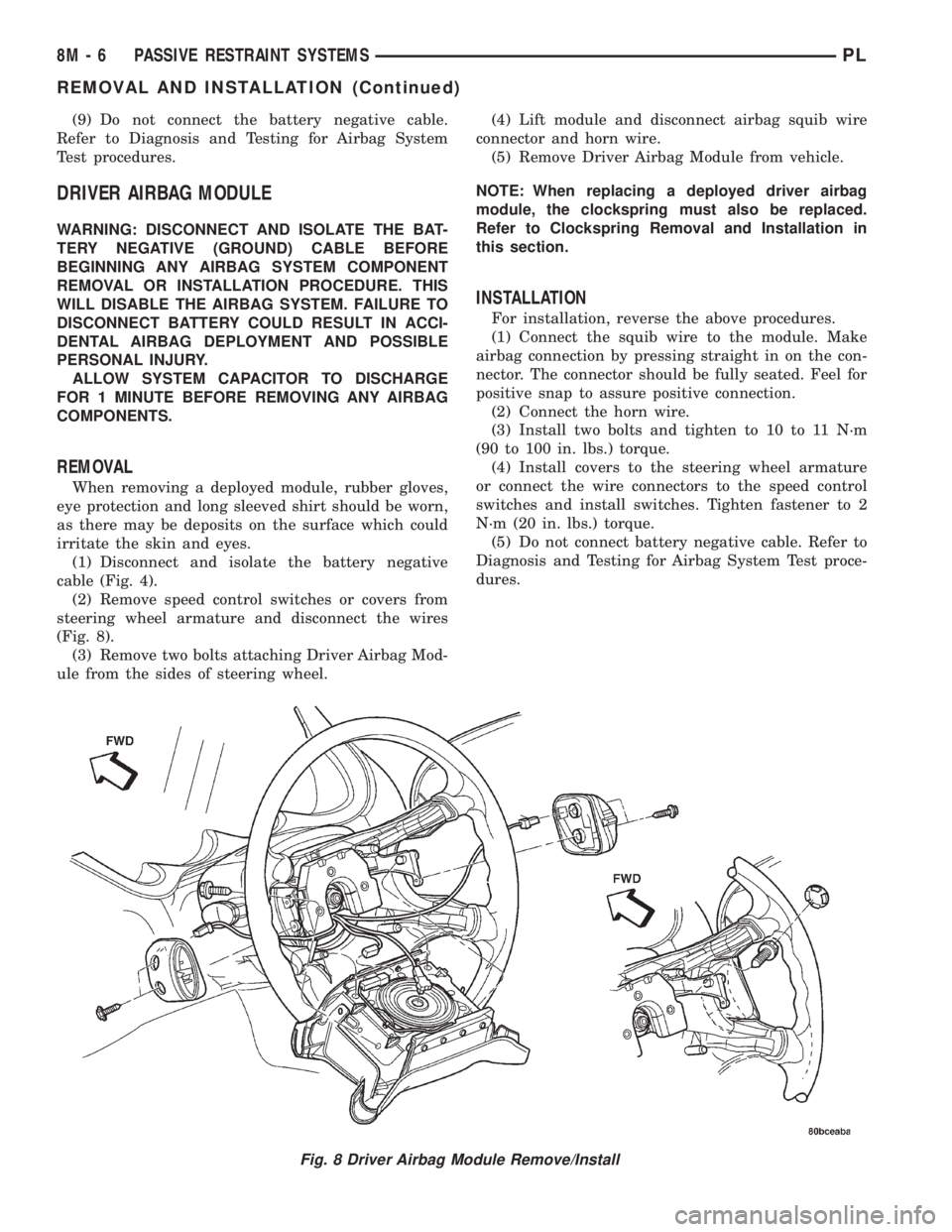

REMOVAL

When removing a deployed module, rubber gloves,

eye protection and long sleeved shirt should be worn,

as there may be deposits on the surface which could

irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable (Fig. 4).

(2) Remove speed control switches or covers from

steering wheel armature and disconnect the wires

(Fig. 8).

(3) Remove two bolts attaching Driver Airbag Mod-

ule from the sides of steering wheel.(4) Lift module and disconnect airbag squib wire

connector and horn wire.

(5) Remove Driver Airbag Module from vehicle.

NOTE: When replacing a deployed driver airbag

module, the clockspring must also be replaced.

Refer to Clockspring Removal and Installation in

this section.

INSTALLATION

For installation, reverse the above procedures.

(1) Connect the squib wire to the module. Make

airbag connection by pressing straight in on the con-

nector. The connector should be fully seated. Feel for

positive snap to assure positive connection.

(2) Connect the horn wire.

(3) Install two bolts and tighten to 10 to 11 N´m

(90 to 100 in. lbs.) torque.

(4) Install covers to the steering wheel armature

or connect the wire connectors to the speed control

switches and install switches. Tighten fastener to 2

N´m (20 in. lbs.) torque.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test proce-

dures.

Fig. 8 Driver Airbag Module Remove/Install

8M - 6 PASSIVE RESTRAINT SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 353 of 1285

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the three module

retaining nuts to 22 to 34 N´m (200 to 300 in. lbs.)

torque. Do not connect battery negative cable. Refer

to Diagnosis and Testing for Airbag System Test pro-

cedures.

DEPLOYED MODULE

REMOVAL

When removing a deployed module, rubber gloves,

eye protection, and a long-sleeved shirt should be

worn, as there may be deposits on the surface which

could irritate the skin and eyes.

(1) Roll/fold airbag towards instrument panel.

(2) Close door over folded airbag and tape door

closed.

(3) Disconnect and isolate the battery negative

cable (Fig. 4).

(4) Remove instrument panel top cover. Refer to

Group 8E Instrument Panel Systems, Instrument

Panel Top Cover Removal and Installation.

(5) Remove three screws to glove box door and

remove door from instrument panel.

(6) Remove three passenger airbag cover screws

attaching cover to top of instrument panel (Fig. 9).

(7) Remove two passenger airbag cover screws

attaching cover to front lower instrument panel.

(8) Remove three module attaching nuts from the

support structure.

(9) Lift module up until the wire connector is visi-

ble and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector (Fig. 10).

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

STEERING WHEEL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 1 MINUTE BEFORE REMOVING ANY AIRBAG

COMPONENTS.

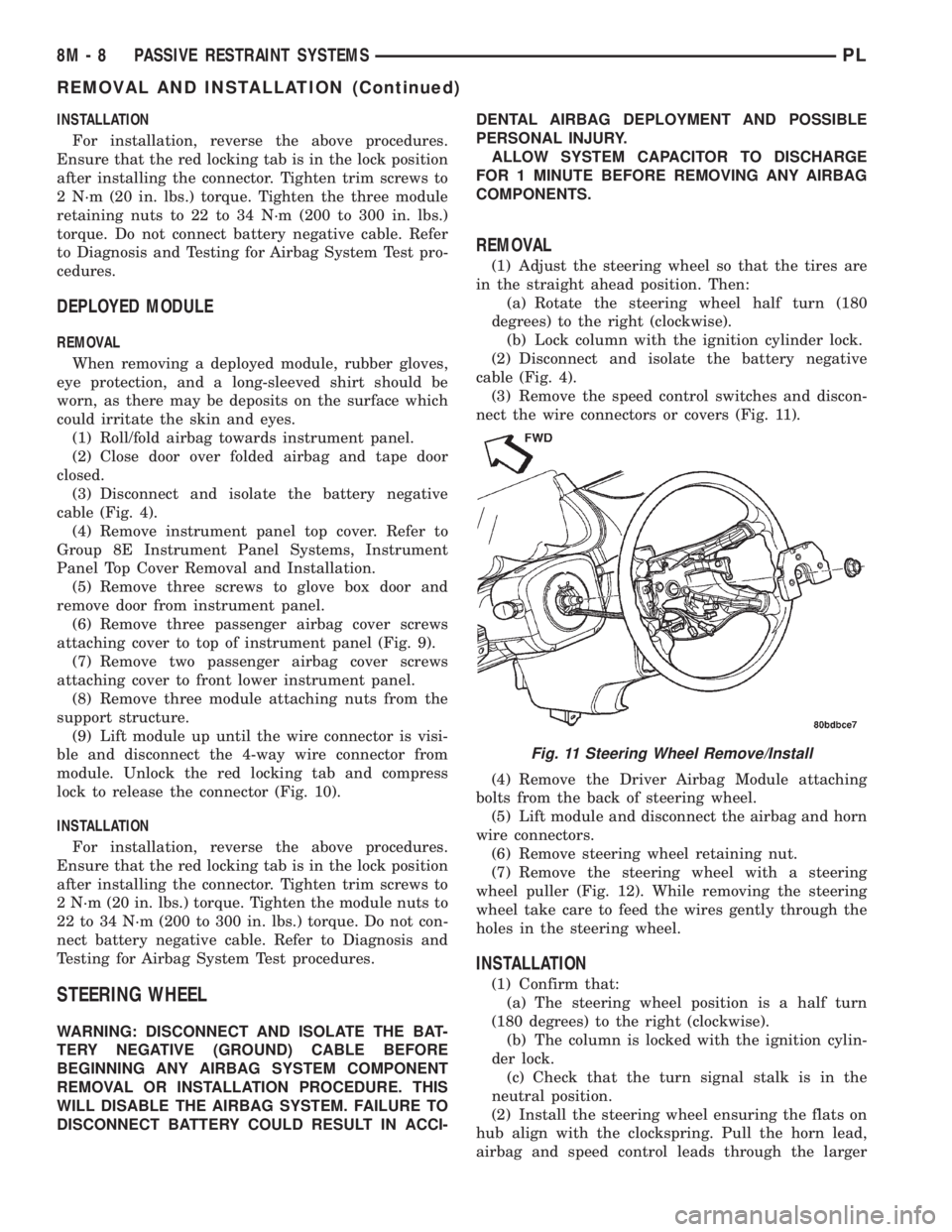

REMOVAL

(1) Adjust the steering wheel so that the tires are

in the straight ahead position. Then:

(a) Rotate the steering wheel half turn (180

degrees) to the right (clockwise).

(b) Lock column with the ignition cylinder lock.

(2) Disconnect and isolate the battery negative

cable (Fig. 4).

(3) Remove the speed control switches and discon-

nect the wire connectors or covers (Fig. 11).

(4) Remove the Driver Airbag Module attaching

bolts from the back of steering wheel.

(5) Lift module and disconnect the airbag and horn

wire connectors.

(6) Remove steering wheel retaining nut.

(7) Remove the steering wheel with a steering

wheel puller (Fig. 12). While removing the steering

wheel take care to feed the wires gently through the

holes in the steering wheel.

INSTALLATION

(1) Confirm that:

(a) The steering wheel position is a half turn

(180 degrees) to the right (clockwise).

(b) The column is locked with the ignition cylin-

der lock.

(c) Check that the turn signal stalk is in the

neutral position.

(2) Install the steering wheel ensuring the flats on

hub align with the clockspring. Pull the horn lead,

airbag and speed control leads through the larger

Fig. 11 Steering Wheel Remove/Install

8M - 8 PASSIVE RESTRAINT SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 354 of 1285

slot. Ensure leads do not get pinched under the steer-

ing wheel.

(3) Install the steering wheel retaining nut, and

tighten it to 61 N´m (45 ft. lbs.) torque.

(4) Install the driver airbag module. Refer to

Driver Airbag Module Removal and Installation in

this section.

(5) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

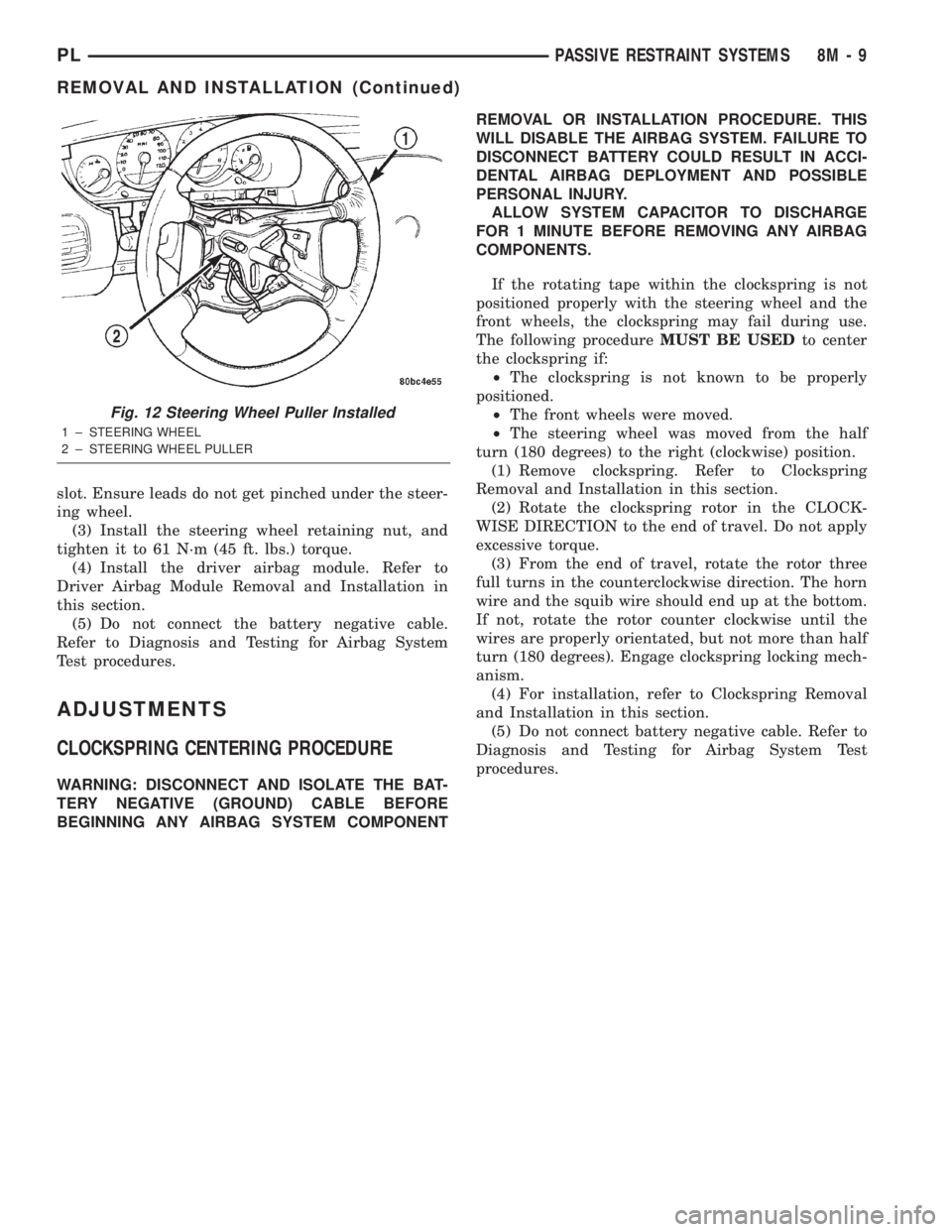

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENTREMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 1 MINUTE BEFORE REMOVING ANY AIRBAG

COMPONENTS.

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedureMUST BE USEDto center

the clockspring if:

²The clockspring is not known to be properly

positioned.

²The front wheels were moved.

²The steering wheel was moved from the half

turn (180 degrees) to the right (clockwise) position.

(1) Remove clockspring. Refer to Clockspring

Removal and Installation in this section.

(2) Rotate the clockspring rotor in the CLOCK-

WISE DIRECTION to the end of travel. Do not apply

excessive torque.

(3) From the end of travel, rotate the rotor three

full turns in the counterclockwise direction. The horn

wire and the squib wire should end up at the bottom.

If not, rotate the rotor counter clockwise until the

wires are properly orientated, but not more than half

turn (180 degrees). Engage clockspring locking mech-

anism.

(4) For installation, refer to Clockspring Removal

and Installation in this section.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test

procedures.

Fig. 12 Steering Wheel Puller Installed

1 ± STEERING WHEEL

2 ± STEERING WHEEL PULLER

PLPASSIVE RESTRAINT SYSTEMS 8M - 9

REMOVAL AND INSTALLATION (Continued)

Page 361 of 1285

The fusible link, fuses and relays are available for

service replacement. The PDC unit cannot be

repaired and is only serviced as a unit with the

engine compartment wire harness. If the PDC is

faulty or damaged, the engine compartment wire har-

ness assembly must be replaced.

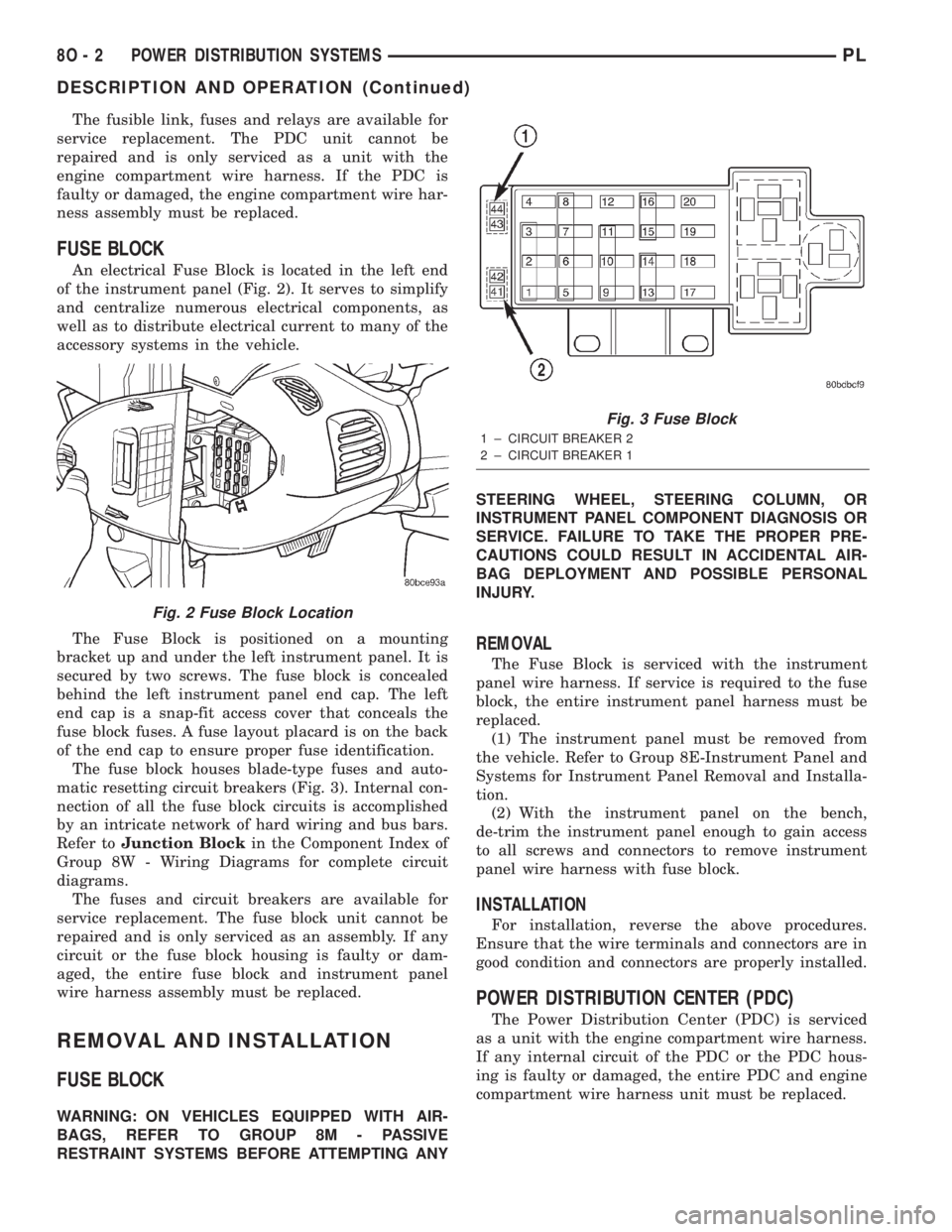

FUSE BLOCK

An electrical Fuse Block is located in the left end

of the instrument panel (Fig. 2). It serves to simplify

and centralize numerous electrical components, as

well as to distribute electrical current to many of the

accessory systems in the vehicle.

The Fuse Block is positioned on a mounting

bracket up and under the left instrument panel. It is

secured by two screws. The fuse block is concealed

behind the left instrument panel end cap. The left

end cap is a snap-fit access cover that conceals the

fuse block fuses. A fuse layout placard is on the back

of the end cap to ensure proper fuse identification.

The fuse block houses blade-type fuses and auto-

matic resetting circuit breakers (Fig. 3). Internal con-

nection of all the fuse block circuits is accomplished

by an intricate network of hard wiring and bus bars.

Refer toJunction Blockin the Component Index of

Group 8W - Wiring Diagrams for complete circuit

diagrams.

The fuses and circuit breakers are available for

service replacement. The fuse block unit cannot be

repaired and is only serviced as an assembly. If any

circuit or the fuse block housing is faulty or dam-

aged, the entire fuse block and instrument panel

wire harness assembly must be replaced.

REMOVAL AND INSTALLATION

FUSE BLOCK

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANYSTEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

The Fuse Block is serviced with the instrument

panel wire harness. If service is required to the fuse

block, the entire instrument panel harness must be

replaced.

(1) The instrument panel must be removed from

the vehicle. Refer to Group 8E-Instrument Panel and

Systems for Instrument Panel Removal and Installa-

tion.

(2) With the instrument panel on the bench,

de-trim the instrument panel enough to gain access

to all screws and connectors to remove instrument

panel wire harness with fuse block.

INSTALLATION

For installation, reverse the above procedures.

Ensure that the wire terminals and connectors are in

good condition and connectors are properly installed.

POWER DISTRIBUTION CENTER (PDC)

The Power Distribution Center (PDC) is serviced

as a unit with the engine compartment wire harness.

If any internal circuit of the PDC or the PDC hous-

ing is faulty or damaged, the entire PDC and engine

compartment wire harness unit must be replaced.

Fig. 2 Fuse Block Location

Fig. 3 Fuse Block

1 ± CIRCUIT BREAKER 2

2 ± CIRCUIT BREAKER 1

8O - 2 POWER DISTRIBUTION SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 375 of 1285

memory to determine whether a valid key is in the

ignition lock cylinder.

The Sentry Key transponder cannot be repaired

and, if faulty or damaged, it must be replaced.

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP

The Sentry Key Immobilizer System (SKIS) uses

the Vehicle Theft Security System (VTSS) indicator

LED to give an indication when the SKIS is faulty or

when the vehicle has been immobilized due to the

use of an invalid ignition key. The LED is controlled

by the instrument cluster circuitry based upon mes-

sages received from the Sentry Key Immobilizer

Module (SKIM) through the Body Control Module

(BCM) on the Programmable Communication Inter-

face (PCI) bus.

The SKIM sends messages to the instrument clus-

ter, via the BCM, to turn the LED on for about three

seconds when the ignition switch is turned to the ON

position as a bulb test. After completion of the bulb

test, the SKIM sends PCI bus messages to keep the

LED off for a duration of about one second. Then the

SKIM sends messages to the instrument cluster cir-

cuitry to turn the LED on or off based upon the

results of the SKIS self-tests. If the VTSS indicator

LED comes on and stays on after the bulb test, it

indicates that the SKIM has detected a system mal-

function and/or that the SKIS has become inopera-

tive. If the SKIM detects an invalid key when the

ignition switch is turned to the ON position, it sends

messages to the instrument cluster to flash the VTSS

indicator LED.

The SKIM can also send messages to the instru-

ment cluster to flash the LED and to generate a sin-

gle audible chime tone. These functions serve as an

indication to the customer that the SKIS has been

placed in its ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this group for more information on

the ªCustomer Learnº programming mode.

The VTSS indicator LED uses a replaceable Light

Emitting Diode (LED) on the instrument cluster elec-

tronic circuit board. Refer to Group 8E - Instrument

Panel Systems for Cluster Lamp Removal and Instal-

lation. If the VTSS indicator LED comes on and

stays on after the bulb test function, diagnosis of the

SKIS should be performed with a DRB IIItscan tool

and the proper Body Diagnostic Procedures Manual.

TRIGGERING THE VTSS

After the VTSS is armed, any of the following will

trigger the system:

²Opening any door.

²Opening the hood.

²Removing the trunk lock cylinder.²Turning the ignition to the RUN/START position

with an invalid Sentry Key.

NOTE: The ignition switch can be turned to the

accessory position without triggering the alarm sys-

tem.

DIAGNOSIS AND TESTING

SENTRY KEY IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System (SKIS) involves the

use of a DRB lllTscan tool and the proper Body

Diagnostic Procedures Manual.

The Sentry Key Immobilizer System (SKIS) and

the Programmable Communication Interface (PCI)

bus network should be diagnosed using a DRB lllt

scan tool. The DRB IIItwill allow confirmation that

the PCI bus is functional, that the Sentry Key Immo-

bilizer Module (SKIM) is placing the proper messages

on the PCI bus, and that the Powertrain Control

Module (PCM) and the instrument cluster are receiv-

ing the PCI bus messages. Refer to the proper Body

Diagnostic Procedures Manual. Refer to Group

8W-Wiring Diagrams for complete circuit descriptions

and diagrams.

(1) Check the fuses in the fuse block. If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Disconnect and isolate the battery negative

cable (Fig. 3). Unplug the wire harness connector at

the SKIM. Check for continuity between the ground

circuit cavity of the SKIM wire harness connector

and a good ground. There should be continuity. If

OK, go to Step 3. If not OK, repair the open circuit to

ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the fuse

block as required.

8Q - 4 VEHICLE THEFT/SECURITY SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 378 of 1285

REMOVAL AND INSTALLATION

DOOR CYLINDER LOCK SWITCH

REMOVAL

(1) Refer to Group 23, Body for door trim and

water shield Removal and Installation.

(2) Remove illuminated entry switch wiring clip

and disconnect connector.

(3) Remove door cylinder lock switch from door

handle.

INSTALLATION

For installation reverse the above procedures.

HOOD AJAR SWITCH

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

remote cable (Fig. 3).

(3) Using a trim stick (special tool #C-4755) or

equivalent, gently pry switch up and out of mounting

bracket.

(4) Disconnect wire harness connector from hood

ajar switch.

(5) Remove switch from vehicle.

INSTALLATION

For installation reverse above procedures.

SENTRY KEY IMMOBILIZER MODULE (SKIM)

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

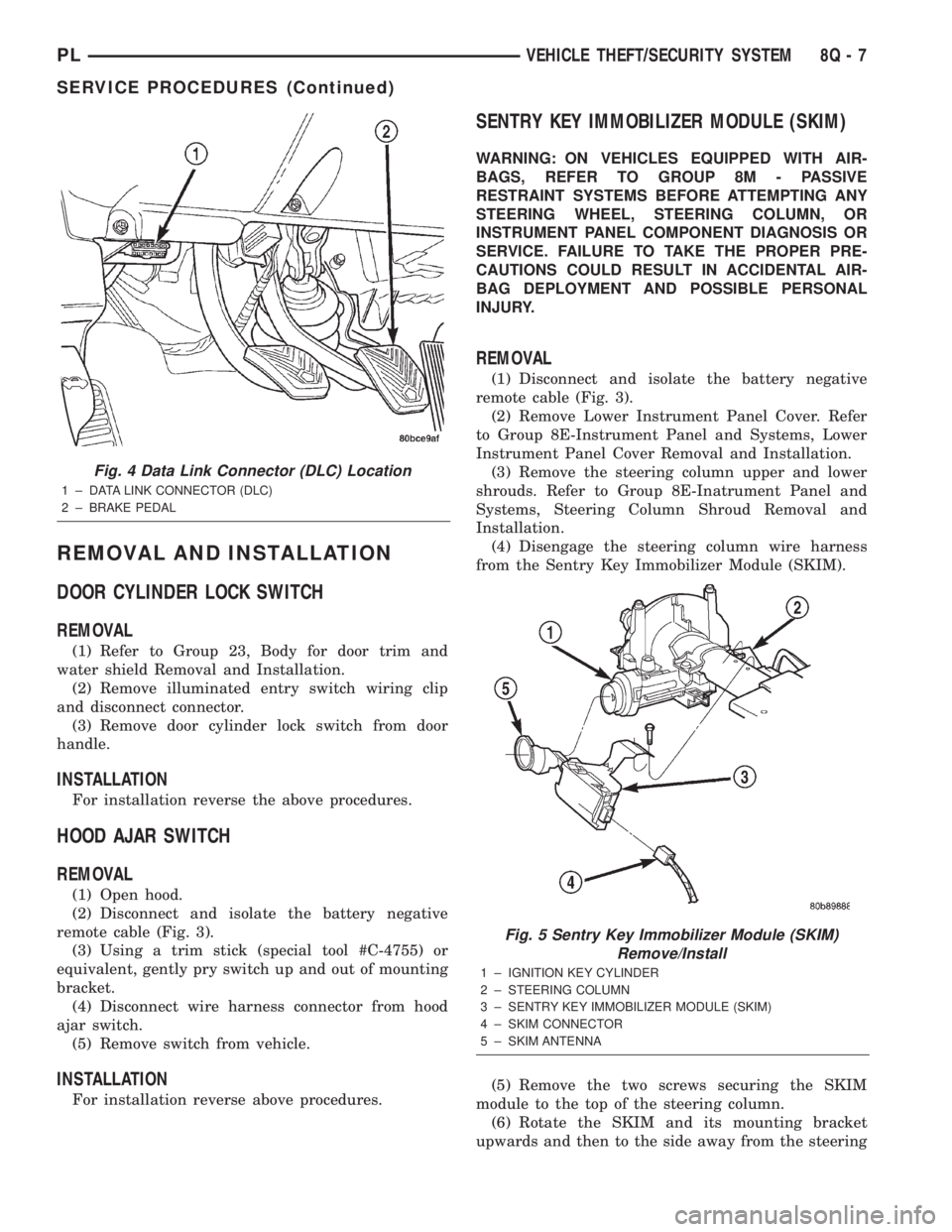

REMOVAL

(1) Disconnect and isolate the battery negative

remote cable (Fig. 3).

(2) Remove Lower Instrument Panel Cover. Refer

to Group 8E-Instrument Panel and Systems, Lower

Instrument Panel Cover Removal and Installation.

(3) Remove the steering column upper and lower

shrouds. Refer to Group 8E-Inatrument Panel and

Systems, Steering Column Shroud Removal and

Installation.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the two screws securing the SKIM

module to the top of the steering column.

(6) Rotate the SKIM and its mounting bracket

upwards and then to the side away from the steering

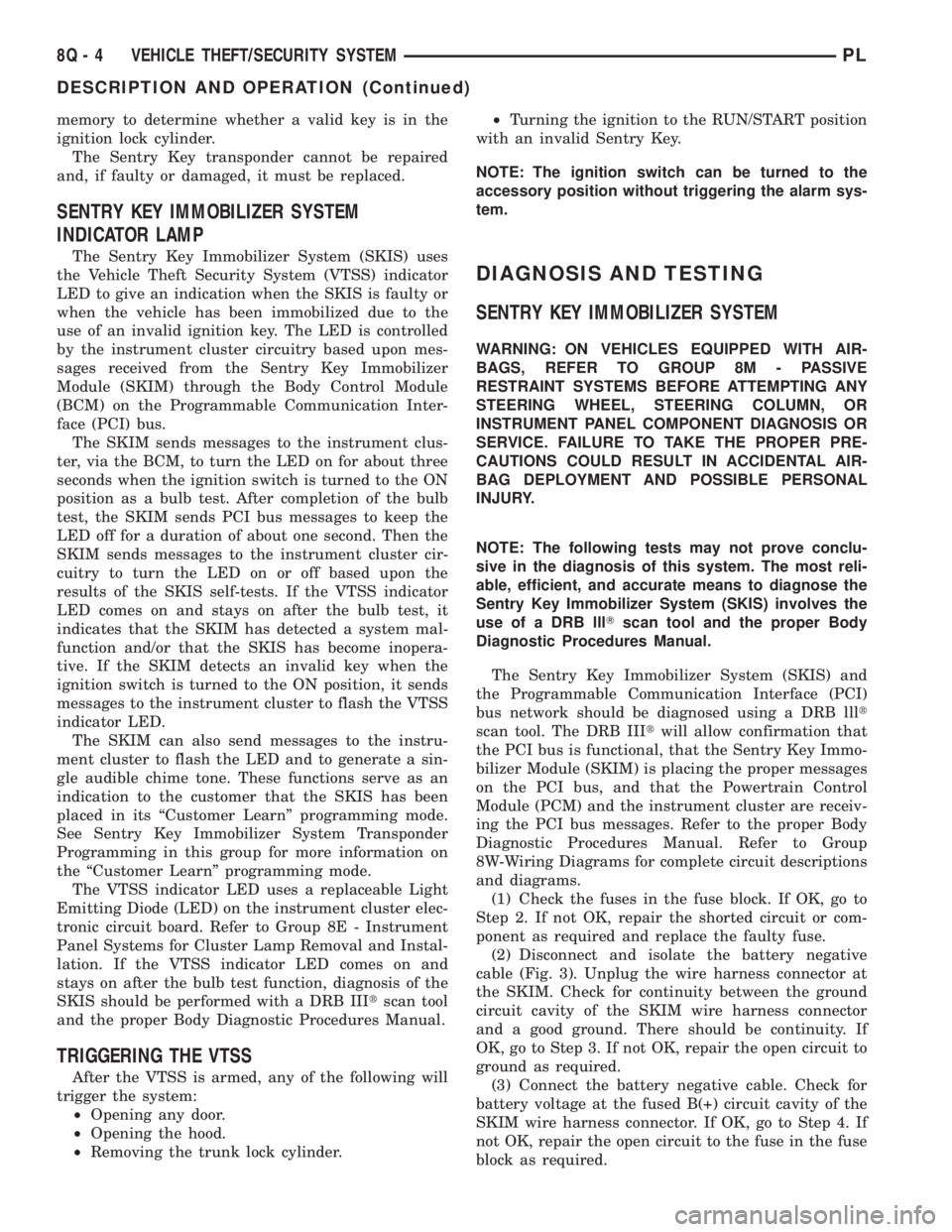

Fig. 4 Data Link Connector (DLC) Location

1 ± DATA LINK CONNECTOR (DLC)

2 ± BRAKE PEDAL

Fig. 5 Sentry Key Immobilizer Module (SKIM)

Remove/Install

1 ± IGNITION KEY CYLINDER

2 ± STEERING COLUMN

3 ± SENTRY KEY IMMOBILIZER MODULE (SKIM)

4 ± SKIM CONNECTOR

5 ± SKIM ANTENNA

PLVEHICLE THEFT/SECURITY SYSTEM 8Q - 7

SERVICE PROCEDURES (Continued)

Page 390 of 1285

CHIME WARNING/REMINDER SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

FASTEN SEAT BELTS......................1

HEADLAMPS LEFT ON.....................1

KEY LEFT IN IGNITION SWITCH.............1CHIME SYSTEM CONDITIONS...............1

REMOVAL AND INSTALLATION

CHIME..................................2

SEAT BELT BUCKLE.......................2

HEADLAMP SWITCH......................2

KEY-IN SWITCH..........................2

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO THE AIRBAG PORTION OF THIS

SECTION FOR STEERING WHEEL OR SWITCH

REMOVAL AND INSTALLATION PROCEDURES.

The seat belt reminder system uses both visual

and audible signals. A combined seat belt and key

reminder chime with a red light on the instrument

panel.

The system will always illuminate the seat belt

reminder lamp for four to eight seconds when the

ignition switch is turned to the ON position. The

CHIME will sound during the same time interval if

the driver's seat belt is not fastened. Passenger belts

are not connected to the system.

The chime will activate if the drivers door is

opened and:

²The key is in the ignition switch, with the igni-

tion switch in either the OFF or accessory (ACC)

position.

²The head lamps are ON.

The chime is integral to the instrument cluster.

DIAGNOSIS AND TESTING

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the igni-

tion switch to the ON position with the driver's seat

belt unbuckled and fully retracted. The seat belt

warning lamp should light for four to eight seconds

and the tone should sound three to five times.

If the lamp does not light, check the connection at

the seat belt retractor and the LED in the instru-

ment cluster. Replace as necessary.

HEADLAMPS LEFT ON

These are the conditions that have to be met for

the headlamps on, chime function to work:

²Headlamps ON.

²Driver's door open.

²Key removed from the ignition switch.

Chime should sound until headlamps are turned

off or driver's door is closed.

If these conditions are met and there is still a

problem with the system, replace the instrument

cluster. Refer to Group 8E-Instrument Panel and

Systems, Instrument Cluster Removal and Installa-

tion.

KEY LEFT IN IGNITION SWITCH

To test the key left in ignition function, insert key

into the ignition and open the driver's door. Chime

should sound until key is removed from ignition or

driver's door is closed.

If these conditions are met and there is still a

problem with the system, replace the instrument

cluster. Refer to Group 8E-Instrument Panel and

Systems, Instrument Cluster Removal and Installa-

tion.

CHIME SYSTEM CONDITIONS

NO TONE WHEN IGNITION SWITCH IS TURNED ON

AND DRIVERS SEAT BELT IS UNBUCKLED

(1) Using an ohmmeter, with the seat belt fully

retracted, check for continuity to ground at Pin 25 of

the cluster harness connector. If OK, go to step 2. If

not OK, repair as necessary.

(2) Using voltmeter, check for battery feed at Pin

21 of the cluster harness connector. Check for igni-

tion feed at Pin 15 of the cluster harness connector.

If not OK, repair as necessary.

PLCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 611 of 1285

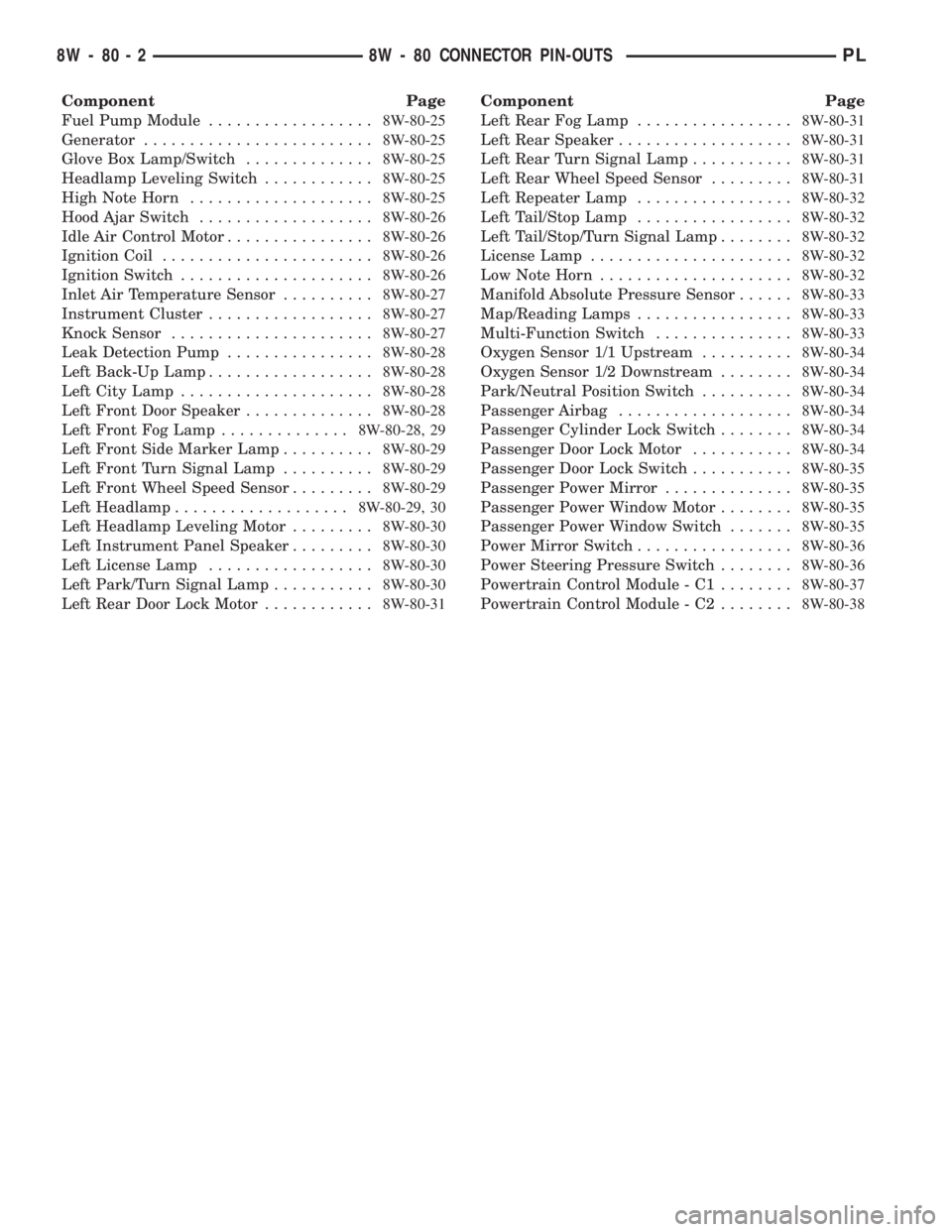

Component Page

Fuel Pump Module..................8W-80-25

Generator.........................8W-80-25

Glove Box Lamp/Switch..............8W-80-25

Headlamp Leveling Switch............8W-80-25

High Note Horn....................8W-80-25

Hood Ajar Switch...................8W-80-26

Idle Air Control Motor................8W-80-26

Ignition Coil.......................8W-80-26

Ignition Switch.....................8W-80-26

Inlet Air Temperature Sensor..........8W-80-27

Instrument Cluster..................8W-80-27

Knock Sensor......................8W-80-27

Leak Detection Pump................8W-80-28

Left Back-Up Lamp..................8W-80-28

Left City Lamp.....................8W-80-28

Left Front Door Speaker..............8W-80-28

Left Front Fog Lamp..............8W-80-28, 29

Left Front Side Marker Lamp..........8W-80-29

Left Front Turn Signal Lamp..........8W-80-29

Left Front Wheel Speed Sensor.........8W-80-29

Left Headlamp...................8W-80-29, 30

Left Headlamp Leveling Motor.........8W-80-30

Left Instrument Panel Speaker.........8W-80-30

Left License Lamp..................8W-80-30

Left Park/Turn Signal Lamp...........8W-80-30

Left Rear Door Lock Motor............8W-80-31Component Page

Left Rear Fog Lamp.................8W-80-31

Left Rear Speaker...................8W-80-31

Left Rear Turn Signal Lamp...........8W-80-31

Left Rear Wheel Speed Sensor.........8W-80-31

Left Repeater Lamp.................8W-80-32

Left Tail/Stop Lamp.................8W-80-32

Left Tail/Stop/Turn Signal Lamp........8W-80-32

License Lamp......................8W-80-32

Low Note Horn.....................8W-80-32

Manifold Absolute Pressure Sensor......8W-80-33

Map/Reading Lamps.................8W-80-33

Multi-Function Switch...............8W-80-33

Oxygen Sensor 1/1 Upstream..........8W-80-34

Oxygen Sensor 1/2 Downstream........8W-80-34

Park/Neutral Position Switch..........8W-80-34

Passenger Airbag...................8W-80-34

Passenger Cylinder Lock Switch........8W-80-34

Passenger Door Lock Motor...........8W-80-34

Passenger Door Lock Switch...........8W-80-35

Passenger Power Mirror..............8W-80-35

Passenger Power Window Motor........8W-80-35

Passenger Power Window Switch.......8W-80-35

Power Mirror Switch.................8W-80-36

Power Steering Pressure Switch........8W-80-36

Powertrain Control Module - C1........8W-80-37

Powertrain Control Module - C2........8W-80-38

8W - 80 - 2 8W - 80 CONNECTOR PIN-OUTSPL

Page 659 of 1285

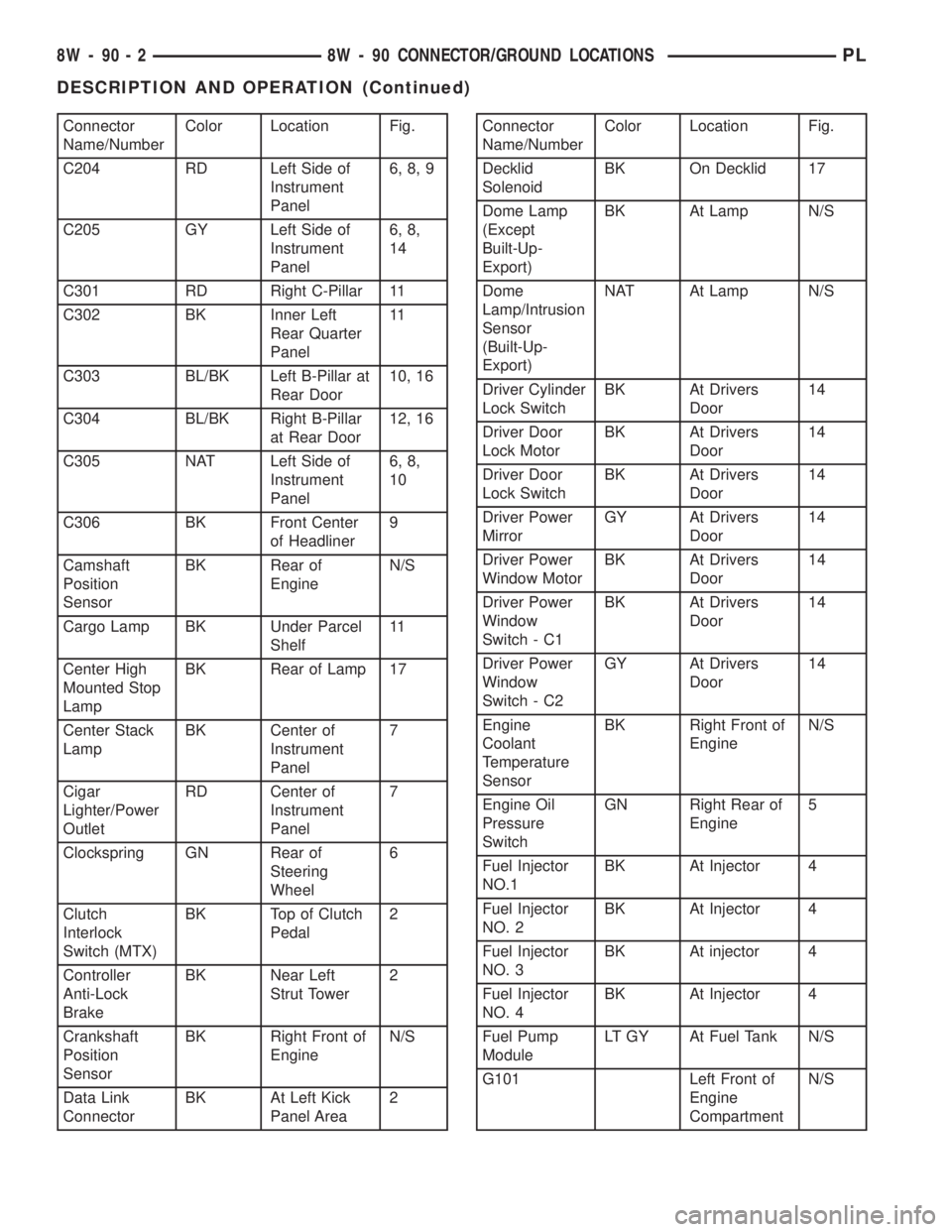

Connector

Name/NumberColor Location Fig.

C204 RD Left Side of

Instrument

Panel6, 8, 9

C205 GY Left Side of

Instrument

Panel6, 8,

14

C301 RD Right C-Pillar 11

C302 BK Inner Left

Rear Quarter

Panel11

C303 BL/BK Left B-Pillar at

Rear Door10, 16

C304 BL/BK Right B-Pillar

at Rear Door12, 16

C305 NAT Left Side of

Instrument

Panel6, 8,

10

C306 BK Front Center

of Headliner9

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf11

Center High

Mounted Stop

LampBK Rear of Lamp 17

Center Stack

LampBK Center of

Instrument

Panel7

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel7

Clockspring GN Rear of

Steering

Wheel6

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal2

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower2

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK At Left Kick

Panel Area2Connector

Name/NumberColor Location Fig.

Decklid

SolenoidBK On Decklid 17

Dome Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Dome

Lamp/Intrusion

Sensor

(Built-Up-

Export)NAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door14

Driver Door

Lock MotorBK At Drivers

Door14

Driver Door

Lock SwitchBK At Drivers

Door14

Driver Power

MirrorGY At Drivers

Door14

Driver Power

Window MotorBK At Drivers

Door14

Driver Power

Window

Switch - C1BK At Drivers

Door14

Driver Power

Window

Switch - C2GY At Drivers

Door14

Engine

Coolant

Temperature

SensorBK Right Front of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine5

Fuel Injector

NO.1BK At Injector 4

Fuel Injector

NO. 2BK At Injector 4

Fuel Injector

NO. 3BK At injector 4

Fuel Injector

NO. 4BK At Injector 4

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 661 of 1285

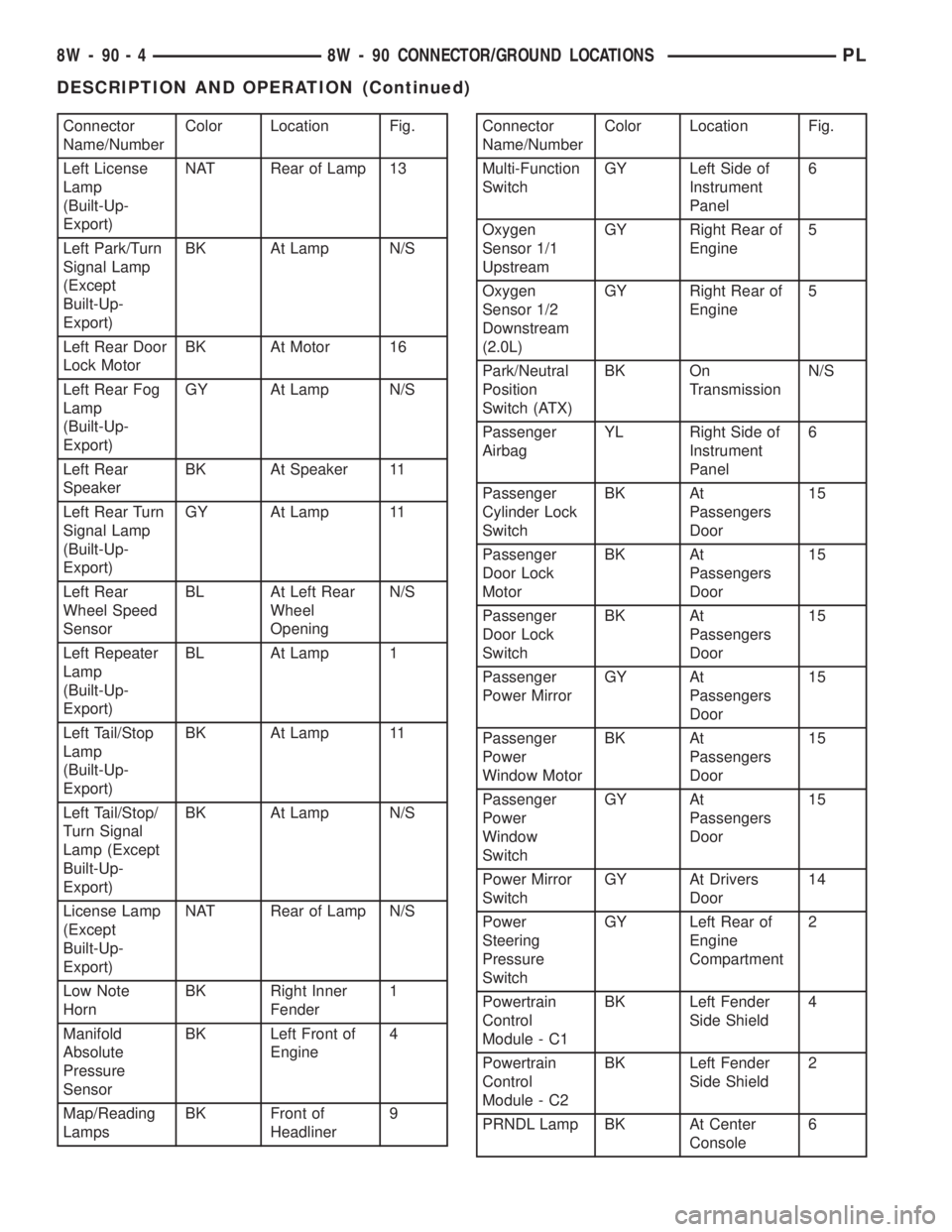

Connector

Name/NumberColor Location Fig.

Left License

Lamp

(Built-Up-

Export)NAT Rear of Lamp 13

Left Park/Turn

Signal Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Left Rear Door

Lock MotorBK At Motor 16

Left Rear Fog

Lamp

(Built-Up-

Export)GY At Lamp N/S

Left Rear

SpeakerBK At Speaker 11

Left Rear Turn

Signal Lamp

(Built-Up-

Export)GY At Lamp 11

Left Rear

Wheel Speed

SensorBL At Left Rear

Wheel

OpeningN/S

Left Repeater

Lamp

(Built-Up-

Export)BL At Lamp 1

Left Tail/Stop

Lamp

(Built-Up-

Export)BK At Lamp 11

Left Tail/Stop/

Turn Signal

Lamp (Except

Built-Up-

Export)BK At Lamp N/S

License Lamp

(Except

Built-Up-

Export)NAT Rear of Lamp N/S

Low Note

HornBK Right Inner

Fender1

Manifold

Absolute

Pressure

SensorBK Left Front of

Engine4

Map/Reading

LampsBK Front of

Headliner9Connector

Name/NumberColor Location Fig.

Multi-Function

SwitchGY Left Side of

Instrument

Panel6

Oxygen

Sensor 1/1

UpstreamGY Right Rear of

Engine5

Oxygen

Sensor 1/2

Downstream

(2.0L)GY Right Rear of

Engine5

Park/Neutral

Position

Switch (ATX)BK On

TransmissionN/S

Passenger

AirbagYL Right Side of

Instrument

Panel6

Passenger

Cylinder Lock

SwitchBK At

Passengers

Door15

Passenger

Door Lock

MotorBK At

Passengers

Door15

Passenger

Door Lock

SwitchBK At

Passengers

Door15

Passenger

Power MirrorGY At

Passengers

Door15

Passenger

Power

Window MotorBK At

Passengers

Door15

Passenger

Power

Window

SwitchGY At

Passengers

Door15

Power Mirror

SwitchGY At Drivers

Door14

Power

Steering

Pressure

SwitchGY Left Rear of

Engine

Compartment2

Powertrain

Control

Module - C1BK Left Fender

Side Shield4

Powertrain

Control

Module - C2BK Left Fender

Side Shield2

PRNDL Lamp BK At Center

Console6

8W - 90 - 4 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)