ad blue DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 397 of 1285

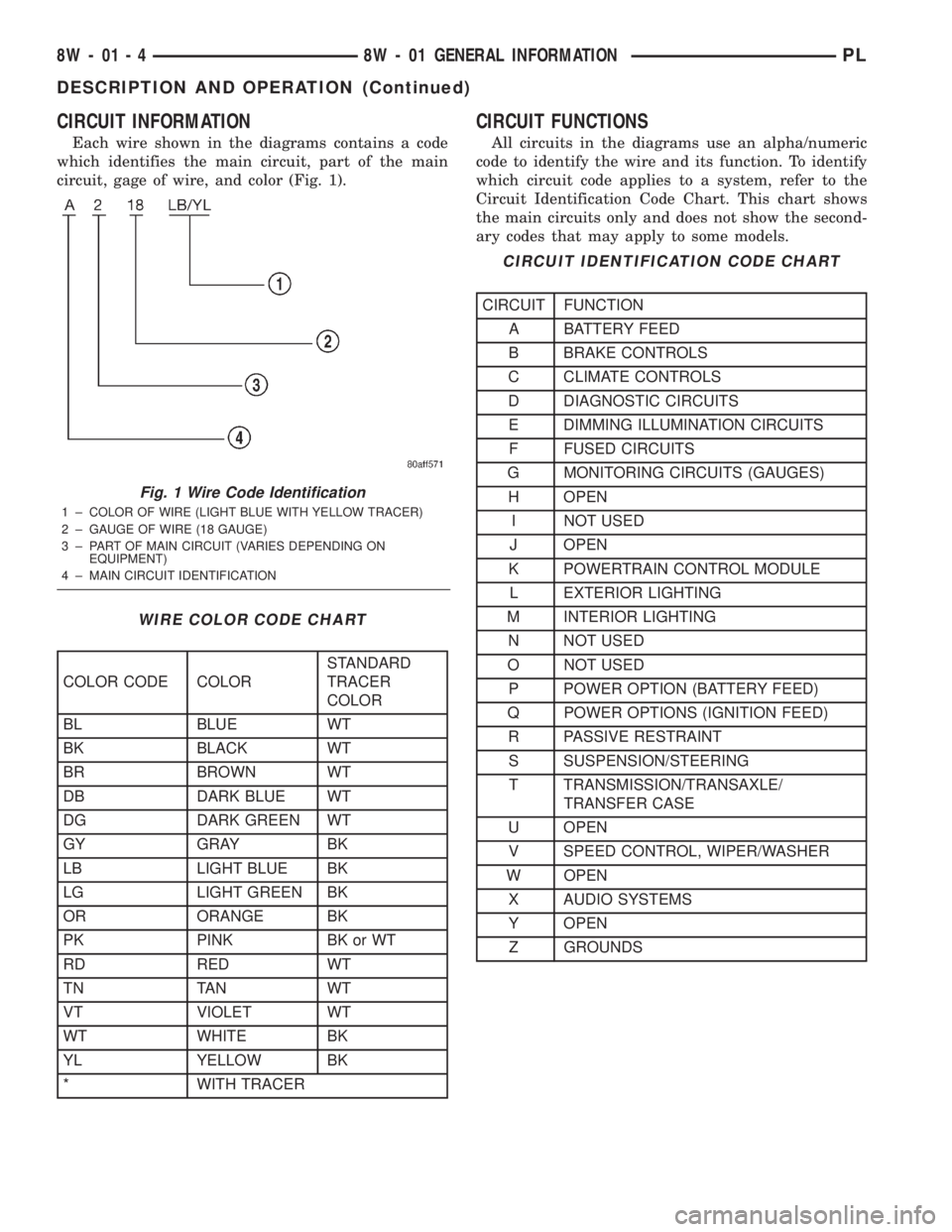

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 1).

CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

Fig. 1 Wire Code Identification

1 ± COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER)

2 ± GAUGE OF WIRE (18 GAUGE)

3 ± PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 ± MAIN CIRCUIT IDENTIFICATION

WIRE COLOR CODE CHART

COLOR CODE COLORSTANDARD

TRACER

COLOR

BL BLUE WT

BK BLACK WT

BR BROWN WT

DB DARK BLUE WT

DG DARK GREEN WT

GY GRAY BK

LB LIGHT BLUE BK

LG LIGHT GREEN BK

OR ORANGE BK

PK PINK BK or WT

RD RED WT

TN TAN WT

VT VIOLET WT

WT WHITE BK

YL YELLOW BK

* WITH TRACER

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS (GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY FEED)

Q POWER OPTIONS (IGNITION FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 624 of 1285

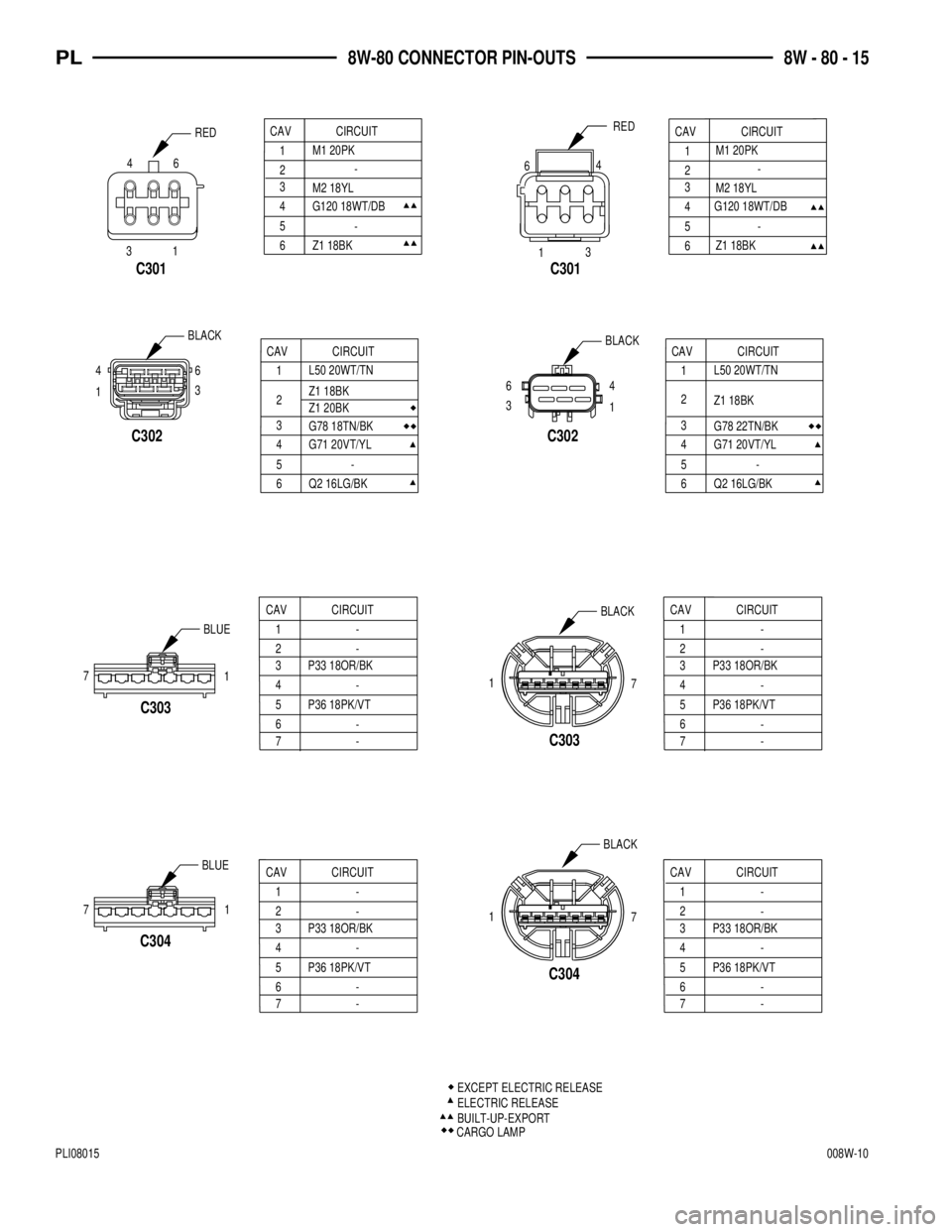

RED

BLACKBLACK

RED

- M1 20PK

G120 18WT/DBM2 18YL-

Z1 18BK Z1 18BK

C301

CAV CIRCUIT

1

2

4 3

6 5

-

C301

5

6 3

4 2 1CIRCUIT CAV

M2 18YL

G120 18WT/DB M1 20PK

1 36 4

-

134

6

-

L50 20WT/TN

G71 20VT/YL G78 18TN/BK

5

6 3

4 1CIRCUIT CAV

C302

Z1 18BK

C302

Q2 16LG/BK

BUILT-UP-EXPORT ELECTRIC RELEASE

CARGO LAMP

Z1 20BK 2

Q2 16LG/BK Z1 18BK CAV CIRCUIT

1

2

4 3

6 5

G78 22TN/BK

G71 20VT/YL L50 20WT/TN

-

1 46

3

3 64

1

EXCEPT ELECTRIC RELEASE

C304P33 18OR/BK

5

6

7 3

4 2 1CIRCUIT CAV

C304

1

7 7

1

P36 18PK/VT-

-

-

-

-- - - - -

P36 18PK/VT

CAV CIRCUIT

1

2

4 3

7 6 5P33 18OR/BK

P33 18OR/BK

5

6

7 3

4 2 1CIRCUIT CAV

P36 18PK/VT-

-

-

-

- - - - - -

P36 18PK/VT 1 7

7 1

C303

CAV CIRCUIT

1

2

4 3

7 6 5P33 18OR/BK

C303

BLUE

BLUE

BLACK

BLACK

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 15

PLI08015008W-10

Page 631 of 1285

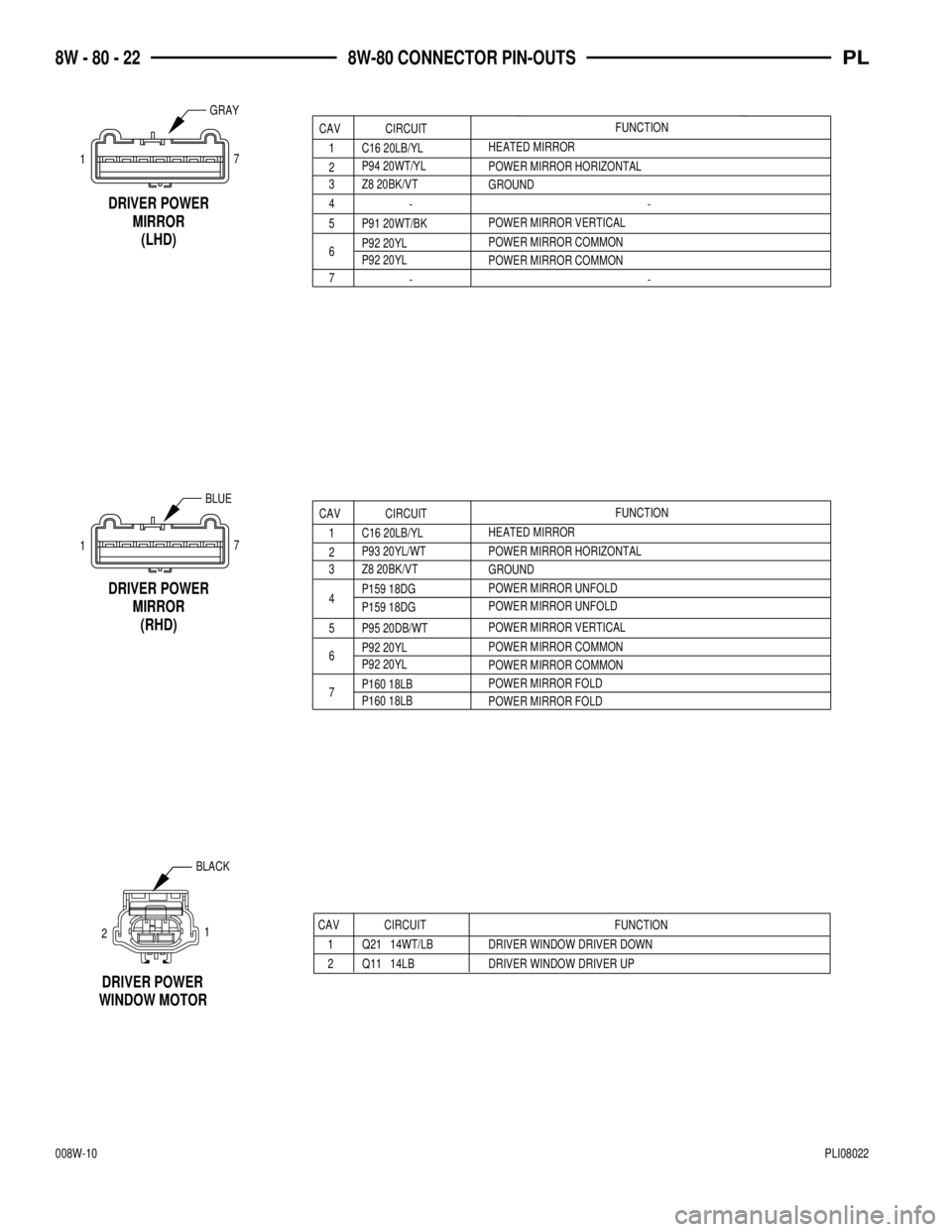

DRIVER POWER

WINDOW MOTOR

1

2

BLACK

DRIVER WINDOW DRIVER UP 14LB Q11 2DRIVER WINDOW DRIVER DOWN 14WT/LB Q21 1

FUNCTION CIRCUIT CAV

POWER MIRROR FOLD POWER MIRROR FOLD

P160 18LBP160 18LBPOWER MIRROR UNFOLD

P159 18DGPOWER MIRROR UNFOLD

P159 18DG 7

17

1

DRIVER POWER

MIRROR

(RHD)POWER MIRROR VERTICAL

P92 20YL P92 20YL P93 20YL/WT C16 20LB/YL

POWER MIRROR HORIZONTAL HEATED MIRRORFUNCTIONP95 20DB/WT

CAV CIRCUIT

1

2

4 3

6 5

Z8 20BK/VT

GROUND

7POWER MIRROR COMMON

POWER MIRROR COMMON

POWER MIRROR COMMON POWER MIRROR COMMON

- - 7

GROUND Z8 20BK/VT

5

6 3

4 2 1CIRCUIT CAVP91 20WT/BK-

FUNCTION

HEATED MIRROR

POWER MIRROR HORIZONTAL C16 20LB/YL

P94 20WT/YL

P92 20YL

P92 20YLPOWER MIRROR VERTICAL-

(LHD)

MIRROR DRIVER POWER

GRAY

BLUE

8W - 80 - 22 8W-80 CONNECTOR PIN-OUTSPL

008W-10PLI08022

Page 640 of 1285

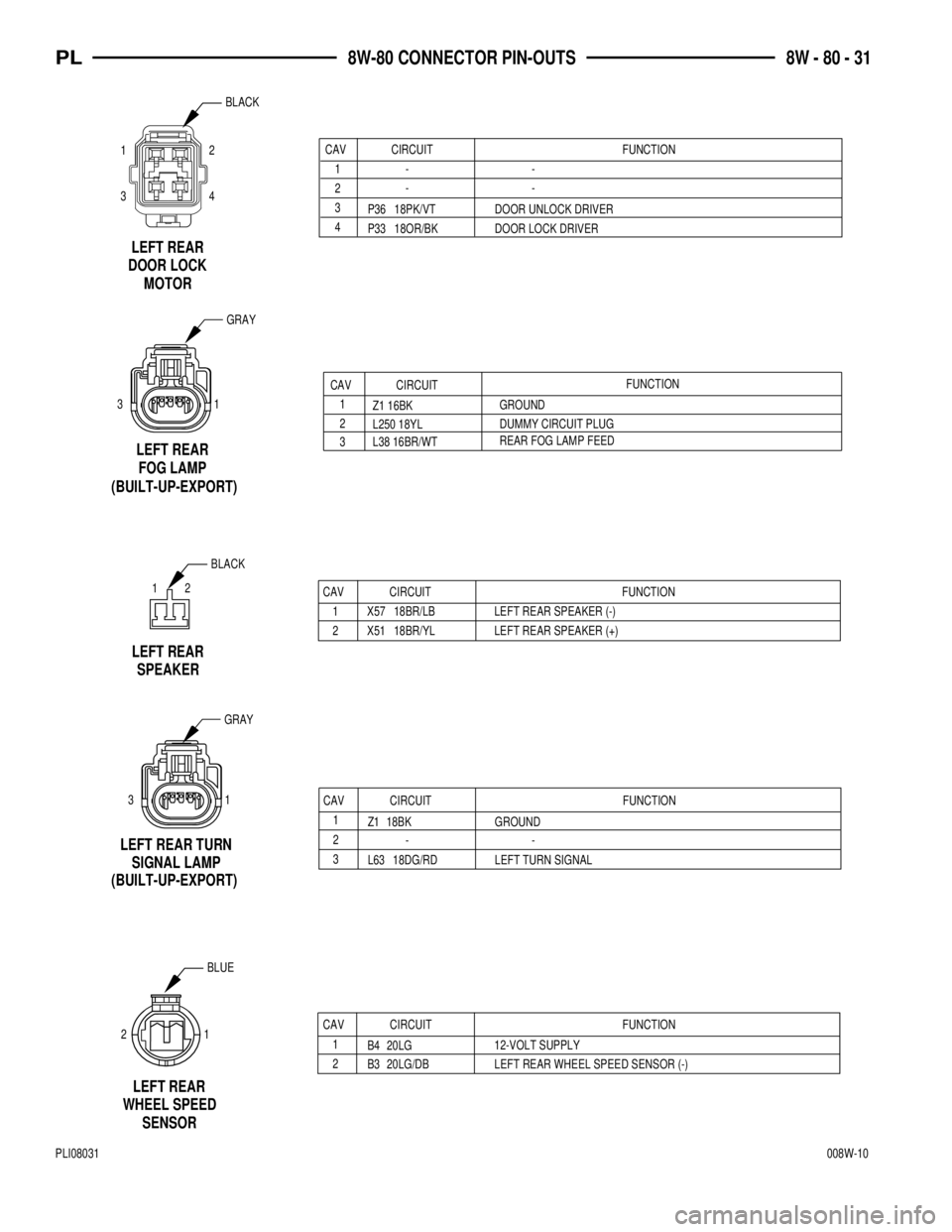

MOTOR DOOR LOCKLEFT REAR

DOOR LOCK DRIVER 18OR/BK P33 DOOR UNLOCK DRIVER 18PK/VT P36

CAV CIRCUIT FUNCTION

1

B3 20LG/DB LEFT REAR WHEEL SPEED SENSOR (-) 2B4 20LG1

BLUE

2

LEFT REAR

WHEEL SPEED

SENSOR SPEAKER LEFT REAR

2 1

BLACK

LEFT REAR SPEAKER (-) 18BR/LB X57

2

LEFT REAR SPEAKER (+) 18BR/YL X51 1

FUNCTION CIRCUIT CAV

12-VOLT SUPPLY BLACK

34

2 1CAV

3

4 2

- - 1

FUNCTION CIRCUIT

--

REAR FOG LAMP FEED

L38 16BR/WT L250 18YL

31

FOG LAMP LEFT REAR

GROUND

Z1 16BKFUNCTION

CAV CIRCUIT

1

2

3

1 3

L63 18DG/RD LEFT TURN SIGNAL

3 2

GROUND 18BK Z1 1

FUNCTION CIRCUIT CAV

(BUILT-UP-EXPORT)LEFT REAR TURN

SIGNAL LAMP

--

(BUILT-UP-EXPORT)

DUMMY CIRCUIT PLUG

GRAY

GRAY

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 31

PLI08031008W-10

Page 644 of 1285

1 2

BLACK

PASSENGER WINDOW DRIVER (UP) 14BR Q12 2PASSENGER WINDOW DRIVER (DOWN) 14VT Q22 1

FUNCTION CIRCUIT CAV

14VT Q22 MASTER WINDOW SWITCH RIGHT FRONT UP 14BR/WT Q16

FUSED IGNITION SWITCH OUTPUT (RUN) 14TN F21 MASTER WINDOW SWITCH RIGHT FRONT DOWN 14VT/WT Q26

14BR Q12

PASSENGER POWER

WINDOW MOTOR

PASSENGER POWER

WINDOW SWITCH

PASSENGER WINDOW DRIVER (DOWN)

PASSENGER WINDOW DRIVER (UP)

GRAY

8

6 5

4

3

2

1

FUNCTION CIRCUIT CAV

5 81 4

--

7F20 20WT

FUSED IGNITION SWITCH OUTPUT (RUN)

F20 20WT

FUSED IGNITION SWITCH OUTPUT (RUN)

Z14 18BK/YL

GROUND 7

17

1

PASSENGER POWER

MIRROR

(RHD)

POWER MIRROR COMMON

- - 7

GROUND Z14 18BK/YL

5

6 3

4 2 1CIRCUIT CAVP95 20DB/WT-

FUNCTION

HEATED MIRROR

POWER MIRROR HORIZONTAL C16 20LB/YL

P93 20YL/WT

P92 20YLPOWER MIRROR VERTICAL-

(LHD)

MIRROR PASSENGER POWER

Z14 18BK/YL

GROUND

GROUND Z14 18BK/YL

POWER MIRROR UNFOLD

P160 18LB P94 20WT/YL C16 20LB/YL

POWER MIRROR HORIZONTAL HEATED MIRRORFUNCTION

P159 18DG/WT

CAV CIRCUIT

1

2

4 3

6 5

Z14 18BK/YL

GROUND

7

POWER MIRROR FOLD

P91 20WT/BKPOWER MIRROR VERTICAL

P92 20YLPOWER MIRROR COMMON

BLACK

CAV CIRCUIT FUNCTION

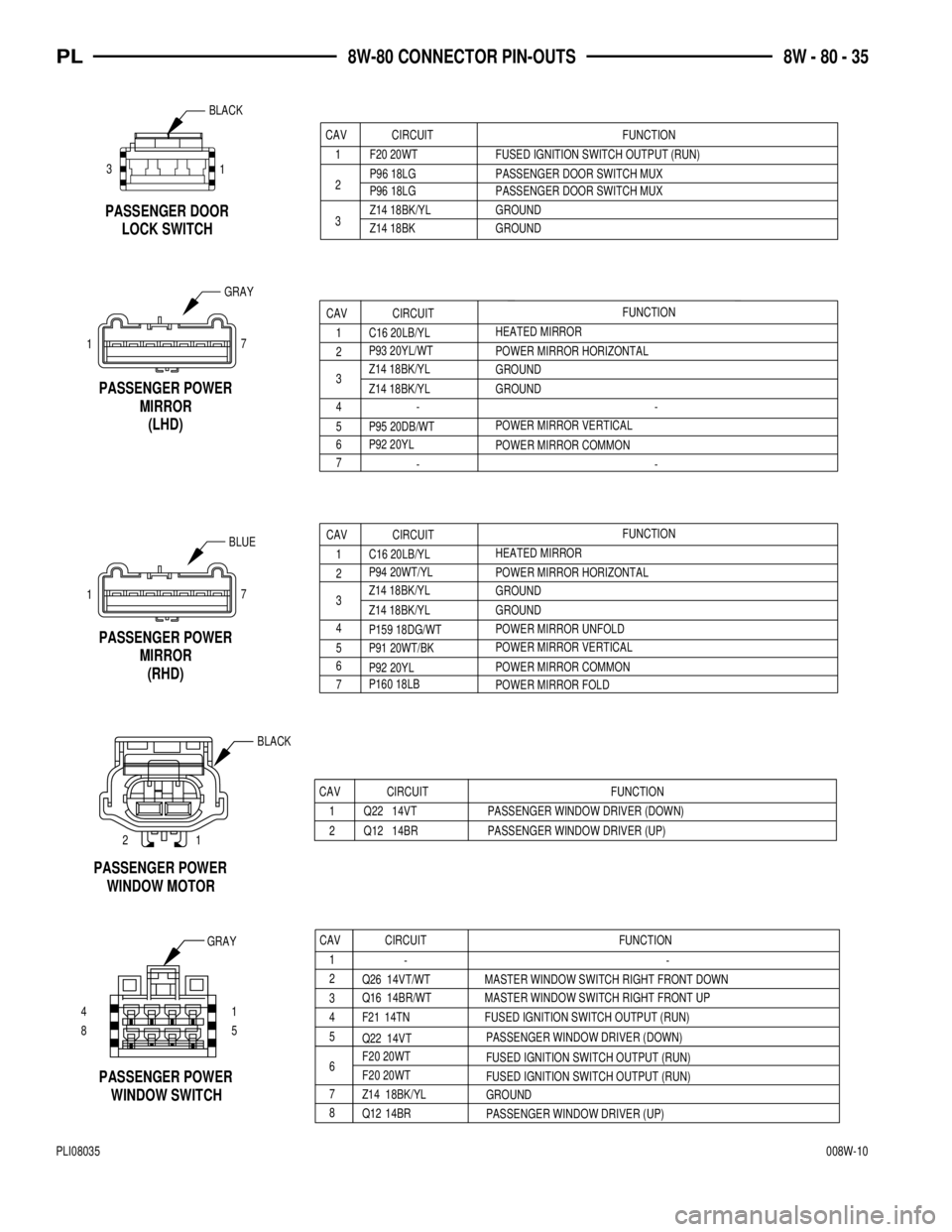

1 F20 20WT FUSED IGNITION SWITCH OUTPUT (RUN)

2P96 18LG PASSENGER DOOR SWITCH MUX

PASSENGER DOOR

LOCK SWITCH

3

1

GROUND Z14 18BK/YL

3PASSENGER DOOR SWITCH MUX P96 18LG

Z14 18BK GROUND

GRAY

BLUE

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 35

PLI08035008W-10

Page 653 of 1285

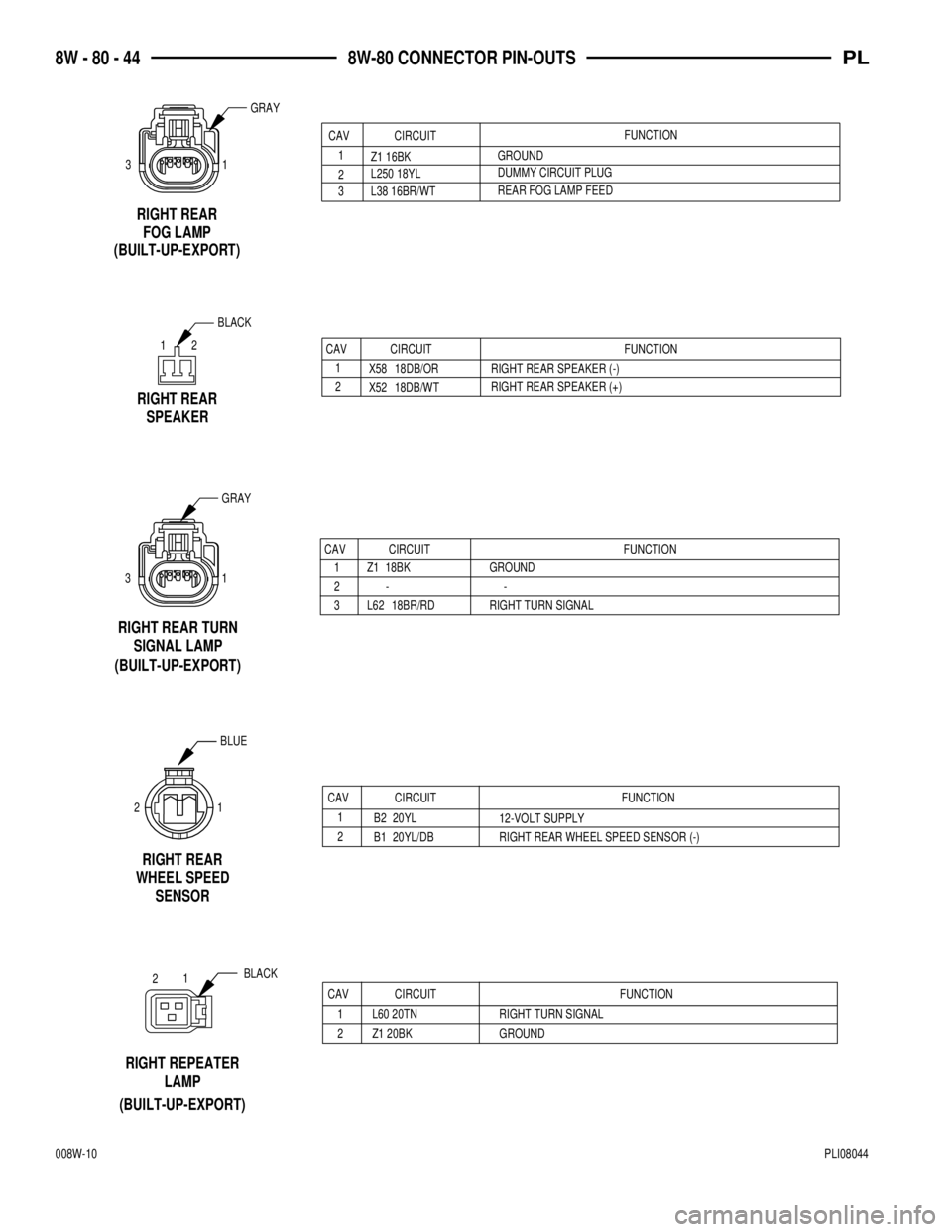

CAV CIRCUIT FUNCTION

1

X52 18DB/WT 2X58 18DB/OR RIGHT REAR SPEAKER (-)

B1 20YL/DB B2 20YL

BLACK

1 2

RIGHT REAR

SPEAKERRIGHT REAR SPEAKER (+)

SENSOR WHEEL SPEEDRIGHT REAR

2BLUE1 12-VOLT SUPPLY

2

RIGHT REAR WHEEL SPEED SENSOR (-) 1

FUNCTION CIRCUIT CAV

GROUND Z1 20BK 2RIGHT TURN SIGNAL L60 20TN 1

FUNCTION CIRCUIT CAV

REAR FOG LAMP FEED

L38 16BR/WTDUMMY CIRCUIT PLUG

L250 18YL

FOG LAMP RIGHT REAR

GROUND

Z1 16BKFUNCTION

CAV CIRCUIT

1

2

331

(BUILT-UP-EXPORT)LAMP RIGHT REPEATER

1 3

(BUILT-UP-EXPORT)

CAV CIRCUIT FUNCTION

1 Z1 18BK GROUND

2

3 L62 18BR/RD RIGHT TURN SIGNAL

RIGHT REAR TURN

SIGNAL LAMP

--

(BUILT-UP-EXPORT)

GRAY

GRAY

BLACK21

8W - 80 - 44 8W-80 CONNECTOR PIN-OUTSPL

008W-10PLI08044

Page 784 of 1285

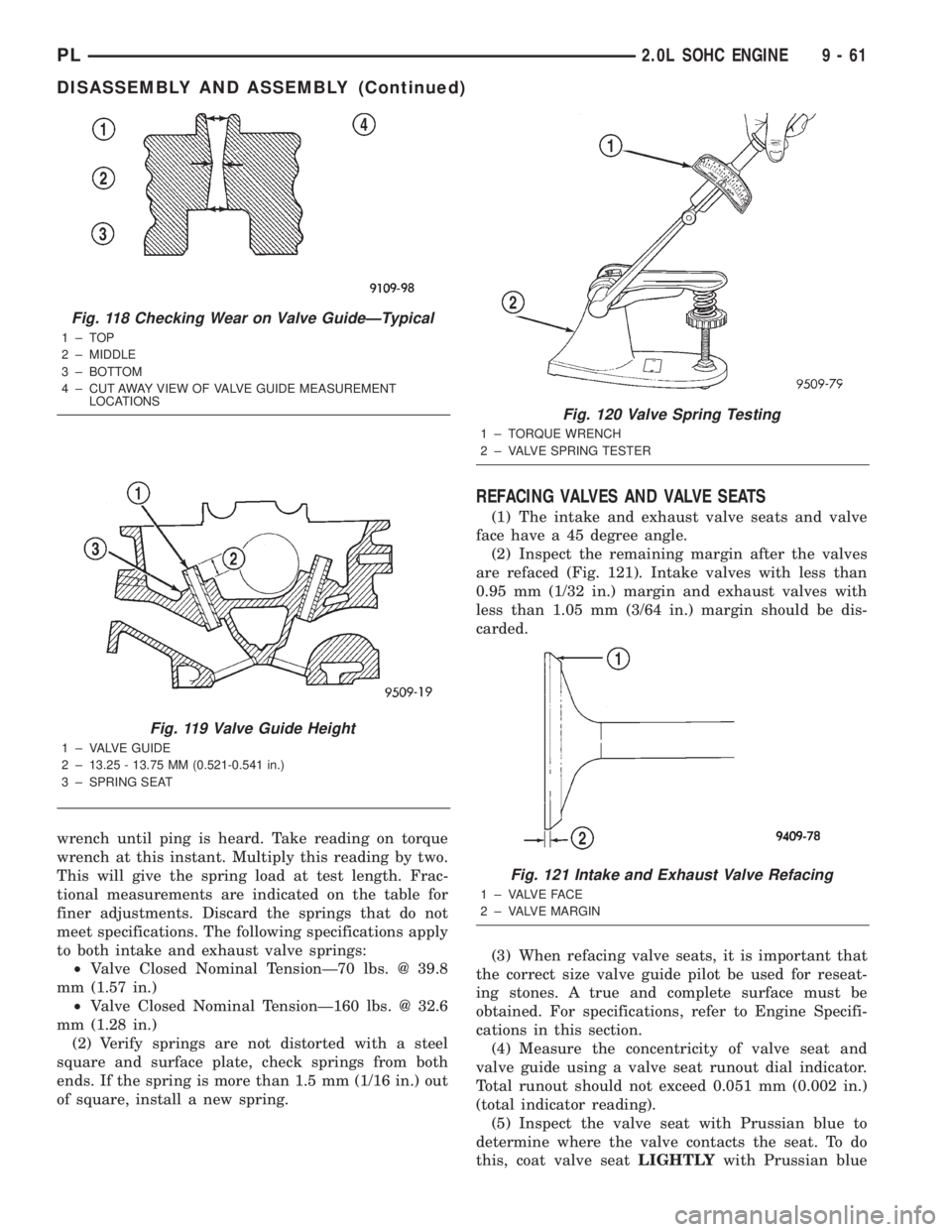

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The following specifications apply

to both intake and exhaust valve springs:

²Valve Closed Nominal TensionÐ70 lbs. @ 39.8

mm (1.57 in.)

²Valve Closed Nominal TensionÐ160 lbs. @ 32.6

mm (1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 in.) out

of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 121). Intake valves with less than

0.95 mm (1/32 in.) margin and exhaust valves with

less than 1.05 mm (3/64 in.) margin should be dis-

carded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For specifications, refer to Engine Specifi-

cations in this section.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed 0.051 mm (0.002 in.)

(total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

Fig. 118 Checking Wear on Valve GuideÐTypical

1±TOP

2 ± MIDDLE

3 ± BOTTOM

4 ± CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 119 Valve Guide Height

1 ± VALVE GUIDE

2 ± 13.25 - 13.75 MM (0.521-0.541 in.)

3 ± SPRING SEAT

Fig. 120 Valve Spring Testing

1 ± TORQUE WRENCH

2 ± VALVE SPRING TESTER

Fig. 121 Intake and Exhaust Valve Refacing

1 ± VALVE FACE

2 ± VALVE MARGIN

PL2.0L SOHC ENGINE 9 - 61

DISASSEMBLY AND ASSEMBLY (Continued)

Page 785 of 1285

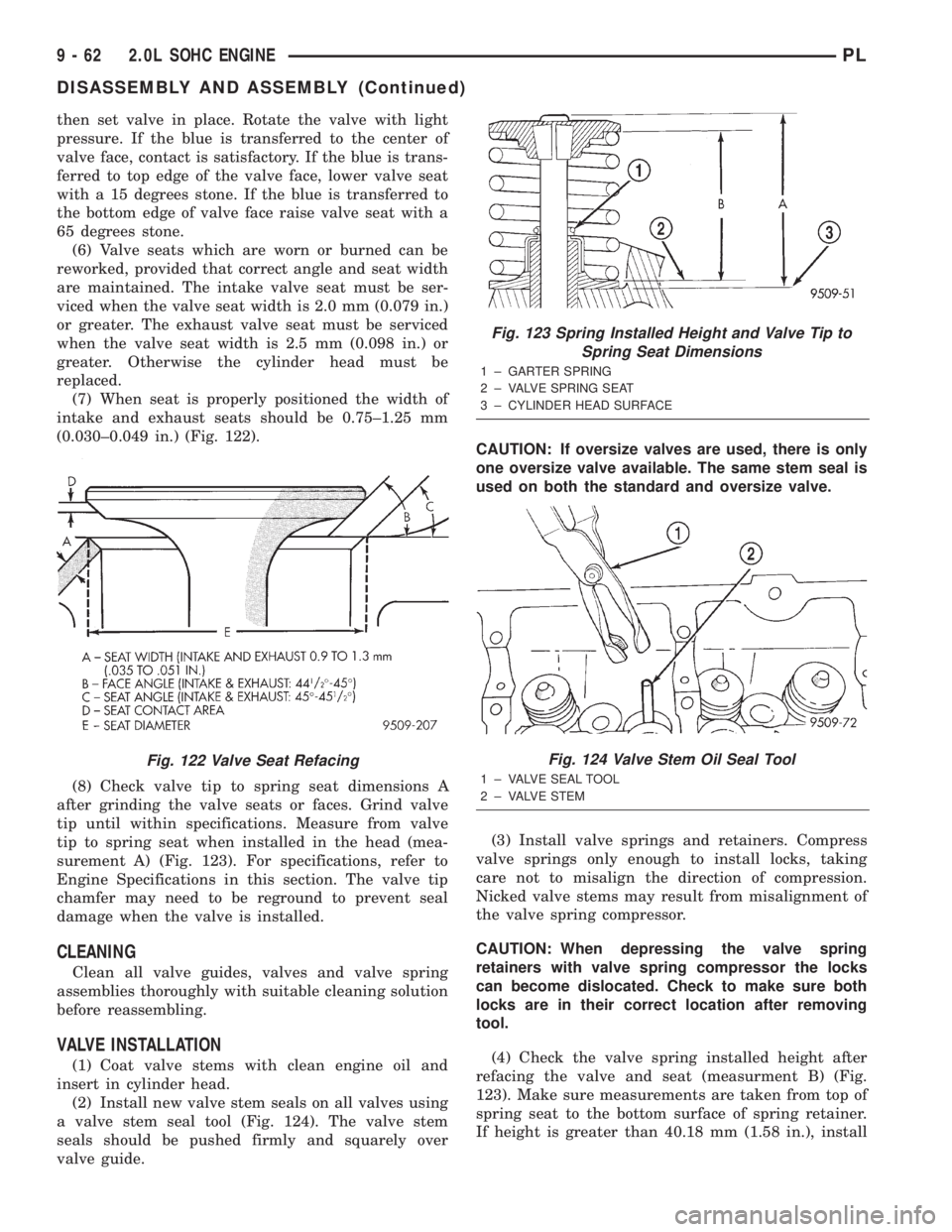

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

(6) Valve seats which are worn or burned can be

reworked, provided that correct angle and seat width

are maintained. The intake valve seat must be ser-

viced when the valve seat width is 2.0 mm (0.079 in.)

or greater. The exhaust valve seat must be serviced

when the valve seat width is 2.5 mm (0.098 in.) or

greater. Otherwise the cylinder head must be

replaced.

(7) When seat is properly positioned the width of

intake and exhaust seats should be 0.75±1.25 mm

(0.030±0.049 in.) (Fig. 122).

(8) Check valve tip to spring seat dimensions A

after grinding the valve seats or faces. Grind valve

tip until within specifications. Measure from valve

tip to spring seat when installed in the head (mea-

surement A) (Fig. 123). For specifications, refer to

Engine Specifications in this section. The valve tip

chamfer may need to be reground to prevent seal

damage when the valve is installed.

CLEANING

Clean all valve guides, valves and valve spring

assemblies thoroughly with suitable cleaning solution

before reassembling.

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves using

a valve stem seal tool (Fig. 124). The valve stem

seals should be pushed firmly and squarely over

valve guide.CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height after

refacing the valve and seat (measurment B) (Fig.

123). Make sure measurements are taken from top of

spring seat to the bottom surface of spring retainer.

If height is greater than 40.18 mm (1.58 in.), install

Fig. 122 Valve Seat Refacing

Fig. 123 Spring Installed Height and Valve Tip to

Spring Seat Dimensions

1 ± GARTER SPRING

2 ± VALVE SPRING SEAT

3 ± CYLINDER HEAD SURFACE

Fig. 124 Valve Stem Oil Seal Tool

1 ± VALVE SEAL TOOL

2 ± VALVE STEM

9 - 62 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 835 of 1285

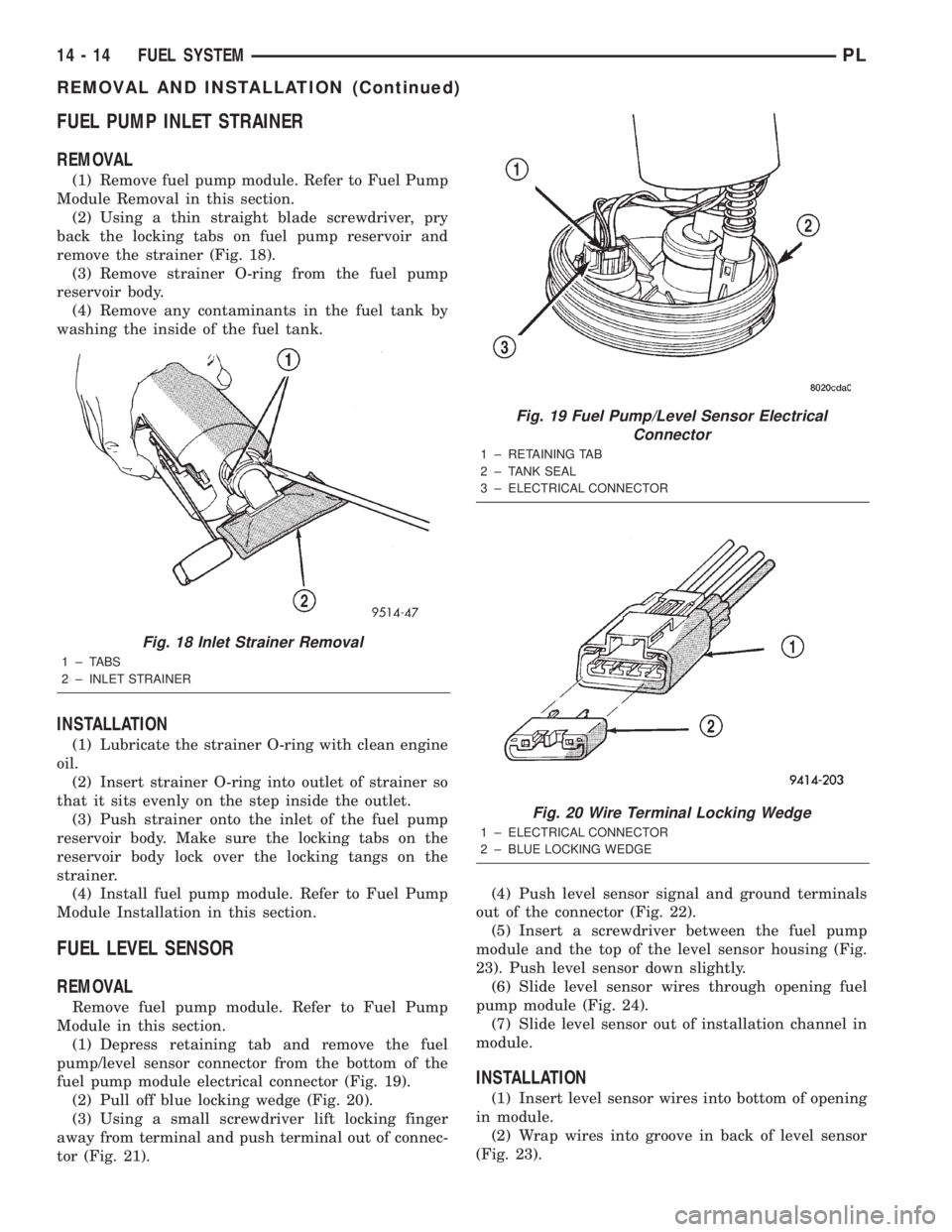

FUEL PUMP INLET STRAINER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 18).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

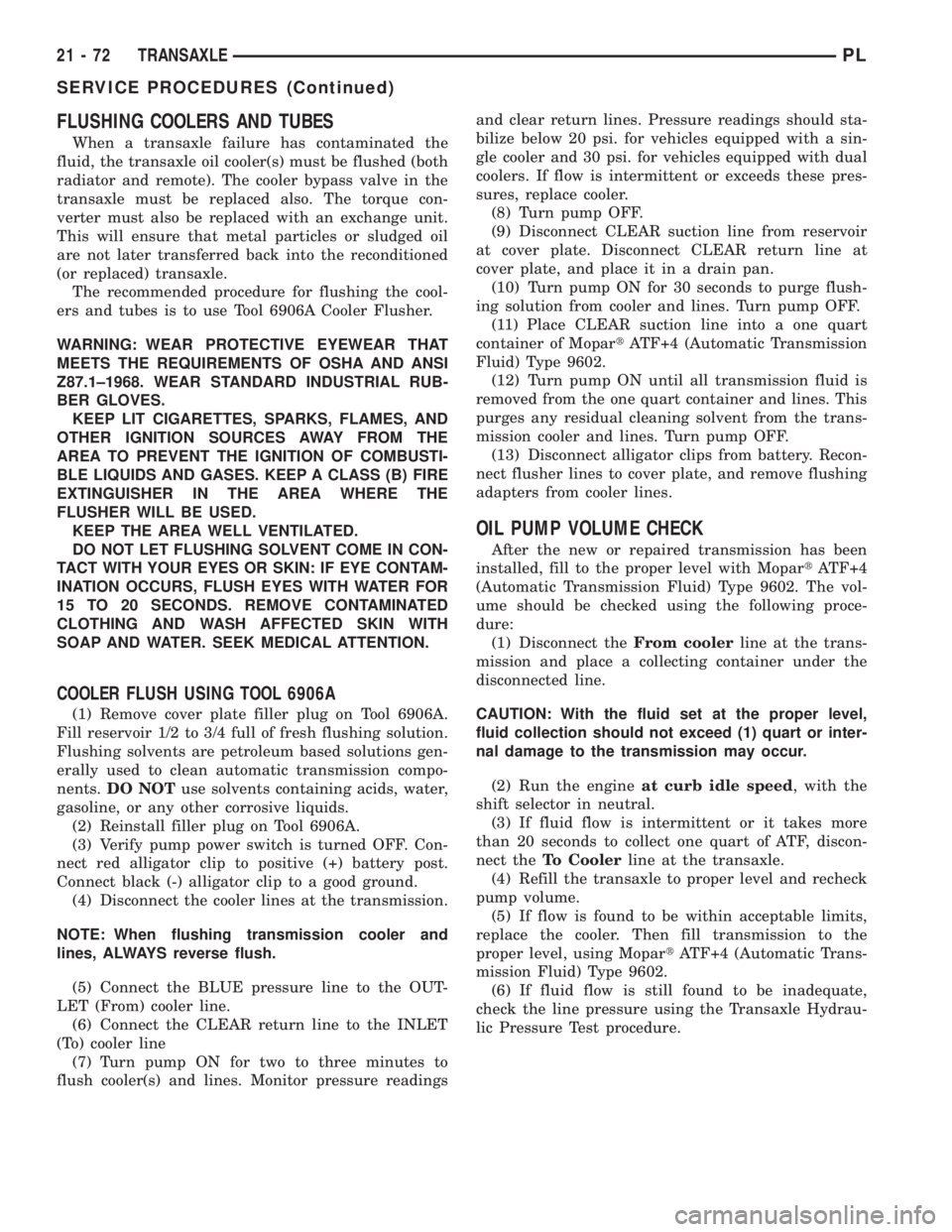

FUEL LEVEL SENSOR

REMOVAL

Remove fuel pump module. Refer to Fuel Pump

Module in this section.

(1) Depress retaining tab and remove the fuel

pump/level sensor connector from the bottom of the

fuel pump module electrical connector (Fig. 19).

(2) Pull off blue locking wedge (Fig. 20).

(3) Using a small screwdriver lift locking finger

away from terminal and push terminal out of connec-

tor (Fig. 21).(4) Push level sensor signal and ground terminals

out of the connector (Fig. 22).

(5) Insert a screwdriver between the fuel pump

module and the top of the level sensor housing (Fig.

23). Push level sensor down slightly.

(6) Slide level sensor wires through opening fuel

pump module (Fig. 24).

(7) Slide level sensor out of installation channel in

module.

INSTALLATION

(1) Insert level sensor wires into bottom of opening

in module.

(2) Wrap wires into groove in back of level sensor

(Fig. 23).

Fig. 18 Inlet Strainer Removal

1±TABS

2 ± INLET STRAINER

Fig. 19 Fuel Pump/Level Sensor Electrical

Connector

1 ± RETAINING TAB

2 ± TANK SEAL

3 ± ELECTRICAL CONNECTOR

Fig. 20 Wire Terminal Locking Wedge

1 ± ELECTRICAL CONNECTOR

2 ± BLUE LOCKING WEDGE

14 - 14 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 985 of 1285

FLUSHING COOLERS AND TUBES

When a transaxle failure has contaminated the

fluid, the transaxle oil cooler(s) must be flushed (both

radiator and remote). The cooler bypass valve in the

transaxle must be replaced also. The torque con-

verter must also be replaced with an exchange unit.

This will ensure that metal particles or sludged oil

are not later transferred back into the reconditioned

(or replaced) transaxle.

The recommended procedure for flushing the cool-

ers and tubes is to use Tool 6906A Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIT CIGARETTES, SPARKS, FLAMES, AND

OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

COOLER FLUSH USING TOOL 6906A

(1) Remove cover plate filler plug on Tool 6906A.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906A.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines. Monitor pressure readingsand clear return lines. Pressure readings should sta-

bilize below 20 psi. for vehicles equipped with a sin-

gle cooler and 30 psi. for vehicles equipped with dual

coolers. If flow is intermittent or exceeds these pres-

sures, replace cooler.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of MopartATF+4 (Automatic Transmission

Fluid) Type 9602.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

OIL PUMP VOLUME CHECK

After the new or repaired transmission has been

installed, fill to the proper level with MopartATF+4

(Automatic Transmission Fluid) Type 9602. The vol-

ume should be checked using the following proce-

dure:

(1) Disconnect theFrom coolerline at the trans-

mission and place a collecting container under the

disconnected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of ATF, discon-

nect theTo Coolerline at the transaxle.

(4) Refill the transaxle to proper level and recheck

pump volume.

(5) If flow is found to be within acceptable limits,

replace the cooler. Then fill transmission to the

proper level, using MopartATF+4 (Automatic Trans-

mission Fluid) Type 9602.

(6) If fluid flow is still found to be inadequate,

check the line pressure using the Transaxle Hydrau-

lic Pressure Test procedure.

21 - 72 TRANSAXLEPL

SERVICE PROCEDURES (Continued)