odometer DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 249 of 1285

DESCRIPTION AND OPERATION

HEADLAMP SWITCH

The headlamp switch is part of the Multi-Function

Switch. Refer to Group 8J, Turn Signal and Flasher

for the Multi-Function Switch Test, Removal and

Installation procedures.

INSTRUMENT CLUSTER

There are two conventional instrument cluster

assemblies available. The clusters electronically drive

the speedometer, odometer, gauges, and tachometer

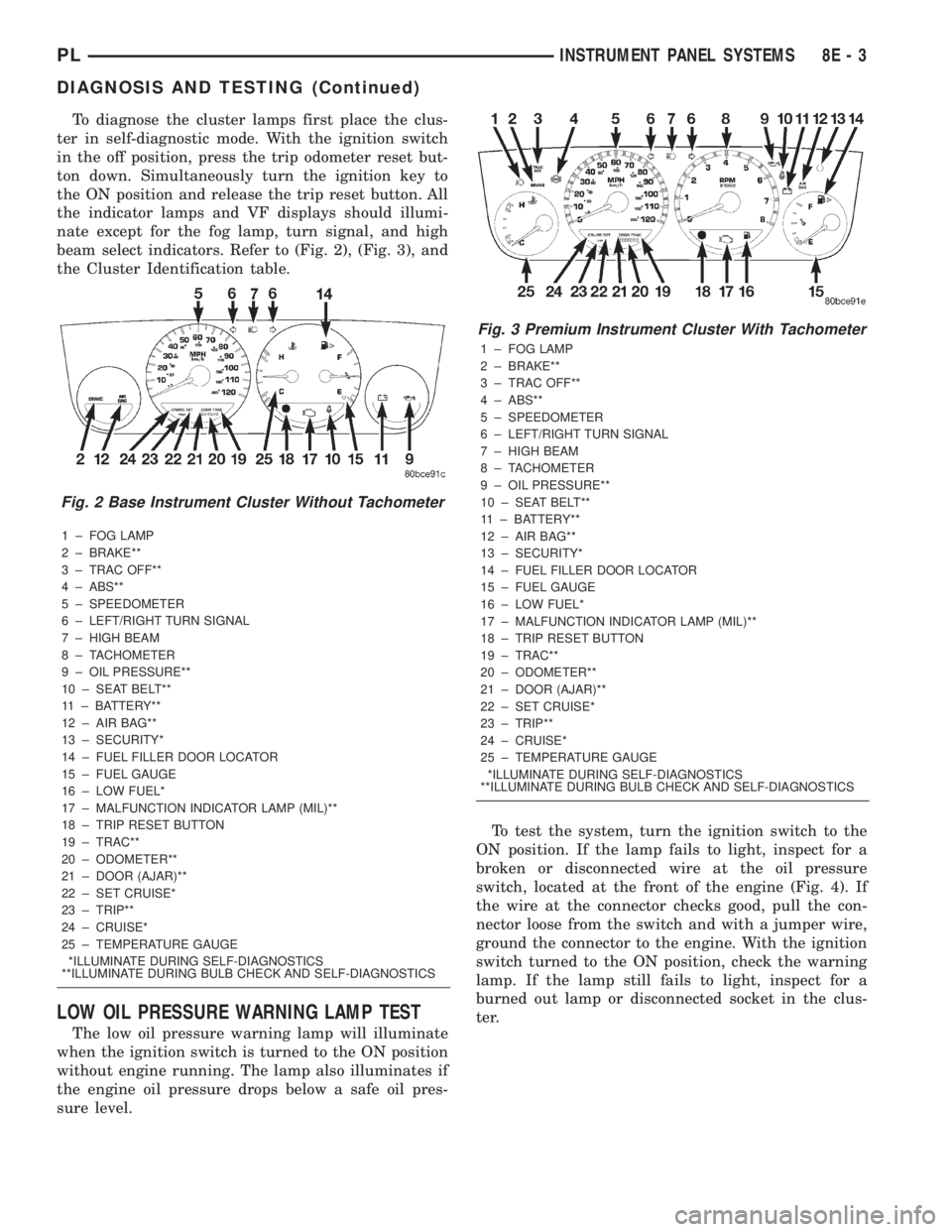

(if equipped). Refer to (Fig. 2) and (Fig. 3).

The instrument cluster controls the courtesy

lamps, it receives and sends messages to other mod-

ules via the PCI bus circuit, it controls all the instru-

ment illumination and the chime is also an integral

part of the cluster. The front turn signals are wired

through the cluster and then go to the front lamps.

The reason being that the DRL module is built into

the cluster (if equipped).

All gauges in the electronic clusters are the analog

type gauges. When the ignition switch is moved to

the OFF position, the cluster drives each gauge to its

lowest position. The individual gauges are not servi-

cable and require complete replacement of the cluster

if one or more gauges are inoperable.

One button is used to switch the display from trip

to total mileage. Holding the button when the display

is in the trip mode will reset the trip mileage. This

button is also used to put the cluster in self-diagnos-

tic mode. Refer to Service Procedures, Cluster Self-

Diagnostics in this section. Most of the indicators will

come on briefly for a bulb heck when the ignition is

turned from OFF to ON. All of the LED's are replace-

able.

In the event that the instrument cluster looses

communication with all other modules on the PCI

bus, the cluster will display ªnobusº in the VF dis-

play. The VF display also displays ªDoorº, ªCruiseº,

ªTracº, and odometer trip or total.

If the cluster does not detect voltage on the cour-

tesy lamp circuit, the message ªFUSEº will alternate

with the odometer/trip odometer for 30 seconds after

the ignition is turned on and for 15 seconds after the

vehicle is first moved. The lack of voltage can be due

to the M1 Fused B(+) (IOD) fuse being open, a bad or

missing courtesy lamp bulb, or a circuit problem.

WARNING AND INDICATOR LAMPS

The instrument cluster has warning lamps and

indicators for the following systems:

²Airbag

²Anti-lock Brakes (ABS) if equipped

²Brake warning

²Charging System²Front fog lamps (if equipped)

²High beam indicator

²Low fuel (premium cluster only)

²Low oil pressure

²Malfunction indicator (service engine soon) lamp

²Right and left turn signals

²Seat belt warning

²Security system

²Trac-Off (ABS equipped vehicles only)

The instrument cluster has a Vacuum Fluorescent

(VF) display for the following systems:

²Cruise

²Door (ajar)

²Odometer

²Set (cruise)

²Trac

²Trip

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM

For testing of this system refer to Group 8M, Pas-

sive Restraint Systems.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when the

parking brake is applied with ignition switch turned

to the ON position. The same lamp will also illumi-

nate if one of the two service brake systems fail the

when brake pedal is applied.

To test the system:

²As the ignition switch is turned to the start posi-

tion the lamp should light.

²Turn ignition switch to the ON position and

apply the parking brake. The lamp should light.

If lamp fails to light inspect for:

²A burned out lamp

²Loose, corroded or damaged socket

²A damaged circuit board

²A broken or disconnected wire at the switch

²Defective switch

To test the service brake warning system, refer to

Group 5, Brakes, Hydraulic System Control Valves.

INSTRUMENT CLUSTER LAMPS

Every time the vehicle is switched to the START/

RUN position, the cluster goes through a BULB

CHECK. This tests most of the indicator lamps and

Vacuum Fluorescent (VF) displays. If only one lamp

is out, remove the instrument cluster and replace the

defective bulb or Light Emitting Diode (LED). If

some or all of the lamps fail to light, refer to the

proper Body Diagnostics Procedures Manual.

8E - 2 INSTRUMENT PANEL SYSTEMSPL

Page 250 of 1285

To diagnose the cluster lamps first place the clus-

ter in self-diagnostic mode. With the ignition switch

in the off position, press the trip odometer reset but-

ton down. Simultaneously turn the ignition key to

the ON position and release the trip reset button. All

the indicator lamps and VF displays should illumi-

nate except for the fog lamp, turn signal, and high

beam select indicators. Refer to (Fig. 2), (Fig. 3), and

the Cluster Identification table.

1 ± FOG LAMP

2 ± BRAKE**

3 ± TRAC OFF**

4 ± ABS**

5 ± SPEEDOMETER

6 ± LEFT/RIGHT TURN SIGNAL

7 ± HIGH BEAM

8 ± TACHOMETER

9 ± OIL PRESSURE**

10 ± SEAT BELT**

11 ± BATTERY**

12 ± AIR BAG**

13 ± SECURITY*

14 ± FUEL FILLER DOOR LOCATOR

15 ± FUEL GAUGE

16 ± LOW FUEL*

17 ± MALFUNCTION INDICATOR LAMP (MIL)**

18 ± TRIP RESET BUTTON

19 ± TRAC**

20 ± ODOMETER**

21 ± DOOR (AJAR)**

22 ± SET CRUISE*

23 ± TRIP**

24 ± CRUISE*

25 ± TEMPERATURE GAUGE

*ILLUMINATE DURING SELF-DIAGNOSTICS

**ILLUMINATE DURING BULB CHECK AND SELF-DIAGNOSTICS

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition switch is turned to the ON position

without engine running. The lamp also illuminates if

the engine oil pressure drops below a safe oil pres-

sure level.To test the system, turn the ignition switch to the

ON position. If the lamp fails to light, inspect for a

broken or disconnected wire at the oil pressure

switch, located at the front of the engine (Fig. 4). If

the wire at the connector checks good, pull the con-

nector loose from the switch and with a jumper wire,

ground the connector to the engine. With the ignition

switch turned to the ON position, check the warning

lamp. If the lamp still fails to light, inspect for a

burned out lamp or disconnected socket in the clus-

ter.

Fig. 2 Base Instrument Cluster Without Tachometer

Fig. 3 Premium Instrument Cluster With Tachometer

1 ± FOG LAMP

2 ± BRAKE**

3 ± TRAC OFF**

4 ± ABS**

5 ± SPEEDOMETER

6 ± LEFT/RIGHT TURN SIGNAL

7 ± HIGH BEAM

8 ± TACHOMETER

9 ± OIL PRESSURE**

10 ± SEAT BELT**

11 ± BATTERY**

12 ± AIR BAG**

13 ± SECURITY*

14 ± FUEL FILLER DOOR LOCATOR

15 ± FUEL GAUGE

16 ± LOW FUEL*

17 ± MALFUNCTION INDICATOR LAMP (MIL)**

18 ± TRIP RESET BUTTON

19 ± TRAC**

20 ± ODOMETER**

21 ± DOOR (AJAR)**

22 ± SET CRUISE*

23 ± TRIP**

24 ± CRUISE*

25 ± TEMPERATURE GAUGE

*ILLUMINATE DURING SELF-DIAGNOSTICS

**ILLUMINATE DURING BULB CHECK AND SELF-DIAGNOSTICS

PLINSTRUMENT PANEL SYSTEMS 8E - 3

DIAGNOSIS AND TESTING (Continued)

Page 288 of 1285

On most vehicles another resistor has been added

to the at rest circuit causing the PCM to never see 5

volts. This was done for diagnostic purposes. If the

switch circuit should open (bad connection) then the

PCM will see the 5 volts and know the circuit is bad.

The PCM will then set an open circuit fault.

STOP LAMP SWITCH

DESCRIPTION

The switch is mounted on the brake pedal mount-

ing bracket under the instrument panel.

OPERATION

Vehicles equipped with the speed control option use

a dual function stop lamp switch. The PCM monitors

the state of the dual function stop lamp switch. Refer

to the Brake section for more information on stop

lamp switch service and adjustment procedures.

The brake switch is equipped with three sets of

contacts, one normally open and the other two nor-

mally closed (brakes disengaged). The PCM sends a

12 volt signal to one of the normally closed contacts

in the brake switch, which is connected to a ground.

With the contacts closed, the 12 volt signal is pulled

to ground causing the signal to go low. The low volt-

age signal, monitored by the PCM, indicates that the

brakes are not applied. When the brakes are applied,

the contacts open, causing the PCM's output voltage

to go high, disengaging the speed control also

grounding the dump solenoid.

The second set of normally closed contacts is sup-

plied battery voltage any time speed control is

selected. From the brake switch, current is routed to

the speed control servo solenoids. The speed control

solenoids (vacuum, vent and dump) are provided this

current any time the speed control is ON and the

brakes are disengaged. When the driver applies the

brakes, the contacts open and current is interrupted

to the solenoids. The normally open contacts are fed

battery voltage. When the brakes are applied, battery

voltage is supplied to the stop lamps.

SERVO CABLE

DESCRIPTION

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage.

OPERATION

This cable causes the throttle control linkage to

open or close the throttle valve in response to move-

ment of the vacuum servo diaphragm.

VACUUM RESERVOIR

OPERATION

The reservoir stores engine vacuum in the reser-

voir. When engine vacuum drops, as in climbing a

grade while driving, the reservoir supplies the vac-

uum needed to maintain proper speed control opera-

tion. The vacuum reservoir cannot be repaired and

must be replaced if faulty.

VEHICLE SPEED SENSOR

The Vehicle Speed Sensor (VSS) is a pulse genera-

tor mounted to an adapter near the transmission out-

put shaft. The sensor is driven through the adapter

by a speedometer pinion gear. The VSS pulse signal

to the speedometer/odometer is monitored by the

PCM speed control circuitry to determine vehicle

speed and to maintain speed control set speed.

REMOVAL AND INSTALLATION

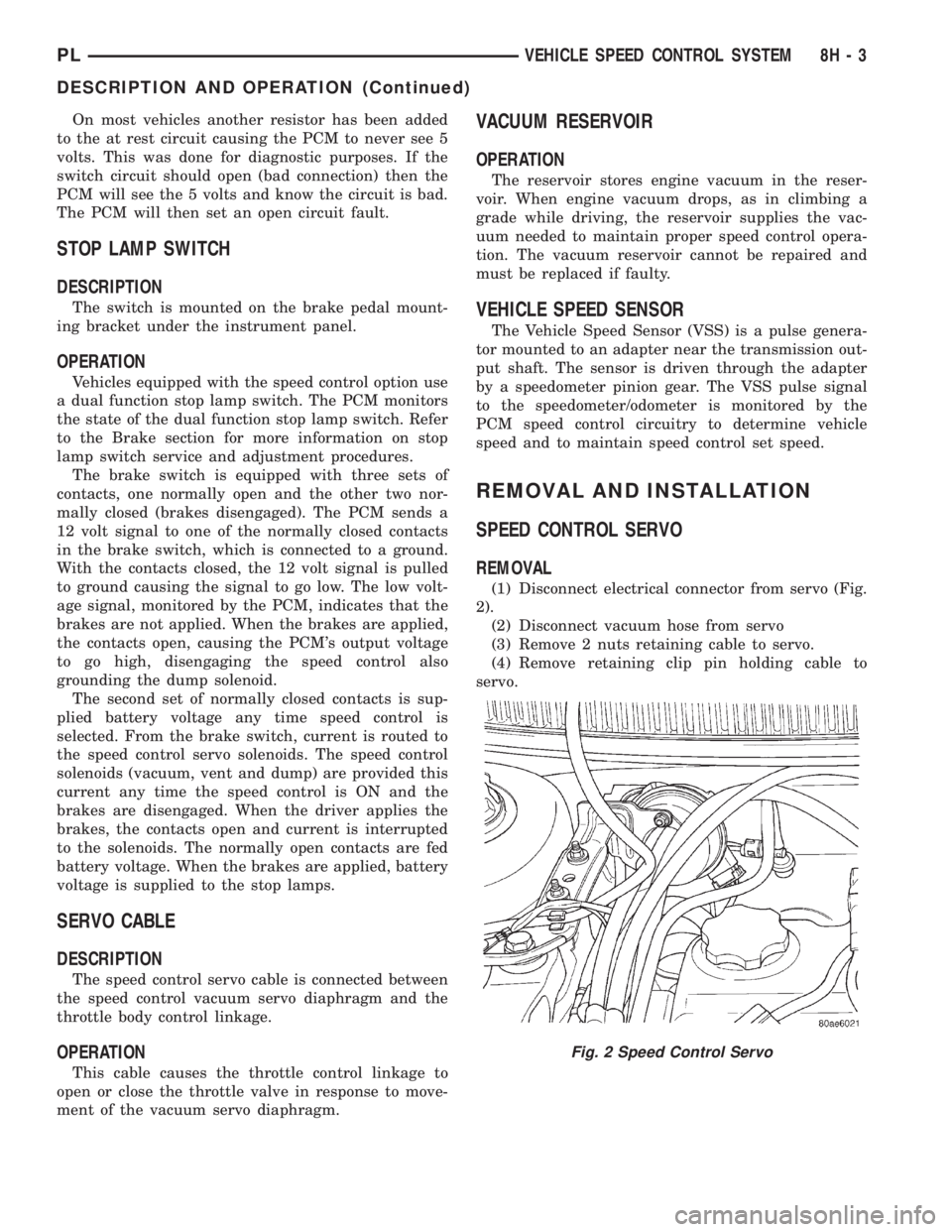

SPEED CONTROL SERVO

REMOVAL

(1) Disconnect electrical connector from servo (Fig.

2).

(2) Disconnect vacuum hose from servo

(3) Remove 2 nuts retaining cable to servo.

(4) Remove retaining clip pin holding cable to

servo.

Fig. 2 Speed Control Servo

PLVEHICLE SPEED CONTROL SYSTEM 8H - 3

DESCRIPTION AND OPERATION (Continued)

Page 513 of 1285

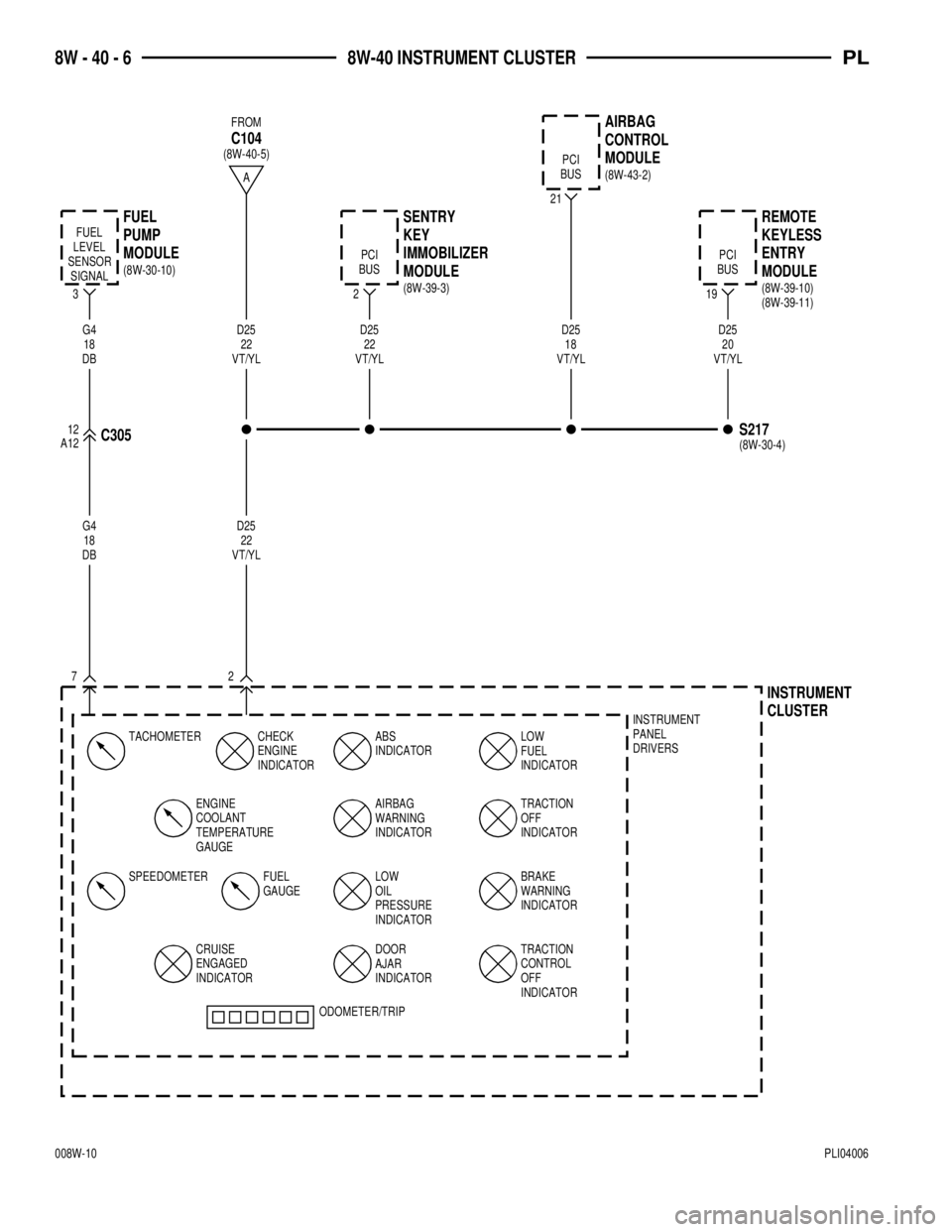

INSTRUMENT

CLUSTER

A (8W-40-5)

21

193

AIRBAG

CONTROL

MODULE

FUEL

PUMP

MODULE

MODULE ENTRY

KEYLESS

REMOTEFROM

C104

A12C30512G4

18

DB

G4

18

DB

D25

18

VT/YLD25

20

VT/YLD25

22

VT/YL

D25

22

VT/YL

S217

FUEL

LEVEL

SENSOR

SIGNALPCI

BUS

BUSPCI

BUSPCI

VT/YL22 D25

2

MODULE IMMOBILIZER

KEY

SENTRY

2 7

INSTRUMENT

PANEL

DRIVERS

SPEEDOMETER FUEL

GAUGE

INDICATOR PRESSURE

OIL

LOW BRAKE

WARNING

INDICATOR TRACTION

OFF

INDICATOR AIRBAG

WARNING

INDICATORLOW

FUEL

INDICATOR ABS

INDICATOR CHECK

ENGINE

INDICATOR

GAUGE TEMPERATURE

COOLANT

ENGINE TACHOMETER

ODOMETER/TRIP

INDICATOR AJAR

DOOR TRACTION

CONTROL

OFF

INDICATOR INDICATOR

ENGAGED

CRUISE(8W-43-2)

(8W-30-10)

(8W-39-10)

(8W-39-11) (8W-39-3)

(8W-30-4)

8W - 40 - 6 8W-40 INSTRUMENT CLUSTERPL

008W-10PLI04006

Page 858 of 1285

position of the throttle blade changes, the resistance

of the TPS changes.

OPERATION

The PCM supplies approximately 5 volts DC to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.35 to 1.03 volts at minimum

throttle opening (idle) to a maximum of 3.1 to 4.0

volts at wide open throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

When the TPS indicates a voltage that is too high,

too low or not believable, the PCM sets a DTC. When

the DTC is set, the MIL is illuminated and the PCM

moves into limp-in mode. Limp-in for the TPS is

divided into three categories:

²Idle

²Part-throttle

²Wide open throttle (WOT)

VEHICLE SPEED SIGNAL (VSS)ÐPCM INPUT

DESCRIPTION

The PCM requires the VSS to be able to control

the following programs:

²Speed Control

²IAC motor (during deceleration)

²Injection pulse width (during deceleration)

²OBD II diagnostics

²PCM mileage EEPROM

²Road speed shutdown

²Speedometer/Odometer (bused message)NOTE: Road Speed Shutdown is the PCM shutting

off fuel injectors above a preset vehicle speed.

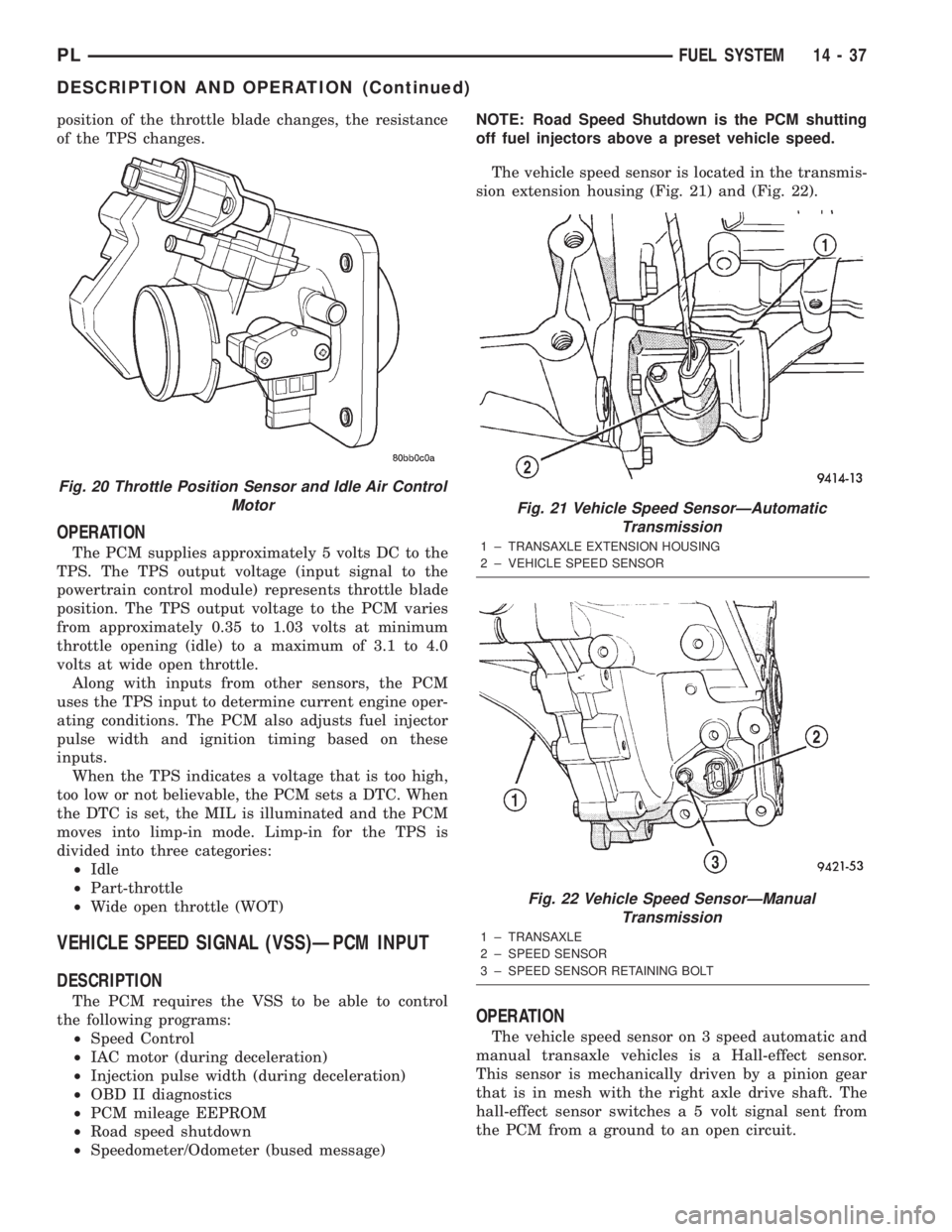

The vehicle speed sensor is located in the transmis-

sion extension housing (Fig. 21) and (Fig. 22).

OPERATION

The vehicle speed sensor on 3 speed automatic and

manual transaxle vehicles is a Hall-effect sensor.

This sensor is mechanically driven by a pinion gear

that is in mesh with the right axle drive shaft. The

hall-effect sensor switches a 5 volt signal sent from

the PCM from a ground to an open circuit.

Fig. 20 Throttle Position Sensor and Idle Air Control

Motor

Fig. 21 Vehicle Speed SensorÐAutomatic

Transmission

1 ± TRANSAXLE EXTENSION HOUSING

2 ± VEHICLE SPEED SENSOR

Fig. 22 Vehicle Speed SensorÐManual

Transmission

1 ± TRANSAXLE

2 ± SPEED SENSOR

3 ± SPEED SENSOR RETAINING BOLT

PLFUEL SYSTEM 14 - 37

DESCRIPTION AND OPERATION (Continued)