transmission fluid DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 4 of 1285

MAINTENANCE SCHEDULES

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

MAINTENANCE SCHEDULES................3

SPECIFICATIONS

UNSCHEDULED INSPECTION................3SCHEDULE ± A...........................3

SCHEDULE ± B...........................4

DESCRIPTION AND OPERATION

MAINTENANCE SCHEDULES

There are two maintenance schedules that show

proper service for your vehicle.

First is Schedule ±A. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is Schedule ±B. It is a schedule for vehi-

cles that are operated under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Extensive idling

²More than 50% of the driving is at sustained

high speeds during hot weather, above 90É F (32É C)

SPECIFICATIONS

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level and add as required.

²Check windshield washer solvent and add as

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten termi-

nals as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission.

Add fluid as required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect the exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponent boots and seals.²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles - 12 000 km) or

every other interval on Schedule ± B (6,000 miles -

10 000 km).

²Check the engine coolant level, hoses, and

clamps.

If mileage is less than 7,500 miles (12 000 km)

yearly, replace the engine oil filter at each oil change.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

FLUID FILL POINTS AND LUBRICATION

LOCATIONS

The fluid fill/check locations and lubrication loca-

tions are located in each applicable group.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change the engine oil.

²Replace the engine oil filter.

15,000 Miles (24 000 km) or at 12 months

²Change the engine oil.

²Replace the engine oil filter.

²Adjust the drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 8 of 1285

JUMP STARTING, TOWING, AND HOISTING

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

JUMP STARTING PROCEDURE...............7

TOWING RECOMMENDATIONS...............7

HOISTING RECOMMENDATIONS.............7SERVICE PROCEDURES

JUMP STARTING PROCEDURE...............7

TOWING RECOMMENDATIONS...............8

HOISTING RECOMMENDATIONS.............9

DESCRIPTION AND OPERATION

JUMP STARTING PROCEDURE

Describes the procedure for starting a disable vehi-

cle.

TOWING RECOMMENDATIONS

Describes the recommended towing procedures.

HOISTING RECOMMENDATIONS

Describes the location of hoisting and jacking

points so that the vehicle can be lifted by a floor jack

or hoist.

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

PLLUBRICATION AND MAINTENANCE 0 - 7

Page 142 of 1285

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid, etc.

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.....Standard

Hydraulic System.......Dual-Diagonally Split

BRAKE PEDAL:

Pedal Ratio..........................3.41

POWER BRAKE BOOSTER:

Make/Type..................Bosch/Vacuum

Mounting Studs.................. M8x1.25

Diaphragm Size/Type........ 205mmTandem

MASTER CYLINDER ASSEMBLY:

Type ........................Dual Tandem

Body Material...........Anodized Aluminum

Reservoir Material.............Polypropelene

MASTER CYLINDER BORE STROKE AND

SPLIT:

NonABS ..............22.23 mm x 34.0 mm

(0.875 in. x 1.34 in.)

ABS . . 23.82 mm x 34.0 mm (0.937 in. x 1.34 in.)

Displacement Split.................. 50/50MASTER CYLINDER FLUID OUTLET PORTS:

Tube Fitting Type...... SAE45ÉInverted Flare

W/ABS - Primary Tube Nut

Thread........................7/16 in.±24

W/ABS - Secondary Tube Nut

Thread........................ 3/8in.±24

W/O ABS - All Tube Nut Threads....7/16 in.±24

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting

Type................ SAE45ÉInverted Flare

All Tube Nut Threads............7/16 in.±24

PROPORTIONING VALVE:

Material.......................Aluminum

Function.....Hydraulic Pressure Proportioning

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts............... 17N´m(145 in. lbs.)

MASTER CYLINDER:

Mounting Nuts.......... 28N´m(250 in. lbs.)

POWER BRAKE BOOSTER:

Mounting Nuts.......... 34N´m(300 in. lbs.)

DISC BRAKE CALIPER:

Caliper Banjo Bolt......... 48N´m(35ft.lbs.)

Guide Pin Bolts.......... 22N´m(192 in. lbs.)

Bleeder Screw........... 15N´m(125 in. lbs.)

WHEEL CYLINDER (REAR):

Mounting Bolts.......... 13N´m(115in.lbs.)

Bleeder Screw............ 10N´m(80in.lbs.)

DRUM BRAKE SHOE SUPPORT PLATE

(REAR):

Mounting Bolts........... 75N´m(55ft.lbs.)

DISC BRAKE ADAPTER (REAR):

Mounting Bolts........... 75N´m(55ft.lbs.)

HUB AND BEARING (REAR):

Retaining Nut.......... 217N´m(160 ft. lbs.)

PARKING BRAKE:

Lever Mounting Nuts..... 28N´m(250 in. lbs.)

TIRE AND WHEEL:

Wheel Mounting Nut...........109±150 N´m

(80±110 ft. lbs.)

INTEGRATED CONTROL UNIT:

Mounting Bolts........... 11N´m(97in.lbs.)

CAB Mounting bolts........ 2N´m(17in.lbs.)

Bracket-to-Frame Rail Bolts.......... 23N´m

(200 in. lbs.)

WHEEL SPEED SENSOR:

Head Mounting bolt...... 12N´m(105 in. lbs.)

PLBRAKES 5 - 63

Page 201 of 1285

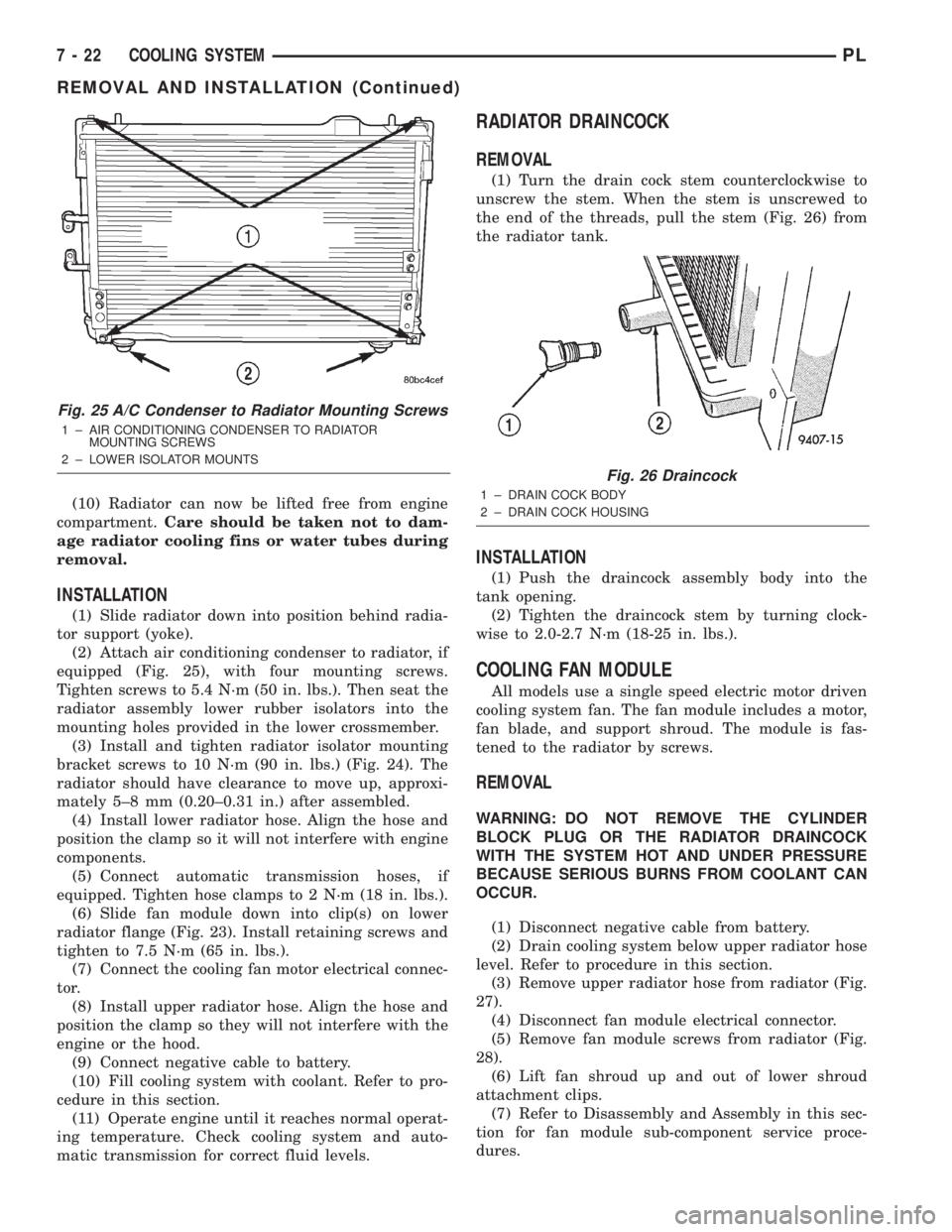

(10) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

INSTALLATION

(1) Slide radiator down into position behind radia-

tor support (yoke).

(2) Attach air conditioning condenser to radiator, if

equipped (Fig. 25), with four mounting screws.

Tighten screws to 5.4 N´m (50 in. lbs.). Then seat the

radiator assembly lower rubber isolators into the

mounting holes provided in the lower crossmember.

(3) Install and tighten radiator isolator mounting

bracket screws to 10 N´m (90 in. lbs.) (Fig. 24). The

radiator should have clearance to move up, approxi-

mately 5±8 mm (0.20±0.31 in.) after assembled.

(4) Install lower radiator hose. Align the hose and

position the clamp so it will not interfere with engine

components.

(5) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 2 N´m (18 in. lbs.).

(6) Slide fan module down into clip(s) on lower

radiator flange (Fig. 23). Install retaining screws and

tighten to 7.5 N´m (65 in. lbs.).

(7) Connect the cooling fan motor electrical connec-

tor.

(8) Install upper radiator hose. Align the hose and

position the clamp so they will not interfere with the

engine or the hood.

(9) Connect negative cable to battery.

(10) Fill cooling system with coolant. Refer to pro-

cedure in this section.

(11) Operate engine until it reaches normal operat-

ing temperature. Check cooling system and auto-

matic transmission for correct fluid levels.

RADIATOR DRAINCOCK

REMOVAL

(1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 26) from

the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening.

(2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N´m (18-25 in. lbs.).

COOLING FAN MODULE

All models use a single speed electric motor driven

cooling system fan. The fan module includes a motor,

fan blade, and support shroud. The module is fas-

tened to the radiator by screws.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain cooling system below upper radiator hose

level. Refer to procedure in this section.

(3) Remove upper radiator hose from radiator (Fig.

27).

(4) Disconnect fan module electrical connector.

(5) Remove fan module screws from radiator (Fig.

28).

(6) Lift fan shroud up and out of lower shroud

attachment clips.

(7) Refer to Disassembly and Assembly in this sec-

tion for fan module sub-component service proce-

dures.

Fig. 25 A/C Condenser to Radiator Mounting Screws

1 ± AIR CONDITIONING CONDENSER TO RADIATOR

MOUNTING SCREWS

2 ± LOWER ISOLATOR MOUNTS

Fig. 26 Draincock

1 ± DRAIN COCK BODY

2 ± DRAIN COCK HOUSING

7 - 22 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 724 of 1285

ENGINE

TABLE OF CONTENTS

page page

STANDARD SERVICE PROCEDURES........... 1

ENGINE DIAGNOSIS........................ 82.0L SOHC ENGINE....................... 15

STANDARD SERVICE PROCEDURES

TABLE OF CONTENTS

page page

GENERAL INFORMATION

FORM-IN-PLACE GASKETS & SEALERS........1

ENGINE GASKET SURFACE PREPARATION.....2

CRANKSHAFT DAMPER BOLT ACCESS PLUG . . . 2

ENGINE CORE PLUGS.....................2

ENGINE PERFORMANCE...................3HONING CYLINDER BORES.................3

MEASURING WITH PLASTIGAGE.............4

REPAIR OF DAMAGED OR WORN THREADS....5

HYDROSTATIC LOCKED ENGINE.............5

CHECKING ENGINE OIL LEVEL..............6

ENGINE OIL SERVICE......................7

GENERAL INFORMATION

FORM-IN-PLACE GASKETS & SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Alwaysinspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANT

MopartBed Plate Sealant is a unique (green-in-

color) anaerobic type gasket material that is specially

made to seal the area between the bedplate and cyl-

inder block without disturbing the bearing clearance

or alignment of these components. The material

cures slowly in the absence of air when torqued

between two metallic surfaces, and will rapidly cure

when heat is applied.

PLENGINE 9 - 1

Page 811 of 1285

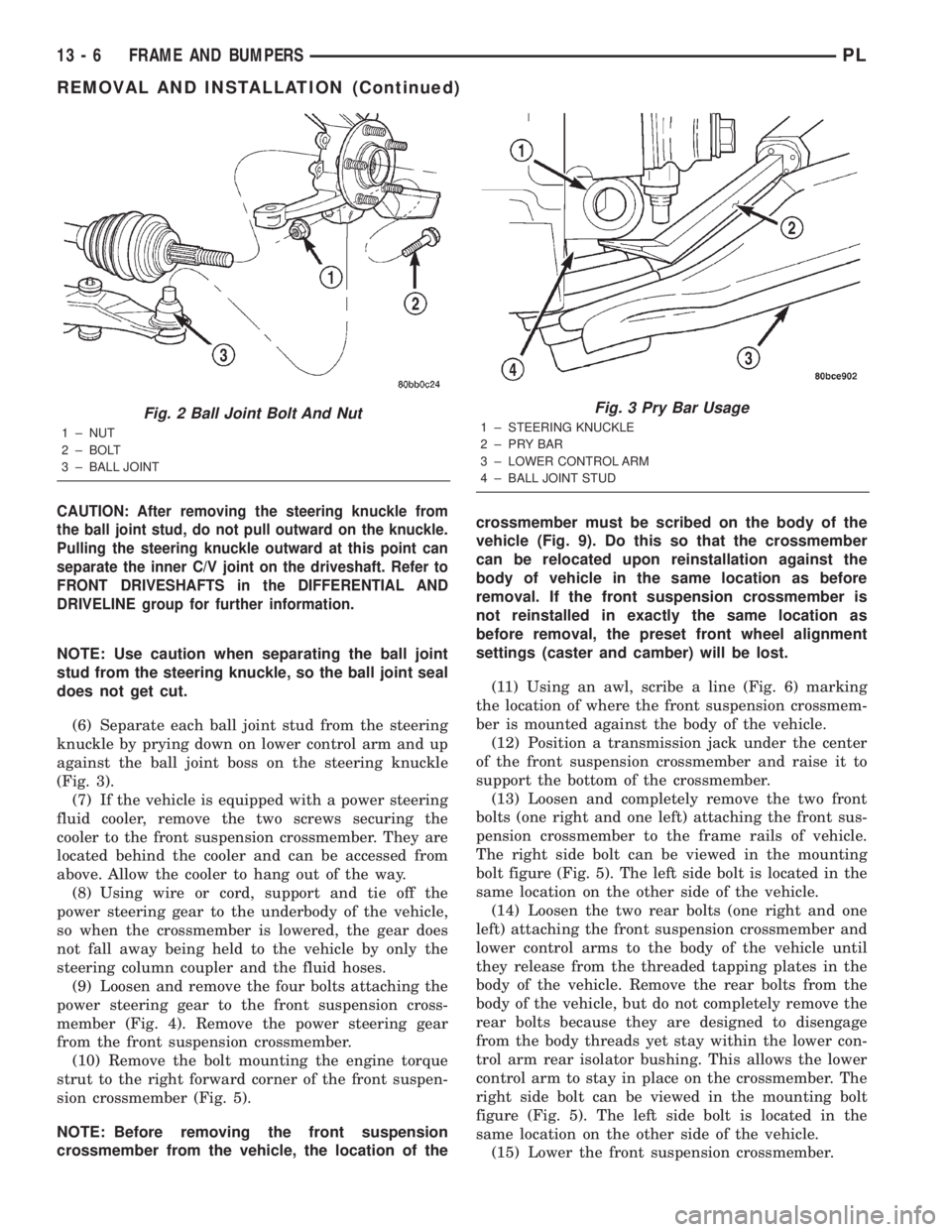

CAUTION: After removing the steering knuckle from

the ball joint stud, do not pull outward on the knuckle.

Pulling the steering knuckle outward at this point can

separate the inner C/V joint on the driveshaft. Refer to

FRONT DRIVESHAFTS in the DIFFERENTIAL AND

DRIVELINE group for further information.

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

(6) Separate each ball joint stud from the steering

knuckle by prying down on lower control arm and up

against the ball joint boss on the steering knuckle

(Fig. 3).

(7) If the vehicle is equipped with a power steering

fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

(8) Using wire or cord, support and tie off the

power steering gear to the underbody of the vehicle,

so when the crossmember is lowered, the gear does

not fall away being held to the vehicle by only the

steering column coupler and the fluid hoses.

(9) Loosen and remove the four bolts attaching the

power steering gear to the front suspension cross-

member (Fig. 4). Remove the power steering gear

from the front suspension crossmember.

(10) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 5).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of thecrossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(11) Using an awl, scribe a line (Fig. 6) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(12) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(13) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(14) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Remove the rear bolts from the

body of the vehicle, but do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(15) Lower the front suspension crossmember.

Fig. 2 Ball Joint Bolt And Nut

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 3 Pry Bar Usage

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

13 - 6 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)

Page 888 of 1285

reduces the power required to drive the pump and

holds down temperature build-up.

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops, the pressure built up in the

steering gear exerts pressure on the spring end of the

flow control valve. The high pressure lifts the relief

valve ball from its seat and allows oil to flow through

a trigger orifice located in the outlet fitting. This

reduces pressure on the spring end of the flow con-

trol valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level.

Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to

remain closed.

POWER STEERING FLUID RESERVOIR

The power steering fluid reservoir is mounted on

the power steering pump using 3 bolts (Fig. 1). It

stores fluid for the power steering system.

The power steering fluid reservoir is considered an

integral part of the power steering pump and is not

serviced separately.

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe the filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature, approximately 21ÉC to 27ÉC

(70ÉF to 80ÉF).

(1) Fill the power steering fluid reservoir to the

proper level and let the fluid settle for at least two

minutes.

(2) Start the engine and let run for a few seconds,

then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING PUMP

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Remove battery cable from the negative post on

the battery.

(2) Siphon as much fluid as possible from the

power steering fluid reservoir.

(3) Remove the power steering pump drive belt

from the power steering pump pulley. Refer to

ACCESSORY DRIVE BELTS in the COOLING SYS-

TEM service manual group for the required removal

and installation procedure.

(4) Remove the hose clamp securing the return

hose to the power steering fluid reservoir. Slide the

hose off the end of the reservoir fitting. (Fig. 2).

(5) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 2).

PLSTEERING 19 - 17

DESCRIPTION AND OPERATION (Continued)

Page 895 of 1285

(13) If the vehicle is equipped with a power steer-

ing fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

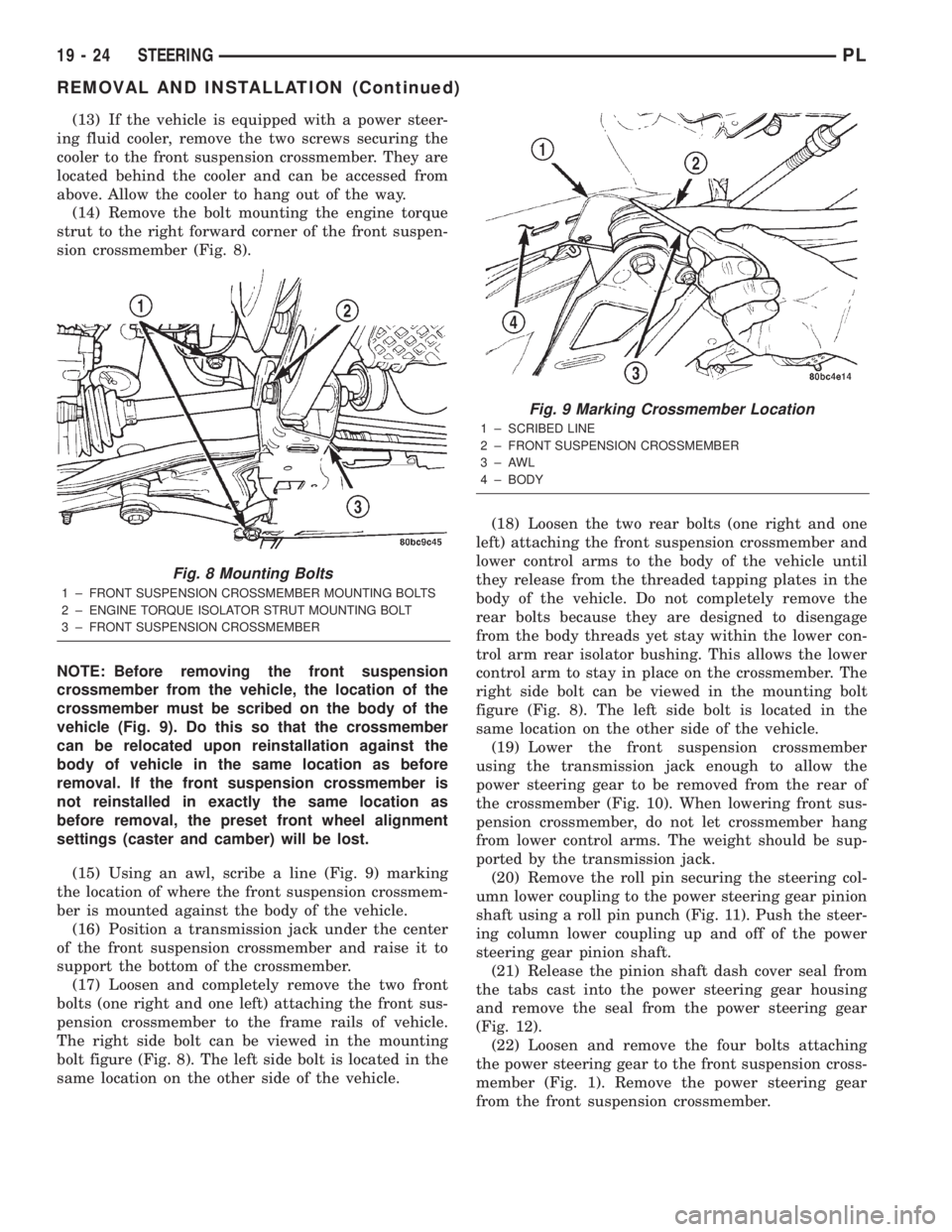

(14) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 8).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

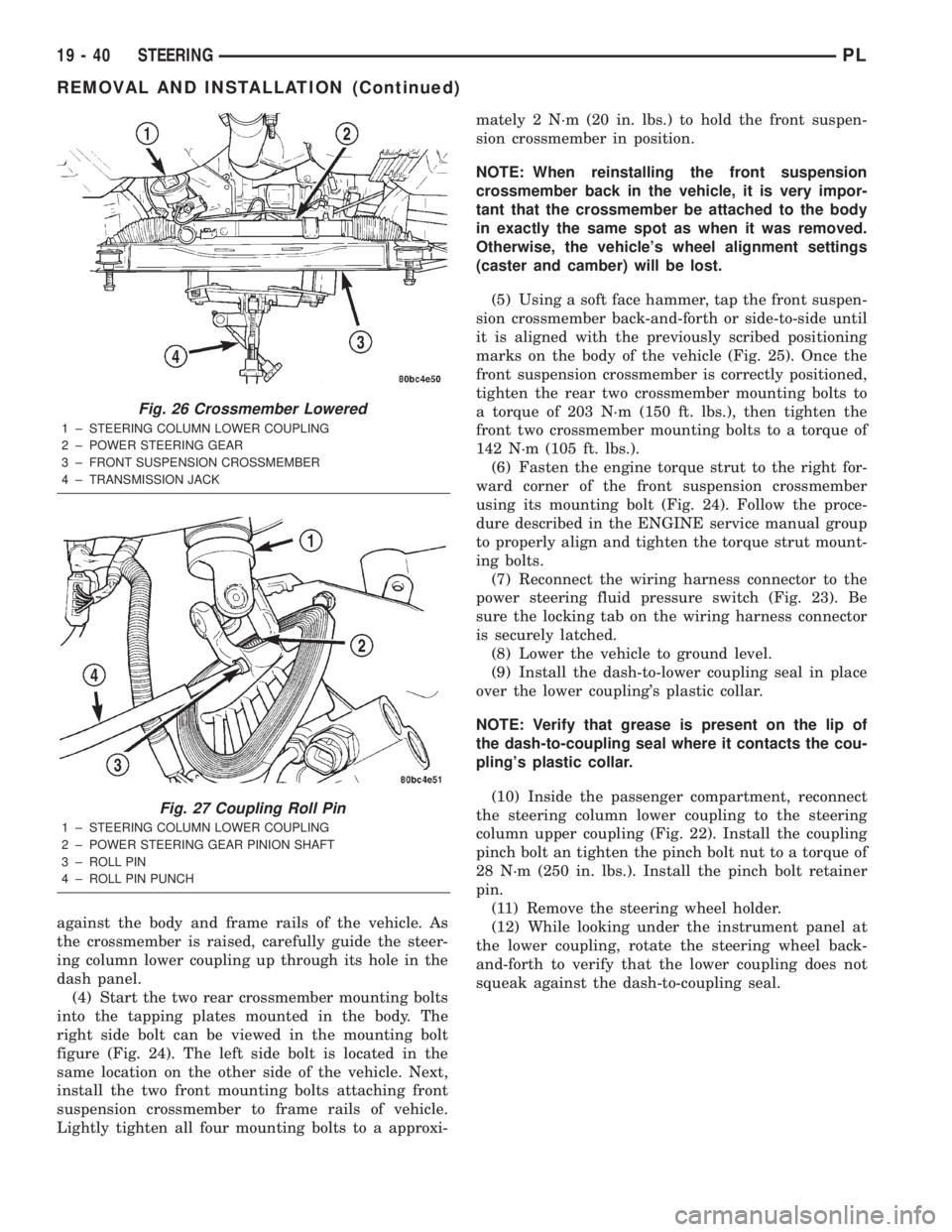

(15) Using an awl, scribe a line (Fig. 9) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(16) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(17) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.(18) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.

(19) Lower the front suspension crossmember

using the transmission jack enough to allow the

power steering gear to be removed from the rear of

the crossmember (Fig. 10). When lowering front sus-

pension crossmember, do not let crossmember hang

from lower control arms. The weight should be sup-

ported by the transmission jack.

(20) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 11). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

(21) Release the pinion shaft dash cover seal from

the tabs cast into the power steering gear housing

and remove the seal from the power steering gear

(Fig. 12).

(22) Loosen and remove the four bolts attaching

the power steering gear to the front suspension cross-

member (Fig. 1). Remove the power steering gear

from the front suspension crossmember.

Fig. 8 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 9 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

19 - 24 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 910 of 1285

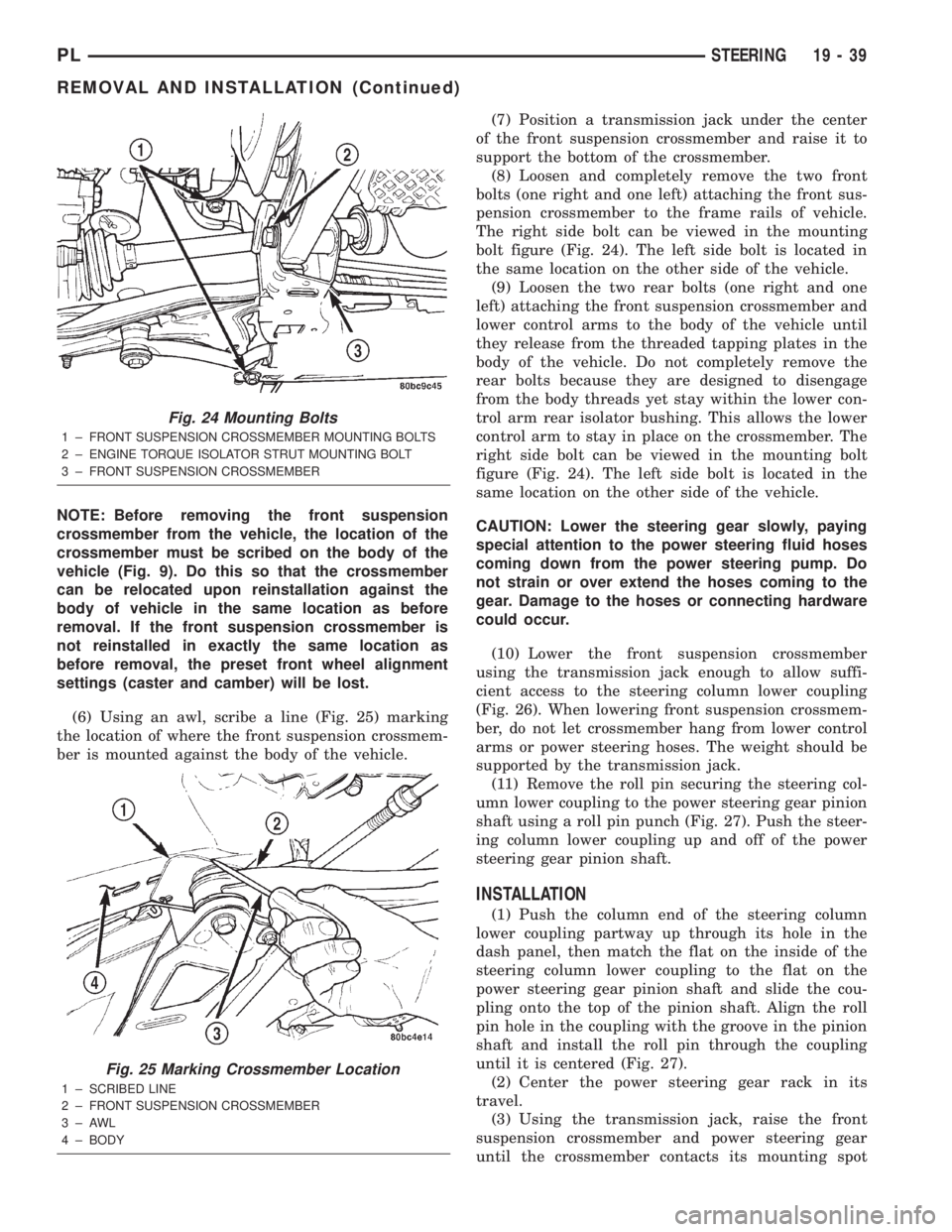

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(6) Using an awl, scribe a line (Fig. 25) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.(7) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(8) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 24). The left side bolt is located in

the same location on the other side of the vehicle.

(9) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle.

CAUTION: Lower the steering gear slowly, paying

special attention to the power steering fluid hoses

coming down from the power steering pump. Do

not strain or over extend the hoses coming to the

gear. Damage to the hoses or connecting hardware

could occur.

(10) Lower the front suspension crossmember

using the transmission jack enough to allow suffi-

cient access to the steering column lower coupling

(Fig. 26). When lowering front suspension crossmem-

ber, do not let crossmember hang from lower control

arms or power steering hoses. The weight should be

supported by the transmission jack.

(11) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 27). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

INSTALLATION

(1) Push the column end of the steering column

lower coupling partway up through its hole in the

dash panel, then match the flat on the inside of the

steering column lower coupling to the flat on the

power steering gear pinion shaft and slide the cou-

pling onto the top of the pinion shaft. Align the roll

pin hole in the coupling with the groove in the pinion

shaft and install the roll pin through the coupling

until it is centered (Fig. 27).

(2) Center the power steering gear rack in its

travel.

(3) Using the transmission jack, raise the front

suspension crossmember and power steering gear

until the crossmember contacts its mounting spot

Fig. 24 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 25 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)

Page 911 of 1285

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(4) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(5) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 25). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(6) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 24). Follow the proce-

dure described in the ENGINE service manual group

to properly align and tighten the torque strut mount-

ing bolts.

(7) Reconnect the wiring harness connector to the

power steering fluid pressure switch (Fig. 23). Be

sure the locking tab on the wiring harness connector

is securely latched.

(8) Lower the vehicle to ground level.

(9) Install the dash-to-lower coupling seal in place

over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(10) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 22). Install the coupling

pinch bolt an tighten the pinch bolt nut to a torque of

28 N´m (250 in. lbs.). Install the pinch bolt retainer

pin.

(11) Remove the steering wheel holder.

(12) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

Fig. 26 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

Fig. 27 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)