automatic transmission DODGE NEON 2005 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: NEON, Model: DODGE NEON 2005 2.GPages: 246, PDF Size: 3.69 MB

Page 80 of 246

added. If the fuel level drops to about 1/2 gallon, the

fuel symbol will begin to flash and the chime will

sound several times.

16. Malfunction Indicator Light

This light is part of an onboard diagnostic

system called OBD that monitors emissions,

engine, and automatic transmission control

systems. The light will illuminate briefly when the key

is in the ON/RUN position before engine start. If the

bulb does not come on when turning the key from

OFF to ON/RUN, have the condition checked

promptly.

Certain conditions such as a loose or missing gas cap,

poor fuel quality, etc., may illuminate the light after

engine start. The vehicle should be serviced if the light

stays on through several of your typical driving cycles. In

most situations, the vehicle will drive normally and will

not require towing.

If the Malfunction Indicator Light flashes when the

engine is running, serious conditions may exist that

could lead to immediate loss of power or severe catalyticconverter damage. The vehicle should be serviced as

soon as possible if this occurs. (See page 166 for more

information.)

17. Odometer/Trip Odometer Reset Knob

Press this knob to switch between the odometer and trip

odometer. While the trip odometer is being displayed,

press and hold this knob for a few seconds to reset the

trip odometer to zero miles/kilometers.

18. Odometer/Trip Odometer

Shows the total distance the vehicle has been driven.

U.S. Federal regulations require that upon transfer of

vehicle ownership, the seller certify to the purchaser the

correct mileage that the vehicle has been driven. There-

fore, if the odometer reading changes during repair or

replacement, be sure to keep a record of the reading

before and after the service so the correct mileage can be

determined.

80 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 111 of 246

STARTING AND OPERATING

CONTENTS

mStarting Procedures....................114

NAutomatic Transaxle...................114

NManual Transaxle.....................114

NNormal Starting......................114

NStarting In Cold Weather

(Below 32ÉF Of 0ÉC)...................115

NExtremely Cold Weather

(Below -20ÉF Or -29ÉC).................115

NIf Engine Fails To Start.................115

NAfter Starting........................116

mAutomatic Transaxle Ð If Equipped........116

NBrake/Transmission Interlock System.......116N

Automatic Transaxle Ignition Interlock System..116

NFour Speed Automatic Transaxle..........117

NReset Mode.........................117

NGear Ranges For Four Speed Automatic

Transaxle...........................117

mManual Transaxle Ð If Equipped..........119

NRecommended Shift Speeds..............120

NDownshifting........................120

mParking Brake.........................121

mBrake System.........................122

NAnti-Lock Brake System (ABS) Ð

If Equipped.........................123

5

Page 116 of 246

CAUTION!

To prevent damage to the starter, do not crank the

engine for more than 15 seconds at a time. Wait 10 to

15 seconds before trying again.

After Starting

The idle speed will automatically decrease as the engine

warms up.

AUTOMATIC TRANSAXLE Ð IF EQUIPPED

CAUTION!

Damage to the transaxle may occur if the following

precautions are not observed:

²Shift into PARK only after the vehicle has come to a

complete stop.

²Shift into or out of REVERSE only after the vehicle has

come to a complete stop and the engine is at idle

speed.

²Do not shift from REVERSE, PARK, or NEUTRAL into

any forward gear when the engine is above idle speed.

²Before shifting into any gear, make sure your foot is

firmly on the brake pedal.

NOTE:You MUST press and hold the brake pedal

down while shifting out of Park.

Brake/Transmission Interlock System

This system prevents you from moving the gear shift out

of Park and into any gear unless the brake pedal is

pressed. This system is active only while the ignition

switch is in the ON positions. Always depress thebrake

pedal first,before moving the gear selector out of PARK.

Automatic Transaxle Ignition Interlock System

This system prevents the key from being removed unless

the shift lever is in PARK and the shift knob push button

is out. It also prevents shifting out of PARK unless the

key is in the ON or RUN positions.

116 STARTING AND OPERATING

Page 121 of 246

CAUTION!

If you skip more than one gear while downshifting

or downshift at too high an engine speed, you could

damage the engine, transaxle, or clutch.

To maintain a safe speed and prolong brake life, shift

down to 2nd or 1st when descending a steep grade.

When turning a corner, or driving up a steep grade, shift

down early so that the engine will not be overburdened.

PARKING BRAKE

When the parking brake is applied with the

ignition on, the Brake Light in the instrument

cluster will come on.

NOTE:This light only shows that the parking brake is

on. It does not show the degree of brake application.

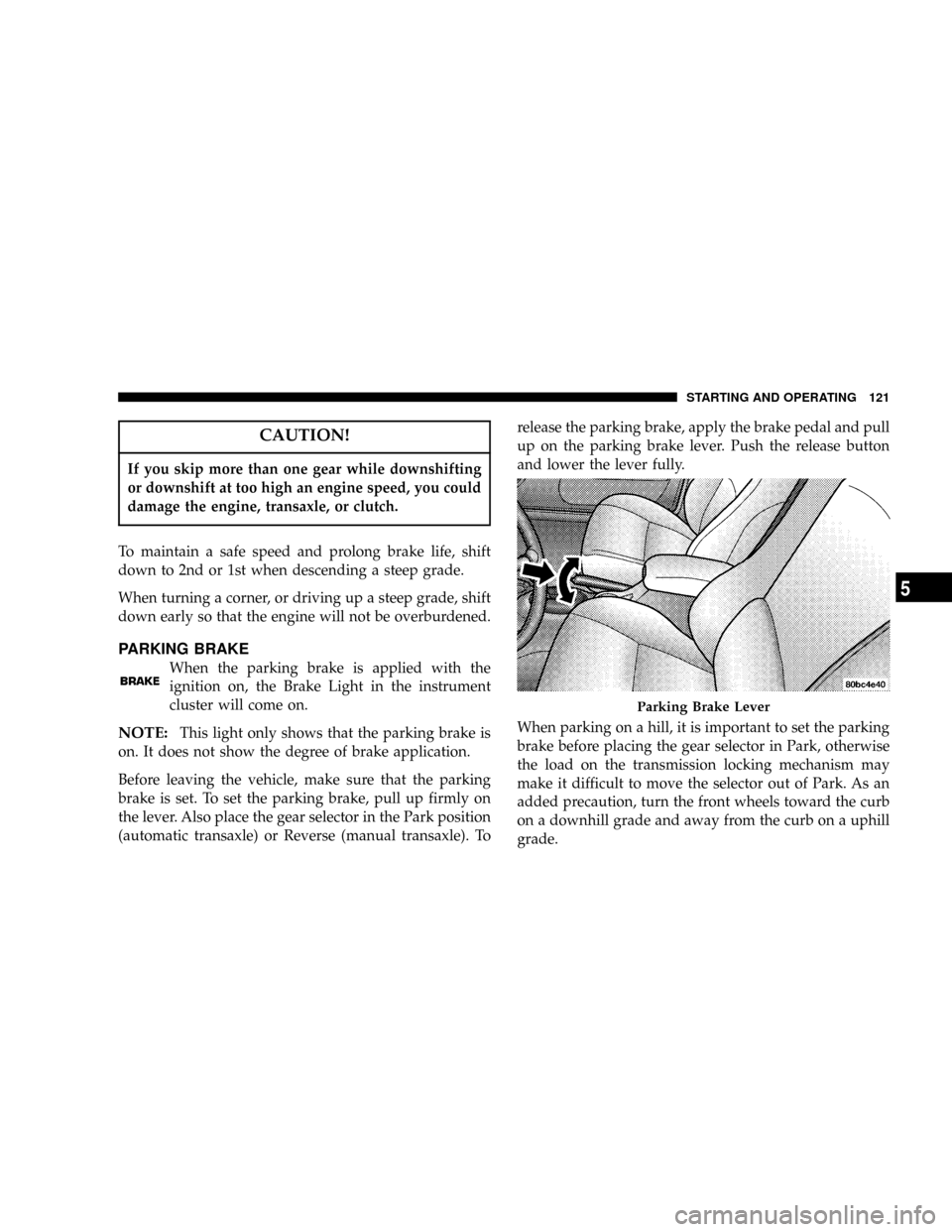

Before leaving the vehicle, make sure that the parking

brake is set. To set the parking brake, pull up firmly on

the lever. Also place the gear selector in the Park position

(automatic transaxle) or Reverse (manual transaxle). Torelease the parking brake, apply the brake pedal and pull

up on the parking brake lever. Push the release button

and lower the lever fully.

When parking on a hill, it is important to set the parking

brake before placing the gear selector in Park, otherwise

the load on the transmission locking mechanism may

make it difficult to move the selector out of Park. As an

added precaution, turn the front wheels toward the curb

on a downhill grade and away from the curb on a uphill

grade.

Parking Brake Lever

STARTING AND OPERATING 121

5

Page 166 of 246

ONBOARD DIAGNOSTIC SYSTEM Ð OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the ªMalfunction Indicator Light.º It will

also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your dealer for service as soon as

possible.CAUTION!

²Prolonged driving with the ªMalfunction Indica-

tor Lightº on could cause further damage to the

emission control system. It could also affect fuel

economy and driveability. The vehicle must be

serviced before any emissions tests can be per-

formed.

²If the ªMalfunction Indicator Lightº is flashing

while the engine is running, severe catalytic con-

verter damage and power loss will soon occur.

Immediate service is required.

166 MAINTAINING YOUR VEHICLE

Page 188 of 246

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum based fluid to contaminate the

brake fluid as seal damage will result!

Automatic Transaxle

All front wheel drive vehicles have a transaxle and

differential assembly contained within a single housing.

Selection of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only manufacturers recommended transmission fluid,

refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type. It is important that the

transmission fluid be maintained at the prescribed level

using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked whenever the vehicle is serviced. Operation with

an improper fluid level will greatly reduce the life of the

transaxle and of the fluid.

Procedure for Checking Fluid Level

Check the fluid level while the transmission is at normal

operating temperature. This occurs after at least 15 miles

(25 km) of driving. At normal operating temperature,

which is approximately 180ÉF ( 82ÉC), the fluid cannot be

held comfortably between the fingertips.

188 MAINTAINING YOUR VEHICLE

Page 190 of 246

CAUTION!

Do not overfill. Dirt and water in the transaxle can

cause serious damage. To prevent dirt and water

from entering the transaxle after checking or replen-

ishing fluid, make certain that the dipstick cap is

seated properly.

Fluid and Filter Changes

Automatic transmission fluid and filter should be

changed as follows:

Maintenance schedule ªAºÐ No change necessary.

Maintenance schedule ªBº± Every 60,000 miles (96 000

km) change fluid and filter under the following condi-

tions:

²Police, taxi, limousine, commercial type operation, or

trailer towing where the vehicle is drivenregularlyfor

more than 45 minutes of continuous operation.

NOTE:Refer to Section 8 of this manual for mainte-

nance schedules.If the transaxle is disassembled for any reason, the fluid

and filter should be changed.

Special Additives

The manufacturer recommends against the addition of

any fluid additives to the transaxle. The only exception to

this policy is the use of special dyes to aid in detecting

fluid leaks. The use of transmission sealers should be

avoided as they may adversely affect seals.

Manual Transaxle

Lubricant Selection

Use only manufacturers recommended transmission

fluid, refer to Recommended Fluids, Lubricants and

Genuine Parts for correct fluid type.

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more that 3/16º (4.76 mm) below the bottom of

the hole.

Add fluid, if necessary, to maintain the proper level.

190 MAINTAINING YOUR VEHICLE

Page 203 of 246

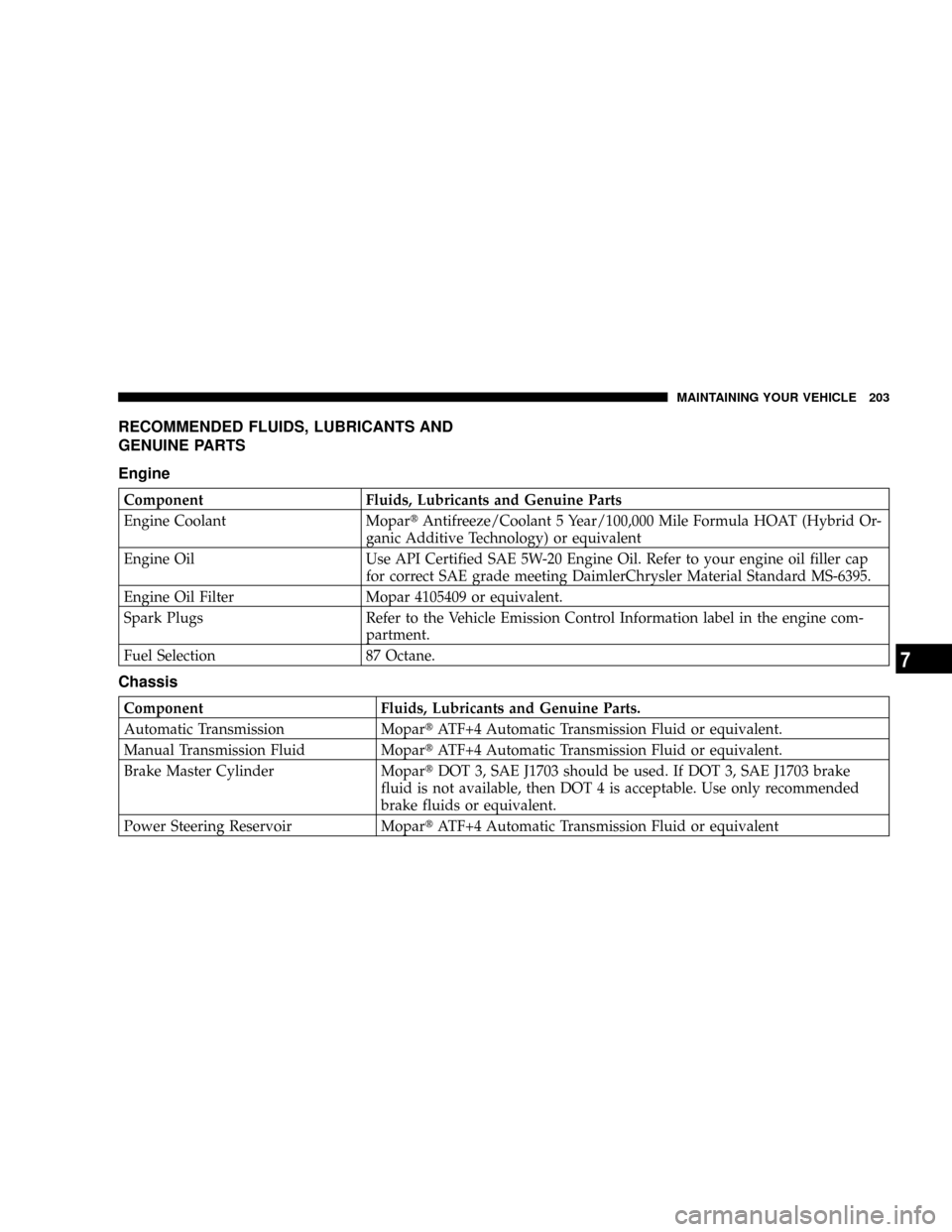

RECOMMENDED FLUIDS, LUBRICANTS AND

GENUINE PARTS

Engine

Component Fluids, Lubricants and Genuine Parts

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology) or equivalent

Engine Oil Use API Certified SAE 5W-20 Engine Oil. Refer to your engine oil filler cap

for correct SAE grade meeting DaimlerChrysler Material Standard MS-6395.

Engine Oil Filter Mopar 4105409 or equivalent.

Spark Plugs Refer to the Vehicle Emission Control Information label in the engine com-

partment.

Fuel Selection 87 Octane.

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4 Automatic Transmission Fluid or equivalent.

Manual Transmission Fluid MopartATF+4 Automatic Transmission Fluid or equivalent.

Brake Master Cylinder MopartDOT 3, SAE J1703 should be used. If DOT 3, SAE J1703 brake

fluid is not available, then DOT 4 is acceptable. Use only recommended

brake fluids or equivalent.

Power Steering Reservoir MopartATF+4 Automatic Transmission Fluid or equivalent

MAINTAINING YOUR VEHICLE 203

7

Page 209 of 246

Schedule ªBº

Follow schedule ªBº if you usually operate your vehicle

under one or more of the following conditions.

Change the automatic transmission fluid and filter every

60,000 miles (96 000 km) if the vehicle is usually operated

under one or more of the conditions marked with anL.

Change the manual transaxle fluid every 48,000 miles (77

000 km) if the vehicle is usually operated under one or

more of the conditions marked with an ².

²Day or night temperatures are below 32ÉF (0ÉC).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16.2 km).

²More than 50% of your driving is sustained high

speeds during hot weather, above 90ÉF (32ÉC).

²Trailer towing.²L

²Taxi, police or delivery service (commercial services).²

L

²Off-road or desert operation.

²If equipped for and operating with E-85 (ethanol)

fuel.

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule ªBº of the

9Maintenance Schedules9section of this manual.

NOTE:IFANYof these apply to you then flush and

replace the engine coolant every 102,000 miles (163 000

km) or 60 months, whichever comes first, and follow

schedule ªBº of the9Maintenance Schedules9section of

this manual.

If none of these apply to you, then change your engine oil

at every interval shown on schedule9A9of the9Mainte-

nance Schedules9section of this manual.

SCHEDULE ªBº 209

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S