lock DODGE NEON SRT 2004 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: NEON SRT, Model: DODGE NEON SRT 2004 2.GPages: 200, PDF Size: 3.23 MB

Page 88 of 200

If the engine fails to start within 15 seconds, turn the key

OFF wait 10 to 15 seconds, then repeat the normal

starting procedure.

WARNING!

Do not attempt to push or tow your vehicle to get it

started. Unburned fuel could enter the catalytic

converter and once the engine has started, ignite and

damage the converter and vehicle. If the vehicle has

a discharged battery, booster cables may be used to

obtain a start from another vehicle. This type of start

can be dangerous if done improperly, so follow the

procedure carefully. See section 6 of this manual for

jump starting instructions.

Extremely Cold Weather (below -20ÉF or -29ÉC)

To insure reliable starting at these temperatures, use of an

externally powered electric engine block heater (available

from your dealer) is recommended.

If Engine Fails to Start

If the engine fails to start after you have followed the

ªNORMAL STARTINGº procedure, it may be flooded.

Push the accelerator pedal all the way to the floor and

hold it there. Crank the engine for no more than 15

seconds. This should clear any excess fuel in case the

engine is flooded. Leave the ignition key in the ON

position, release the accelerator pedal and repeat the

ªNORMAL STARTINGº procedure.

WARNING!

Never pour fuel or other flammable liquid into the

throttle body air inlet opening in an attempt to start

the vehicle. This could result in flash fire causing

serious personal injury.

88 STARTING AND OPERATING

Page 94 of 200

BRAKE SYSTEM

Your vehicle is equipped with power assisted brakes as

standard equipment. In the event power assist is lost for

any reason (for example, repeated brake applications

with the engine off), the brakes will still function. The

effort required to brake the vehicle will be much greater

than that required with the power system operating.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

If either of the two hydraulic systems lose normal capa-

bility, the remaining system will still function with some

loss of overall braking effectiveness. This will be evident

by increased pedal travel during application and greater

pedal force required to slow or stop. In addition, if themalfunction is caused by an internal leak, as the brake

fluid in the master cylinder drops, the brake warning

indicator will light.

Anti-Lock Brake System (ABS)

The ABS gives increased vehicle stability and brake

performance under most braking conditions. The system

automatically ªpumpsº the brakes during severe braking

conditions to prevent wheel lock up.

All vehicle wheels and tires must be the same size and

tires must be properly inflated to produce accurate

signals for the computer. However, the system will

compensate when the compact spare is in use.

During stops where ABS is activated, a vibration of the

brake pedal may be felt and associated system noises

may be heard.

NOTE:Pumping of the brake pedal will diminish the

effectiveness of Anti-lock brakes and may lead to an

accident. Pumping makes the stopping distance longer.

Just press firmly on your brake pedal when you need to

slow down or stop.

94 STARTING AND OPERATING

Page 95 of 200

WARNING!

²Anti-lock system (ABS) cannot prevent the natu-

ral laws of physics from acting on the vehicle, nor

can it increase braking or steering efficiency be-

yond that afforded by the condition of the vehicle

brakes and tires or the traction afforded.

²The ABS cannot prevent accidents, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro-

planing. Only a safe, attentive, and skillful driver

can prevent accidents.

²The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

POWER STEERING

The power assisted steering system of your SRT-4 pro-

vides mechanical steering capability in the event power

assist is lost.

If for some reason the hydraulic pressure is interrupted,

it will still be possible to steer your vehicle. Under these

conditions you will observe a substantial increase in

steering effort.

STARTING AND OPERATING 95

5

Page 120 of 200

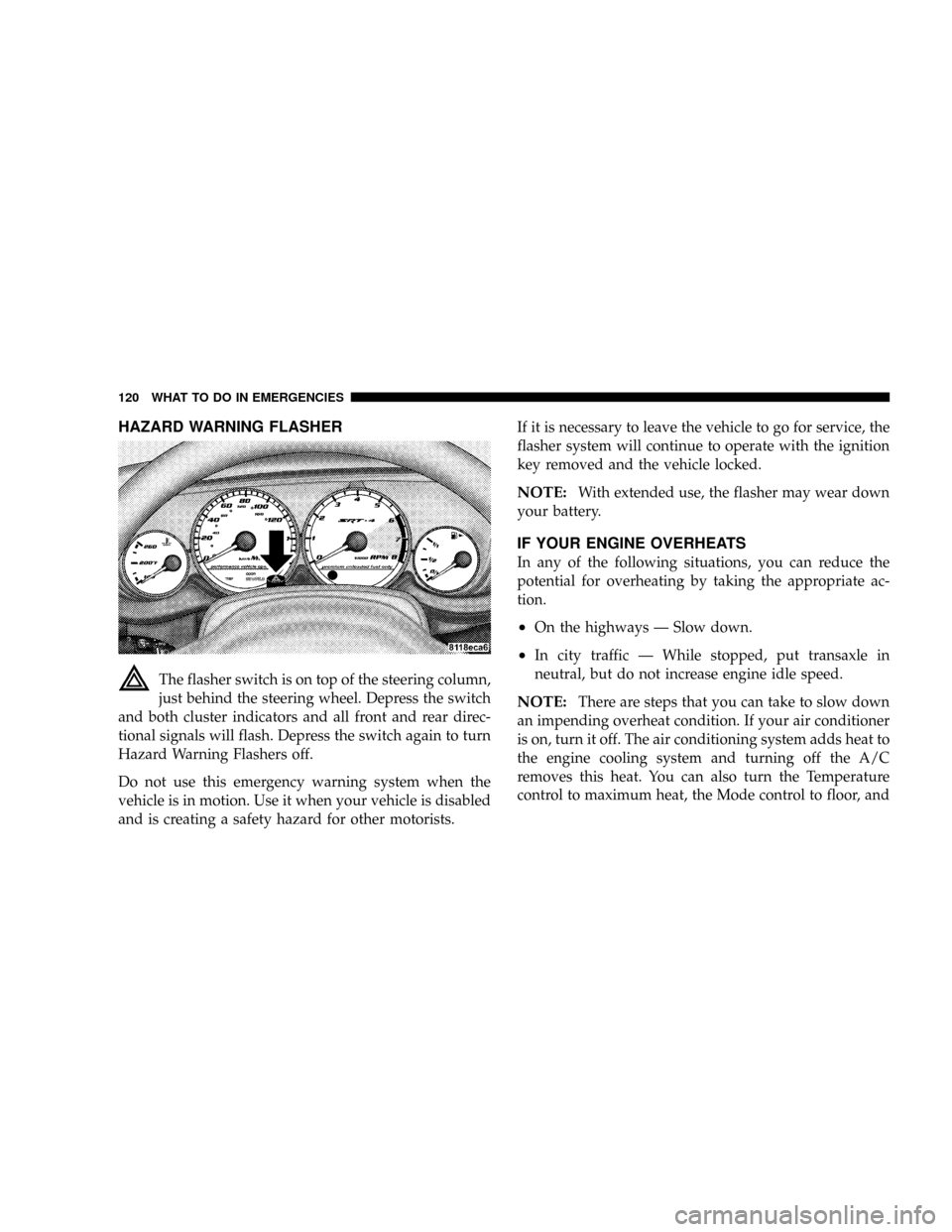

HAZARD WARNING FLASHER

The flasher switch is on top of the steering column,

just behind the steering wheel. Depress the switch

and both cluster indicators and all front and rear direc-

tional signals will flash. Depress the switch again to turn

Hazard Warning Flashers off.

Do not use this emergency warning system when the

vehicle is in motion. Use it when your vehicle is disabled

and is creating a safety hazard for other motorists.If it is necessary to leave the vehicle to go for service, the

flasher system will continue to operate with the ignition

key removed and the vehicle locked.

NOTE:With extended use, the flasher may wear down

your battery.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate ac-

tion.

²On the highways Ð Slow down.

²In city traffic Ð While stopped, put transaxle in

neutral, but do not increase engine idle speed.

NOTE:There are steps that you can take to slow down

an impending overheat condition. If your air conditioner

is on, turn it off. The air conditioning system adds heat to

the engine cooling system and turning off the A/C

removes this heat. You can also turn the Temperature

control to maximum heat, the Mode control to floor, and

120 WHAT TO DO IN EMERGENCIES

Page 122 of 200

JACKING AND TIRE CHANGING

WARNING!

²Getting under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on you.

You could be crushed. Never get any part of your

body under a vehicle that is on a jack. Never start

or run the engine while the vehicle is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

²Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

Preparations For Jacking

Park the vehicle on a firm level surface, avoid ice or

slippery areas, and set the parking brake. Place the gear

selector in REVERSE.

²Turn on the Hazard Warning Flasher.

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if changing the right

front tire, block the left rear

wheel.

²Passengers should not remain in the vehicle while the

vehicle is being jacked.

Instructions

The spare wheel, scissors jack, and lug wrench are

stowed under the spare tire cover in the rear cargo area.

Do not attempt to raise this vehicle using a bumper jack.

1. Remove the spare wheel, scissors jack and lug wrench

from stowage.

122 WHAT TO DO IN EMERGENCIES

Page 125 of 200

7. Finish tightening the nuts. Push down on the wrench

while tightening the wheel nuts. Alternate nuts until each

nut has been tightened twice. Correct wheel nut torque is

100 ft. lbs. (135 N´m.). If you are not sure about the

tightness, have them checked with a torgue wrench by

your dealer or at a service station.

8. Remove the wheel blocks and lower the jack until it is

free. Stow the lug wrench, replaced tire, and jack. Secure

all parts using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

9. Adjust the tire pressure as soon as possible.

NOTE:The spare tire well is designed to hold the

compact spare tire or a deflated (flat) tire. A fully inflated

tire will not fit in the spare tire well.

JUMP-STARTING PROCEDURES DUE TO A LOW

BATTERY

WARNING!

Take care to avoid the radiator cooling fan whenever

the hood is raised. It can start anytime the ignition

switch is on. You can be hurt by the fan.

WARNING!

Do not attempt to push or tow your vehicle to get it

started. Unburned fuel could enter the catalytic

converter and once the engine has started, ignite and

damage the converter and vehicle. If the vehicle has

a discharged battery, booster cables may be used to

obtain a start from another vehicle. This type of start

can be dangerous if done improperly, so follow this

procedure carefully.

WHAT TO DO IN EMERGENCIES 125

6

Page 130 of 200

TOWING A DISABLED VEHICLE

With Ignition Key

Your vehicle may be towed if the gearshift lever is in

NEUTRAL. If the transaxle is not operative, the vehicle

must be towed with the front wheels off the ground.

CAUTION!

If the vehicle being towed requires steering, the

ignition switch must be in the OFF position, not in

the LOCK or ACCESSORY positions.

If it is necessary to use the accessories while being towed

(wipers, defrosters, etc.), the key must be in the ON

position, not the ACCESSORY position. Make certain the

transaxle remains in NEUTRAL.

Without The Ignition Key

Special care must be taken when the vehicle is towed

with the ignition in the LOCK position. A dolly should be

used under the front wheels if the rear wheels are raised.

Proper towing equipment is necessary to prevent dam-

age to the vehicle.

Towing This Vehicle Behind Another Vehicle (Flat

Towing With All Four Wheels On The Ground)

Your vehicle may be towed at any legal highway speed,

for any distance, if the transaxle is in neutral.

130 WHAT TO DO IN EMERGENCIES

Page 145 of 200

Power Steering Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid types.

Front Suspension Ball Joints

There are two front suspension lower ball joints that are

permanently lubricated. Inspect these ball joints when-

ever under-vehicle service is done. Damaged seals

should be replaced to prevent leakage or grease contami-

nation.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, trunk and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

MAINTAINING YOUR VEHICLE 145

7

Page 146 of 200

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild non abrasive cleaner, or use the washer solvent. This

will remove accumulations of salt or road film and help

reduce streaking and smearing.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield. Avoid using the wiper blades to

remove frost or ice from the windshield. Make sure that

they are not frozen to the glass before turning them on to

avoid damaging the blade. Keep the blade rubber out of

contact with petroleum products such as engine oil,

gasoline, etc.

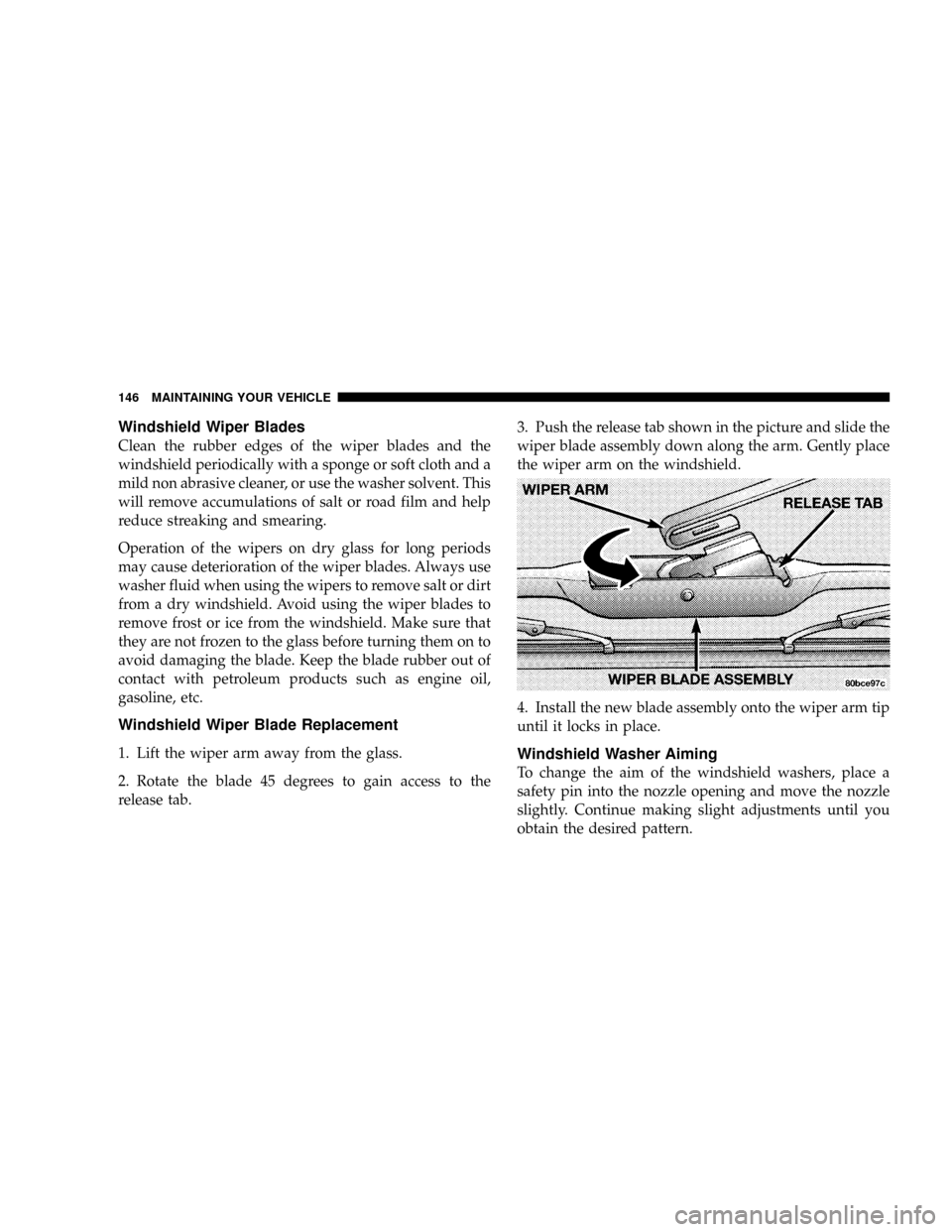

Windshield Wiper Blade Replacement

1. Lift the wiper arm away from the glass.

2. Rotate the blade 45 degrees to gain access to the

release tab.3. Push the release tab shown in the picture and slide the

wiper blade assembly down along the arm. Gently place

the wiper arm on the windshield.

4. Install the new blade assembly onto the wiper arm tip

until it locks in place.Windshield Washer Aiming

To change the aim of the windshield washers, place a

safety pin into the nozzle opening and move the nozzle

slightly. Continue making slight adjustments until you

obtain the desired pattern.

146 MAINTAINING YOUR VEHICLE

Page 164 of 200

Front Park/Turn Signal Lights

1. Remove the headlight assembly

2. Twist the bulb socket 1/4 turn and remove.

3. Pull the bulb from the socket and replace.

Front Sidemarker Light

1. Remove the screws and push-pins from the front

fender splash shield.

2. Reach between the fender and the splash shield, grasp

the bulb and socket assembly and turn it counterclock-

wise. Remove the bulb and socket assembly from the

light housing.

3. Pull the bulb out of the socket and replace the bulb.

Reinstall the bulb and socket assembly and replace the

fender splash shield.

Tail/Stop, Rear Turn Signals and Back-up Lights

1. Open the trunk and move the trunk liner away from

the rear light mounting area.

2. Twist the bulb socket 1/4 turn to remove it from the

housing.

3. Pull bulb from socket and replace

Center High Mounted Stop Light

1. Twist the socket 1/4 turn and remove it from the

housing.

2. Pull the bulb out of the socket and replace.

164 MAINTAINING YOUR VEHICLE