RADIATOR DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1477 of 2627

(9) Install rocker housing and bolts. Tighten to 24

Nm (18 lb. ft.).

(10) Install fuel injector(Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(11) Install injector harness nuts. Tighten to 1.25

Nm (11 lb. in.).

(12) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Install wire harness P-clip to cylinder head

behind filter housing 24 N´m (18 ft. lbs.).

(14) Connect the IAT/MAP sensor connector.

(15) Install the fuel filter canister assembly and

torque mounting bolts to 24 N´m (18 ft. lbs.).

(16) Connect fuel lift pump, WIF sensor, and fuel

heater.

(17) Remove the engine lift bracket at rear of cyl-

inder head.

CAUTION: Failure to follow procedure will result in

fuel leaks and/or fuel system failure.

(18)Install the fuel rail and high pressure

fuel lines as follows:

(a) Hand tighten fuel rail bolts.

(b) Hand tighten fuel drain line to pressure lim-

iting valve. Hand tighten banjo bolt at fuel filter

housing.

(c) Hand tighten fuel rail-to-cylinder head high

pressure fuel lines.(d) Install fuel line brace bolts-to-intake mani-

fold finger tight.

(e) Hand tighten fuel pump to fuel rail line.

(f) Torque fuel line nuts at cylinder head to 30

Nm ( 22 ft. lbs.).

(g) Torque fuel line nuts at fuel rail to 30 Nm

(22 ft. lbs.)

(h) Using a back up wrench, torque fuel pump to

fuel rail line to 37 Nm (27 ft. lbs.). At injection

pump.

(i) Torque fuel pump to fuel rail line to 37 Nm

(27 ft. lbs.) at fuel rail.

(j) Torque fuel drain banjo bolt at pressure lim-

iting valve and front of fuel filter housing to 24 Nm

(18 ft. lbs.).

(k) Torque fuel line brace bolts to 24 N´m (18 ft.

lbs.).

(l) Torque rail bolts to 24 Nm (18 ft. lbs.).

(m) Connect fuel pressure sensor.

(19) Install the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(20) Reposition number 6 fuel line shield and

torque to 43 N´m (32 ft. lbs.).

(21) Install the fuel filter to injection pump low

pressure line. Inspect and replace sealing washers if

necessary. Torque banjo bolts to 24 N´m (18 ft. lbs.).

(22) Connect fuel return line at back of cylinder

head hand tight.

(23) Connect fuel return line at filter housing hand

tight.

(24) Torque banjo connections at cylinder head and

fuel filter housing to 24 Nm (18 ft. lbs.)

(25) Install bracket to rear of filter housing.

Torque to 24 Nm (18 ft. lbs.).

(26) Using new gaskets, install the intake grid

heater and air inlet housing. Torque bolts to 24 N´m

(18 ft. lbs.).

(27) Install wire harness P-clip and push on clip to

air inlet housing.

(28) Connect engine oil level indicator tube at fuel

filter housing and at air inlet housing.

(29) Connect the APPS connector.

(30) Install the APPS assembly to the cylinder

head bracket and torque bolts to 24 N´m (18 ft. lbs.).

(31) Install the throttle linkage cover.

(32) Install the charge air cooler-to-air inlet hous-

ing duct assembly. Torque all clamps to 11 N´m (100

in. lbs.).

(33) Connect intake grid heater wires.

(34) Secure engine harness to front of cylinder

head with bolt at four locations.

(35) Connect engine coolant temperature sensor

connector.

(36) Connect radiator upper hose to thermostat

housing.

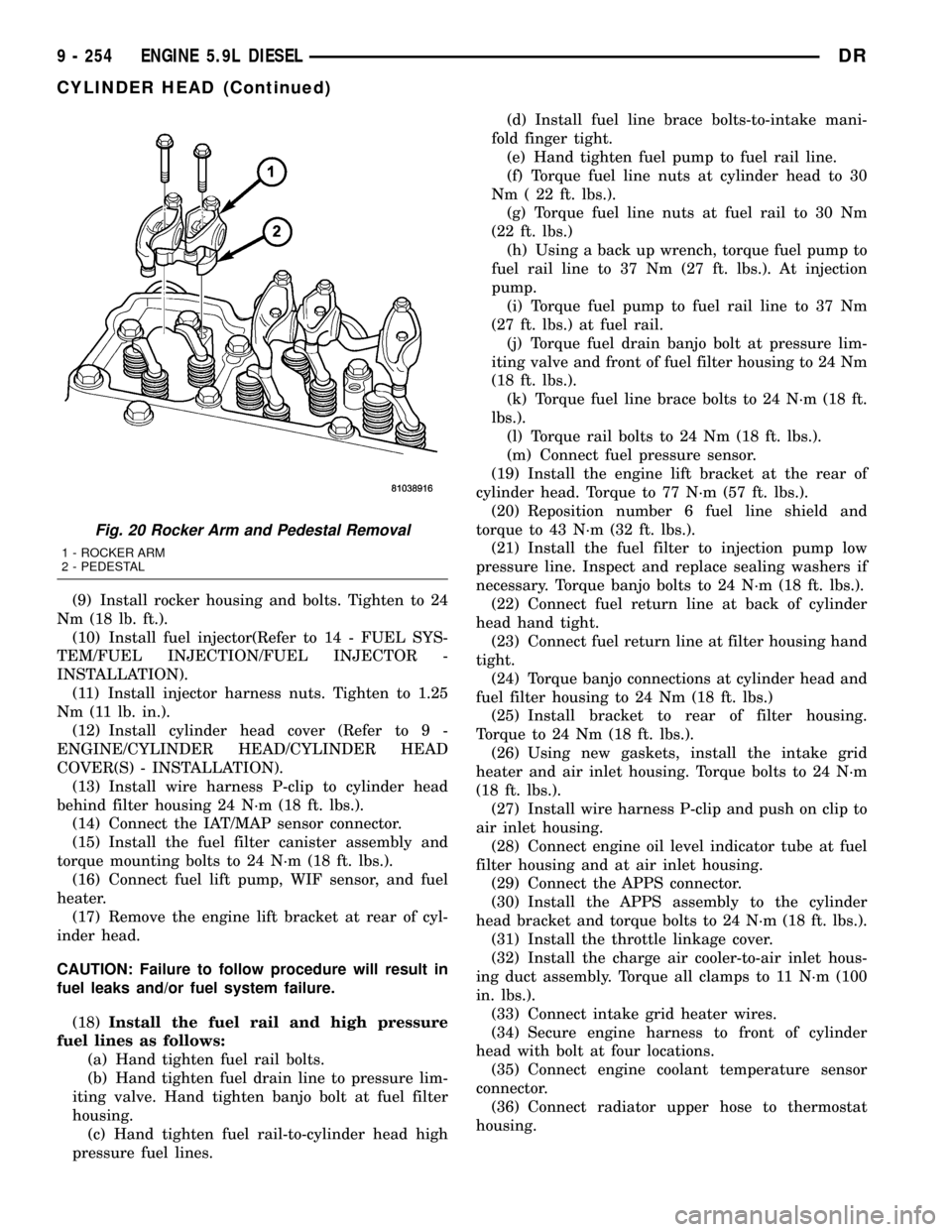

Fig. 20 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

9 - 254 ENGINE 5.9L DIESELDR

CYLINDER HEAD (Continued)

Page 1478 of 2627

(37) Rotate generator into position. Install upper

bolt and torque upper and lower bolts.

(38)

Install wire harness push-on clip below bracket.

(39) Install wire harness P-clip to top of bracket.

(40) Install fan support and torque to 32 N´m (24

ft. lbs.).

(41) Install cooling fan/drive refer to (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(42) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(43) Install exhaust manifold/turbocharger assem-

bly, using new gaskets. Start all bolts/spacers by

hand. Torque bolts to 43 N´m (32 ft. lbs.).

(44) Install exhaust manifold heat shield to

exhaust manifold studs. Install retaining nuts.Torque

to 15 N´m (11 ft. lbs.).

(45) Install exhaust bolt retention straps across

cylinders5&6.

(46) Connect turbocharger oil drain tube. Torque

clamp to 8 N´m (71 in. lbs.).

(47) Perform the turbocharger pre-lube procedure.

Refer to Group 11, Exhaust System and Turbo-

charger for the correct procedure.

(48) Connect the turbocharger oil supply line.

Torque to 24 N´m (18 ft. lbs.).

(49) Install air cleaner housing and duct.

(50) Connect air inlet temperature/pressure sensor.

(51) Raise vehicle on hoist.

(52) Install exhaust pipe to turbocharger elbow.

Torque bolts to 11 N´m (100 in. lbs.).

(53) Lower vehicle.

(54) Fill engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(55) Start engine and check for leaks.

CYLINDER HEAD COVER(S)

REMOVAL

REMOVALÐCYLINDER HEAD COVER

(1) Disconnect both battery negative cables.

(2) Remove oil fill cap.

(3) Remove the breather cover.

(4) Disconnect the breather hose and breather

drain tube from the breather housing.

(5) Remove cylinder head cover bolts.

(6) Remove the cylinder head cover.

REMOVALÐROCKER HOUSING

(1) Remove cylinder head cover as outlined in this

section.

(2) Disconnect rocker housing injector harness con-

nectors.(3) Remove injector harness nuts from injectors.

(4) Remove rocker housing bolts.

(5) Remove rocker housing and gasket.

CLEANING

Using a suitable solvent, Clean and dry gasket

mating surfaces on cylinder head and rocker housing.

Wipe gasket dry and inspect for re-use.

INSPECTION

The cylinder head cover gasket and rocker hous-

ing gasket, are reusable.However, should cracks,

nicks, or tears be present in the rubber/silicone construc-

tion, the defective components should be replaced. Also

replace gasket if it is no longer flexible. Inspect o-rings

on cylinder head cover bolts.Do not reuse gasket if it

has been removed from the groove in the rocker

housing or cylinder head cover.

INSTALLATION

INSTALLATIONÐCYLINDER HEAD COVER

(1) Inspect cylinder head cover gasket for cuts and

proper installation in groove. Replace if damaged.

(2)

Position cylinder cover on top of rocker housing.

(3) Install bolts.

(4) Starting with the center bolt, torque to 24 N´m

(18 ft. lbs.).

(5) Install breather hose to breather.

(6) Install breather drain hose to breather.

(7) Install breather cover and wire harness clip.

Torque to 24 N´m (18 ft. lbs.).

INSTALLATION - ROCKER HOUSING

(1) Inspect rocker housing gasket for cuts, nicks,

or tears. Replace if damaged or if gasket has come

out of groove.

(2) Inspect rocker housing gasket for proper instal-

lation in groove. Gasket bead must be centered in

groove. A gasket bead that is tilted to the side will

cause an oil leak.

CAUTION: When installing rocker housing onto cyl-

inder head, do not slide housing from side to side,

The gasket could fall out or be damaged.

(3) Install the rocker housing. Carefully guide the

rocker housing evenly down onto the cylinder head.

(4) Install rocker housing bolts and tighten finger

tight.

(5) Torque bolts, working from center out, to 24

Nm (18ft. lbs.).

(6) Install injector harness nuts to injector sole-

noid. Torque to 1.25 Nm (11 in. lbs.).

(7) Connect rocker housing injector harness con-

nections.

DRENGINE 5.9L DIESEL 9 - 255

CYLINDER HEAD (Continued)

Page 1491 of 2627

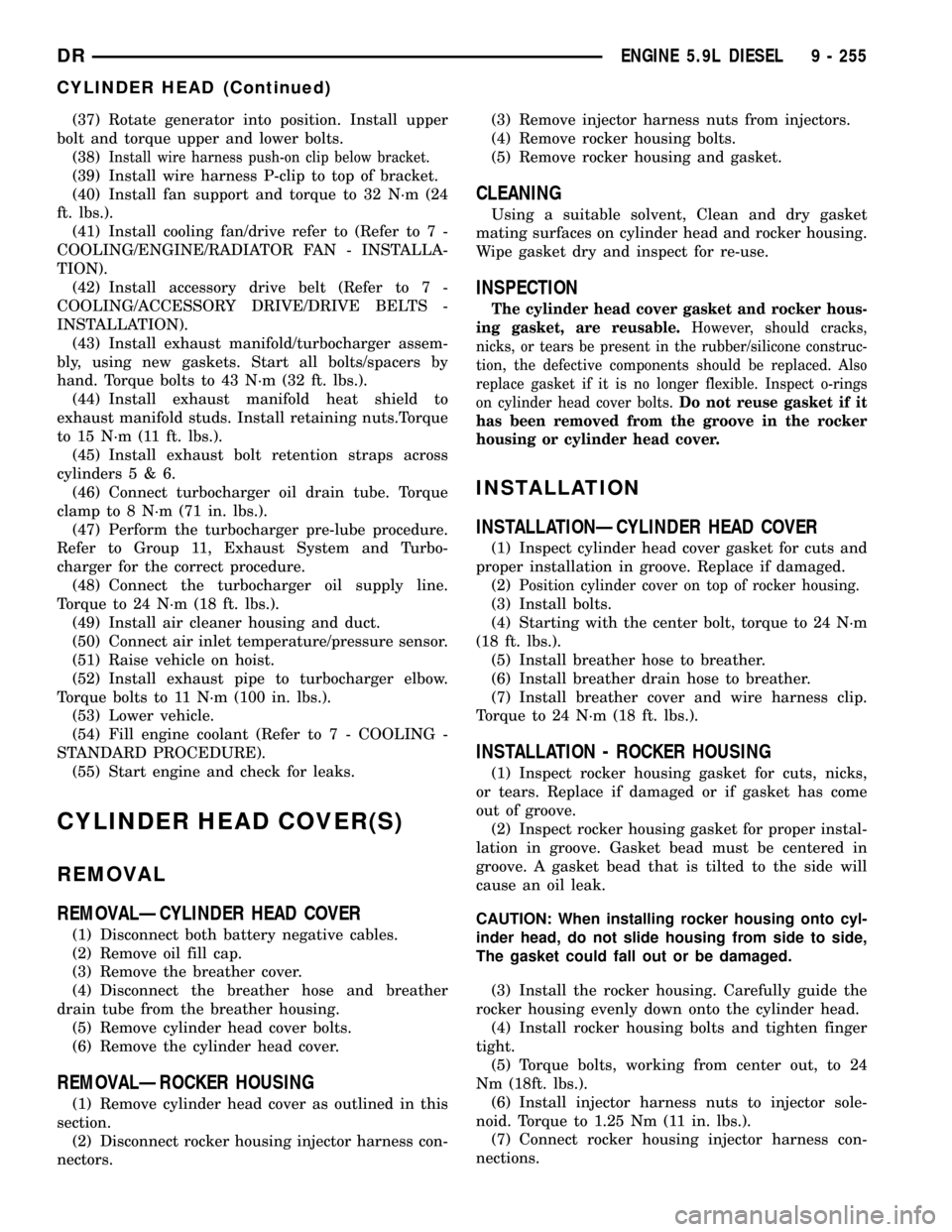

Inspect the cylinder bores for damage or excessive

wear.

Measure the cylinder bores (Fig. 54). If the cylin-

der bores exceed the limit, (Refer to 9 - ENGINE/EN-

GINE BLOCK - STANDARD PROCEDURE).

BORE SPECIFICATIONS

BORE DIAMETER

Min. 102.000 mm (4.0157 in.)

Max. 102.116 mm (4.0203 in.)

OUT OF ROUNDNESS

Max. 0.038 mm (0.0015 in.)

TAPER

Max. 0.076 mm (.003 in.)

Inspect the camshaft bores for scoring or excessive

wear.

Measure the camshaft bores (Refer to 9 - ENGINE

- SPECIFICATIONS).

If a bore exceeds the limit, (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - STANDARD PROCEDURE).

Inspect the tappet bores for scoring or excessive

wear.

Measure tappet bore from bottom of block. Mini-

mum tappet bore diameter 16.000 mm (0.0630 in.).

Maximum tappet bore 16.055 mm. (0.632 in.).

If out of limits, replace the cylinder block.

CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS

NOTE: Measure the diameter of each bore. If the

camshaft bore for the first or rear cam bushing is

worn beyond the limit, install a new service bush-

ing. Inspect the rest of the camshaft bores for dam-

age or excessive wear.If the bores without a

bushing are worn beyond the limit, the engine must

be removed for machining and installation of ser-

vice bushings. If badly worn, replace the cylinder

block.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Remove the bushing from the No.1 bore and

No.7 using a universal cam bushing tool.

(3) Mark the cylinder block so you can align the oil

hole in the cylinder block with the oil hole in the

bushing.

REMOVAL - CAMSHAFT

(1) Disconnect both battery negative cables.

(2) Recover A/C refrigerant (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

(3) Raise vehicle on hoist.

(4) Drain engine coolant into container suitable for

re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(5) Lower vehicle.

(6) Remove radiator upper hose.

(7) Remove viscous fan/drive assembly and fan

shroud (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL).

(8) Disconnect the coolant recovery bottle hose

from the radiator filler neck.

(9) Disconnect lower radiator hose from radiator

outlet.

(10)Automatic Transmission models:Discon-

nect transmission oil cooler lines from front of radia-

tor using Special Tool 6931 (unless equipped with

finger-release disconnect).

(11) Remove radiator mounting screws and lift

radiator out of engine compartment.

(12) Remove upper radiator support panel.

(13) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(14) Disconnect charge air cooler piping from the

cooler inlet and outlet.

Fig. 54 Cylinder Bore Diameter

9 - 268 ENGINE 5.9L DIESELDR

ENGINE BLOCK (Continued)

Page 1495 of 2627

(6) Remove the wooden dowel rods and rubber

bands from the tappets.

(7) Lubricate the push rods with engine oil and

install in their original location.Verify that they

are seated in the tappets.

(8) Lubricate the valve tips with engine oil and

install the crossheads in their original locations.

(9) Lubricate the crossheads and push rod sockets

with engine oil and install the rocker arms and ped-

estals in their original locations. Tighten bolts to 36

N´m (27 ft. lbs.) torque.

(10)Verify valve lash adjustment (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

(11) Install the cylinder head cover and reusable

gasket (Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(12) Install gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION). Install front crankshaft dust

seal.

(13) Install the crankshaft damper with the speed

indicator ring (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - INSTALLATION).

(14) Install the fan support/hub assembly Refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(15) Install the power steering pump.

(16) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft. lbs.).

(17) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(18) Install the charge air cooler (with a/c con-

denser and auxiliary transmission oil cooler, if

equipped) and tighten the mounting bolts to 2 N´m

(17 in. lbs.) torque.

(19) Connect charge air cooler inlet and outlet

pipes. Tighten clamps to 11 N´m (95 in. lbs.) torque.

(20) Install the radiator upper support panel.

(21) Close radiator petcock and lower the radiator

into the engine compartment. Tighten the mounting

bolts to 11 N´m (95 in. lbs.) torque.

(22) Raise vehicle on hoist.

(23) Connect radiator lower hose and install

clamp.

(24) Connect transmission auxiliary oil cooler lines

(if equipped).

(25) Lower vehicle.

(26) Install the fan shroud and tighten the mount-

ing screws to 6 N´m (50 in. lbs.) torque.

(27) Install the electronically controlled viscous

fan/drive assembly. Connect harness connector.(Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).(28) Install the coolant recovery and windshield

washer fluid reservoirs to the fan shroud.

(29) Connect the coolant recovery hose to the radi-

ator filler neck.

(30) Add engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(31) Charge A/C system with refrigerant (if A/C

equipped) (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(32) Connect the battery negative cables.

(33) Start engine and check for engine oil and cool-

ant leaks.

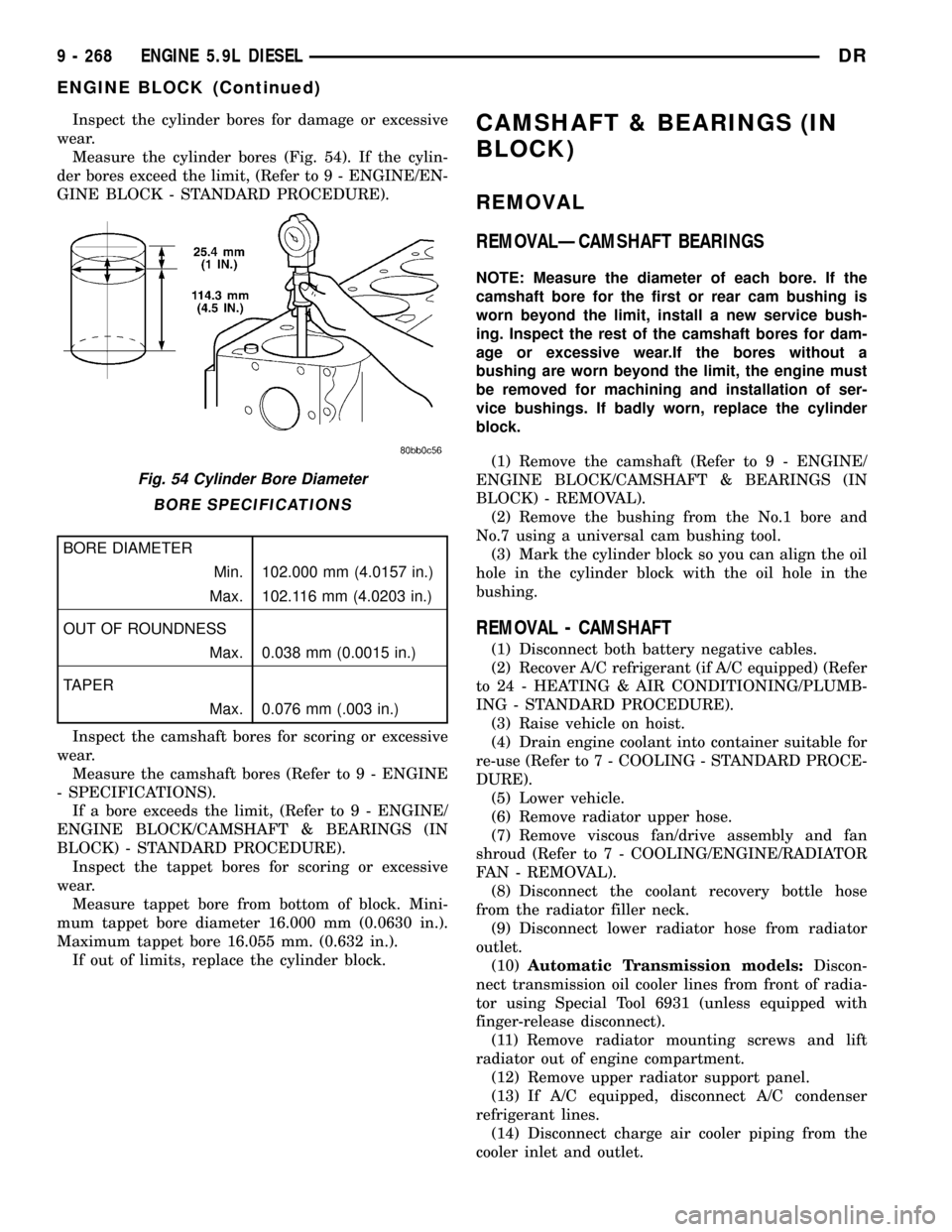

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE

(1) Measure the connecting rod bore with bearings

removedand the bolts tightened to 100 N´m (73 ft.

lbs.) torque..

(2) Measure the connecting rod bore with the bear-

ingsinstalledand the bolts tightened to 100 N´m

(73 ft. lbs.) torque.

Measure within 20É arc from each side of the part-

ing line. Also measure 90É from parting line.

Record the smallest and largest diameter.

Measure the diameter of the rod journal at the

location shown (Fig. 63). Calculate the average diam-

eter for each side of the journal.

Determine minimum bearing clearance by calculat-

ing the differance between the smallest connecting

rod bore diameter with the bearing installed and the

average diameter for each side of the crankshaft jour-

nal.

Determine the maximum bearing clearance by cal-

culating the difference between the largest connect-

ing rod bore diameter and the average diameter with

the bearing installed for each side of the crankshaft

journal.

DESCRIPTION MEASUREMENT

CONNECTING ROD

BORE, BEARINGS

REMOVEDMIN. 72.99 mm (2.874

in.)

MAX. 73.01 mm (2.875

in.)

CONNECTING ROD

BORE, BEARINGS

INSTALLEDMIN. 69.05 mm (2.719

in.)

MAX. 69.10 mm (2.720

in.)

9 - 272 ENGINE 5.9L DIESELDR

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1498 of 2627

CRANKSHAFT OIL SEAL - FRONT

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle from radia-

tor filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8)

Remove the fan shroud-to-radiator mounting bolts.

(9)Remove viscous fan/drive assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove cooling fan shroud and fan assembly

from the vehicle.

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper and speed

indicator ring.

(15) Remove power steering pump.

(16) Remove accessory drive belt tensioner.

(17) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces. Remove crank

seal dust shield with cover.

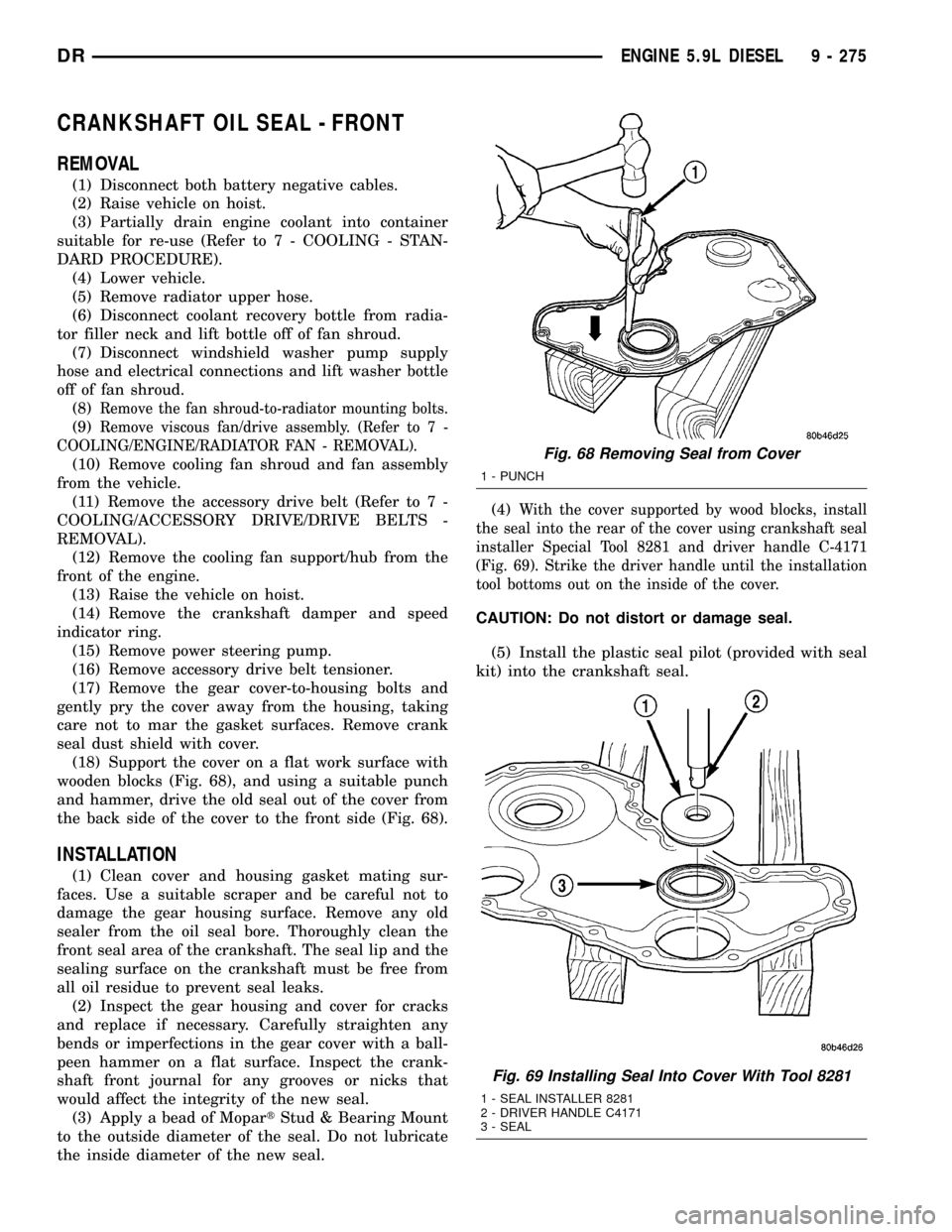

(18) Support the cover on a flat work surface with

wooden blocks (Fig. 68), and using a suitable punch

and hammer, drive the old seal out of the cover from

the back side of the cover to the front side (Fig. 68).

INSTALLATION

(1) Clean cover and housing gasket mating sur-

faces. Use a suitable scraper and be careful not to

damage the gear housing surface. Remove any old

sealer from the oil seal bore. Thoroughly clean the

front seal area of the crankshaft. The seal lip and the

sealing surface on the crankshaft must be free from

all oil residue to prevent seal leaks.

(2) Inspect the gear housing and cover for cracks

and replace if necessary. Carefully straighten any

bends or imperfections in the gear cover with a ball-

peen hammer on a flat surface. Inspect the crank-

shaft front journal for any grooves or nicks that

would affect the integrity of the new seal.

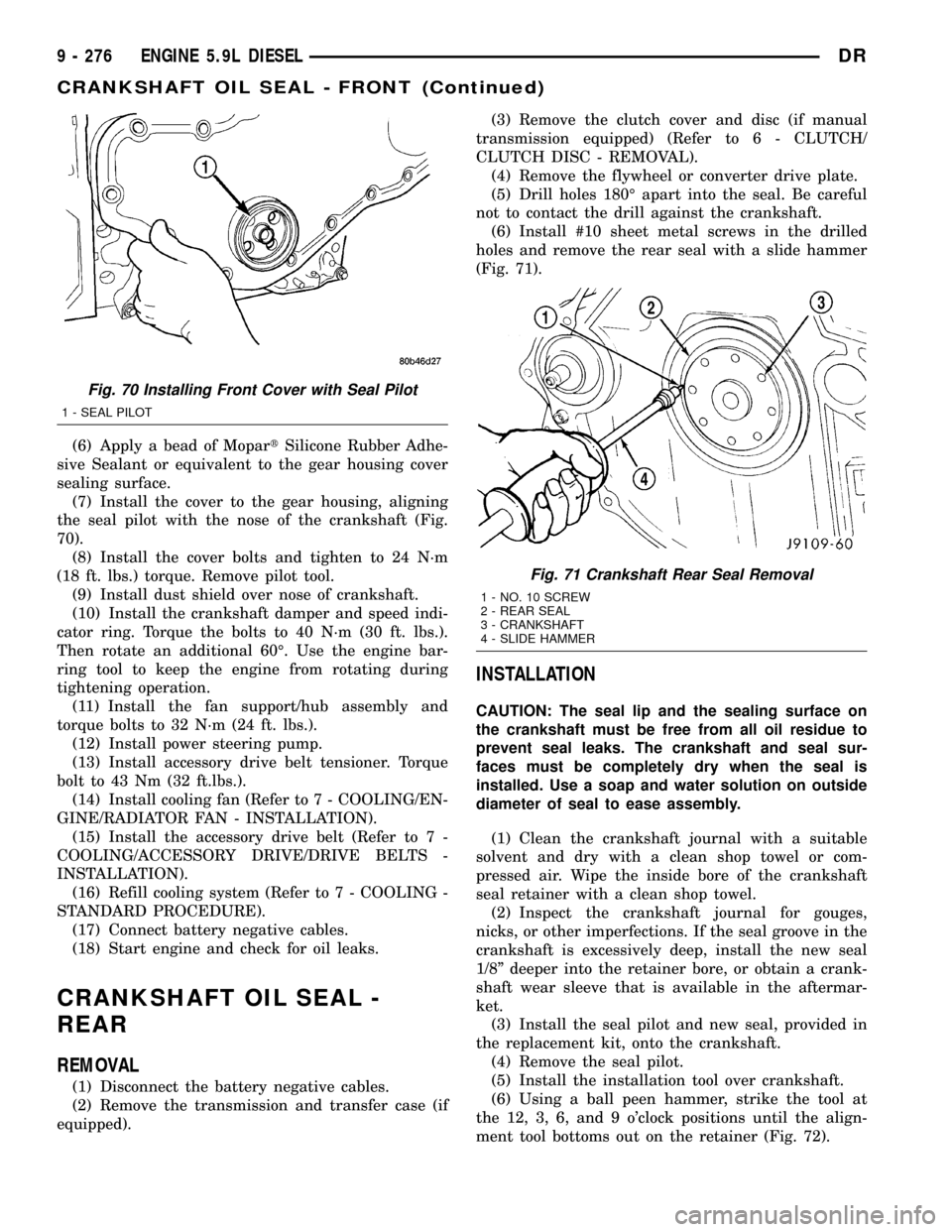

(3) Apply a bead of MopartStud & Bearing Mount

to the outside diameter of the seal. Do not lubricate

the inside diameter of the new seal.(4)

With the cover supported by wood blocks, install

the seal into the rear of the cover using crankshaft seal

installer Special Tool 8281 and driver handle C-4171

(Fig. 69). Strike the driver handle until the installation

tool bottoms out on the inside of the cover.

CAUTION: Do not distort or damage seal.

(5) Install the plastic seal pilot (provided with seal

kit) into the crankshaft seal.

Fig. 68 Removing Seal from Cover

1 - PUNCH

Fig. 69 Installing Seal Into Cover With Tool 8281

1 - SEAL INSTALLER 8281

2 - DRIVER HANDLE C4171

3 - SEAL

DRENGINE 5.9L DIESEL 9 - 275

Page 1499 of 2627

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the cover to the gear housing, aligning

the seal pilot with the nose of the crankshaft (Fig.

70).

(8) Install the cover bolts and tighten to 24 N´m

(18 ft. lbs.) torque. Remove pilot tool.

(9) Install dust shield over nose of crankshaft.

(10) Install the crankshaft damper and speed indi-

cator ring. Torque the bolts to 40 N´m (30 ft. lbs.).

Then rotate an additional 60É. Use the engine bar-

ring tool to keep the engine from rotating during

tightening operation.

(11) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(12) Install power steering pump.

(13) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft.lbs.).

(14) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(15) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(16) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Connect battery negative cables.

(18) Start engine and check for oil leaks.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 71).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-

shaft wear sleeve that is available in the aftermar-

ket.

(3) Install the seal pilot and new seal, provided in

the replacement kit, onto the crankshaft.

(4) Remove the seal pilot.

(5) Install the installation tool over crankshaft.

(6) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 72).

Fig. 70 Installing Front Cover with Seal Pilot

1 - SEAL PILOT

Fig. 71 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

9 - 276 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1509 of 2627

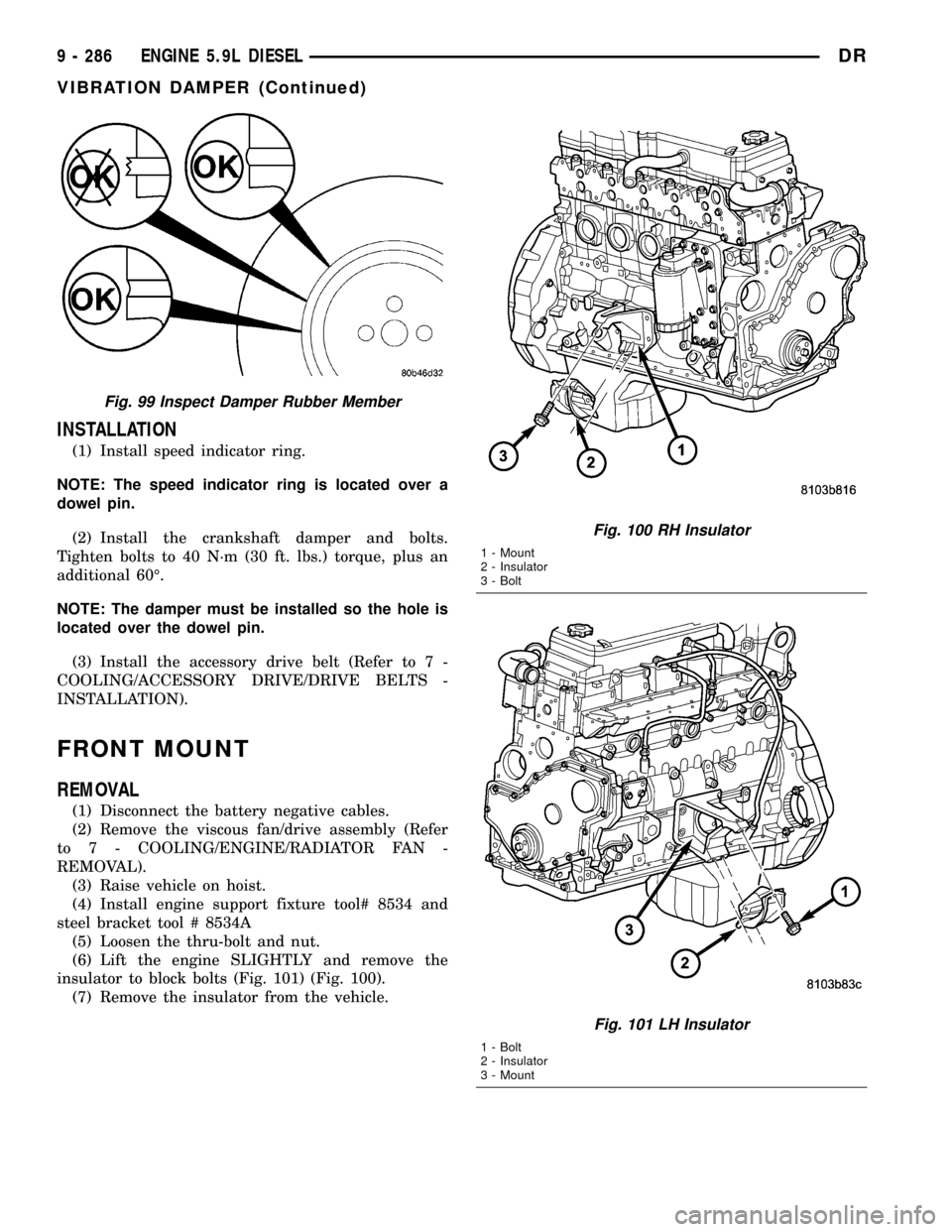

INSTALLATION

(1) Install speed indicator ring.

NOTE: The speed indicator ring is located over a

dowel pin.

(2) Install the crankshaft damper and bolts.

Tighten bolts to 40 N´m (30 ft. lbs.) torque, plus an

additional 60É.

NOTE: The damper must be installed so the hole is

located over the dowel pin.

(3) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

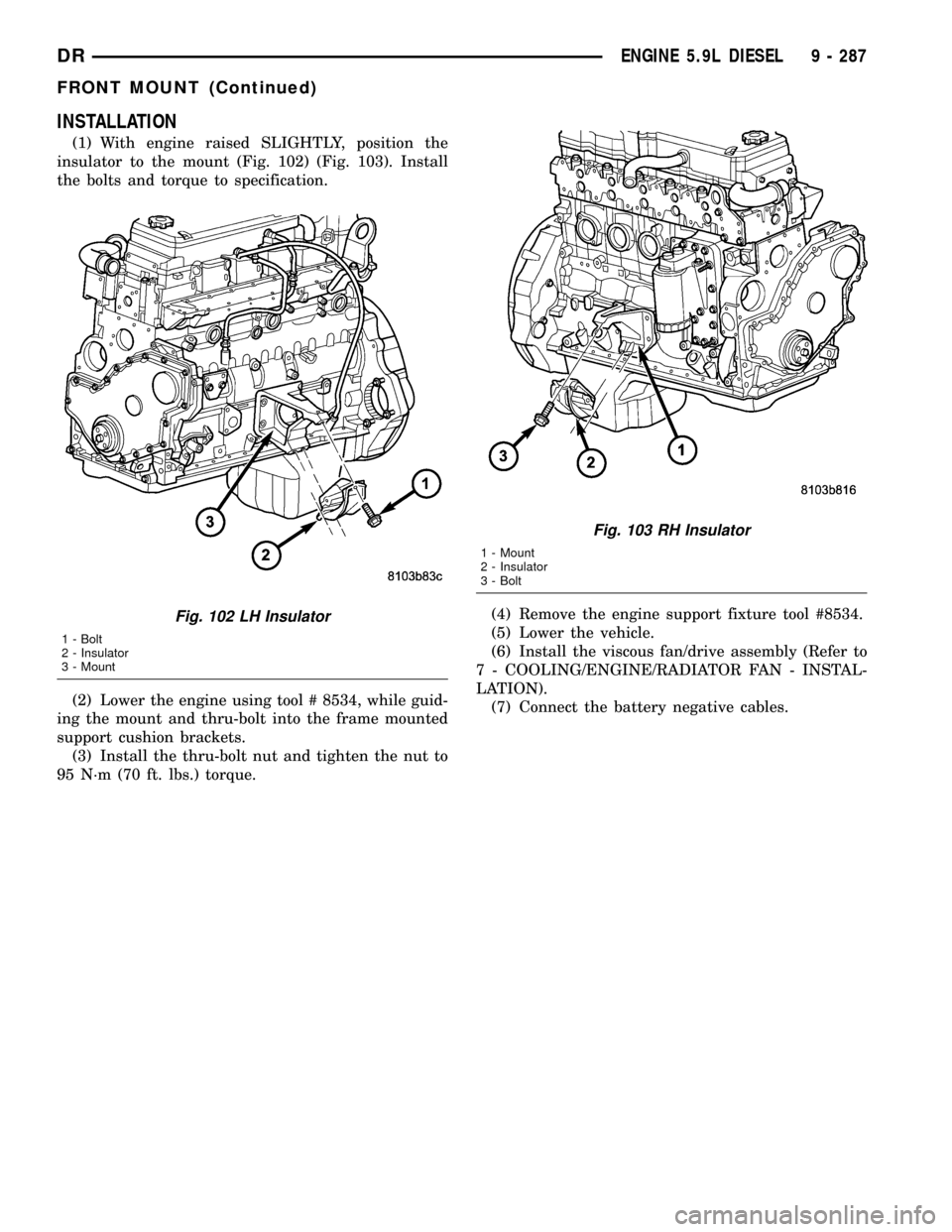

FRONT MOUNT

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the viscous fan/drive assembly (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(3) Raise vehicle on hoist.

(4) Install engine support fixture tool# 8534 and

steel bracket tool # 8534A

(5) Loosen the thru-bolt and nut.

(6) Lift the engine SLIGHTLY and remove the

insulator to block bolts (Fig. 101) (Fig. 100).

(7) Remove the insulator from the vehicle.

Fig. 99 Inspect Damper Rubber Member

Fig. 100 RH Insulator

1 - Mount

2 - Insulator

3 - Bolt

Fig. 101 LH Insulator

1 - Bolt

2 - Insulator

3 - Mount

9 - 286 ENGINE 5.9L DIESELDR

VIBRATION DAMPER (Continued)

Page 1510 of 2627

INSTALLATION

(1) With engine raised SLIGHTLY, position the

insulator to the mount (Fig. 102) (Fig. 103). Install

the bolts and torque to specification.

(2) Lower the engine using tool # 8534, while guid-

ing the mount and thru-bolt into the frame mounted

support cushion brackets.

(3) Install the thru-bolt nut and tighten the nut to

95 N´m (70 ft. lbs.) torque.(4) Remove the engine support fixture tool #8534.

(5) Lower the vehicle.

(6) Install the viscous fan/drive assembly (Refer to

7 - COOLING/ENGINE/RADIATOR FAN - INSTAL-

LATION).

(7) Connect the battery negative cables.

Fig. 102 LH Insulator

1 - Bolt

2 - Insulator

3 - Mount

Fig. 103 RH Insulator

1 - Mount

2 - Insulator

3 - Bolt

DRENGINE 5.9L DIESEL 9 - 287

FRONT MOUNT (Continued)

Page 1517 of 2627

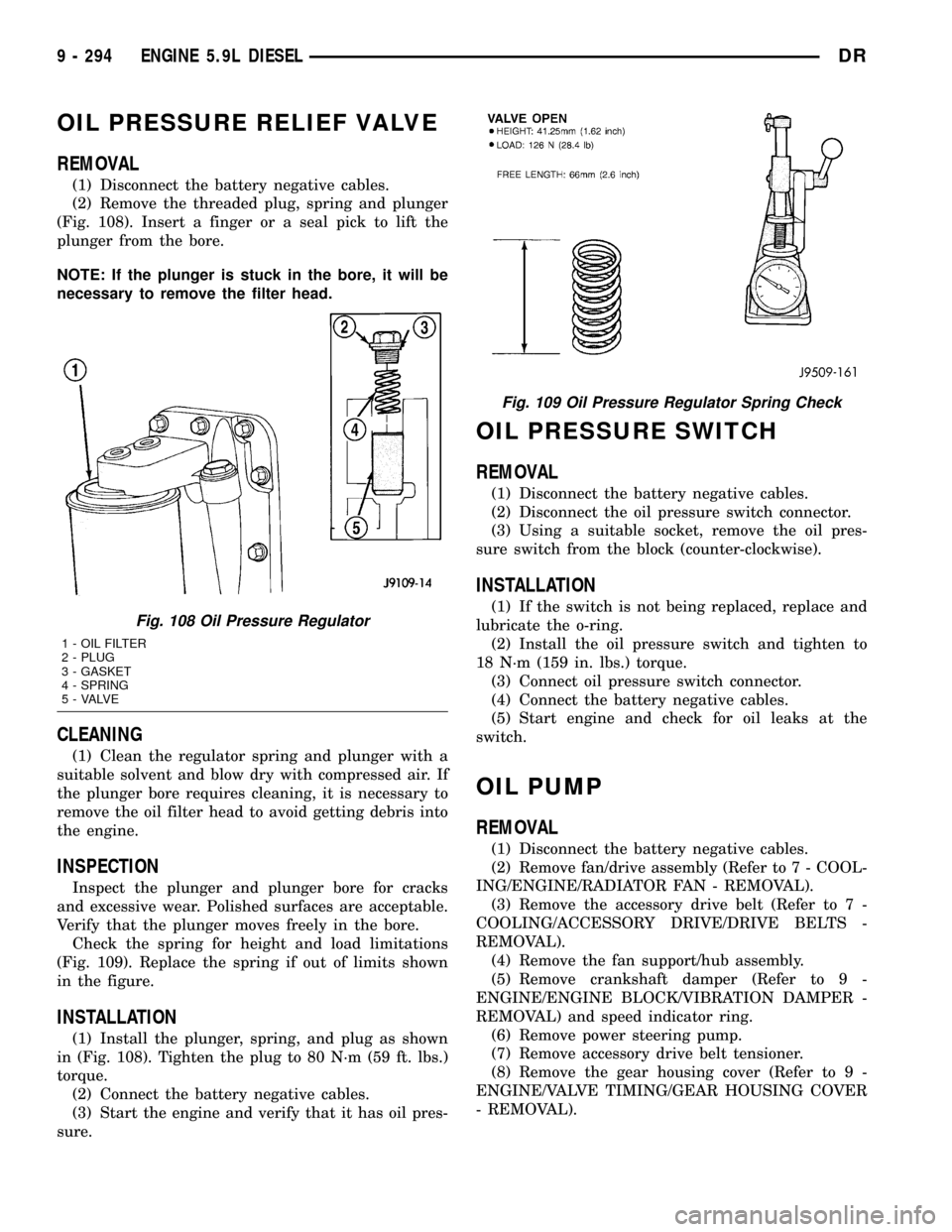

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the threaded plug, spring and plunger

(Fig. 108). Insert a finger or a seal pick to lift the

plunger from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

(1) Clean the regulator spring and plunger with a

suitable solvent and blow dry with compressed air. If

the plunger bore requires cleaning, it is necessary to

remove the oil filter head to avoid getting debris into

the engine.

INSPECTION

Inspect the plunger and plunger bore for cracks

and excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations

(Fig. 109). Replace the spring if out of limits shown

in the figure.

INSTALLATION

(1) Install the plunger, spring, and plug as shown

in (Fig. 108). Tighten the plug to 80 N´m (59 ft. lbs.)

torque.

(2) Connect the battery negative cables.

(3) Start the engine and verify that it has oil pres-

sure.

OIL PRESSURE SWITCH

REMOVAL

(1) Disconnect the battery negative cables.

(2) Disconnect the oil pressure switch connector.

(3) Using a suitable socket, remove the oil pres-

sure switch from the block (counter-clockwise).

INSTALLATION

(1) If the switch is not being replaced, replace and

lubricate the o-ring.

(2) Install the oil pressure switch and tighten to

18 N´m (159 in. lbs.) torque.

(3) Connect oil pressure switch connector.

(4) Connect the battery negative cables.

(5) Start engine and check for oil leaks at the

switch.

OIL PUMP

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the fan support/hub assembly.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(6) Remove power steering pump.

(7) Remove accessory drive belt tensioner.

(8) Remove the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL).

Fig. 108 Oil Pressure Regulator

1 - OIL FILTER

2 - PLUG

3 - GASKET

4 - SPRING

5 - VALVE

Fig. 109 Oil Pressure Regulator Spring Check

9 - 294 ENGINE 5.9L DIESELDR

Page 1519 of 2627

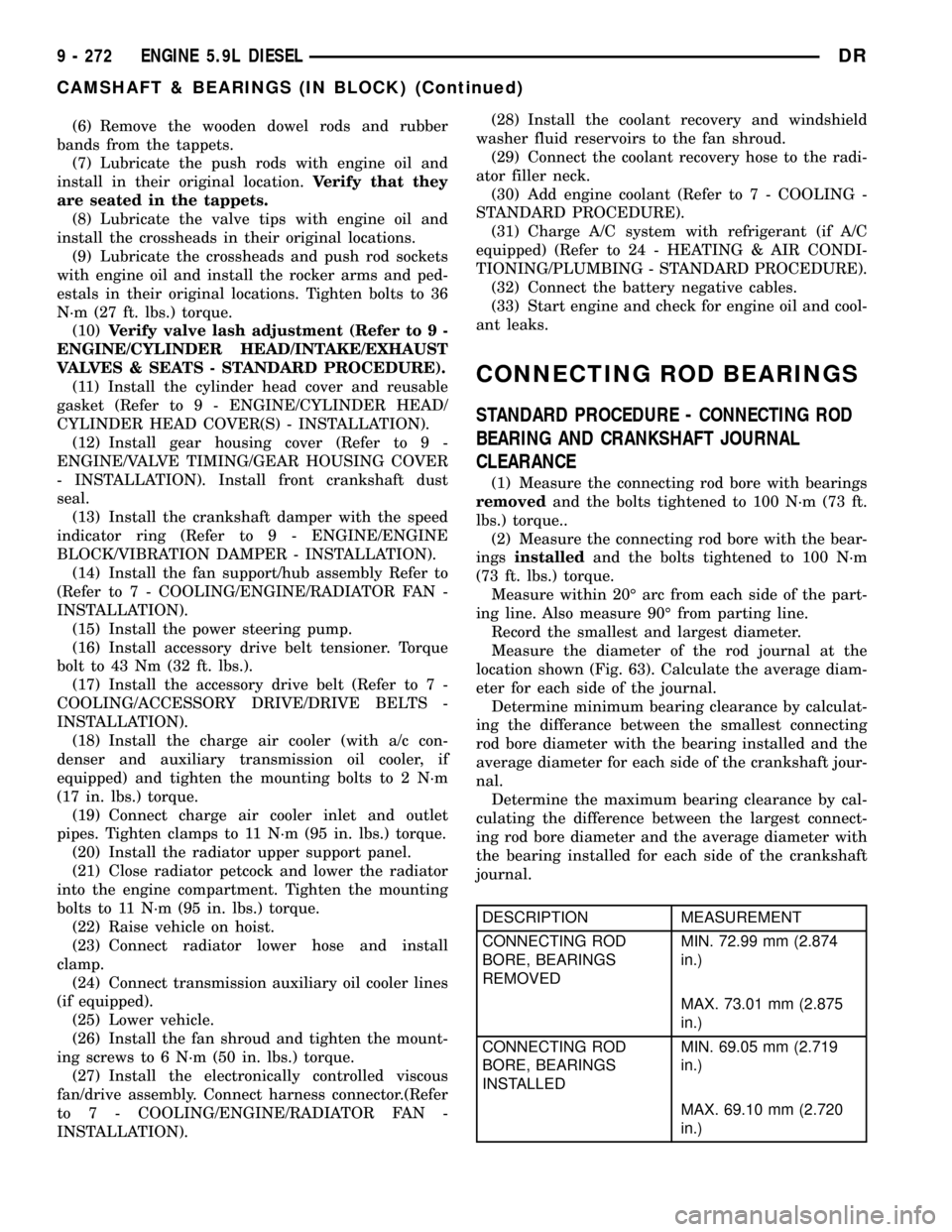

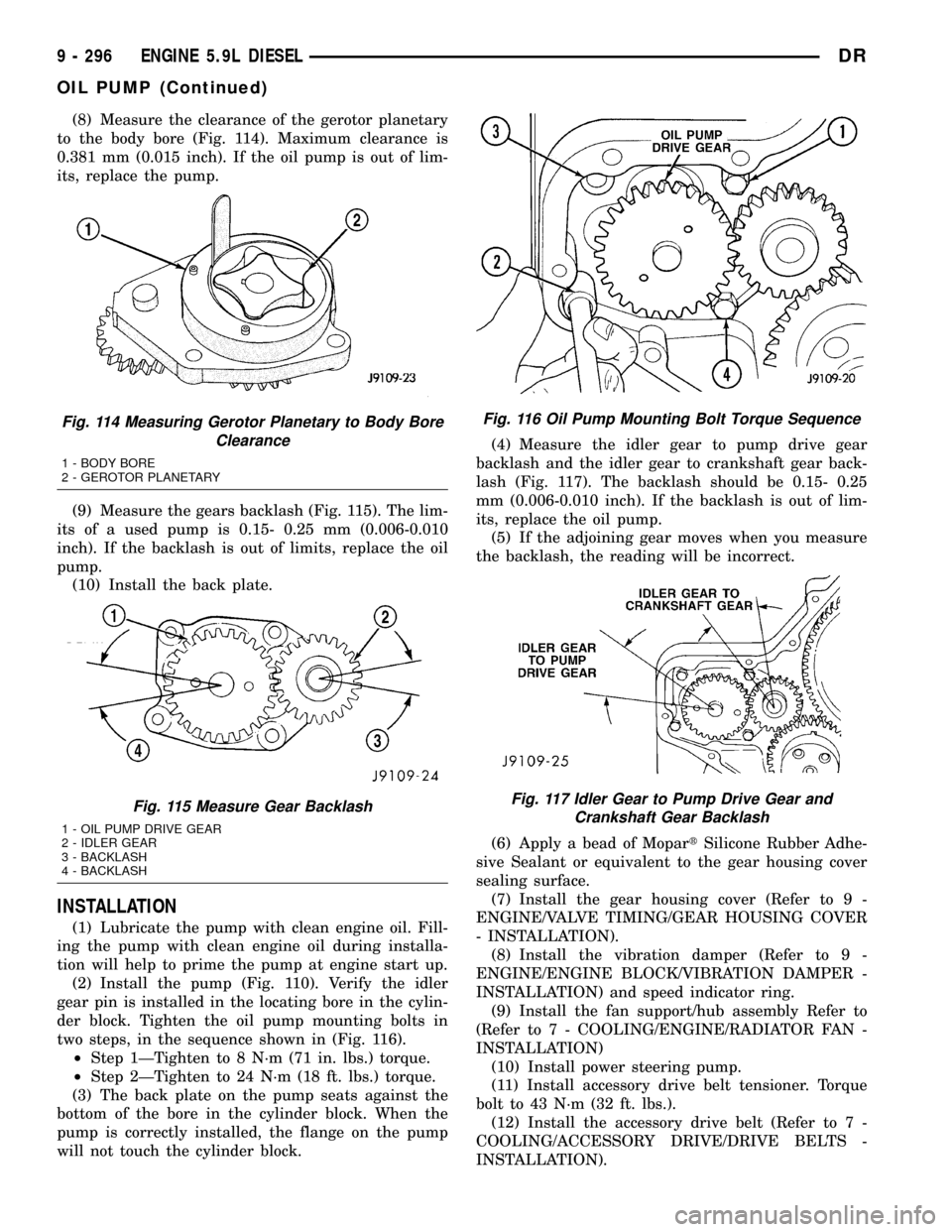

(8) Measure the clearance of the gerotor planetary

to the body bore (Fig. 114). Maximum clearance is

0.381 mm (0.015 inch). If the oil pump is out of lim-

its, replace the pump.

(9) Measure the gears backlash (Fig. 115). The lim-

its of a used pump is 0.15- 0.25 mm (0.006-0.010

inch). If the backlash is out of limits, replace the oil

pump.

(10) Install the back plate.

INSTALLATION

(1) Lubricate the pump with clean engine oil. Fill-

ing the pump with clean engine oil during installa-

tion will help to prime the pump at engine start up.

(2) Install the pump (Fig. 110). Verify the idler

gear pin is installed in the locating bore in the cylin-

der block. Tighten the oil pump mounting bolts in

two steps, in the sequence shown in (Fig. 116).

²Step 1ÐTighten to 8 N´m (71 in. lbs.) torque.

²Step 2ÐTighten to 24 N´m (18 ft. lbs.) torque.

(3) The back plate on the pump seats against the

bottom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.(4) Measure the idler gear to pump drive gear

backlash and the idler gear to crankshaft gear back-

lash (Fig. 117). The backlash should be 0.15- 0.25

mm (0.006-0.010 inch). If the backlash is out of lim-

its, replace the oil pump.

(5) If the adjoining gear moves when you measure

the backlash, the reading will be incorrect.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

(8) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION) and speed indicator ring.

(9) Install the fan support/hub assembly Refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION)

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.).

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 114 Measuring Gerotor Planetary to Body Bore

Clearance

1 - BODY BORE

2 - GEROTOR PLANETARY

Fig. 115 Measure Gear Backlash

1 - OIL PUMP DRIVE GEAR

2 - IDLER GEAR

3 - BACKLASH

4 - BACKLASH

Fig. 116 Oil Pump Mounting Bolt Torque Sequence

Fig. 117 Idler Gear to Pump Drive Gear and

Crankshaft Gear Backlash

9 - 296 ENGINE 5.9L DIESELDR

OIL PUMP (Continued)