RADIATOR DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1905 of 2627

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should also be replaced when-

ever a failure generates sludge and debris. This is

necessary because normal converter flushing proce-

dures will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, thegeartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at

curb idle speed, the transmission in NEUTRAL and

the transmission fluid at normal operating tempera-

ture.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.

The transmission fluid level can be checked two

ways.

PROCEDURE ONE

(1) Transmission fluid must be at normal operat-

ing temperature for accurate fluid level check. Drive

vehicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to NEUTRAL.

(6) Clean top of filler tube and dipstick to keep

dirt from entering tube.

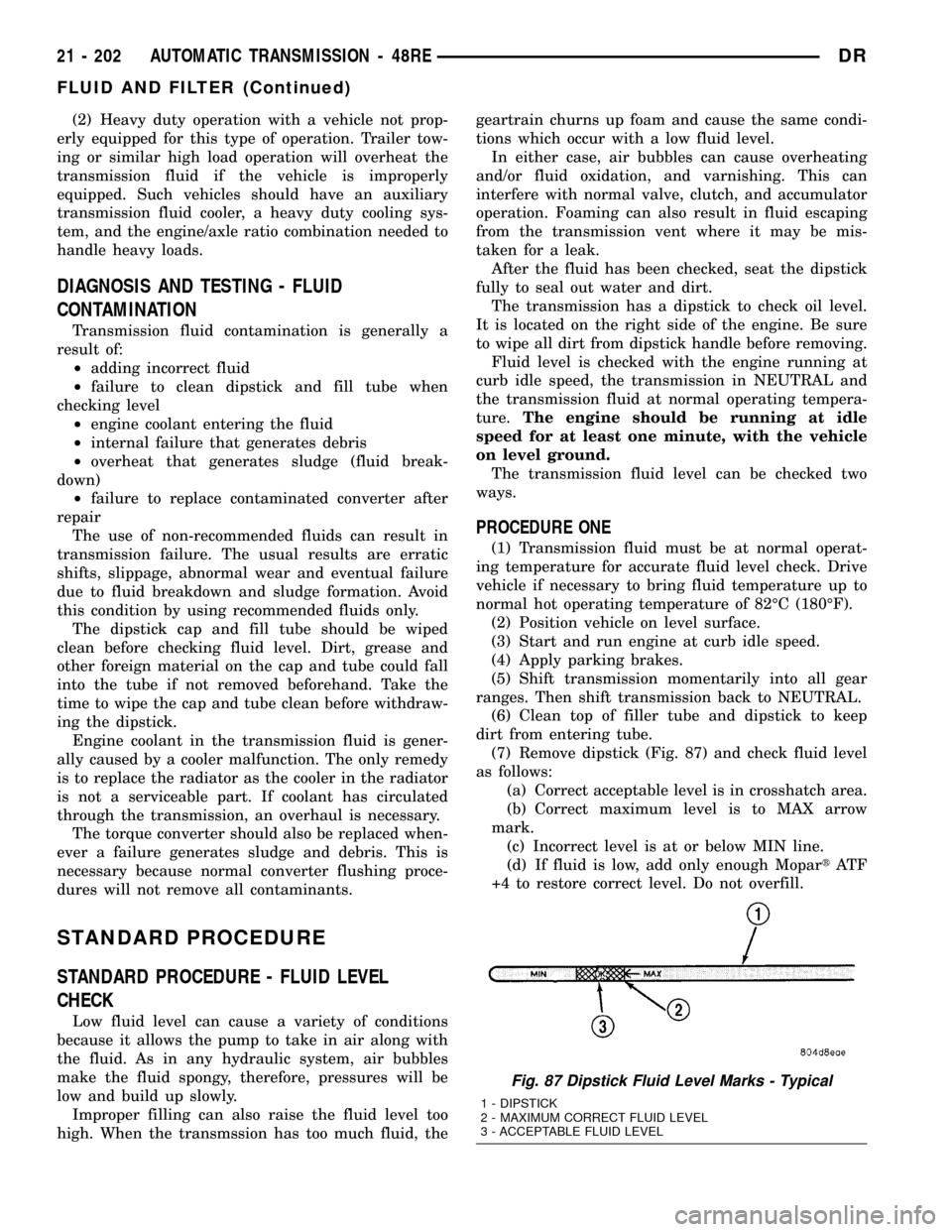

(7) Remove dipstick (Fig. 87) and check fluid level

as follows:

(a) Correct acceptable level is in crosshatch area.

(b) Correct maximum level is to MAX arrow

mark.

(c) Incorrect level is at or below MIN line.

(d) If fluid is low, add only enough MopartAT F

+4 to restore correct level. Do not overfill.

Fig. 87 Dipstick Fluid Level Marks - Typical

1 - DIPSTICK

2 - MAXIMUM CORRECT FLUID LEVEL

3 - ACCEPTABLE FLUID LEVEL

21 - 202 AUTOMATIC TRANSMISSION - 48REDR

FLUID AND FILTER (Continued)

Page 1964 of 2627

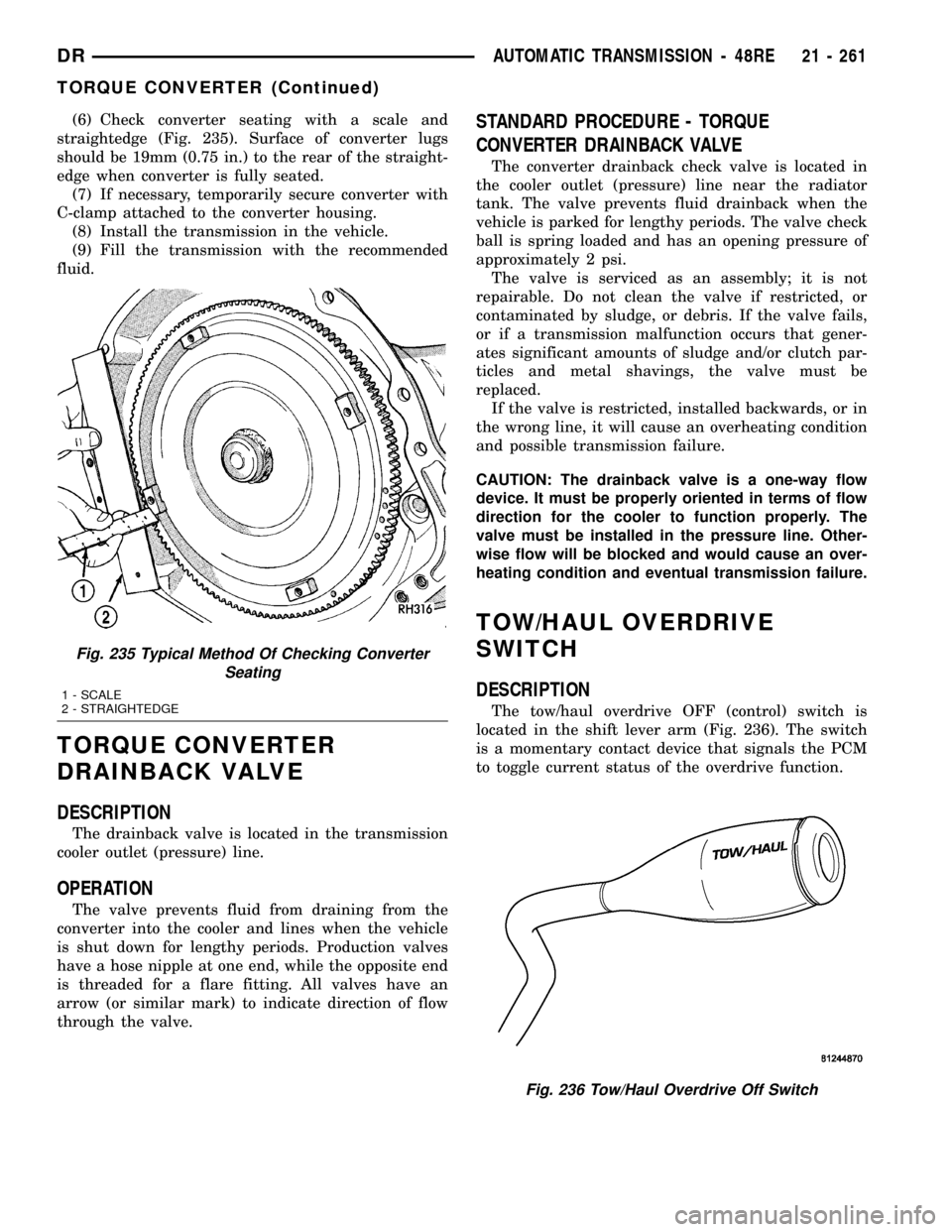

(6) Check converter seating with a scale and

straightedge (Fig. 235). Surface of converter lugs

should be 19mm (0.75 in.) to the rear of the straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

(9) Fill the transmission with the recommended

fluid.

TORQUE CONVERTER

DRAINBACK VALVE

DESCRIPTION

The drainback valve is located in the transmission

cooler outlet (pressure) line.

OPERATION

The valve prevents fluid from draining from the

converter into the cooler and lines when the vehicle

is shut down for lengthy periods. Production valves

have a hose nipple at one end, while the opposite end

is threaded for a flare fitting. All valves have an

arrow (or similar mark) to indicate direction of flow

through the valve.

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

tank. The valve prevents fluid drainback when the

vehicle is parked for lengthy periods. The valve check

ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not

repairable. Do not clean the valve if restricted, or

contaminated by sludge, or debris. If the valve fails,

or if a transmission malfunction occurs that gener-

ates significant amounts of sludge and/or clutch par-

ticles and metal shavings, the valve must be

replaced.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow

device. It must be properly oriented in terms of flow

direction for the cooler to function properly. The

valve must be installed in the pressure line. Other-

wise flow will be blocked and would cause an over-

heating condition and eventual transmission failure.

TOW/HAUL OVERDRIVE

SWITCH

DESCRIPTION

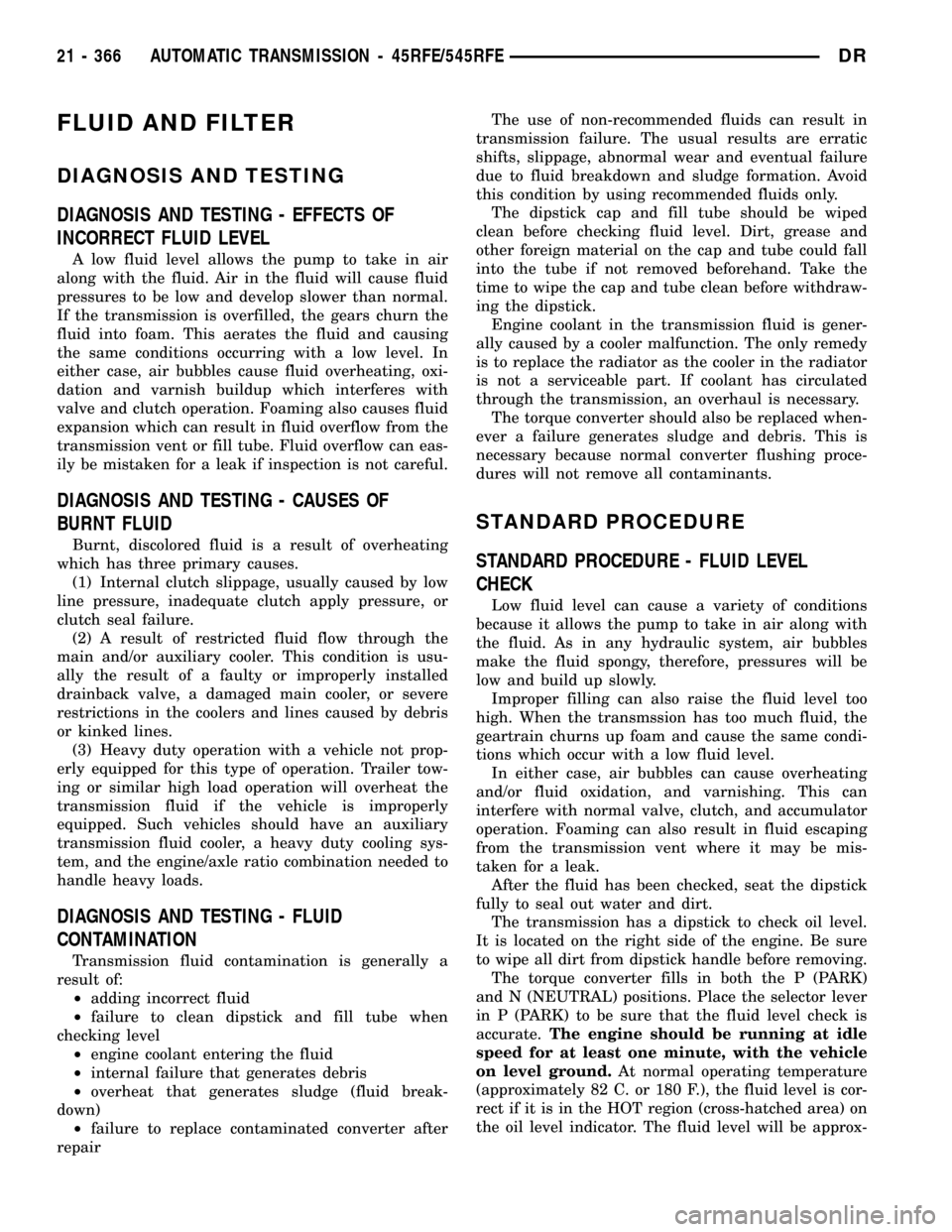

The tow/haul overdrive OFF (control) switch is

located in the shift lever arm (Fig. 236). The switch

is a momentary contact device that signals the PCM

to toggle current status of the overdrive function.

Fig. 235 Typical Method Of Checking Converter

Seating

1 - SCALE

2 - STRAIGHTEDGE

Fig. 236 Tow/Haul Overdrive Off Switch

DRAUTOMATIC TRANSMISSION - 48RE 21 - 261

TORQUE CONVERTER (Continued)

Page 2069 of 2627

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repairThe use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should also be replaced when-

ever a failure generates sludge and debris. This is

necessary because normal converter flushing proce-

dures will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground.At normal operating temperature

(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

21 - 366 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2308 of 2627

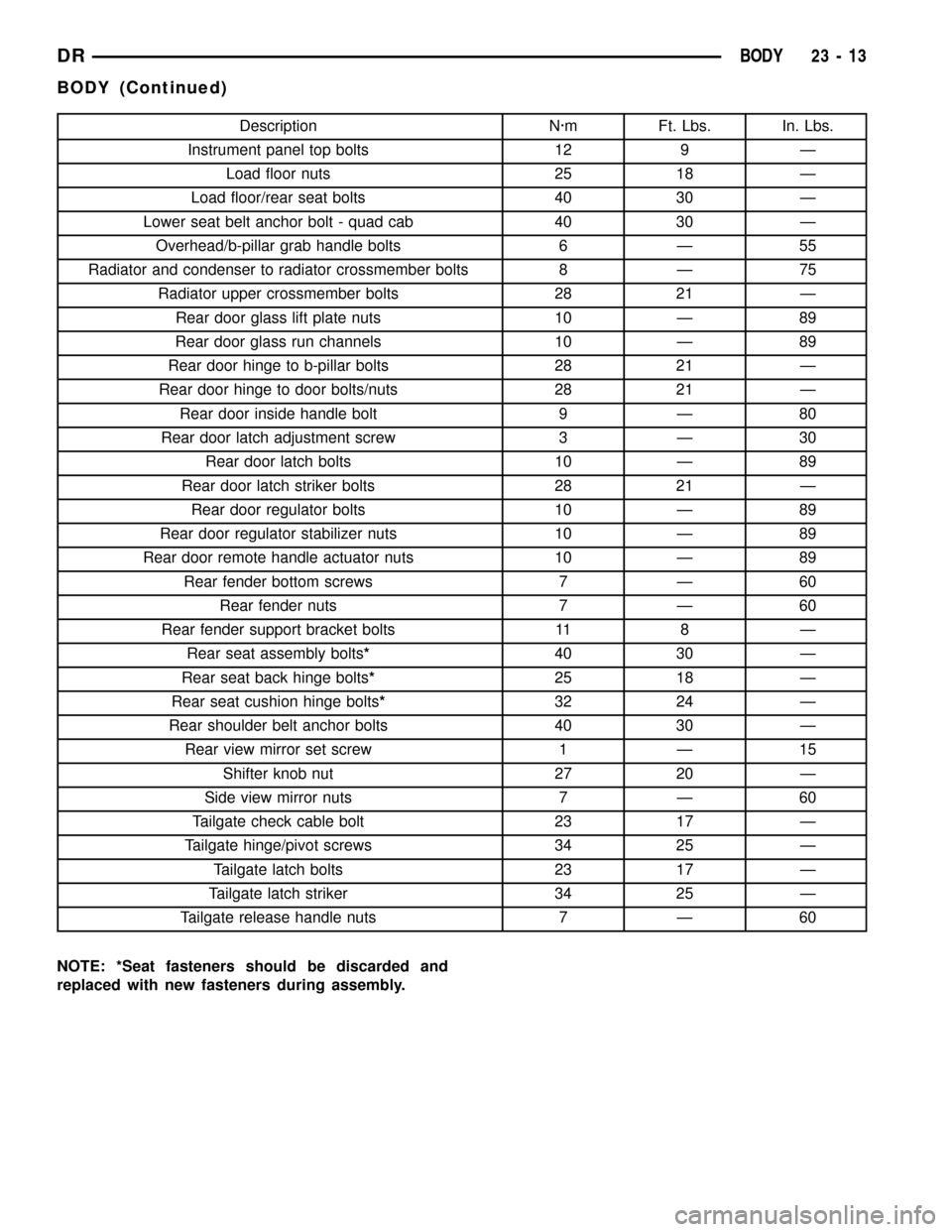

Description N´m Ft. Lbs. In. Lbs.

Instrument panel top bolts 12 9 Ð

Load floor nuts 25 18 Ð

Load floor/rear seat bolts 40 30 Ð

Lower seat belt anchor bolt - quad cab 40 30 Ð

Overhead/b-pillar grab handle bolts 6 Ð 55

Radiator and condenser to radiator crossmember bolts 8 Ð 75

Radiator upper crossmember bolts 28 21 Ð

Rear door glass lift plate nuts 10 Ð 89

Rear door glass run channels 10 Ð 89

Rear door hinge to b-pillar bolts 28 21 Ð

Rear door hinge to door bolts/nuts 28 21 Ð

Rear door inside handle bolt 9 Ð 80

Rear door latch adjustment screw 3 Ð 30

Rear door latch bolts 10 Ð 89

Rear door latch striker bolts 28 21 Ð

Rear door regulator bolts 10 Ð 89

Rear door regulator stabilizer nuts 10 Ð 89

Rear door remote handle actuator nuts 10 Ð 89

Rear fender bottom screws 7 Ð 60

Rear fender nuts 7 Ð 60

Rear fender support bracket bolts 11 8 Ð

Rear seat assembly bolts*40 30 Ð

Rear seat back hinge bolts*25 18 Ð

Rear seat cushion hinge bolts*32 24 Ð

Rear shoulder belt anchor bolts 40 30 Ð

Rear view mirror set screw 1 Ð 15

Shifter knob nut 27 20 Ð

Side view mirror nuts 7 Ð 60

Tailgate check cable bolt 23 17 Ð

Tailgate hinge/pivot screws 34 25 Ð

Tailgate latch bolts 23 17 Ð

Tailgate latch striker 34 25 Ð

Tailgate release handle nuts 7 Ð 60

NOTE: *Seat fasteners should be discarded and

replaced with new fasteners during assembly.

DRBODY 23 - 13

BODY (Continued)

Page 2331 of 2627

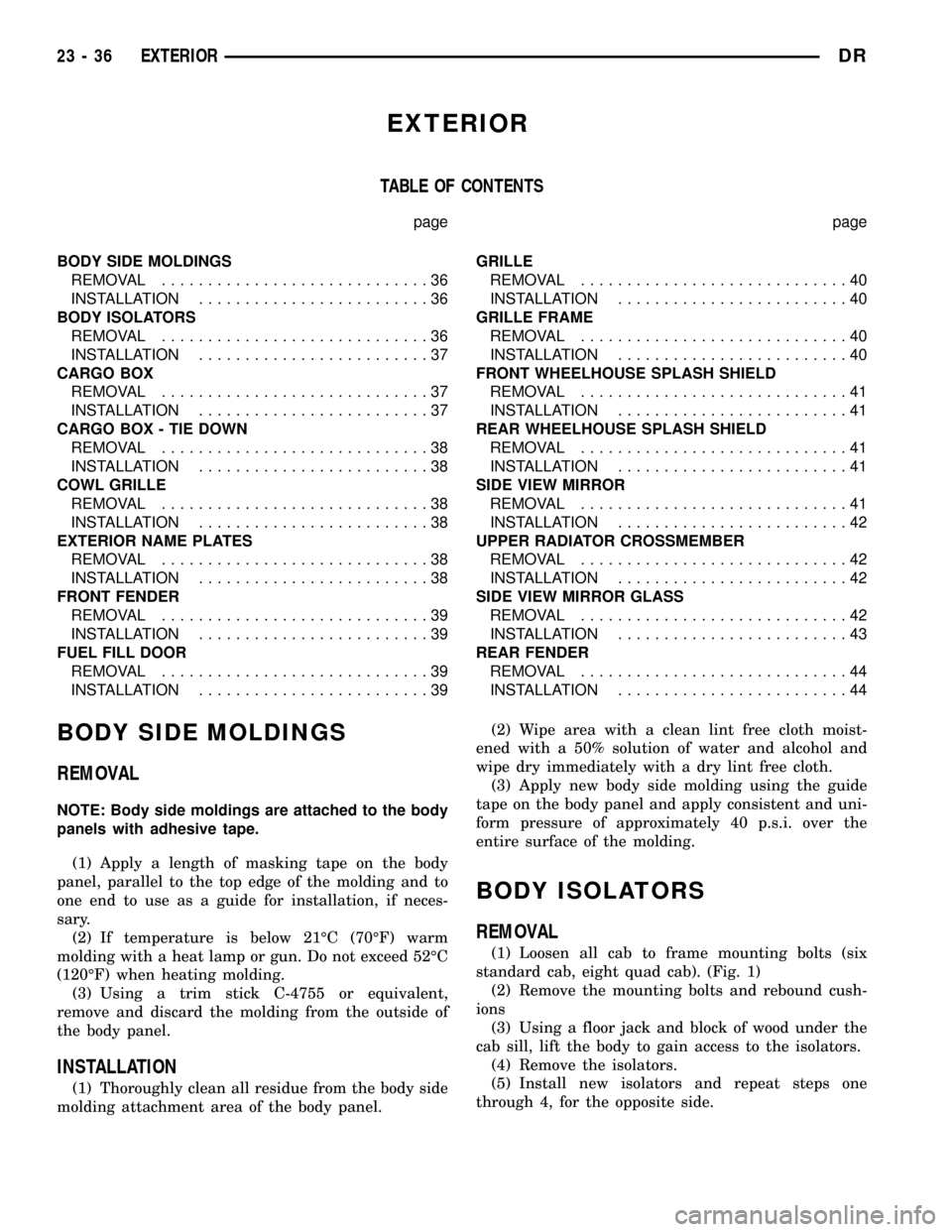

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL.............................36

INSTALLATION.........................36

BODY ISOLATORS

REMOVAL.............................36

INSTALLATION.........................37

CARGO BOX

REMOVAL.............................37

INSTALLATION.........................37

CARGO BOX - TIE DOWN

REMOVAL.............................38

INSTALLATION.........................38

COWL GRILLE

REMOVAL.............................38

INSTALLATION.........................38

EXTERIOR NAME PLATES

REMOVAL.............................38

INSTALLATION.........................38

FRONT FENDER

REMOVAL.............................39

INSTALLATION.........................39

FUEL FILL DOOR

REMOVAL.............................39

INSTALLATION.........................39GRILLE

REMOVAL.............................40

INSTALLATION.........................40

GRILLE FRAME

REMOVAL.............................40

INSTALLATION.........................40

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL.............................41

INSTALLATION.........................41

REAR WHEELHOUSE SPLASH SHIELD

REMOVAL.............................41

INSTALLATION.........................41

SIDE VIEW MIRROR

REMOVAL.............................41

INSTALLATION.........................42

UPPER RADIATOR CROSSMEMBER

REMOVAL.............................42

INSTALLATION.........................42

SIDE VIEW MIRROR GLASS

REMOVAL.............................42

INSTALLATION.........................43

REAR FENDER

REMOVAL.............................44

INSTALLATION.........................44

BODY SIDE MOLDINGS

REMOVAL

NOTE: Body side moldings are attached to the body

panels with adhesive tape.

(1) Apply a length of masking tape on the body

panel, parallel to the top edge of the molding and to

one end to use as a guide for installation, if neces-

sary.

(2) If temperature is below 21ÉC (70ÉF) warm

molding with a heat lamp or gun. Do not exceed 52ÉC

(120ÉF) when heating molding.

(3) Using a trim stick C-4755 or equivalent,

remove and discard the molding from the outside of

the body panel.

INSTALLATION

(1) Thoroughly clean all residue from the body side

molding attachment area of the body panel.(2) Wipe area with a clean lint free cloth moist-

ened with a 50% solution of water and alcohol and

wipe dry immediately with a dry lint free cloth.

(3) Apply new body side molding using the guide

tape on the body panel and apply consistent and uni-

form pressure of approximately 40 p.s.i. over the

entire surface of the molding.

BODY ISOLATORS

REMOVAL

(1) Loosen all cab to frame mounting bolts (six

standard cab, eight quad cab). (Fig. 1)

(2) Remove the mounting bolts and rebound cush-

ions

(3) Using a floor jack and block of wood under the

cab sill, lift the body to gain access to the isolators.

(4) Remove the isolators.

(5) Install new isolators and repeat steps one

through 4, for the opposite side.

23 - 36 EXTERIORDR

Page 2337 of 2627

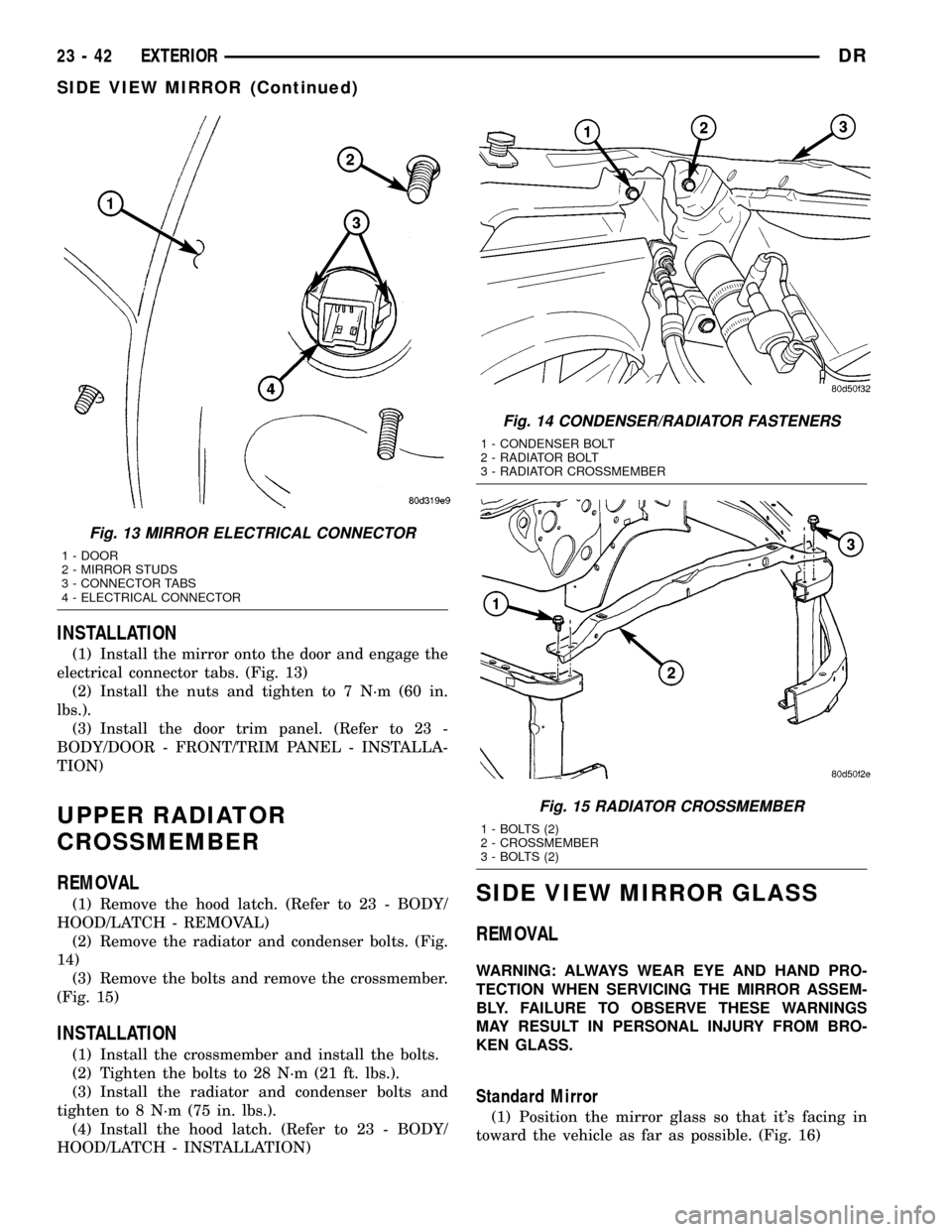

INSTALLATION

(1) Install the mirror onto the door and engage the

electrical connector tabs. (Fig. 13)

(2) Install the nuts and tighten to 7 N´m (60 in.

lbs.).

(3) Install the door trim panel. (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION)

UPPER RADIATOR

CROSSMEMBER

REMOVAL

(1) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)

(2) Remove the radiator and condenser bolts. (Fig.

14)

(3) Remove the bolts and remove the crossmember.

(Fig. 15)

INSTALLATION

(1) Install the crossmember and install the bolts.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.).

(3) Install the radiator and condenser bolts and

tighten to 8 N´m (75 in. lbs.).

(4) Install the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - INSTALLATION)

SIDE VIEW MIRROR GLASS

REMOVAL

WARNING: ALWAYS WEAR EYE AND HAND PRO-

TECTION WHEN SERVICING THE MIRROR ASSEM-

BLY. FAILURE TO OBSERVE THESE WARNINGS

MAY RESULT IN PERSONAL INJURY FROM BRO-

KEN GLASS.

Standard Mirror

(1) Position the mirror glass so that it's facing in

toward the vehicle as far as possible. (Fig. 16)

Fig. 13 MIRROR ELECTRICAL CONNECTOR

1 - DOOR

2 - MIRROR STUDS

3 - CONNECTOR TABS

4 - ELECTRICAL CONNECTOR

Fig. 14 CONDENSER/RADIATOR FASTENERS

1 - CONDENSER BOLT

2 - RADIATOR BOLT

3 - RADIATOR CROSSMEMBER

Fig. 15 RADIATOR CROSSMEMBER

1 - BOLTS (2)

2 - CROSSMEMBER

3 - BOLTS (2)

23 - 42 EXTERIORDR

SIDE VIEW MIRROR (Continued)

Page 2342 of 2627

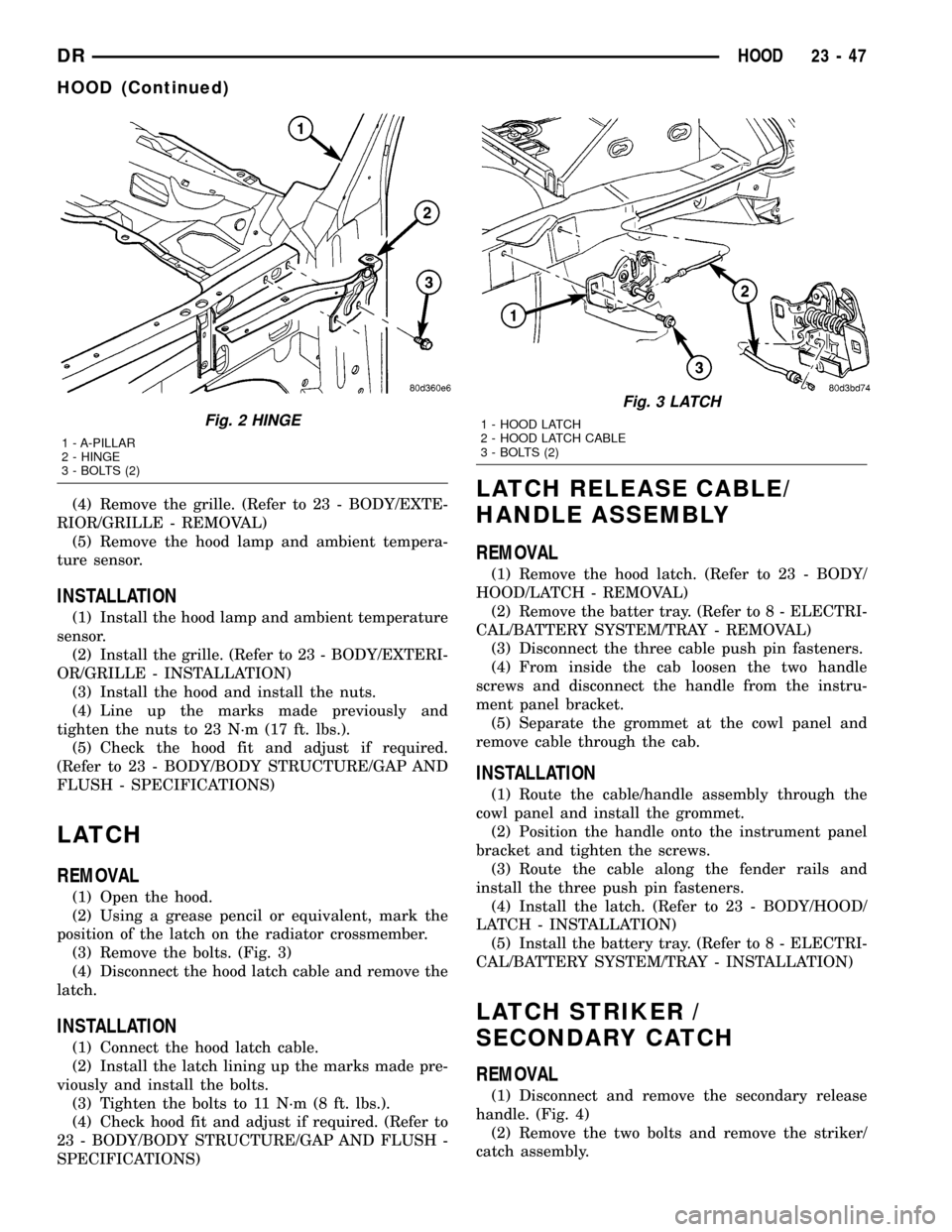

(4) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(5) Remove the hood lamp and ambient tempera-

ture sensor.

INSTALLATION

(1) Install the hood lamp and ambient temperature

sensor.

(2) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

(3) Install the hood and install the nuts.

(4) Line up the marks made previously and

tighten the nuts to 23 N´m (17 ft. lbs.).

(5) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

LATCH

REMOVAL

(1) Open the hood.

(2) Using a grease pencil or equivalent, mark the

position of the latch on the radiator crossmember.

(3) Remove the bolts. (Fig. 3)

(4) Disconnect the hood latch cable and remove the

latch.

INSTALLATION

(1) Connect the hood latch cable.

(2) Install the latch lining up the marks made pre-

viously and install the bolts.

(3) Tighten the bolts to 11 N´m (8 ft. lbs.).

(4) Check hood fit and adjust if required. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

LATCH RELEASE CABLE/

HANDLE ASSEMBLY

REMOVAL

(1) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)

(2) Remove the batter tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL)

(3) Disconnect the three cable push pin fasteners.

(4) From inside the cab loosen the two handle

screws and disconnect the handle from the instru-

ment panel bracket.

(5) Separate the grommet at the cowl panel and

remove cable through the cab.

INSTALLATION

(1) Route the cable/handle assembly through the

cowl panel and install the grommet.

(2) Position the handle onto the instrument panel

bracket and tighten the screws.

(3) Route the cable along the fender rails and

install the three push pin fasteners.

(4) Install the latch. (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION)

(5) Install the battery tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION)

LATCH STRIKER /

SECONDARY CATCH

REMOVAL

(1) Disconnect and remove the secondary release

handle. (Fig. 4)

(2) Remove the two bolts and remove the striker/

catch assembly.

Fig. 2 HINGE

1 - A-PILLAR

2 - HINGE

3 - BOLTS (2)

Fig. 3 LATCH

1 - HOOD LATCH

2 - HOOD LATCH CABLE

3 - BOLTS (2)

DRHOOD 23 - 47

HOOD (Continued)

Page 2415 of 2627

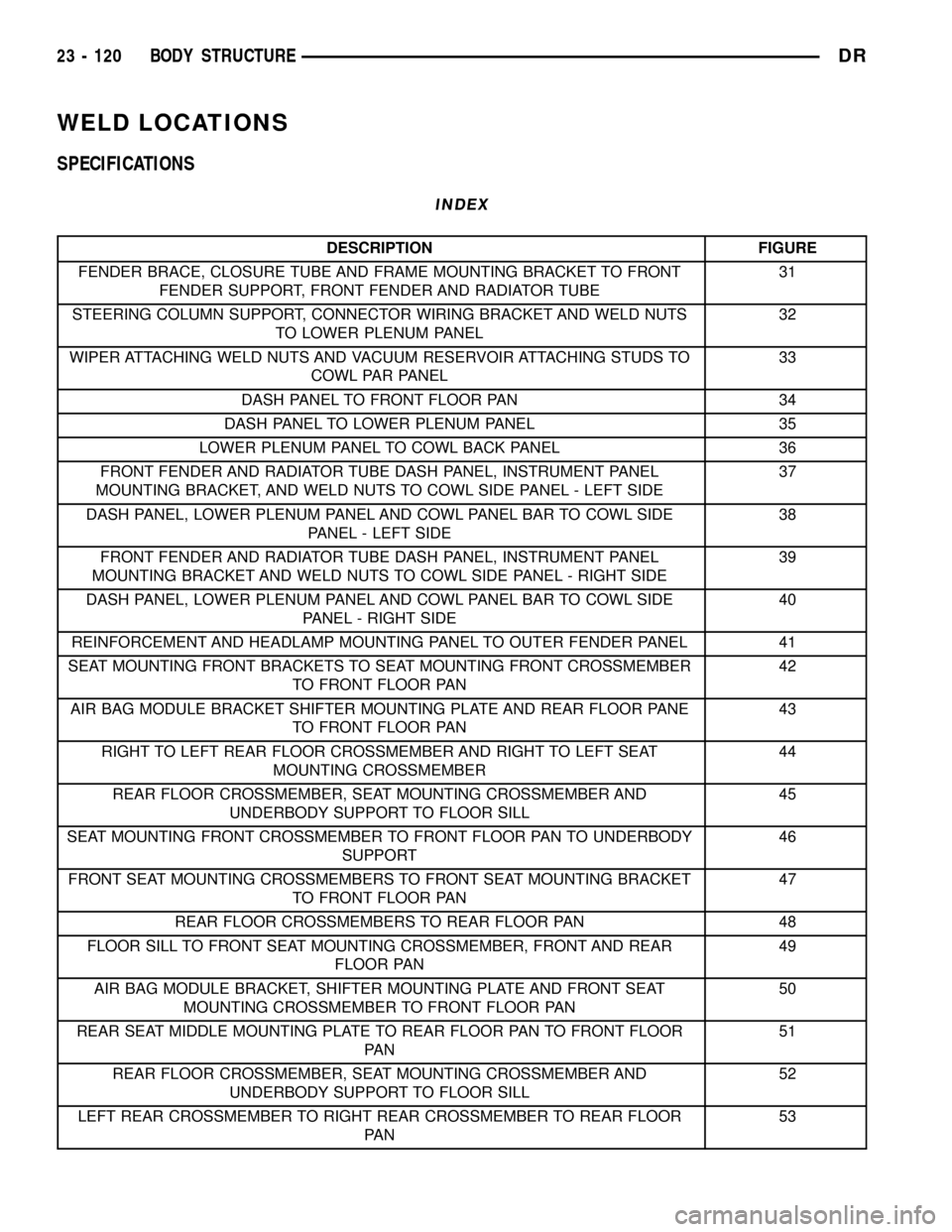

WELD LOCATIONS

SPECIFICATIONS

INDEX

DESCRIPTION FIGURE

FENDER BRACE, CLOSURE TUBE AND FRAME MOUNTING BRACKET TO FRONT

FENDER SUPPORT, FRONT FENDER AND RADIATOR TUBE31

STEERING COLUMN SUPPORT, CONNECTOR WIRING BRACKET AND WELD NUTS

TO LOWER PLENUM PANEL32

WIPER ATTACHING WELD NUTS AND VACUUM RESERVOIR ATTACHING STUDS TO

COWL PAR PANEL33

DASH PANEL TO FRONT FLOOR PAN 34

DASH PANEL TO LOWER PLENUM PANEL 35

LOWER PLENUM PANEL TO COWL BACK PANEL 36

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET, AND WELD NUTS TO COWL SIDE PANEL - LEFT SIDE37

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - LEFT SIDE38

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET AND WELD NUTS TO COWL SIDE PANEL - RIGHT SIDE39

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - RIGHT SIDE40

REINFORCEMENT AND HEADLAMP MOUNTING PANEL TO OUTER FENDER PANEL 41

SEAT MOUNTING FRONT BRACKETS TO SEAT MOUNTING FRONT CROSSMEMBER

TO FRONT FLOOR PAN42

AIR BAG MODULE BRACKET SHIFTER MOUNTING PLATE AND REAR FLOOR PANE

TO FRONT FLOOR PAN43

RIGHT TO LEFT REAR FLOOR CROSSMEMBER AND RIGHT TO LEFT SEAT

MOUNTING CROSSMEMBER44

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL45

SEAT MOUNTING FRONT CROSSMEMBER TO FRONT FLOOR PAN TO UNDERBODY

SUPPORT46

FRONT SEAT MOUNTING CROSSMEMBERS TO FRONT SEAT MOUNTING BRACKET

TO FRONT FLOOR PAN47

REAR FLOOR CROSSMEMBERS TO REAR FLOOR PAN 48

FLOOR SILL TO FRONT SEAT MOUNTING CROSSMEMBER, FRONT AND REAR

FLOOR PAN49

AIR BAG MODULE BRACKET, SHIFTER MOUNTING PLATE AND FRONT SEAT

MOUNTING CROSSMEMBER TO FRONT FLOOR PAN50

REAR SEAT MIDDLE MOUNTING PLATE TO REAR FLOOR PAN TO FRONT FLOOR

PA N51

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL52

LEFT REAR CROSSMEMBER TO RIGHT REAR CROSSMEMBER TO REAR FLOOR

PA N53

23 - 120 BODY STRUCTUREDR

Page 2488 of 2627

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING

SYSTEM REQUIREMENTS...............1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

OPERATION - HEATER AND AIR

CONDITIONER........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................3DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST..................6

SPECIFICATIONS - A/C SYSTEM............7

CONTROLS.............................9

DISTRIBUTION..........................26

PLUMBING.............................41

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating,

ventilation and air conditioning (HVAC) system, the

engine cooling system must be properly maintained.

The use of a bug screen is not recommended. Any

obstructions in front of the radiator or A/C condenser

will reduce the performance of the A/C and engine

cooling systems.

The engine cooling system includes the radiator,

thermostat, radiator hoses and the engine coolant

pump. Refer to Cooling for more information before

opening or attempting any service to the engine cool-

ing system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

A manually controlled single zone type heating-air

conditioning system or a manually controlled dual

zone type heating-air conditioning system is available

on this model.

All vehicles are equipped with a common heater,

ventilation and air conditioning (HVAC) housing (Fig.

1). The system combines air conditioning, heating,

and ventilating capabilities in a single unit housing

mounted within the passenger compartment under

the instrument panel. The HVAC housing includes:

²Blower motor

²Blower motor resistor block²Heater core

²Evaporator coil

²Blend door and actuator

²Defrost door and actuator

²Mode door and actuator

²Recirculation door and actuator

Based upon the system and mode selected, condi-

tioned air can exit the HVAC housing through one or

a combination of the three main housing outlets:

defrost, panel or floor. The defrost outlet is located on

the top of the housing, the panel outlet is located on

the face of the housing and the floor outlet is located

on the bottom of the housing. Once the conditioned

air exits the unit housing, it is further directed

through molded plastic ducts to the various outlets in

the vehicle interior. These outlets and their locations

are as follows:

²Defroster Outlet- A single large defroster out-

let is located in the center of the instrument panel

top cover, near the base of the windshield.

²Side Window Demister Outlets- There are

two side window demister outlets, one is located at

each outboard end of the instrument panel top cover,

near the belt line at the A-pillars.

²Panel Outlets- There are four panel outlets in

the instrument panel, one located near each outboard

end of the instrument panel facing the rear of the

vehicle and two located near the top of the instru-

ment panel center bezel.

²Front Floor Outlets- There are two front floor

outlets, one located above each side of the floor panel

center tunnel near the dash panel.

OPERATION - HEATER AND AIR CONDITIONER

The heating and air conditioning systems pulls

outside (ambient) air through the cowl opening at the

base of the windshield, then into the plenum cham-

DRHEATING & AIR CONDITIONING 24 - 1

Page 2493 of 2627

Condition Possible Causes Correction

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid, Suction, and Discharge Line in this

group. Inspect the refrigerant lines for kinks, tight

bends or improper routing. Correct the routing or

replace the refrigerant line, if required.

2. Restricted refrigerant flow

through the fixed orifice tube.2. See A/C Orifice Tube in this group. Replace

the liquid line, if required.

3. Restricted refrigerant flow

through the condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST

Review Safety Warnings and Cautions before per-

forming this procedure (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION).

Check the coolant level, drive belt tension, vacuum

line connections, radiator air flow and fan operation.

Start engine and allow to warm up to normal tem-

perature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap andturn it to the first safety stop. Allow pressure to

escape through the overflow tube. When the system

stabilizes, remove the cap completely.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two heater hoses. With the engine idling at normal

operating temperature, set the temperature control

to maximum heat, the mode control to the floor posi-

tion, and the blower in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged from the floor outlets. Com-

pare the test thermometer reading to the Tempera-

ture Reference chart.

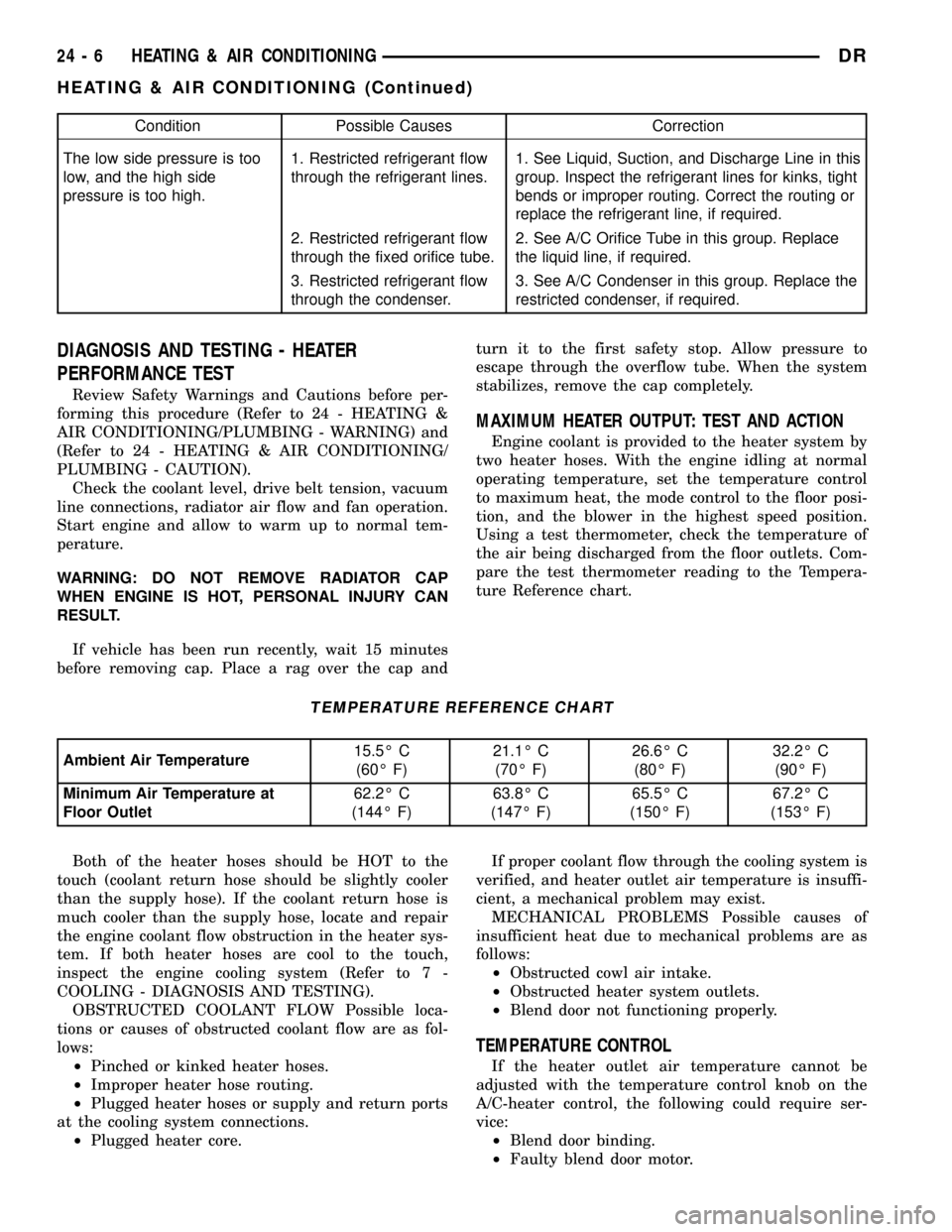

TEMPERATURE REFERENCE CHART

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

Both of the heater hoses should be HOT to the

touch (coolant return hose should be slightly cooler

than the supply hose). If the coolant return hose is

much cooler than the supply hose, locate and repair

the engine coolant flow obstruction in the heater sys-

tem. If both heater hoses are cool to the touch,

inspect the engine cooling system (Refer to 7 -

COOLING - DIAGNOSIS AND TESTING).

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow are as fol-

lows:

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²Plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is insuffi-

cient, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible causes of

insufficient heat due to mechanical problems are as

follows:

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend door not functioning properly.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

A/C-heater control, the following could require ser-

vice:

²Blend door binding.

²Faulty blend door motor.

24 - 6 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)