RADIATOR DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2503 of 2627

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the discharge

line. The transducer will change its internal resis-

tance in response to the pressures it monitors. The

Powertrain Control Module (PCM) or the Engine

Control Module (ECM) depending on engine applica-

tion, provides a five volt reference signal and a sen-

sor ground to the transducer, then monitors the

output voltage of the transducer on a sensor return

circuit to determine refrigerant pressure. The PCM/

ECM is programmed to respond to this and other

sensor inputs by controlling the operation of the air

conditioning compressor clutch and the radiator cool-

ing fan to help optimize air conditioning system per-

formance and to protect the system components from

damage. The A/C pressure transducer input to the

PCM/ECM will also prevent the air conditioning com-

pressor clutch from engaging when ambient temper-

atures are below about 10É C (50É F) due to the

pressure/temperature relationship of the refrigerant.

The Schrader-type valve in the discharge line fitting

permits the A/C pressure transducer to be removed

or installed without disturbing the refrigerant in the

system. The A/C pressure transducer is diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER

The A/C pressure transducer is tested using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. Before testing the A/C pressure

transducer, be certain that the transducer wire har-

ness connection is clean of corrosion and properly

connected. For the air conditioning system to operate,

an A/C pressure transducer voltage reading between

0.451 and 4.519 volts is required. Voltages outside

this range indicate a low or high refrigerant system

pressure condition to the Powertrain Control Module

(PCM) or Engine Control Module (ECM) depending

on engine application. The PCM/ECM is programmed

to respond to a low or high refrigerant system pres-

sure by suppressing operation of the compressor.

Refer to the A/C Pressure Transducer Voltage chart

for the possible conditions indicated by the trans-

ducer voltage reading.

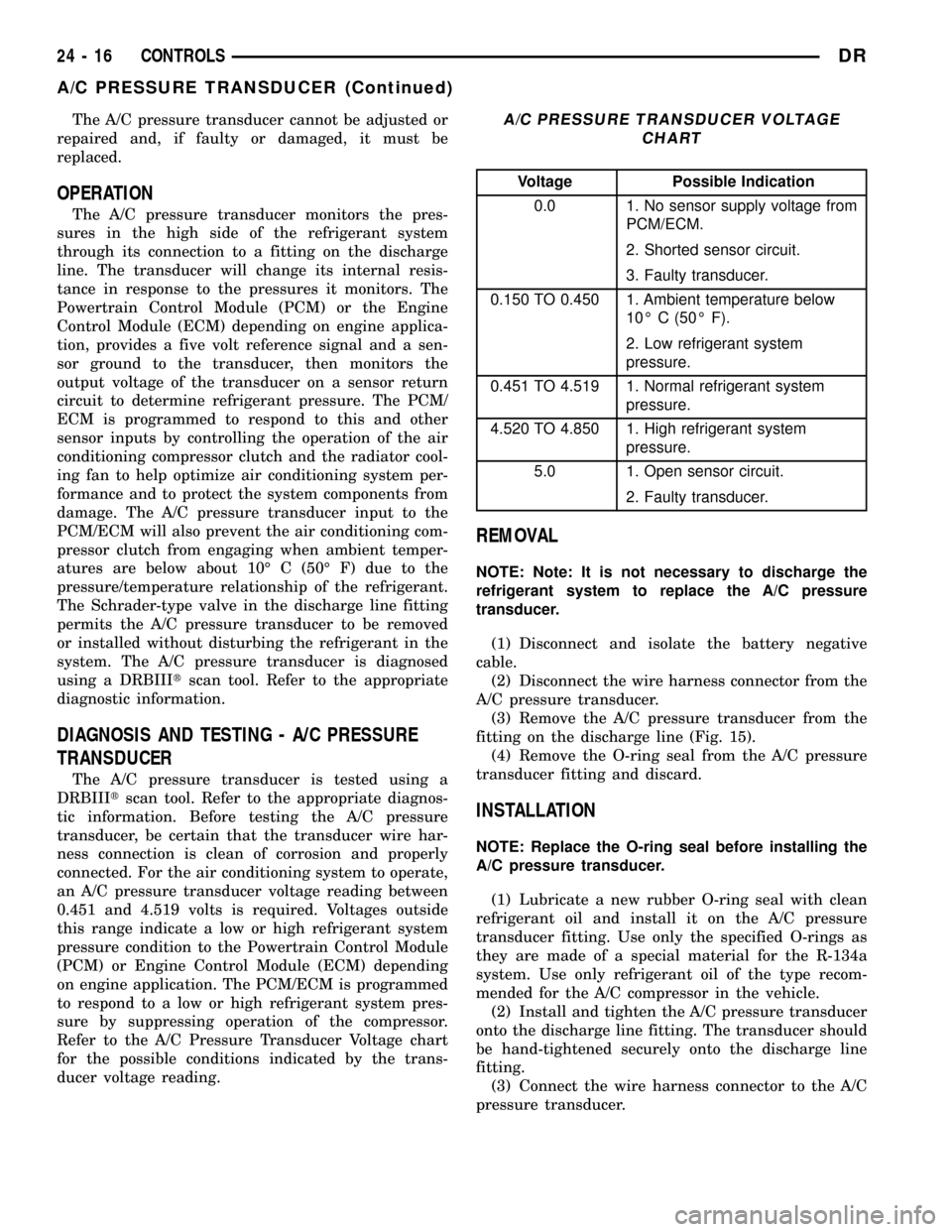

A/C PRESSURE TRANSDUCER VOLTAGE

CHART

Voltage Possible Indication

0.0 1. No sensor supply voltage from

PCM/ECM.

2. Shorted sensor circuit.

3. Faulty transducer.

0.150 TO 0.450 1. Ambient temperature below

10É C (50É F).

2. Low refrigerant system

pressure.

0.451 TO 4.519 1. Normal refrigerant system

pressure.

4.520 TO 4.850 1. High refrigerant system

pressure.

5.0 1. Open sensor circuit.

2. Faulty transducer.

REMOVAL

NOTE: Note: It is not necessary to discharge the

refrigerant system to replace the A/C pressure

transducer.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connector from the

A/C pressure transducer.

(3) Remove the A/C pressure transducer from the

fitting on the discharge line (Fig. 15).

(4) Remove the O-ring seal from the A/C pressure

transducer fitting and discard.

INSTALLATION

NOTE: Replace the O-ring seal before installing the

A/C pressure transducer.

(1) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the A/C pressure

transducer fitting. Use only the specified O-rings as

they are made of a special material for the R-134a

system. Use only refrigerant oil of the type recom-

mended for the A/C compressor in the vehicle.

(2) Install and tighten the A/C pressure transducer

onto the discharge line fitting. The transducer should

be hand-tightened securely onto the discharge line

fitting.

(3) Connect the wire harness connector to the A/C

pressure transducer.

24 - 16 CONTROLSDR

A/C PRESSURE TRANSDUCER (Continued)

Page 2529 of 2627

REFRIGERANT OIL

DESCRIPTION.........................68

OPERATION...........................69

STANDARD PROCEDURE - REFRIGERANT

OIL LEVEL...........................69

SERVICE PORT VALVE CORE

DESCRIPTION.........................70

REMOVAL - SERVICE PORT VALVE CORES . . 70

INSTALLATION.........................70

SUCTION LINE

DESCRIPTION.........................70REMOVAL

REMOVAL - 5.9L DIESEL ENGINE.........70

REMOVAL - 3.7L/4.7L AND 5.7L HEMI

ENGINE.............................71

INSTALLATION

INSTALLATION - 5.9L DIESEL ENGINE.....72

INSTALLATION - 3.7L/4.7L AND 5.7L HEMI

ENGINE.............................73

PLUMBING

DESCRIPTION - REFRIGERANT LINE

The refrigerant lines and hoses are used to carry

the refrigerant between the various air conditioning

system components. A barrier hose design with a

nylon tube, which is sandwiched between rubber lay-

ers, is used for the R-134a air conditioning system on

this vehicle. This nylon tube helps to further contain

the R-134a refrigerant, which has a smaller molecu-

lar structure than R-12 refrigerant. The ends of the

refrigerant hoses are made from lightweight alumi-

num or steel, and commonly use braze-less fittings.

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from an exhaust manifold.

OPERATION- REFRIGERANT LINES

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

The refrigerant lines and hoses are coupled with

other components of the HVAC system with either

O-rings or dual plane seals.

The refrigerant lines and hoses cannot be repaired

and, if faulty or damaged, they must be replaced.

WARNING

ENGINE COOLING SYSTEM

WARNING: THE ENGINE COOLING SYSTEM IS

DESIGNED TO DEVELOP INTERNAL PRESSURES

OF 97 TO 123 KILOPASCALS (14 TO 18 POUNDS

PER SQUARE INCH). DO NOT REMOVE OR

LOOSEN THE COOLANT PRESSURE CAP, CYLIN-

DER BLOCK DRAIN PLUGS, RADIATOR DRAIN,

RADIATOR HOSES, HEATER HOSES, OR HOSE

CLAMPS WHILE THE ENGINE COOLING SYSTEM IS

HOT AND UNDER PRESSURE. FAILURE TO

OBSERVE THIS WARNING CAN RESULT IN SERI-

OUS BURNS FROM THE HEATED ENGINE COOL-

ANT. ALLOW THE VEHICLE TO COOL FOR A

MINIMUM OF 15 MINUTES BEFORE OPENING THE

COOLING SYSTEM FOR SERVICE.

24 - 42 PLUMBINGDR

Page 2539 of 2627

(11) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Reconnect the battery negative cable.

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow next to the

engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When air passes through the condenser fins, the

high-pressure refrigerant gas within the A/C con-

denser gives up its heat. The refrigerant then con-

denses as it leaves the A/C condenser and becomes a

high-pressure liquid. The volume of air flowing over

the condenser fins is critical to the proper cooling

performance of the air conditioning system. There-fore, it is important that there are no objects placed

in front of the radiator grille openings at the front of

the vehicle or foreign material on the condenser fins

that might obstruct proper air flow. Also, any factory-

installed air seals or shrouds must be properly rein-

stalled following radiator or A/C condenser service.

The A/C condenser cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

REMOVAL - 3.7, 4.7 AND 5.7L ENGINES

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 10).

(4) Disconnect the discharge line from the con-

denser.

(5) Remove the seal from the discharge line fitting

and discard.

(6) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(7) Remove the plastic cover from the condenser

outlet stud.

(8) Remove the nut that secures the liquid line fit-

ting to the condenser outlet.

(9) Disconnect the liquid line from the condenser.

(10) Remove the seal from the liquid line fitting

and discard.

(11) Install plugs in, or tape over the liquid line

fitting and condenser outlet port.

(12) Disconnect the wire harness connector from

the condenser cooling fan motor (Fig. 11).

(13) Remove the two bolts that secure the con-

denser to the front upper crossmember.

(14) Remove the condenser/cooling fan assembly

from the vehicle.

(15) Place the condenser/cooling fan assembly on a

flat work area and remove the four screws that

secure the cooling fan to the condenser.

(16) Separate the cooling fan from the condenser.

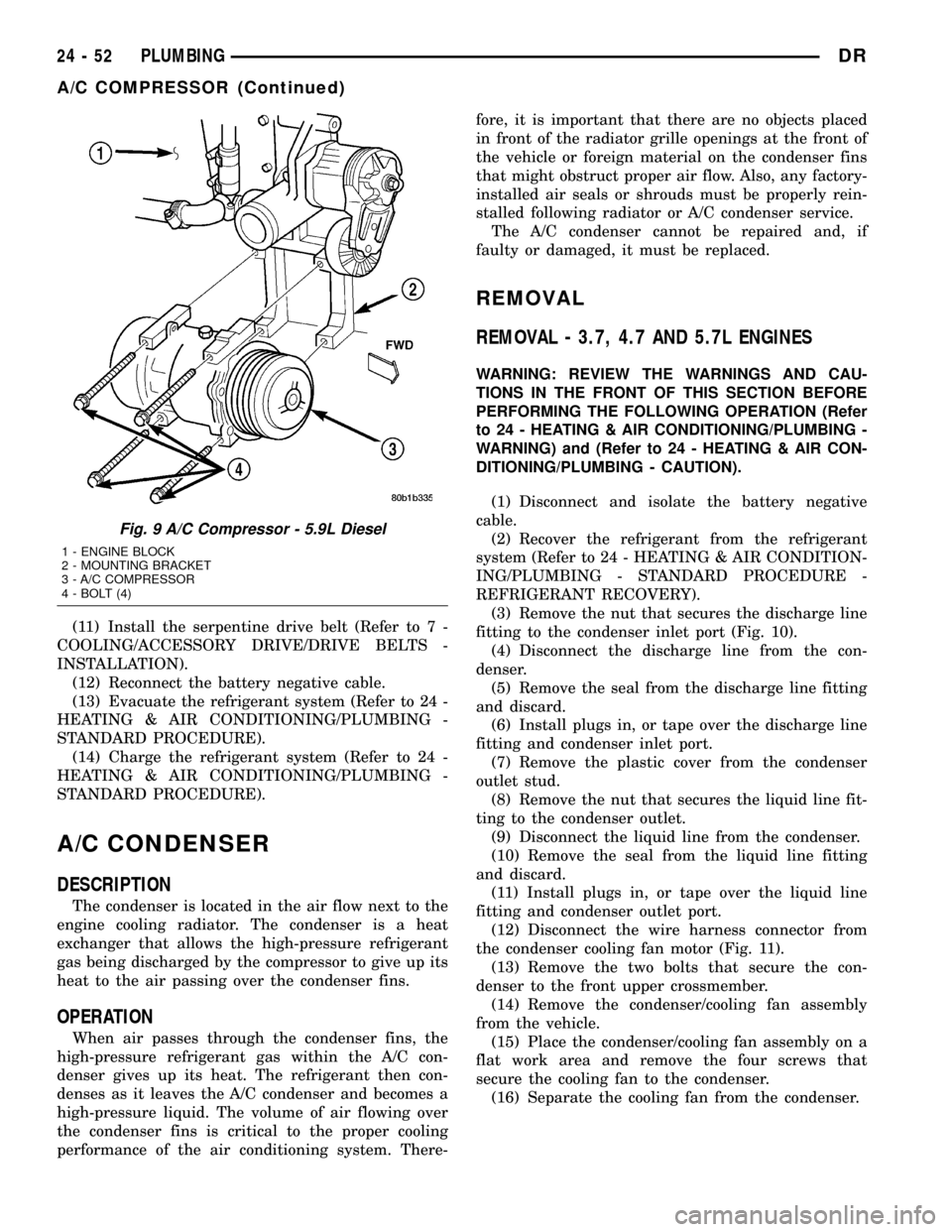

Fig. 9 A/C Compressor - 5.9L Diesel

1 - ENGINE BLOCK

2 - MOUNTING BRACKET

3 - A/C COMPRESSOR

4 - BOLT (4)

24 - 52 PLUMBINGDR

A/C COMPRESSOR (Continued)

Page 2592 of 2627

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF..........21-201,21-366

BUSHING - INSTALLATION.............19-19

BUSHING - INSTALLATION, TORSION

BAR CROSS MEMBER..................2-15

BUSHING - REMOVAL.................19-19

BUSHING - REMOVAL, TORSION BAR

CROSSMEMBER......................2-13

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING................21-440

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING................21-440

BUSHINGS - 2WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-15

BUSHINGS - 2WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - 4WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-14

BUSHINGS - 4WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - INSTALLATION.............2-43

BUSHINGS - REMOVAL.................2-43

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE........................23-11

BYPASS - DESCRIPTION, WATER PUMP . . . 7-59

BYPASS - OPERATION, WATER PUMP.....7-60

C205F - ADJUSTMENTS, FRONT AXLE.....3-32

C205F - DIAGNOSIS AND TESTING,

FRONT AXLE.........................3-27

C205F - INSTALLATION, FRONT AXLE.....3-31

C205F - REMOVAL, FRONT AXLE...........3-31

C205F - SPECIAL TOOLS, FRONT AXLE....3-40

C205F - SPECIFICATIONS, FRONT AXLE....3-39

CAB - INSTALLATION, QUAD......8O-36,8O-61

CAB - INSTALLATION, STANDARD . . 8O-35,8O-61

CAB - REMOVAL, QUAD..........8O-33,8O-60

CAB - REMOVAL, STANDARD......8O-32,8O-59

CAB BACK PANEL TRIM -

INSTALLATION, REAR.................23-69

CAB BACK PANEL TRIM - REMOVAL,

REAR..............................23-68

CAB CLEARANCE LAMP - INSTALLATION . . 8L-12

CAB CLEARANCE LAMP - REMOVAL.....8L-11

CABLE - ADJUSTMENTS, THROTTLE

VALVE ............................21-254

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, SPARK PLUG.....8I-21

CABLE - DESCRIPTION, THROTTLE

VALVE ............................21-253

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-4

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT..................21-210,21-368

CABLE - INSTALLATION................8P-5

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-15

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-38

CABLE - INSTALLATION, GEARSHIFT....21-211,

21-370

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-7

CABLE - INSTALLATION, LEFT REAR......5-39

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - INSTALLATION, RIGHT REAR.....5-38

CABLE - INSTALLATION, SPARK PLUG....8I-22

CABLE - INSTALLATION, THROTTLE

CONTROL.....................14-40,14-84

CABLE - OPERATION...................8P-4

CABLE - OPERATION, ANTENNA BODY

.....8A-4

CABLE - OPERATION, SPARK PLUG

.......8I-21

CABLE - REMOVAL

....................8P-4

CABLE - REMOVAL, ANTENNA BODY

......8A-6

CABLE - REMOVAL, CHECK

.............23-15

CABLE - REMOVAL, FRONT PARKING

BRAKE

..............................5-36

CABLE - REMOVAL, GEARSHIFT

. . 21-210,21-369

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA

...........................8A-7

CABLE - REMOVAL, LEFT REAR

..........5-38

CABLE - REMOVAL, REAR PARK BRAKE

. . . 5-37

CABLE - REMOVAL, RIGHT REAR

.........5-37

CABLE - REMOVAL, SPARK PLUG

........8I-22

CABLE - REMOVAL, THROTTLE

CONTROL

.....................14-38,14-83CABLE, ADJUSTMENTS - GEARSHIFT . . . 21-212,

21-370

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-4

CABLE ROUTING, 5.7L V-8 ENGINE -

FIRING ORDER........................8I-4

CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH RELEASE........23-47

CABLE/HANDLE ASSEMBLY - REMOVAL,

LATCH RELEASE.....................23-47

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-15

CABLES - INSTALLATION, BATTERY......8F-17

CABLES - OPERATION, BATTERY........8F-15

CABLES - REMOVAL, BATTERY..........8F-16

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-3

CALIPER ADAPTER MOUNT -

INSTALLATION, DISC BRAKE............5-22

CALIPERS - DESCRIPTION, DISC BRAKE . . . 5-16

CALIPERS - OPERATION, DISC BRAKE.....5-16

CAM BORE REPAIR - STANDARD

PROCEDURE........................9-267

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-4

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING CLUTCH....21-237

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING CLUTCH.....21-236

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING CLUTCH . . 21-236

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH...........................21-236

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING CLUTCH . . . 21-237

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING CLUTCH....21-236

CAMSHAFT - INSTALLATION.......9-206,9-271

CAMSHAFT - REMOVAL..........9-205,9-268

CAMSHAFT BEARINGS - INSTALLATION . . . 9-271

CAMSHAFT BEARINGS - REMOVAL......9-268

CAMSHAFT CORE HOLE PLUG -

INSTALLATION.......................9-206

CAMSHAFT CORE HOLE PLUG -

REMOVAL..........................9-205

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-71

CAMSHAFT POSITION SENSOR -

DESCRIPTION.........................8I-7

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-72

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................8I-10

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-71

CAMSHAFT POSITION SENSOR -

OPERATION..........................8I-7

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-72

CAMSHAFT POSITION SENSOR -

REMOVAL............................8I-9

CAMSHAFT(S) - DESCRIPTION.......9-25,9-35

CAMSHAFT(S) - INSTALLATION......9-27,9-36

CAMSHAFT(S) - LEFT - DESCRIPTION....9-114

CAMSHAFT(S) - LEFT - INSTALLATION....9-116

CAMSHAFT(S) - LEFT - REMOVAL.......9-115

CAMSHAFT(S) - REMOVAL..........9-25,9-35

CAMSHAFT(S) - RIGHT - DESCRIPTION . . . 9-119

CAMSHAFT(S) - RIGHT - INSTALLATION . . 9-120

CAMSHAFT(S) - RIGHT - REMOVAL......9-119

CANISTER - DESCRIPTION, VAPOR......25-22

CANISTER - INSTALLATION, VAPOR......25-22

CANISTER - OPERATION, VAPOR........25-22

CANISTER - REMOVAL, VAPOR..........25-22

CAP - DESCRIPTION, FUEL FILLER.......25-13

CAP - DESCRIPTION, RADIATOR

PRESSURE

..........................7-57

CAP - DIAGNOSIS AND TESTING,

RADIATOR

...........................7-58

CAP - OPERATION, FUEL FILLER

........25-13

CAP - OPERATION, RADIATOR

PRESSURE

..........................7-58

CAPACITIES, SPECIFICATIONS - FLUID

......0-5CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-21

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-21

CAPACITOR - OPERATION, IGNITION

COIL...............................8I-21

CAPACITOR - REMOVAL, IGNITION COIL . . . 8I-21

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR.....7-58

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, DOUBLE...................3-17

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, DOUBLE................3-16

CARGO BOX - INSTALLATION...........23-37

CARGO BOX - INSTALLATION, WITH.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - INSTALLATION, WITHOUT . . 8L-22,

8L-23,8L-24,8L-8,8L-9

CARGO BOX - REMOVAL...............23-37

CARGO BOX - REMOVAL, WITH....8L-22,8L-24,

8L-7,8L-9

CARGO BOX - REMOVAL, WITHOUT.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - TIE DOWN -

INSTALLATION.......................23-38

CARGO BOX - TIE DOWN - REMOVAL....23-38

CARGO LAMP INDICATOR -

DESCRIPTION.......................8J-20

CARGO LAMP INDICATOR - OPERATION . . 8J-20

CARPETS AND FLOOR MATS -

INSTALLATION.......................23-65

CARPETS AND FLOOR MATS - REMOVAL . . . 23-65

CASCADE OVERFLOW VALVE -

DESCRIPTION.......................14-66

CASCADE OVERFLOW VALVE -

OPERATION.........................14-66

CASE - DESCRIPTION, TRANSFER.........0-4

CASE - NV241 GENII - ASSEMBLY,

TRANSFER.........................21-428

CASE - NV241 GENII - CLEANING,

TRANSFER.........................21-426

CASE - NV241 GENII - DESCRIPTION,

TRANSFER.........................21-415

CASE - NV241 GENII - DIAGNOSIS AND

TESTING, TRANSFER.................21-416

CASE - NV241 GENII - DISASSEMBLY,

TRANSFER.........................21-417

CASE - NV241 GENII - INSPECTION,

TRANSFER.........................21-426

CASE - NV241 GENII - INSTALLATION,

TRANSFER.........................21-438

CASE - NV241 GENII - OPERATION,

TRANSFER.........................21-415

CASE - NV241 GENII - REMOVAL,

TRANSFER.........................21-417

CASE - NV243 - ASSEMBLY, TRANSFER . . 21-496

CASE - NV243 - CLEANING, TRANSFER . . 21-493

CASE - NV243 - DESCRIPTION,

TRANSFER.........................21-482

CASE - NV243 - DIAGNOSIS AND

TESTING, TRANSFER.................21-483

CASE - NV243 - DISASSEMBLY,

TRANSFER.........................21-484

CASE - NV243 - INSPECTION, TRANSFER . 21-493

CASE - NV243 - INSTALLATION,

TRANSFER.........................21-505

CASE - NV243 - OPERATION, TRANSFER . 21-483

CASE - NV243 - REMOVAL, TRANSFER . . 21-484

CASE - NV244 - DIAGNOSIS AND

TESTING, TRANSFER.................21-513

CASE - NV244 GENII - ASSEMBLY,

TRANSFER.........................21-525

CASE - NV244 GENII - CLEANING,

TRANSFER.........................21-523

CASE - NV244 GENII - DESCRIPTION,

TRANSFER.........................21-512

CASE - NV244 GENII - DISASSEMBLY,

TRANSFER.........................21-514

CASE - NV244 GENII - INSPECTION,

TRANSFER.........................21-523

CASE - NV244 GENII - INSTALLATION,

TRANSFER

.........................21-534

CASE - NV244 GENII - OPERATION,

TRANSFER

.........................21-513

CASE - NV244 GENII - REMOVAL,

TRANSFER

.........................21-514

CASE - NV271 - ASSEMBLY, TRANSFER

. . 21-461

CASE - NV271 - CLEANING, TRANSFER

. . 21-459

DRINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2595 of 2627

CONTROL MODULE - DESCRIPTION,

AIRBAG............................8O-11

CONTROL MODULE - DESCRIPTION,

FRONT...........................8W-97-5

CONTROL MODULE - DESCRIPTION,

FRONT..............................8E-5

CONTROL MODULE - DESCRIPTION,

TRANSFER CASE.....................8E-16

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-20

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT...................8W-97-5

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT......................8E-5

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-13

CONTROL MODULE - INSTALLATION,

ENGINE.............................8E-4

CONTROL MODULE - INSTALLATION,

FRONT...........................8W-97-6

CONTROL MODULE - INSTALLATION,

FRONT..............................8E-5

CONTROL MODULE - OPERATION,

AIRBAG............................8O-11

CONTROL MODULE - OPERATION,

FRONT...........................8W-97-5

CONTROL MODULE - OPERATION,

FRONT..............................8E-5

CONTROL MODULE - OPERATION,

TRANSFER CASE.....................8E-16

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-20

CONTROL MODULE - REMOVAL, AIRBAG . 8O-12

CONTROL MODULE - REMOVAL, ENGINE . . . 8E-4

CONTROL MODULE - REMOVAL, FRONT . 8W-97-6

CONTROL MODULE - REMOVAL, FRONT . . . 8E-5

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-28

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-29

CONTROL MOTOR - OPERATION, IDLE

AIR ...............................14-28

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-29

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-405

CONTROL RELAY - OPERATION,

TRANSMISSION.....................21-405

CONTROL SWITCH - DESCRIPTION,

LUMBAR...........................8N-17

CONTROL SWITCH - OPERATION,

LUMBAR...........................8N-18

CONTROL SWITCH - REMOVAL,

LUMBAR...........................8N-18

CONTROLLED VISCOUS FAN DRIVE -

DIAGNOSIS AND TESTING,

ELECTRONICALLY.....................7-52

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-3

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-3

CONTROLLER ANTILOCK BRAKE -

OPERATION..........................8E-3

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-3

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE ELECTRICAL.............21-262

CONVERTER - DESCRIPTION, CATALYTIC

. . . 11-6

CONVERTER - DESCRIPTION, TORQUE

. . 21-255,

21-399

CONVERTER - INSTALLATION, TORQUE

. . 21-260,

21-404

CONVERTER - OPERATION, CATALYTIC

....11-6

CONVERTER - OPERATION, TORQUE

....21-259,

21-403

CONVERTER - REMOVAL, TORQUE

.....21-260,

21-404

CONVERTER DRAINBACK VALVE -

DESCRIPTION, TORQUE

..............21-261

CONVERTER DRAINBACK VALVE -

OPERATION, TORQUE

................21-261

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE, TORQUE

......21-261

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING

......21-144,21-318

COOLANT - DESCRIPTION, ENGINE

.......7-31

COOLANT - DESCRIPTION, ENGINE

........0-3

COOLANT - DESCRIPTION, HOAT

.........7-32COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL..................7-19

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR...............7-54,7-56

COOLANT LEVEL CHECK - STANDARD

PROCEDURE.........................7-17

COOLANT RECOVERY CONTAINER- GAS

ENGINES - DESCRIPTION...............7-33

COOLANT RECOVERY CONTAINER- GAS

ENGINES - INSTALLATION...............7-33

COOLANT RECOVERY CONTAINER- GAS

ENGINES - OPERATION.................7-33

COOLANT RECOVERY CONTAINER- GAS

ENGINES - REMOVAL..................7-33

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-38

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-41

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-38

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-39

COOLANT THERMOSTAT - 3.7L/4.7L -

DESCRIPTION, ENGINE.................7-44

COOLANT THERMOSTAT - 3.7L/4.7L -

INSTALLATION, ENGINE................7-45

COOLANT THERMOSTAT - 3.7L/4.7L -

OPERATION, ENGINE...................7-44

COOLANT THERMOSTAT - 3.7L/4.7L -

REMOVAL, ENGINE....................7-45

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-46

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE..................7-47

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE...................7-46

COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE....................7-47

COOLANT THERMOSTAT - 8.0L -

DESCRIPTION, ENGINE.................7-48

COOLANT THERMOSTAT - 8.0L -

INSTALLATION, ENGINE................7-49

COOLANT THERMOSTAT - 8.0L -

OPERATION, ENGINE...................7-48

COOLANT THERMOSTAT - 8.0L -

REMOVAL, ENGINE....................7-49

COOLANT THERMOSTAT-5.7L -

DESCRIPTION, ENGINE.................7-41

COOLANT THERMOSTAT-5.7L -

INSTALLATION, ENGINE................7-43

COOLANT THERMOSTAT-5.7L -

OPERATION, ENGINE...................7-41

COOLANT THERMOSTAT-5.7L -

REMOVAL, ENGINE....................7-42

COOLER - 5.9L DIESEL - DESCRIPTION,

TRANS..............................7-68

COOLER - 5.9L DIESEL - OPERATION,

TRANS..............................7-69

COOLER - DESCRIPTION, TRANS.........7-67

COOLER - INSTALLATION, AIR TO OIL.....7-70

COOLER - INSTALLATION, FLUID........19-43

COOLER - INSTALLATION, RETURN

HOSE - GEAR TO................19-44,19-45

COOLER - INSTALLATION, RETURN

HOSE - RESERVOIR TO...........19-44,19-45

COOLER - INSTALLATION, TRANS........7-68

COOLER - INSTALLATION, WATER-TO-

AIR

................................7-70

COOLER - OPERATION, TRANS

...........7-67

COOLER - REMOVAL, AIR TO OIL

.........7-69

COOLER - REMOVAL, FLUID

............19-43

COOLER - REMOVAL, RETURN HOSE -

GEAR TO

......................19-44,19-45

COOLER - REMOVAL, RETURN HOSE -

RESERVOIR TO

.................19-44,19-45

COOLER - REMOVAL, TRANS

............7-68

COOLER - REMOVAL, WATER TO OIL

......7-69

COOLER AND PLUMBING - CLEANING,

CHARGE AIR

........................11-17

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR

............11-16

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR

........................11-17

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR

...........11-17

COOLER AND PLUMBING - OPERATION,

CHARGE AIR

........................11-16COOLER AND PLUMBING - REMOVAL,

CHARGE AIR........................11-17

COOLER SYSTEM - LEAKS - DIAGNOSIS

AND TESTING, CHARGE AIR............11-16

COOLING, SPECIAL TOOLS..............7-20

COOLING SYSTEM - ALL GAS ENGINES -

STANDARD PROCEDURE, DRAINING......7-17

COOLING SYSTEM - ALL GAS ENGINES -

STANDARD PROCEDURE, REFILLING......7-18

COOLING SYSTEM - OPERATION..........7-5

COOLING SYSTEM - TESTING FOR

LEAKS - DIAGNOSIS AND TESTING........7-5

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, DRAINING.....7-18

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, REFILLING.....7-19

COOLING SYSTEM CLEANING/REVERSE

FLUSHING - STANDARD PROCEDURE.....7-17

COOLING SYSTEM DIESEL ENGINE -

DIAGNOSIS AND TESTING...............7-7

COOLING SYSTEM FLOW - 5.9L DIESEL

- DESCRIPTION........................7-3

COOLING SYSTEM FLOW 3.7L/4.7L/5.7L

ENGINE - DESCRIPTION.................7-1

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION, ENGINE.................24-1

COOLING SYSTEM, WARNING - ENGINE . . 24-42

CORE - DESCRIPTION, HEATER.........24-63

CORE - DESCRIPTION, SERVICE PORT

VALVE .............................24-70

CORE - INSTALLATION, HEATER.........24-63

CORE - INSTALLATION, SERVICE PORT

VALVE .............................24-70

CORE - OPERATION, HEATER...........24-63

CORE - REMOVAL, HEATER............24-63

CORE HOLE PLUG - INSTALLATION,

CAMSHAFT.........................9-206

CORE HOLE PLUG - REMOVAL,

CAMSHAFT.........................9-205

CORE PLUGS - INSTALLATION..........9-131

CORE PLUGS - REMOVAL..............9-131

CORES - REMOVAL, SERVICE PORT

VALVE .............................24-70

COUPLER - DESCRIPTION,

REFRIGERANT LINE...................24-67

COUPLER - INSTALLATION,

REFRIGERANT LINE...................24-68

COUPLER - OPERATION, REFRIGERANT

LINE...............................24-67

COUPLER - REMOVAL, REFRIGERANT

LINE...............................24-68

COUPLING - INSTALLATION, UPPER

STEERING..........................19-13

COUPLING - REMOVAL, UPPER

STEERING..........................19-13

COVER - DESCRIPTION, STRUCTURAL . . . 9-145,

9-216,9-57

COVER - FRONT - INSTALLATION, SEAT

BACK CUSHION......................23-82

COVER - FRONT - INSTALLATION, SEAT

CUSHION...........................23-83

COVER - FRONT - REMOVAL, SEAT BACK

CUSHION...........................23-82

COVER - FRONT - REMOVAL, SEAT

CUSHION...........................23-83

COVER - INSTALLATION...............23-16

COVER - INSTALLATION, ACM

..........8O-10

COVER - INSTALLATION, CENTER SEAT

BACK INERTIA HINGE

.................23-77

COVER - INSTALLATION, CENTER SEAT

CUSHION

...........................23-79

COVER - INSTALLATION, CYLINDER

HEAD

..............................9-255

COVER - INSTALLATION, DIFFERENTIAL

....3-97

COVER - INSTALLATION, GEAR HOUSING

. 9-301

COVER - INSTALLATION, INSTRUMENT

PANEL TOP

.........................23-59

COVER - INSTALLATION, REAR DOOR

SILL TRIM

..........................23-71

COVER - INSTALLATION, SHIFT

. . . 21-129,21-87

COVER - INSTALLATION, STEERING

COLUMN OPENING

...................23-60

COVER - INSTALLATION, STRUCTURAL

. . . 9-145,

9-216,9-57

COVER - INSTALLATION, TIMING/CHAIN

. . 9-227

COVER - OPERATION, STRUCTURAL

.....9-145,

9-216,9-57

8 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2596 of 2627

COVER - REAR - INSTALLATION, SEAT

BACK CUSHION......................23-84

COVER - REAR - INSTALLATION, SEAT

CUSHION...........................23-84

COVER - REAR - REMOVAL, SEAT BACK

CUSHION...........................23-84

COVER - REAR - REMOVAL, SEAT

CUSHION...........................23-84

COVER - REMOVAL...................23-16

COVER - REMOVAL, ACM..............8O-10

COVER - REMOVAL, CENTER SEAT BACK

INERTIA HINGE......................23-77

COVER - REMOVAL, CENTER SEAT

CUSHION...........................23-79

COVER - REMOVAL, CYLINDER HEAD....9-255

COVER - REMOVAL, DIFFERENTIAL.......3-97

COVER - REMOVAL, GEAR HOUSING.....9-301

COVER - REMOVAL, INSTRUMENT

PANEL TOP.........................23-58

COVER - REMOVAL, REAR DOOR SILL

TRIM..............................23-71

COVER - REMOVAL, SHIFT.......21-129,21-87

COVER - REMOVAL, STEERING COLUMN

OPENING...........................23-60

COVER - REMOVAL, STRUCTURAL . 9-145,9-216,

9-57

COVER - REMOVAL, TIMING/CHAIN......9-227

COVER - REMOVAL, WHEEL............22-14

COVERING - INSTALLATION, UNDER

SEAT STORAGE BIN..................23-80

COVERING - REMOVAL, UNDER SEAT

STORAGE BIN.......................23-80

COVER(S) - DESCRIPTION, CYLINDER

HEAD..........................9-122,9-27

COVER(S) - INSTALLATION, CYLINDER

HEAD......................9-201,9-28,9-37

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN...................9-171,9-81

COVER(S) - REMOVAL, CYLINDER HEAD . 9-201,

9-28,9-37

COVER(S) - REMOVAL, TIMING BELT /

CHAIN.........................9-170,9-81

COWL GRILLE - INSTALLATION.........23-38

COWL GRILLE - REMOVAL.............23-38

COWL TRIM - INSTALLATION...........23-66

COWL TRIM - REMOVAL...............23-66

C-PILLAR LOWER TRIM - INSTALLATION . . 23-67

C-PILLAR LOWER TRIM - REMOVAL.....23-66

C-PILLAR UPPER TRIM - INSTALLATION . . 23-67

C-PILLAR UPPER TRIM - REMOVAL......23-67

CRANKCASE BREATHER - INSTALLATION . . 9-243

CRANKCASE BREATHER - REMOVAL.....9-242

CRANKSHAFT - DESCRIPTION......9-131,9-40

CRANKSHAFT - INSPECTION........9-132,9-41

CRANKSHAFT - INSTALLATION . 9-132,9-207,9-42

CRANKSHAFT - REMOVAL....9-131,9-206,9-40

CRANKSHAFT AND GEAR -

DESCRIPTION.......................9-273

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE, CONNECTING

ROD BEARING.......................9-272

CRANKSHAFT MAIN BEARING - FITTING

- STANDARD PROCEDURE........9-134,9-207

CRANKSHAFT MAIN BEARINGS -

INSPECTION...................9-135,9-208

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........9-136,9-208,9-275,9-46

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL............9-135,9-208,9-275,9-46

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........9-138,9-209,9-276,9-47

CRANKSHAFT OIL SEAL - REAR -

REMOVAL............9-137,9-209,9-276,9-47

CRANKSHAFT POSITION SENSOR -

DESCRIPTION..................14-23,14-72

CRANKSHAFT POSITION SENSOR -

INSTALLATION..................14-25,14-73

CRANKSHAFT POSITION SENSOR -

OPERATION....................14-23,14-72

CRANKSHAFT POSITION SENSOR -

REMOVAL

.....................14-24,14-73

CRANKSHAFT REAR OIL SEAL RETAINER

- INSTALLATION

................9-210,9-277

CRANKSHAFT REAR OIL SEAL RETAINER

- REMOVAL

....................9-209,9-277

CROSS MEMBER BUSHING -

INSTALLATION, TORSION BAR

...........2-15

CROSSHEADS - CLEANING

.............9-251CROSSHEADS - INSPECTION...........9-252

CROSSMEMBER - INSTALLATION, FRONT . 13-22

CROSSMEMBER - INSTALLATION,

TRANSMISSION......................13-24

CROSSMEMBER - INSTALLATION,

UPPER RADIATOR....................23-42

CROSSMEMBER - REMOVAL, FRONT.....13-22

CROSSMEMBER - REMOVAL,

TRANSMISSION......................13-24

CROSSMEMBER - REMOVAL, UPPER

RADIATOR..........................23-42

CROSSMEMBER BUSHING - REMOVAL,

TORSION BAR........................2-13

CRUISE INDICATOR - DESCRIPTION......8J-22

CRUISE INDICATOR - OPERATION.......8J-22

CUMMINS TURBO DIESEL -

MAINTENANCE SCHEDULES, 24-VALVE....0-12

CUP HOLDER - INSTALLATION..........23-51

CUP HOLDER - REMOVAL..............23-51

CURTAIN AIRBAG - DESCRIPTION, SIDE . . 8O-56

CURTAIN AIRBAG - INSTALLATION, SIDE . . 8O-58

CURTAIN AIRBAG - OPERATION, SIDE....8O-56

CURTAIN AIRBAG - REMOVAL, SIDE.....8O-57

CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-83

CUSHION / COVER - FRONT -

INSTALLATION, SEAT BACK............23-82

CUSHION / COVER - FRONT - REMOVAL,

SEAT ..............................23-83

CUSHION / COVER - FRONT - REMOVAL,

SEAT BACK.........................23-82

CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-84

CUSHION / COVER - REAR -

INSTALLATION, SEAT BACK............23-84

CUSHION / COVER - REAR - REMOVAL,

SEAT ..............................23-84

CUSHION / COVER - REAR - REMOVAL,

SEAT BACK.........................23-84

CUSHION - INSTALLATION, CENTER

SEAT ..............................23-79

CUSHION - REMOVAL, CENTER SEAT.....23-79

CUSHION COVER - INSTALLATION,

CENTER SEAT.......................23-79

CUSHION COVER - REMOVAL, CENTER

SEAT ..............................23-79

CUSHION FRAME - REAR -

INSTALLATION, SEAT.................23-85

CUSHION FRAME - REAR - REMOVAL,

SEAT ..............................23-85

CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-8

CV JOINT-INNER - INSTALLATION........3-25

CV JOINT-INNER - REMOVAL............3-25

CV JOINT-OUTER - INSTALLATION........3-23

CV JOINT-OUTER - REMOVAL............3-22

CYLINDER - DESCRIPTION, MASTER......5-24

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK.......19-11

CYLINDER - INSTALLATION, KEY........19-12

CYLINDER - INSTALLATION, LOAD

FLOOR SUPPORT....................23-72

CYLINDER - INSTALLATION, LOCK.......23-24

CYLINDER - INSTALLATION, SUPPORT....23-48

CYLINDER - OPERATION, MASTER........5-25

CYLINDER - REMOVAL, KEY............19-12

CYLINDER - REMOVAL, LOAD FLOOR

SUPPORT..........................23-72

CYLINDER - REMOVAL, LOCK...........23-24

CYLINDER - REMOVAL, SUPPORT.......23-48

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-26

CYLINDER BLOCK REFACING -

STANDARD PROCEDURE...............9-264

CYLINDER BORE - DE-GLAZE -

STANDARD PROCEDURE...............9-264

CYLINDER BORE HONING - STANDARD

PROCEDURE....................9-128,9-38

CYLINDER BORE REPAIR - STANDARD

PROCEDURE

........................9-265

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING

. 9-186,9-8,

9-93

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING

......9-186,9-8,9-93

CYLINDER COMPRESSION/LEAKAGE

TESTS - DIAGNOSIS AND TESTING

......9-239

CYLINDER HEAD - CLEANING

......9-200,9-251CYLINDER HEAD - DESCRIPTION . . . 9-107,9-249

CYLINDER HEAD - INSPECTION....9-200,9-252

CYLINDER HEAD - INSTALLATION.......9-200

CYLINDER HEAD - INSTALLATION, LEFT . . 9-112

CYLINDER HEAD - INSTALLATION,

RIGHT.............................9-113

CYLINDER HEAD - LEFT - INSTALLATION . . . 9-24

CYLINDER HEAD - LEFT - REMOVAL......9-22

CYLINDER HEAD - OPERATION..........9-199

CYLINDER HEAD - REMOVAL......9-200,9-249

CYLINDER HEAD - REMOVAL, LEFT......9-108

CYLINDER HEAD - REMOVAL, RIGHT.....9-110

CYLINDER HEAD - RIGHT -

INSTALLATION........................9-34

CYLINDER HEAD - RIGHT - REMOVAL.....9-33

CYLINDER HEAD COVER -

INSTALLATION.......................9-255

CYLINDER HEAD COVER - REMOVAL.....9-255

CYLINDER HEAD COVER(S) -

DESCRIPTION...................9-122,9-27

CYLINDER HEAD COVER(S) -

INSTALLATION...............9-201,9-28,9-37

CYLINDER HEAD COVER(S) - REMOVAL . . 9-201,

9-28,9-37

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING........................9-21

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING.............9-199

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER........5-25

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-2

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR . . 9-190,9-240,

9-9,9-94

DAMPER - INSPECTION, VIBRATION.....9-285

DAMPER - INSTALLATION..............19-36

DAMPER - INSTALLATION, VIBRATION . . . 9-144,

9-215,9-286,9-56

DAMPER - REMOVAL.................19-36

DAMPER - REMOVAL, VIBRATION . . 9-144,9-215,

9-285,9-55

DATA LINK CONNECTOR - DESCRIPTION . . . 8E-3

DATA LINK CONNECTOR - OPERATION.....8E-3

DATA PLATE - DESCRIPTION, ENGINE....9-248

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-11

DAY / NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-11

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-11

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-12

DEFINITION - DESCRIPTION, TRIP........25-4

DEFOGGER RELAY - DESCRIPTION,

REAR WINDOW.......................8G-2

DEFOGGER RELAY - INSTALLATION,

REAR WINDOW.......................8G-4

DEFOGGER RELAY - OPERATION, REAR

WINDOW............................8G-3

DEFOGGER RELAY - REMOVAL, REAR

WINDOW............................8G-3

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-4

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-4

DEFOGGER SYSTEM - DIAGNOSIS AND

TESTING, REAR WINDOW

..............8G-2

DEFROST DOOR - INSTALLATION

........24-31

DEFROST DOOR - REMOVAL

...........24-31

DEFROST DOOR ACTUATOR -

DESCRIPTION

.......................24-20

DEFROST DOOR ACTUATOR -

INSTALLATION

.......................24-21

DEFROST DOOR ACTUATOR -

OPERATION

.........................24-21

DEFROST DOOR ACTUATOR - REMOVAL

. . 24-21

DEFROSTER DUCT - INSTALLATION

......24-32

DEFROSTER DUCT - REMOVAL

..........24-32

DE-GLAZE - STANDARD PROCEDURE,

CYLINDER BORE

.....................9-264

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS

...............8M-4

DEMISTER DUCTS - INSTALLATION,

INSTRUMENT PANEL

..................24-37

DEMISTER DUCTS - REMOVAL,

INSTRUMENT PANEL

..................24-36

DRINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 2597 of 2627

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-7

DETECTION ASSY - DESCRIPTION,

NATURAL VAC LEAK..................25-23

DETECTION ASSY - INSTALLATION,

NATURAL VAC LEAK..................25-25

DETECTION ASSY - OPERATION,

NATURAL VAC LEAK..................25-23

DETECTION ASSY - REMOVAL, NATURAL

VAC LEAK..........................25-24

DETECTION PUMP - DESCRIPTION, LEAK . 25-13

DETECTION PUMP - INSTALLATION,

LEAK..............................25-16

DETECTION PUMP - OPERATION, LEAK . . . 25-14

DETECTION PUMP - REMOVAL, LEAK....25-16

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-1

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-5

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.................21-176,21-337

DIESEL - CLEANING, RADIATOR - 5.9L....7-56

DIESEL - CLEANING, RADIATOR FAN -

5.9L................................7-35

DIESEL - CLEANING, WATER PUMP -

5.9L................................7-62

DIESEL - DESCRIPTION.................14-62

DIESEL - DESCRIPTION, 5.9L............11-3

DIESEL - DESCRIPTION, BELT

TENSIONER - 5.9L.....................7-23

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-3

DIESEL - DESCRIPTION, ENGINE 5.9L....9-232

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-37

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-46

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-52

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-56

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-68

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-62

DIESEL - FUEL INJECTOR FIRING ORDER . 14-48

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-56

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-35

DIESEL - INSPECTION, TAILPIPE - 5.9L . . . 11-10

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-62

DIESEL - INSTALLATION................11-8

DIESEL - INSTALLATION...............14-62

DIESEL - INSTALLATION.....19-26,19-31,19-42

DIESEL - INSTALLATION, BELT

TENSIONER - 5.9L.....................7-24

DIESEL - INSTALLATION, DRIVE BELT -

5.9L

................................7-29

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L

........................7-38

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L

...........7-47

DIESEL - INSTALLATION, EXCEPT

........14-19

DIESEL - INSTALLATION, MUFFLER -

5.9L

...............................11-10

DIESEL - INSTALLATION, RADIATOR -

5.9L

................................7-57

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L

..............................7-36

DIESEL - INSTALLATION, TAILPIPE - 5.9L

. 11-11

DIESEL - INSTALLATION, WATER PUMP -

5.9L

................................7-62

DIESEL - MAINTENANCE SCHEDULES,

24-VALVE CUMMINS TURBO

.............0-12

DIESEL - OPERATION, BELT TENSIONER

- 5.9L

..............................7-23

DIESEL - OPERATION, ENGINE BLOCK

HEATER - 5.9L

........................7-38

DIESEL - OPERATION, ENGINE COOLANT

THERMOSTAT - 5.9L

...................7-46DIESEL - OPERATION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-52

DIESEL - OPERATION, RADIATOR - 5.9L . . . 7-56

DIESEL - OPERATION, TRANS COOLER -

5.9L................................7-69

DIESEL - OPERATION, WATER PUMP -

5.9L................................7-62

DIESEL - REMOVAL....................11-7

DIESEL - REMOVAL...................14-62

DIESEL - REMOVAL.........19-25,19-30,19-41

DIESEL - REMOVAL, BELT TENSIONER -

5.9L................................7-23

DIESEL - REMOVAL, DRIVE BELT - 5.9L....7-29

DIESEL - REMOVAL, ENGINE BLOCK

HEATER - 5.9L........................7-38

DIESEL - REMOVAL, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-47

DIESEL - REMOVAL, EXCEPT...........14-17

DIESEL - REMOVAL, MUFFLER - 5.9L.....11-10

DIESEL - REMOVAL, RADIATOR - 5.9L.....7-56

DIESEL - REMOVAL, RADIATOR FAN -

5.9L................................7-35

DIESEL - REMOVAL, TAILPIPE - 5.9L.....11-10

DIESEL - REMOVAL, WATER PUMP -

5.9L................................7-62

DIESEL - SPECIFICATIONS, 5.9L.........9-244

DIESEL - TORQUE, FUEL SYSTEM -

EXCEPT.............................14-3

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-1

DIESEL ENGINE - DIAGNOSIS AND

TESTING............................11-5

DIESEL ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-7

DIESEL ENGINE - INSTALLATION........8R-17

DIESEL ENGINE - INSTALLATION, 5.9L . . . 24-54,

24-58,24-72

DIESEL ENGINE - INSTALLATION,

EXCEPT............................8R-17

DIESEL ENGINE - REMOVAL............8R-16

DIESEL ENGINE - REMOVAL, 5.9L . . 24-53,24-56,

24-70

DIESEL ENGINE - REMOVAL, EXCEPT....8R-15

DIESEL ENGINE - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM 5.9L........................7-18

DIESEL ENGINE - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM 5.9L........................7-19

DIESEL ENGINE - TORQUE, FUEL

SYSTEM............................14-48

DIESEL ENGINE, SPECIAL TOOLS - 5.9L . . 9-246

DIESEL ENGINES - DESCRIPTION,

ENGINE OIL...........................0-2

DIESEL FUEL SYSTEM - DESCRIPTION . . . 14-45

DIESEL FUEL SYSTEM, SPECIAL TOOLS . . 14-49

DIESEL ONLY - ASSEMBLY, 5.9L..........7-70

DIESEL ONLY - DISASSEMBLY, 5.9L.......7-70

DIFFERENTIAL - ASSEMBLY . . . 3-129,3-156,3-47,

3-73,3-99

DIFFERENTIAL - DISASSEMBLY....3-128,3-155,

3-47,3-72,3-98

DIFFERENTIAL - INSTALLATION....3-130,3-157,

3-48,3-74,3-99

DIFFERENTIAL - REMOVAL

. . . 3-127,3-155,3-46,

3-72,3-97

DIFFERENTIAL CASE BEARINGS -

INSTALLATION

....3-106,3-134,3-161,3-48,3-75

DIFFERENTIAL CASE BEARINGS -

REMOVAL

........3-105,3-134,3-161,3-48,3-75

DIFFERENTIAL COVER - INSTALLATION

....3-97

DIFFERENTIAL COVER - REMOVAL

........3-97

DIFFERENTIAL TRAC-RITE - ASSEMBLY

. . 3-133,

3-161

DIFFERENTIAL TRAC-RITE - CLEANING

. . . 3-132,

3-160

DIFFERENTIAL TRAC-RITE -

DESCRIPTION

..................3-131,3-158

DIFFERENTIAL TRAC-RITE -

DISASSEMBLY

..................3-131,3-158

DIFFERENTIAL TRAC-RITE - INSPECTION

. 3-132,

3-160

DIFFERENTIAL TRAC-RITE - OPERATION

. . 3-131,

3-158

DIFFERENTIAL-TRAC-LOK - ASSEMBLY

. . . 3-103

DIFFERENTIAL-TRAC-LOK -

DESCRIPTION

.......................3-100DIFFERENTIAL-TRAC-LOK - DIAGNOSIS

AND TESTING.......................3-100

DIFFERENTIAL-TRAC-LOK -

DISASSEMBLY.......................3-101

DIFFERENTIAL-TRAC-LOK - OPERATION . . . 3-100

DIMENSIONS - SPECIFICATIONS, BODY

OPENING...........................23-99

DIMENSIONS - SPECIFICATIONS, FRAME . . 13-16

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DIODE REPLACEMENT - STANDARD

PROCEDURE........................24-45

DISC - INSTALLATION, CLUTCH...........6-5

DISC - REMOVAL, CLUTCH...............6-5

DISC BRAKE CALIPER ADAPTER MOUNT

- INSTALLATION......................5-22

DISC BRAKE CALIPERS - DESCRIPTION....5-16

DISC BRAKE CALIPERS - OPERATION.....5-16

DISC BRAKE ROTOR, DIAGNOSIS AND

TESTING............................5-32

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - DESCRIPTION, A/C....24-56

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-1

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION DUCT - INSTALLATION,

FLOOR.............................24-34

DISTRIBUTION DUCT - REMOVAL,

FLOOR.............................24-33

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER...................8W-97-2

DOME LAMP - DESCRIPTION...........8L-26

DOME LAMP - INSTALLATION..........8L-26

DOME LAMP - OPERATION.............8L-26

DOME LAMP - REMOVAL..............8L-26

DOOR - INSTALLATION...........23-18,23-28

DOOR - INSTALLATION, BLEND.........24-27

DOOR - INSTALLATION, DEFROST.......24-31

DOOR - INSTALLATION, FUEL FILL.......23-39

DOOR - INSTALLATION, MODE..........24-38

DOOR - INSTALLATION, RECIRCULATION . . 24-40

DOOR - REMOVAL...............23-18,23-28

DOOR - REMOVAL, BLEND.............24-27

DOOR - REMOVAL, DEFROST...........24-31

DOOR - REMOVAL, FUEL FILL..........23-39

DOOR - REMOVAL, MODE..............24-38

DOOR - REMOVAL, RECIRCULATION.....24-39

DOOR ACTUATOR - DESCRIPTION,

BLEND.............................24-17

DOOR ACTUATOR - DESCRIPTION,

DEFROST...........................24-20

DOOR ACTUATOR - DESCRIPTION,

MODE.............................24-23

DOOR ACTUATOR - DESCRIPTION,

RECIRCULATION.....................24-24

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-18

DOOR ACTUATOR - INSTALLATION,

DEFROST...........................24-21

DOOR ACTUATOR - INSTALLATION,

MODE.............................24-23

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-25

DOOR ACTUATOR - OPERATION, BLEND . . 24-17

DOOR ACTUATOR - OPERATION,

DEFROST...........................24-21

DOOR ACTUATOR - OPERATION, MODE . . . 24-23

DOOR ACTUATOR - OPERATION,

RECIRCULATION

.....................24-24

DOOR ACTUATOR - REMOVAL, BLEND

....24-17

DOOR ACTUATOR - REMOVAL, DEFROST

. . 24-21

DOOR ACTUATOR - REMOVAL, MODE

....24-23

DOOR ACTUATOR - REMOVAL,

RECIRCULATION

.....................24-24

DOOR AJAR INDICATOR - DESCRIPTION

. . 8J-23

DOOR AJAR INDICATOR - OPERATION

....8J-23

DOOR AJAR SWITCH - DESCRIPTION

....8L-27

DOOR AJAR SWITCH - OPERATION

......8L-27

DOOR GLASS - INSTALLATION

.....23-20,23-30

DOOR GLASS - REMOVAL

........23-20,23-30

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT

................23-92

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR

.................23-93

10 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2599 of 2627

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL...................7-39

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - DESCRIPTION...............7-44

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - INSTALLATION..............7-45

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - OPERATION.................7-44

ENGINE COOLANT THERMOSTAT -

3.7L/4.7L - REMOVAL..................7-45

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION................7-46

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION................7-47

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION..................7-46

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL....................7-47

ENGINE COOLANT THERMOSTAT - 8.0L -

DESCRIPTION........................7-48

ENGINE COOLANT THERMOSTAT - 8.0L -

INSTALLATION........................7-49

ENGINE COOLANT THERMOSTAT - 8.0L -

OPERATION..........................7-48

ENGINE COOLANT THERMOSTAT - 8.0L -

REMOVAL...........................7-49

ENGINE COOLANT THERMOSTAT-5.7L -

DESCRIPTION........................7-41

ENGINE COOLANT THERMOSTAT-5.7L -

INSTALLATION........................7-43

ENGINE COOLANT THERMOSTAT-5.7L -

OPERATION..........................7-41

ENGINE COOLANT THERMOSTAT-5.7L -

REMOVAL.............................7-42

ENGINE COOLING SYSTEM

REQUIREMENTS - DESCRIPTION.........24-1

ENGINE COOLING SYSTEM, WARNING....24-42

ENGINE DATA PLATE - DESCRIPTION.....9-248

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING......9-183,9-4,9-94

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING..........9-187,9-7

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING . . . 9-185,9-188,9-233,

9-6,9-92

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING......9-183,9-4,9-90

ENGINE FIRING ORDER, 3.7L V-6.........8I-4

ENGINE FIRING ORDER, 4.7L V-8.........8I-4

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE.........................9-10

ENGINE OIL - DIESEL ENGINES -

DESCRIPTION.........................0-2

ENGINE OIL AND LUBRICANTS -

DESCRIPTION.........................0-1

ENGINE OIL LEAK - DIAGNOSIS AND

TESTING..................9-152,9-220,9-64

ENGINE OIL LEVEL - STANDARD

PROCEDURE........................9-292

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING.......................9-289

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING, CHECKING.....9-152,9-220,9-65

ENGINE OIL SERVICE - STANDARD

PROCEDURE..........9-153,9-222,9-292,9-71

ENGINE, SPECIAL TOOLS - 4.7L.........9-103

ENGINE, SPECIAL TOOLS - 5.7L.........9-196

ENGINE, SPECIAL TOOLS - 5.9L DIESEL . . 9-246

ENGINE, SPECIFICATIONS - 5.7L........9-192

ENGINE TEMPERATURE GAUGE -

DESCRIPTION.......................8J-24

ENGINE TEMPERATURE GAUGE -

OPERATION.........................8J-24

ENGINE TIMING - VERIFICATION -

STANDARD PROCEDURE...............9-167

ENGINES - CLEANING, RADIATOR FAN -

GAS................................7-34

ENGINES - DESCRIPTION, COOLANT

RECOVERY CONTAINER- GAS

............7-33

ENGINES - DESCRIPTION, ENGINE OIL -

DIESEL

..............................0-2

ENGINES - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH-GAS

.................7-50

ENGINES - INSPECTION, RADIATOR FAN

- GAS

...............................7-34

ENGINES - INSTALLATION, 3.7, 4.7 AND

5.7L

..........................24-53,24-55ENGINES - INSTALLATION, COOLANT

RECOVERY CONTAINER- GAS............7-33

ENGINES - INSTALLATION, RADIATOR

FAN - GAS...........................7-34

ENGINES - OPERATION, COOLANT

RECOVERY CONTAINER- GAS............7-33

ENGINES - OPERATION, FAN DRIVE

VISCOUS CLUTCH-GAS.................7-50

ENGINES - REMOVAL, 3.7, 4.7 AND 5.7L . 24-52,

24-55

ENGINES - REMOVAL, COOLANT

RECOVERY CONTAINER- GAS............7-33

ENGINES - REMOVAL, RADIATOR FAN -

GAS................................7-33

ENGINES - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM - ALL

GAS................................7-17

ENGINES - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM - ALL

GAS................................7-18

ENHANCED SEATBELT REMINDER

PROGRAMMING - STANDARD

PROCEDURE........................8J-35

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS....................8N-7

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-7

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS....................8N-8

ENTRY MODULE - OPERATION, REMOTE

KEYLESS............................8N-7

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS............................8N-7

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS..............8N-8

ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE KEYLESS......8N-9

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-46

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-12

ETC INDICATOR - DESCRIPTION.........8J-25

ETC INDICATOR - OPERATION..........8J-25

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-47

EVAP SYSTEM - DESCRIPTION..........25-10

EVAP SYSTEM - TORQUE..............25-11

EVAPORATOR - DESCRIPTION, A/C.......24-59

EVAPORATOR - INSTALLATION, A/C......24-60

EVAPORATOR - OPERATION, A/C........24-59

EVAPORATOR - REMOVAL, A/C..........24-60

EVAPORATOR TEMPERATURE SENSOR -

DESCRIPTION.......................24-22

EVAPORATOR TEMPERATURE SENSOR -

INSTALLATION.......................24-22

EVAPORATOR TEMPERATURE SENSOR -

OPERATION.........................24-22

EVAPORATOR TEMPERATURE SENSOR -

REMOVAL..........................24-22

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-12

EVAP/PURGE SOLENOID - INSTALLATION . 25-12

EVAP/PURGE SOLENOID - OPERATION....25-12

EVAP/PURGE SOLENOID - REMOVAL.....25-12

EXHAUST MANIFOLD - CLEANING . . 9-163,9-226,

9-298

EXHAUST MANIFOLD - DESCRIPTION....9-161,

9-226,9-74

EXHAUST MANIFOLD - INSPECTION.....9-163,

9-227,9-298

EXHAUST MANIFOLD - INSTALLATION . . . 9-164,

9-227,9-298,9-74

EXHAUST MANIFOLD - OPERATION......9-226

EXHAUST MANIFOLD - REMOVAL . . 9-161,9-226,

9-298,9-74

EXHAUST PIPE - INSPECTION.......11-7,11-8

EXTENSION HOUSING BUSHING AND

SEAL - INSTALLATION................21-440

EXTENSION HOUSING BUSHING AND

SEAL - REMOVAL

...................21-440

EXTENSION HOUSING SEAL -

INSTALLATION

. . . 21-128,21-201,21-507,21-536,

21-85

EXTENSION HOUSING SEAL - REMOVAL

. 21-128,

21-201,21-507,21-536,21-85

EXTENSION HOUSING SEAL AND DUST

BOOT - INSTALLATION

.........21-476,21-571

EXTENSION HOUSING SEAL AND DUST

BOOT - REMOVAL

.............21-476,21-571EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-3

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR HANDLE - INSTALLATION.....23-21,

23-30

EXTERIOR HANDLE - REMOVAL....23-20,23-30

EXTERIOR LAMPS, SPECIFICATIONS......8L-7

EXTERIOR NAME PLATES -

INSTALLATION.......................23-38

EXTERIOR NAME PLATES - REMOVAL....23-38

FAILURE - DIAGNOSIS AND TESTING,

CYLINDER HEAD GASKET..............9-199

FAN - 5.9L DIESEL - CLEANING,

RADIATOR...........................7-35

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR...........................7-35

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR...........................7-36

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR...........................7-35

FAN - GAS ENGINES - CLEANING,

RADIATOR...........................7-34

FAN - GAS ENGINES - INSPECTION,

RADIATOR...........................7-34

FAN - GAS ENGINES - INSTALLATION,

RADIATOR...........................7-34

FAN - GAS ENGINES - REMOVAL,

RADIATOR...........................7-33

FAN DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICALLY CONTROLLED

VISCOUS............................7-52

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-50

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-52

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-52

FAN DRIVE VISCOUS CLUTCH-GAS

ENGINES - DESCRIPTION...............7-50

FAN DRIVE VISCOUS CLUTCH-GAS

ENGINES - OPERATION.................7-50

FASCIA - INSTALLATION, FRONT.........13-3

FASCIA - REMOVAL, FRONT.............13-2

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-5

FASTENER USAGE - DESCRIPTION......Intro.-8

FENDER - INSTALLATION, FRONT........23-39

FENDER - INSTALLATION, REAR.........23-44

FENDER - REMOVAL, FRONT...........23-39

FENDER - REMOVAL, REAR............23-44

FENDER MARKER LAMP - INSTALLATION . 8L-18

FENDER MARKER LAMP - REMOVAL.....8L-17

FENDER RAIL REPAIR - STANDARD

PROCEDURE, HYDROFORM............13-11

FILL - STANDARD PROCEDURE,

TRANSMISSION...............21-204,21-368

FILL DOOR - INSTALLATION, FUEL.......23-39

FILL DOOR - REMOVAL, FUEL..........23-39

FILLER CAP - DESCRIPTION, FUEL.......25-13

FILLER CAP - OPERATION, FUEL........25-13

FILTER - INSTALLATION, INLET..........14-20

FILTER - INSTALLATION, OIL . 9-155,9-223,9-293,

9-70

FILTER - REMOVAL, INLET.............14-20

FILTER - REMOVAL, OIL . 9-154,9-223,9-293,9-70

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-47

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-50

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-50

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-50

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-50

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID

...........21-203,21-367

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL

...................14-5

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL

.....................14-6

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION

............23-74

FINISH - DESCRIPTION, BASECOAT/

CLEARCOAT

.........................23-73

12 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2600 of 2627

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-48

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING...........9-129

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-134,9-207

FITTING - STANDARD PROCEDURE,

PISTON...................9-139,9-211,9-51

FITTING - STANDARD PROCEDURE,

PISTON RING.........9-142,9-213,9-284,9-53

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING............9-49

FITTING, STANDARD PROCEDURE -

MAIN BEARING.......................9-44

FITTINGS - STANDARD PROCEDURE,

HANDLING TUBING...................24-45

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT......................14-8

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED....................5-10

FLARING - STANDARD PROCEDURE, ISO . . . 5-11

FLEX PLATE - INSTALLATION . . 9-138,9-210,9-48

FLEX PLATE - REMOVAL.......9-138,9-210,9-48

FLOOR - INSTALLATION, LOAD..........23-72

FLOOR - REMOVAL, LOAD.............23-71

FLOOR CONSOLE - INSTALLATION.......23-67

FLOOR CONSOLE - REMOVAL...........23-67

FLOOR DISTRIBUTION DUCT -

INSTALLATION.......................24-34

FLOOR DISTRIBUTION DUCT - REMOVAL . 24-33

FLOOR MATS - INSTALLATION, CARPETS . 23-65

FLOOR MATS - REMOVAL, CARPETS.....23-65

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-62

FLOOR SHIFT BOOT - REMOVAL, 4WD....23-62

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-72

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-72

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-3

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-54,7-56

FLOW 3.7L/4.7L/5.7L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-43

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT............21-201,21-366

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE........21-203,21-367

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING................21-202,21-366

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-23

FLUID COOLER - INSTALLATION.........19-43

FLUID COOLER - REMOVAL............19-43

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-441,21-476,21-507,21-537,

21-571

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-44

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-44

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

.........21-144,21-318

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-201,

21-366

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE

..............................5-23FLUID LEVEL CHECK - STANDARD

PROCEDURE.................21-202,21-366

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-43

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER...........................8R-10

FLUID RESERVOIR - INSTALLATION.......5-24

FLUID RESERVOIR - REMOVAL..........5-23

FLUID, SPECIFICATIONS - BRAKE.........5-23

FLUSH - SPECIFICATIONS, GAP.........23-95

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-40

FLYWHEEL - ASSEMBLY................6-11

FLYWHEEL - DIAGNOSIS AND TESTING....6-10

FLYWHEEL - DISASSEMBLY.............6-11

FLYWHEEL - INSTALLATION.............6-11

FLYWHEEL - REMOVAL.................6-11

FOG LAMP - INSTALLATION............8L-12

FOG LAMP - REMOVAL................8L-12

FOG LAMP RELAY - DESCRIPTION.......8L-12

FOG LAMP RELAY - INSTALLATION........8L-13

FOG LAMP RELAY - OPERATION.........8L-13

FOG LAMP RELAY - REMOVAL..........8L-13

FOOTMANS LOOP BRACKETS -

INSTALLATION, SEAT BACK REAR.......23-85

FOOTMANS LOOP BRACKETS -

REMOVAL, SEAT BACK REAR...........23-85

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE . . 9-239,9-9,

9-94

FRAME - INSTALLATION, GRILLE........23-40

FRAME - REAR - INSTALLATION, SEAT

CUSHION...........................23-85

FRAME - REAR - REMOVAL, SEAT

CUSHION...........................23-85

FRAME - REMOVAL, GRILLE............23-40

FRAME DIMENSIONS - SPECIFICATIONS . . 13-16

FRAME H-SECTION REPLACEMENT -

STANDARD PROCEDURE, REAR.........13-13

FRAME RAIL TIP REPLACEMENT -

STANDARD PROCEDURE, LIGHT DUTY

FRONT..............................13-4

FREE MODULE - INSTALLATION, HANDS . . . 8T-2

FREE MODULE - REMOVAL, HANDS.......8T-2

FRONT - INSTALLATION....5-16,5-21,5-22,5-34

FRONT - INSTALLATION...............22-14

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL.............9-136,9-208,9-275,9-46

FRONT - INSTALLATION, PROPELLER

SHAFT - HD...........................3-7

FRONT - INSTALLATION, PROPELLER

SHAFT- LD............................3-7

FRONT - INSTALLATION, SEAT..........23-81

FRONT - INSTALLATION, SEAT BACK

CUSHION / COVER...................23-82

FRONT - INSTALLATION, SEAT CUSHION

/ COVER............................23-83

FRONT - REMOVAL........5-13,5-17,5-21,5-33

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL................9-135,9-208,9-275,9-46

FRONT - REMOVAL, PROPELLER SHAFT

- HD ................................3-7

FRONT - REMOVAL, PROPELLER SHAFT-

LD ..................................3-6

FRONT - REMOVAL, SEAT..............23-81

FRONT - REMOVAL, SEAT BACK

CUSHION / COVER...................23-82

FRONT - REMOVAL, SEAT CUSHION /

COVER.............................23-83

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-2

FRONT AXLE - 9 1/4 AA -

ADJUSTMENTS

.......................3-59

FRONT AXLE - 9 1/4 AA - DIAGNOSIS

AND TESTING

........................3-54

FRONT AXLE - 9 1/4 AA - INSTALLATION

. . . 3-58

FRONT AXLE - 9 1/4 AA - REMOVAL

......3-57

FRONT AXLE - 9 1/4 AA - SPECIAL

TOOLS

..............................3-64FRONT AXLE - 9 1/4 AA -

SPECIFICATIONS......................3-63

FRONT AXLE - C205F - ADJUSTMENTS....3-32

FRONT AXLE - C205F - DIAGNOSIS AND

TESTING............................3-27

FRONT AXLE - C205F - INSTALLATION.....3-31

FRONT AXLE - C205F - REMOVAL........3-31

FRONT AXLE - C205F - SPECIAL TOOLS . . . 3-40

FRONT AXLE - C205F - SPECIFICATIONS . . . 3-39

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT.....................21-216

FRONT BEARING - REMOVAL, OUTPUT

SHAFT............................21-216

FRONT BRAKE HOSE - INSTALLATION.....5-13

FRONT BUMPER - INSTALLATION.........13-2

FRONT BUMPER - REMOVAL............13-2

FRONT CENTER SEAT BELT -

INSTALLATION......................8O-31

FRONT CENTER SEAT BELT - REMOVAL . . 8O-30

FRONT CENTER SEAT BELT &

RETRACTOR - INSTALLATION...........8O-29

FRONT CENTER SEAT BELT &

RETRACTOR - REMOVAL..............8O-29

FRONT CLUTCH - ASSEMBLY..........21-207

FRONT CLUTCH - DESCRIPTION........21-205

FRONT CLUTCH - DISASSEMBLY.......21-205

FRONT CLUTCH - INSPECTION.........21-206

FRONT CLUTCH - OPERATION.........21-205

FRONT CONTROL MODULE -

DESCRIPTION.....................8W-97-5

FRONT CONTROL MODULE -

DESCRIPTION........................8E-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING.....................8W-97-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING........................8E-5

FRONT CONTROL MODULE -

INSTALLATION....................8W-97-6

FRONT CONTROL MODULE -

INSTALLATION........................8E-5

FRONT CONTROL MODULE - OPERATION . 8W-97-5

FRONT CONTROL MODULE - OPERATION . . 8E-5

FRONT CONTROL MODULE - REMOVAL . 8W-97-6

FRONT CONTROL MODULE - REMOVAL....8E-5

FRONT CROSSMEMBER - INSTALLATION . . 13-22

FRONT CROSSMEMBER - REMOVAL.....13-22

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-92

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-92

FRONT DOOR INNER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR INNER BELT MOLDING -

REMOVAL..........................23-93

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR OUTER BELT MOLDING -

REMOVAL..........................23-92

FRONT FASCIA - INSTALLATION..........13-3

FRONT FASCIA - REMOVAL..............13-2

FRONT FENDER - INSTALLATION........23-39

FRONT FENDER - REMOVAL............23-39

FRONT FRAME RAIL TIP REPLACEMENT

- STANDARD PROCEDURE, LIGHT

DUTY...............................13-4

FRONT HOSE - REMOVAL...............5-12

FRONT MOUNT - INSTALLATION . . . 9-147,9-218,

9-287,9-59

FRONT MOUNT - REMOVAL . . 9-146,9-217,9-286,

9-58

FRONT OUTBOARD SEAT BELT BUCKLE -