fig DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2037 of 2627

o-ring is properly installed and is free of any debris.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) If a replacement transmission is being

installed, transfer any components necessary, such as

the manual shift lever and shift cable bracket, from

the original transmission onto the replacement trans-

mission.

(3) Lubricate oil pump seal lip with transmission

fluid.

(4) Align converter and oil pump.(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

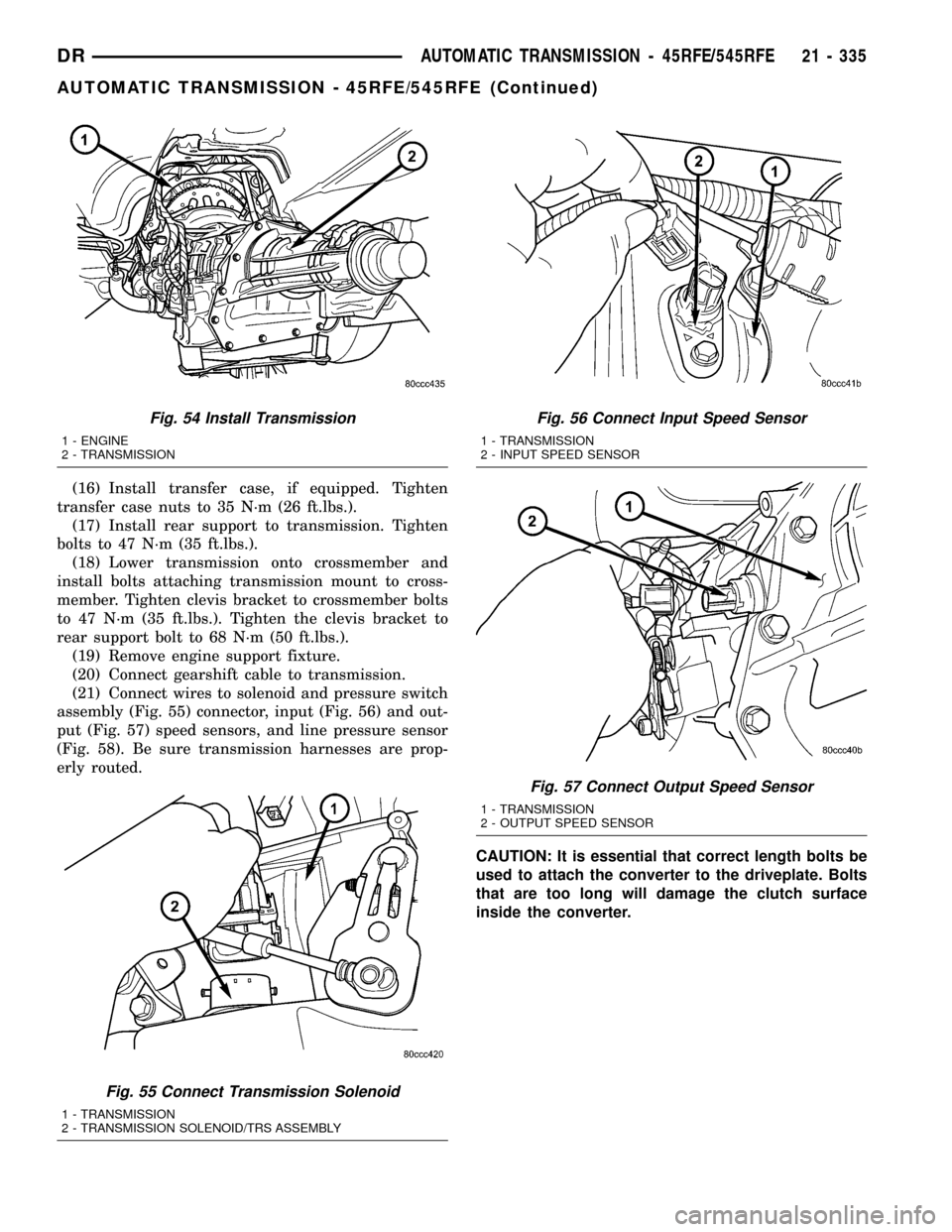

(6) Check converter seating with steel scale and

straightedge (Fig. 53). Surface of converter lugs

should be at least 13mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Apply a light coating of MopartHigh Temp

Grease to the torque converter hub pocket in the rear

pocket of the engine's crankshaft.

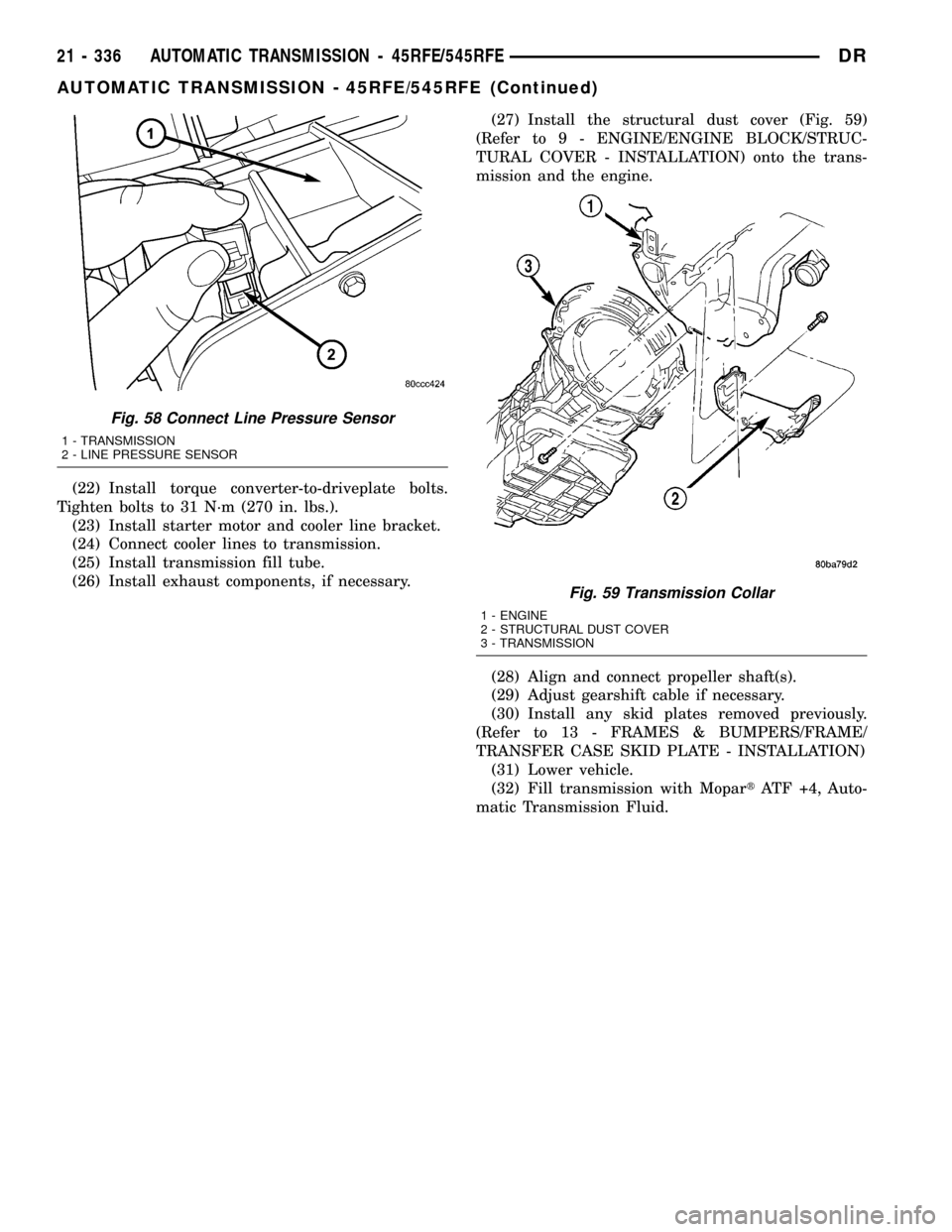

(11) Raise transmission (Fig. 54) and align the

torque converter with the drive plate and transmis-

sion converter housing with the engine block.

(12) Move transmission forward. Then raise, lower

or tilt transmission to align the converter housing

with engine block dowels.

(13) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft. Verify that no wires, or the transmission

vent hose, have become trapped between the engine

block and the transmission.

(14) Install two bolts to attach the transmission to

the engine.

(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

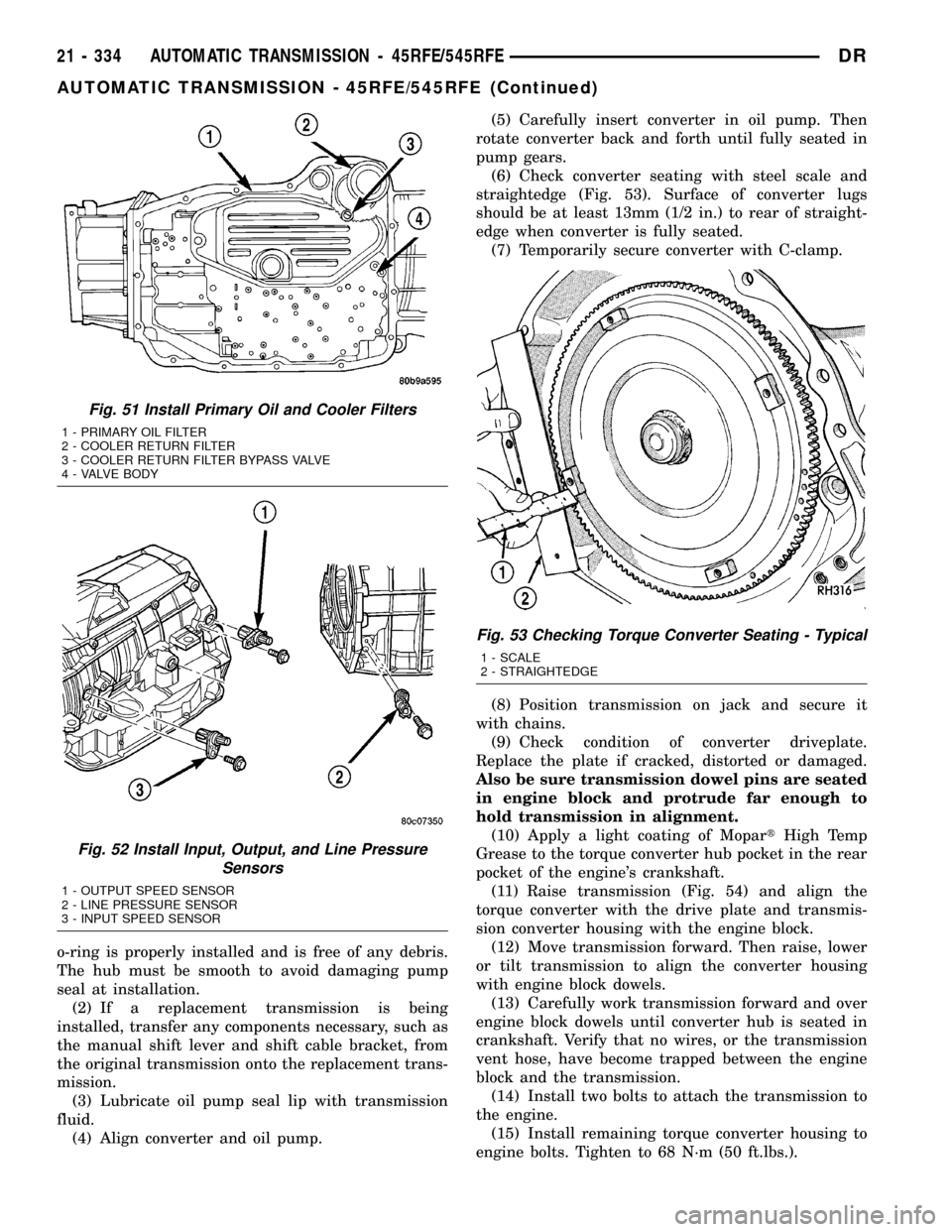

Fig. 51 Install Primary Oil and Cooler Filters

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

Fig. 52 Install Input, Output, and Line Pressure

Sensors

1 - OUTPUT SPEED SENSOR

2 - LINE PRESSURE SENSOR

3 - INPUT SPEED SENSOR

Fig. 53 Checking Torque Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 334 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2038 of 2627

(16) Install transfer case, if equipped. Tighten

transfer case nuts to 35 N´m (26 ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Connect gearshift cable to transmission.

(21) Connect wires to solenoid and pressure switch

assembly (Fig. 55) connector, input (Fig. 56) and out-

put (Fig. 57) speed sensors, and line pressure sensor

(Fig. 58). Be sure transmission harnesses are prop-

erly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

Fig. 54 Install Transmission

1 - ENGINE

2 - TRANSMISSION

Fig. 55 Connect Transmission Solenoid

1 - TRANSMISSION

2 - TRANSMISSION SOLENOID/TRS ASSEMBLY

Fig. 56 Connect Input Speed Sensor

1 - TRANSMISSION

2 - INPUT SPEED SENSOR

Fig. 57 Connect Output Speed Sensor

1 - TRANSMISSION

2 - OUTPUT SPEED SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 335

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2039 of 2627

(22) Install torque converter-to-driveplate bolts.

Tighten bolts to 31 N´m (270 in. lbs.).

(23) Install starter motor and cooler line bracket.

(24) Connect cooler lines to transmission.

(25) Install transmission fill tube.

(26) Install exhaust components, if necessary.(27) Install the structural dust cover (Fig. 59)

(Refer to 9 - ENGINE/ENGINE BLOCK/STRUC-

TURAL COVER - INSTALLATION) onto the trans-

mission and the engine.

(28) Align and connect propeller shaft(s).

(29) Adjust gearshift cable if necessary.

(30) Install any skid plates removed previously.

(Refer to 13 - FRAMES & BUMPERS/FRAME/

TRANSFER CASE SKID PLATE - INSTALLATION)

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission Fluid.

Fig. 58 Connect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

Fig. 59 Transmission Collar

1 - ENGINE

2 - STRUCTURAL DUST COVER

3 - TRANSMISSION

21 - 336 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2065 of 2627

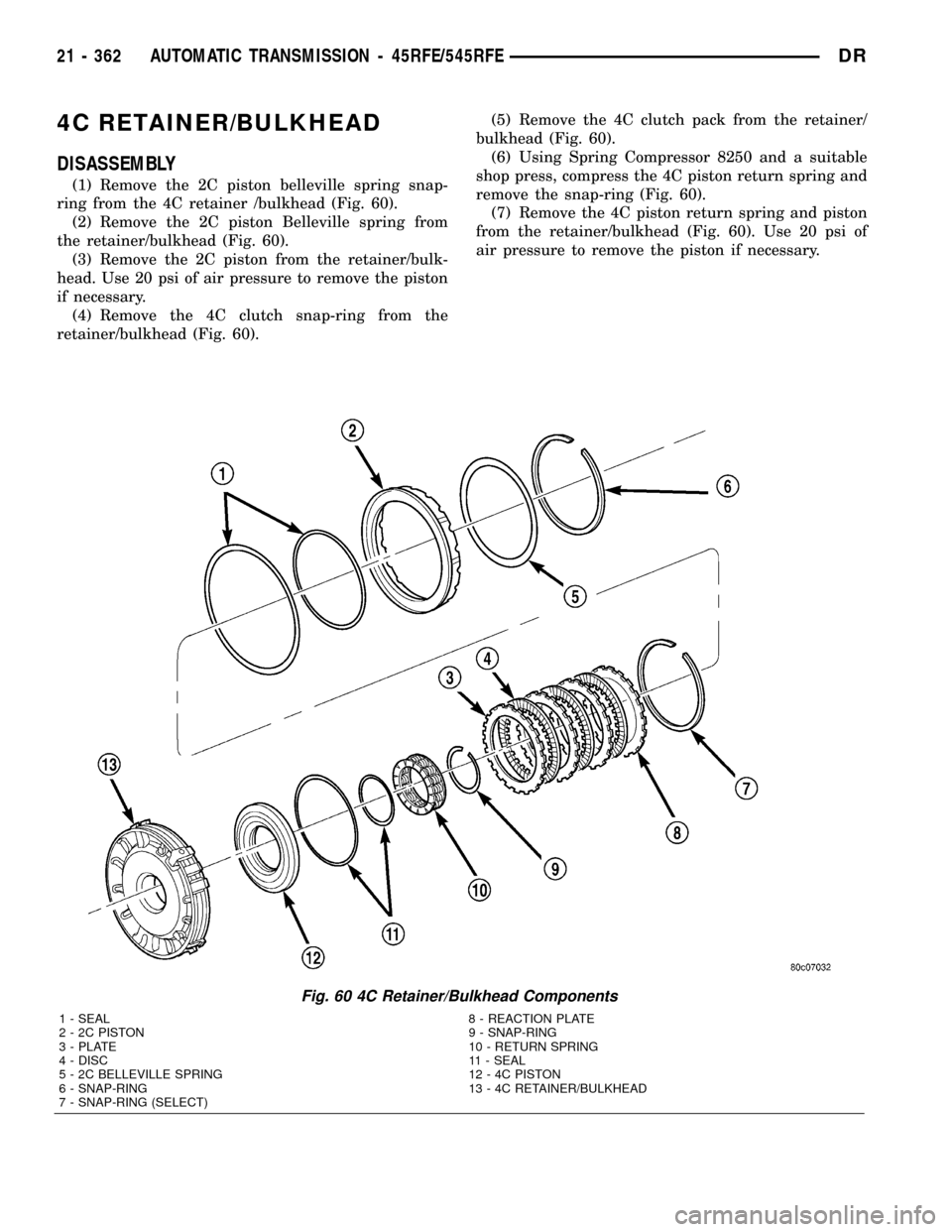

4C RETAINER/BULKHEAD

DISASSEMBLY

(1) Remove the 2C piston belleville spring snap-

ring from the 4C retainer /bulkhead (Fig. 60).

(2) Remove the 2C piston Belleville spring from

the retainer/bulkhead (Fig. 60).

(3) Remove the 2C piston from the retainer/bulk-

head. Use 20 psi of air pressure to remove the piston

if necessary.

(4) Remove the 4C clutch snap-ring from the

retainer/bulkhead (Fig. 60).(5) Remove the 4C clutch pack from the retainer/

bulkhead (Fig. 60).

(6) Using Spring Compressor 8250 and a suitable

shop press, compress the 4C piston return spring and

remove the snap-ring (Fig. 60).

(7) Remove the 4C piston return spring and piston

from the retainer/bulkhead (Fig. 60). Use 20 psi of

air pressure to remove the piston if necessary.

Fig. 60 4C Retainer/Bulkhead Components

1 - SEAL 8 - REACTION PLATE

2 - 2C PISTON 9 - SNAP-RING

3 - PLATE 10 - RETURN SPRING

4 - DISC 11 - SEAL

5 - 2C BELLEVILLE SPRING 12 - 4C PISTON

6 - SNAP-RING 13 - 4C RETAINER/BULKHEAD

7 - SNAP-RING (SELECT)

21 - 362 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2066 of 2627

ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install new seals on the 2C and 4C pistons

(Fig. 60).

(3) Lubricate all seals with MopartATF +4 prior

to installation.

(4) Install the 4C piston into the 4C retainer/bulk-

head (Fig. 60).

(5) Position the 4C piston return spring onto the

4C piston.

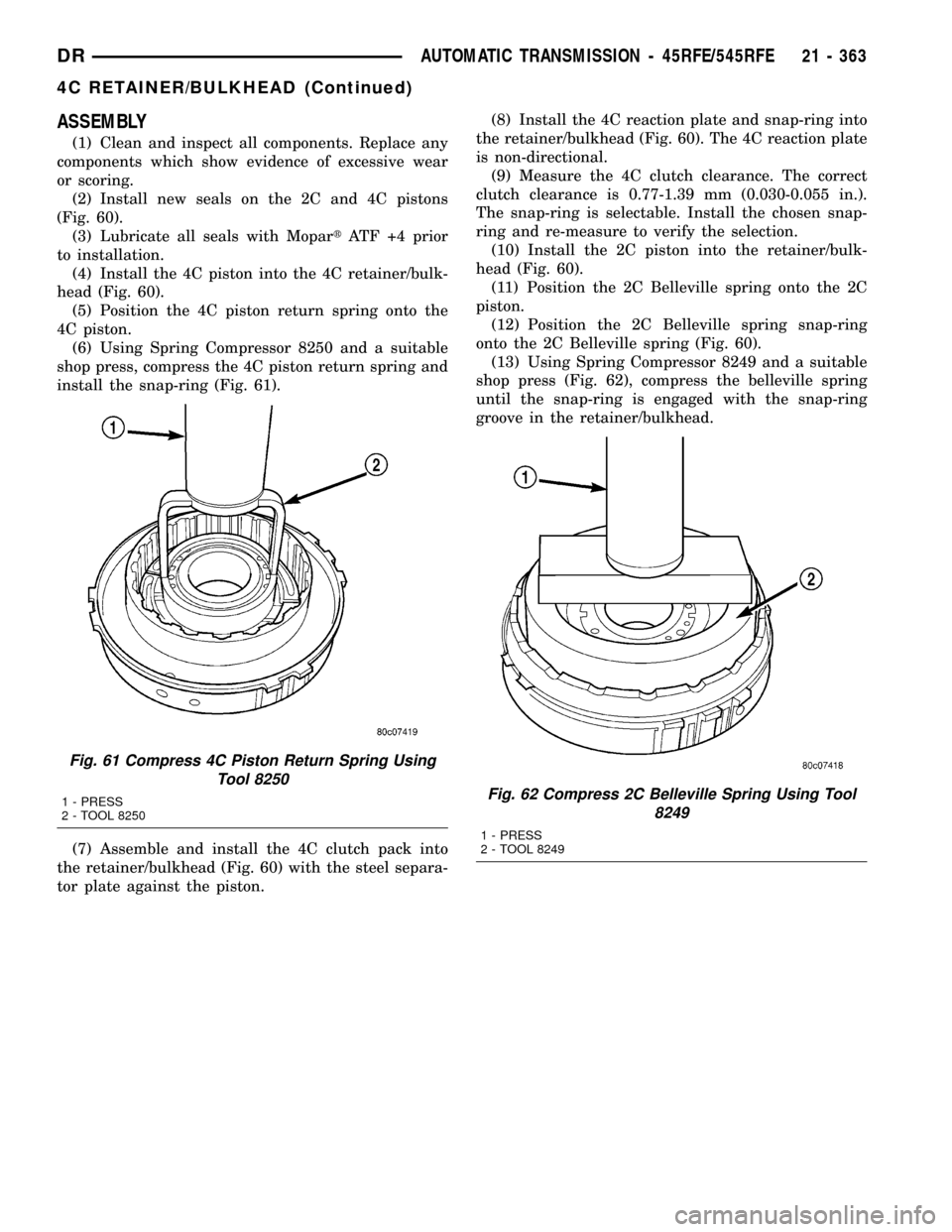

(6) Using Spring Compressor 8250 and a suitable

shop press, compress the 4C piston return spring and

install the snap-ring (Fig. 61).

(7) Assemble and install the 4C clutch pack into

the retainer/bulkhead (Fig. 60) with the steel separa-

tor plate against the piston.(8) Install the 4C reaction plate and snap-ring into

the retainer/bulkhead (Fig. 60). The 4C reaction plate

is non-directional.

(9) Measure the 4C clutch clearance. The correct

clutch clearance is 0.77-1.39 mm (0.030-0.055 in.).

The snap-ring is selectable. Install the chosen snap-

ring and re-measure to verify the selection.

(10) Install the 2C piston into the retainer/bulk-

head (Fig. 60).

(11) Position the 2C Belleville spring onto the 2C

piston.

(12) Position the 2C Belleville spring snap-ring

onto the 2C Belleville spring (Fig. 60).

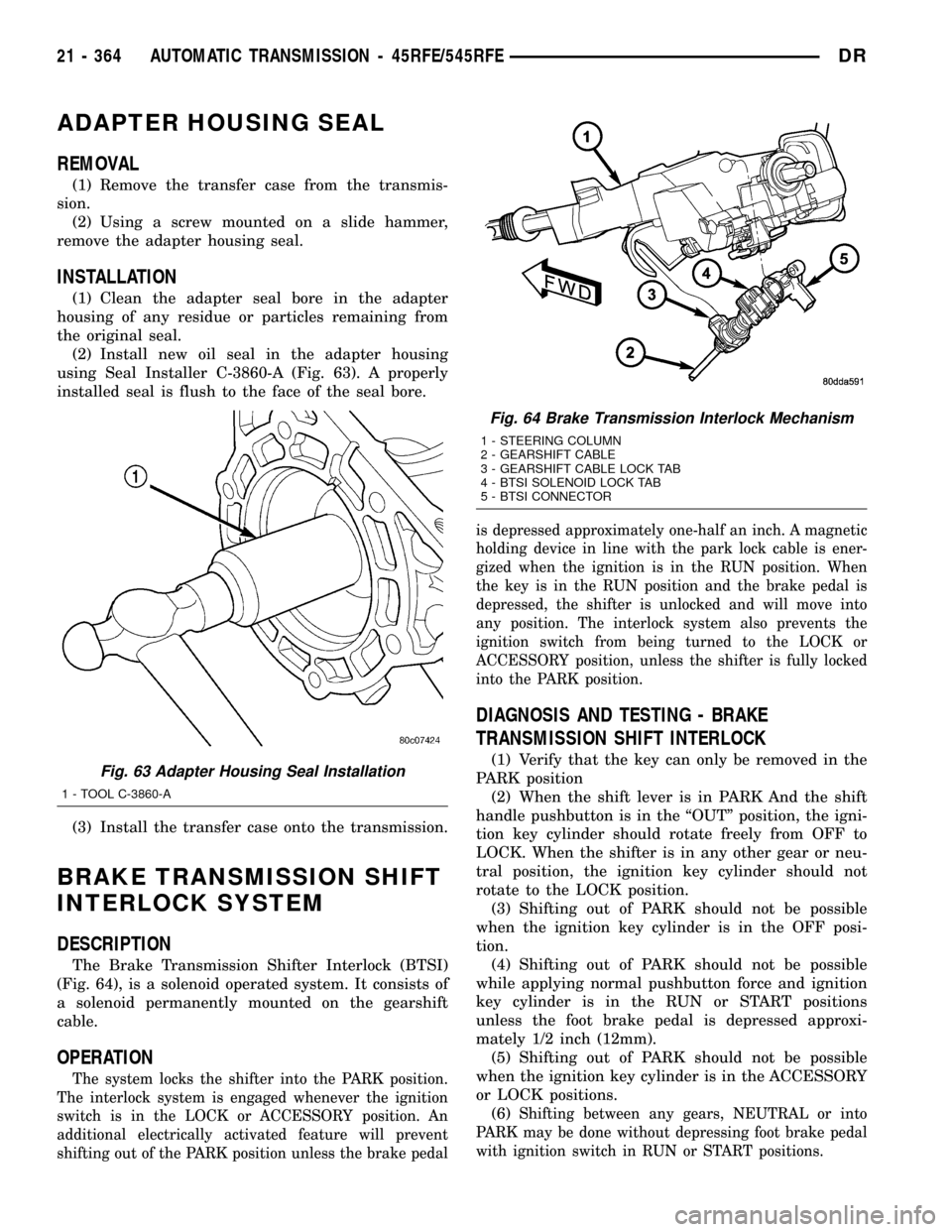

(13) Using Spring Compressor 8249 and a suitable

shop press (Fig. 62), compress the belleville spring

until the snap-ring is engaged with the snap-ring

groove in the retainer/bulkhead.

Fig. 61 Compress 4C Piston Return Spring Using

Tool 8250

1 - PRESS

2 - TOOL 8250Fig. 62 Compress 2C Belleville Spring Using Tool

8249

1 - PRESS

2 - TOOL 8249

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 363

4C RETAINER/BULKHEAD (Continued)

Page 2067 of 2627

ADAPTER HOUSING SEAL

REMOVAL

(1) Remove the transfer case from the transmis-

sion.

(2) Using a screw mounted on a slide hammer,

remove the adapter housing seal.

INSTALLATION

(1) Clean the adapter seal bore in the adapter

housing of any residue or particles remaining from

the original seal.

(2) Install new oil seal in the adapter housing

using Seal Installer C-3860-A (Fig. 63). A properly

installed seal is flush to the face of the seal bore.

(3) Install the transfer case onto the transmission.

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM

DESCRIPTION

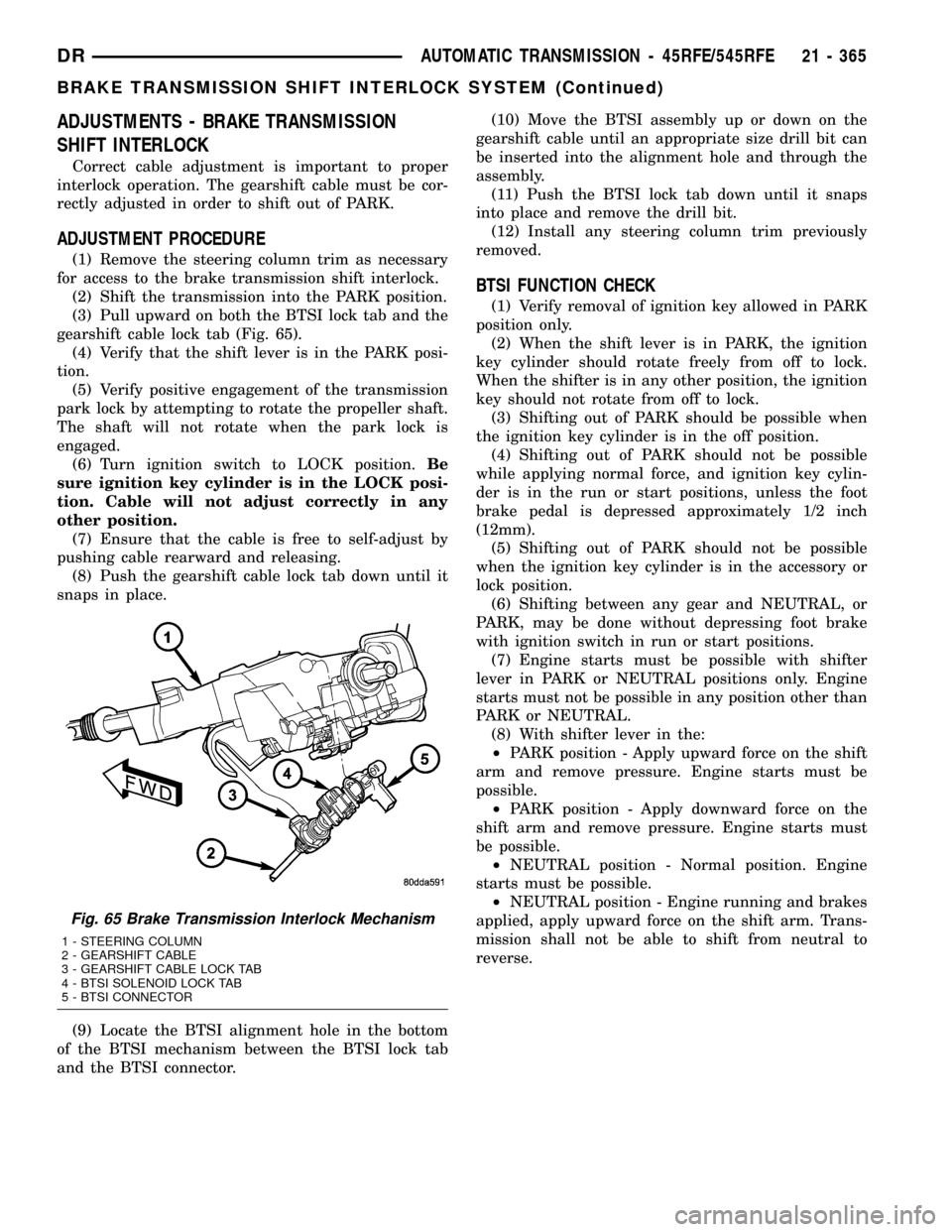

The Brake Transmission Shifter Interlock (BTSI)

(Fig. 64), is a solenoid operated system. It consists of

a solenoid permanently mounted on the gearshift

cable.

OPERATION

The system locks the shifter into the PARK position.

The interlock system is engaged whenever the ignition

switch is in the LOCK or ACCESSORY position. An

additional electrically activated feature will prevent

shifting out of the PARK position unless the brake pedalis depressed approximately one-half an inch. A magnetic

holding device in line with the park lock cable is ener-

gized when the ignition is in the RUN position. When

the key is in the RUN position and the brake pedal is

depressed, the shifter is unlocked and will move into

any position. The interlock system also prevents the

ignition switch from being turned to the LOCK or

ACCESSORY position, unless the shifter is fully locked

into the PARK position.

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK

(1) Verify that the key can only be removed in the

PARK position

(2) When the shift lever is in PARK And the shift

handle pushbutton is in the ªOUTº position, the igni-

tion key cylinder should rotate freely from OFF to

LOCK. When the shifter is in any other gear or neu-

tral position, the ignition key cylinder should not

rotate to the LOCK position.

(3) Shifting out of PARK should not be possible

when the ignition key cylinder is in the OFF posi-

tion.

(4) Shifting out of PARK should not be possible

while applying normal pushbutton force and ignition

key cylinder is in the RUN or START positions

unless the foot brake pedal is depressed approxi-

mately 1/2 inch (12mm).

(5) Shifting out of PARK should not be possible

when the ignition key cylinder is in the ACCESSORY

or LOCK positions.

(6)

Shifting between any gears, NEUTRAL or into

PARK may be done without depressing foot brake pedal

with ignition switch in RUN or START positions.

Fig. 63 Adapter Housing Seal Installation

1 - TOOL C-3860-A

Fig. 64 Brake Transmission Interlock Mechanism

1 - STEERING COLUMN

2 - GEARSHIFT CABLE

3 - GEARSHIFT CABLE LOCK TAB

4 - BTSI SOLENOID LOCK TAB

5 - BTSI CONNECTOR

21 - 364 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2068 of 2627

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK

Correct cable adjustment is important to proper

interlock operation. The gearshift cable must be cor-

rectly adjusted in order to shift out of PARK.

ADJUSTMENT PROCEDURE

(1) Remove the steering column trim as necessary

for access to the brake transmission shift interlock.

(2) Shift the transmission into the PARK position.

(3) Pull upward on both the BTSI lock tab and the

gearshift cable lock tab (Fig. 65).

(4) Verify that the shift lever is in the PARK posi-

tion.

(5) Verify positive engagement of the transmission

park lock by attempting to rotate the propeller shaft.

The shaft will not rotate when the park lock is

engaged.

(6) Turn ignition switch to LOCK position.Be

sure ignition key cylinder is in the LOCK posi-

tion. Cable will not adjust correctly in any

other position.

(7) Ensure that the cable is free to self-adjust by

pushing cable rearward and releasing.

(8) Push the gearshift cable lock tab down until it

snaps in place.

(9) Locate the BTSI alignment hole in the bottom

of the BTSI mechanism between the BTSI lock tab

and the BTSI connector.(10) Move the BTSI assembly up or down on the

gearshift cable until an appropriate size drill bit can

be inserted into the alignment hole and through the

assembly.

(11) Push the BTSI lock tab down until it snaps

into place and remove the drill bit.

(12) Install any steering column trim previously

removed.

BTSI FUNCTION CHECK

(1) Verify removal of ignition key allowed in PARK

position only.

(2) When the shift lever is in PARK, the ignition

key cylinder should rotate freely from off to lock.

When the shifter is in any other position, the ignition

key should not rotate from off to lock.

(3) Shifting out of PARK should be possible when

the ignition key cylinder is in the off position.

(4) Shifting out of PARK should not be possible

while applying normal force, and ignition key cylin-

der is in the run or start positions, unless the foot

brake pedal is depressed approximately 1/2 inch

(12mm).

(5) Shifting out of PARK should not be possible

when the ignition key cylinder is in the accessory or

lock position.

(6) Shifting between any gear and NEUTRAL, or

PARK, may be done without depressing foot brake

with ignition switch in run or start positions.

(7) Engine starts must be possible with shifter

lever in PARK or NEUTRAL positions only. Engine

starts must not be possible in any position other than

PARK or NEUTRAL.

(8) With shifter lever in the:

²PARK position - Apply upward force on the shift

arm and remove pressure. Engine starts must be

possible.

²PARK position - Apply downward force on the

shift arm and remove pressure. Engine starts must

be possible.

²NEUTRAL position - Normal position. Engine

starts must be possible.

²NEUTRAL position - Engine running and brakes

applied, apply upward force on the shift arm. Trans-

mission shall not be able to shift from neutral to

reverse.

Fig. 65 Brake Transmission Interlock Mechanism

1 - STEERING COLUMN

2 - GEARSHIFT CABLE

3 - GEARSHIFT CABLE LOCK TAB

4 - BTSI SOLENOID LOCK TAB

5 - BTSI CONNECTOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 365

BRAKE TRANSMISSION SHIFT INTERLOCK SYSTEM (Continued)

Page 2070 of 2627

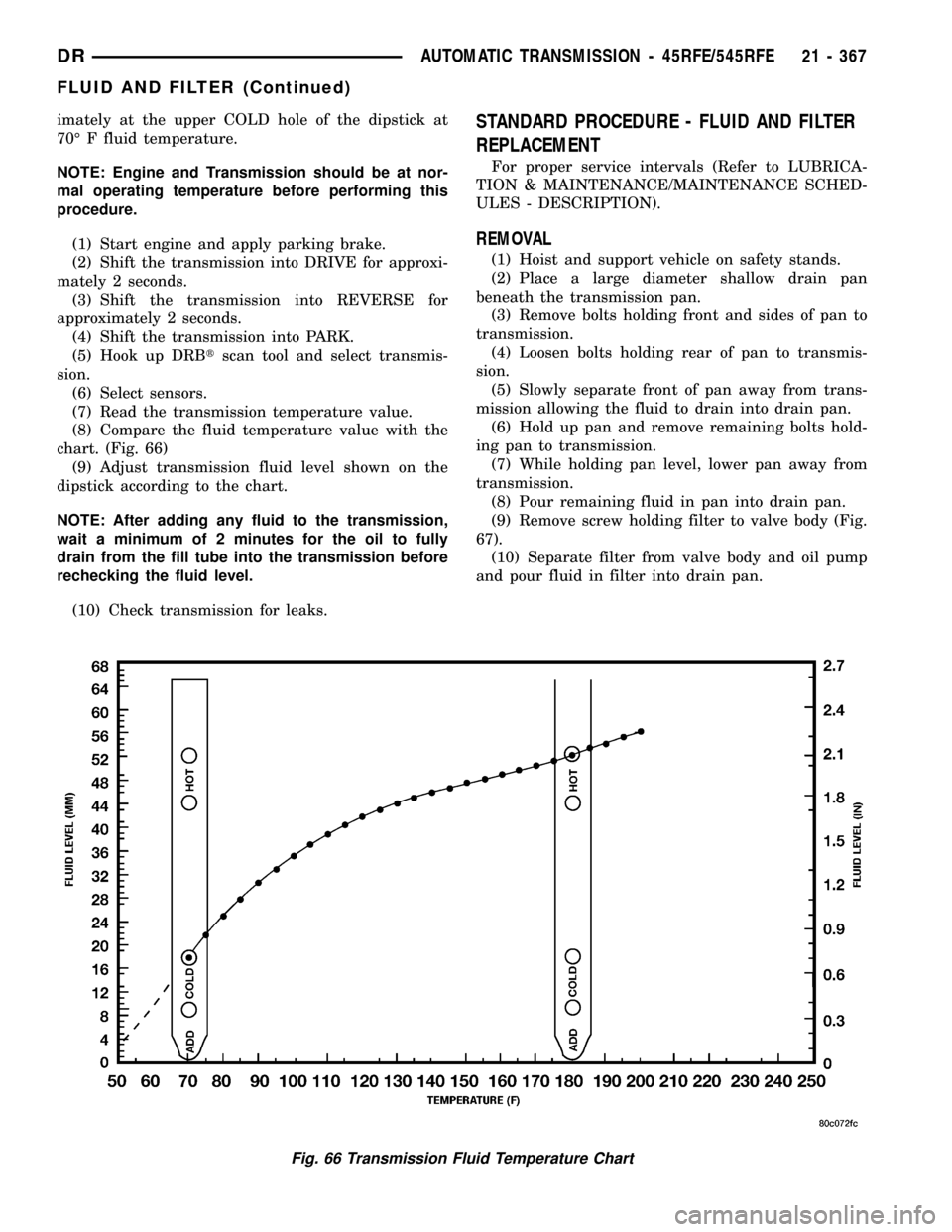

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5) Hook up DRBtscan tool and select transmis-

sion.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

chart. (Fig. 66)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4) Loosen bolts holding rear of pan to transmis-

sion.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

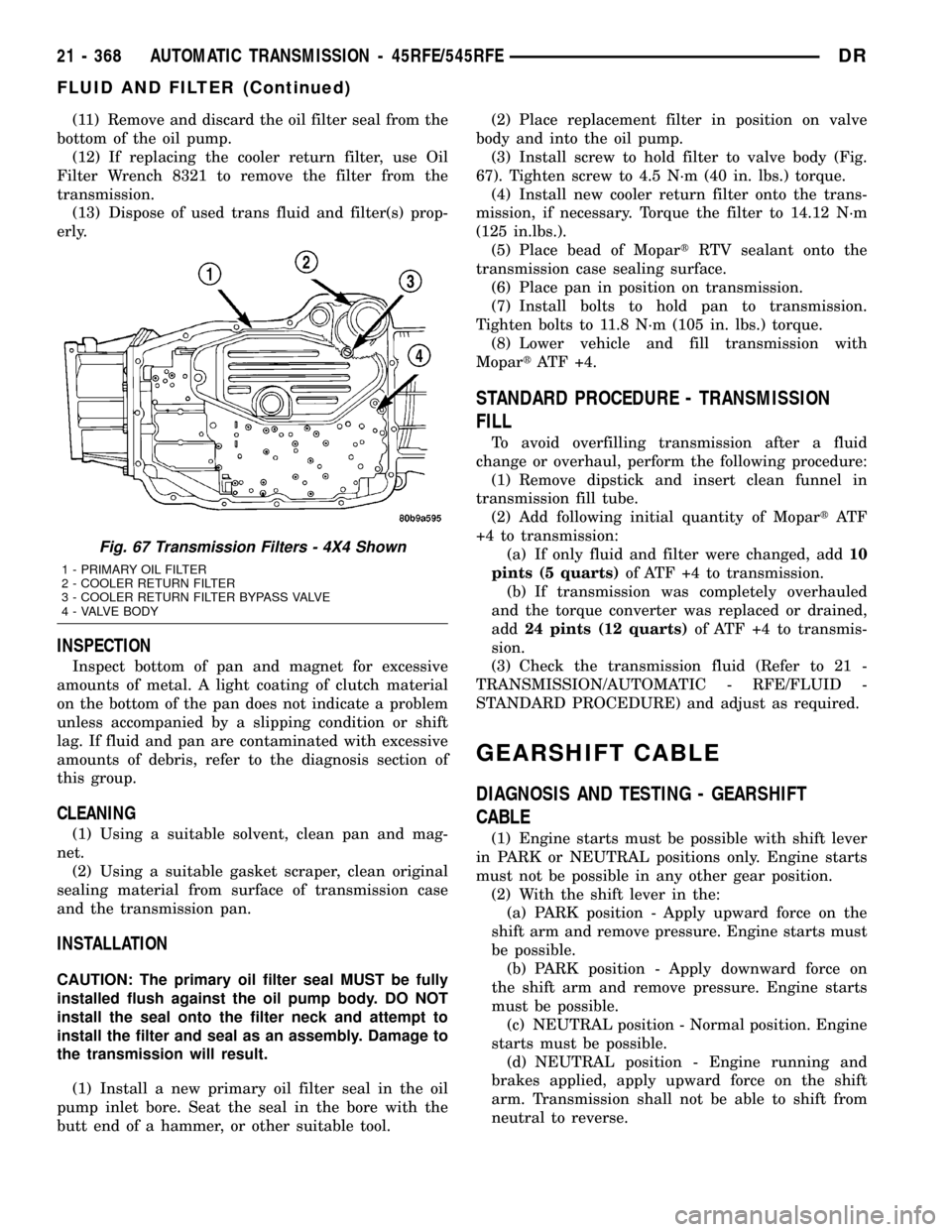

(9) Remove screw holding filter to valve body (Fig.

67).

(10) Separate filter from valve body and oil pump

and pour fluid in filter into drain pan.

Fig. 66 Transmission Fluid Temperature Chart

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 367

FLUID AND FILTER (Continued)

Page 2071 of 2627

(11) Remove and discard the oil filter seal from the

bottom of the oil pump.

(12) If replacing the cooler return filter, use Oil

Filter Wrench 8321 to remove the filter from the

transmission.

(13) Dispose of used trans fluid and filter(s) prop-

erly.

INSPECTION

Inspect bottom of pan and magnet for excessive

amounts of metal. A light coating of clutch material

on the bottom of the pan does not indicate a problem

unless accompanied by a slipping condition or shift

lag. If fluid and pan are contaminated with excessive

amounts of debris, refer to the diagnosis section of

this group.

CLEANING

(1) Using a suitable solvent, clean pan and mag-

net.

(2) Using a suitable gasket scraper, clean original

sealing material from surface of transmission case

and the transmission pan.

INSTALLATION

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(1) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.(2) Place replacement filter in position on valve

body and into the oil pump.

(3) Install screw to hold filter to valve body (Fig.

67). Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(4) Install new cooler return filter onto the trans-

mission, if necessary. Torque the filter to 14.12 N´m

(125 in.lbs.).

(5) Place bead of MopartRTV sealant onto the

transmission case sealing surface.

(6) Place pan in position on transmission.

(7) Install bolts to hold pan to transmission.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(8) Lower vehicle and fill transmission with

MopartATF +4.

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of MopartAT F

+4 to transmission:

(a) If only fluid and filter were changed, add10

pints (5 quarts)of ATF +4 to transmission.

(b) If transmission was completely overhauled

and the torque converter was replaced or drained,

add24 pints (12 quarts)of ATF +4 to transmis-

sion.

(3) Check the transmission fluid (Refer to 21 -

TRANSMISSION/AUTOMATIC - RFE/FLUID -

STANDARD PROCEDURE) and adjust as required.

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE

(1) Engine starts must be possible with shift lever

in PARK or NEUTRAL positions only. Engine starts

must not be possible in any other gear position.

(2) With the shift lever in the:

(a) PARK position - Apply upward force on the

shift arm and remove pressure. Engine starts must

be possible.

(b) PARK position - Apply downward force on

the shift arm and remove pressure. Engine starts

must be possible.

(c) NEUTRAL position - Normal position. Engine

starts must be possible.

(d) NEUTRAL position - Engine running and

brakes applied, apply upward force on the shift

arm. Transmission shall not be able to shift from

neutral to reverse.

Fig. 67 Transmission Filters - 4X4 Shown

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

21 - 368 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

FLUID AND FILTER (Continued)

Page 2072 of 2627

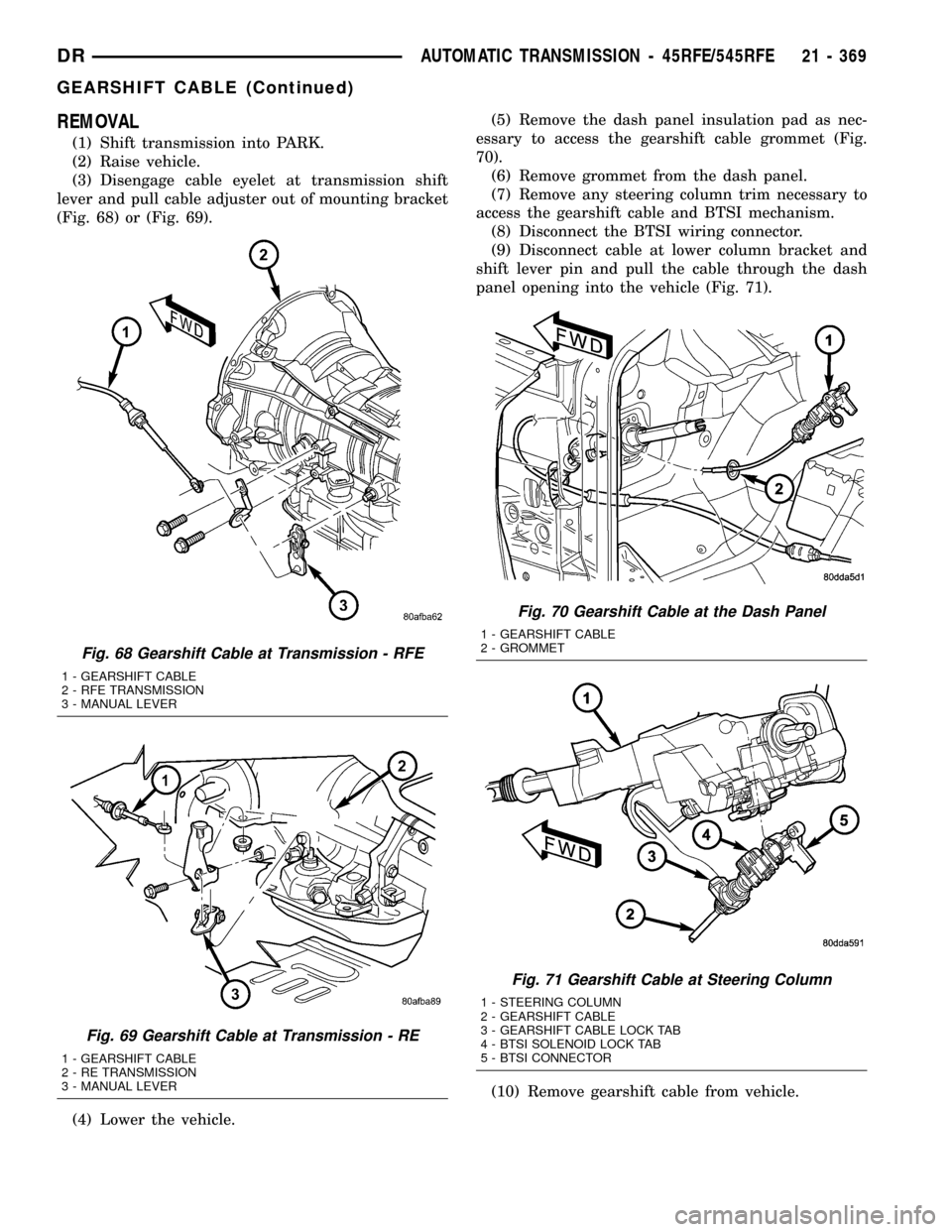

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Disengage cable eyelet at transmission shift

lever and pull cable adjuster out of mounting bracket

(Fig. 68) or (Fig. 69).

(4) Lower the vehicle.(5) Remove the dash panel insulation pad as nec-

essary to access the gearshift cable grommet (Fig.

70).

(6) Remove grommet from the dash panel.

(7) Remove any steering column trim necessary to

access the gearshift cable and BTSI mechanism.

(8) Disconnect the BTSI wiring connector.

(9) Disconnect cable at lower column bracket and

shift lever pin and pull the cable through the dash

panel opening into the vehicle (Fig. 71).

(10) Remove gearshift cable from vehicle.

Fig. 68 Gearshift Cable at Transmission - RFE

1 - GEARSHIFT CABLE

2 - RFE TRANSMISSION

3 - MANUAL LEVER

Fig. 69 Gearshift Cable at Transmission - RE

1 - GEARSHIFT CABLE

2 - RE TRANSMISSION

3 - MANUAL LEVER

Fig. 70 Gearshift Cable at the Dash Panel

1 - GEARSHIFT CABLE

2 - GROMMET

Fig. 71 Gearshift Cable at Steering Column

1 - STEERING COLUMN

2 - GEARSHIFT CABLE

3 - GEARSHIFT CABLE LOCK TAB

4 - BTSI SOLENOID LOCK TAB

5 - BTSI CONNECTOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 369

GEARSHIFT CABLE (Continued)